Method for forming pavement of highway resisting large deformation of ground

A molding method and large deformation technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of occupying a lot of arable land, low resistance to deformation, affecting the normal use of roads, etc. Operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

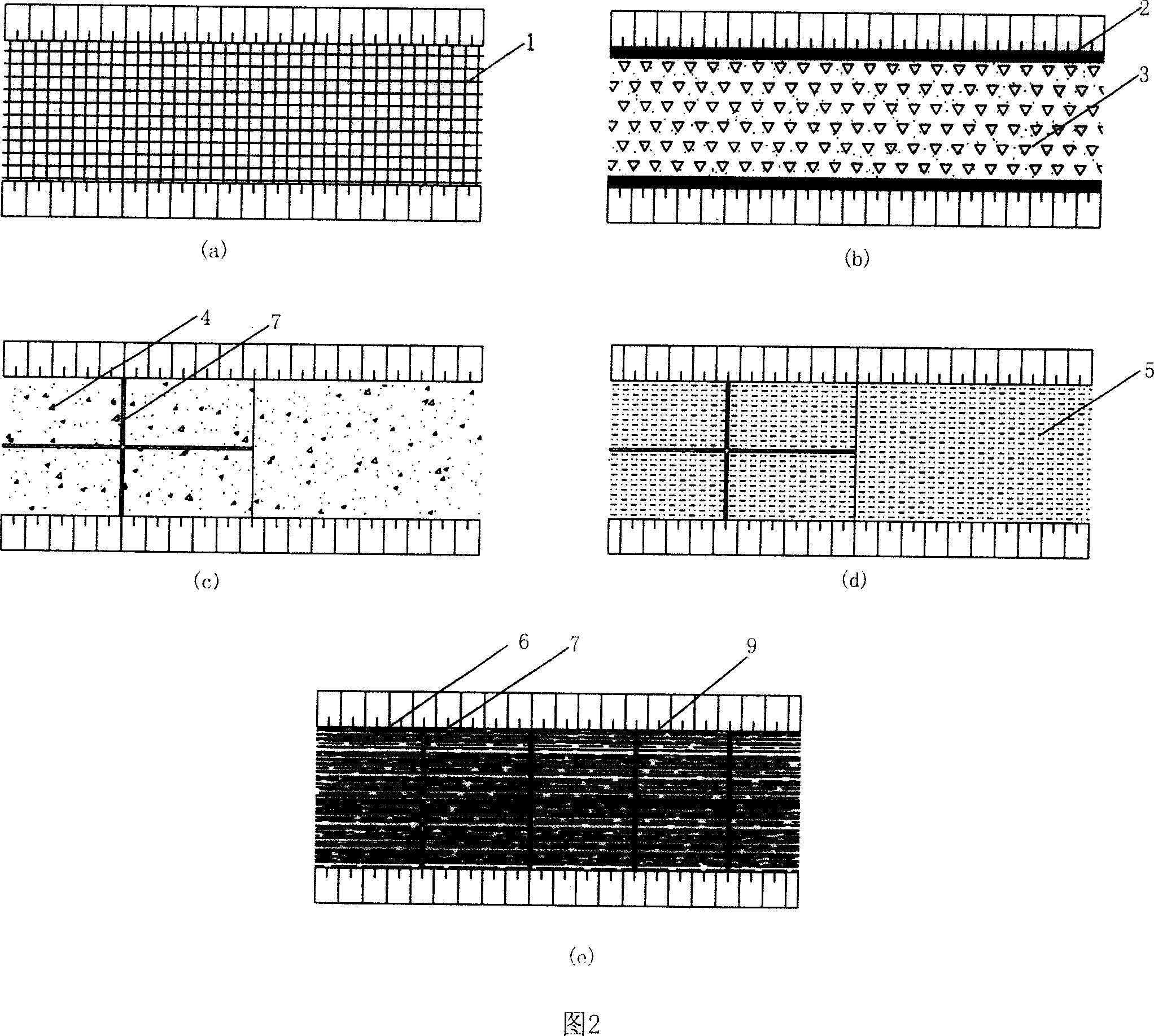

[0015] Fig. 1 is the road surface cross-sectional structural schematic diagram of the large surface deformation-resistant highway pavement molding method. In order to provide the anti-deformation ability of the road surface, a layer of tensile geotechnical material 1 is first laid on the full section of the top layer of the subgrade 8, and the tensile material can be geogrid. Or geotextile, as shown in Figure 2(a). Reserve a side width 2 of 20 cm to 30 cm on both sides of the subgrade 8 on the geotechnical material 1, wrap the side width 2 with lime soil or lime soil for wrapping, and pave a 10 cm to 15 cm gravel cushion 3, as shown in Figure 2(b ) shown in ); then integrally pave one deck of lime-flyash soil layer 4, fill rubber material according to the size shear deformation joint 7 of the fly-ash upper plate, as shown in Fig. 2 (c); Fly ash soil layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com