Processing and manufacturing method of heat exchanger

A processing and manufacturing heat exchanger technology, applied in the field of heat exchanger processing and manufacturing, can solve the problems of increasing the deformation of the upper tube sheet, affecting the dimensional accuracy of the upper tube sheet, and requiring extremely high flatness, etc., to achieve the effect of ensuring dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The manufacturing method of a heat exchanger according to the present invention will be further described in detail through specific examples below.

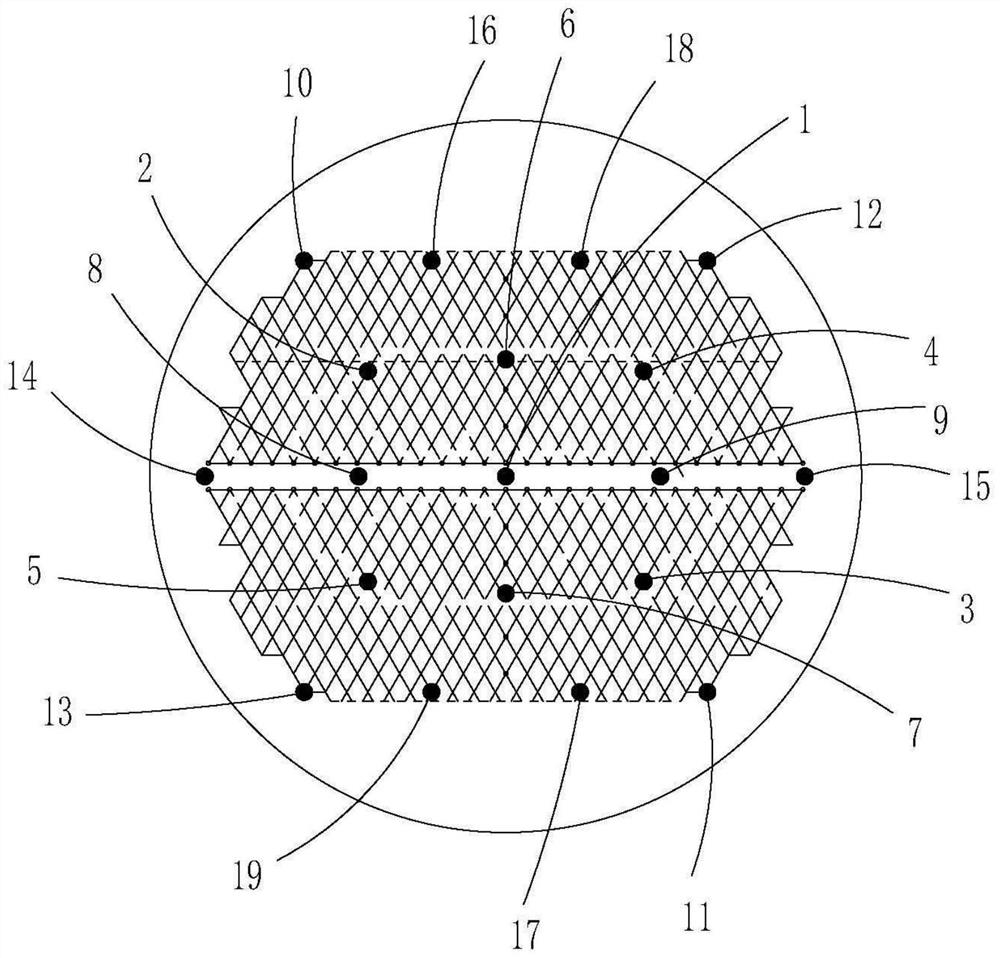

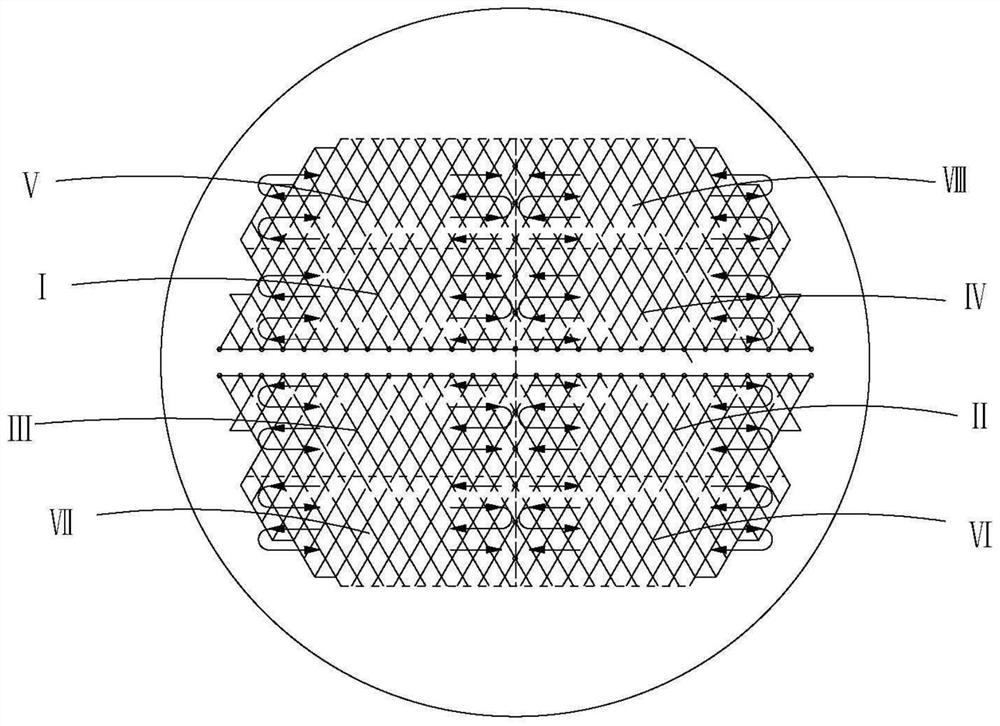

[0013] A processing and manufacturing method for a heat exchanger, comprising the following steps: A. The cylinder body includes a top nipple and several other nipples arranged below the top nipple. The length of the top nipple is 400 mm. The lower plane of the plate, the welding groove of the top sub-section and the welding groove of the upper tube sheet are machined; B. Then, the upper tube sheet and the top sub-joint are welded, flaw detected and heat treated to obtain the upper tube sheet assembly; C. Then machine all the processing surfaces of the upper tube plate assembly except the lower plane of the upper tube plate. After machining, the thickness of the upper tube plate is the design value of the upper tube plate thickness + 2mm; D. Next, carry out machining on the upper tube plate Drill holes to form several upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com