Plastic insert heating softening apparatus

A softening device and inlay technology, applied in the field of plastic inlay heating and softening device, can solve the problems of operator safety threat, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

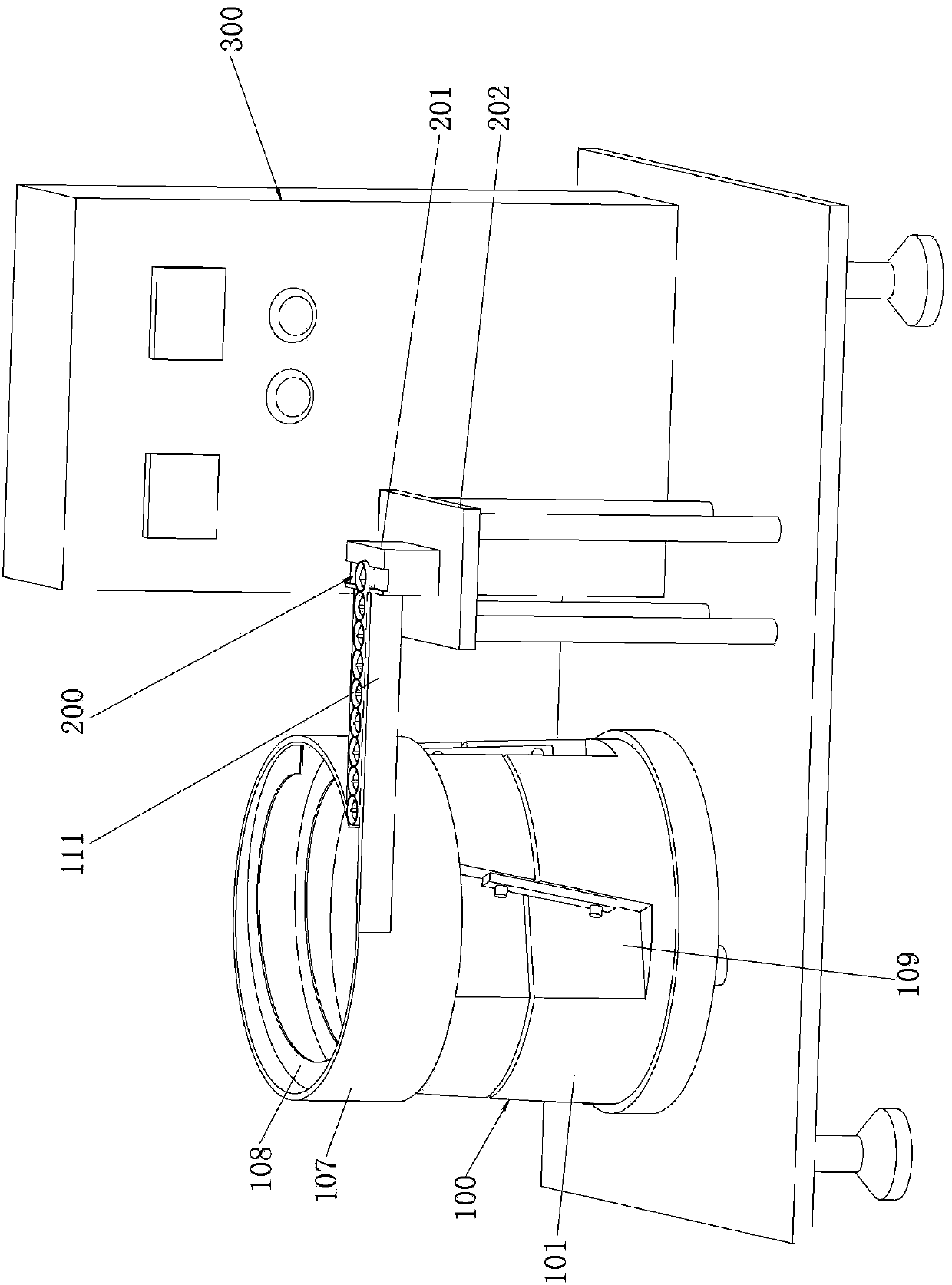

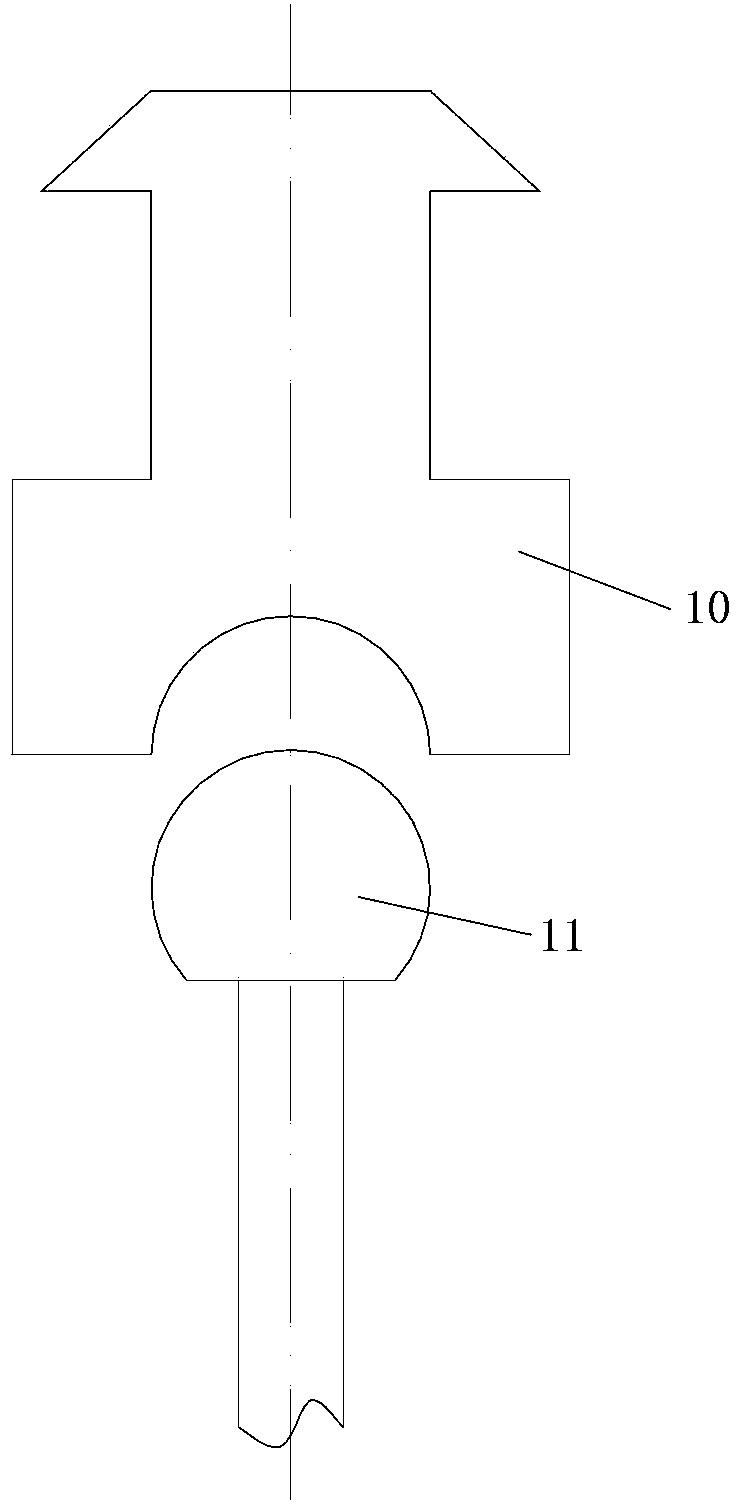

[0025] refer to figure 1 , the heating and softening device for plastic parts of the present invention includes a vibrating feeding device 100, and the plastic parts received from the lower part of the vibrating feeding device are sent to the output port on the upper part of the vibrating feeding device according to a prescribed path in sequence through vibration and the heater 200 located at the output of the vibrating feeding device, after receiving the plastic parts sent out by the vibrating feeding device, the plastic parts are heated; and the controller 300 connected with the vibrating feeding device and the heater respectively, the controller provides The vibrating feeding device provides alternating voltage to make the vibrator vibrate, and the controller provides the heater with the working voltage required for heating and controls the heating temperature of the heater. Each part is described in detail below:

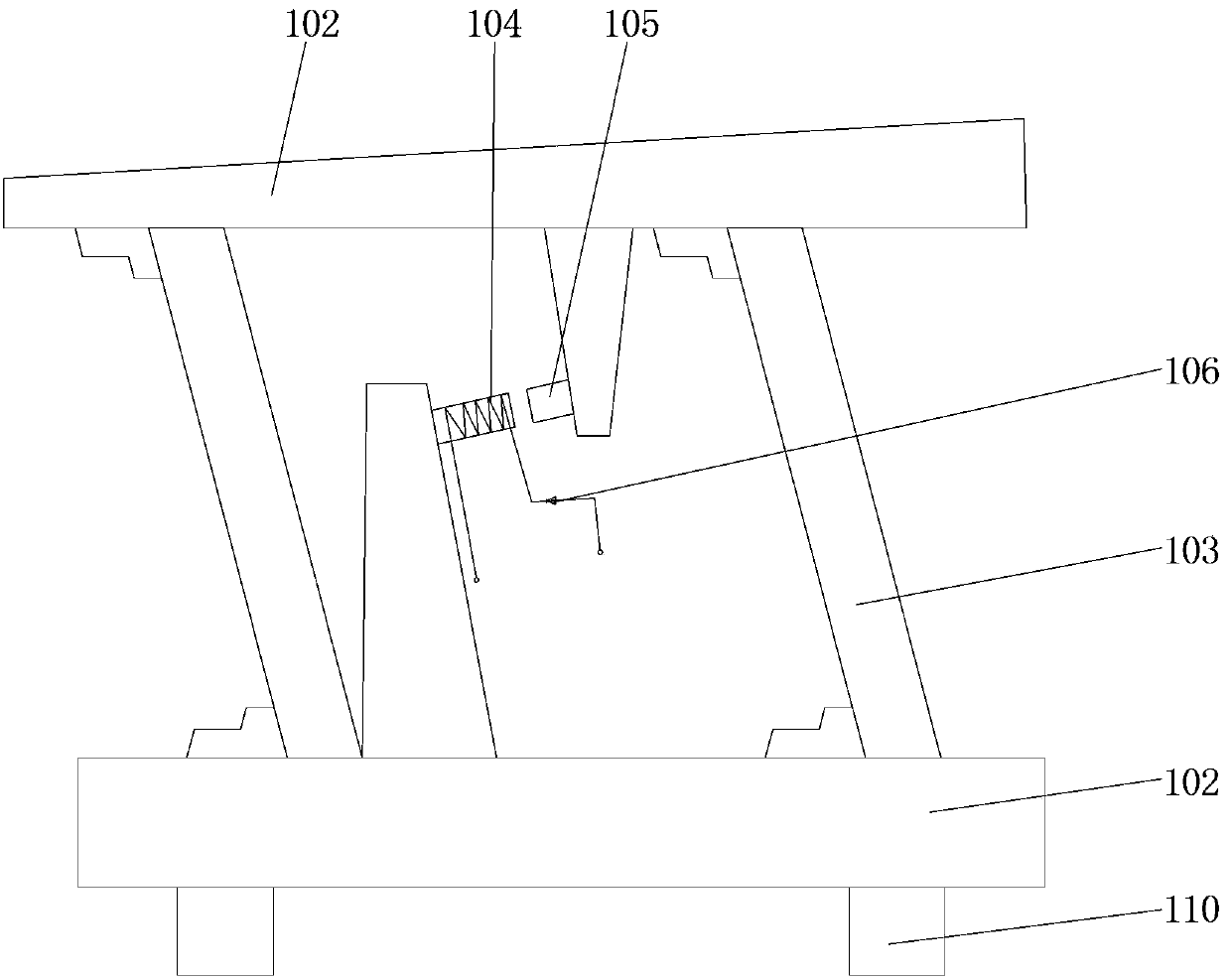

[0026] refer to figure 1 and figure 2 , The vibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com