Square cabin composite plate

A composite board and adhesive technology, used in the field of shelter composite boards, can solve problems such as debonding of the adhesive layer, achieve the effect of small thermal stress and reduce the problem of debonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

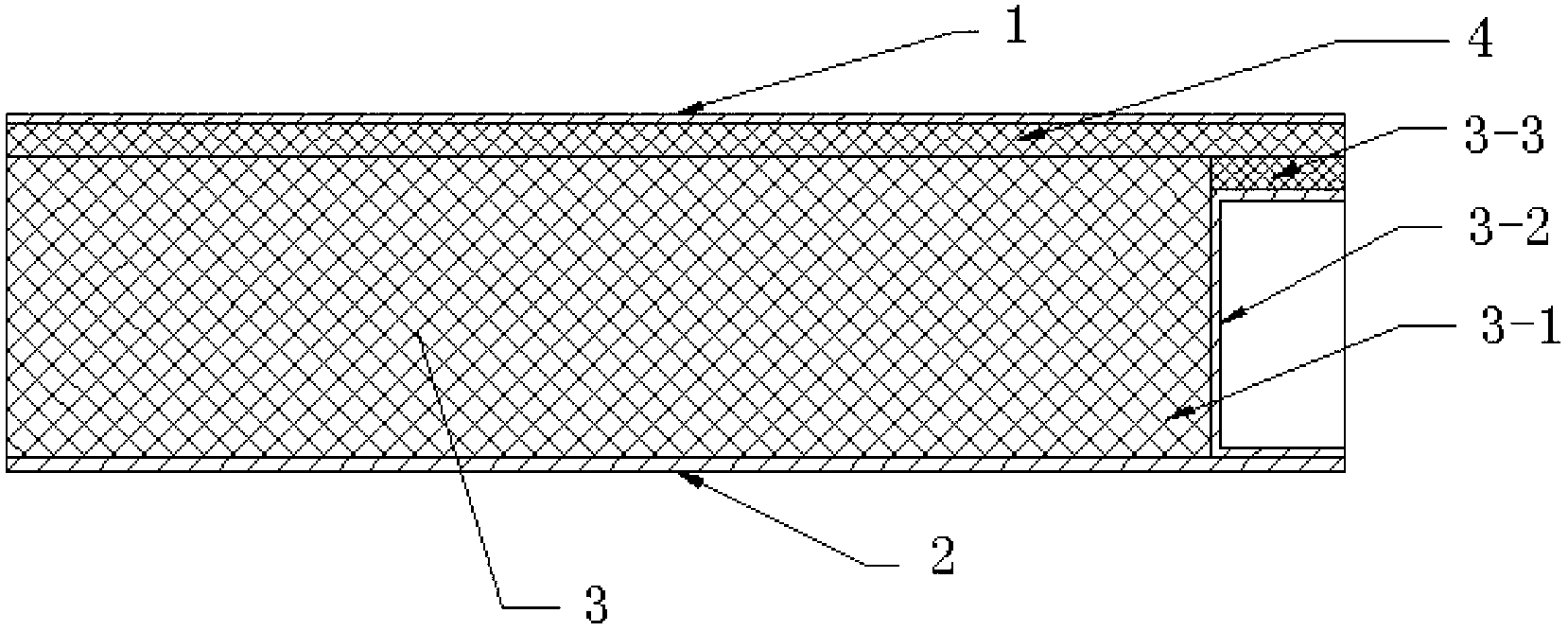

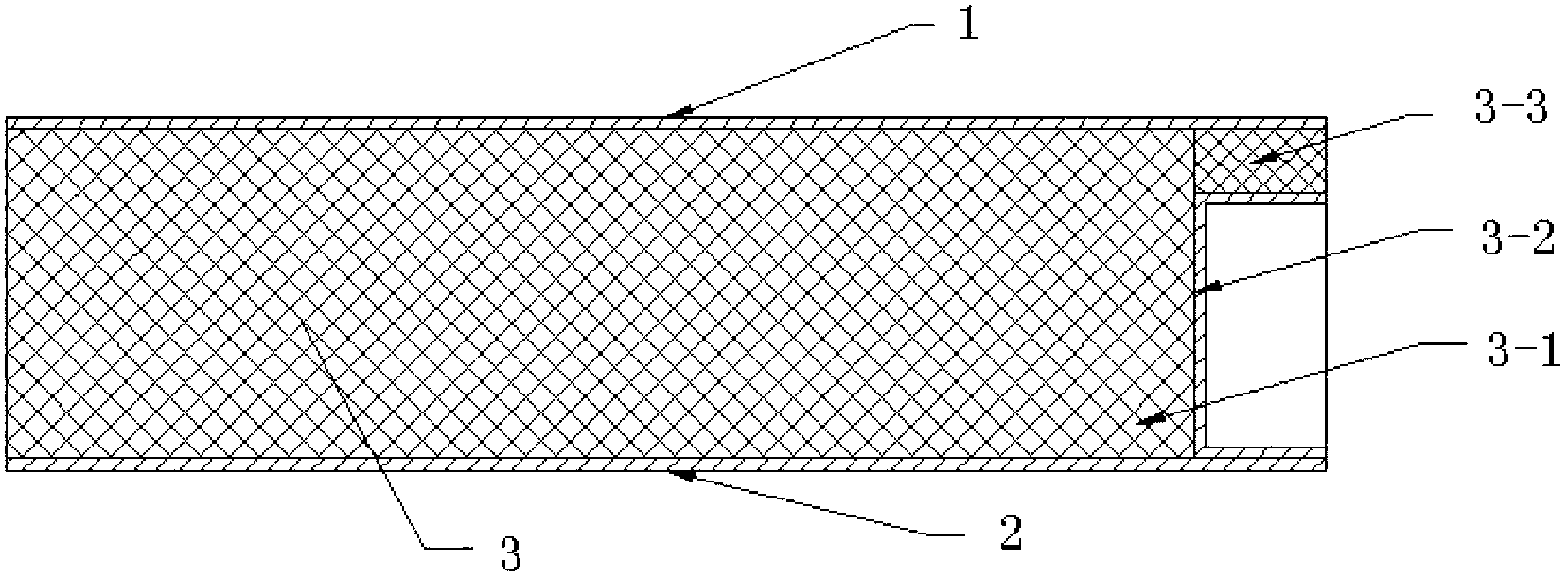

[0021] A composite panel for a shelter, comprising an outer skin 1, an inner skin 2 and an interlayer 3, the interlayer 3 comprising polyurethane foam 3-1, a steel skeleton 3-2 and basswood 3-2 on the outside of the steel skeleton 3-2 3. The rubber layer 4 is arranged between the outer skin 1, the polyurethane foam 3-1 and the basswood 3-3 and bonded with an adhesive, and the outer skin 1 is aluminum alloy.

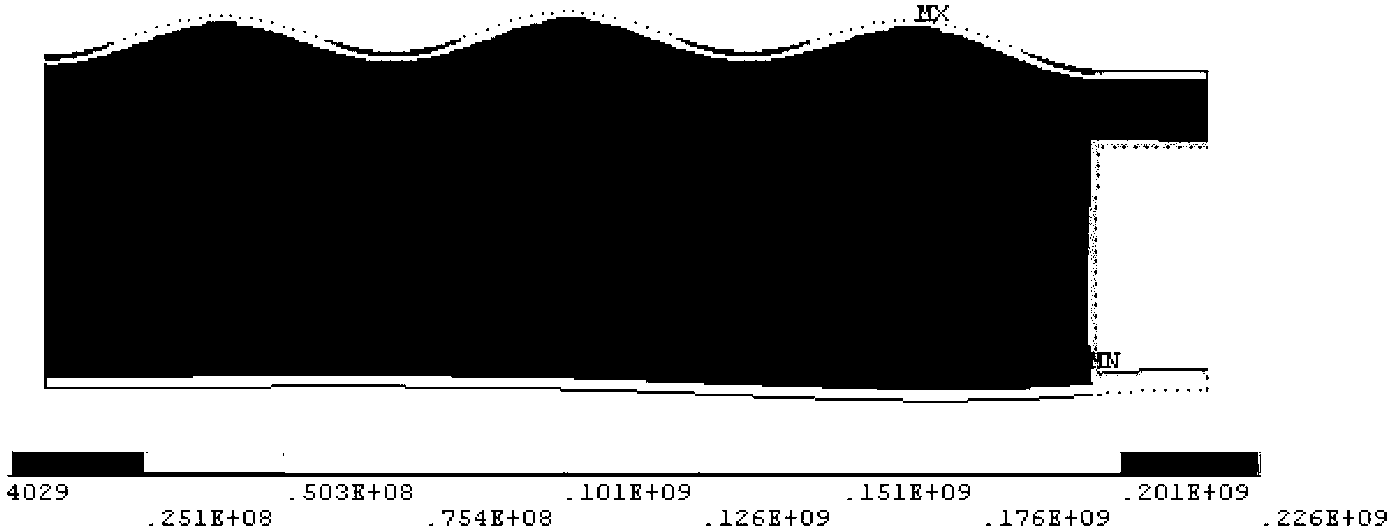

[0022] Theoretical analysis of feasibility of the present invention:

[0023] When the top layer of the shelter is exposed to high temperature sunlight and the cabin maintains room temperature, the outer skin 1 is subjected to a high thermal load. The elastic modulus of the rubber layer 4 is smaller than that of the aluminum alloy and the polyurethane foam 3-1, and the deformation degree of the aluminum alloy and the polyurethane foam 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com