Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Affects dimensional accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

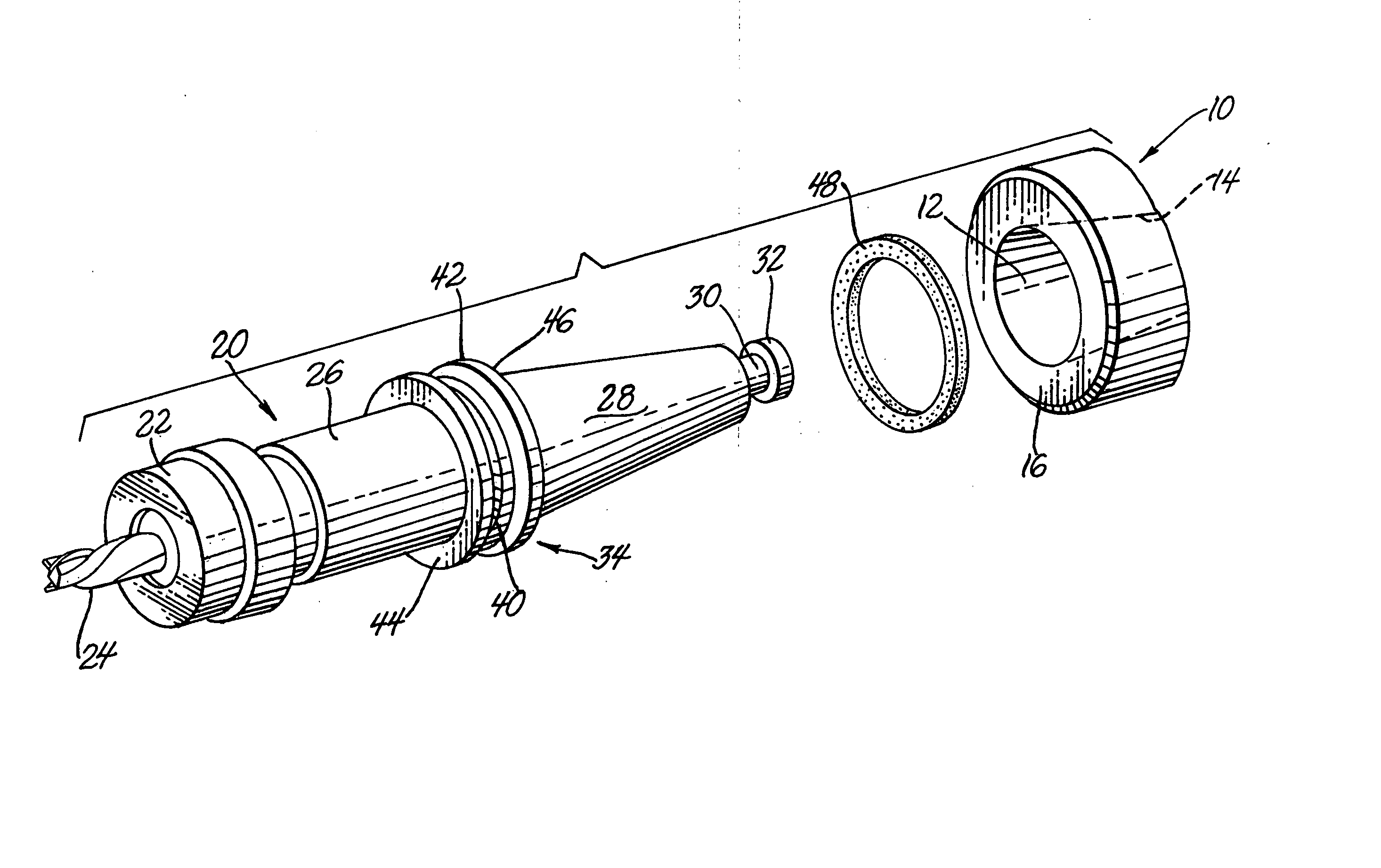

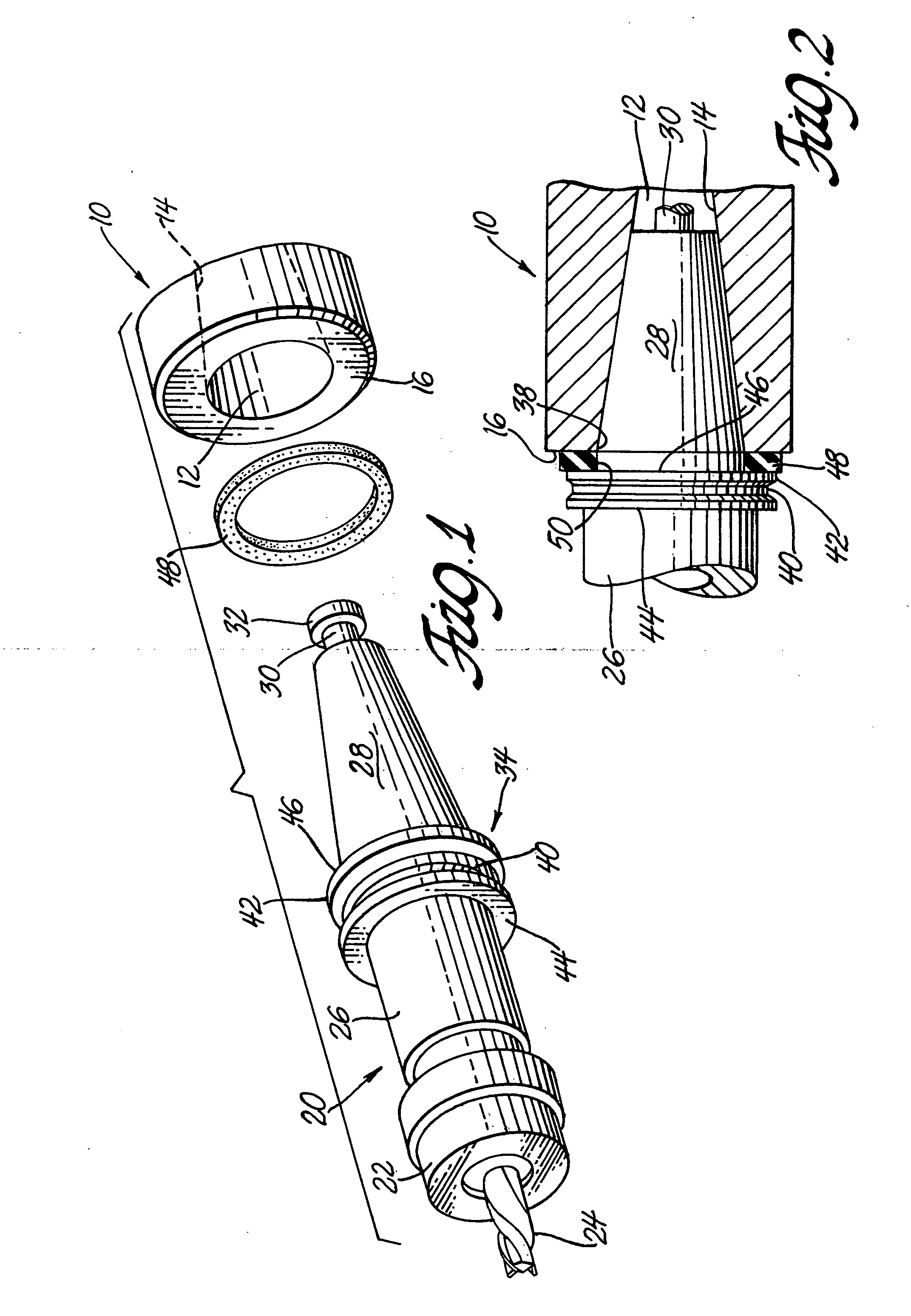

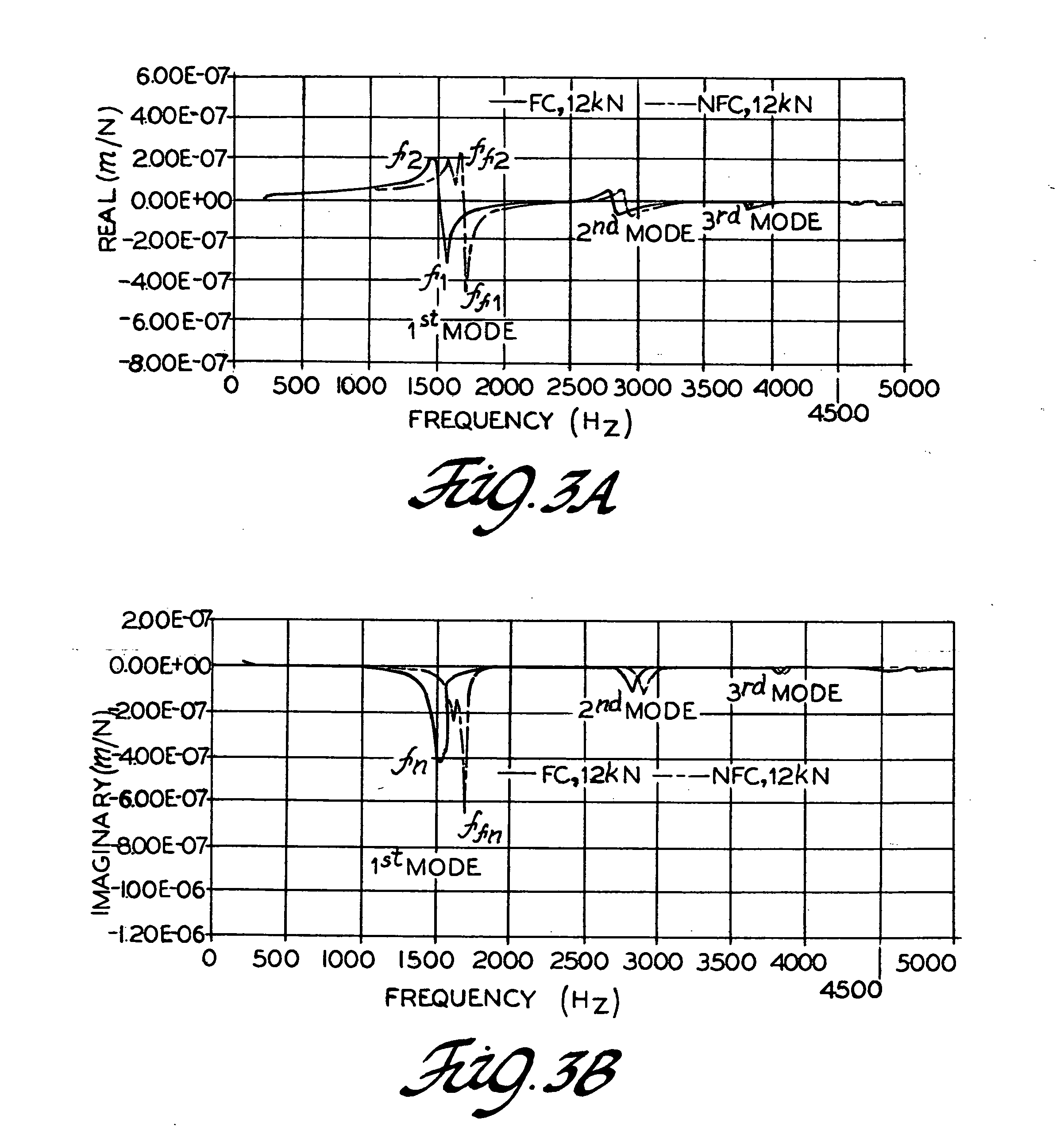

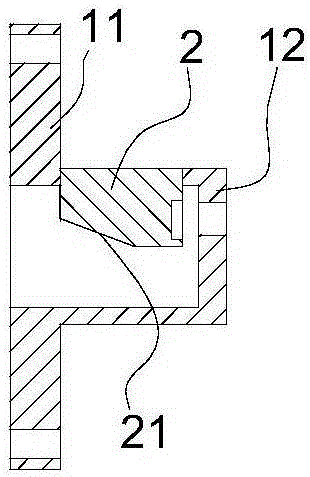

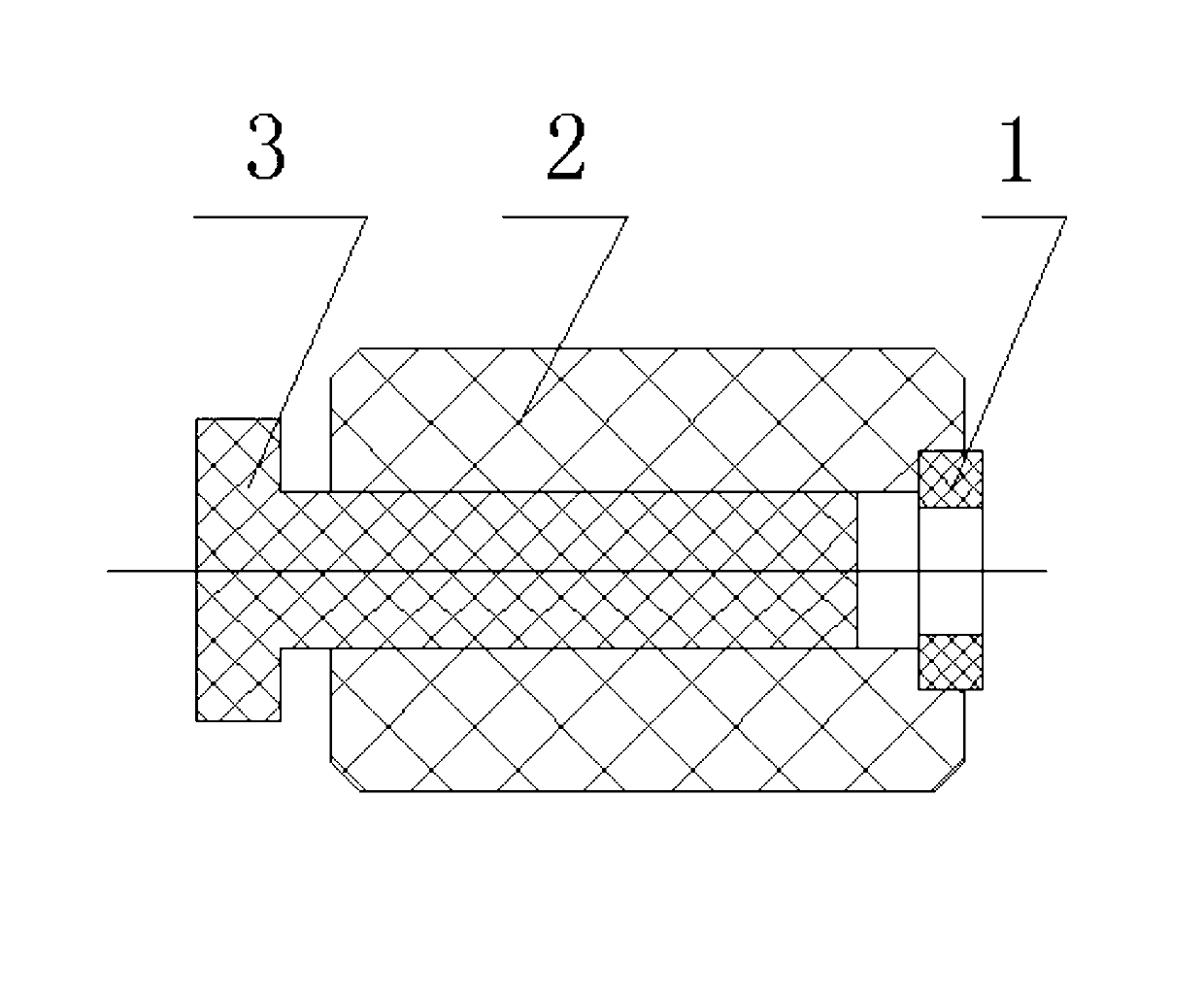

Spacer adapter for toolholders

InactiveUS20050214087A1Reduce vibrationSuitable flexibilityWorkpiecesMilling machinesEngineeringShaft collar

A toolholder for a cutting tool is disclosed for use with a machine tool having a main shaft or spindle with a flared or tapered end socket. The toolholder has a tool-holding end for a cutting tool and a tapered shank end for placement in the tapered socket of the machine tool spindle. The toolholder also has an annular flange near its tapered shank, the flange or collar generally being used for location and gripping by a tool exchange mechanism. An elastic spacer ring is used and compressed between said flange and the face of said machine tool shaft in machining operations for dampening vibrations and flexing of the toolholder and cutting tool.

Owner:GENERAL MOTORS COMPANY

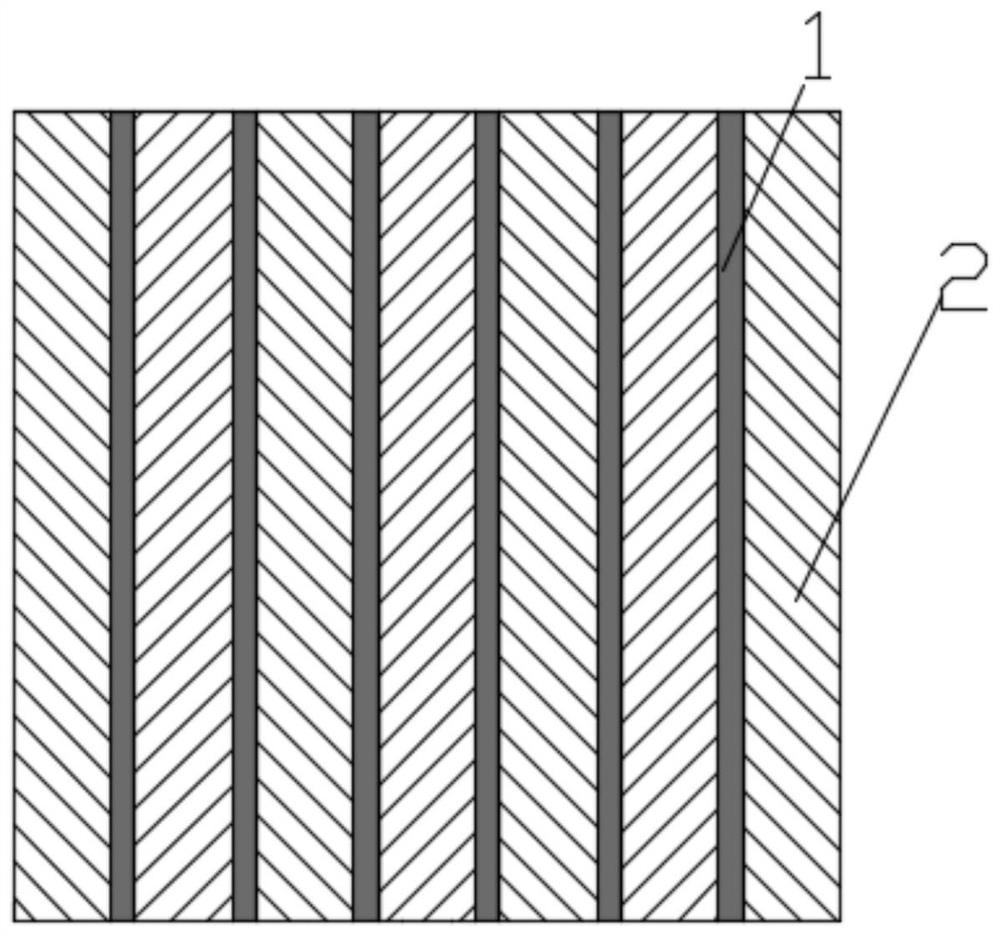

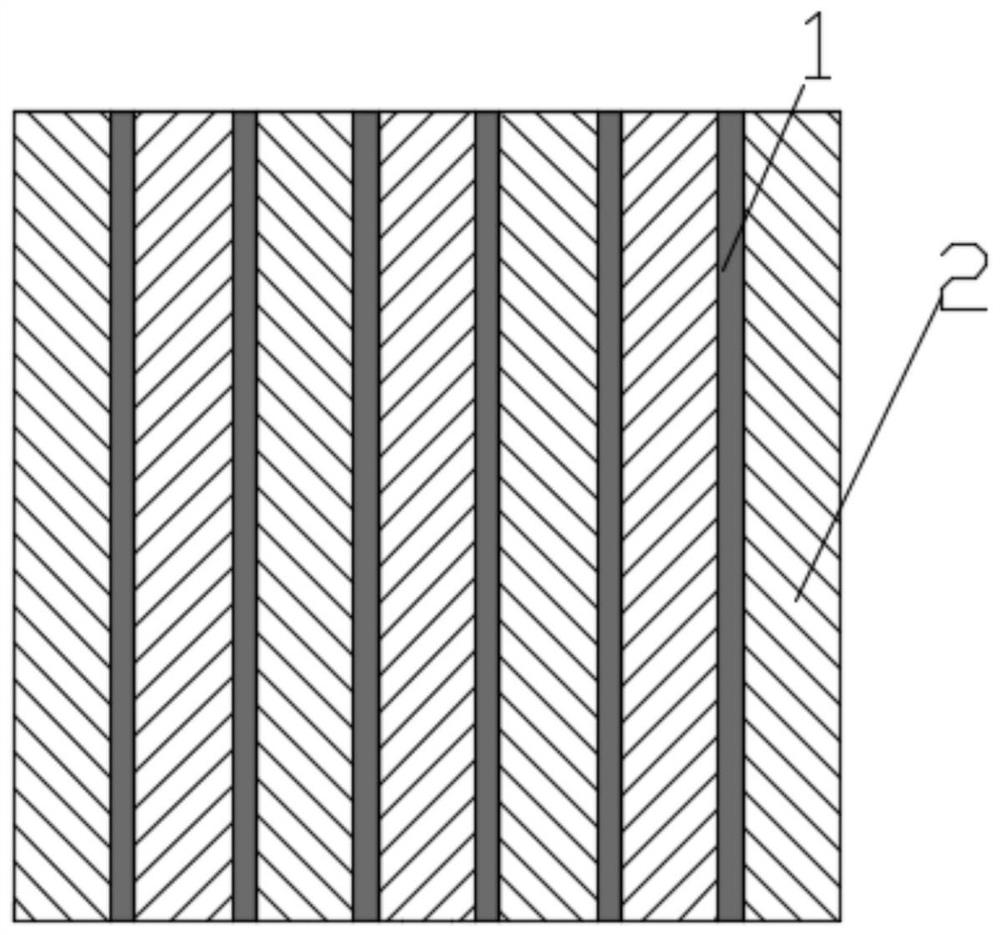

Production technology for single-sided PCB

InactiveCN105578784AQuality improvementImprove adsorption capacityInsulating substrate metal adhesion improvementNon-metallic protective coating applicationResistPre treatment

The invention relates to the technical field of PCBs, in particular to a production technology for a single-sided PCB. The technology sequentially comprises a single-sided copper foil substrate pretreatment step, a line coating and exposing treatment step, a line developing, etching and de-inking treatment step, a targeting hole treatment step, a solder resist pretreatment step, a solder resist developing step, a lettering treatment step, a molding treatment step, a testing step and an antioxidant treatment step. Surface polish-brush treatment is carried out on a copper foil substrate in a polish-brush manner; a photosensitive ink layer and a solder resist ink layer coat the surface of the copper foil substrate; relatively high adsorption capacity is provided among the photosensitive ink layer, the solder resist ink layer and the copper foil substrate; and the produced PCB is good in quality. A V-shaped board-dividing groove formed by cutting treatment on the copper foil substrate by a V-Cut process is free of a burr in subsequent board division. According to the production technology provided by the invention, targeting hole treatment is firstly carried out on the copper foil substrate; and then solder resist and baking treatment is carried out on the copper foil substrate, so that the dimensional accuracy of a targeting hole is high.

Owner:湖北碧辰科技股份有限公司 +1

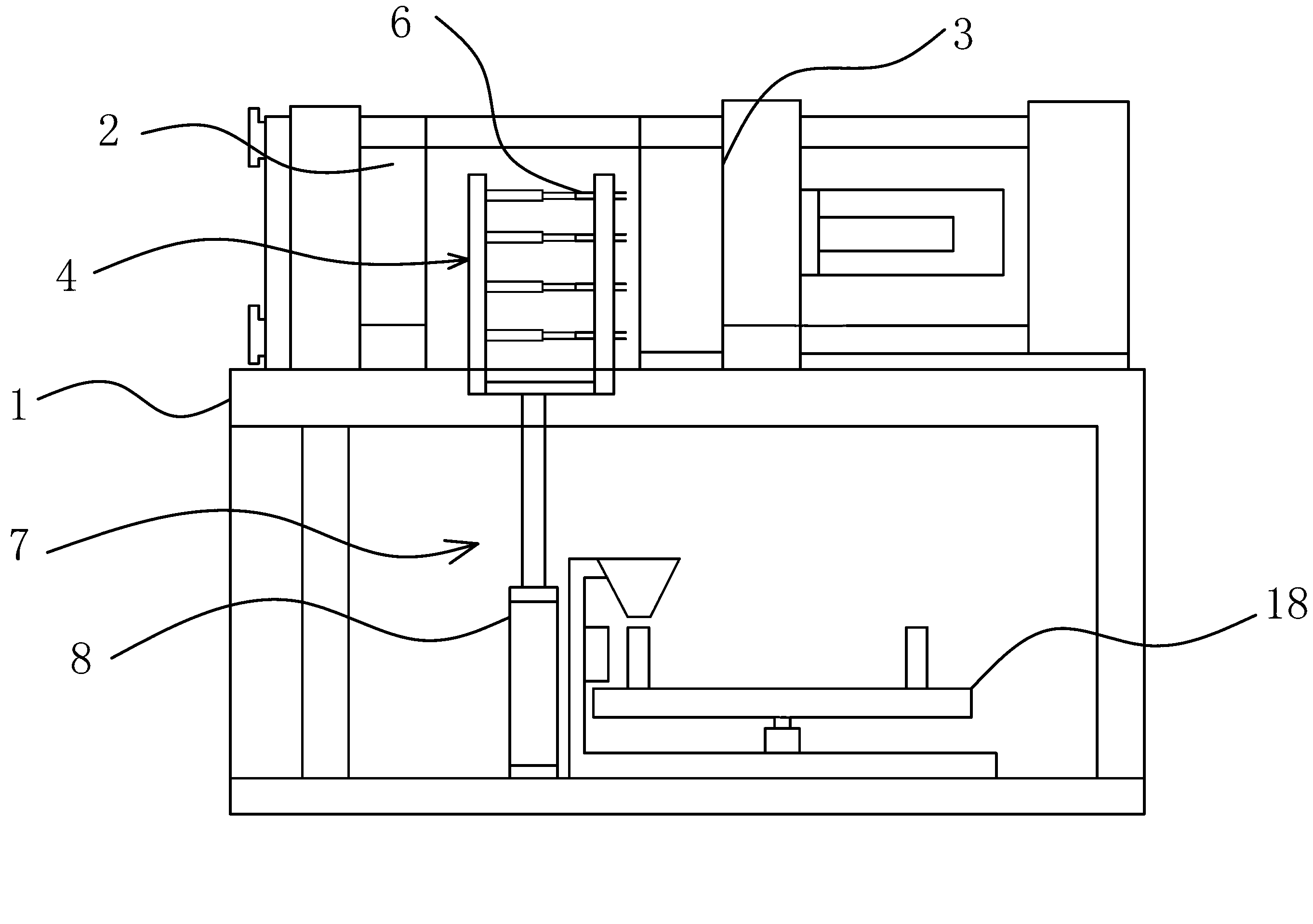

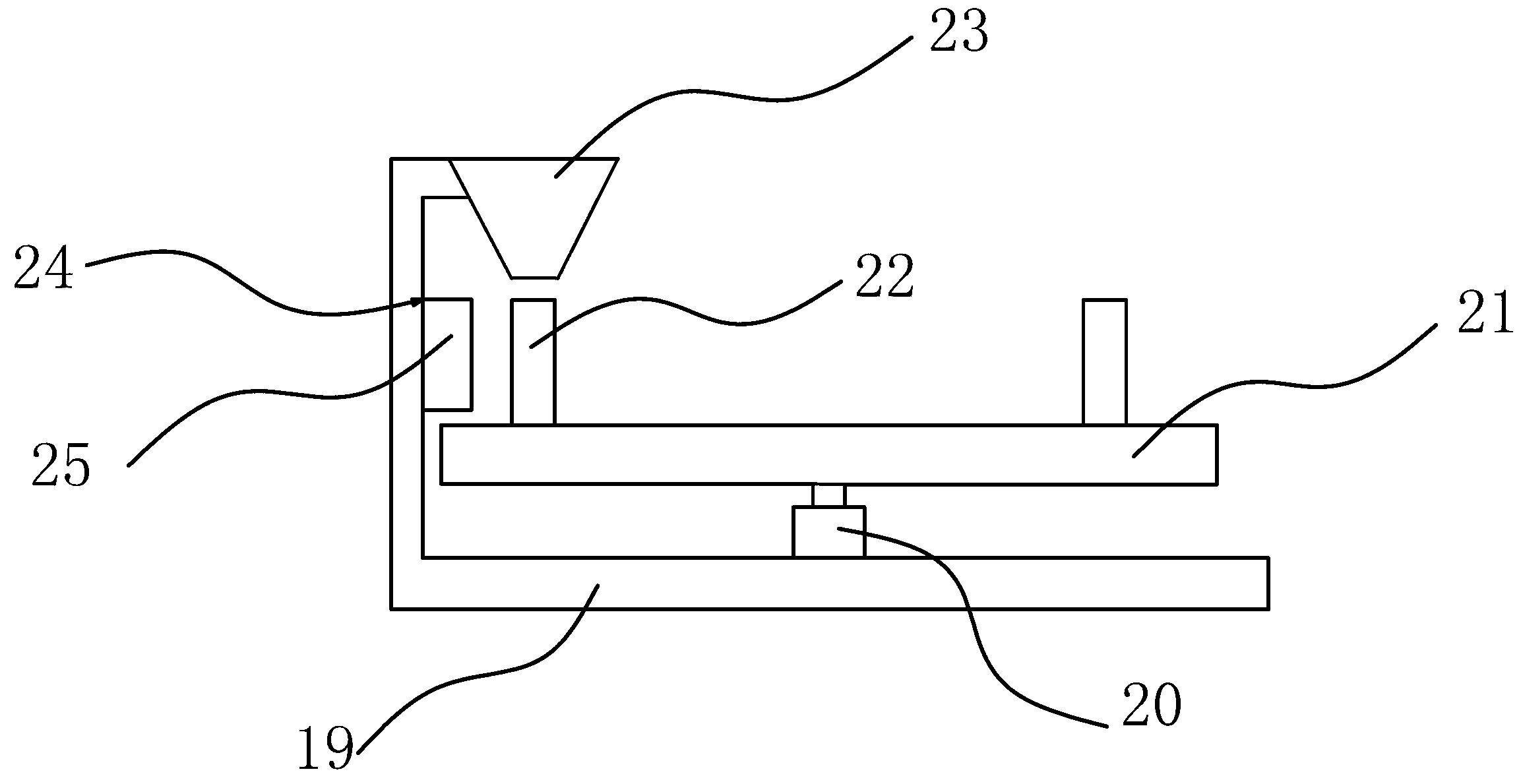

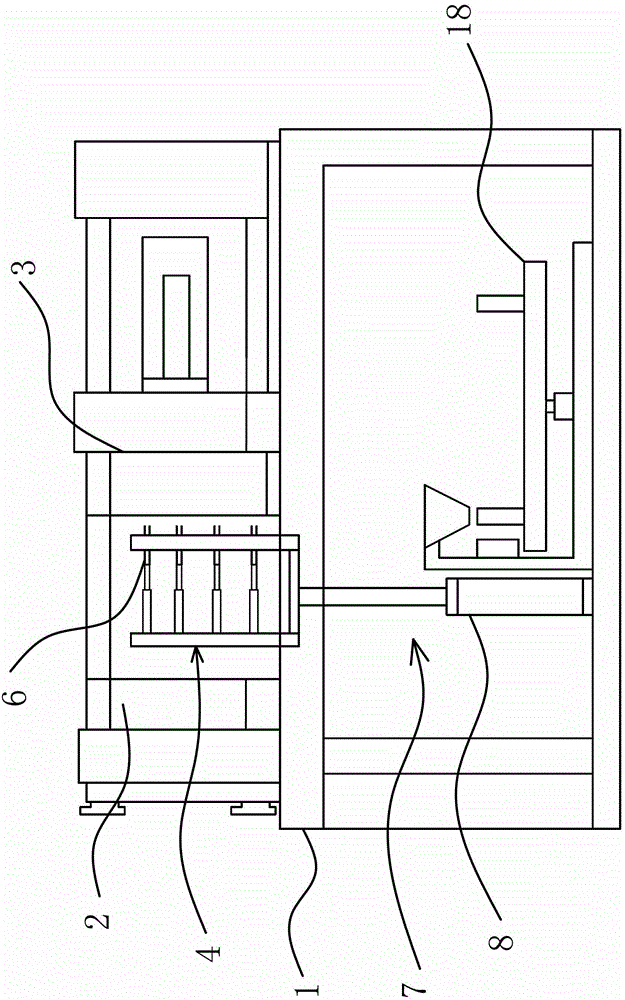

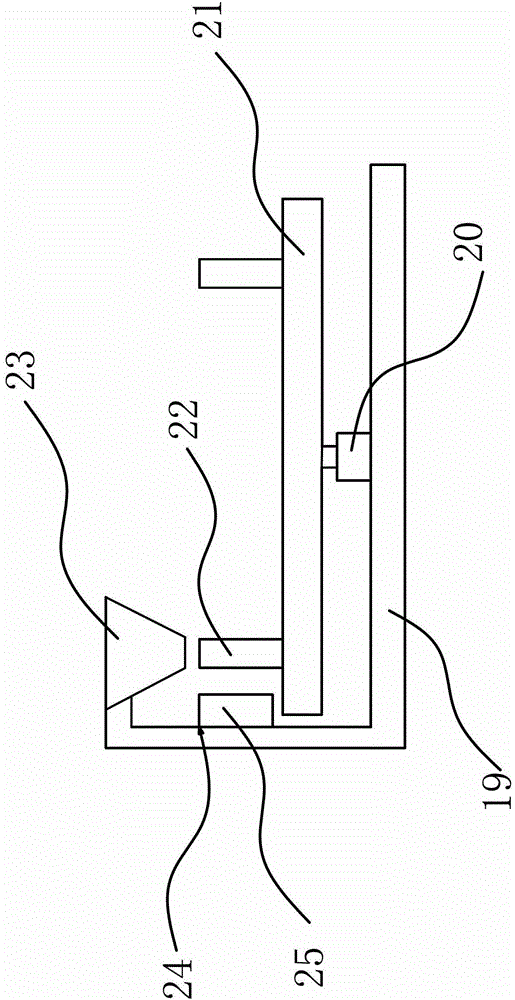

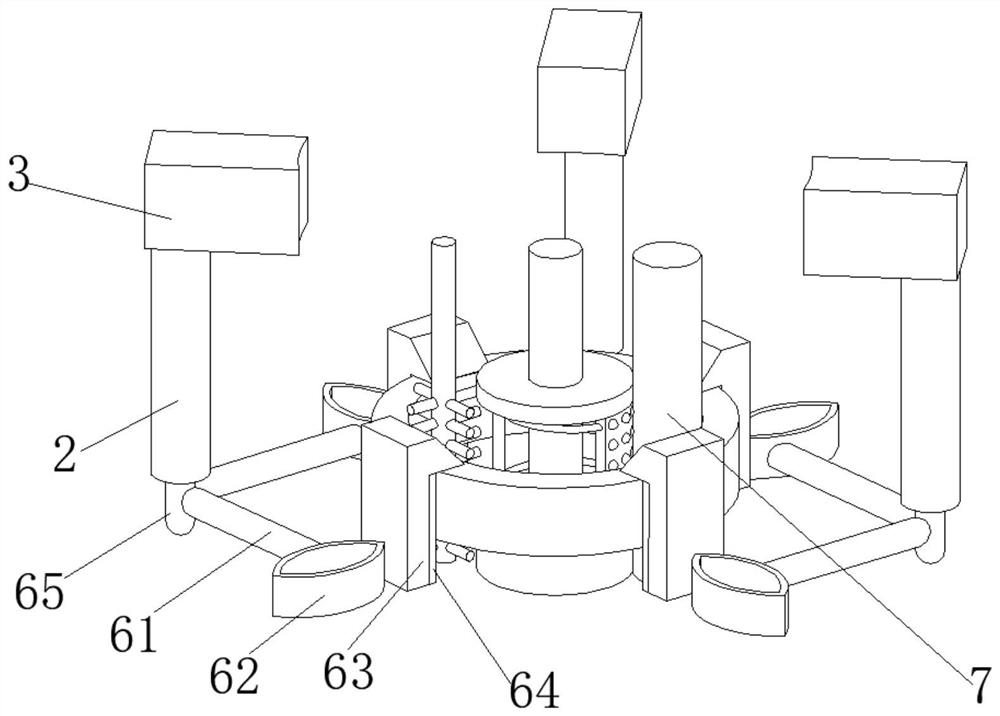

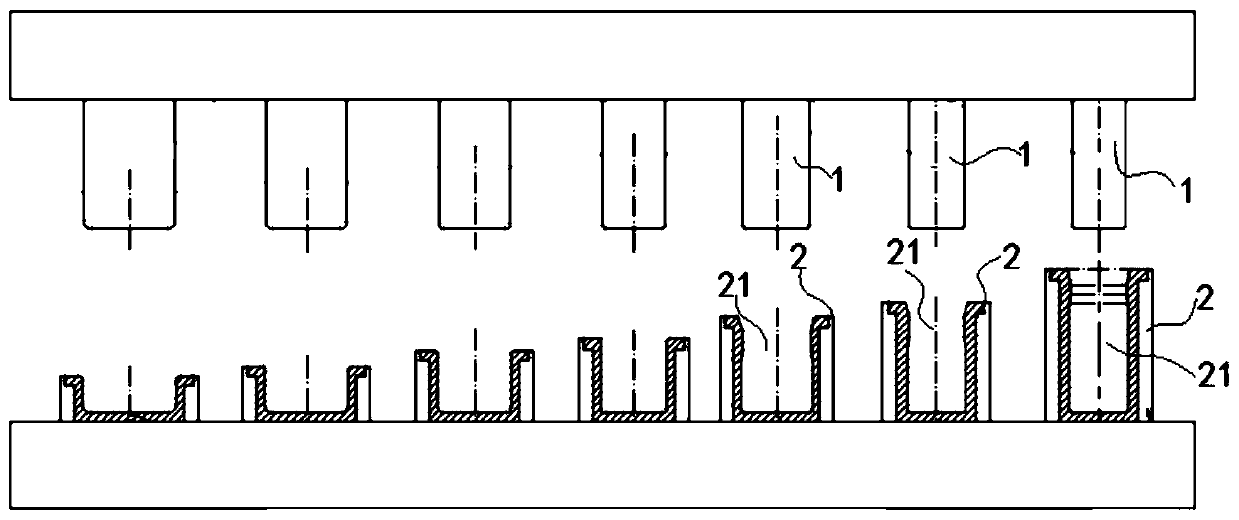

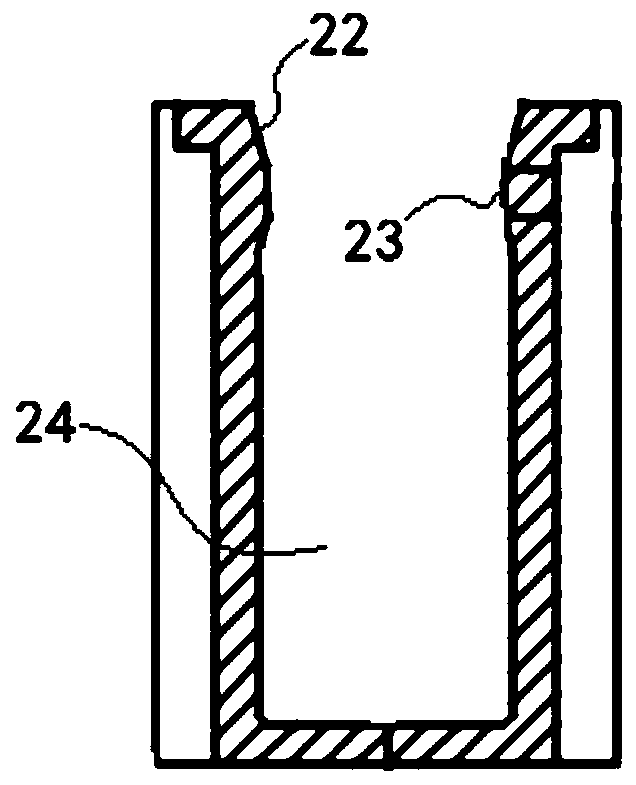

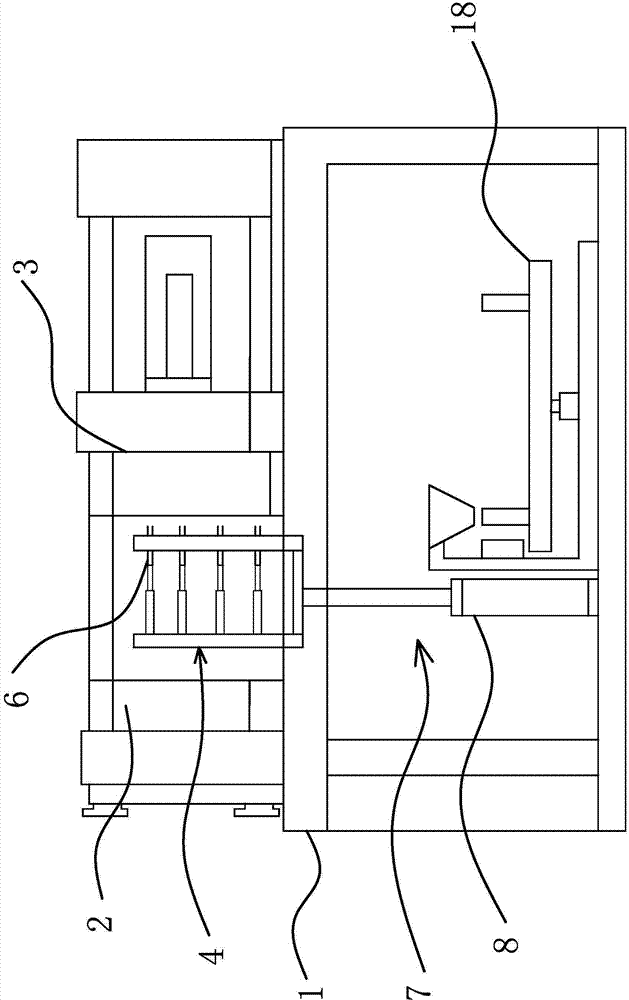

Injection molding machine for producing plastic bottle caps

InactiveCN103302822AImprove running stabilitySimple installation and maintenanceEngineeringReciprocating motion

Owner:佛山市顺德区山德塑胶五金有限公司

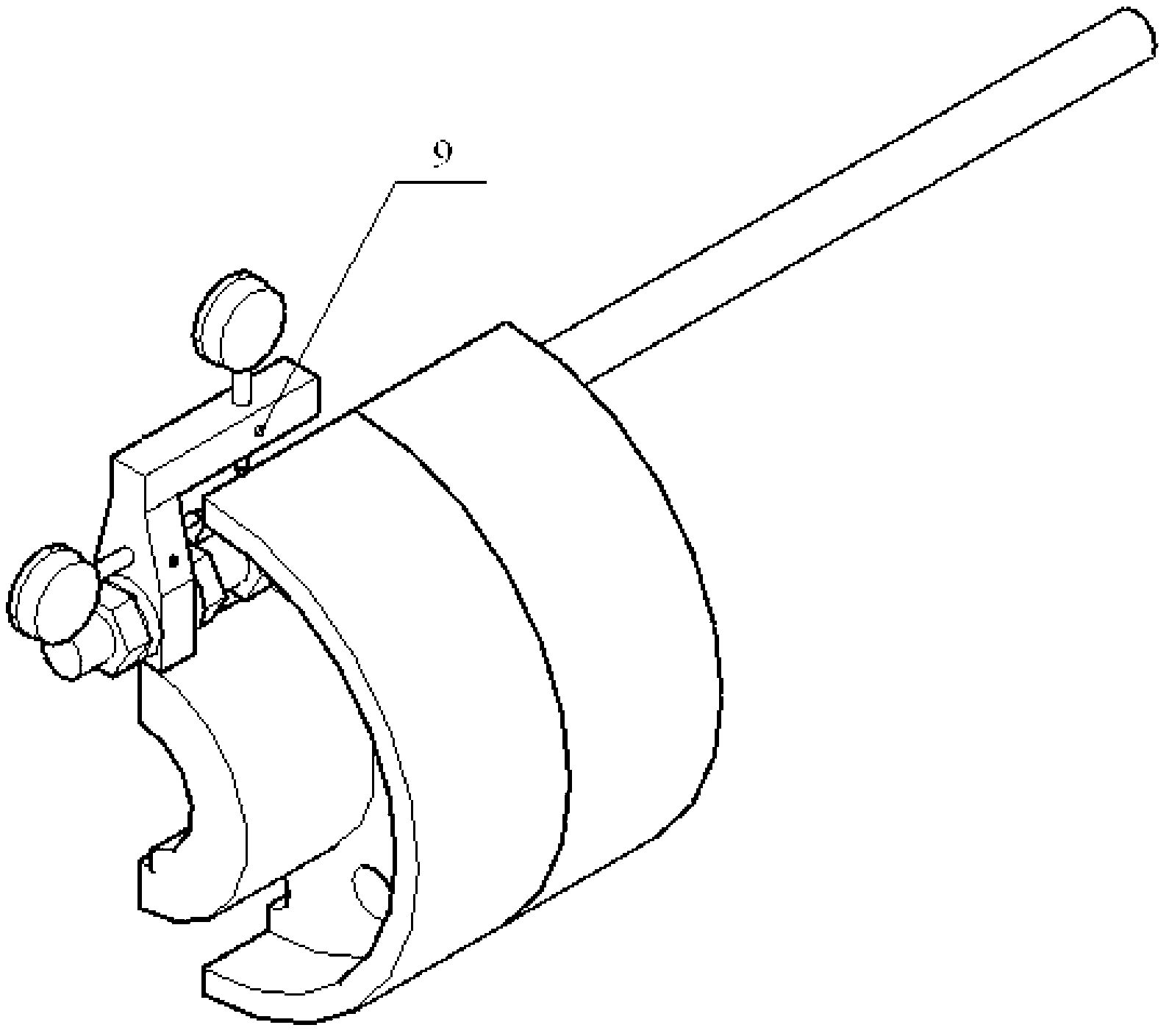

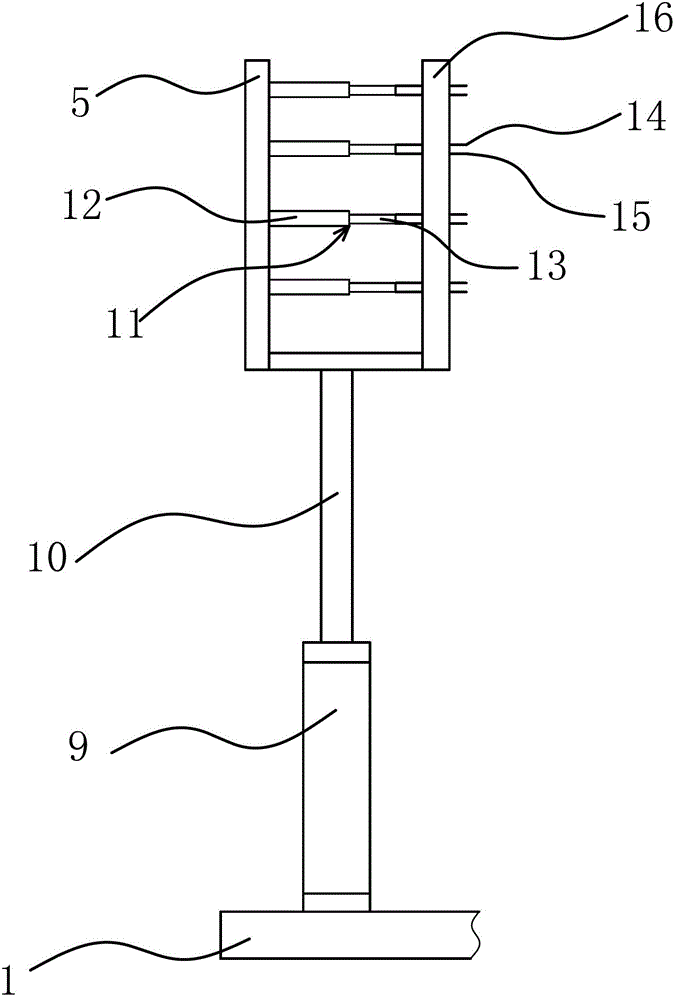

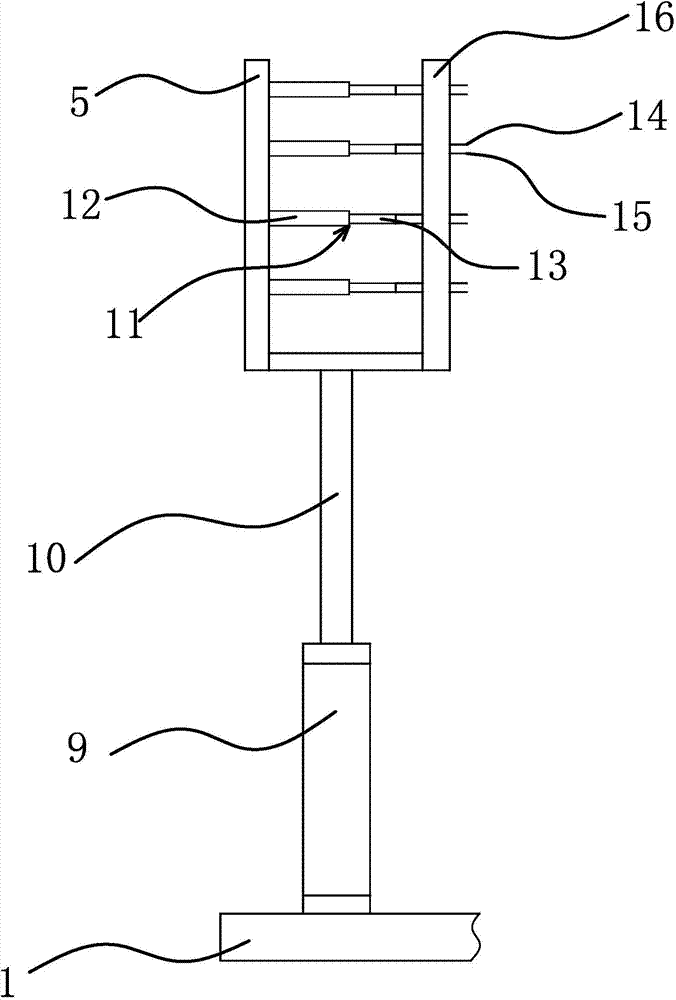

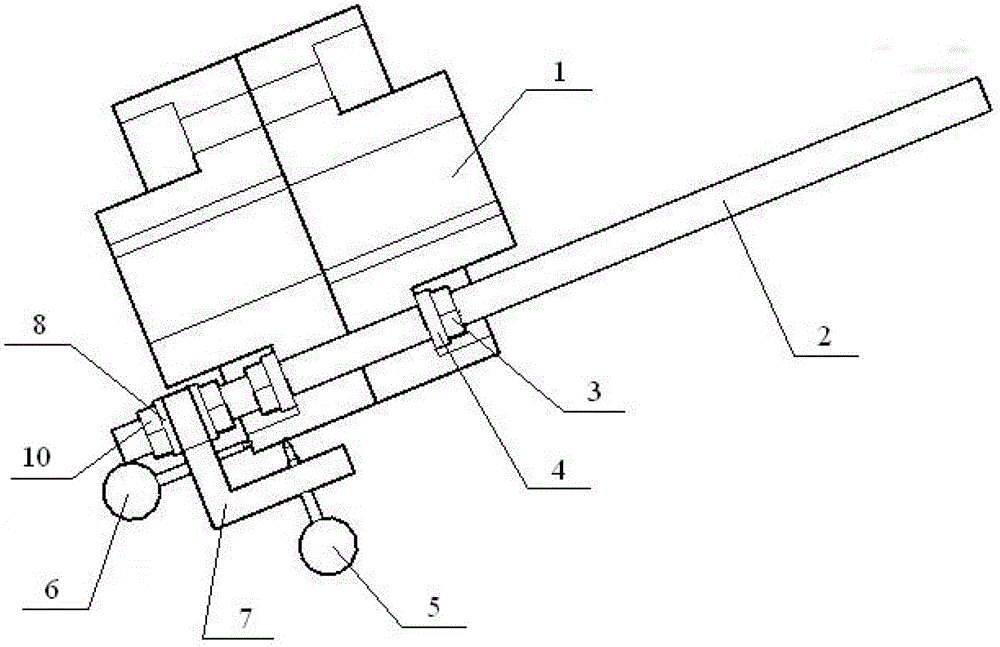

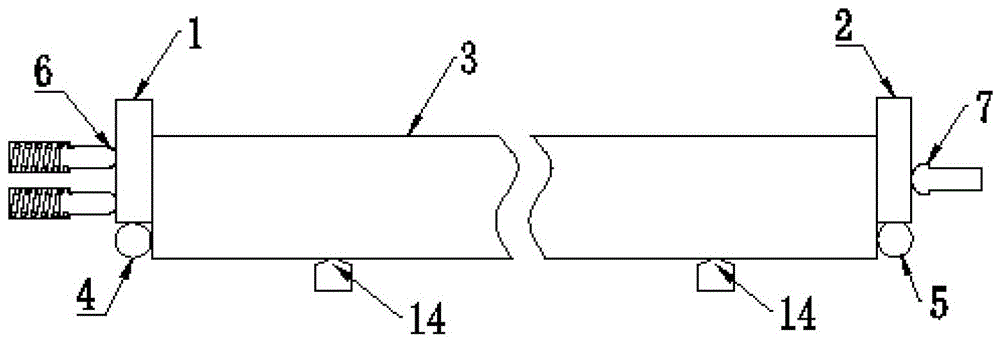

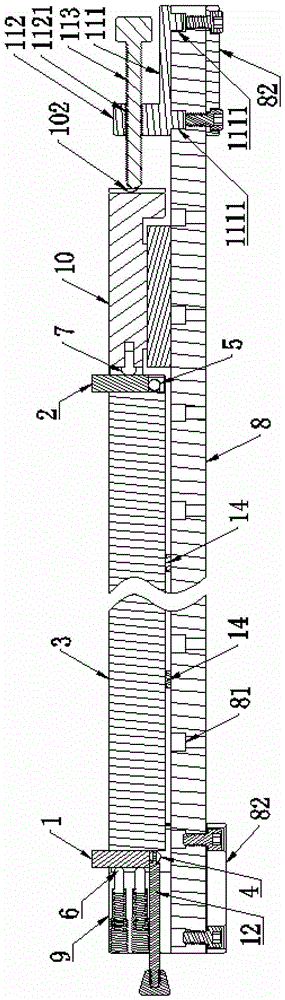

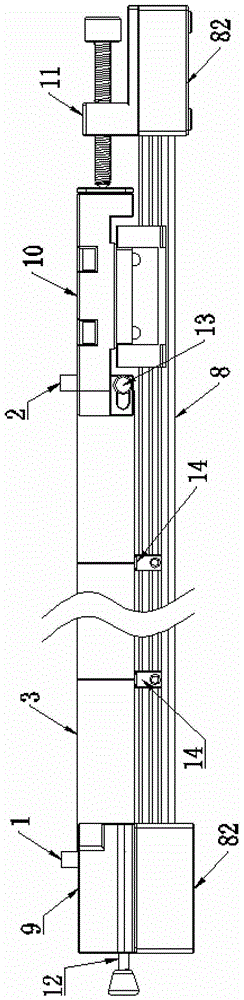

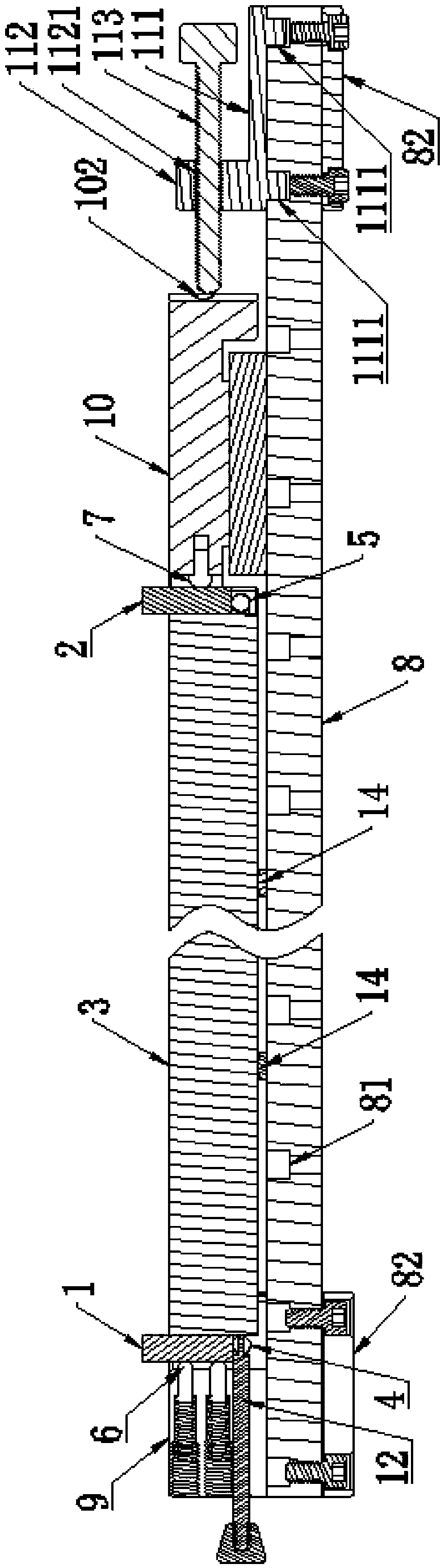

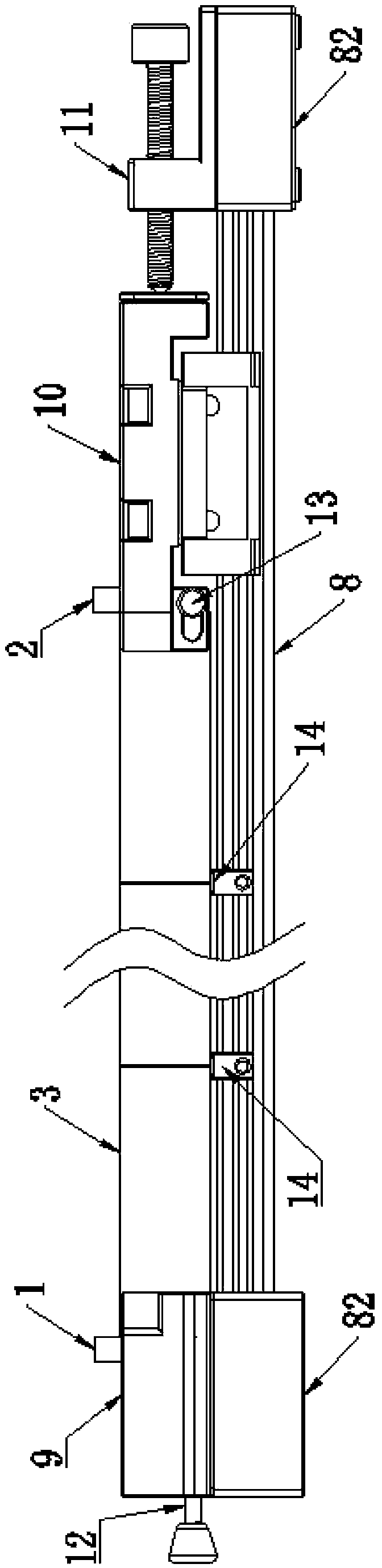

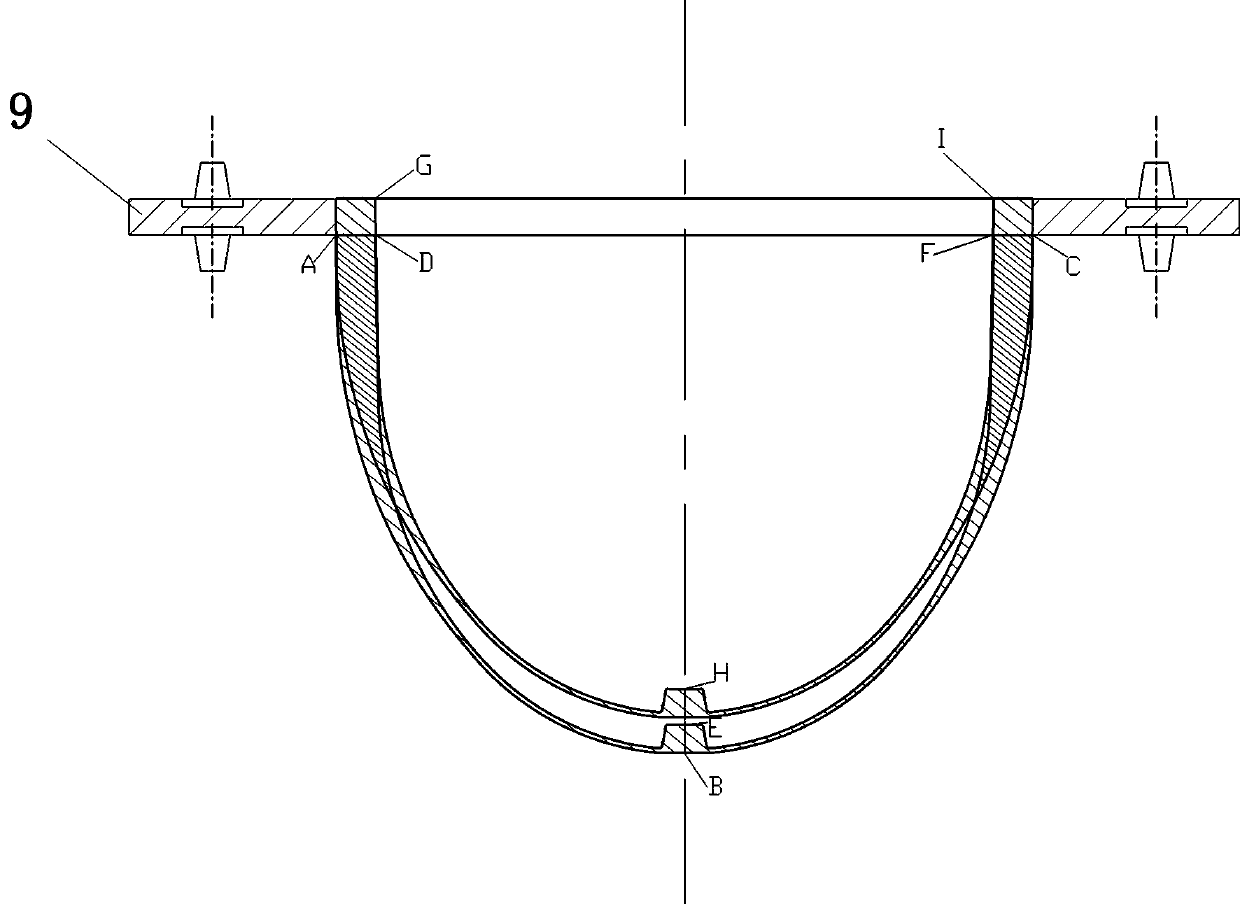

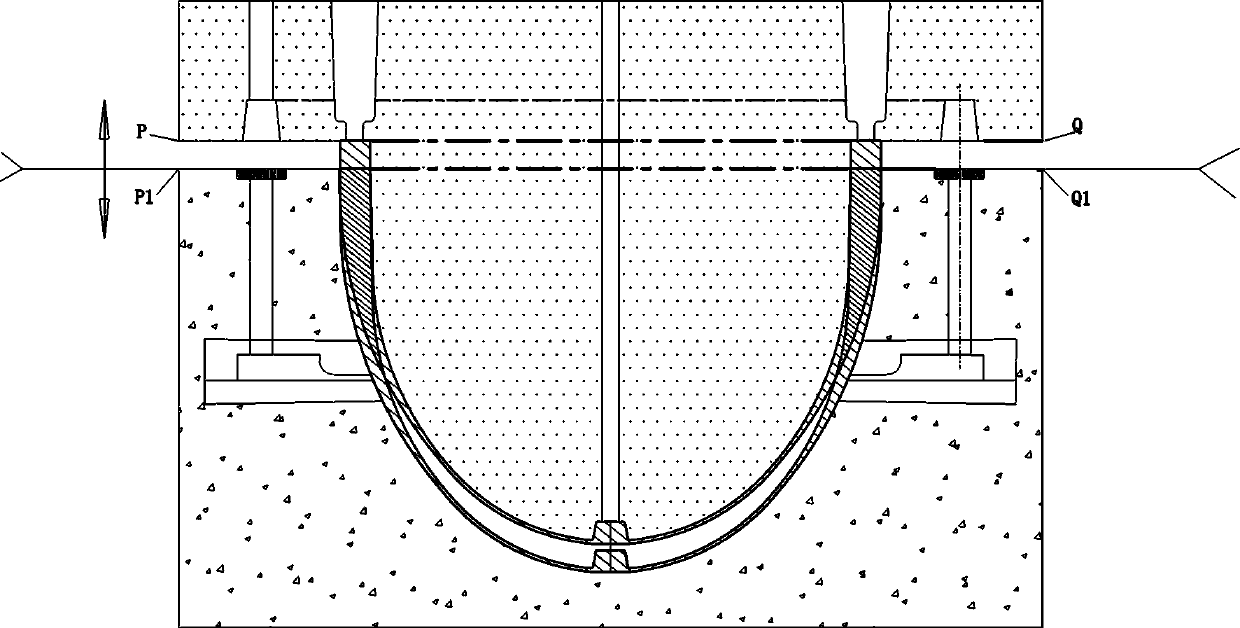

Device for synchronously measuring axial displacement and radial displacement of a rigid coupler

ActiveCN103267465ASimple structureEasy to operateMechanical measuring arrangementsMeasurement deviceAccuracy and precision

The invention discloses a device for synchronously measuring axial displacement and radial displacement of a rigid coupler. The device comprises a supporting rod which is connected in opposite connecting holes of two half couplers in a penetrating mode, a support is fixedly installed on the supporting rod, an axial measuring device measuring the axial displacement of the coupler and a radial measuring device measuring the radial displacement of the coupler are arranged on the support, threads are arranged on the supporting rod, the supporting rod and the coupler are connected through a pair of nuts I which are arranged on the supporting rod and positioned on the two sides of the coupler, and the support is installed on the supporting rod in a sleeved mode and fixed through a pair of nuts II. The device is simple in structure and convenient to operate, by the adoption of the axial measuring device and the radial measuring device which are installed on the support, axial displacement deviations and radial displacement deviations of the rigid coupler can be measured simultaneously, accumulative errors caused by separated measuring are reduced to the maximum, and measurement accuracy is improved substantially.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

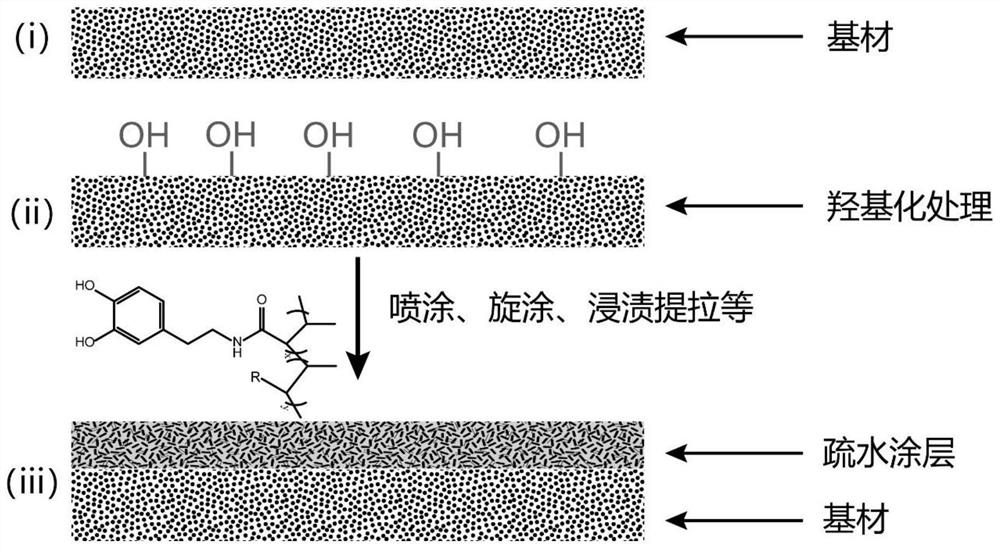

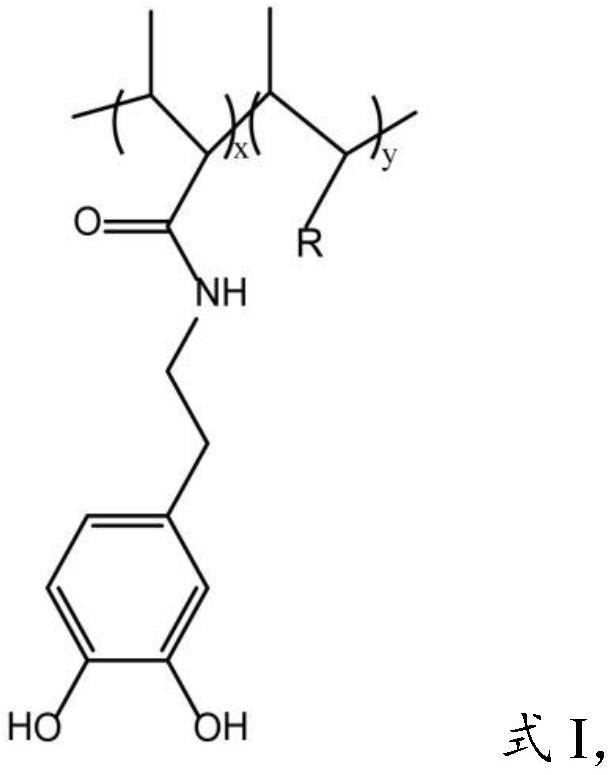

Hydrophobic moisture-resistant coating as well as preparation method and application thereof

The invention provides a hydrophobic moisture-resistant coating as well as a preparation method and application thereof, and belongs to the technical field of coatings. The prepared dopamine copolymer has an excellent adhesion characteristic, the coating and the surface of a pretreated base material are combined together through chemical covalent bonds, excellent bonding performance is given to the hydrophobic moisture-resistant coating and a substrate, and the bonding strength of the coating and the substrate is greatly enhanced; by adding the filler, the diffusion path of water molecules is increased, the diffusion rate of the water molecules is effectively reduced, meanwhile, the interaction between the hydrophobic moisture-resistant coating and the water molecules is weak, the moisture adsorption capacity is low, and therefore the function of blocking moisture for a long time is achieved. The hydrophobic moisture-resistant coating provided by the invention can be applied to the surface and interface fields of building external wall thermal insulation, roof waterproof and thermal insulation integration, building boards, thermal insulation and moisture-resistant materials of refrigerator cars and refrigeration houses, external protective layers of precise instruments and the like, and can effectively avoid oxidation and swelling deformation of wrapped materials due to moisture absorption of the materials, and influences on the dimensional precision of precision parts.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Injection molding machine for producing plastic bottle caps

Owner:佛山市顺德区山德塑胶五金有限公司

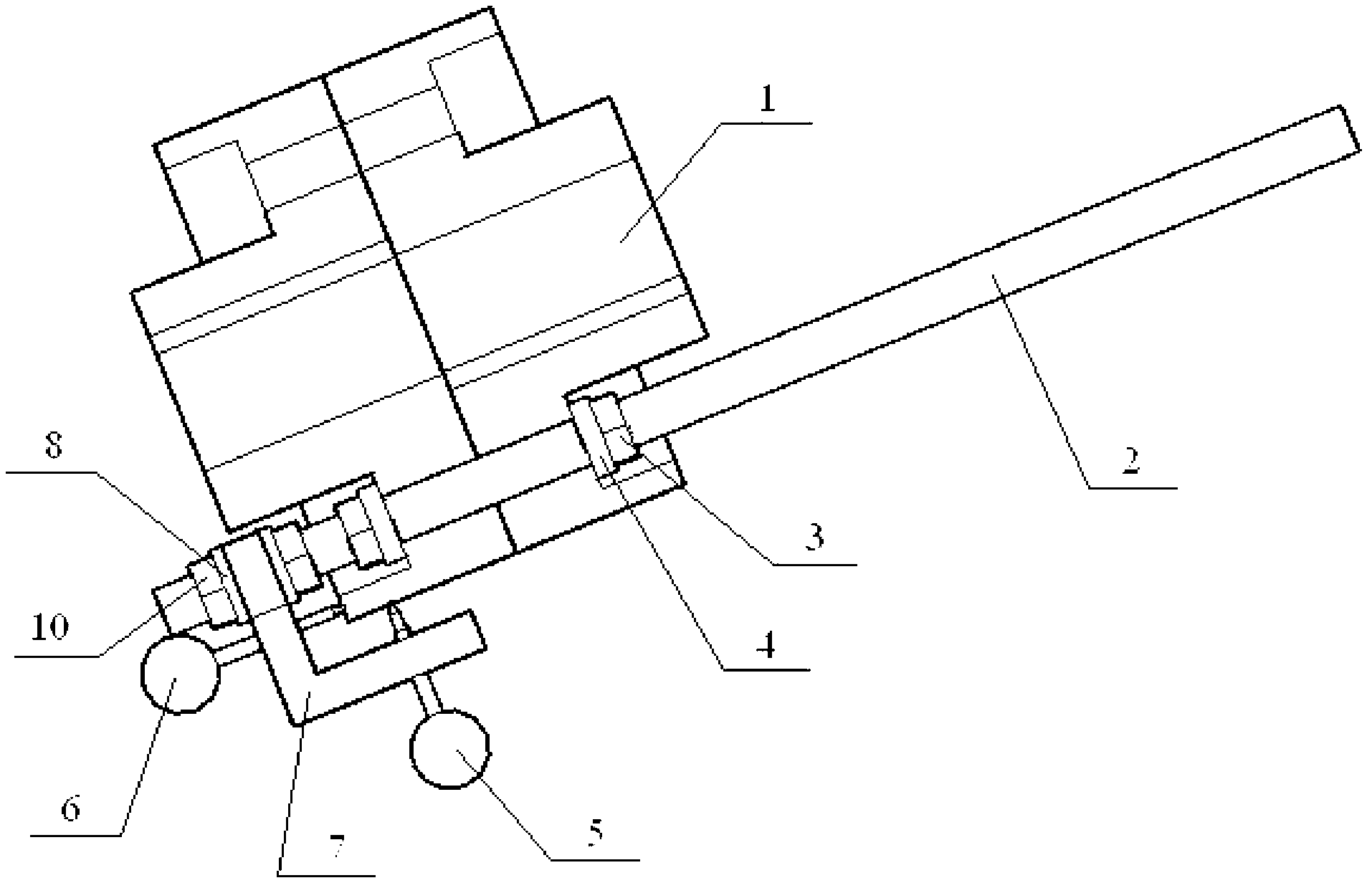

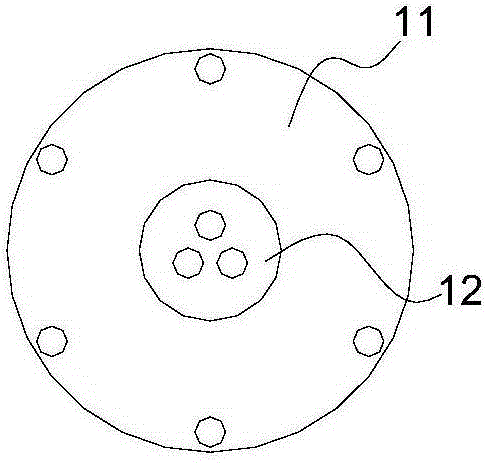

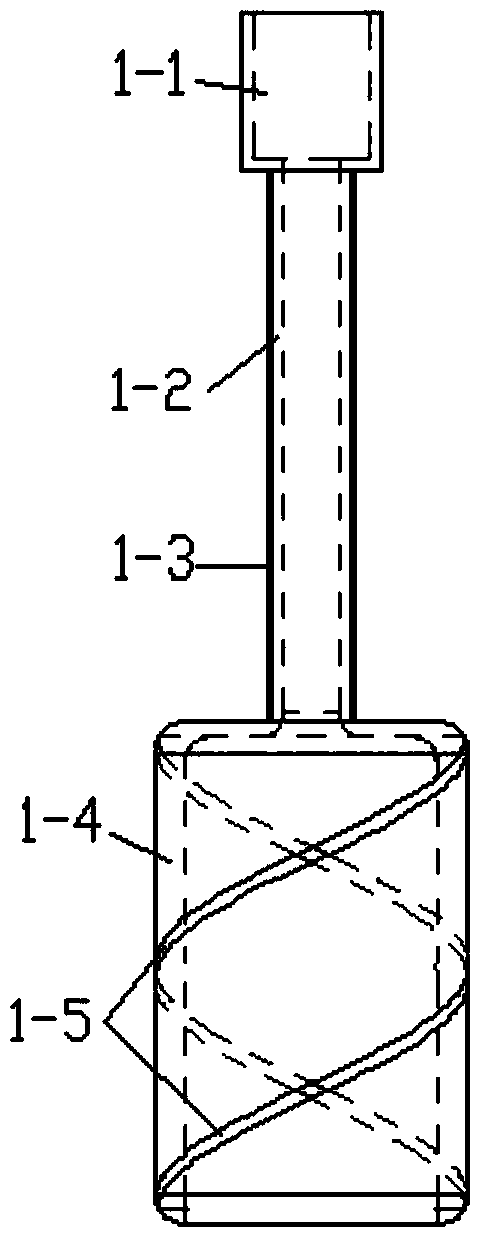

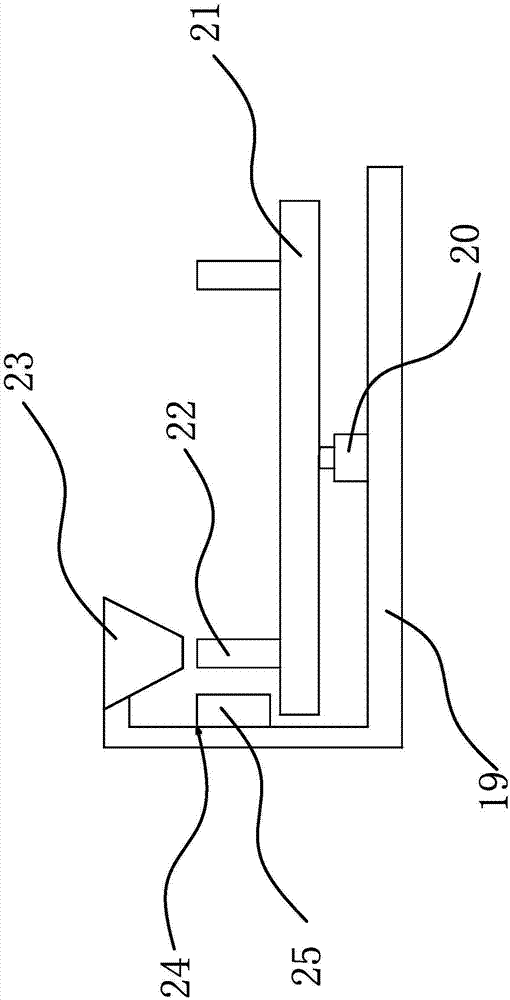

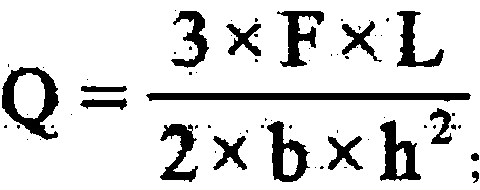

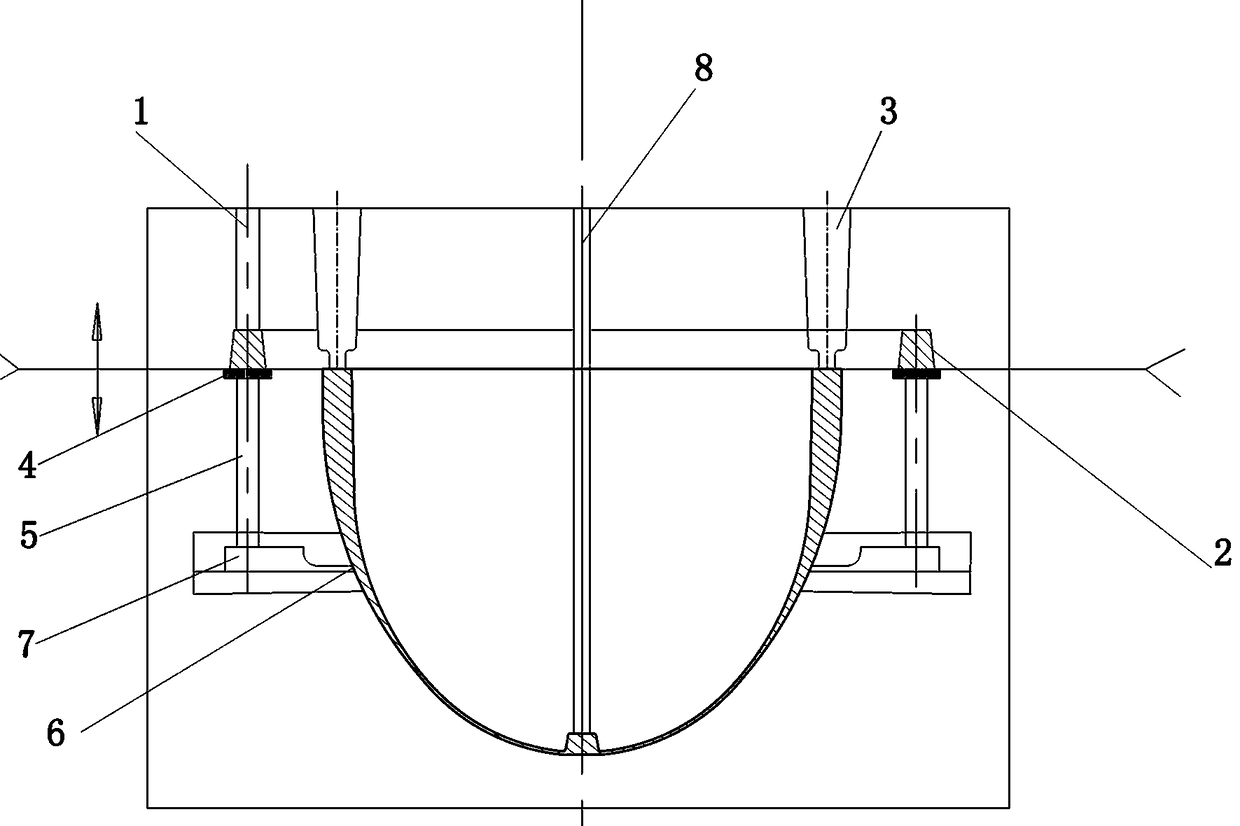

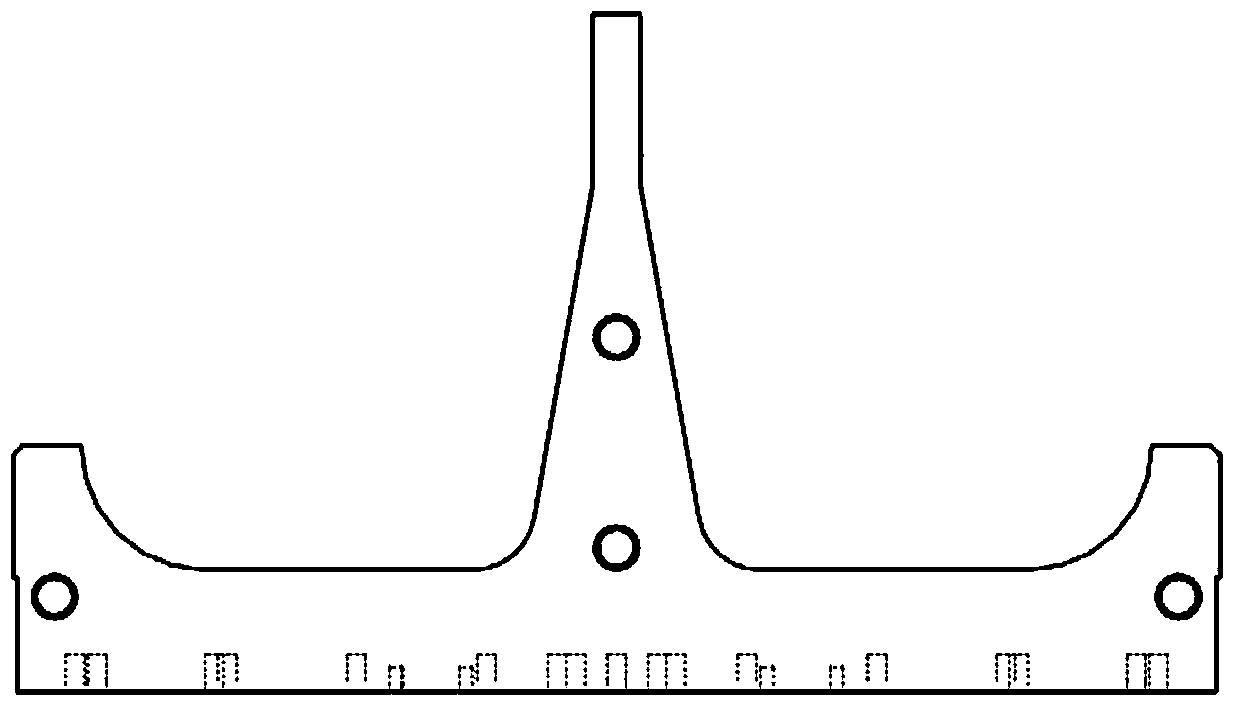

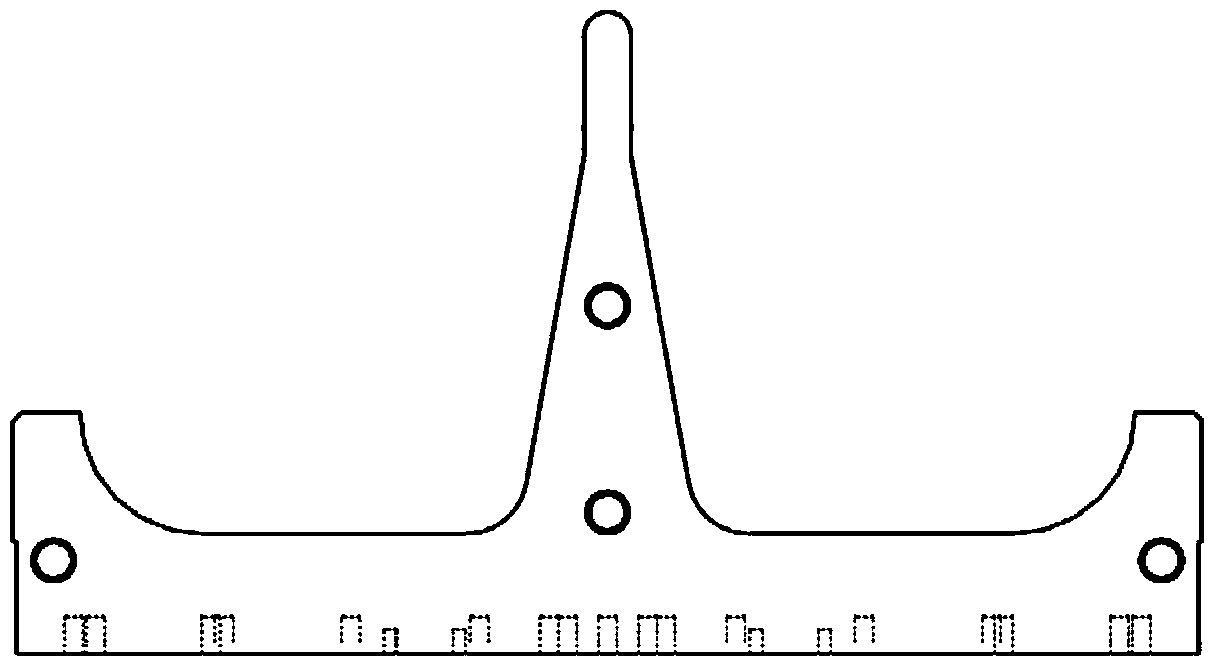

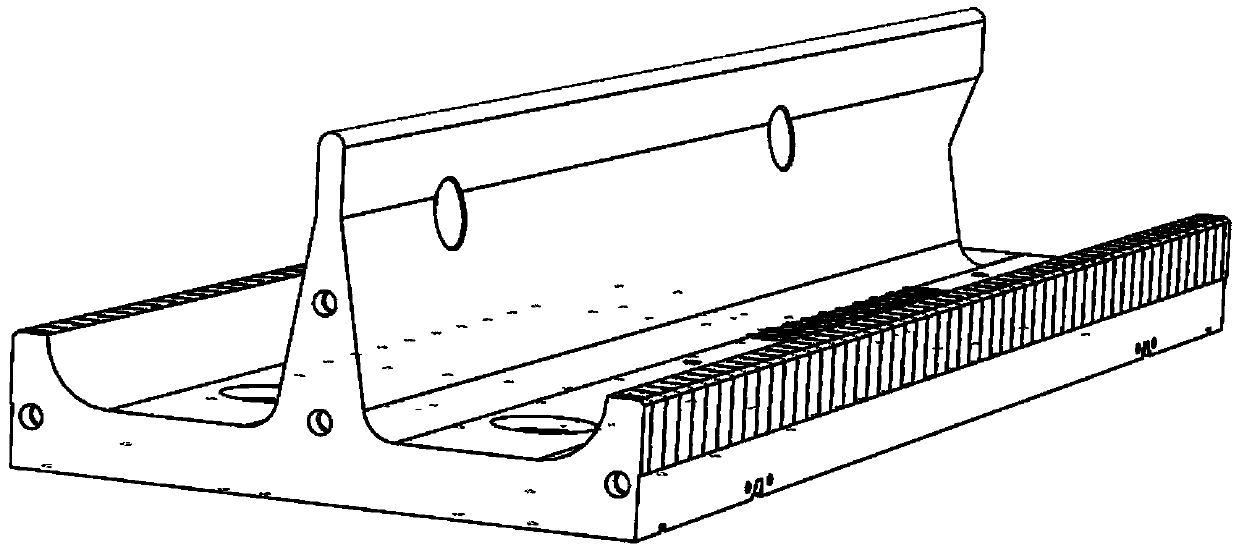

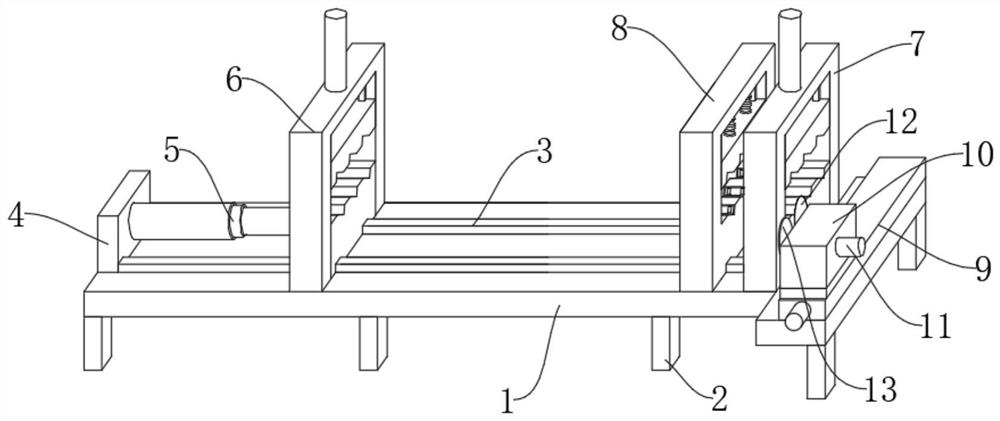

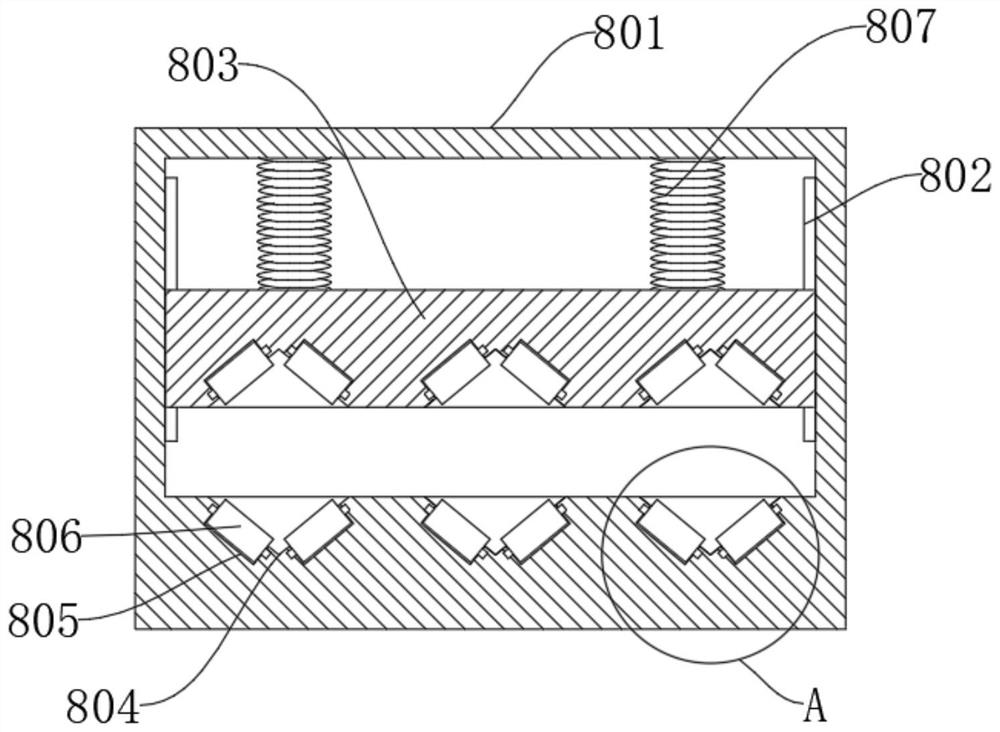

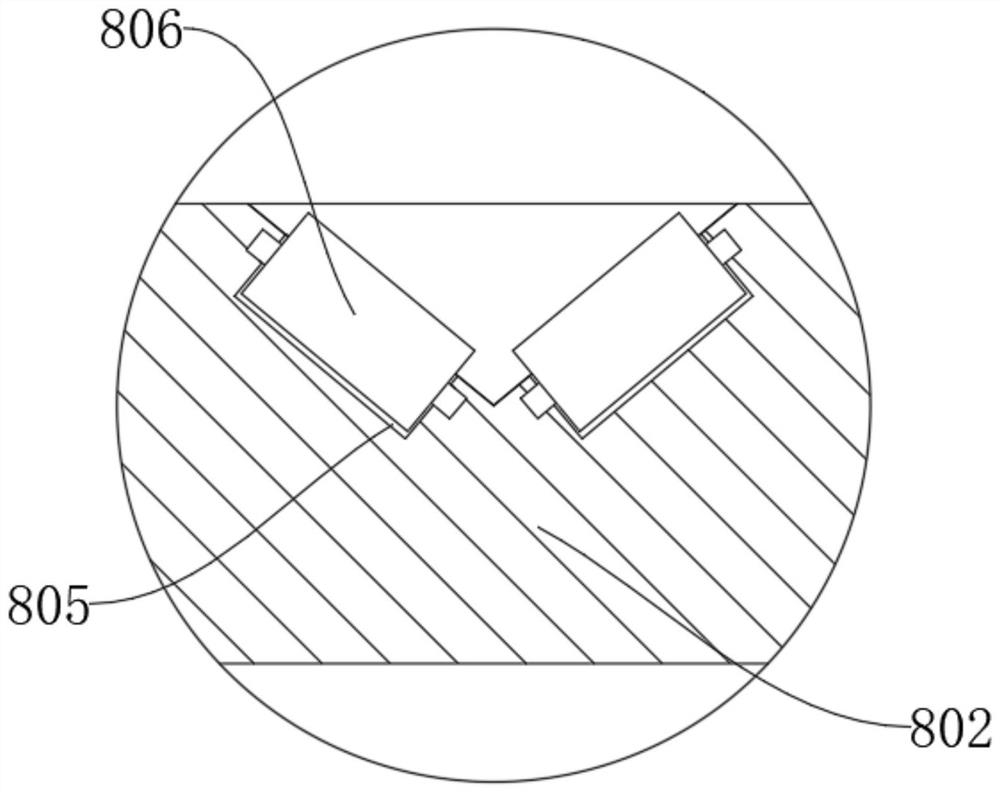

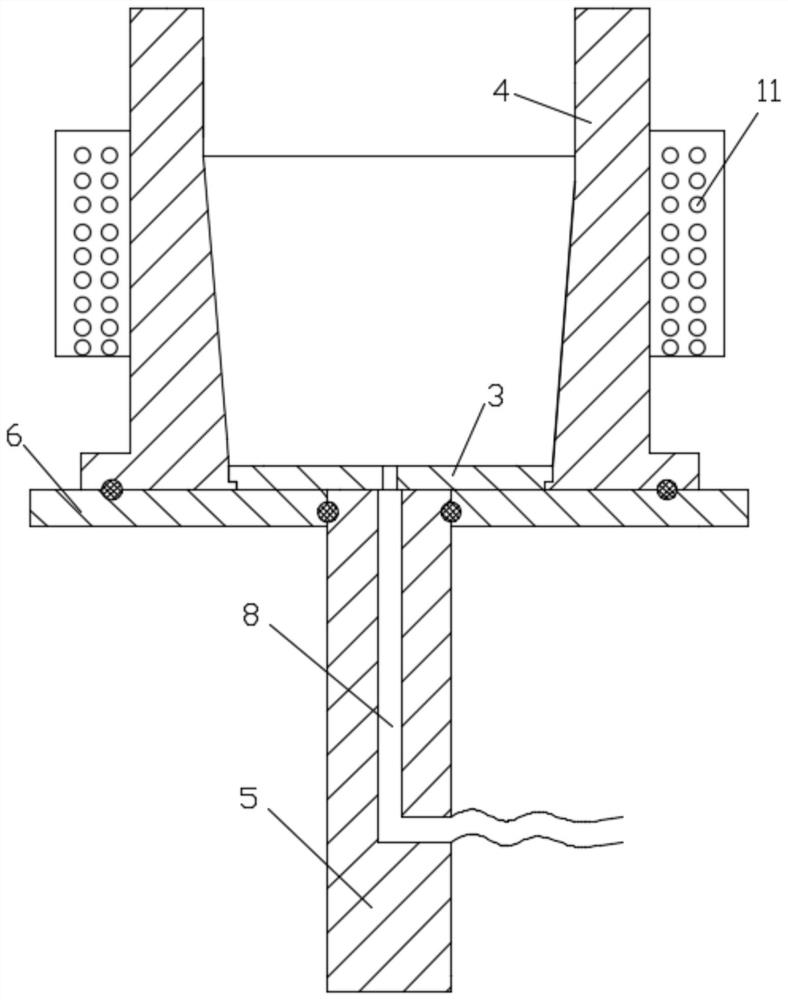

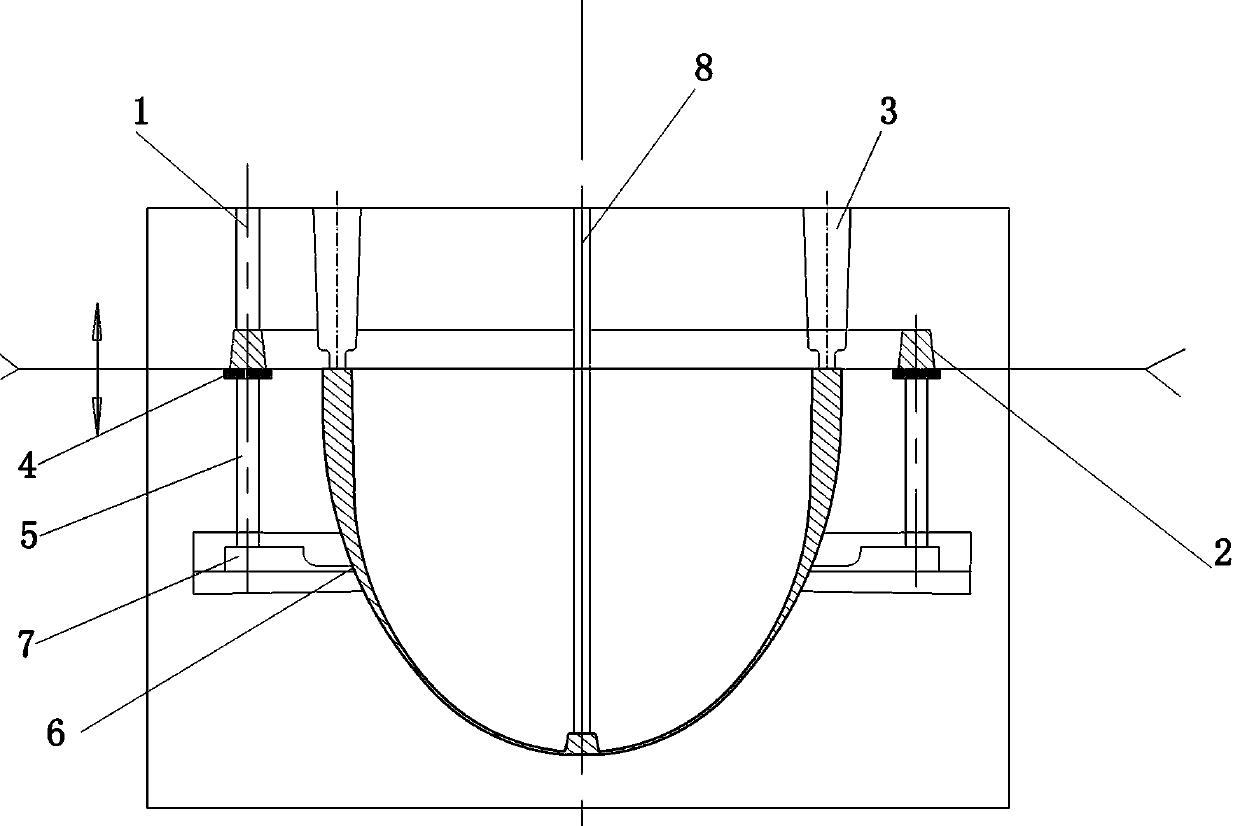

Sloping cover sleeve product machining clamp

ActiveCN105171486AAffects mass accuracyAffects dimensional accuracyWork clamping meansPositioning apparatusArchitectural engineeringEconomic benefits

The invention discloses a sloping cover sleeve product machining clamp. The sloping cover sleeve product machining clamp comprises a locating block, locating clamping jaws, a guide rod and a base, wherein the locating block comprises a lug boss raised in the middle and a supporting platform arranged on the edge; the locating block and the base are fixedly arranged, and center shafts of the locating block and the base are intersected; the base is fixedly connected to a machine tool; the lug boss is of a hollow structure, and through holes are formed in the side surfaces of the lug boss in directions vertical to the center shaft; the locating clamping jaws are arranged in the through holes, and first wedge-shaped surfaces are formed at one sides, which face to the center shaft of the lug boss, of the locating clamping jaws; and the guide rod is arranged in the hollow structure of the lug boss, the top of the guide rod is supported against the first wedge-shaped surfaces, and the bottom of the guide rod is connected to a feed shaft of the machine tool. The sloping cover sleeve product machining clamp has the advantages of good repeatability and accuracy consistency, high machining efficiency and reliability, good appearance quality of product surfaces, high size accuracy, good machining stability, high degree of automation, low cost, and easy maintenance and assembly and has good economic benefits.

Owner:武汉泛洲中越合金有限公司

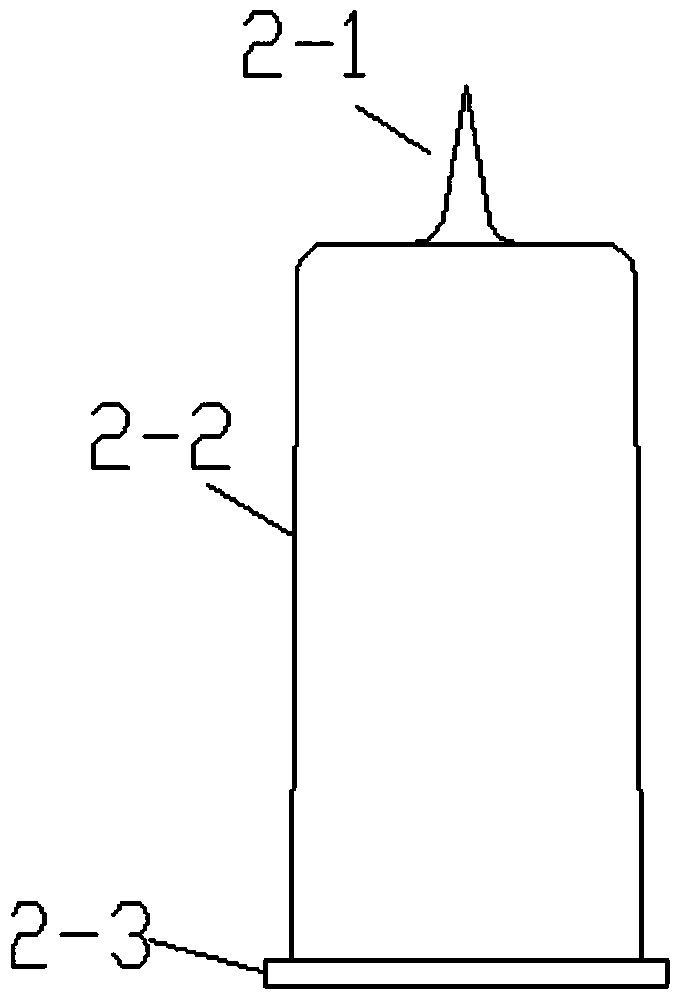

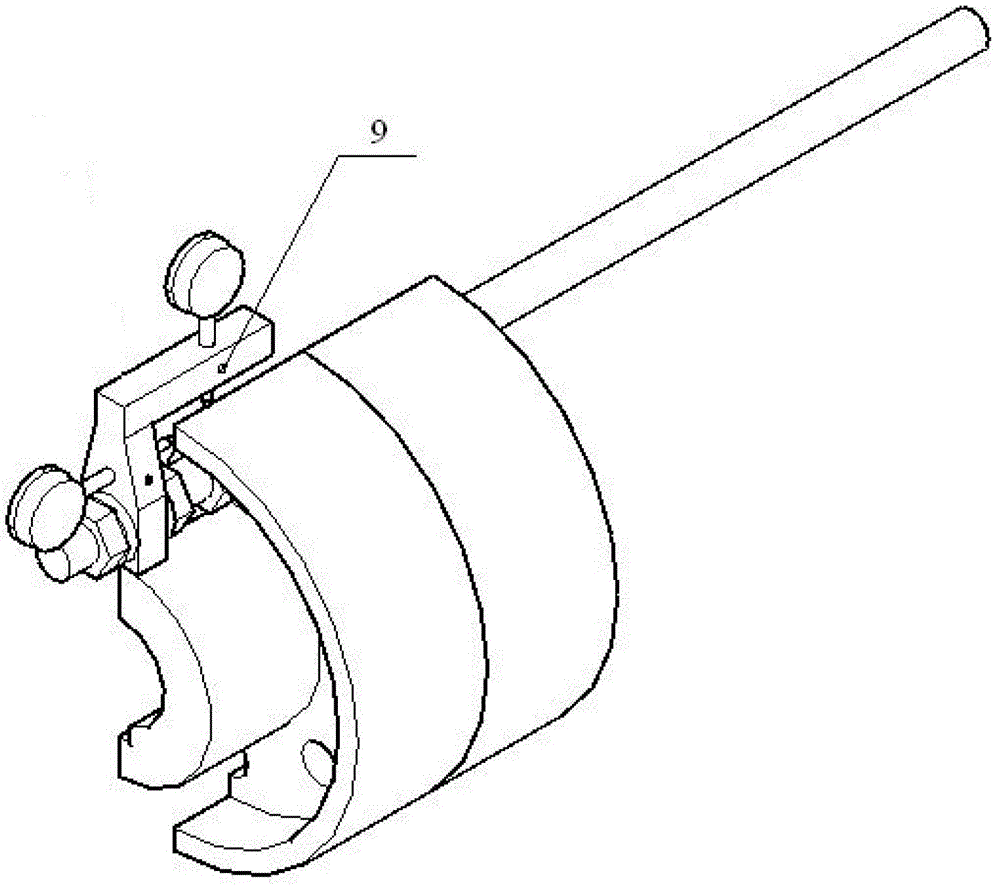

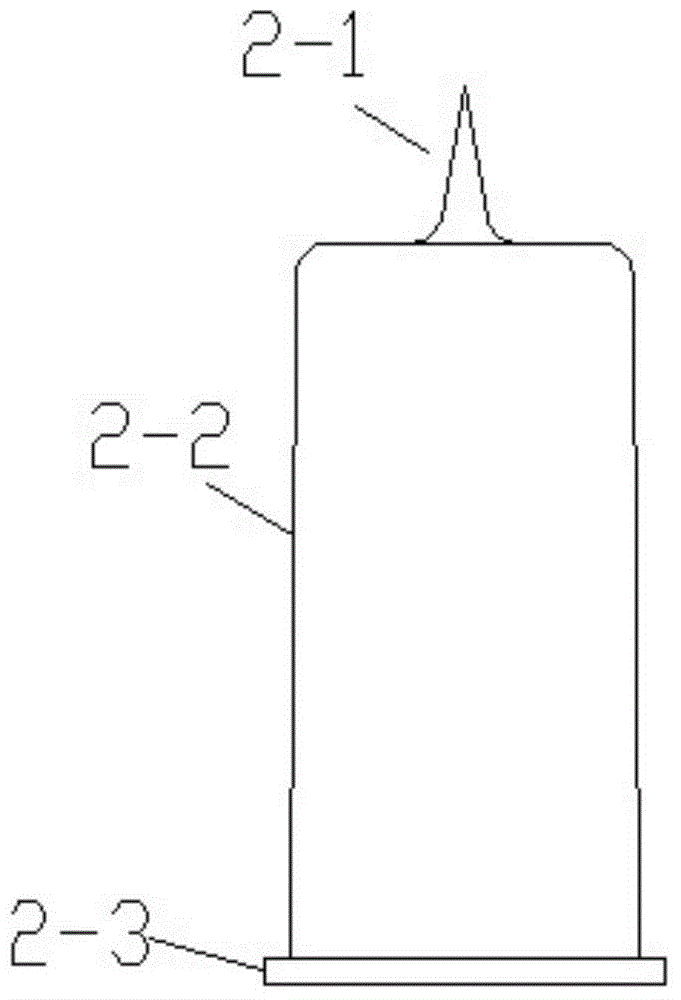

Cathode for use in numerical control electrolysis, turning and boring machining of pressure storing cavity

ActiveCN103706900AIncrease pressureSolution to short lifeMachining electrodesElectrical-based machining electrodesNumerical controlElectrolysis

The invention discloses a cathode for use in numerical control electrolysis, turning and boring machining of a pressure storing cavity, belonging to the field of cathodes for use in electrolytic machining. The cathode comprises a cathode body and a shunting body, wherein the cathode body is a revolving body which is hollow inside; one end of the cathode body is taken as a clamping portion, and the other end of the cathode body is taken as a working portion; a neck portion is arranged between the clamping portion and the working portion; the outer diameter of the neck portion is smaller than that of the working portion; the outer wall of the neck portion is provided with an insulating layer; the working portion is provided with a spiral liquid outlet; the middle of the shunting block is provided with a conical revolving body; the top of the conical revolving body is provided with an apex, and the bottom of the conical revolving body is provided with a positioning cylinder; the shunting block is arranged in the cavity of the working portion of the cathode body, thereby forming a flow channel with an annular section; the positioning cylinder is fixedly connected with the lower end of the working portion. A cathode for machining the die cavity of a revolving body with a slender inlet cavity and a large pressure storing cavity is provided. A machining surface is good in quality and free from fine cracks. The machined pressure storing cavity can bear high pressure, and is long in service life.

Owner:常州林胜金属科技有限公司

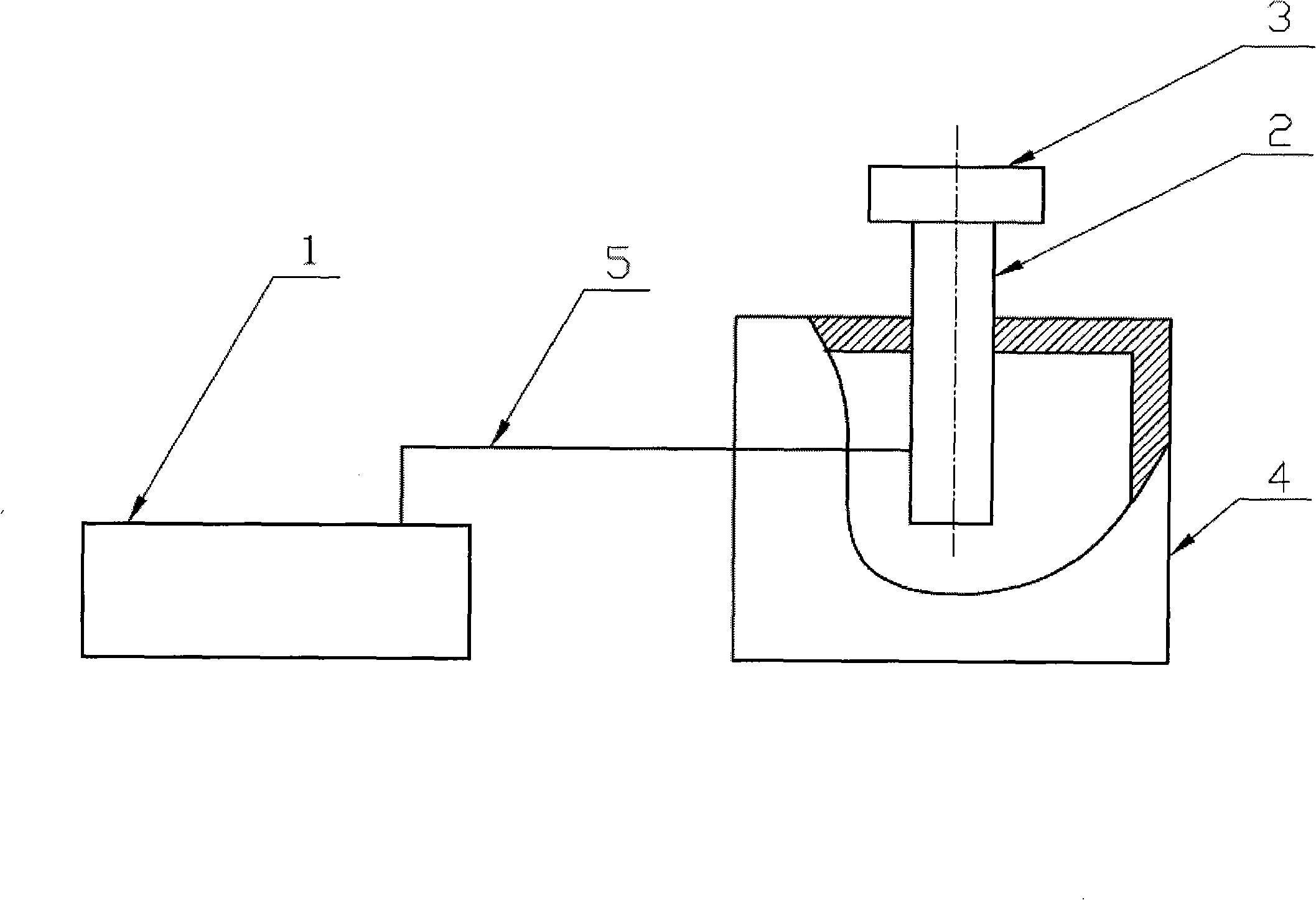

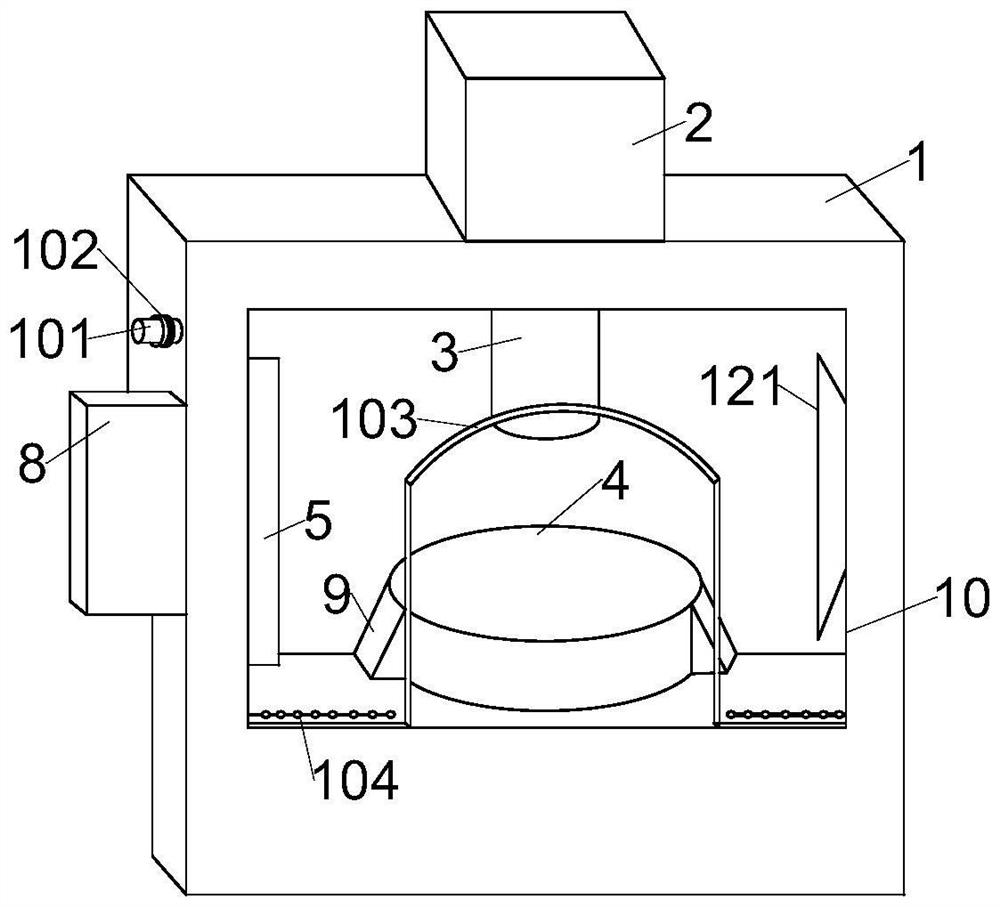

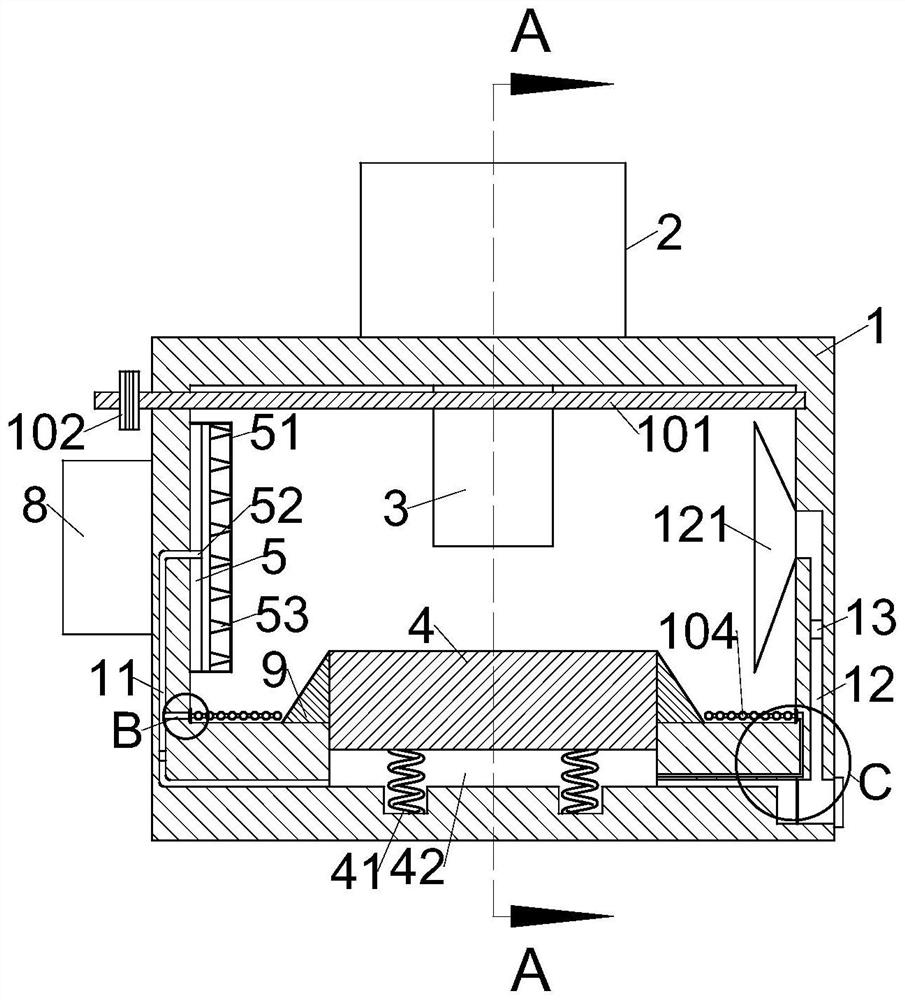

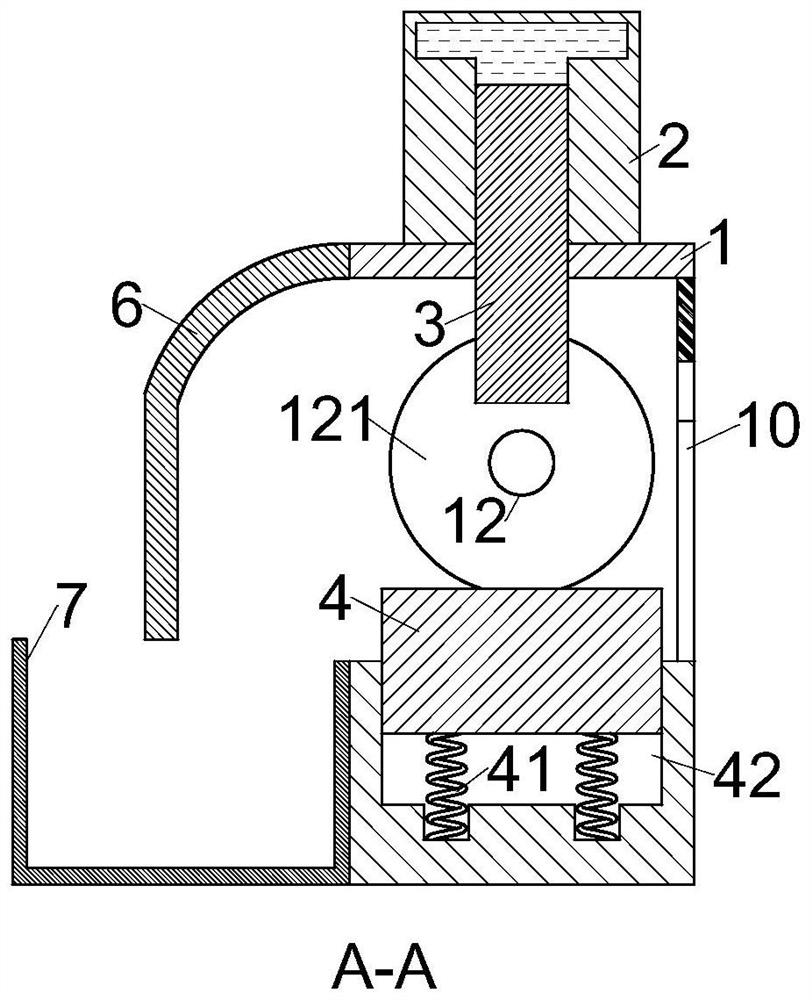

Apparatus and method of polymer photoresist ultrasonic ageing effect

InactiveCN101276159AEfficient combinationReduce internal stressSemiconductor/solid-state device manufacturingPhotosensitive material processingStress concentrationTransducer

The present invention provides a device and method of polymer photoresist ultrasound aging, belonging to ultrasonic application field, characterized in that the polymer photoresist ultrasound aging device includes an ultrasonic generator, an ultrasonic transducer, a worktable and a casing, the characteristics is that the worktable is connected with the ultrasonic transducer, the casing supports the worktable which is suspended with the transducer. The method of the polymer photoresist ultrasound aging is characterized in that the silicon is cleaned in the standard process, coated with the photoresist after dried, exposing under the uv, ensuring SU-8 adhesive crosslink after dried; the adhesive layer is processed with an ultrasound aging: the ultrasonic generator transmits a high frequency electrical signal to drive the ultrasonic transducer vibrate and transmitting to the worktable. The invention has effects and advantages of effectively reducing the internal stress of the polymer photoresist layer, avoiding phenomena of baseboard bend, stress concentration, sticking affecting the size precision and the structure of the adhesive layer, ensuring the process parameter have more elasticity, providing conditions in order to obtaining more effective, more diversified parameter combination, reducing the research and development costs.

Owner:DALIAN UNIV OF TECH

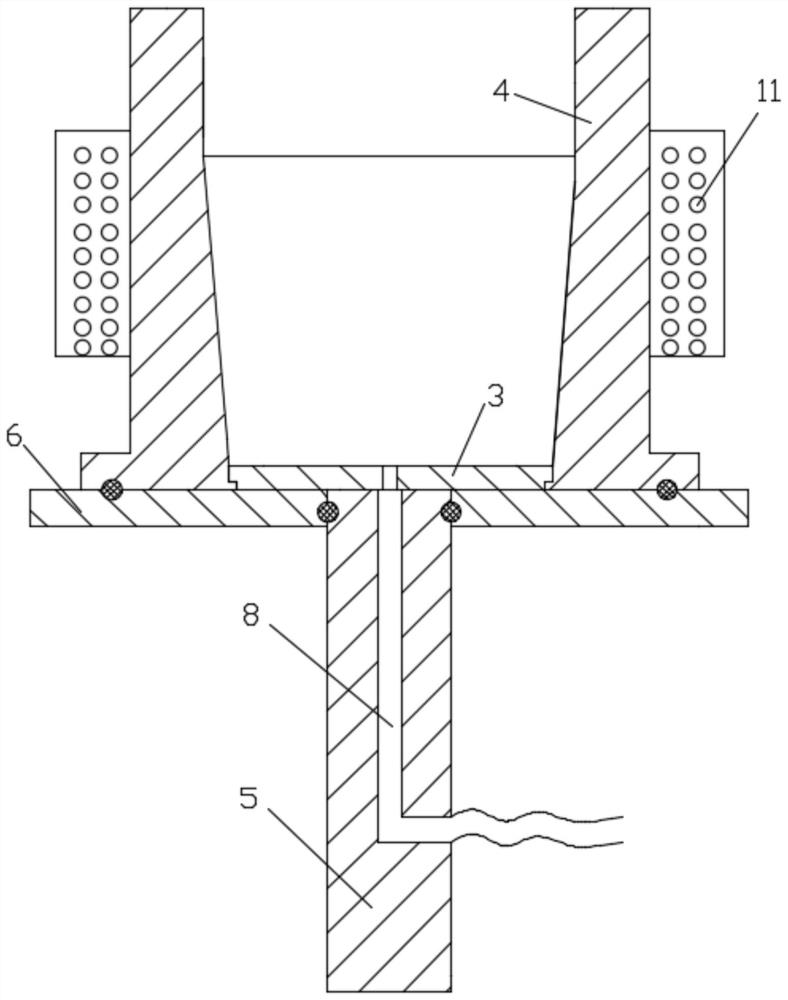

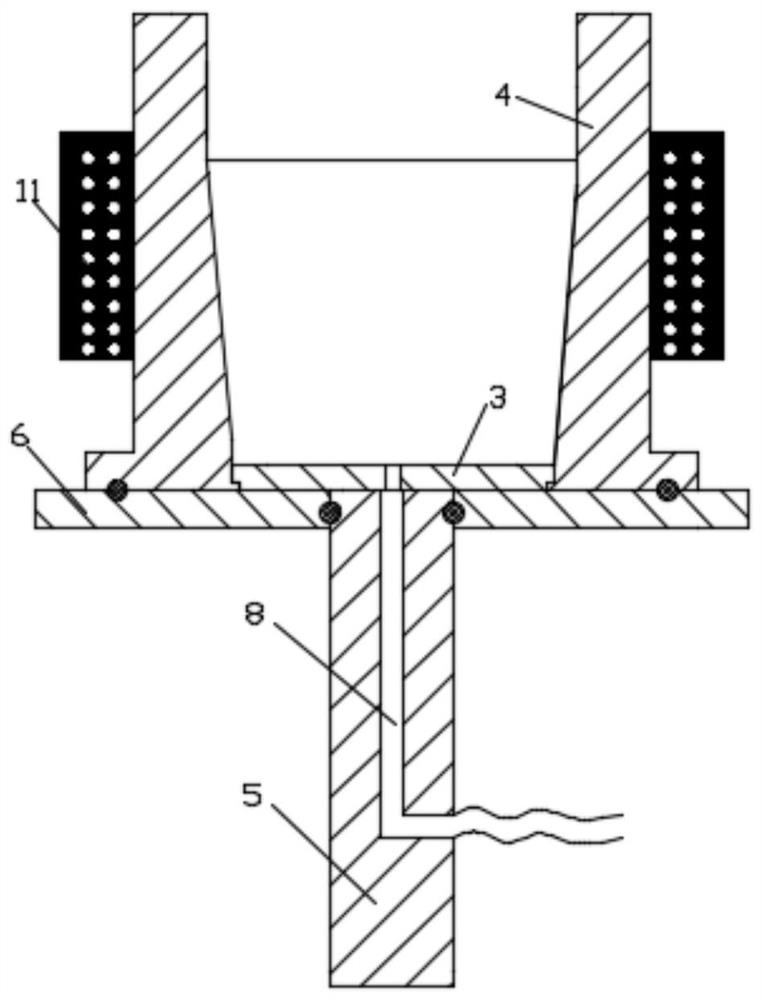

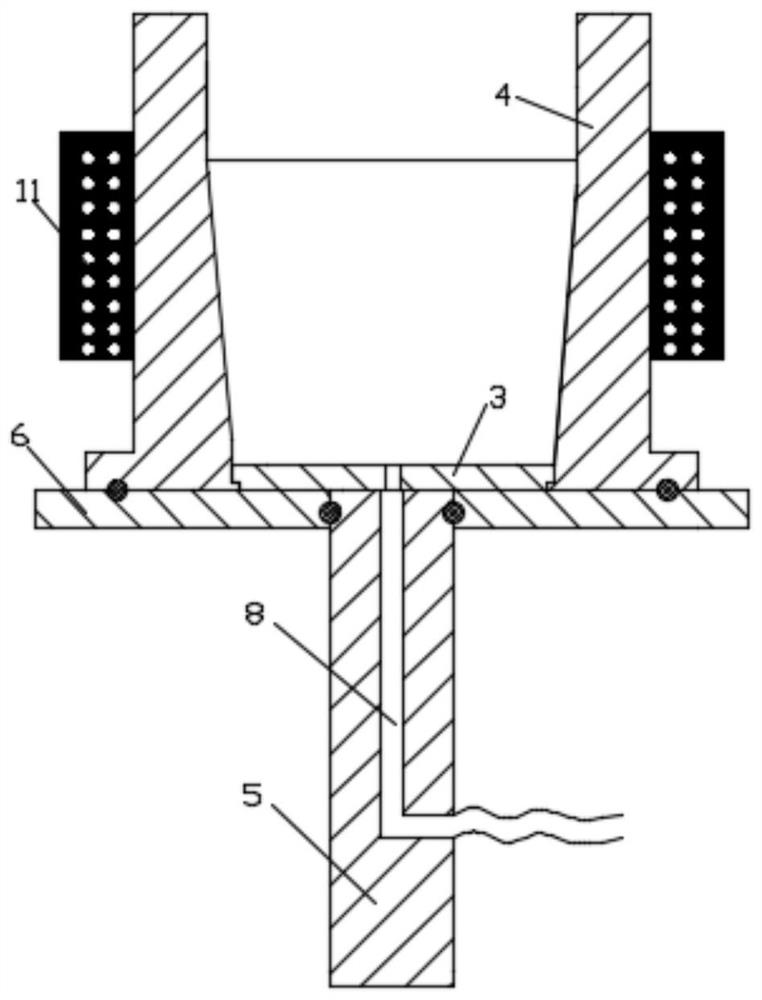

Process for preparing metal-based ceramic composite material through secondary pressure application

The invention relates to a process for preparing a metal-based ceramic composite material through secondary pressure application. A device used in the process comprises a product forming die assembly, a cover die, a bottom plate, a press ejector rod, a workbench and a secondary pressurizing base plate, the workbench is installed on a press, the cover die is installed on the upper surface of the workbench in a matched mode, the bottom plate is matched with the middle of the cover die, the product forming die assembly is arranged on the bottom plate, the bottom face of the bottom plate abuts against the press ejector rod, the press ejector rod penetrates through the workbench, and the bottom plate and the product forming die assembly are controlled to move up and down in a cavity of the cover die through lifting of the press ejector rod. Powder is directly filled into the product forming die assembly, so that the preparation process of a prefabricated part is omitted; in the process of die-casting and metal cementation, a metal core part which is gradually solidified is subjected to secondary pressure application; and the prepared composite material is high in compactness and low in porosity, and the quality and performance of the product are greatly improved.

Owner:JIANGNAN UNIV

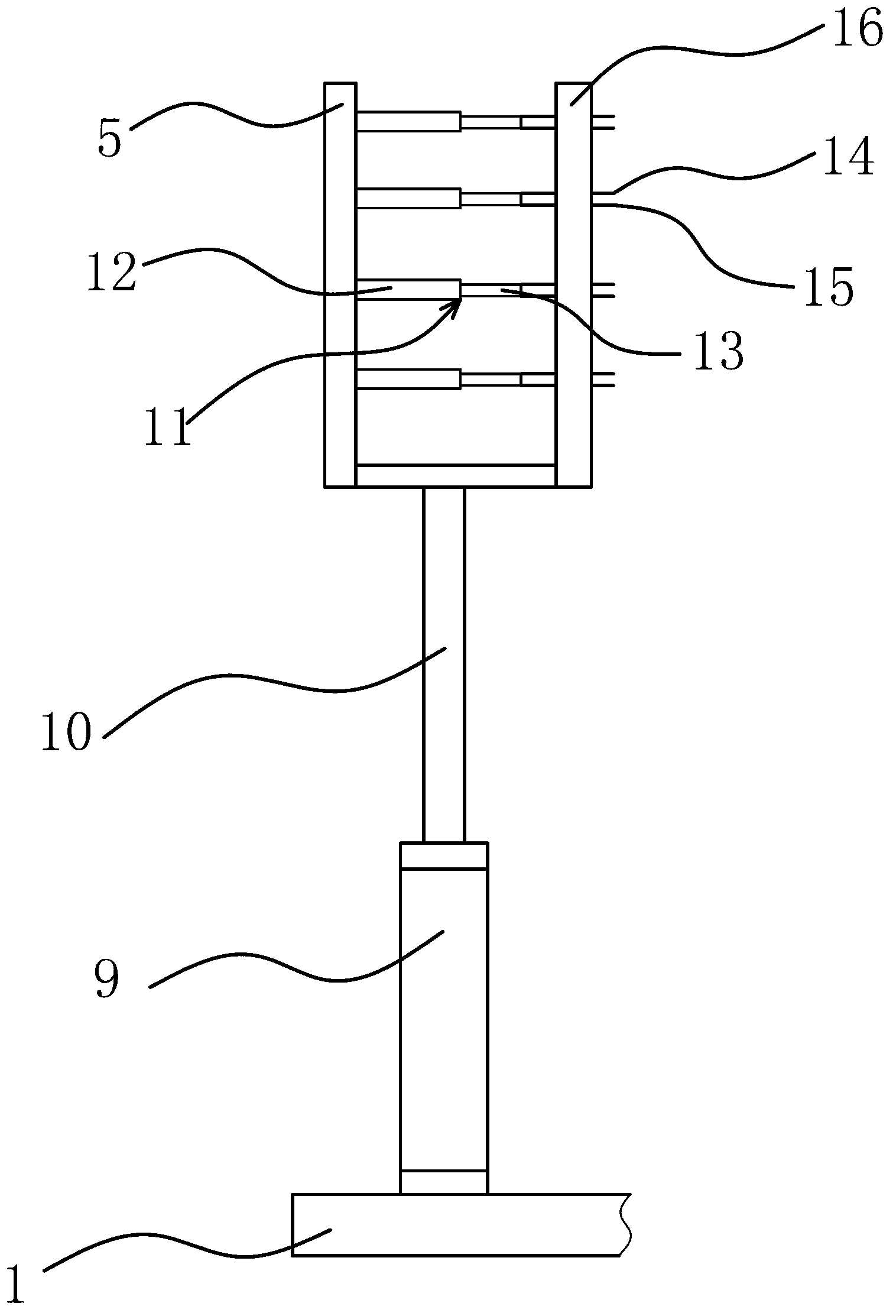

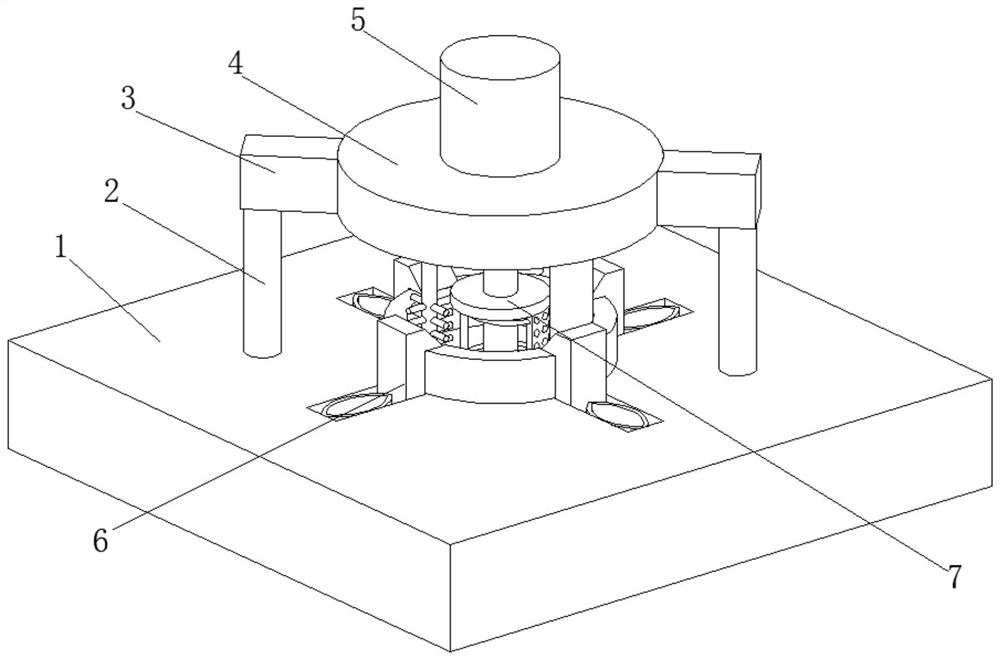

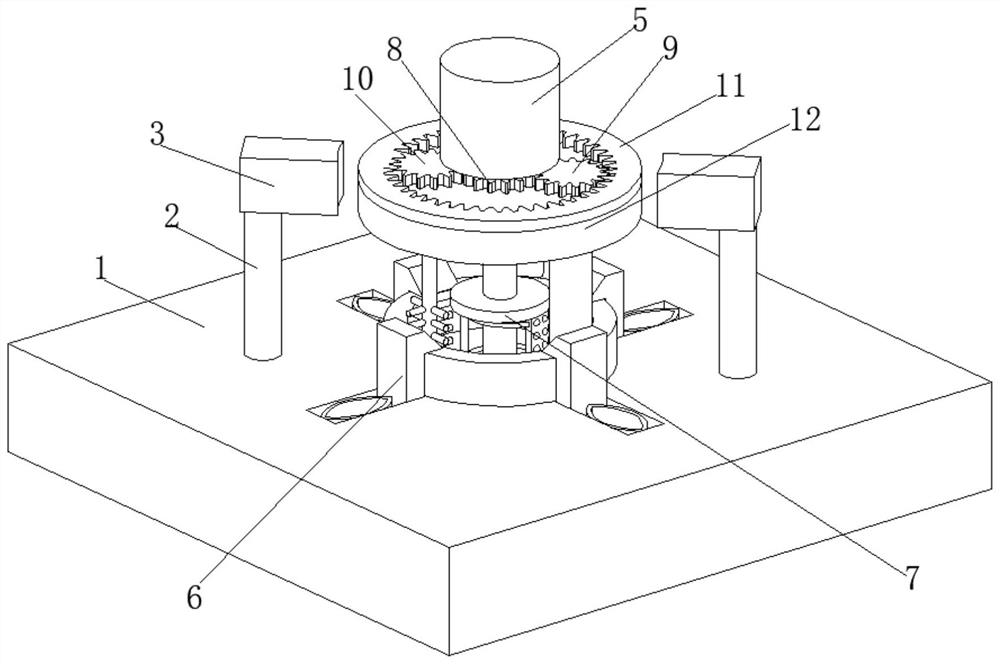

Precise bearing inner ring grinding equipment

InactiveCN113601287AAchieve refixationImplement automatic installationRevolution surface grinding machinesGrinding work supportsGear wheelElectric machinery

The invention relates to the technical field of bearings, and discloses precision bearing inner ring grinding equipment which comprises a workbench. A supporting column is welded to the top of the workbench; a fixing block is in contact with the top end of the supporting column; a fixing plate is welded to the surface of the fixing block; a motor is connected to the top of the fixing plate through a bolt; a fixing mechanism is arranged on the inner wall of the workbench; a cleaning mechanism is arranged at the bottom end of the fixing plate; a transmission gear is welded to the output end of the motor; a first gear and a second gear are engaged with the surface of the transmission gear; inner fluted discs are engaged with the surfaces of the first gear and the second gear; and rotary discs are rotatably connected to the bottom ends of the inner fluted discs. According to the precision bearing inner ring grinding equipment provided by the invention, automatic fixing of a bearing ring can be achieved through the fixing mechanism, so that the situation that the bearing ring shakes in the grinding process, and consequently the grinding precision is reduced is prevented; and meanwhile, the replacement speed of the bearing ring is increased, so that the working efficiency is improved, and convenience and rapidness are achieved.

Owner:张永华

Method for relieving shell expansion of 3D printing photosensitive resin mold in investment casting

InactiveCN113102688APrice controlLow viscosityAdditive manufacturing apparatusFoundry mouldsParaffin waxThermal dilatation

The invention discloses a method for relieving shell expansion of a 3D printing photosensitive resin mold in investment casting. The method comprises the steps that the surface of the photosensitive resin mold is coated with low-temperature wax to form a uniform wax layer, wherein the low-temperature wax is a mixture of paraffin and stearic acid, the content of the paraffin is 80-95 wt%, and the content of the stearic acid is 5-20 wt%. The surface of the photosensitive resin mold is coated with the uniform wax layer, the wax layer is in a molten state under high-temperature steam, and molten wax liquid can flow out of a mold shell or be absorbed by the mold shell of a porous structure, so that a gap is reserved between the photosensitive resin mold and the mold shell, the gap provides a buffer space for thermal expansion of the photosensitive resin mold, the pressure on the mold shell is reduced, and in this way, the shell expansion problem of the photosensitive resin mold in the dewaxing process is relieved.

Owner:SHANGHAI UNION TECH

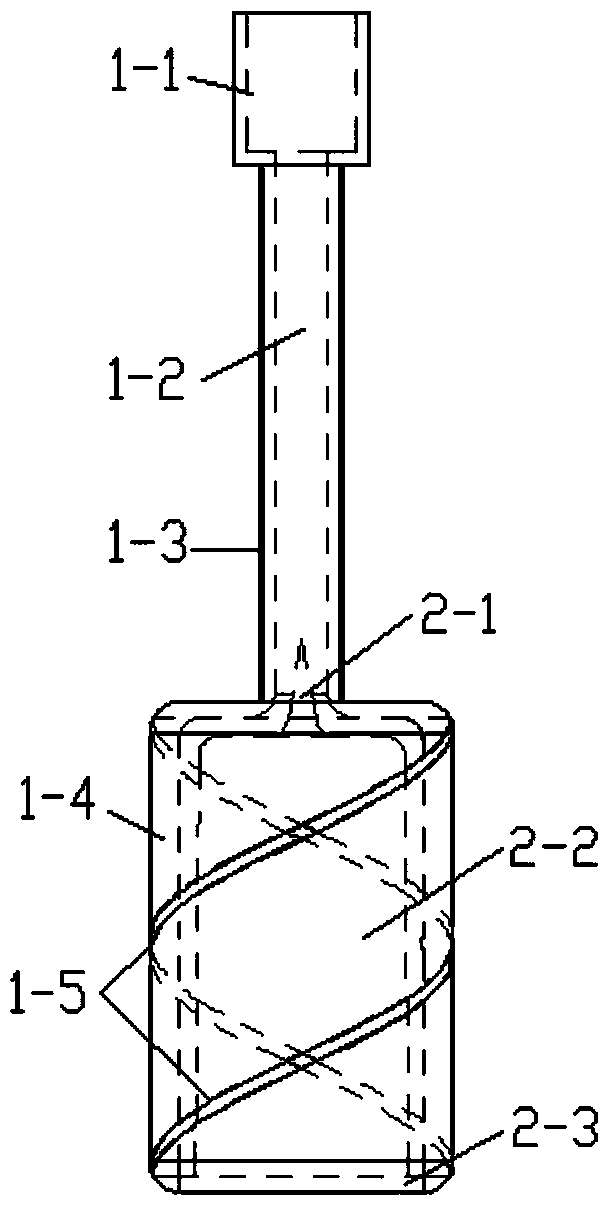

Deep cylinder piece high-thinning-rate deep drawing technology

The invention discloses a deep cylinder piece high-thinning-rate deep drawing technology, and belongs to the technical field of plastic material processing. The deep cylinder piece high-thinning-ratedeep drawing technology comprises the three steps of preliminary forming, pre-thinning and stepped forming. During pre-thinning and stepped forming, a high-thinning-rate deep drawing die is adopted for deep drawing, the possibility of quality defects of workpieces can be reduced, and during stepped forming in the last stage, the segmented deep drawing thinning manner is adopted for the workpiecesin the technology, the quality defects caused by the excessive deep drawing depth are effectively overcome, and accordingly a thin-wall deep cylinder piece with the high thinning rate can be obtainedthrough deep drawing.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Injection molding machine with demolding detecting device

InactiveCN104494072AAvoid failureImprove running stabilityReciprocating motionInjection molding machine

The invention provides an injection molding machine with a demolding detecting device, belonging to the technical field of moulds and solving the technical problems of relatively poor operation stability and the like of the injection molding machine in the prior art. The injection molding machine comprises a stand, wherein the stand is provided with a fixed mold plate and a moving mold plate which are connected through a pull rod, the moving mold plate and the fixed mold plate are closed to form a plurality of mold cavities for molding plastic bottle caps, and openings of the plastic bottle caps are outwards arranged after the plastic bottle caps are molded. The injection molding machine also comprises a piece taking device, wherein the piece taking device comprises a piece taking plate; the piece taking plate is provided with a clamping structure capable of fixing or loosing the plastic bottle caps; a rack is fixedly provided with a lifting mechanism capable of driving the piece taking plate to do lifting reciprocation and is also provided with a holding frame for holding the plastic bottle caps; and the holding frame is provided with a demolding detecting device for detecting whether all the plastic bottle caps fall off from the mold cavities. The injection molding machine has the advantages of good operation stability and the like.

Owner:海宁王骏新材料有限公司

A kind of sponge alumina and its preparation method and application

ActiveCN106830898BImprove thermal shock resistanceImprove toughnessCeramicwareAluminium hydroxideAluminium oxides

The invention provides sponge aluminum oxide and a preparation method and application thereof. The preparation method of the sponge aluminum oxide comprises the following steps of using an aluminum oxide aggregate soaked by an aluminum oxide sol as a calcining raw material, wrapping the surface of the aluminum oxide aggregate by an aluminum oxide sol layer containing aluminum oxide, and calcining, so as to obtain the sponge aluminum oxide with a coating structure that the inner layer is a porous aluminum oxide aggregate and the outer layer is a latticed aluminum oxide wrapper. The special sponge structure body with the coating structure can greatly improve the anti-heat vibration property and high-temperature toughness of the aluminum oxide. The sponge aluminum oxide has the advantages that the anti-heat vibration property and high-temperature toughness are excellent; the sponge aluminum oxide can be directly applied to various fire-retardant or ceramic products to improve the anti-heat vibration property and high-temperature toughness of the product, the degrading of the high-temperature property caused by the production of other low-temperature phase or glass phase is avoided, and the influence to the size accuracy of the product due to the production of the second phase in the shaped products is also avoided.

Owner:河南和成无机新材料股份有限公司

Casting method of propeller fairing with great wall thickness difference

The invention provides a casting method of a propeller fairing with a great wall thickness difference. The casting method of the propeller fairing comprises the following steps that 1, mold manufacturing is carried out, specifically, a wooden mold is manufactured according to the shape and the inner cavity size of the fairing; 2, molding is carried out, specifically, a lower mold and a mold core are manufactured through the wooden mold, a sprue, cross pouring gates communicating with the sprue and gate risers are arranged in an upper mold, and inner sprues and inner pouring gates are arrangedin the lower mold; 3, mold closing is carried out, specifically, the mold core is installed in a mold cavity of the lower mold, and the upper mold is assembled on the lower mold; 4, smelting is carried out, specifically, raw materials for casting are smelted, and the brand of the casting materials is QT450-12; 5, inoculation is carried out, specifically, an inoculant is added to the bottom of a casting ladle before discharging, and the inoculant is added to a pouring basin for flow inoculation before pouring; 6, pouring is carried out, specifically, smelted and inoculated molten steel is poured into the sprue for pouring through a pouring cup; and 7, treatment is carried out, a pouring and riser system is cut off, the surface of a product is polished to be smooth and flat, and the size andsurface quality of the product are checked. The casting method can reduce distortion of graphite and improve the molding quality of a casting.

Owner:YICHANG MARINE DIESEL ENGINE

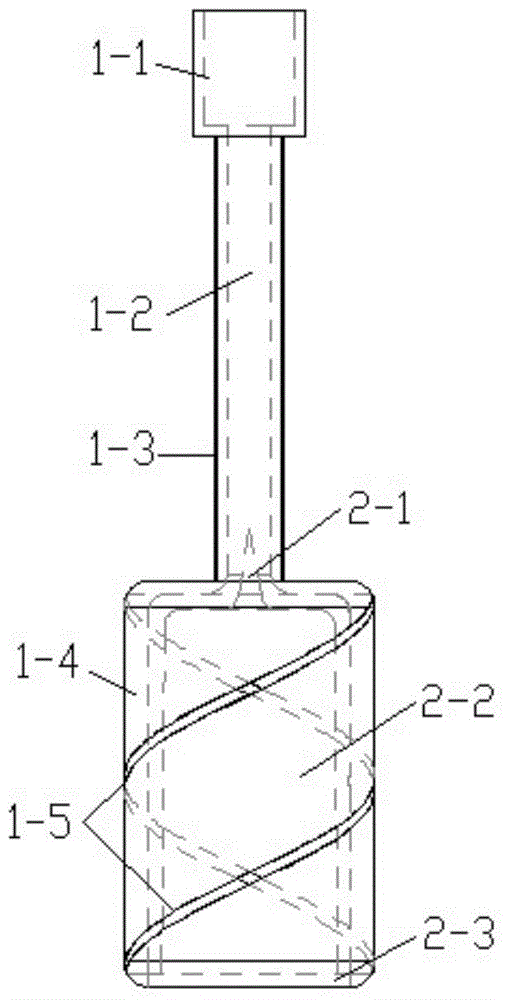

Simple processing method of removing burrs of non-metal holder inner hole and end face junction

InactiveCN103100942ASimple structureEasy to manufactureEdge grinding machinesGrinding work supportsHand heldEngineering

Disclosed is a simple processing method of removing burrs of a non-metal holder inner hole and a end face junction. The external diameter of a non-metal holder (1) is D, and the width of the non-metal holder (1) is L. burr removing needs special tools. A push rod (3) is placed in a through hole of a jig (2) and the non-metal holder is arranged inside a clamping hole. The method includes the following steps: when a left hand or right hand turns the external diameter of the jig, the left hand or the right hand holds the special tools and removes the burrs of the inner hole at one end of the non-metal holder and the end face junction, pushes the push rod out of the non-metal holder from the clamping hole after burr-removing of one side is finished, relocating the non-metal holder into the clamping hole after burr-removing of the other side is finished, and the whole process of burr-removing of the inner hole at one end of the non-metal holder and the end face junction is finished by repeat of the above steps. Accuracy of the non-metal holder is not influenced, no scratch of a human finger is caused, labor intensity is lowered and working efficiency is improved.

Owner:LUOYANG BEARING RES INST CO LTD

A device for synchronously measuring axial and radial displacements of rigid couplings

ActiveCN103267465BSimple structureEasy to operateMechanical measuring arrangementsAxial displacementCoupling

The invention discloses a device for synchronously measuring axial displacement and radial displacement of a rigid coupler. The device comprises a supporting rod which is connected in opposite connecting holes of two half couplers in a penetrating mode, a support is fixedly installed on the supporting rod, an axial measuring device measuring the axial displacement of the coupler and a radial measuring device measuring the radial displacement of the coupler are arranged on the support, threads are arranged on the supporting rod, the supporting rod and the coupler are connected through a pair of nuts I which are arranged on the supporting rod and positioned on the two sides of the coupler, and the support is installed on the supporting rod in a sleeved mode and fixed through a pair of nuts II. The device is simple in structure and convenient to operate, by the adoption of the axial measuring device and the radial measuring device which are installed on the support, axial displacement deviations and radial displacement deviations of the rigid coupler can be measured simultaneously, accumulative errors caused by separated measuring are reduced to the maximum, and measurement accuracy is improved substantially.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

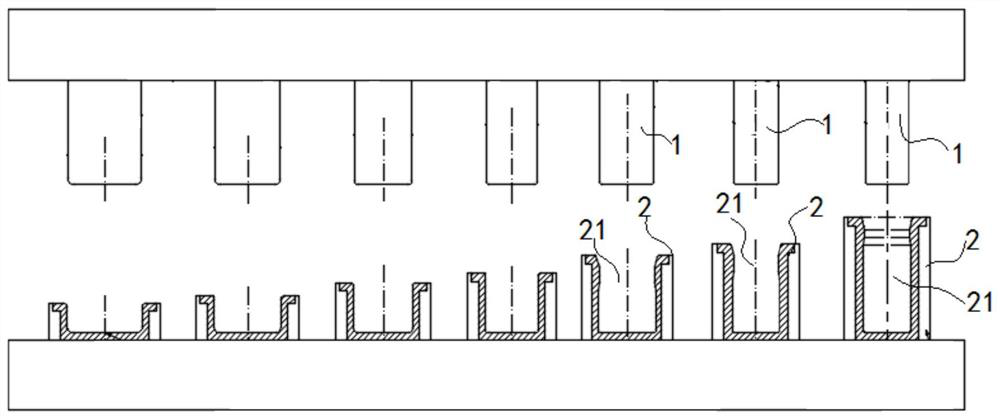

Machining method for modulation line of radio frequency quadrupole single-vane pole head

The invention relates to the technical field of a manufacturing process of a radio frequency quadrupole single-vane pole head serving as a core component of a linear accelerator, in particular to a machining method for a modulation line of the radio frequency quadrupole single-vane pole head. According to the method, a trial cutting test of a cutter is performed before finish machining by a disc forming cutter, and appropriate machining parameters are selected; machining requirements are met through multiple cutting in the machining process, the machining accuracy of the modulation line of the single-vane pole head is detected by a trilinear coordinates measuring instrument and is better than the acceptance indicators, and the consistency is good; the whole machining and measuring process of the modulation line of the single-vane pole head needs to be performed in a constant temperature environment, the dimension error is controlled within plus / minus 20 mu m, the pole head profile tolerance is better than plus / minus 20 mu m, the pole head symmetry tolerance e is better than plus / minus 20 mu m, the surface roughness of the modulation line of the pole head reaches 0.8 mu m, and the stability and reliability of the performance of the radio frequency quadrupole linear accelerator are guaranteed effectively.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

A High Thinning Ratio Deep Drawing Process for Deep Tube Parts

The invention discloses a deep cylinder piece high-thinning-rate deep drawing technology, and belongs to the technical field of plastic material processing. The deep cylinder piece high-thinning-ratedeep drawing technology comprises the three steps of preliminary forming, pre-thinning and stepped forming. During pre-thinning and stepped forming, a high-thinning-rate deep drawing die is adopted for deep drawing, the possibility of quality defects of workpieces can be reduced, and during stepped forming in the last stage, the segmented deep drawing thinning manner is adopted for the workpiecesin the technology, the quality defects caused by the excessive deep drawing depth are effectively overcome, and accordingly a thin-wall deep cylinder piece with the high thinning rate can be obtainedthrough deep drawing.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Cutting device good in safety and capable of machining conductive copper pipes of different specifications

PendingCN113977283AAffects dimensional accuracyFit tightlyOther manufacturing equipments/toolsStructural engineeringGrinding wheel

The invention discloses a cutting device good in safety and capable of machining conductive copper pipes of different specifications, and belongs to the technical field of conductive copper pipe machining, the cutting device comprises a supporting base, a feeding locking supporting assembly and a guiding assembly, the supporting base is of a T-shaped structure, and two feeding sliding rails are connected to the upper portion of the supporting base through screws. The floating supporting force can be provided for the floating grinding wheel through a floating supporting pressure spring, so that the floating grinding wheel can be tightly attached to the cut-off opening of a conductive copper pipe, polishing and deburring operation is conducted on the cut-off opening of the conductive copper pipe, the trouble of manual deburring is omitted, meanwhile, the situation that the end of the conductive copper pipe is subjected to large pressure during grinding, and the dimensional accuracy of the conductive copper pipe is influenced can be avoided, a V-shaped pressing groove is formed to press and fix the conductive copper pipe, the device can be suitable for pressing and cutting off the conductive copper pipes with different pipe diameters, automatic cutting-off machining of three copper pipes can be completed at a time, and efficiency is extremely high.

Owner:镇江市正源智能科技有限公司

Splicing and fixing structure of block gauge and device adopting the structure

ActiveCN103808218BAvoid micro deformationAffects dimensional accuracyUsing mechanical meansDegrees of freedomEngineering

The invention discloses a splicing and fixing structure of block gauges and a device utilizing same. The block gauges are in surface contact with each other, line or point support is formed at the bottoms of the block gauges, the block gauges which are arranged on the bilateral sides are of point contact abutting structures, and accordingly the degrees of freedom of attachment is high, the accuracy is high, and the use is scientific and good in comparison with block gauge clamps in the prior art; the one side of block gauges of the block gauges which are arranged on the bilateral sides are of point contact elastic abutting structures, the fixed attachment pressing force is provided, and accordingly the size accuracy of the block gauges cannot be affected by the micro deformation caused by too large force of the block gauges; a linear guide rail is good in linearity and moves without radial clearance, mobile block gauge seats move along the direction of the linear guide rail, and accordingly the linear force is uniform and stable; in addition, block gauge supports which are used for performing supporting are arranged corresponding to the positions of supporting points of the block gauges and accordingly the micro deformation of the block gauges especially the long gauge blocks can be effectively avoided.

Owner:恒洁利(南通)设备制造有限公司

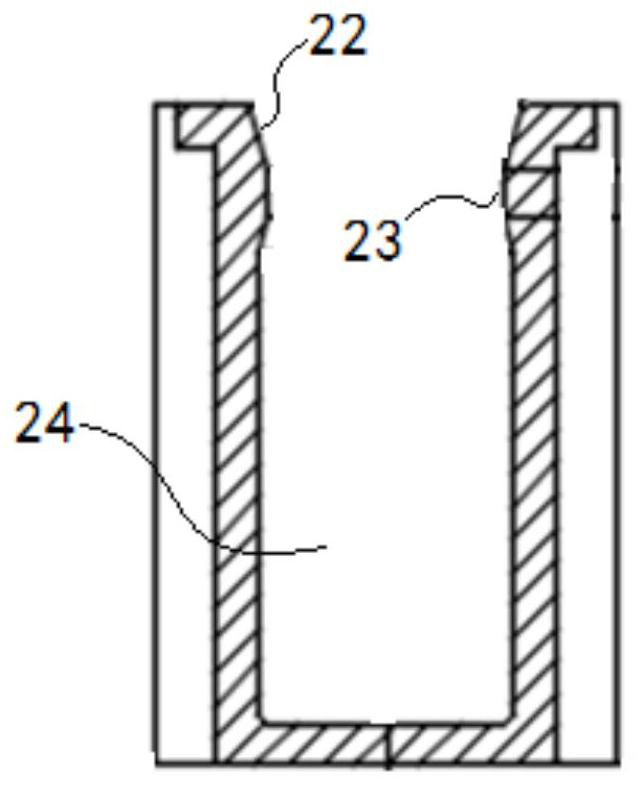

A process for preparing metal matrix ceramic composites by secondary pressure

The invention relates to a process for preparing metal-based ceramic composite materials by applying secondary pressure, which includes a product forming mold assembly, a sleeve mold, a bottom plate, a press rod, a workbench and a secondary pressure backing plate, and the workbench is installed on On the press, the upper surface of the workbench is equipped with a set mold, and the middle part of the set mold is equipped with a bottom plate. The product forming mold assembly is placed above the bottom plate. The ejector pin of the press is passed through the workbench, and the bottom plate and the product forming mold assembly are controlled to move up and down in the cavity of the mold through the lifting of the press ejector pin; by directly filling the powder into the product forming mold assembly, eliminating The preparation process of the prefabricated part; in the process of die-casting metal infiltration, a second pressure is applied to the gradually solidified metal core; the composite material thus prepared has high density, low porosity, and the quality and performance of the product are greatly improved.

Owner:JIANGNAN UNIV

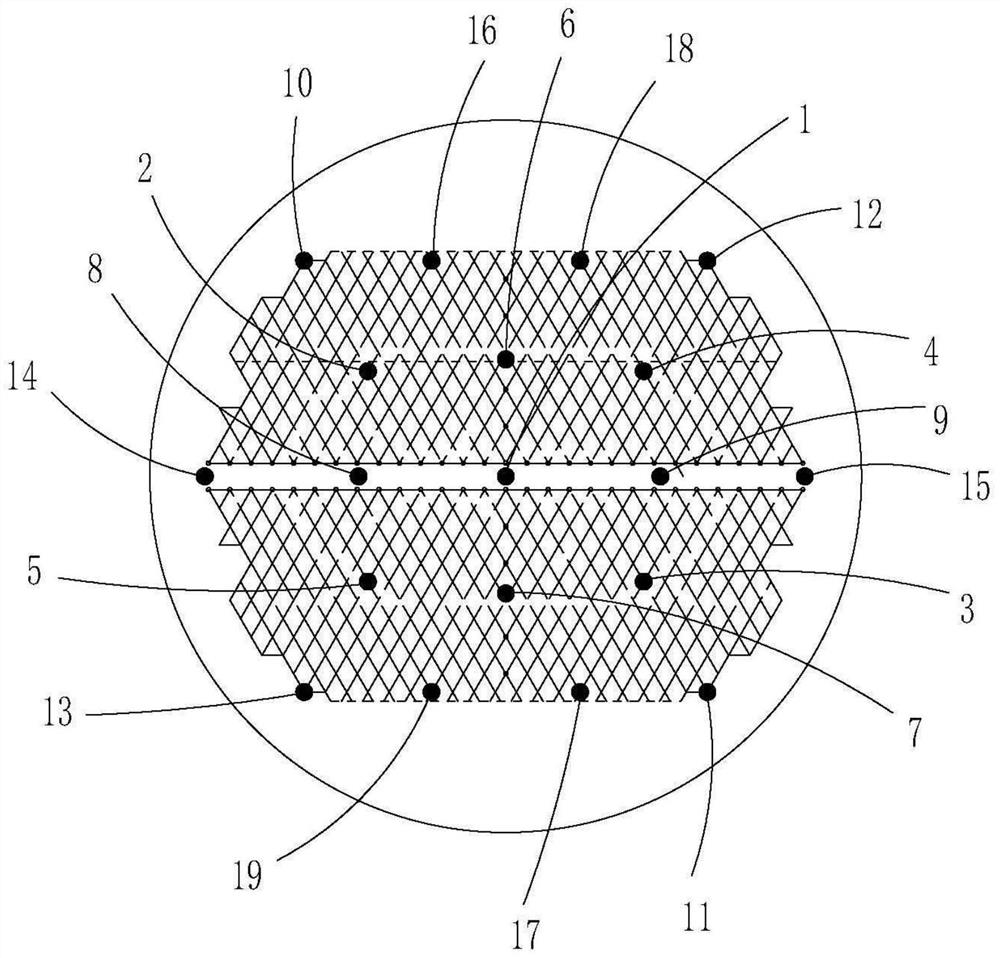

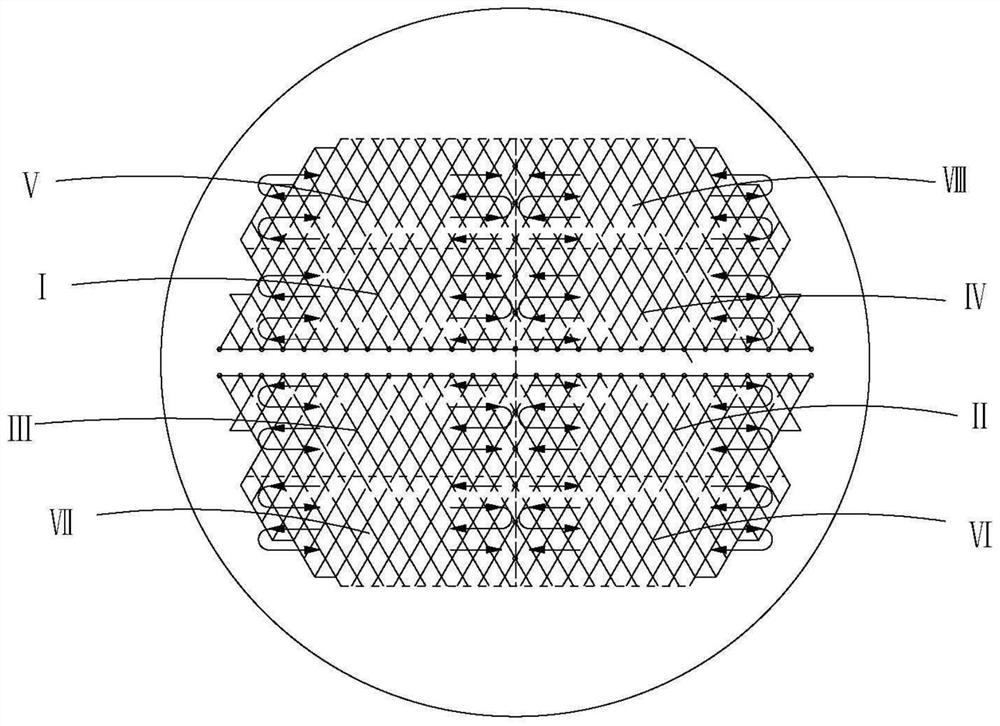

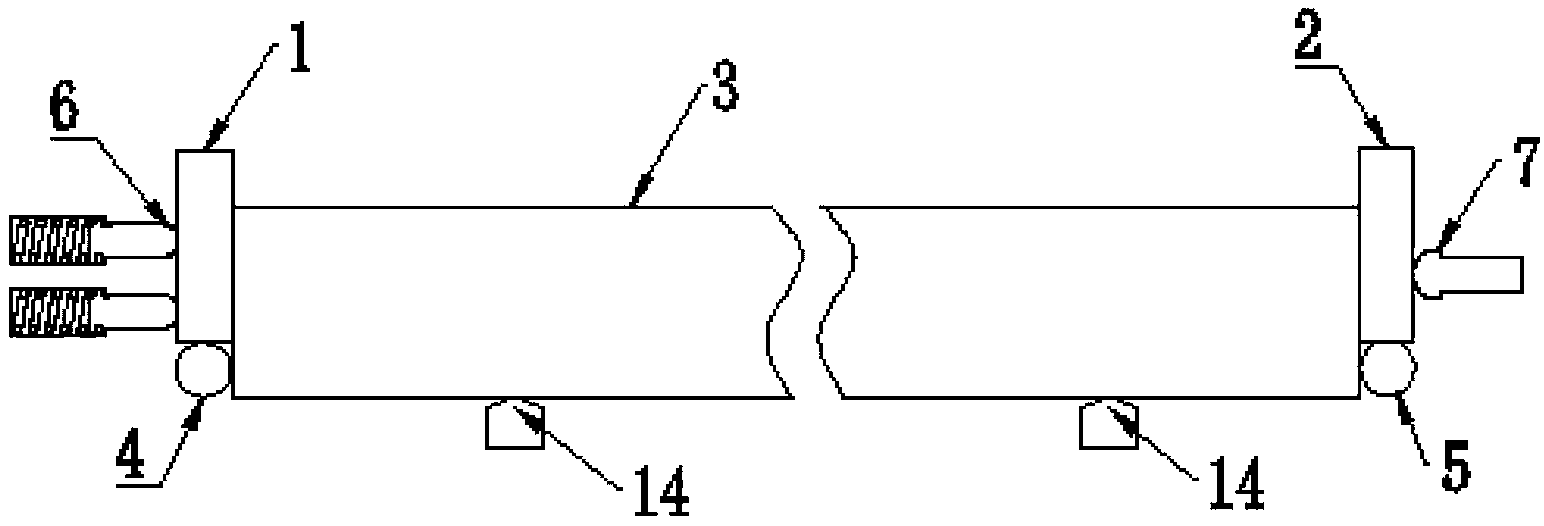

Processing and manufacturing method of heat exchanger

PendingCN114485252AAffects dimensional accuracyInfluence of Dimensional AccuracyHeat exchanger casingsHeat exchanger fasteningEngineeringMachining

The invention relates to a machining and manufacturing method of a heat exchanger. The machining and manufacturing method comprises the following steps that A, the lower plane of an upper tube plate is machined; b, performing assembly welding and flaw detection on the upper tube plate and the top pup joint; c, all the machining faces, except for the lower plane of the upper tube plate, of the upper tube plate assembly are machined; d, drilling the upper tube plate and the lower tube plate; e, a plurality of other pup joints are subjected to assembly welding, flaw detection and heat treatment; f, the upper tube plate assembly and the short section assembly are installed, welded and subjected to flaw detection; g, mounting a pull rod, a sleeve and a baffle plate in the barrel; h, mounting a heat exchange tube in the barrel in a penetrating manner; i, assembling the lower tube plate; j, the tube heads are welded to the upper tube plate and the lower tube plate respectively, and the following sequence is adopted during welding: the tube heads of the heat exchange tubes adjacent to the pull rods are welded firstly, and then the remaining tube heads are subjected to regional cross symmetric welding; k, mechanically cutting off the extension part of the pipe head; l, performing local heat treatment; and M, finally installing a sealing head. Therefore, the size precision of the upper tube plate is greatly improved.

Owner:ZHANGHUAJI SUZHOU HEAVY EQUIP CO LTD

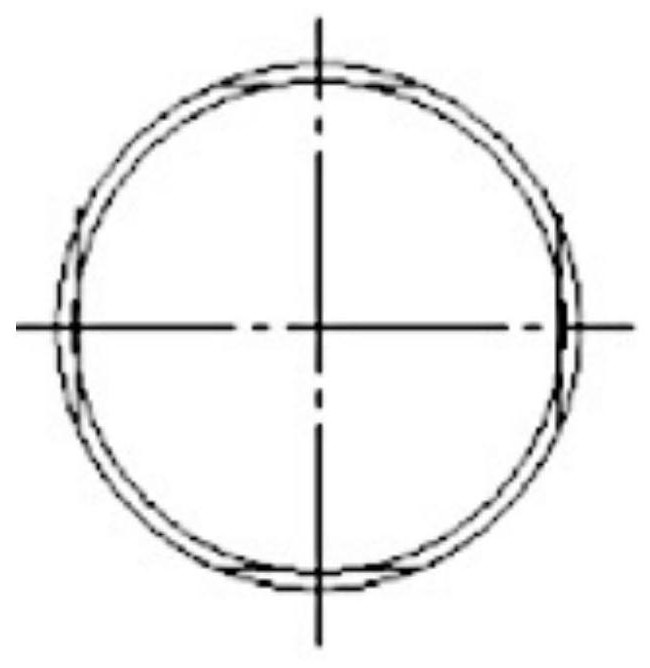

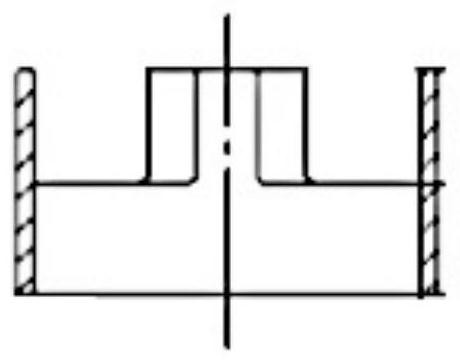

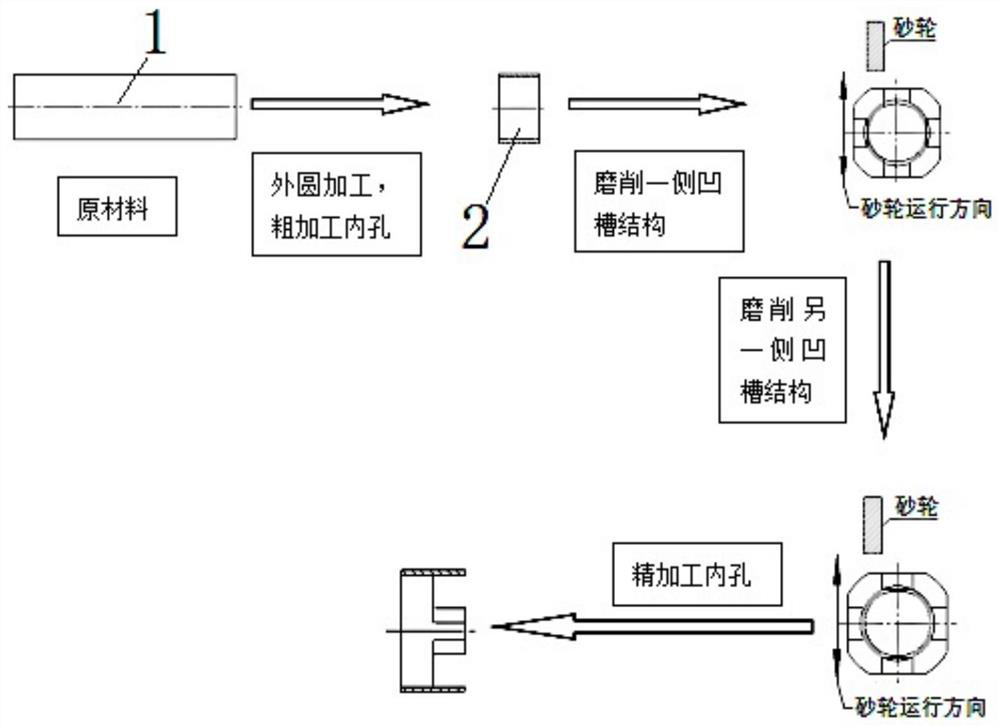

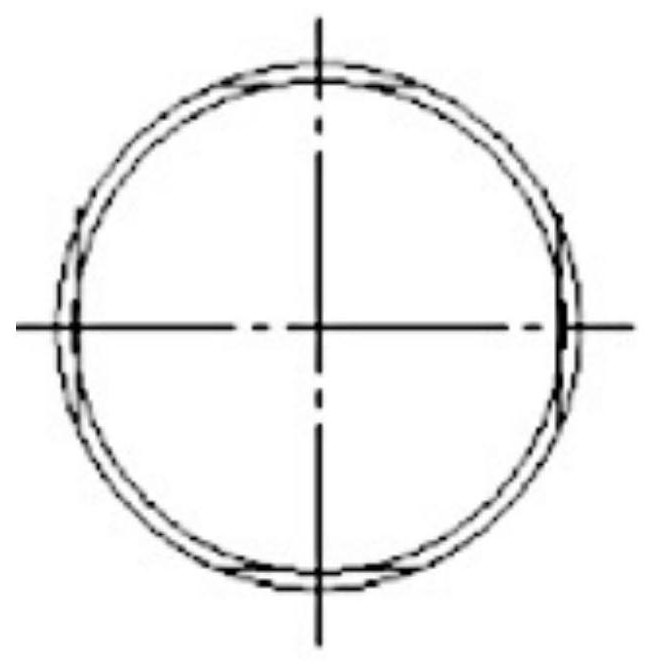

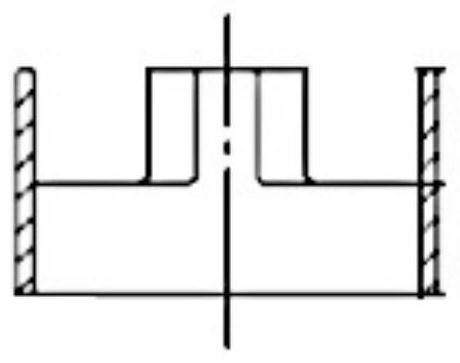

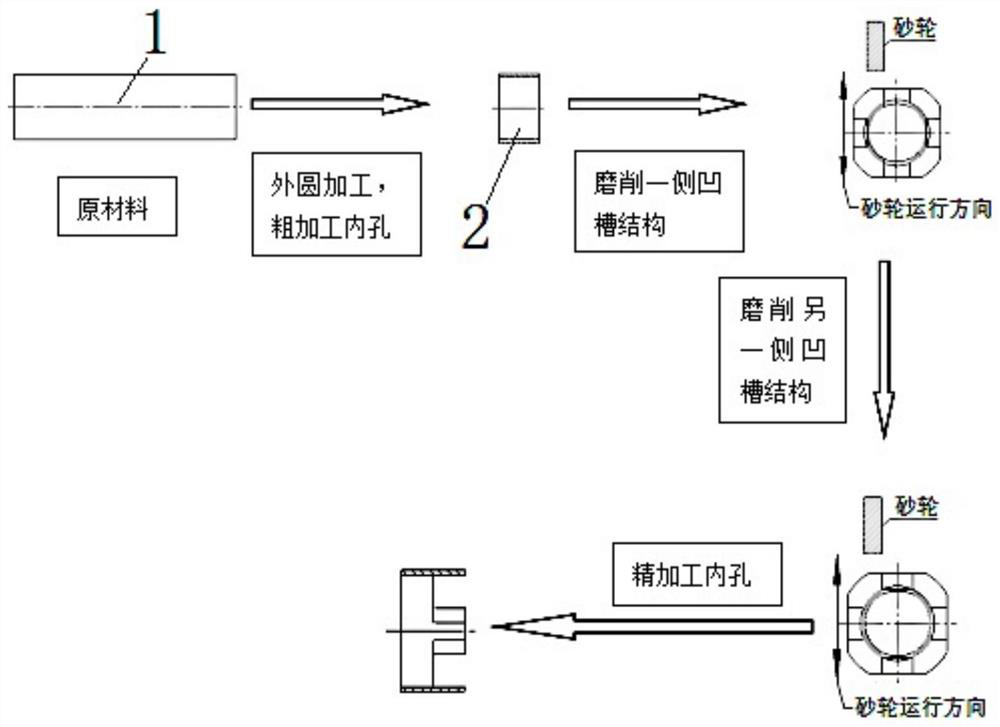

A processing method for thin-wall lock ring parts with grooves

The invention discloses a method for processing parts such as thin-walled lock rings with grooves. The raw material is processed to the outer circle, and the inner hole is rough-machined, and a machining allowance is reserved for the inner hole to obtain a semi-finished part; Grinding and processing the groove structure; on the semi-finished parts with the preset groove structure, the inner hole is finished, and the thin-walled locking ring parts with grooves are produced; the present invention combines the structural characteristics of the thin-walled locking ring parts, firstly Cylindrical processing and rough machining of the inner hole, and then use the groove grinding process to realize the processing of the thin-walled groove; by processing the inner hole in two steps, the accuracy of the inner hole is improved, and at the same time, the wall thickness of the part is increased during the groove grinding process, The difficulty of the groove grinding process is reduced; the invention can obtain an accurate surface on the part, avoid the generation of large-area burrs, effectively reduce the processing error of the part, reduce the probability of fracture of thin-walled teeth, and improve the quality of the part. Simple, high pass rate.

Owner:AECC AVIATION POWER CO LTD

Splicing and fixing structure of block gauges and device utilizing same

ActiveCN103808218AAvoid micro deformationAffects dimensional accuracyUsing mechanical meansEngineeringDegrees of freedom

The invention discloses a splicing and fixing structure of block gauges and a device utilizing same. The block gauges are in surface contact with each other, line or point support is formed at the bottoms of the block gauges, the block gauges which are arranged on the bilateral sides are of point contact abutting structures, and accordingly the degrees of freedom of attachment is high, the accuracy is high, and the use is scientific and good in comparison with block gauge clamps in the prior art; the one side of block gauges of the block gauges which are arranged on the bilateral sides are of point contact elastic abutting structures, the fixed attachment pressing force is provided, and accordingly the size accuracy of the block gauges cannot be affected by the micro deformation caused by too large force of the block gauges; a linear guide rail is good in linearity and moves without radial clearance, mobile block gauge seats move along the direction of the linear guide rail, and accordingly the linear force is uniform and stable; in addition, block gauge supports which are used for performing supporting are arranged corresponding to the positions of supporting points of the block gauges and accordingly the micro deformation of the block gauges especially the long gauge blocks can be effectively avoided.

Owner:恒洁利(南通)设备制造有限公司

Casting method of thruster shroud with widely different wall thickness

ActiveCN109079108BAdequate responseImprove distortionFoundry mouldsFoundry coresGraphiteMolten steel

Owner:YICHANG MARINE DIESEL ENGINE

Method for machining grooved thin-walled lock ring part

The invention discloses a method for machining a grooved thin-walled lock ring part. The method comprises the steps that cylindrical lathe cutting of a raw material is carried out, rough machining ofan inner hole is carried out, and the inner hole is reserved for machining allowance to obtain a semi-finished part; a groove grinding process is adopted, and a groove structure is machined through grinding at the end of the semi-finished part; and finish machining of the inner hole is carried out on the semi-finished part with the preset groove structure to obtain the grooved thin-walled lock ring part. the method combines the structural characteristics of the thin-walled lock ring part, cylindrical lathe cutting and rough machining of the inner hole are carried out firstly, and then the groove grinding process is adopted to achieve the machining of a thin-walled groove; through machining the inner hole in two steps, the accuracy of the inner hole is improved, and during the groove grinding process, the wall thickness of the part is increased, and the difficulty of the groove grinding process is reduced; according to the method, a precise surface can be obtained on the part, the generation of large-area burrs is avoided, machining errors of the part are effectively reduced, the probability of fracture of a thin-walled tooth is reduced, the quality of the part is improved, the machining process is simple, and the percent of pass is high.

Owner:AECC AVIATION POWER CO LTD

Rapid forging hydraulic press

PendingCN114210899AEasy to removeImprove work efficiencyForging/hammering/pressing machinesForging press drivesInlet channelStructural engineering

The invention belongs to the technical field of hydraulic forging presses, and particularly relates to a rapid hydraulic forging press which comprises a shell, a hydraulic device, a hydraulic rod, a stress base and a cleaning device, the hydraulic device is fixedly connected to the outer surface of the shell, the hydraulic rod is installed in the hydraulic device, the stress base is arranged under the hydraulic rod, and the cleaning device is arranged on the outer surface of the shell. A spring is fixedly connected to the lower surface of the stress base, the other end of the spring is fixedly connected to the lower surface of the shell, a cavity is formed between the stress base and the shell, an air outlet channel and an air inlet channel are formed in the shell, one end of the air outlet channel and one end of the air inlet channel are communicated with the cavity, and one-way valves are arranged in the air outlet channel and the air inlet channel. One side of the shell is rotatably connected with a cleaning device, the rear side of the shell is fixedly connected with a collecting cover, and a collecting box is arranged below the collecting cover. Through the cleaning device, oxide skin generated during metal forging can be better removed, and the forging efficiency of workers and the quality of forgings are improved.

Owner:张鹏亮

Cathode for CNC electrolytic turning and boring of pressure storage cavity

ActiveCN103706900BIncrease pressureSolution to short lifeMachining electrodesElectrical-based machining electrodesNumerical controlElectrolysis

The invention discloses a cathode for use in numerical control electrolysis, turning and boring machining of a pressure storing cavity, belonging to the field of cathodes for use in electrolytic machining. The cathode comprises a cathode body and a shunting body, wherein the cathode body is a revolving body which is hollow inside; one end of the cathode body is taken as a clamping portion, and the other end of the cathode body is taken as a working portion; a neck portion is arranged between the clamping portion and the working portion; the outer diameter of the neck portion is smaller than that of the working portion; the outer wall of the neck portion is provided with an insulating layer; the working portion is provided with a spiral liquid outlet; the middle of the shunting block is provided with a conical revolving body; the top of the conical revolving body is provided with an apex, and the bottom of the conical revolving body is provided with a positioning cylinder; the shunting block is arranged in the cavity of the working portion of the cathode body, thereby forming a flow channel with an annular section; the positioning cylinder is fixedly connected with the lower end of the working portion. A cathode for machining the die cavity of a revolving body with a slender inlet cavity and a large pressure storing cavity is provided. A machining surface is good in quality and free from fine cracks. The machined pressure storing cavity can bear high pressure, and is long in service life.

Owner:常州林胜金属科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com