Shell assembly of high-speed optical signal transmitting device and high-speed optical signal transmitting device

A technology for transmitting devices and housing components, which is applied in the field of housing components and high-speed optical signal transmitting devices, which can solve the problems of long wiring, affecting the performance of optical transmitting devices, reducing the operating bandwidth of driving chips and semiconductor lasers, and reducing the overall Low cost, reduced thermal interference, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

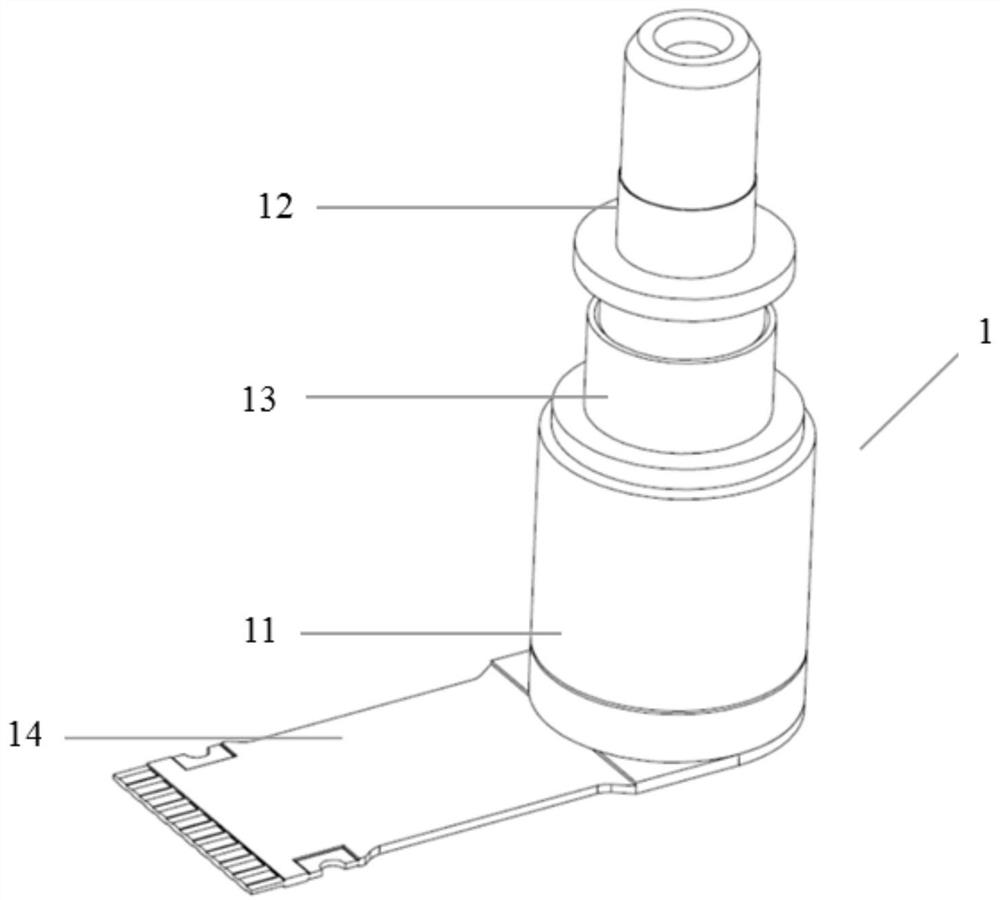

[0043] The light-emitting device 1 provided by the present invention operates at a rate of 25Gb / s and above, and mainly includes 4 components, a housing TO-CAN 11, a connector Receptacle 12, a mounting ring Z-ring 13 and a flexible circuit board FPC 14, a The appearance of the light-emitting device is as figure 1 shown. The housing TO-CAN 11 is used to package electronic components and optical devices; the connector Receptacle 12 is used to connect with the external optical fiber connector 2; the installation ring Z-ring 13 is used for the connection between the connector Receptacle 12 and the housing TO-CAN 11 Coupling welding; the flexible circuit board FPC 14 is used to connect the main board 31 of the optical transceiver module 3 .

[0044] The use mode of the light emitting device 1 is placed in the optical transceiver module 3 for the emission of optical signals, and the use mode of the light emitting device is as follows: figure 2 shown. One end of the connector Rec...

Embodiment 2

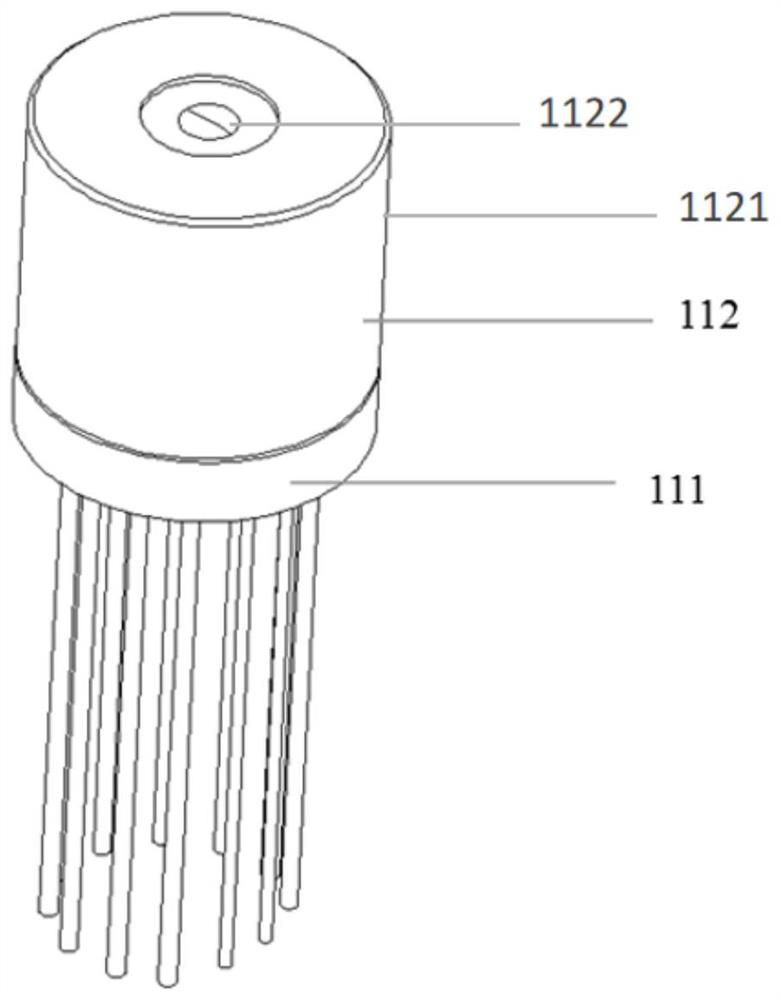

[0053] The TO-Header 111 and the TO-Cap 112 of the housing TO-CAN of the light-emitting device 1 embodiment 2 provided by the present invention are the same as those in Example 1, as image 3 , Figure 4 , Figure 5 shown. The schematic diagram of the components inside the shell TO-CAN is as follows: Figure 11 shown. A heat sink substrate 1131 is placed on the TO-Header 111 . The laser 1132 and the driving chip 1133 are placed adjacent to each other and installed on the heat sink substrate 1131 . A heating resistor 1134 is also placed on the heat sink substrate 1131 .

[0054] The heat sink substrate 1131 is pasted on the header TO-Header 111 by glue, the semiconductor laser LD 1132 is welded or glued on the conductive pattern 11311 on the surface of the heat sink substrate 1131 by gold-tin soldering, and the driver chip 1133 is also pasted on the conductive pattern 1131 by conductive glue. heat sink on the substrate 1131 . A photodetector 1142 is mounted on the side f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com