Rotor core and rotor shaft press-fitting assembly line

A technology of rotor iron core and rotor shaft, which is applied in the manufacture of stator/rotor body, electromechanical device, and motor generator, etc. It can solve the problem of uneven clamping force, inability to apply workpiece clamping of various specifications, and troublesome adjustment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]In the following, the technical solutions of the present invention will be further described in detail through embodiments and in conjunction with the drawings.

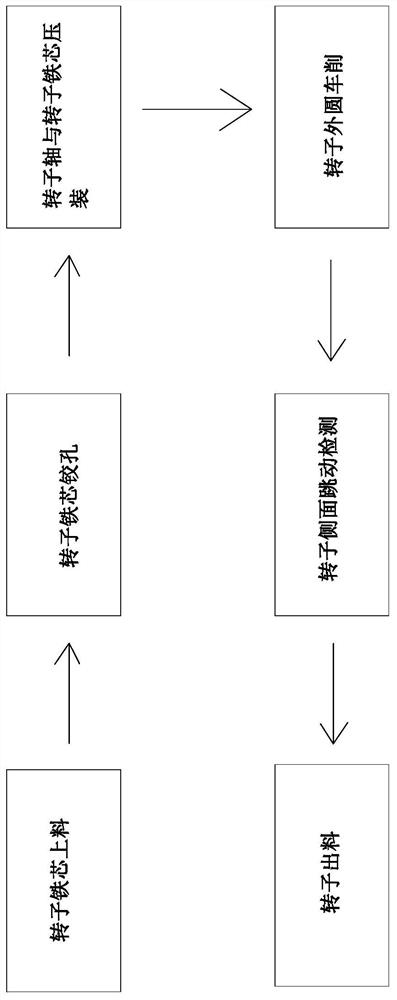

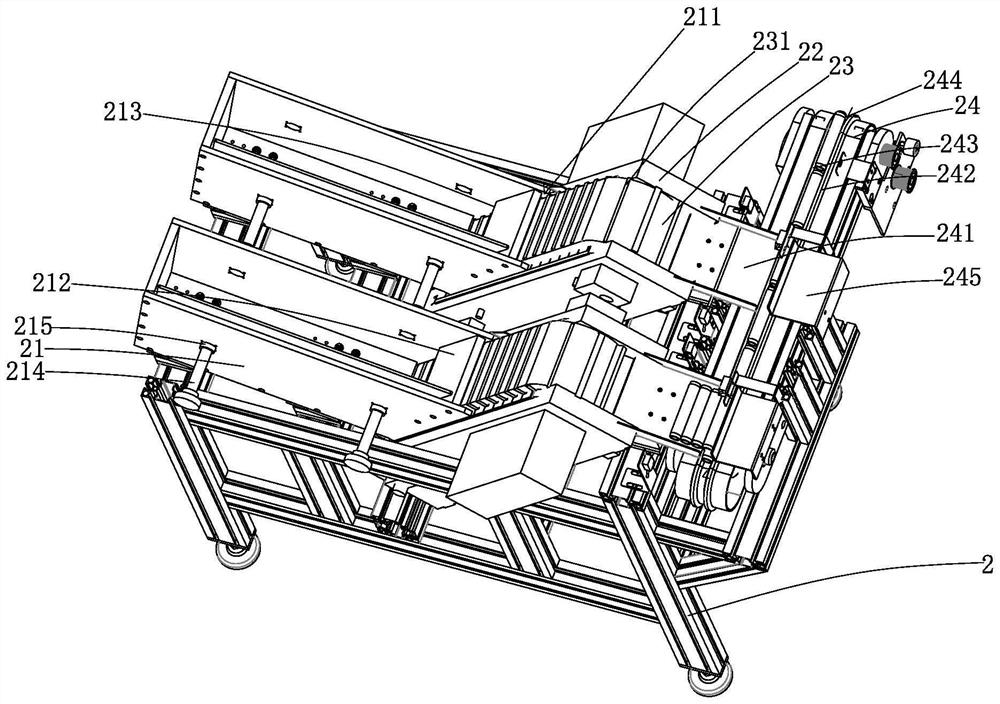

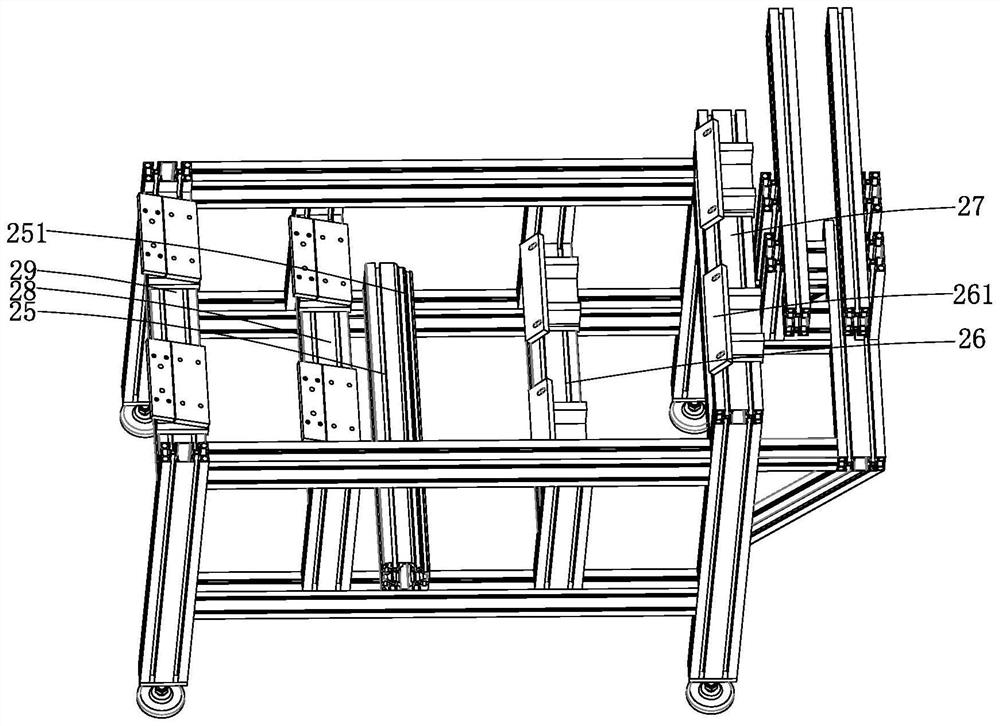

[0035]Such asFigure 1-17 As shown, a rotor core and rotor shaft press assembly line, including rotor core automatic feeding equipment, rotor core automatic reaming equipment, rotor shaft and rotor core press assembly equipment, and rotor external turning Equipment, rotor side runout detection equipment, and rotor automatic discharging equipment. The rotor core automatic reaming equipment includes a first bottom plate 1. A first fixed plate 11 is provided above the first bottom plate 1, and a first fixed plate 11 is provided with a A V-shaped clamping block 111 and a second V-shaped clamping block 112 arranged opposite to the first V-shaped clamping block 111, the first V-shaped clamping block 111 and the second V-shaped clamping block 112 are relatively movable, and the first fixing plate 11 The upper part corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com