Flooring products and methods of making the same

a technology of floor coverings and products, applied in the field of floor covering products, can solve the problems of cupping or doming of products, serious quality control issues and application restraints, and failure of melamine surface adhesion to the core, and achieve the effect of improving moisture resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

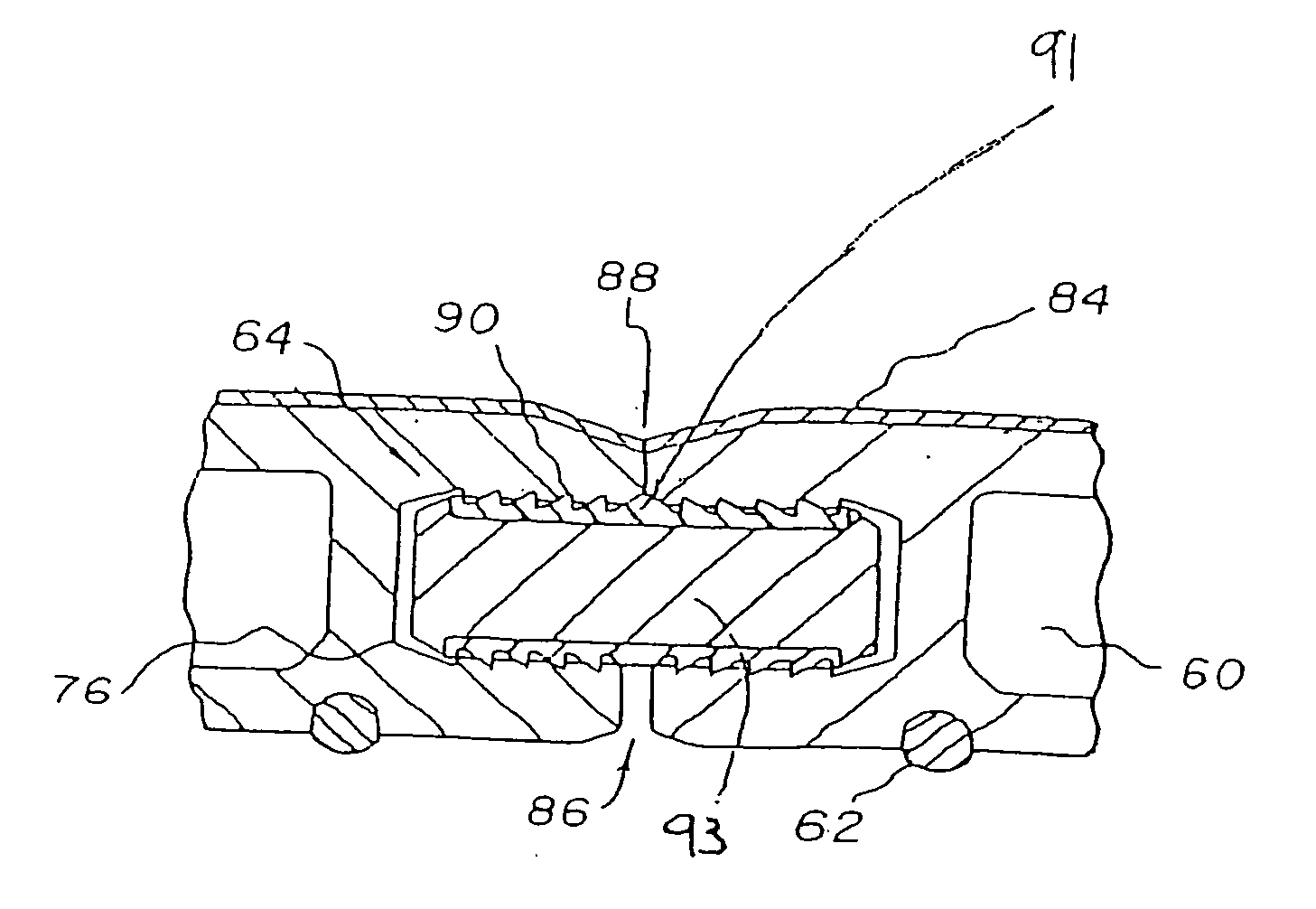

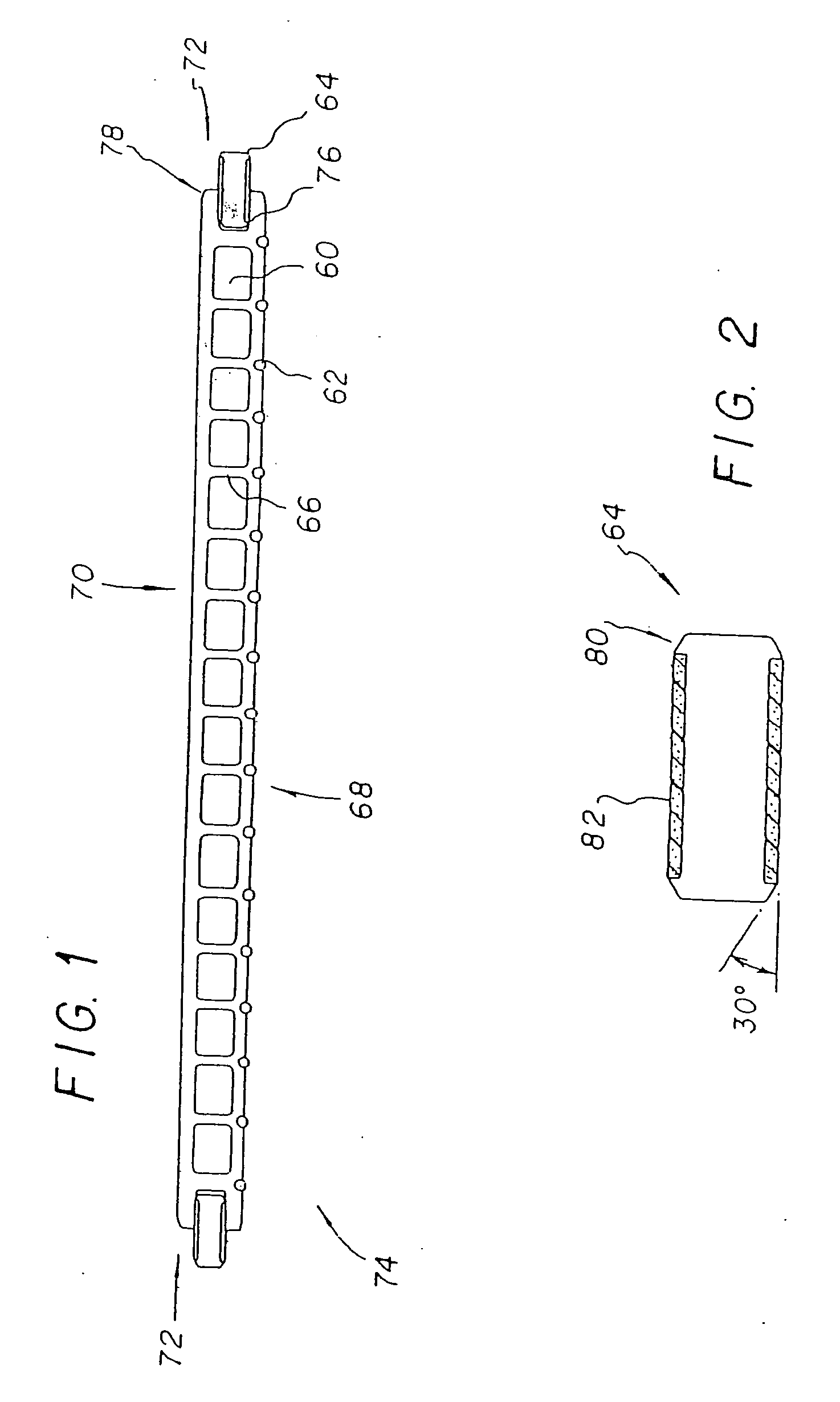

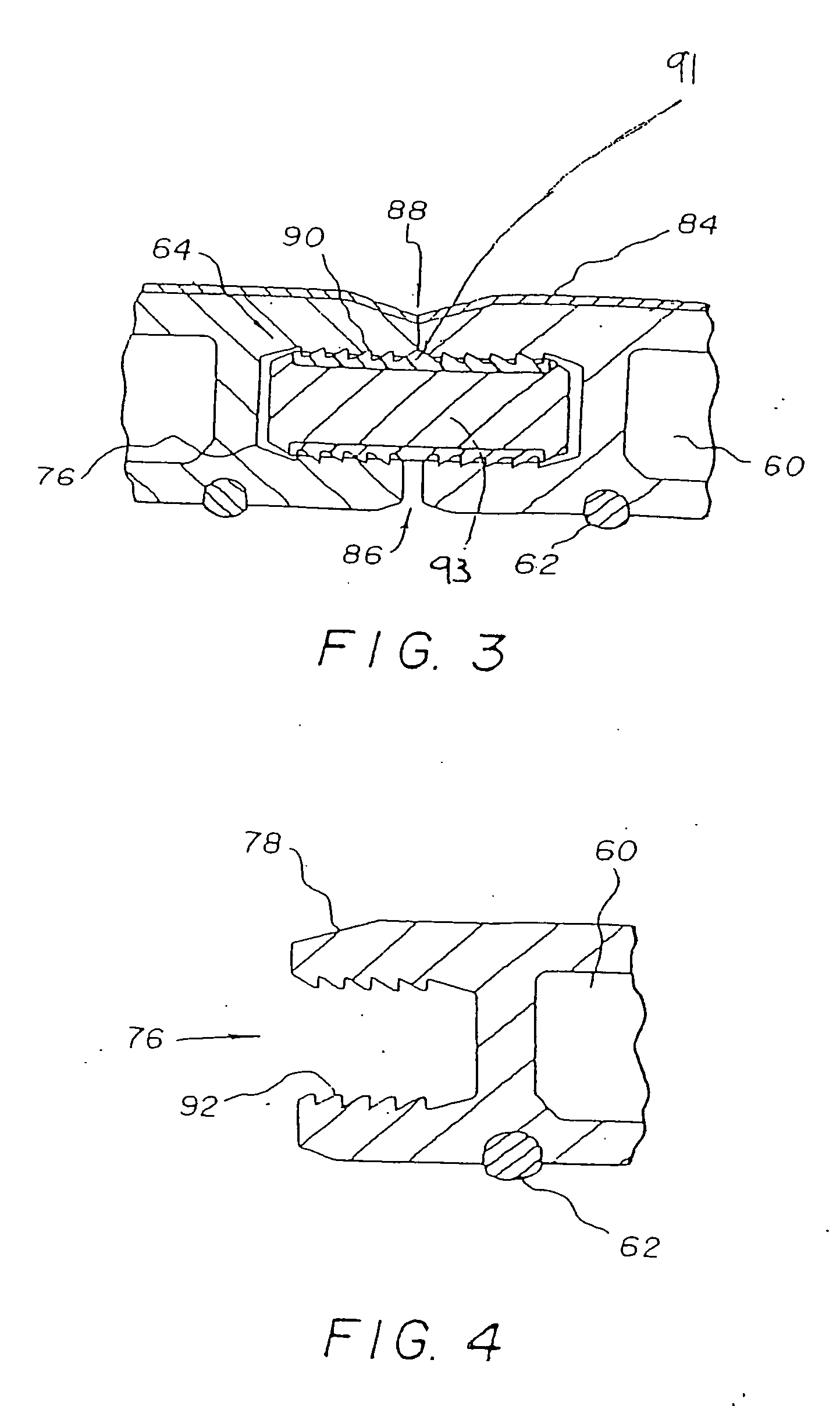

Image

Examples

example 1

Laminated Overlay (T-11) on Wood Composite Base with a Hot Melt Polyurethane Adhesive.

[0114] The laminated overlay layer utilized included a top layer that was 0.004 inches thick and was composed of a cross-linked melamine-impregnated paper containing aluminum oxide. The top layer was designed to be clear and to protect the decorative print layer below it. The second layer, which was located under the top layer, was a gravure-printed paper for decorative purposes. The third layer (bottom layer), which was located under the second layer, was composed of cross-linked phenolic impregnated Kraft paper. The purpose for the bottom layer was to provide support and stability for the top two layers during processing.

[0115] The three layers that made the laminated overlay were consolidated under heat and pressure in a continuous consolidation procedure performed on a Grecon unit.

Section A

[0116] The core of the plank was extruded wood fiber composite having the following formulation:

Map...

example 2

Wood Veneer Overlay on Wood Composite Base

[0124] The core was prepared as described above in Example 1, Section A, using the TS-110 extruder from American Maplan Company. However, the decorative element adhered to the top of the core was an actual wood veneer. The wood veneer included polyester back with a thin (0.006 inches thickness) red oak veneer adhered to the top of the polyester. The polyester was used to hold the thin veneer to be processed as a continuous coil when it was wrapped onto the extruded wood composite base. The veneer overlay was adhered to the wood composite base with a hot melt polyurethane adhesive Forbo (Reichhold) 2U-316.

[0125] The temperature and other conditions at which the veneer was wrapped and the method of laminating the veneer to the wood composite were the same as the conditions and method described in Example 1, Section B, with the exception that cooling water was not in contact with the face of the wood veneer.

[0126] To protect the red oak vene...

example 3

Vulcanized Cellulose on Wood Composite Base

[0131] The core was prepared as described above in Example 1, Section A, using the TS-110 extruder from American Maplan Company. However, the decorative element adhered to the top of the plank was a vulcanized cellulose layer with a printed wood grain design. The vulcanized cellulose layer was supplied by NVF Company and is known as Yorkite Vulcanized Fiber (YVF). The vulcanized cellulose layer was prepared by soaking cellulose fibers in CaCl2. The fibers were then compacted and heated to form a cross-linked cellulosic layer. The vulcanized cellulose layer used in this example was 0.020 inches thick.

[0132] The YVF overlay was adhered to the wood composite base with a hot melt polyurethane adhesive, such as Forbo / Swift 20-316. The temperature and other conditions at which the YVF was wrapped and the method of laminating of the YVF to the wood composite base were the same as the conditions and method described in Example 1, with the excepti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com