Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Avoid micro deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet light curing optical adhesive

InactiveCN103160212AReduce hardnessMolecular chain flexibility is highNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveUltraviolet lights

The invention relates to an ultraviolet light curing optical adhesive. By weight, the ultraviolet light polymerization optical adhesive comprises 50-100 parts of prepolymer, 20-90 parts of inertia resin, 35-70 parts of monomer, 5-12 parts of photoinitiator, 2-3 parts of coupling agents and 1-2 parts of addition agents. Contraction generated by curing of the ultraviolet light curing optical adhesive is very small, hardness of curing material is small, the flexibility of molecular chains is high and internal stress generated by curing is further absorbed.

Owner:YANTAI DARBOND TECH

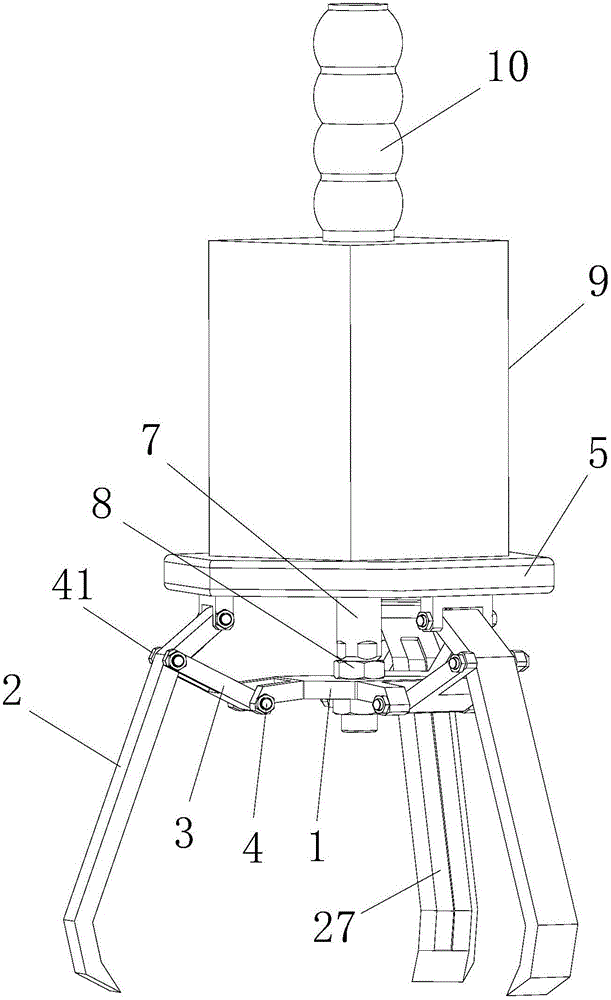

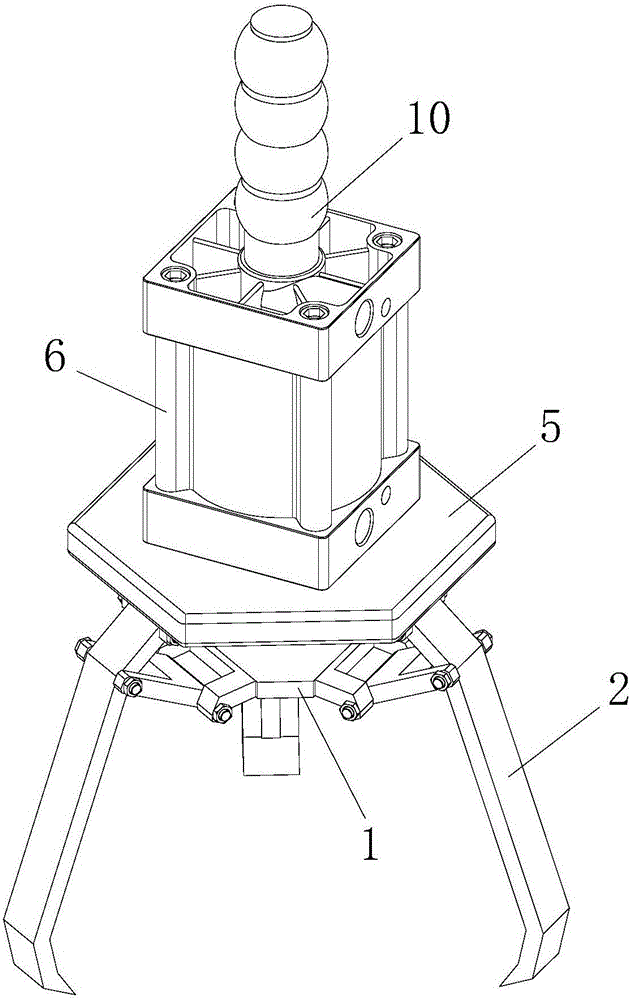

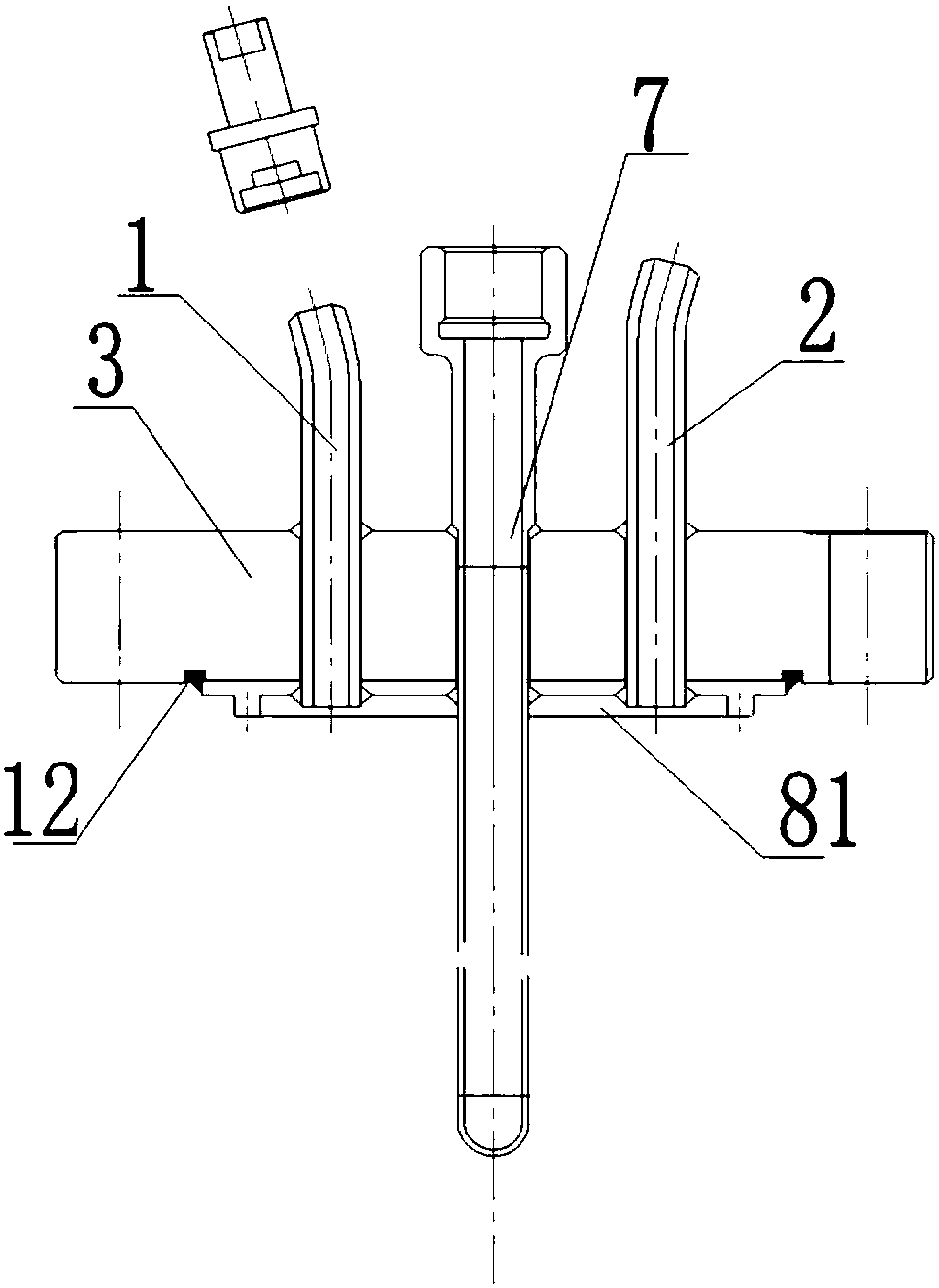

Three-claw clamp

InactiveCN105690170ASimple structureEasy to useMetal working apparatusEngineeringMechanical engineering

The invention discloses a three-claw clamp which comprises a chuck and three clamping claws, wherein the three clamping claws are uniformly mounted on the chuck; one side of each of the three clamping claws is movably mounted on the chuck through a hinge piece; the other sides of the three clamping claws are mounted on a fixing disk through double-head studs; a cylinder is mounted on the fixing disk, and a cylinder rod is mounted in the cylinder and penetrates through the cylinder so as to be connected with the chuck through a hex nut; a protection cover is mounted on the outer side of the cylinder, and a threaded shank is mounted at the upper end of the cylinder; elastic antiskid pads are mounted on the clamping claws. The three-claw clamp provided by the invention is simple in structure and convenient to use; the clamping claws are mounted on the chuck and the fixing disk through the double-head studs and are convenient to remove and mount; the elastic antiskid pads are arranged on the clamping claws, so that micro deformation of a clamped piece in a clamping process can be prevented, and the product yield of the clamped piece is increased.

Owner:黄斌

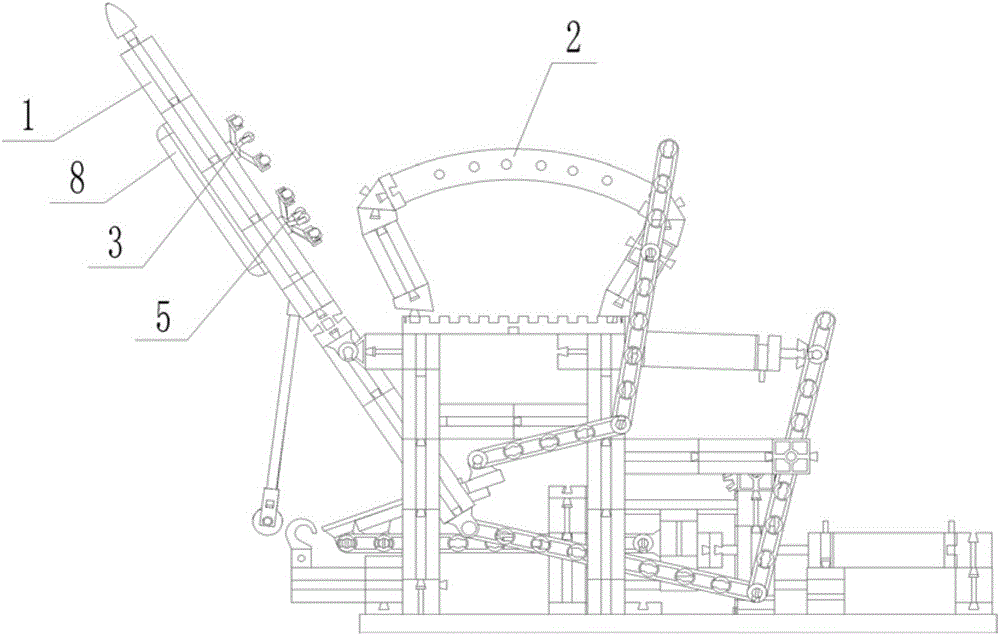

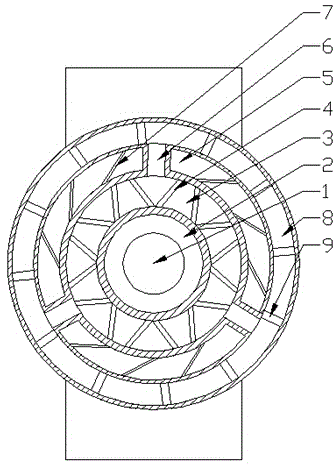

Massage armchair for preventing micro-deformation of vertebral column

PendingCN106619014AImprove comfortAvoid micro deformationChiropractic devicesRoller massageScoliosisMassage

The invention relates to a massage armchair for preventing micro-deformation of a vertebral column. The massage armchair for preventing micro-deformation of the vertebral column comprises a backrest (1), wherein a mounting base (8) is fixedly arranged on the backrest (1); two groups of rotating wheel mechanisms are symmetrically arranged on two sides of a central axis of the mounting base (8) and correspond to upper and lower positions of two sides on the periphery of the vertebral column of a human body; and the two groups of rotating wheel mechanisms comprises a first rotating wheel mechanism (3), a second rotating wheel mechanism (4), a third rotating wheel mechanism (5) and a fourth rotating wheel mechanism (6). Compared with the prior art, the massage armchair for preventing micro-deformation of the vertebral column has the beneficial effects that by combined loading of axial traction and transverse traction which are generated by the two groups of rotating wheel mechanisms which are arranged symmetrically, and the optimal scoliosis correction effect is achieved; and meanwhile, the traction force can further be increased indirectly by the rotating wheel mechanisms to improve the comfortable sensation of the human body in a massage process for preventing micro-deformation of the vertebral column.

Owner:BEIJING UNION UNIVERSITY

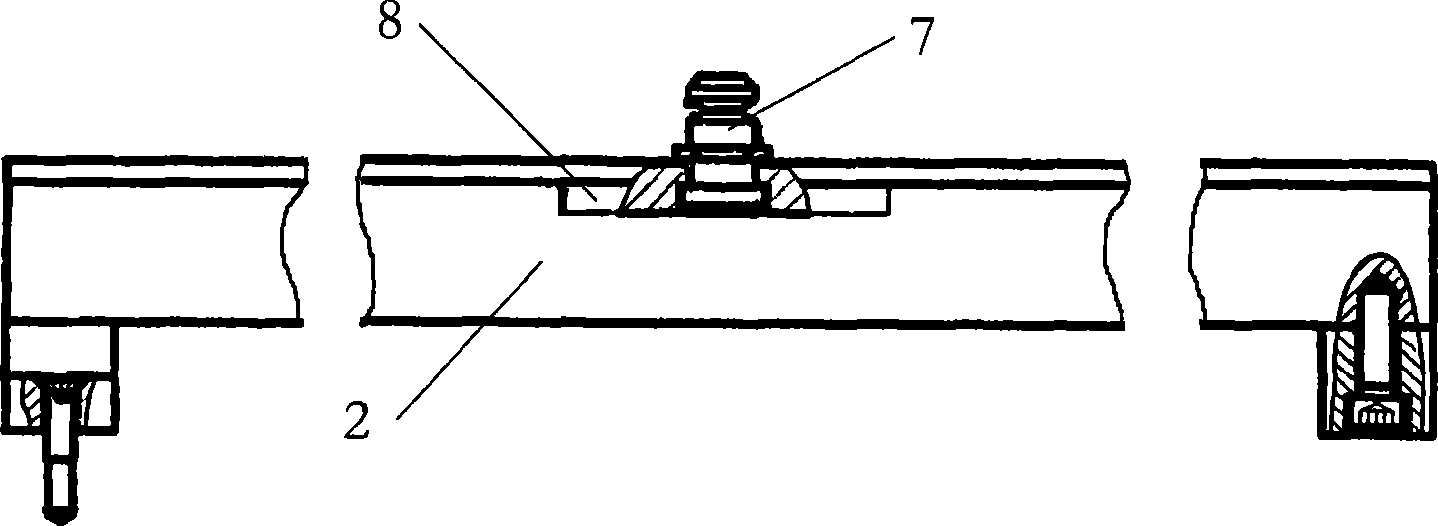

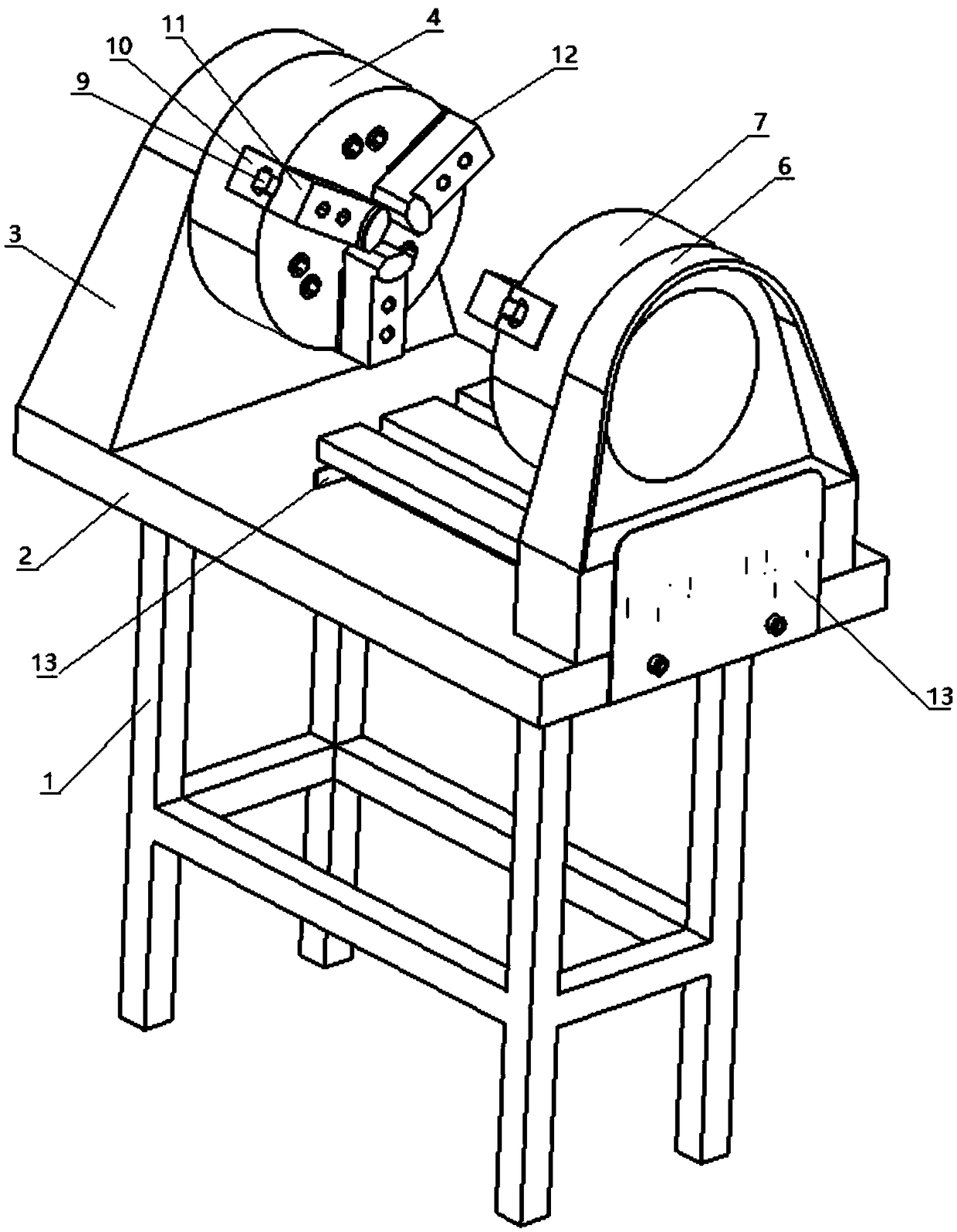

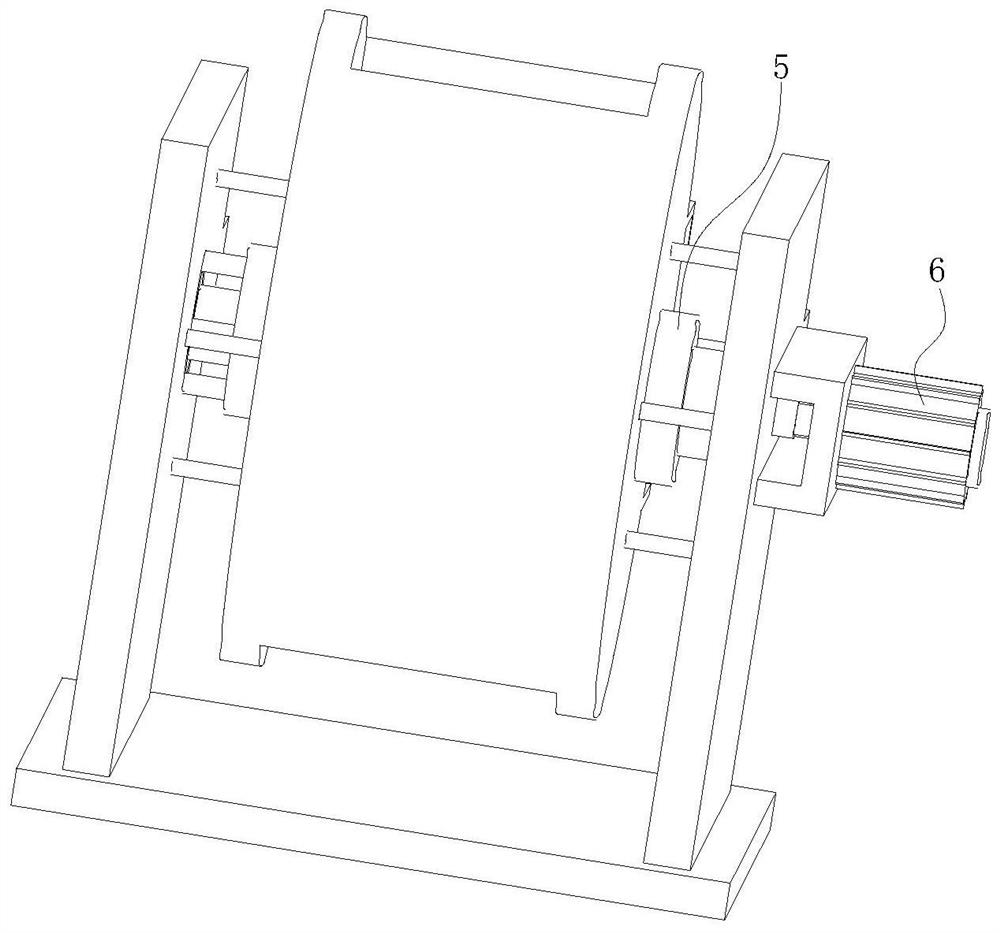

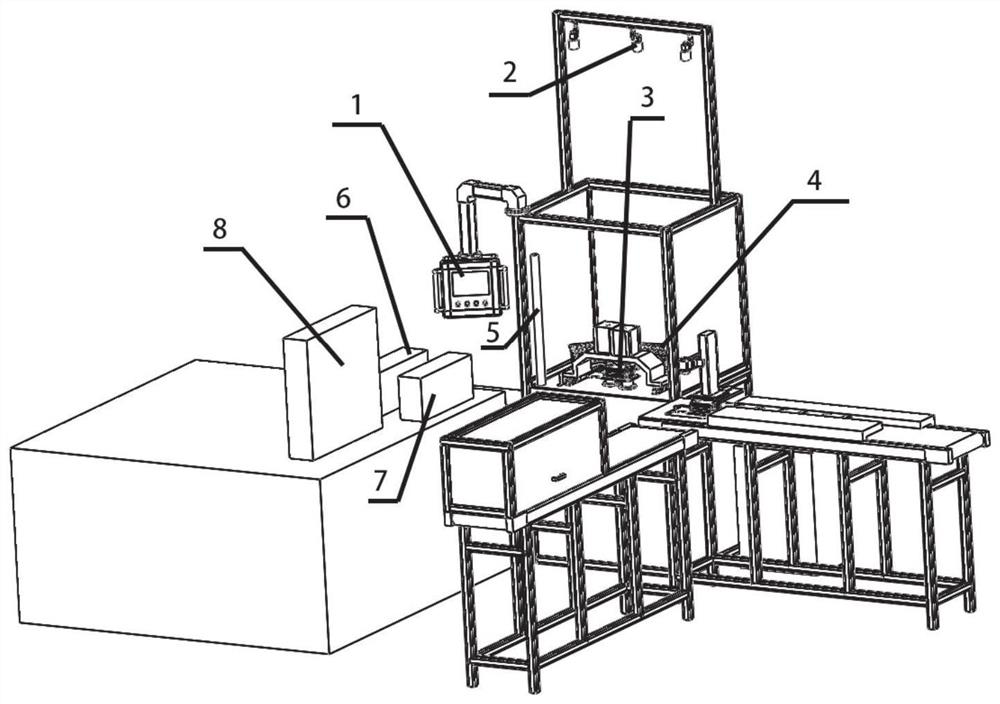

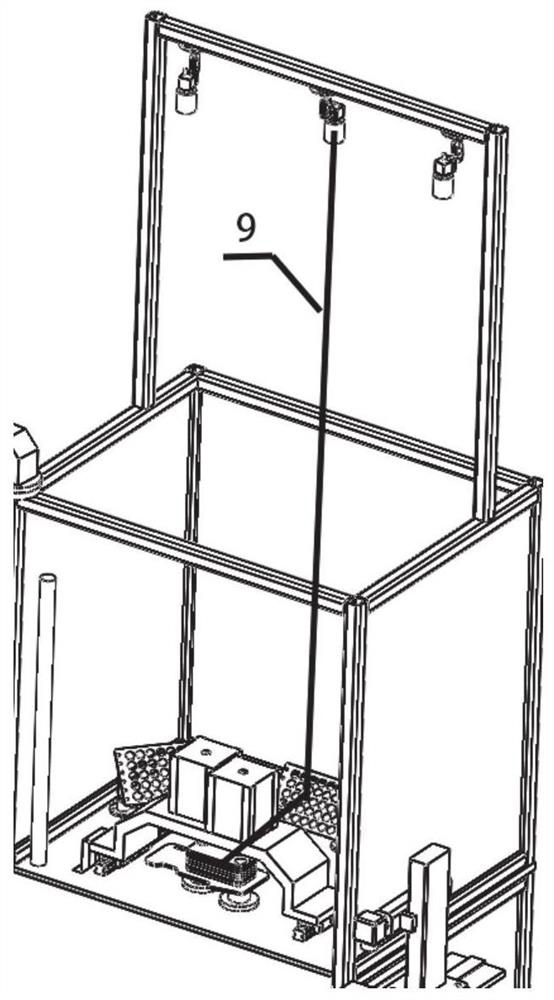

Calibration device for petroleum thread single parameter inspection tester

InactiveCN101469964AAvoid micro deformationGood measurement calibration effectAngles/taper measurementsOil fieldSingle measure

The invention discloses an apparatus suitable for accuracy calibration of multiple-pipe material measuring one-way instrument. A high precision workbench 2 is provided on a base plate, one end of the workbench is provided with a universal fixture 3, an adjusting rack 5 arranging a standard displacement apparatus is provided on an appropriate position of a bar-shaped slot 4 of the workbench 2, a conical gauge chucking tool 6 is provided on the base plate at one side of the workbench 2. The invention can calibrate one-way instrument of each country, be used for the steel tube producing enterprise, the oil field mechanical manufacturing enterprise, the pipe material quality detection department and the pipe material using unit, also can be used as standard transferring means of country and locality metering departments.

Owner:NAT INST OF METROLOGY CHINA

Pressure adjustor

InactiveCN105888627AShorten speedIncrease contact areaConstructionsFluid removalOil productionGas lift

The invention discloses a pressure adjustor which comprises a shell. An adjusting cavity, a gas inlet cavity and a transition cavity are formed in the shell. A gas bag is arranged in the adjusting cavity. The adjusting cavity is communicated with the gas inlet cavity through a vent hole. The gas inlet cavity is communicated with the transition cavity through a small hole. Communicating holes are formed in the two sides of the gas inlet cavity. An ejector rod is arranged in the middle of the gas inlet cavity. The vertical section of the ejector rod is sleeved with a return spring. The top of the vertical section of the ejector rod penetrates through the vent hole and then upwards extends to be connected with the gas bag. A first ball is arranged at the bottom of the horizontal section of the ejector rod. A gasket is arranged on the inner wall of the gas inlet cavity. A sealing hole coaxial with the small hole is formed in the middle of the gasket. In order to solve the problem that in the prior art, during gas-lift production, high-pressure gas flow is not accurately adjusted, and then oil production efficiency is reduced, the different cavities are arranged for linkage control over high-pressure gas flow, so the circulation of high-pressure gas flow between a casing pipe and an oil pipe is more smooth, adjustment is more accurate, and gas-lift production efficiency is improved.

Owner:CHENGDU NORTH OIL EXPLORATION DEV TECH

Crankshaft grinding machine servo center frame

ActiveCN105856006ASupportiveHas a guiding roleRevolution surface grinding machinesGrinding work supportsBall screwEngineering

The invention discloses a crankshaft grinding machine servo center frame comprising a supporting frame, a first positioning rod, a second positioning rod and two sets of driving assemblies. The second positioning rod comprises an inclined driving segment. Each driving assembly comprises a spiral transmission mechanism and a motor driving the spiral transmission mechanism. The first positioning rod is in the shape of a straight rod, a rod body of the first positioning rod is horizontally distributed, and the positioning end face of the first positioning rod is vertically distributed. The second positioning rod further comprises a supporting segment, and a supporting face of the supporting segment is arranged to be horizontal. An ejecting block is vertically distributed; a supporting block is horizontally distributed; a 90-degree included angle is formed between two positioning faces, the two positioning faces perform auxiliary positioning on a crankshaft jointly, deformation of the crankshaft under the effect of dead load can be prevented, and micro deformation of the crankshaft under extruding force of a grinding wheel of a grinding machine can be prevented as well; and servo motor drive and ball screw nut pair transmission are adopted, the changing extruding force of the grinding wheel of the grinding machine can be offset in real time in the grinding process, and the grinding precision required by an outer circle of a connection journal of the crankshaft is achieved.

Owner:SICHUAN FEIYA AUTO PARTS CO LTD

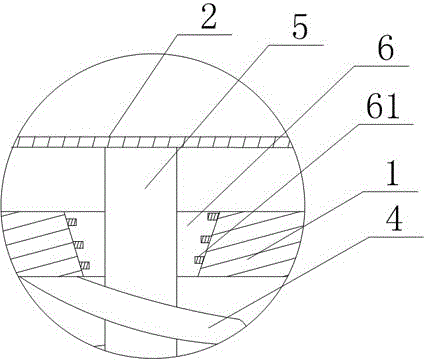

Multi-roller calendering device

ActiveCN106180189AAvoid micro deformationSmall diameterMetal rolling stand detailsMetal rolling arrangementsEngineeringMechanical engineering

The invention discloses a multi-roller calendering device which comprises a pressing mechanism, a gap fine-adjustment mechanism, a first pressing roller, a second pressing roller, a first calendering roller and a second calendering roller, wherein the first calendering roller and the second calendering roller are located between the first pressing roller and the second pressing roller. The first pressing roller drives the first calendering roller to rotate, and the second pressing roller drives the second calendering roller to rotate. Pressure of the pressing mechanism acts on the first pressing roller. The gap fine-adjustment mechanism is located between the first pressing roller and the second pressing roller and used for adjusting the working gap between the first calendering roller and the second calendering roller. Materials are subjected to calendering molding in the working gap. The multi-roller calendering device has the beneficial effects that pressure of the pressing mechanism acts on the corresponding pressing roller, uniform stress of the pressing rollers is applied to the calendering rollers in the longitudinal direction, the defect of uneven longitudinal arrangement of a lithium film due to the overlarge gap of the calendering rollers is overcome, and the defect of the uneven thickness of the lithium film due to deformation of the calendering rollers is also overcome.

Owner:CONTEMPORARY AMPEREX TECH CO

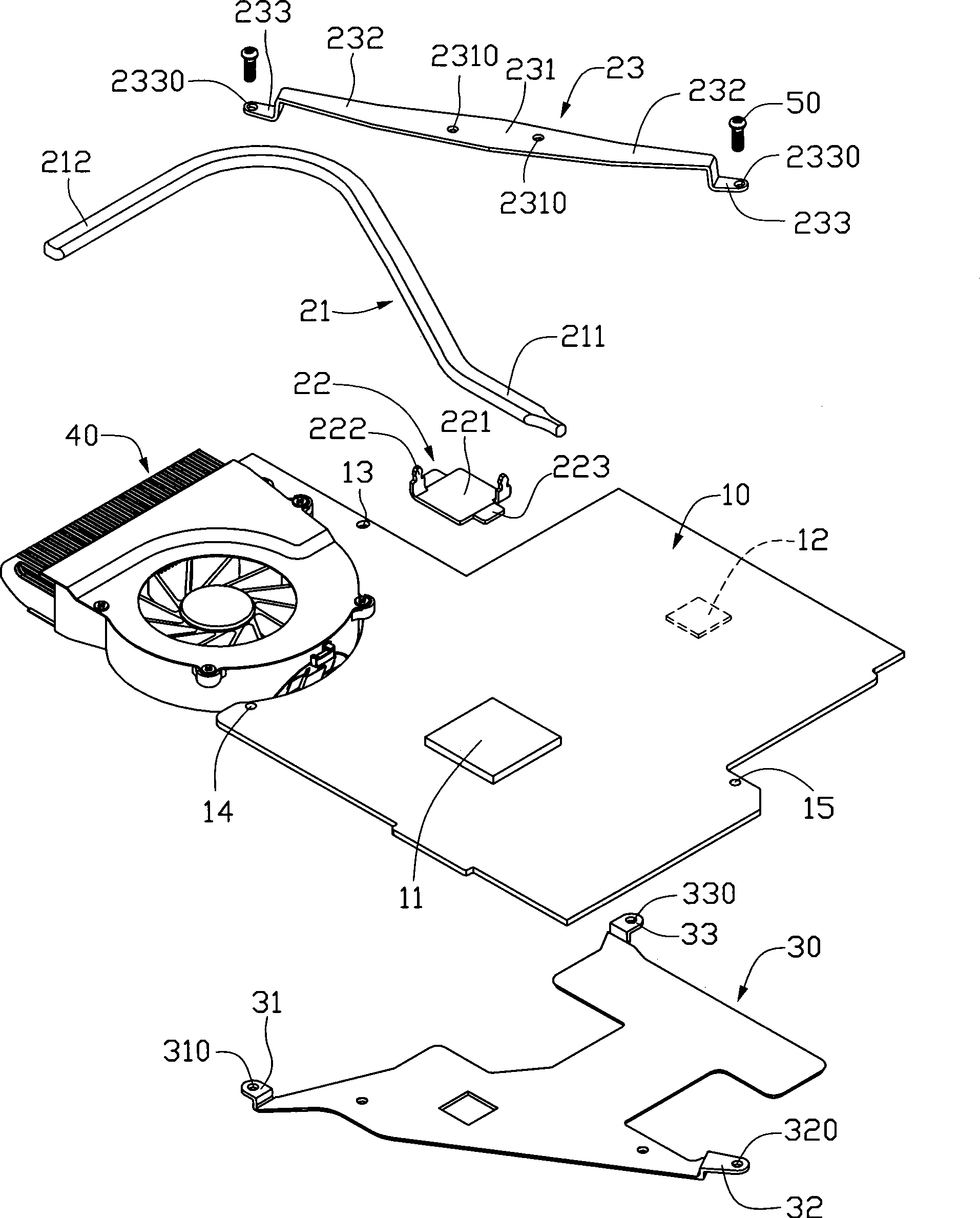

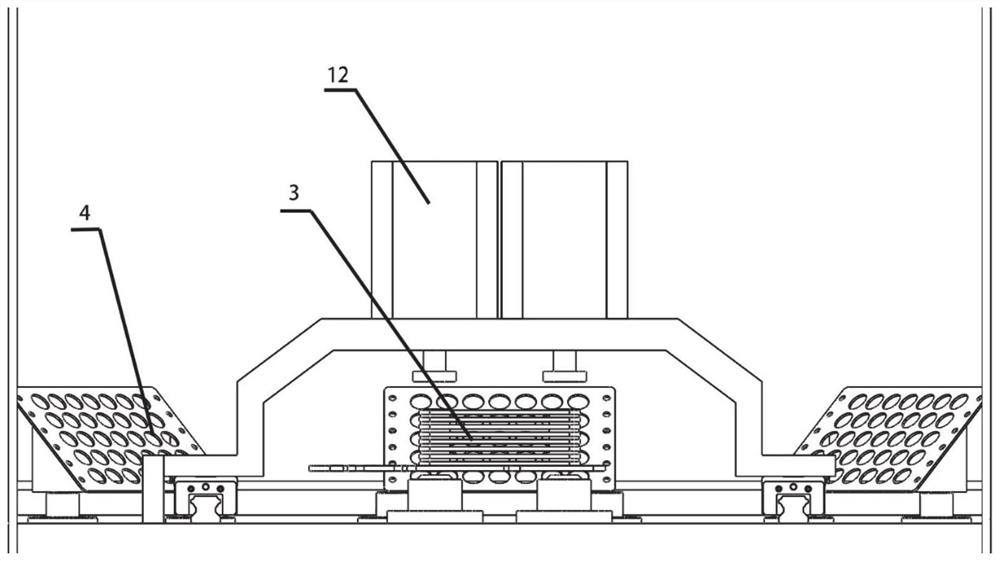

Radiator and fixed device for hot pipe

InactiveCN101466233ACannot be assembledAvoid micro deformationSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

The invention relates to a device used for fixing a heat pipe, comprising a panel and an elastic piece. The panel comprises a contact plate which is used for carrying the heat pipe and two protruded posts which extend out along the same direction at the two sides of the contact plate, wherein, the heat pipe is arranged between the two protruded posts, and the free end of each protruded post is provided with at least one bump. The elastic piece comprises a press part, two connecting parts formed by extending from the two ends of the press part, and two locking parts formed by extending from the connecting parts, wherein, the press part is provided with two locking holes, the locking holes can detachably press and span the bump on the protruded post, so as to be sheathed on the lower part of the bump and cause the press part to press the heat pipe to the contact plate. In the device used for fixing the heat pipe in the invention, the elastic piece is clamped on the panel by the bump; the panel is formed by integral bending; the manufacturing process is simple, the producing speed is rapid; when in assembly, the elastic piece can be easily arranged on the panel only by the positive force generated by downward pressing of fingers, and the assembly program is simple.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

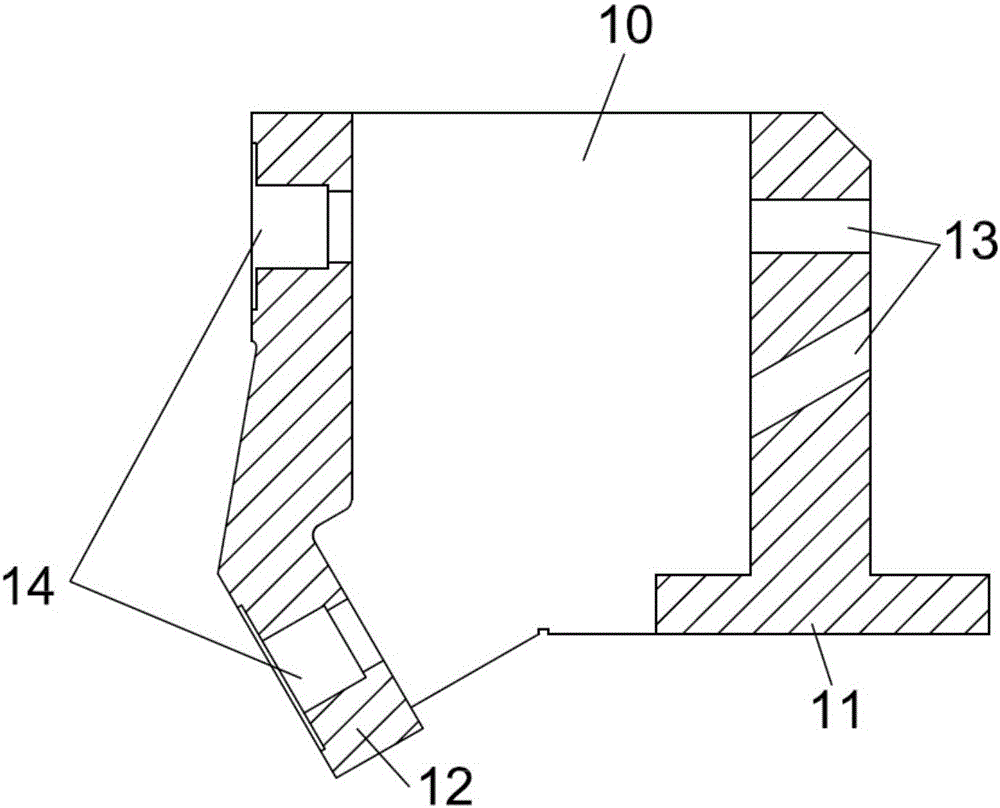

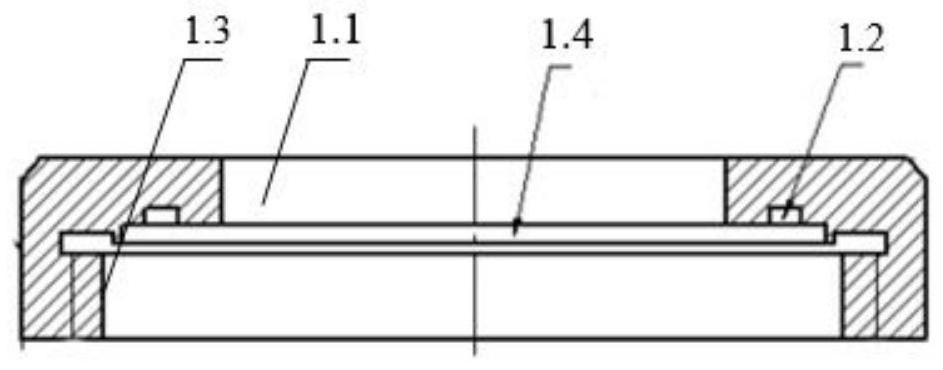

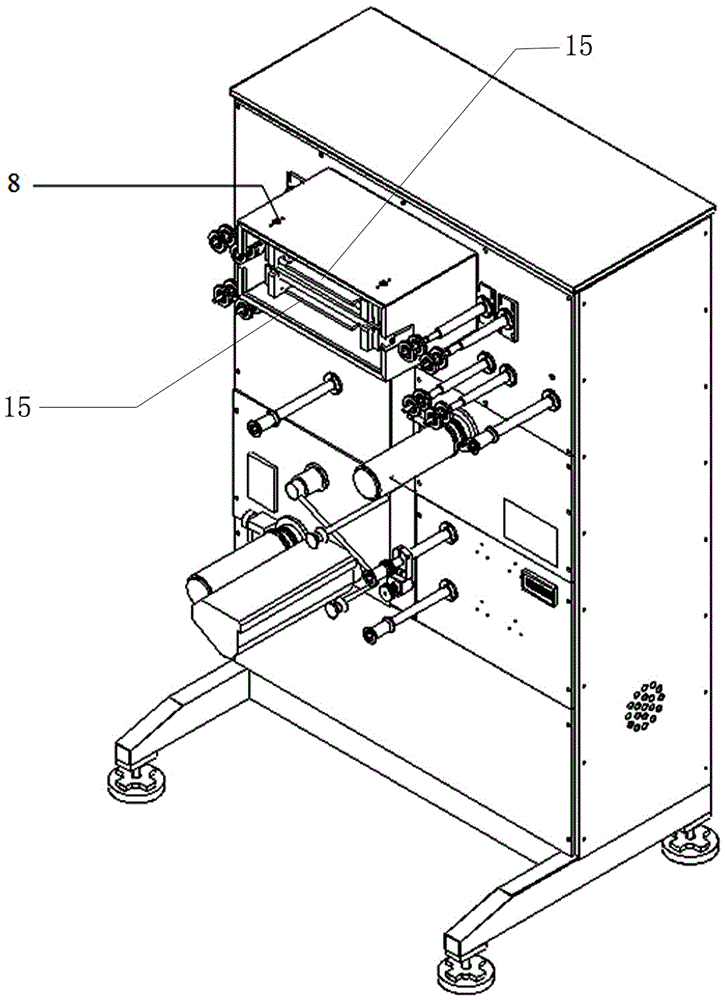

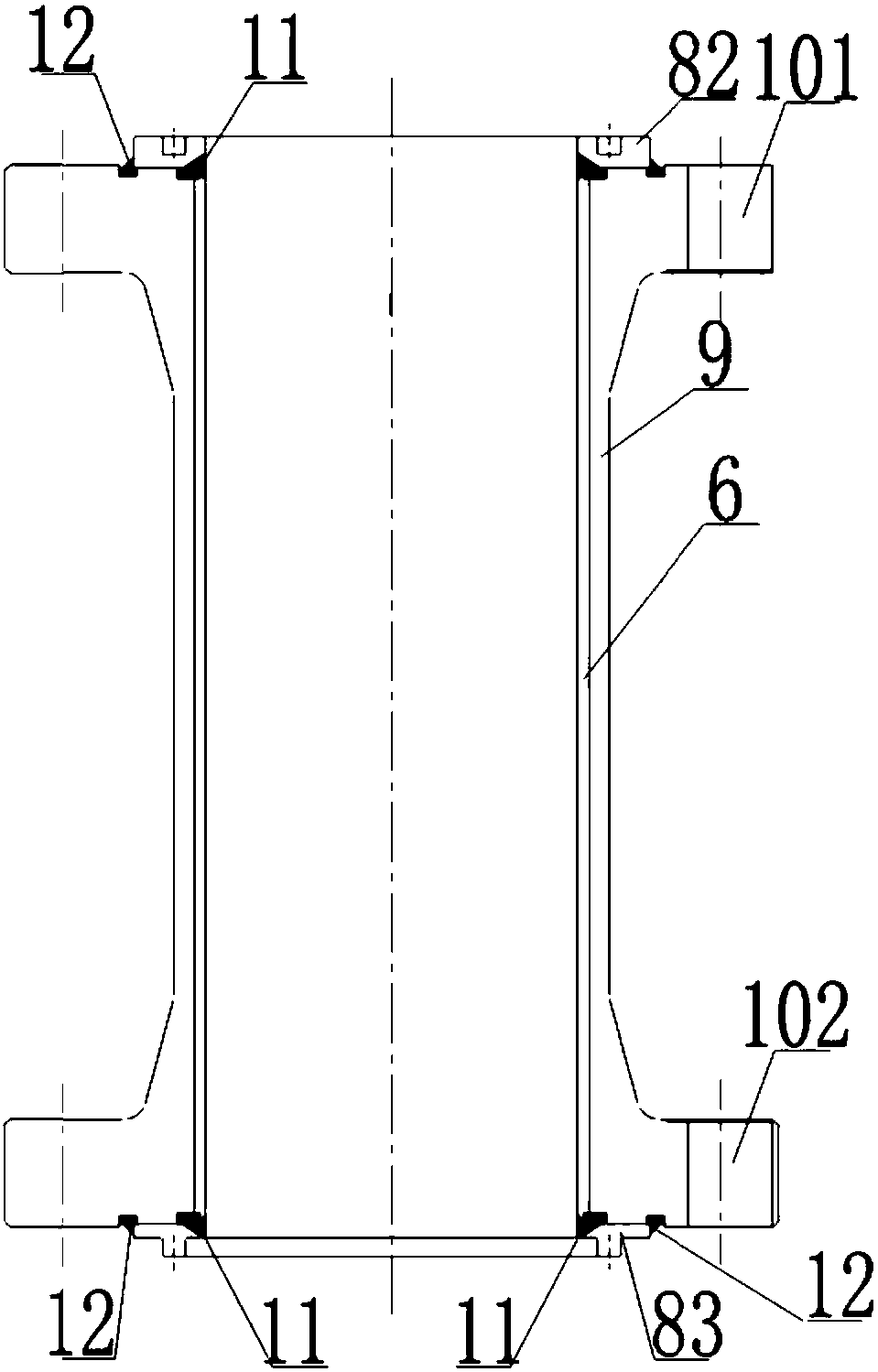

Sealing and fixing device for testing aerospace gyro motor in high-temperature and low-temperature environment

ActiveCN112198429AEasy to replaceEasy to disassembleMeasurement instrument housingEnvironmental/reliability testsMotor testingElectric machine

The invention relates to a sealing and fixing device for testing an aerospace gyro motor in a high-temperature and low-temperature environment. The sealing and fixing device comprises an end cover, ashell, a base and a motor mounting bracket; the end cover is fixedly connected with the upper end of the shell through threads; high and low temperature resistant silica glass is mounted in an upper glass interlayer mounting concave table of the end cover and a lower glass interlayer mounting concave table of the shell; an upper sealing ring and a lower sealing ring are embedded in an upper annular groove of the end cover and a lower annular groove of the shell respectively, and the upper sealing ring and the lower sealing ring are distributed to be tightly attached to the upper end face and the lower end face of the high-temperature-resistant and low-temperature-resistant silica glass; the shell is arranged above the base, the flange end of the shell is fixedly connected with the base through screws, and the annular boss at the lower end of the shell is in insertion fit with the annular groove in the upper end of the base in a clearance fit mode. The motor mounting bracket is arrangedin the annular groove in the upper end of the base, and the motor mounting bracket and the base are fixed through screws and positioned through positioning pins. Under the temperature environment within the range of -10 DEG C to +80 DEG C, a stable working state can be provided for the motor.

Owner:TIANJIN NAVIGATION INSTR RES INST

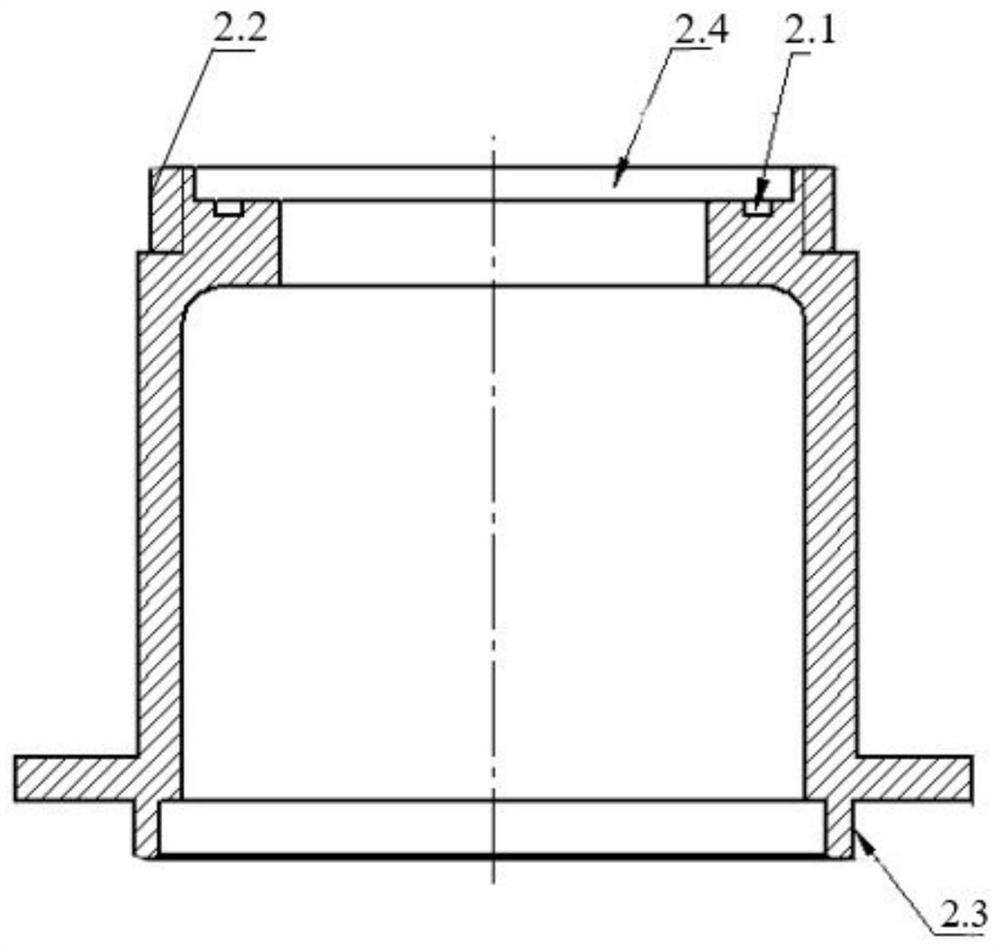

Large high-speed electromotor whole structure

InactiveCN101087081AMeet the design requirementsMeet the use requirementsMagnetic circuit stationary partsManufacturing stator/rotor bodiesResonanceEngineering

A kind of large-scale high-speed machine complete texture, motor includes engine base, end cap, stator, axes, rotor and bearing, thereinto, the engine base is box structure, two dabbers or above are set on upper, lower, lest and right side board, wall of engine base is processed by steel plate whose thickness is 40mm+-3; the end cap is one-shot formed by steel plate whose thickness is 50mm+-3, contact face between end cap and engine base and bearing are smooth, they are sealed with each other; stator, the iron core of the stator fixed with three integral round steel plate whose thickness is 20mm+-3, the iron core of the stator is shaped with built-in craftwork; axes and rotor iron core are processed by thermal process; the bearing is end bracket type bearing, and possesses two floating type seals, outer possesses outer cover. Advantages are: optimization design makes resonance of motor and other electric property fulfill design requirement, and it can fulfill operating requirement of open-air or dust is big, box structure can increase rigidity of engine base, and decrease resonance of motor.

Owner:SHANGHAI LUFA ELECTRIC GRP

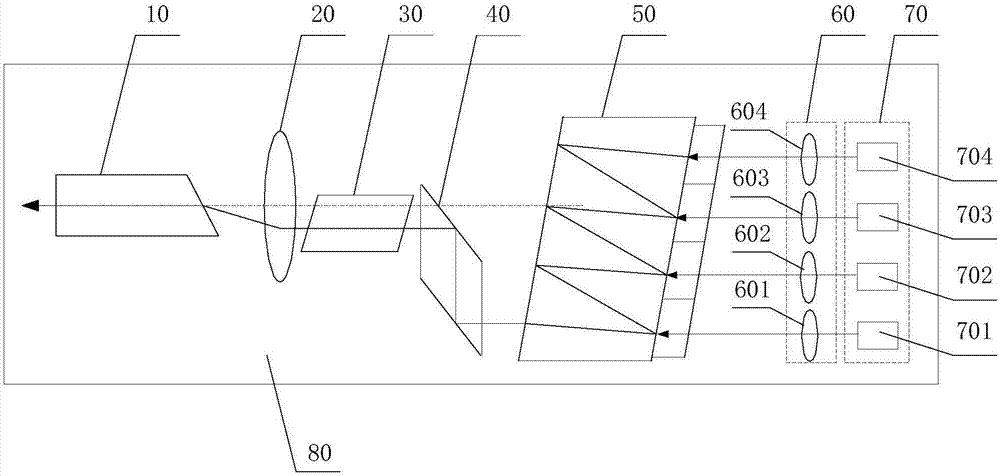

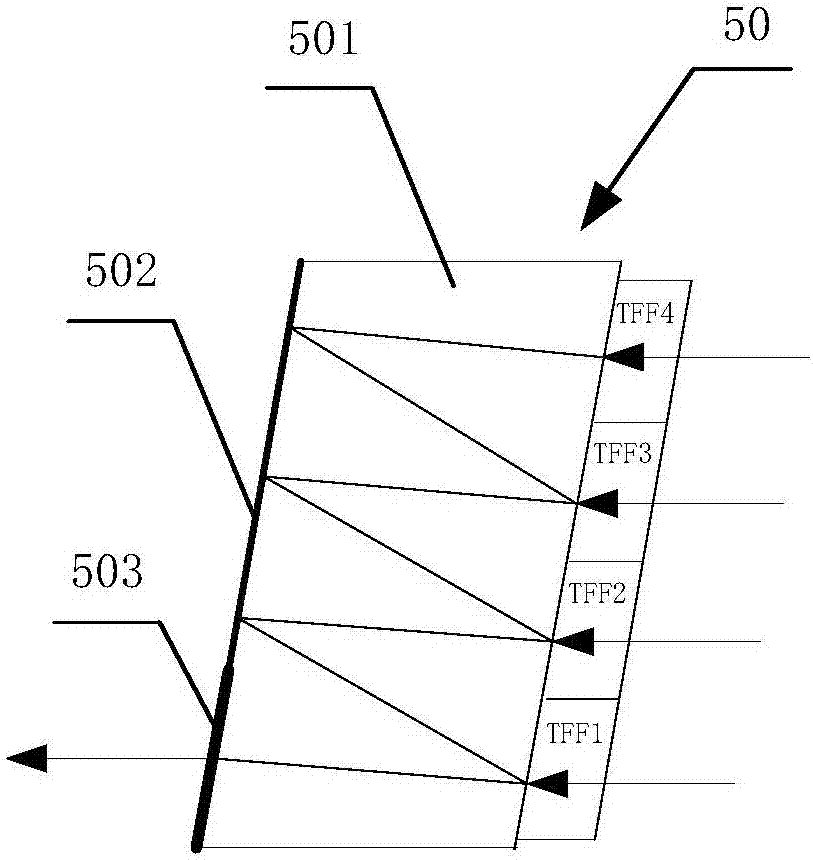

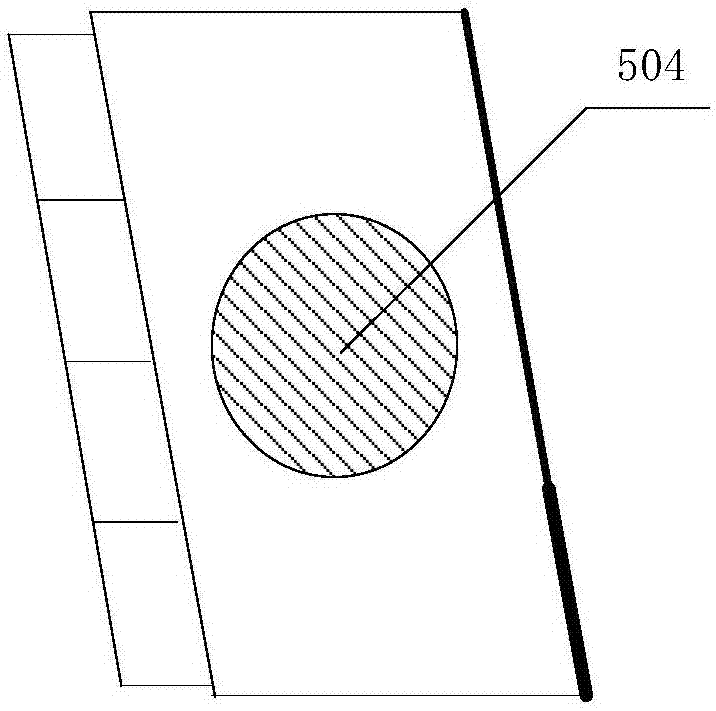

Optical module

InactiveCN107132626AAvoid micro deformationHigh speedCoupling light guidesMultiplexingOptical Module

The invention relates to an optical module. To be specific, the optical module is structured in such a way that an optical multiplexing assembly is adopted, a protruding structure is designed on a pedestal used for fixing the optical multiplexing assembly, and the protruding structure is used for controlling the coverage area of glue at the bottom of the optical multiplexing assembly after the surface mounting of the optical multiplexing assembly. In this way, during surface mounting of the optical multiplexing assembly, the coverage area of glue on the optical multiplexing assembly can be well controlled even if a lot of glue is utilized. Therefore, residual stress acting on the optical multiplexing assembly after solidification of the glue can be controlled effectively, and the stability of optical power output by an optical emitter in the optical module is ensured.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

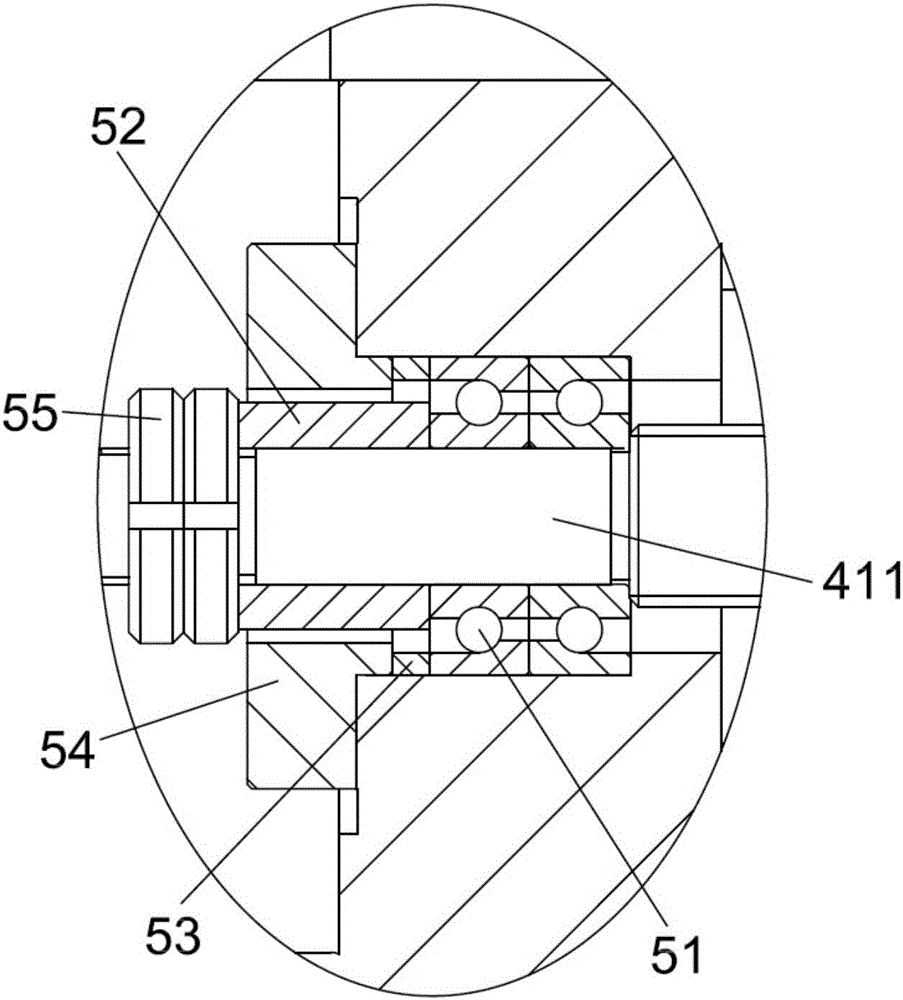

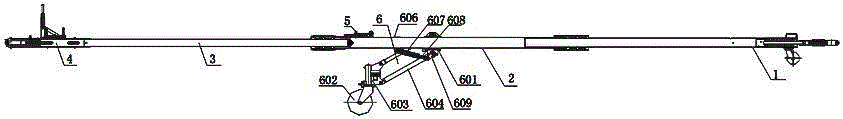

Three-section crawler telescoping airplane traction device

The invention discloses a three-section crawler telescoping airplane traction device. The airplane traction device comprises a head assembly (1), an outer cylinder assembly (2), a telescopic sleeve assembly (3), an airplane wheel connector (4), a capstan assembly (5) and a lifting mechanism (6), wherein the outer cylinder assembly (2) comprises an outer cylinder (201) and a case boy (202); crawler-type bearings (203) are arranged on the side walls of the case body (202); the telescopic sleeve assembly (3) comprises a telescopic rod A (301), a guide head (302), rolling wheels (303) and rotating shafts (304); the head assembly (1) comprises a telescopic rod B (101), a shaft sleeve (102), a pull-ring connector (103) and a pull ring (104); the telescopic rod B (101) and the telescopic rod A (103) are arranged in the outer cylinder (201) in a sleeving manner. The airplane traction device disclosed by the invention has the benefits that the airplane traction device can quickly stretch out and draw back, is convenient to operate, and has no loose components; the whole airplane traction device is convenient to park and store, and carry and transfer, and the ground area occupied by the airplane traction device during transfer is reduced.

Owner:成都航利装备科技有限公司

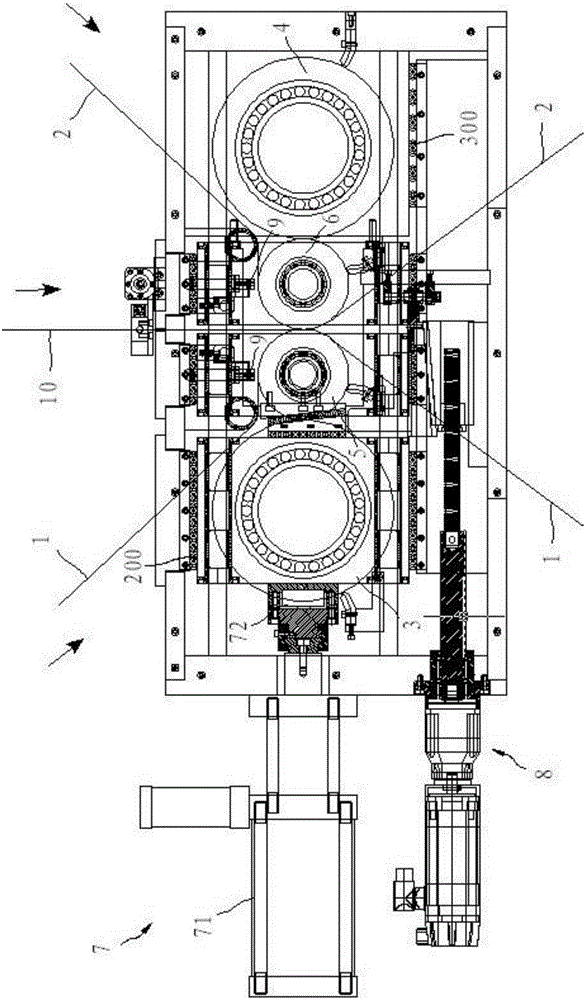

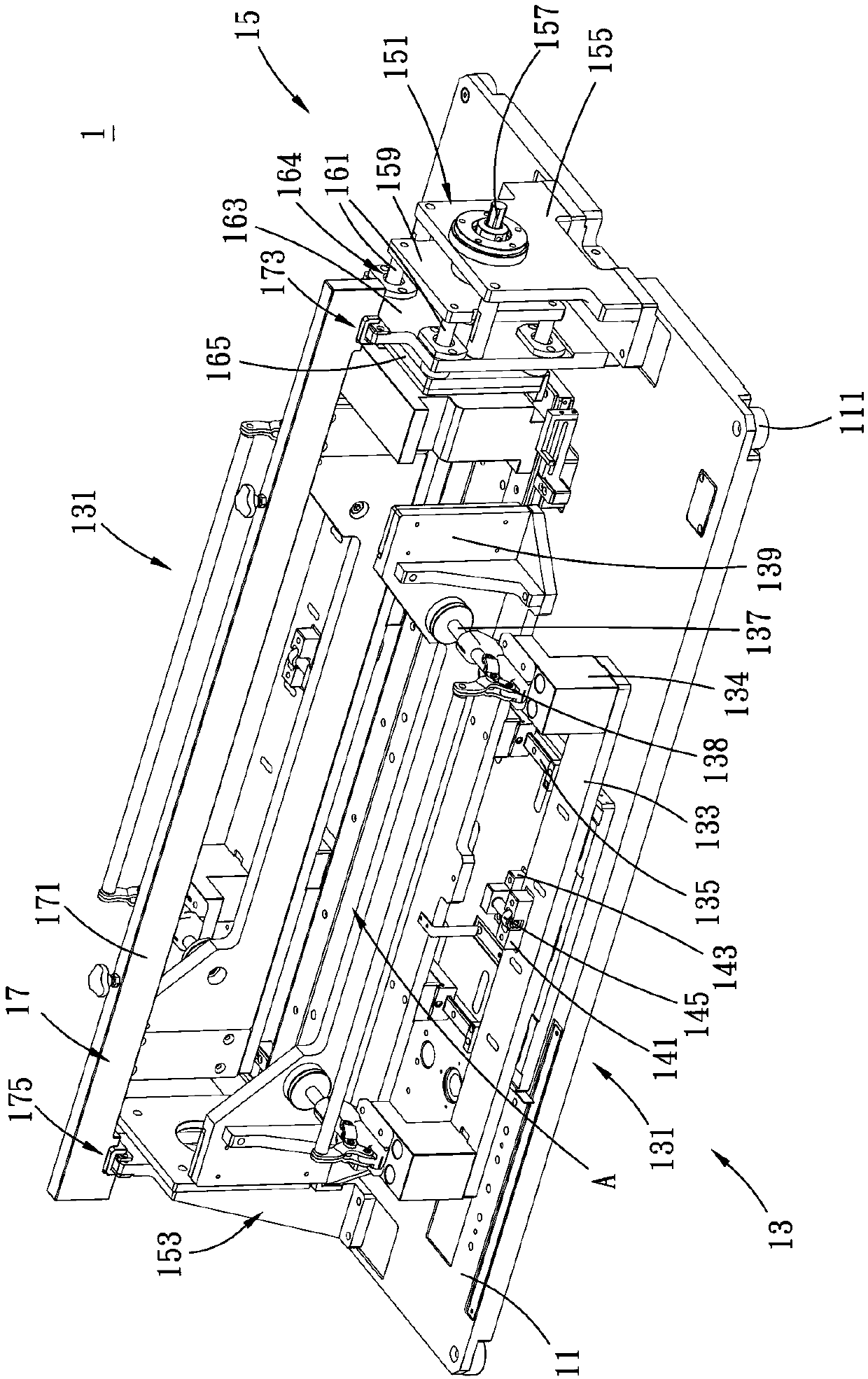

Secondary positioning table suitable for bearing workpiece machining and positioning method

The invention relate to the field of bearing workpiece machining, in particular to a secondary positioning table suitable for bearing workpiece machining and a positioning method. The secondary positioning table comprises a base supporting table, a positioning device fixed to the base supporting table, and a movable conveying device matched with the positioning device. The positioning device comprises a fixed chuck support, a fixed chuck base, a fixed chuck inner grabbing finger, a movable chuck support, a movable chuck base and a movable chuck inner grabbing finger. The fixed chuck support and the movable chuck support are arranged at the two ends of the upper surface of the base supporting table in parallel. The fixed chuck base is arranged on the inner side of the upper portion of the fixed chuck support. The fixed chuck inner grabbing finger is arranged on the fixed chuck base. The movable chuck base is arranged on the inner side of the upper portion of the movable chuck support. The movable chuck inner grabbing finger is arranged on the movable chuck base. The fixed chuck base and the movable chuck base are coaxially arranged. The movable conveying device is fixedly arranged at the position, on one side of the movable chuck support, of the base supporting table. The movable chuck support is axially slidingly connected to the movable conveying device.

Owner:BEIFANG UNIV OF NATITIES

Safe and stable scissor jack and using method thereof

The invention discloses a safe and stable scissor jack and a using method thereof. The scissor jack is simple in structure, good in stability, high in safety and long in service life, and belongs to the technical field of jacks. The scissor jack comprises a base, a jacking plate, a supporting assembly, a rocking handle and a threaded screw rod; the supporting assembly comprises an upper left supporting rod, a lower left supporting rod, an upper right supporting rod, a lower right supporting rod, a left connecting block and a right connecting block; the first end of each upper supporting rod isrotationally connected to the jacking plate, and the second end of each upper supporting rod is rotationally connected to the connecting block in the corresponding direction; the first end of each lower supporting rod is rotationally connected to the base, and the second end of each lower supporting rod is rotationally connected to the connecting block in the corresponding direction; the right connecting block is provided with a through threaded hole, the first end of the threaded screw rod is fixedly connected to the left connecting block, and the second end of the threaded screw rod penetrates through the threaded hole and extends out; a rod hole matched with the rocking handle is formed in the second end of the threaded screw rod; and a permanent magnet chuck is fixedly embedded in theouter exposed surface, parallel to the threaded screw rod, of the right connecting block.

Owner:宁波天胜传动件有限公司

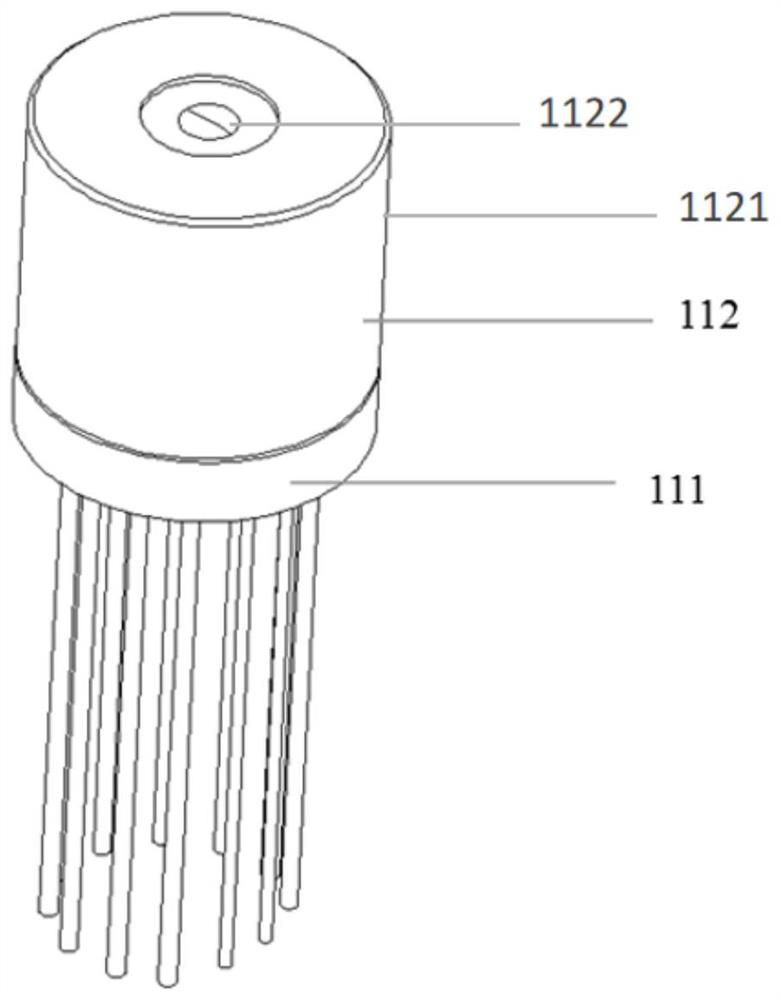

Shell assembly of high-speed optical signal transmitting device and high-speed optical signal transmitting device

InactiveCN113839301AIncrease bandwidth usageSimplify workLaser detailsElectromagnetic transmittersParasitic capacitanceEngineering

The invention relates to a shell assembly of a high-speed optical signal transmitting device and the high-speed optical signal transmitting device. The shell assembly comprises a shell, a heat sink substrate, a laser and a driving chip, the heat sink substrate, the laser and the driving chip are packaged in the shell, and the laser and the driving chip are adjacently placed on the heat sink substrate according to the axis direction of the shell. The driving chip and the laser are adjacently arranged on the heat sink substrate and packaged in the shell, so that a connecting line of the driving chip and the laser is as short as possible, long wiring between the driving chip and a semiconductor laser is avoided, the parasitic inductance and the parasitic capacitance caused by the long wiring are reduced, and the use bandwidth of a light emitting device is improved, so that the high-speed optical signal transmitting device can easily work at the speed of 25Gb / s and above, and is more suitable for being applied to the high-speed optical communication devices. Meanwhile, a non-turning linear light path design is adopted, a part of light turning elements and procedures are reduced, and the cost of the high-speed optical signal transmitting device is effectively reduced.

Owner:成都英思嘉半导体技术有限公司

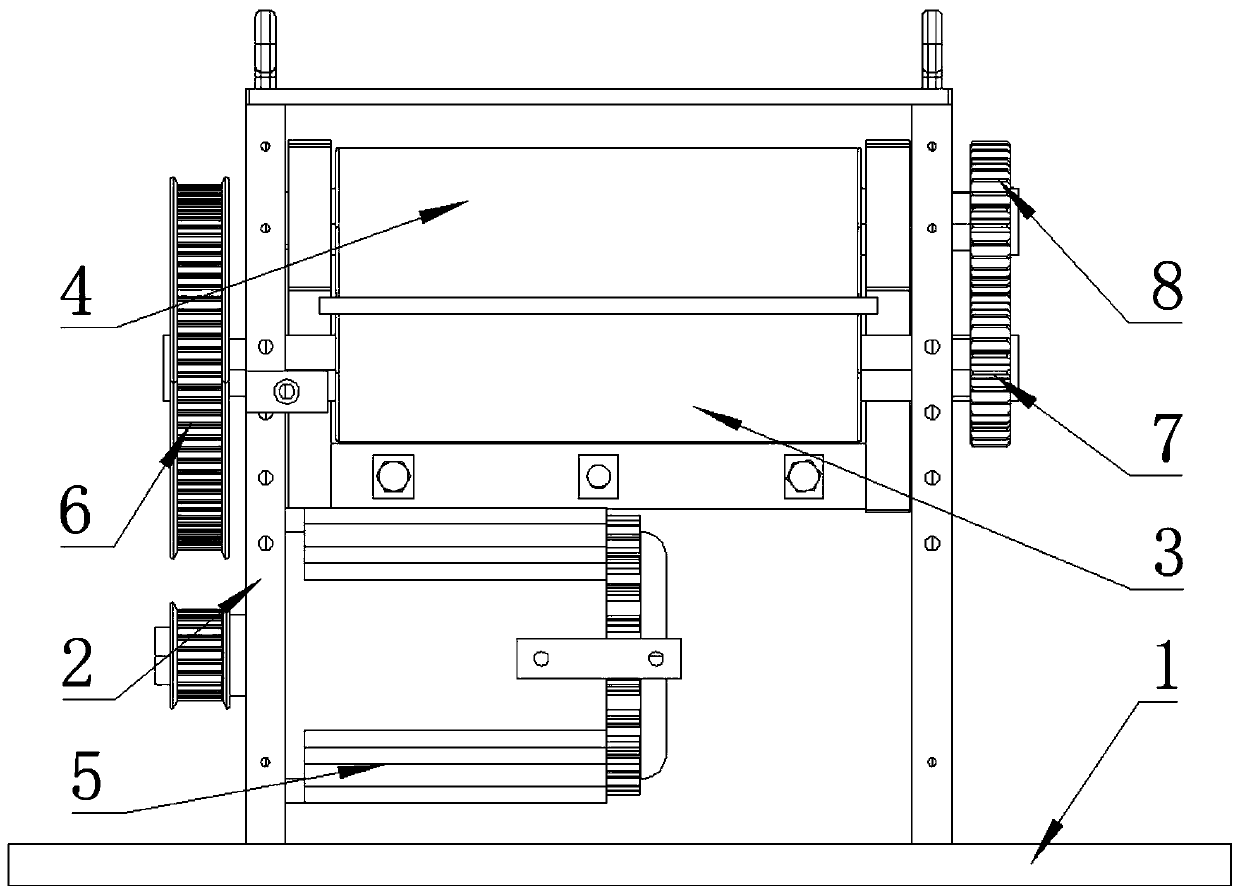

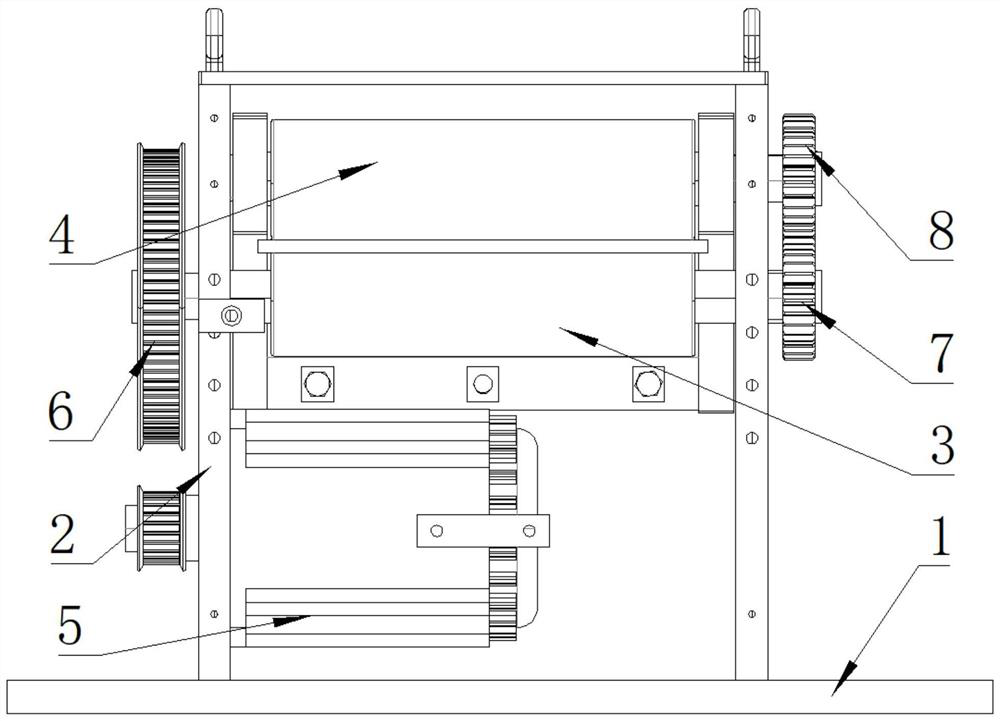

NCK high-speed servo feeder and control method thereof

InactiveCN110479895AReduce equipment costsLower control costsMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

Owner:扬州铭诚鑫智能科技有限公司

Atmospheric pressure low-temperature plasma continuous treatment apparatus and method for fiber tows

ActiveCN106245312AAvoid temperatureAvoid micro-deformationUltrasonic/sonic fibre treatmentTreatment effectEngineering

The invention discloses an atmospheric pressure low-temperature plasma continuous treatment apparatus and method for fiber tows. The treatment apparatus comprises a low-temperature plasma generating device, a discharging device and a winding device and is characterized in that one side of a feed port of the low-temperature plasma generating device and one side of a discharge port are provided with a plurality of staggered auxiliary guide wheels correspondingly, and fiber tows conveyed from the discharging device are wound sequentially around the staggered auxiliary guide wheels so that the fiber tows are passed through a discharge area of the plasma generating device many times in a reciprocating manner and are then passed to the winding device; the auxiliary guide wheels are metal guide wheels and are grounded through a conductive medium. The treatment apparatus is reasonable in structural design, is operable in atmospheric air, is low in operating cost and high in treatment efficiency and is simple to operate with good safety and reliability, and the size and process setting of a treatment area of the apparatus can be flexibly adjusted according to the specific dimensional and treatment effect requirements of a workpiece.

Owner:NANJING SUMAN PLASMA TECH CO LTD

Process technique for high-rotational speed injection made gear

The invention relates to the gear processing field, in particular to a processing technology of a high-speed injection gear, sensing devices are arranged in a gear die and a gear forming machine, various data indications in the gear processing procedure are measured and counted in time, and the gear processing procedure is controlled according to the data indications, thereby producing the high-speed injection gear with high precision, low cost, and long service life.

Owner:TOHKATSU PLASTIC TIANJIN

Reactor with thin-wall lining and production method of reactor

ActiveCN108160018AAvoid prone bulgesAvoid leakage and other failure problemsChemical/physical/physico-chemical processesNuclear engineeringFlange

The invention discloses a reactor with a thin-wall lining and a production method of the reactor. The reactor with the thin-wall lining comprises a blind flange, an upper shell and a lower shell whichare fixedly connected in sequence; each of the upper shell and the lower shell comprises an inner-layer cylinder and an outer-layer cylinder which are connected by a hot jacket; a material inlet, a material outlet and a test insertion hole are formed in the blind flange; and the inner-layer cylinder of the upper shell, the inner-layer cylinder of the lower shell, the blind flange as well as the material inlet, the material outlet and the test insertion hole in the blind flange form a sealed reaction cavity. The reactor has the advantages that the inner-layer cylinder and the outer-layer cylinder are connected by a hot jacket structure, so that the invalidation problem that a reactor produced in the prior art is easy to swell and leak can be effectively avoided under the condition that thesize is suited; and due to the arrangement of the upper shell and the lower shell, cup joint is conveniently realized.

Owner:HEFEI GENERAL MACHINERY RES INST +1

Processing and developing process of intelligent automatic gearbox

PendingCN111702427AAvoid micro deformationGuaranteed machining accuracyIndustrial engineeringProcessing accuracy

The invention discloses a processing and developing process of an intelligent automatic gearbox. The processing and developing process of the intelligent automatic gearbox comprises the following operation steps that S1, a blank is casted; S2, a bottom plane after rough milling is used as a rough reference surface, and during rough milling, a filler block is fixed to a gearbox body blank; S3, a bottom plane after finishing milling is used as the finishing reference surface, and during finishing milling, a filler block is fixed to a gearbox body blank; S4, hole processing is carried out; S5, front steps on the front of the gearbox body blank is subjected to rough milling and semi-finish milling in sequence; S6, the bottom surface of the gearbox body blank is drilled and tapped to make threaded holes; and S7, fine boring is carried out on shaft holes; S8, oiling and sealing are carried out after the cleaning inspection is qualified. The small deformation of a gearbox body under pressurecan be effectively avoided by additionally arranging the filler block on the inner side of the processing surface to effectively ensure the processing accuracy of the gearbox body. The method of simultaneous processing on two sides is adopted to avoid processing accumulation of errors when planes are changed.

Owner:WUXI GAOTIAN MACHINERY

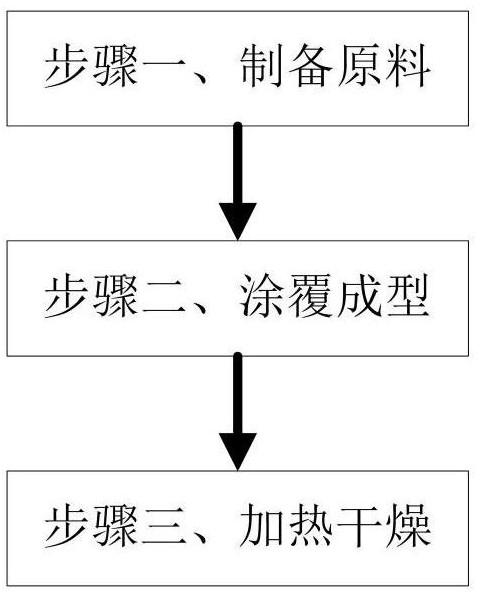

Molded packaging box manufacturing and shaping treatment process

ActiveCN112644837AEvenly heatedSame degree of dehydrationDrying solid materials with heatBoxesPaperboardProcess engineering

The invention belongs to the field of packaging material manufacturing, and particularly relates to a molded packaging box manufacturing and shaping treatment process. The process comprises the following steps of, 1, preparing raw materials, specifically, cutting and crushing waste paperboards, adding water, mixing and cooking, and uniformly stirring to obtain paper pulp; 2, coating and forming, specifically, uniformly coating the surface of a mold with the paper pulp prepared in the step 1, and demolding to obtain a molded packaging box which is not completely dried; and 3, heating and drying, specifically, heating and drying the molded packaging box which is not completely dried and prepared in the step 2, wherein the step 3 is completed by adopting a molded packaging box manufacturing and shaping treatment device in a matching manner. In the drying process of the molded packaging box, it is guaranteed that the dehydration degrees of all parts of the molded packaging box are the same, moisture is prevented from being absorbed by the molded packaging box again, the molded packaging box does not need to be taken manually, and deformation of the molded packaging box is avoided.

Owner:LINQUAN YATAI PACKING

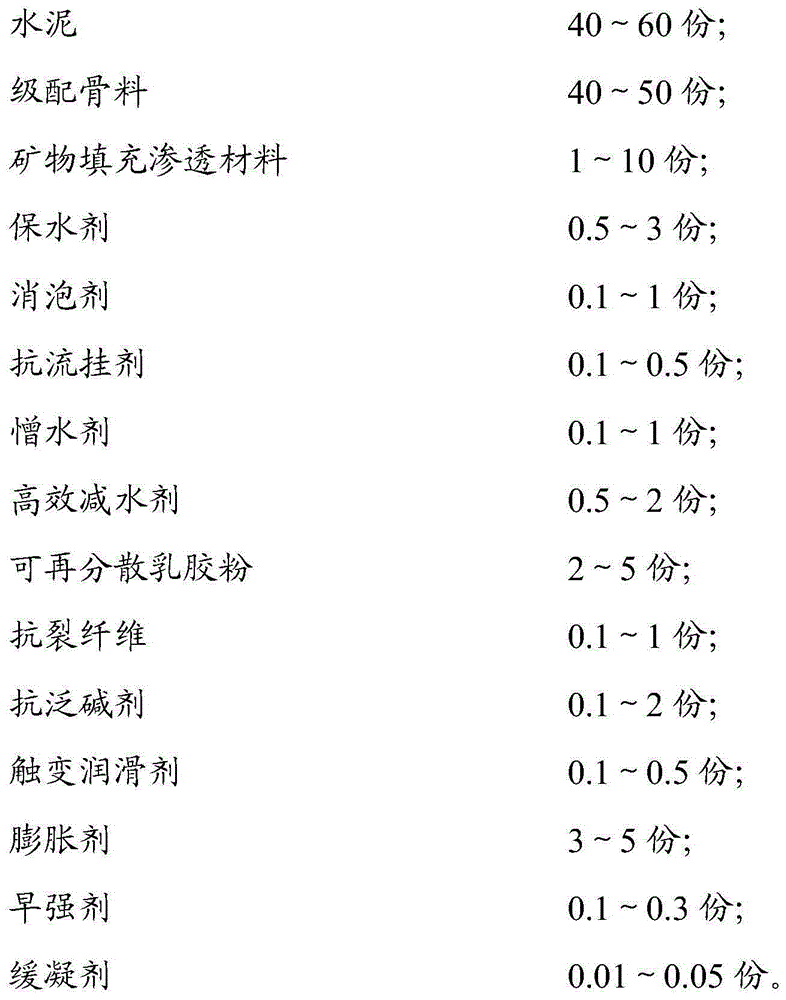

Waterproof tile adhesive material

The invention discloses a waterproof ceramic tile adhesive material which is prepared from the following components in parts by weight: 40-60 parts of cement, 40-50 parts of grading aggregate, 1-10 parts of mineral filling permeable material, 0.5-3 parts of water retaining agent, 0.1-1 part of antifoaming agent, 0.1-0.5 part of anti-sagging agent, 0.1-1 part of water repellent, 0.5-2 parts of superplasticizer, 2-5 parts of re-dispersible latex powder, 0.1-1 part of anti-cracking fiber, 0.1-2 parts of anti-saltpetering agent, 0.1-0.5 part of thixotropic lubricant, 3-5 parts of expanding agent, 0.1-0.3 part of early strength agent and 0.01-0.05 part of retarder. The waterproof ceramic tile adhesive material disclosed by the invention can be used for pasting ceramic tiles, realizes a waterproof anti-permeation function with low shrinkage and high compaction, has the characteristics of high bonding strength and strong environmental adaptability, and provides a guarantee to the building and personal safety.

Owner:广东龙马新材料科技有限公司

Downhole pressure regulator

InactiveCN105888628AImprove sealing performanceImprove work efficiencyConstructionsFluid removalOil productionPressure regulator

The invention discloses a downhole pressure regulator which comprises a shell. The shell is internally provided with an adjusting cavity, an air inlet cavity and a transition cavity. The adjusting cavity is internally provided with an air bag and communicated with the air inlet cavity through a ventilation hole, the air inlet cavity is communicated with the transition cavity through a small hole, communication holes are formed in the two sides of the air inlet cavity, an ejector rod is arranged in the middle of the air inlet cavity, a vertical section of the ejector rod is sleeved with a return spring, the top of the vertical section of the ejector rod penetrates through the ventilation hole and then extends upwards to be connected with the air bag, a first ball is arranged at the bottom of a horizontal section of the ejector rod, a gasket is arranged on the inner wall of the air inlet cavity, and the middle of the gasket is provided with a sealing hole coaxial with the small hole. In order to solve the problem that during gas-lift oil production in the prior art, adjustment of high-pressure gas flow is not accurate and accordingly oil recovery efficiency is reduced, different cavities are arranged for linkage control over the high-pressure gas flow, so that flow of the high-pressure gas flow between a casing pipe and an oil pipe is smoother, adjustment is more precise, and accordingly gas-lift oil production efficiency is further improved.

Owner:CHENGDU NORTH OIL EXPLORATION DEV TECH

High-efficiency superheater

The invention relates to a high-efficiency superheater which is arranged in a superheating flue and comprises a first-stage heating flue and a second-stage heating flue sleeving outside the first-stage heating flue, wherein the first-stage heating flue comprises a flue gas channel A; heat exchange fins A are arranged in the flue gas channel A; an annular heating chamber A is formed in the outer wall of the flue gas channel A; the second-stage heating channel comprises an annular heating chamber B; an annular flue gas channel B is arranged between the inner wall of the annular heating chamber B and the outer wall of the annular heating chamber A; the annular heating chamber B and the annular heating chamber A are communicated through a plurality of connecting pipes; a conical groove is formed in one side, toward the superheating flue, of the superheater; the axis of the conical groove is coaxial with the flue gas channel A; the bottom surface edge of the conical groove is positioned in the outer wall surface of the annular heating chamber B. A dividing wall type heat exchanger with an annular structure replaces an original dividing wall type heat exchanger with an array pipeline structure, so the flowing resistance of high-temperature flue gas flowing in the superheater is reduced.

Owner:临沂恩科开发建设有限公司

Automobile oil cooler pseudo soldering detection system and method based on machine vision

PendingCN113030111AImprove efficiencyIncrease contrastOptically investigating flaws/contaminationProcess engineeringMechanical engineering

The invention discloses an automobile oil cooler pseudo soldering detection system and method based on machine vision, and the system comprises: an image collection device which is used for collecting images before and after stamping of an oil cooler; and a cold solder joint detection module which is used for analyzing the images before and after stamping of the oil cooler, obtaining the areas of gap areas corresponding to the images before and after stamping, determining the number and the positions of interlayer gap areas with area changes in the images before and after stamping, and according to the number and the position of the interlayer gap area with the area change, determining the number and the position of cold joint of the oil cooler. The accuracy of cold solder joint detection of the oil cooler is improved.

Owner:SHANDONG UNIV

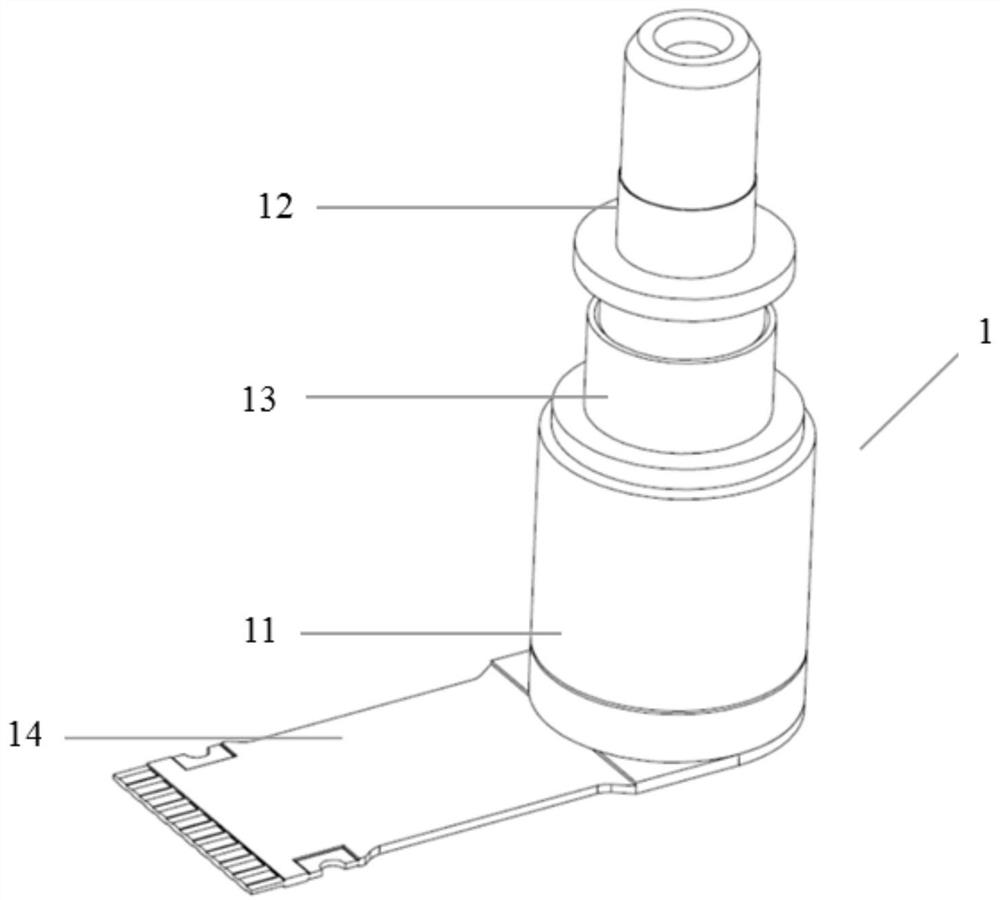

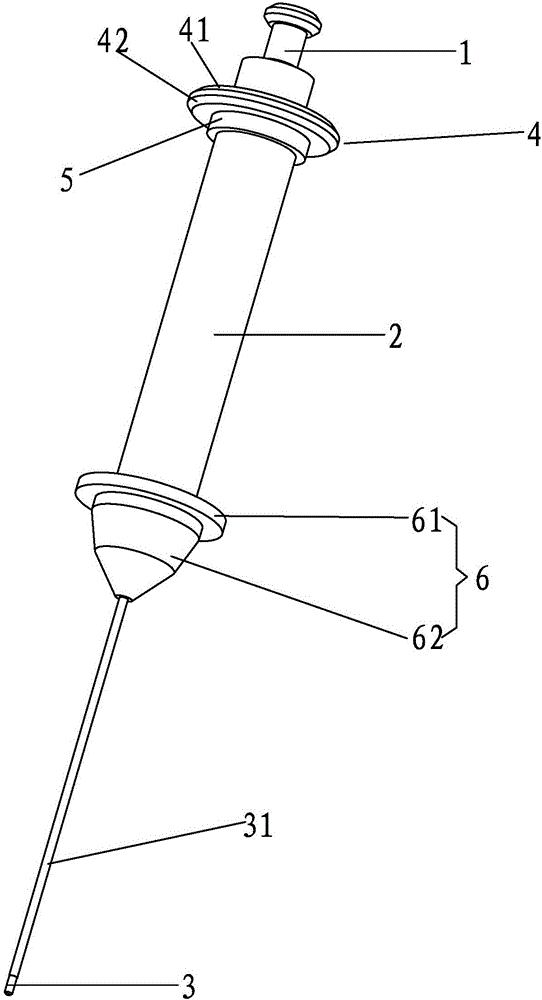

Injector of pipeline-free automatic liquid dropping machine

ActiveCN106676799AReliable clampingStable clampingTextile treatment machine arrangementsSpecial surfacesEngineeringRepeatability

The invention provides an injector of a pipeline-free automatic liquid dropping machine. The injector comprises a push handle, a cylinder body and a transfusion needle, and further comprises a dish-shaped device, the dish-shaped device is a hollow cylinder which extends in the axial direction of the cylinder body, and is located above the cylinder body, a cylindrical guiding ring is arranged where the lower end face of the dish-shaped device extends downward, the cylindrical guiding ring is sleeved with the upper end of the cylinder body in a tightly matched mode, the upper end of the outer side face of the dish-shaped device is an upper conical face which dwindles from bottom to top, and the lower end of the outer side face of the dish-shaped device is a lower conical face which dwindles from top to bottom; the outer side wall of the transfusion needle is provided with a non-hydrophilic structure. According to the injector of the pipeline-free automatic liquid dropping machine, the stability of clamping and the repeatability of a clamped pose is guaranteed when the injector is clamped, the deformation quantity of the injector is reduced, and achievement of precise and reliable titration is benefited; through the match of the on-hydrophilic structure of the transfusion needle, the surface friction of the transfusion needle can be reduced, fast dripping of adhered liquid on the surface of the injector is guaranteed, and the problem of titration errors due to liquid dripping in the liquid titration process is avoided.

Owner:HUAQIAO UNIVERSITY

A kind of nck high-speed servo feeder and its control method

InactiveCN110479895BReduce equipment costsLower control costsMetal-working feeding devicesPositioning devicesControl engineeringStructural engineering

Owner:扬州铭诚鑫智能科技有限公司

Clamping jig

InactiveCN109926777AAvoid micro deformationEasy to operateWelding/cutting auxillary devicesWork holdersEngineeringUltimate tensile strength

The invention discloses a clamping jig. The clamping jig comprises a base, a side pressing holding structure, a pressing holding structure and a fixing piece. The base is provided with a machining area, and the object to be machined is placed in the machining area. The side pressing holding structure and the pressing holding structure separately correspond to the machining area, the extrusion directions of the side pressing holding structure and the pressing holding structure face into the machining area, and the extrusion directions of the side pressing holding structure and the pressing holding structure are different. The side pressing holding structure and the pressing holding structure extrude the object to be machined in the machining area, wherein the side pressing holding structureand the pressing holding structure can be applied to products with different lengths and widths, furthermore, when the pressing holding structure needs to apply a larger pressing holding force, the problem that the extrusion machining state of a product is affected due to micro-deformation of the pressing holding structure is prone to being caused, and therefore, the fixing piece can be used forstrengthening the structural strength of the pressing holding structure.

Owner:惠州市世育五金制品有限责任公司

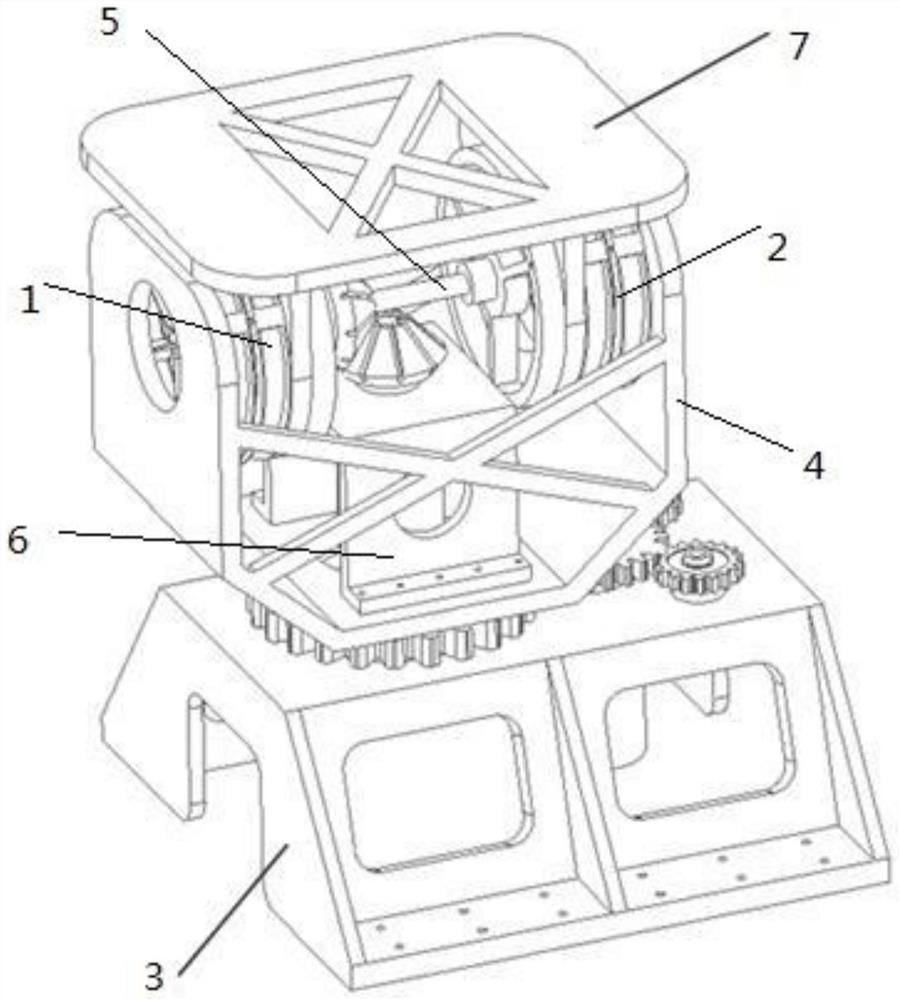

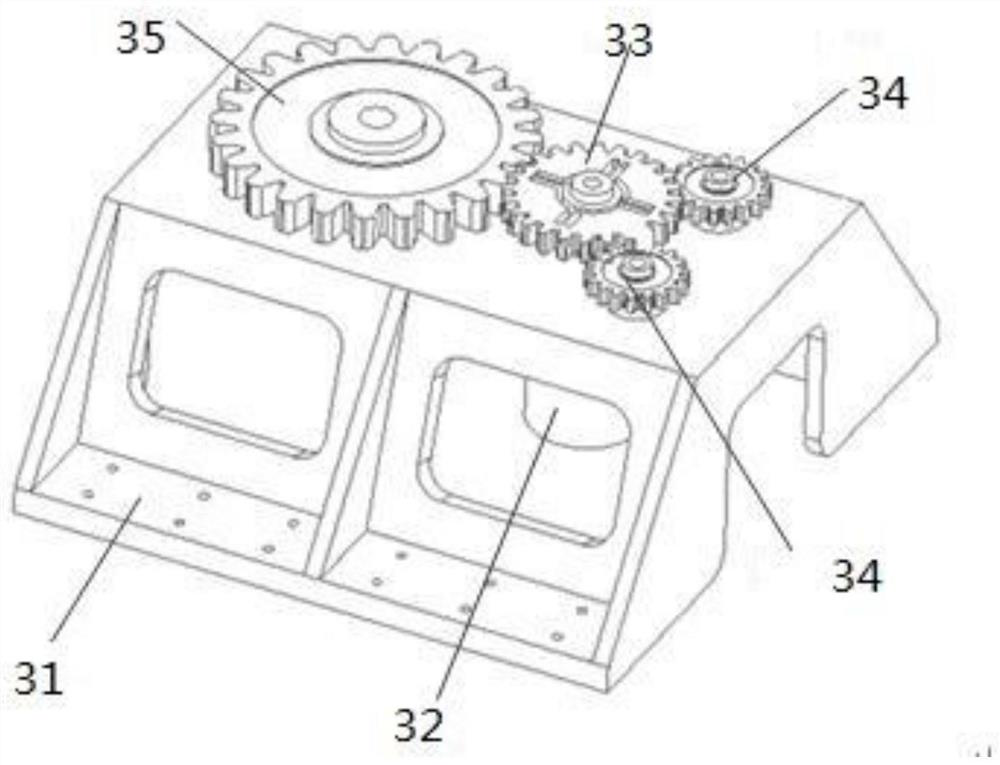

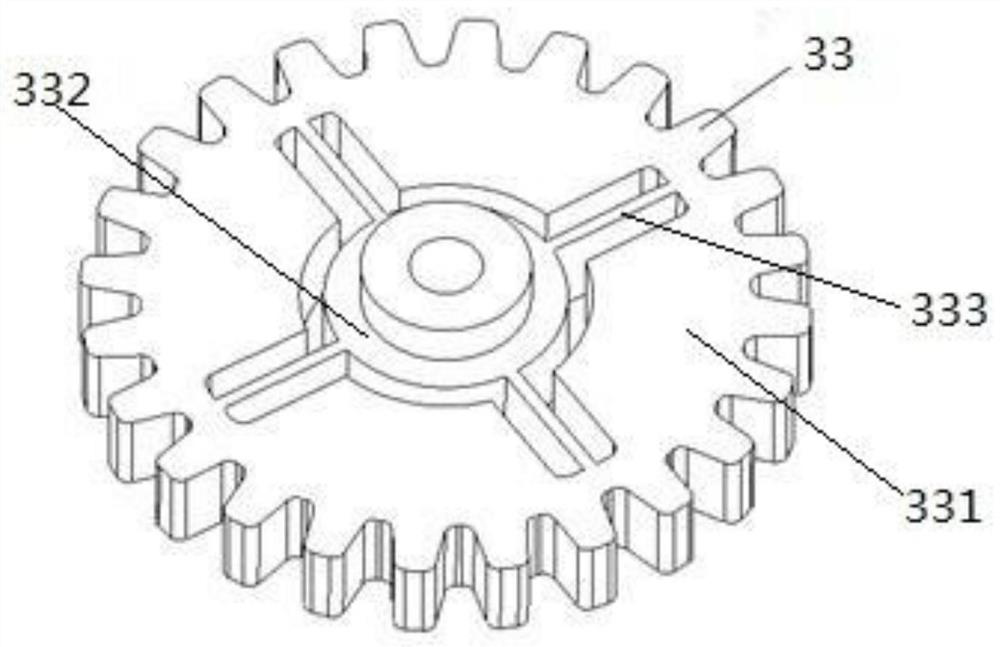

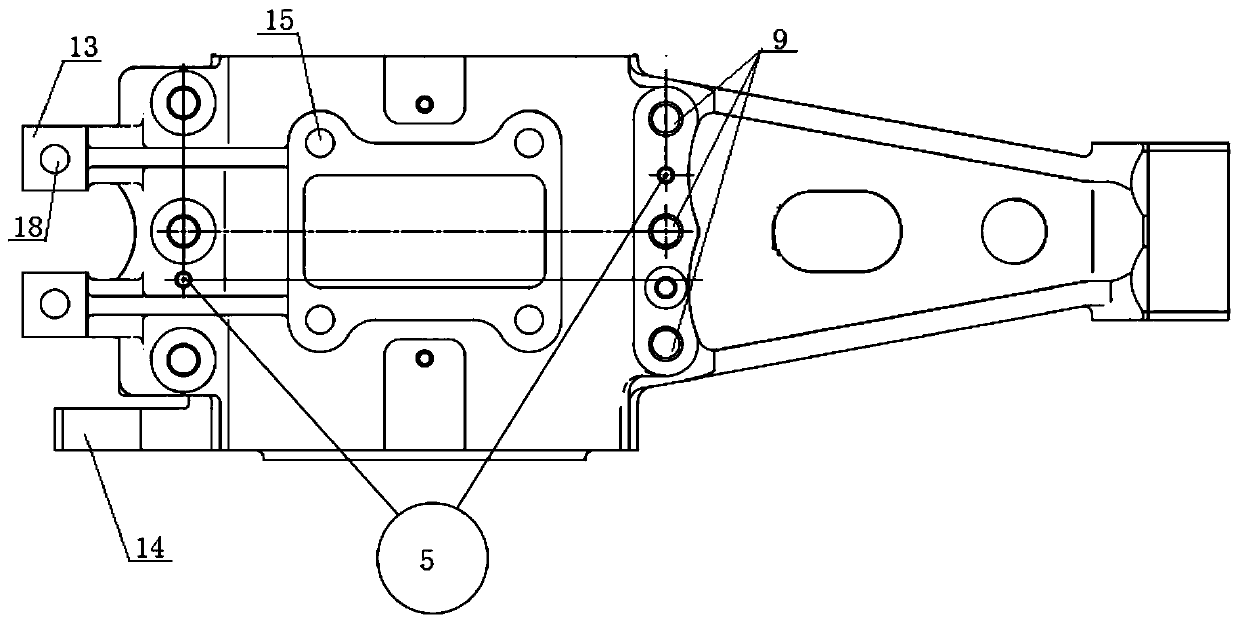

Pointing mechanism with micro-vibration isolation characteristic

ActiveCN112467384AEffective vibration isolationLower natural frequencyAntenna supports/mountingsDrive wheelGear wheel

The invention provides a pointing mechanism with a micro-vibration isolation characteristic, and the mechanism comprises a first flexible support device, a second flexible support device, an azimuth angle movement mechanism and a rotary disc bearing gear, wherein the bottom of a pitching support base is fixedly connected to the azimuth angle movement mechanism; a first side ring of the first flexible supporting device is fixedly installed on the inner side of one end of the pitching supporting base, a fourth side ring of the second flexible supporting device is fixedly installed on the inner side of the other end of the pitching supporting base, one side of a first lug plate of the pitching platform is fixedly installed on a second side wheel, and the other side of the first lug plate is fixedly installed on a first driven wheel. One side of the second lug plate is fixedly installed on the third side wheel, and the other side of the second lug plate of the pitching platform is fixedlyinstalled on the second driven wheel. And a driving bevel gear of the driving mechanism is meshed with the driven bevel gear. According to the invention, the rigidity of a local structure on a micro-vibration transmission path can be reduced, and micro-vibration is isolated, so that the influence of micro-vibration on the control precision of the pointing mechanism is effectively solved.

Owner:TIANJIN AEROSPACE ELECTROMECHANICAL EQUIP RES INST

A Micro-deformation Control Technology of Split Type Axle Box

ActiveCN107900608BAvoid micro deformationMicro-deformation prevention and controlSand blastingSingle element

The invention relates to a micro-deformation control process for a split axle box body. The micro-deformation control process specifically comprises the following steps: carrying out blank casting onan upper box body and a lower box body separately; carrying out rough machining on single elements; carrying out heat treatment on the single elements; carrying out finish machining on the single elements; carrying out box combination, machining a bearing hole, a node hole and the two end surfaces of the axle box body and a node, machining a labyrinth groove in the inner surface of the bearing hole as well as a shock absorber seat, a cowcatcher installation seat, a top surface, a bottom surface and a cylinder which surround the axle box body by taking the machined bearing hole, node hole and end surfaces as location reference; carrying out semi-finish milling and boring for the bearing hole; carrying out box splitting, and then placing the box bodies under a room-temperature condition andcarrying out aging treatment separately; carrying out fine trimming on a box splitting surface; carrying out box combination and carrying out semi-finish milling and boring for the bearing hole; carrying out box splitting, and then carrying out polishing; and carrying out box combination again, detecting the axle box body subjected to the box combination, and then carrying out sand blasting and painting. According to the micro-deformation control process disclosed by the invention, the micro-deformation of the axle box body is prevented and controlled simultaneously in many aspects through reasonable optimization for a process flow and optimization for process parameters, so that the product pass percent is increased, the production period is ensured, and the production cost is lowered.

Owner:CRRC QINGDAO SIFANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com