Molded packaging box manufacturing and shaping treatment process

A technology for processing and packaging boxes, applied in the directions of boxes, furnace types, dry solid materials, etc., can solve the problems of micro-deformation of molded packaging boxes, uneven heating, and different degrees of dehydration of molded packaging boxes, so as to avoid micro deformation. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

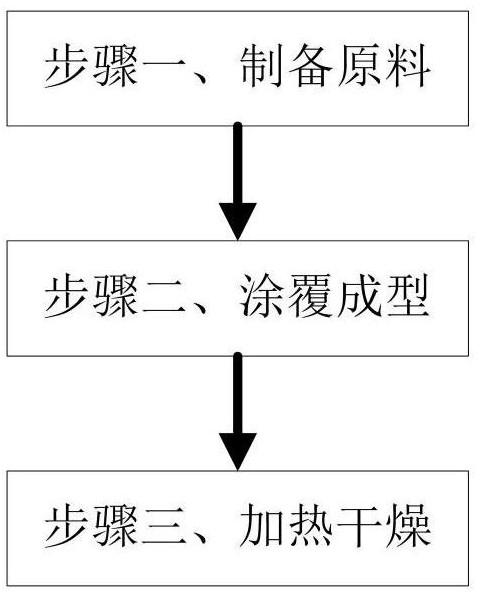

[0035] Such as figure 1 As shown, this embodiment provides a molded packaging box manufacturing and shaping treatment process, including the following steps:

[0036] Step 1. Preparation of raw materials: cutting and crushing the waste cardboard, adding water, mixing and cooking, stirring evenly to obtain pulp.

[0037] Step 2. Coating and molding: evenly coat the pulp prepared in step 1 on the surface of the mold, and obtain an incompletely dried molded packaging box after demoulding.

[0038] Step 3, heating and drying: heat and dry the incompletely dried molded packaging box prepared in step 2.

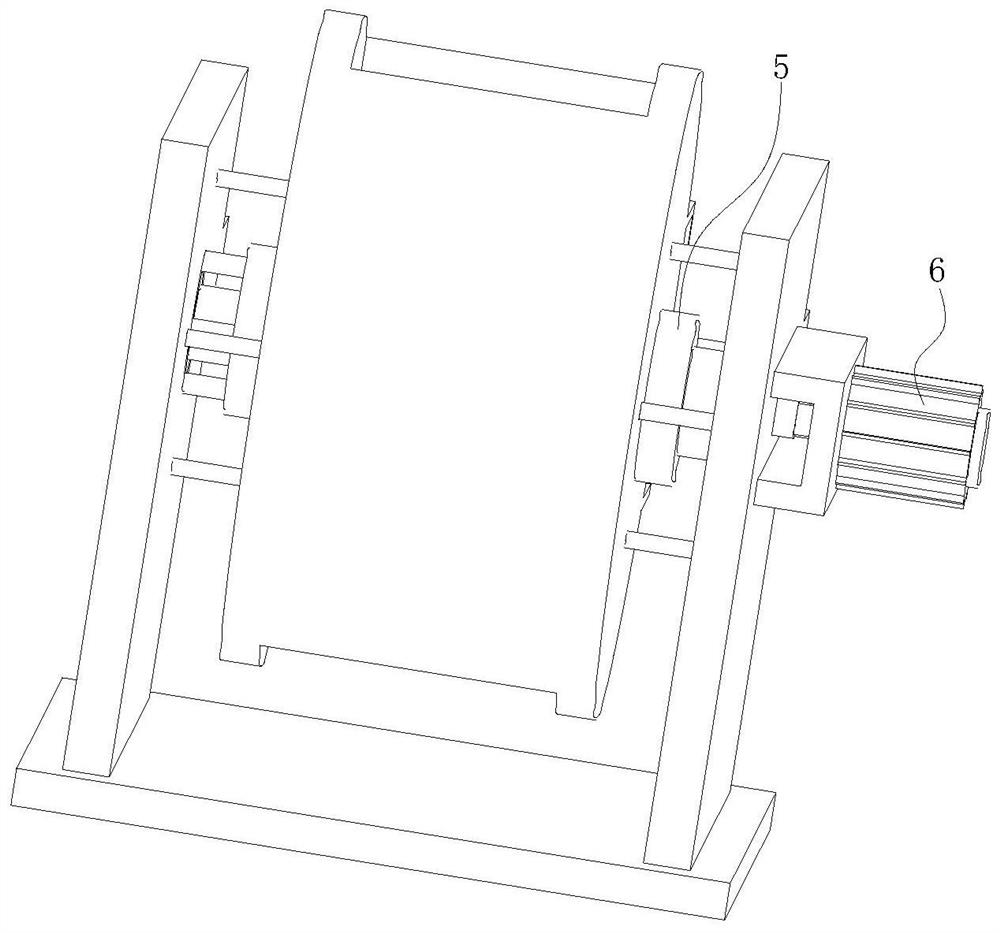

[0039] Among them, step three uses such as Figure 2 to Figure 6 A molded packaging box manufacturing and shaping treatment device is shown in cooper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com