Structure and construction process for reducing power impact response at back of seamless bridge abutment

A technology of seamless bridge and dynamic shock, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of poor settlement of transition sections of seamless bridges, large settlement and deformation of flexible structures, etc., to avoid poor settlement of roads and bridges, avoid bridge head The effect of jumping and reducing additional stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

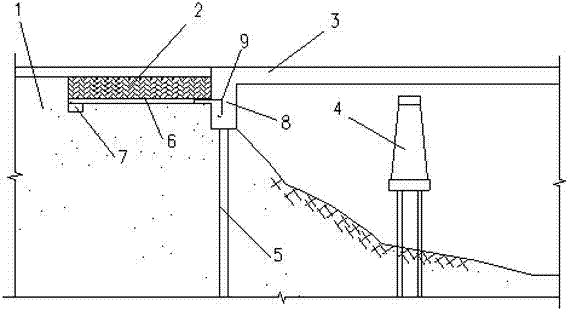

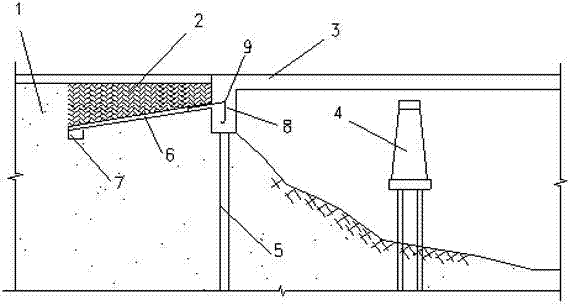

[0022] refer to Figure 1 to Figure 2 , the present invention relates to a structure for reducing the dynamic impact response behind the abutment of a seamless bridge, including a slab, a seamless bridge and a soil foundation, the slab is buried in a certain depth of filling soil behind the abutment, and the steel bar is connected to the back wall Integral connection, backfill with light weight, good hardening, low compressibility, fast compaction, and strong water permeability materials to absorb part of the impact energy and reduce the impact of passing vehicles on the slab, using embedded slabs The covering soil within the length range and the soil at the end of the board form a common thick and long elastic body to absorb the expansion and contraction defor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com