Hydraulic fixture used for machining precision forging blade tenon root

A hydraulic and vane technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems that the accuracy is not easy to guarantee, it is unfavorable for repeated use, and the pre-tightening force cannot be accurately controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

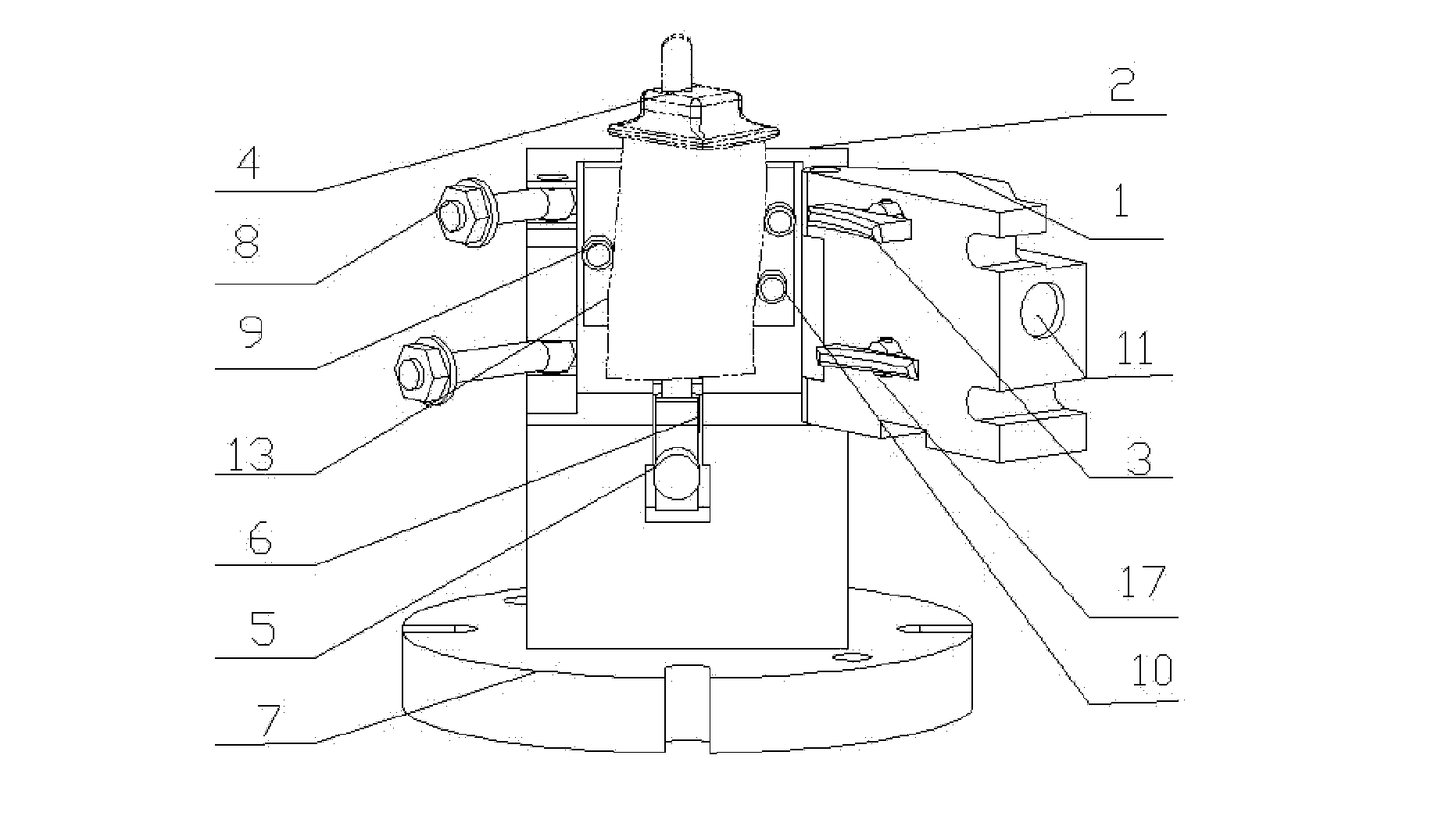

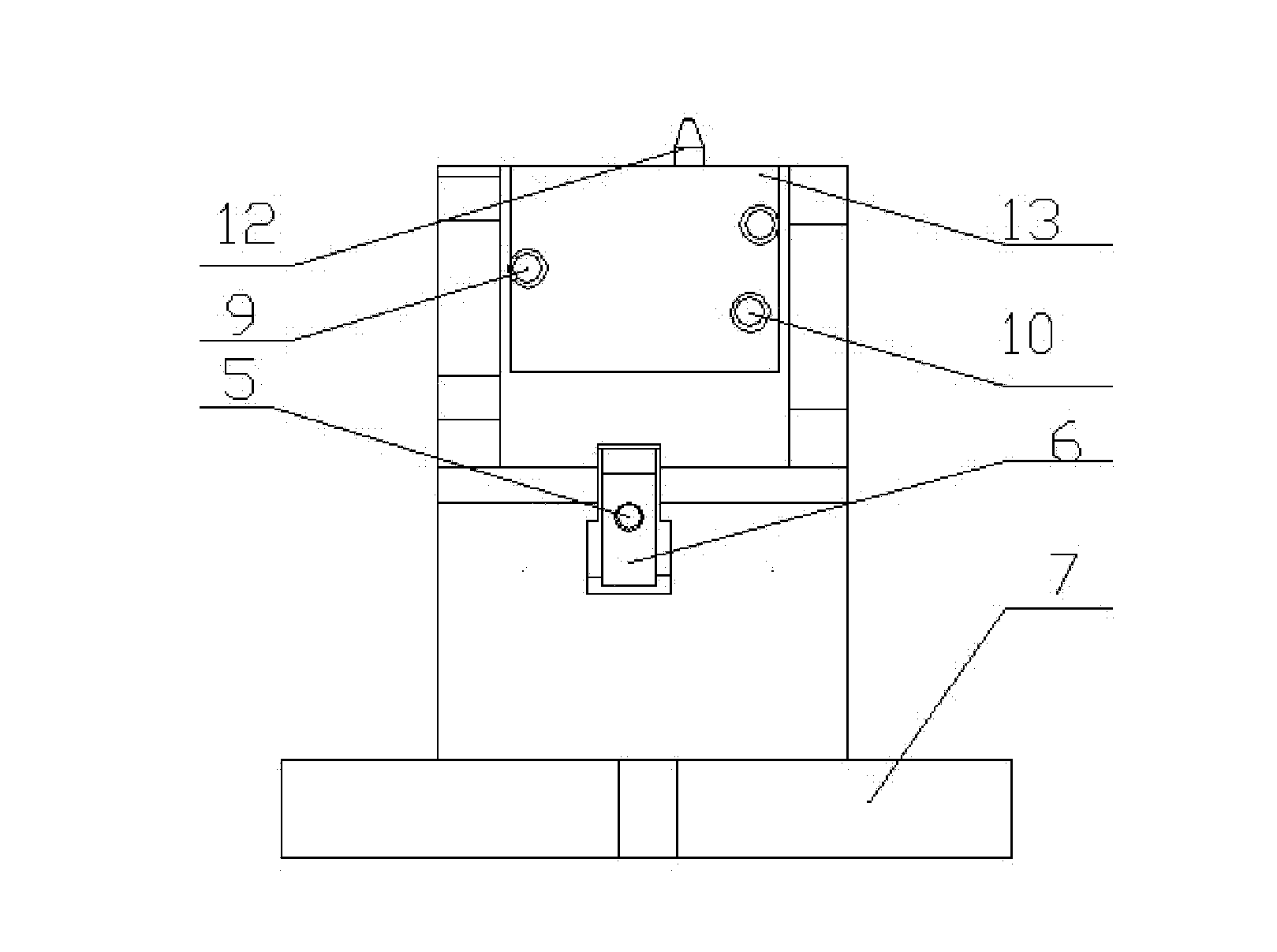

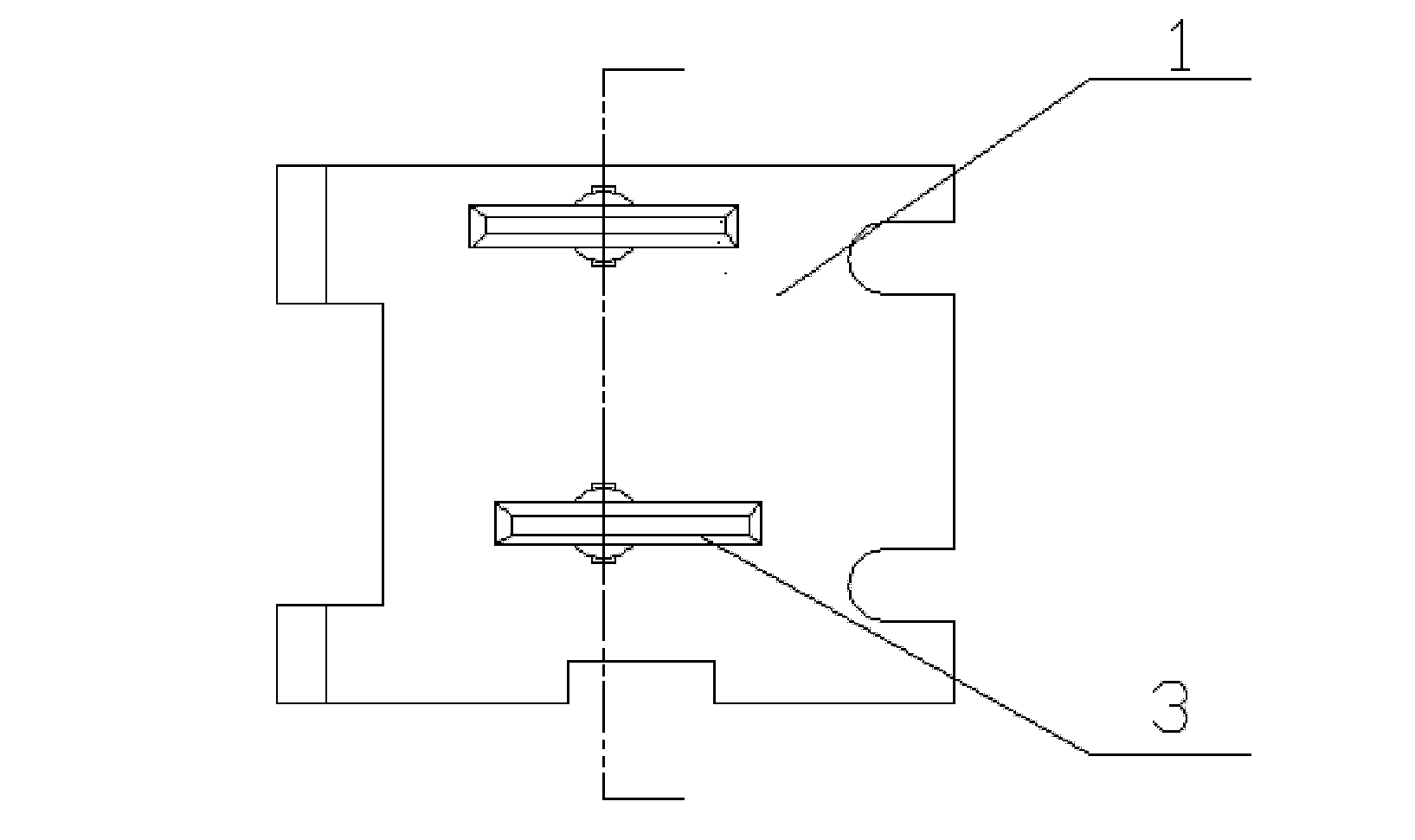

[0021] This embodiment is a hydraulic fixture for precision forging blade tenon root processing. The hydraulic fixture is composed of the box cover 1 in contact with the blade back, the fixture box 2 in contact with the leaf pot, the clamping gasket 3, the blade 4, the fastening screw 5, the positioning block of the process table 6, the rotating table 7, the fastening bolt 8. Conical positioning pin 9, positioning pin 10, pressure adjustment rod 11, fixed pin 12, positioning block 13, oil hole plug 14, piston 15, hydraulic chamber 16, rotating pin 17;

[0022] Such as figure 1 As shown, the fixture box 2 of the hydraulic fixture is fixedly connected with the turntable 7, and the turntable 7 is installed on the machine tool table; two fastening bolts 8 for free rotation are installed on one side of the fixture box 2, and the other side It is connected with the case cover 1 by a pin shaft. The other side of the box cover 1 is provided with two grooves matching the outer diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com