Apparatus and method of polymer photoresist ultrasonic ageing effect

A technology of ultrasonic aging and photoresist, which is applied in photosensitive material processing, electrical components, semiconductor/solid-state device manufacturing, etc., to achieve the effects of reducing research and development costs, avoiding substrate bending, and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

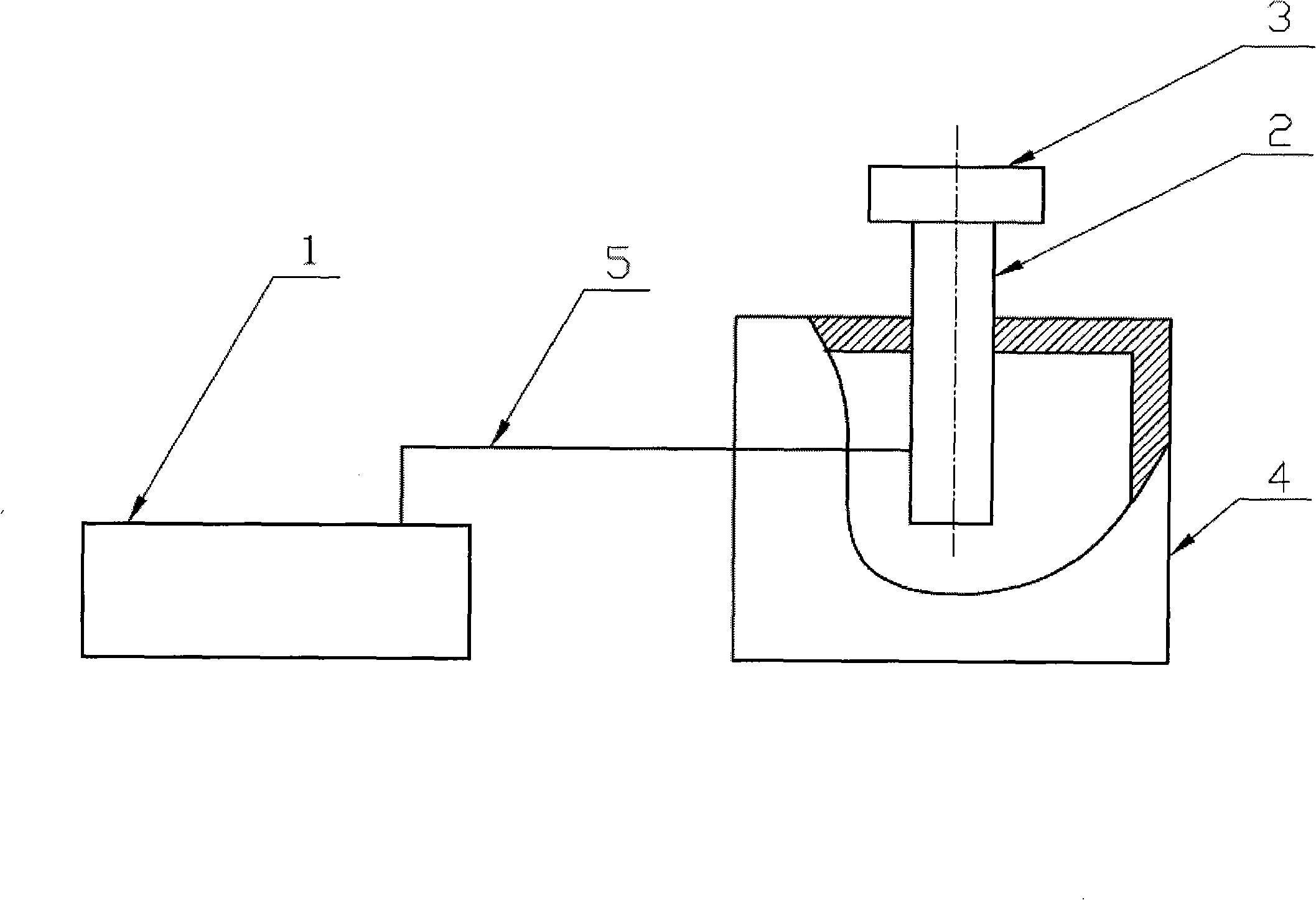

Image

Examples

Embodiment

[0012] To carry out ultrasonic aging by using the invention, firstly, a photoresist microstructure is made on a silicon wafer. The fabrication process of the photoresist microstructure includes silicon wafer cleaning, gluing, pre-baking, exposure, post-baking, and development.

[0013] Firstly, the silicon wafer is cleaned, using the standard process of cleaning silicon wafers in the laboratory, successively boil the silicon wafer with concentrated sulfuric acid, No. 1 cleaning solution, and No. 2 cleaning solution, then rinse it with deionized water, and finally put it in an oven for drying. After drying, make a photoresist layer, spin SU-8 photoresist by spin coating, put it on a hot plate for drying, then expose it to ultraviolet light, and then put it on a hot plate and dry it to make the SU-8 glue cross-linked .

[0014] Since the stress of the photoresist structure mainly occurs during the post-baking process, the adhesive layer is subjected to ultrasonic aging after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com