Three-claw clamp

A technology of three-jaw clips and collets, which is applied in metal processing and other directions, can solve problems such as difficult disassembly and installation, poor roundness, deformation, etc., and achieves the effects of easy disassembly and installation, improved product yield, and simple fixture structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments.

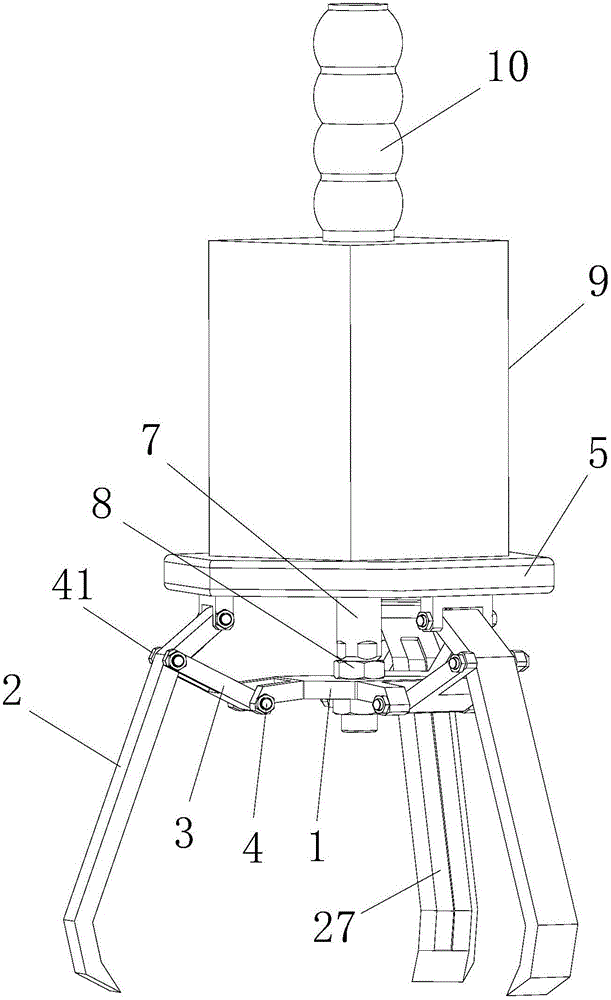

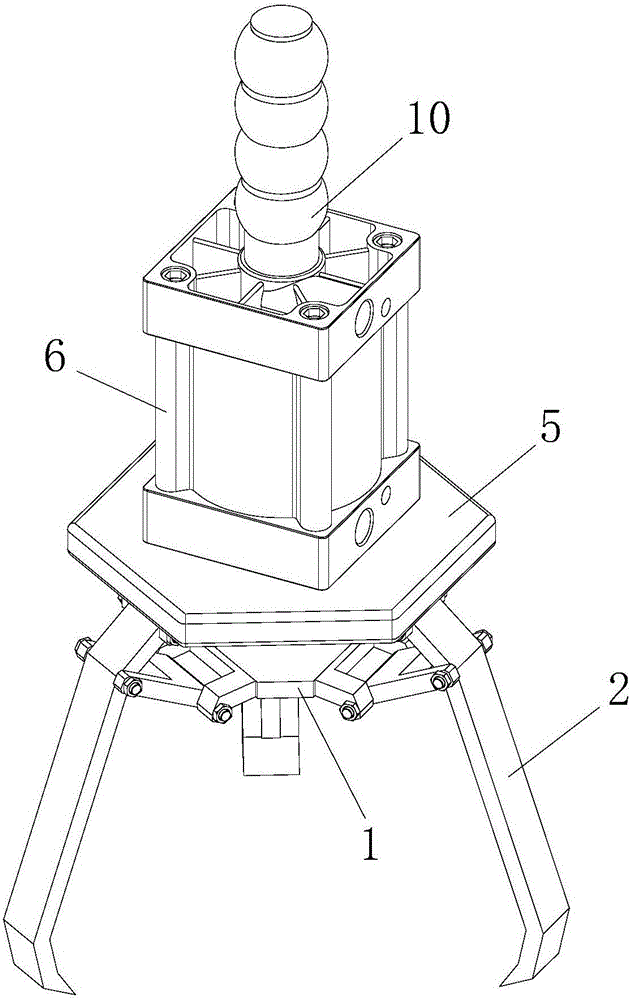

[0028] Such as Figure 1-Figure 5 As shown, it includes a chuck 1 and three clamping jaws 2. The three clamping jaws 2 are evenly installed on the chuck 1, and one side of the three clamping jaws 2 is movable through a hinge 3 Installed on the chuck 1, the other side of the three clamping jaws 2 is installed on the fixed plate 5 through the double-headed stud 4, and a cylinder 6 is installed on the fixed plate 5, and the cylinder 6 A cylinder rod 7 is installed inside, the cylinder rod 7 passes through the cylinder 6 and is connected to the chuck 1 by a hexagon nut 8. A protective cover 9 is installed on the outside of the cylinder 6 and a threaded handle is installed on the upper end of the cylinder 6 10.

[0029] Such as Image 6 As shown, the chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com