Radiator and fixed device for hot pipe

A technology of fixing device and heat dissipation device, which is applied in the direction of electrical solid devices, cooling/ventilation/heating transformation, semiconductor/solid device components, etc., which can solve the problem of affecting heat dissipation performance, increasing thermal resistance, and the inability of heat pipe 32 and die casting 31 full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

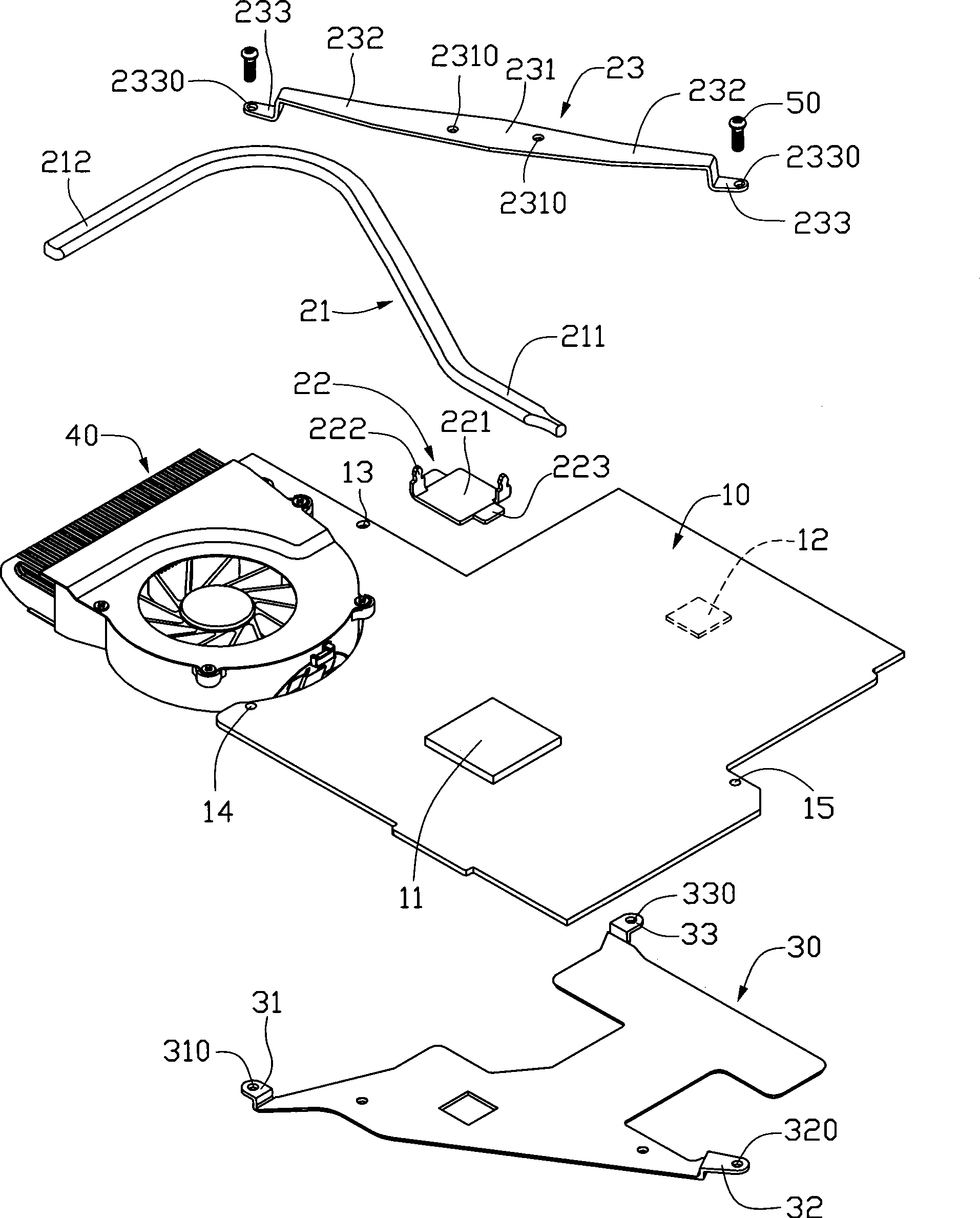

[0017] Figure 1 to Figure 3 Shown is a preferred embodiment of the heat pipe cooling device of the present invention. The heat pipe cooling device includes a radiator 40 disposed on the side of the circuit board 10 , a heat pipe 21 and a heat pipe fixing device 20 for fixing the heat pipe 21 on the circuit board 10 . The heat pipe 21 is a flat heat pipe, generally L-shaped, and includes an evaporation end 211 and a condensation end 212 . The condensing end 212 of the heat pipe 21 is fixedly connected to the radiator 40 , and transfers the heat absorbed by the evaporating end 211 to the radiator 40 . The evaporation end 211 of the heat pipe 21 performs heat exchange with the heating electronic component 11 on the circuit board 10 through the heat pipe fixing device 20 , and is fixed on the circuit board 10 through the heat pipe fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com