Sealing and fixing device for testing aerospace gyro motor in high-temperature and low-temperature environment

A gyro motor, sealed and fixed technology, applied in the direction of motor generator testing, environmental/reliability testing, measuring devices, etc., can solve the problems of motor bearing parts such as rust, production troubles, scrapping, etc., to prolong the service life, disassembly and assembly Simplicity and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The present invention will be described in further detail below with reference to the drawings and specific embodiments. The following embodiments are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

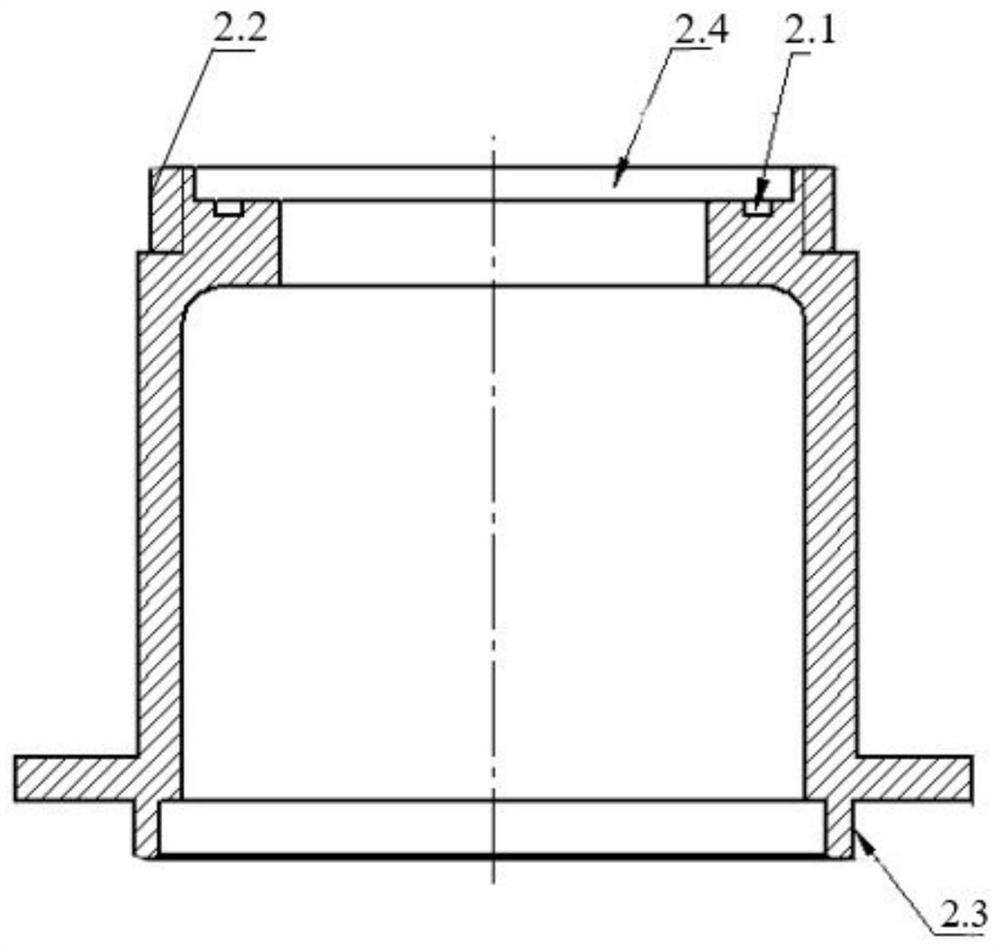

[0026]A kind of sealing fixing device for testing aerospace gyro motor in high and low temperature environment, please refer toFigure 1-4, The invention points: including the end cover 1, the shell 2, the base 4, the motor mounting bracket 3.

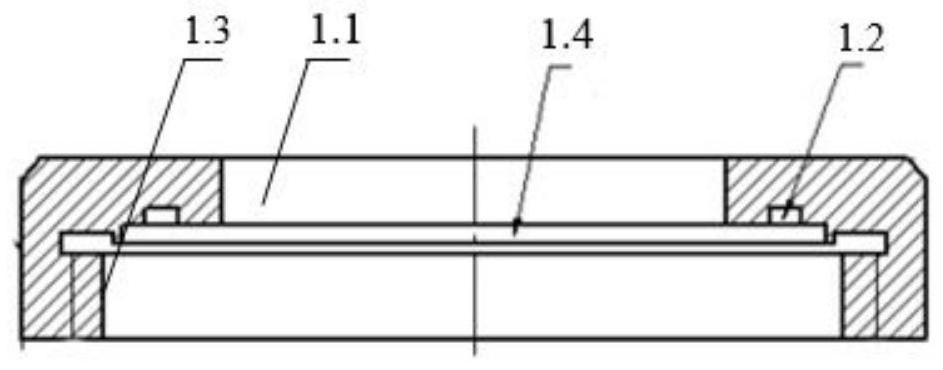

[0027]The end cover is a buckle cover structure. A central hole 1.1 is provided on the top of the end cap, an internal thread 1.3 is provided on the inner circle of the side of the end cap, an upper glass interlayer installation recess 1.4 is provided on the top inner end surface of the end cap, and an upper glass interlayer installation recess is provided The upper end of the table is provided with an upper ring groove 1.2 for installing the sealing ring.

[0028]The casing is a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com