Automobile oil cooler pseudo soldering detection system and method based on machine vision

A machine vision and detection system technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems that affect the detection speed and detection efficiency of the production line, cannot guarantee the efficiency and accuracy of detection, missed detection and false detection, etc., to achieve The workpiece imaging effect is good, the lighting conditions are stable, and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

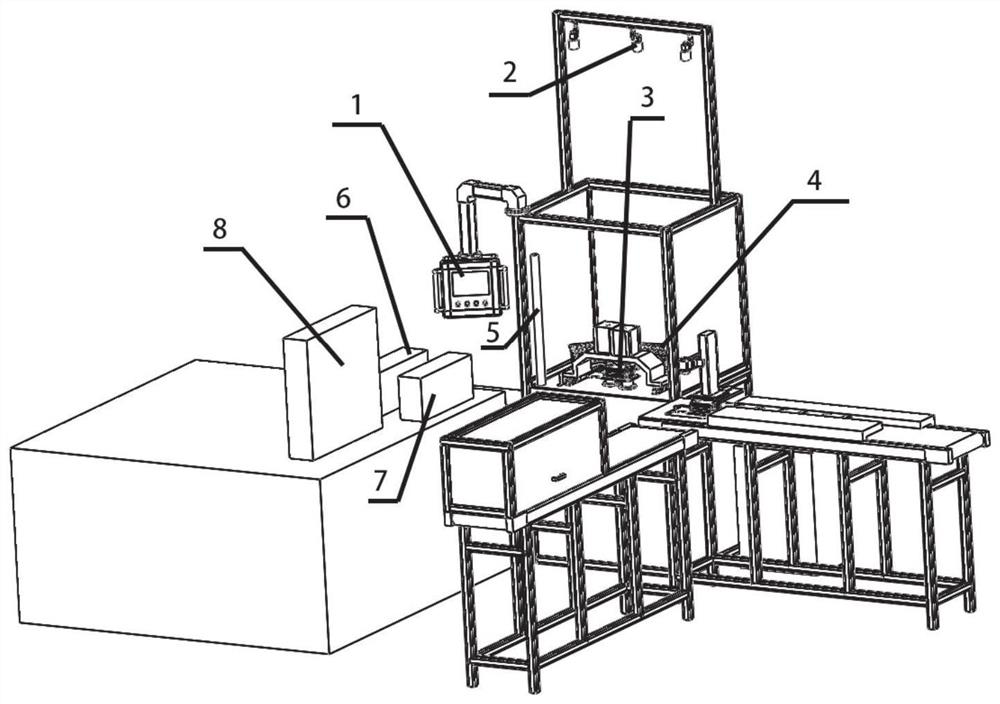

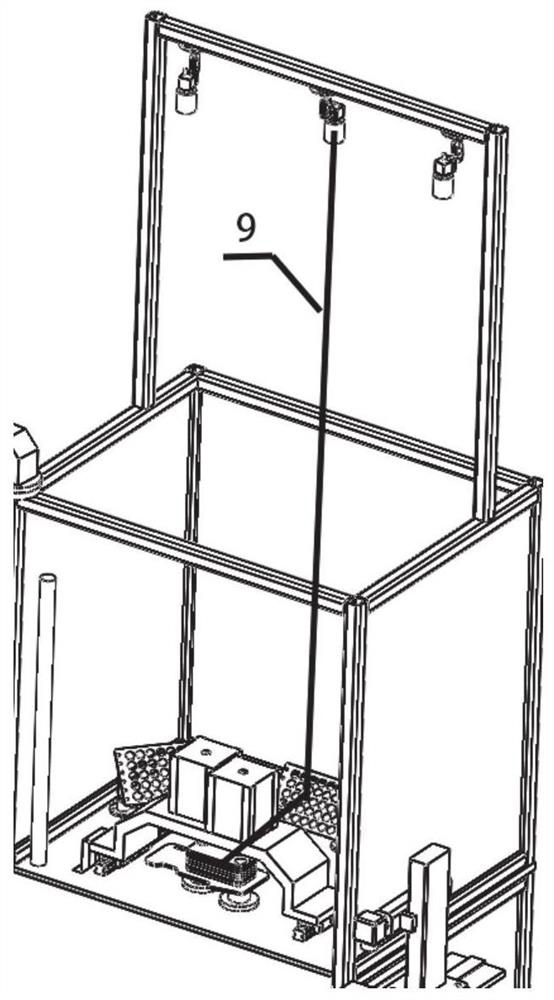

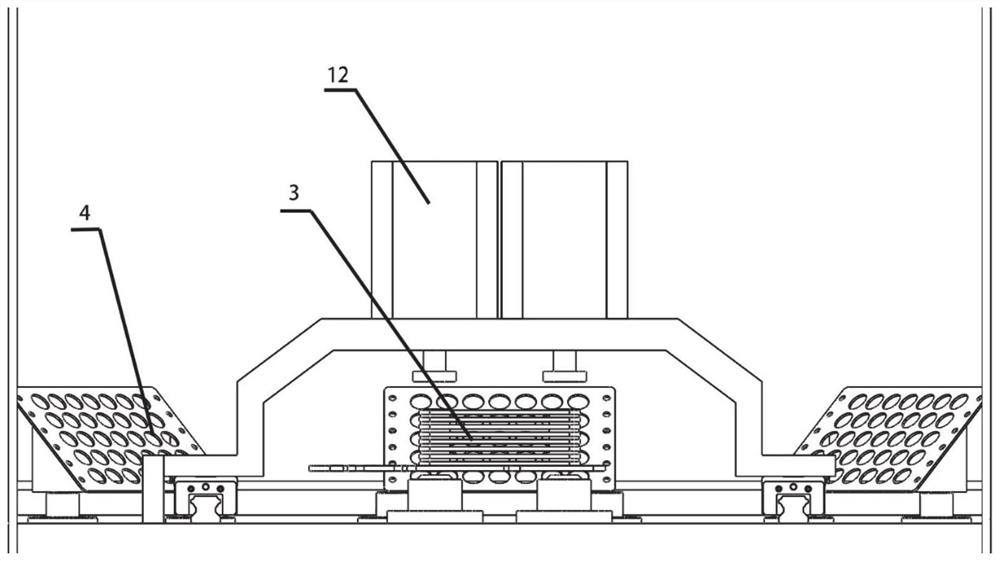

[0035] In this embodiment, a machine vision-based automobile oil cooler virtual welding detection system is disclosed, including:

[0036] An image acquisition device, used to acquire images before and after stamping of the oil cooler;

[0037] The virtual welding detection module is used to analyze the images before and after stamping of the oil cooler, obtain the area of the void area corresponding to the image before and after stamping, and determine the number and position of the interlayer void area with area change in the image before and after stamping; according to the area change The number and location of interlayer void areas determine the number and location of virtual welds in the oil cooler.

[0038] Further, it also includes:

[0039] The controller is used to receive the compression signal of the compression oil cooler and the stamping completion signal of the oil cooler, and send the signal to the industrial computer;

[0040] The industrial computer is us...

Embodiment 2

[0085] In this embodiment, a machine vision-based method for detecting false welding of an automobile oil cooler is disclosed, including:

[0086] Collect images before and after stamping of the oil cooler;

[0087] Analyze the images before and after stamping of the oil cooler respectively, and obtain the area and position of the void area corresponding to the images before and after stamping;

[0088] Determining the number and location of interlaminar void regions with area changes in the images before and after stamping;

[0089] According to the number and location of interlayer void areas where area changes occur, the number and location of the oil cooler's virtual welds are determined.

Embodiment 3

[0091] In this embodiment, an electronic device is disclosed, including a memory, a processor, and computer instructions stored in the memory and executed on the processor. When the computer instructions are executed by the processor, a method disclosed in Embodiment 2 is completed. The steps described in a machine vision-based method for detecting false welding of an automobile oil cooler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com