High-toughness aluminum lithium alloy and preparation method thereof

An aluminum-lithium alloy and high-strength technology, which is applied in the field of high-strength and toughness aluminum-lithium alloy and its preparation, can solve the problem of not being able to greatly reduce the anisotropy of the alloy, and achieve the effect of reducing the anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

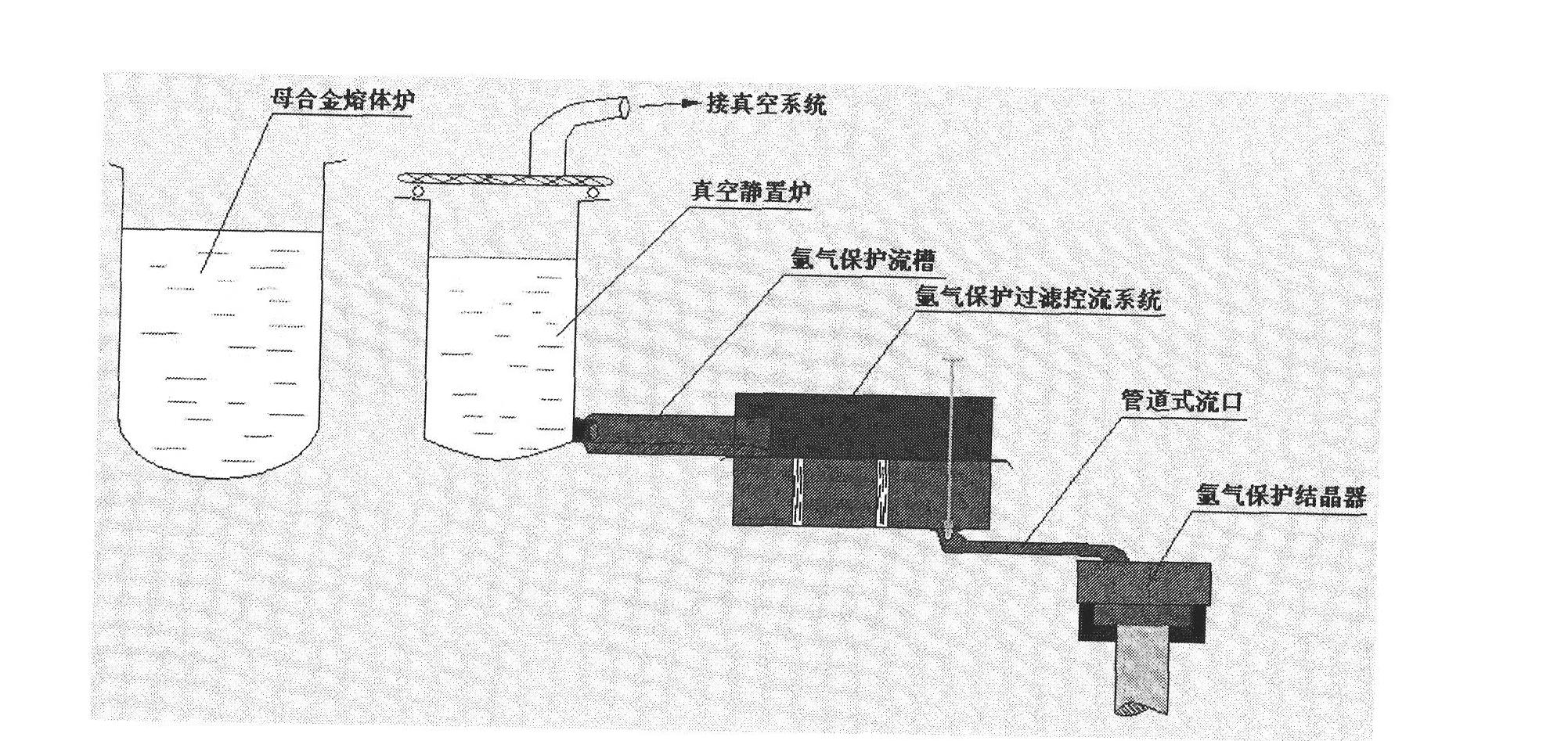

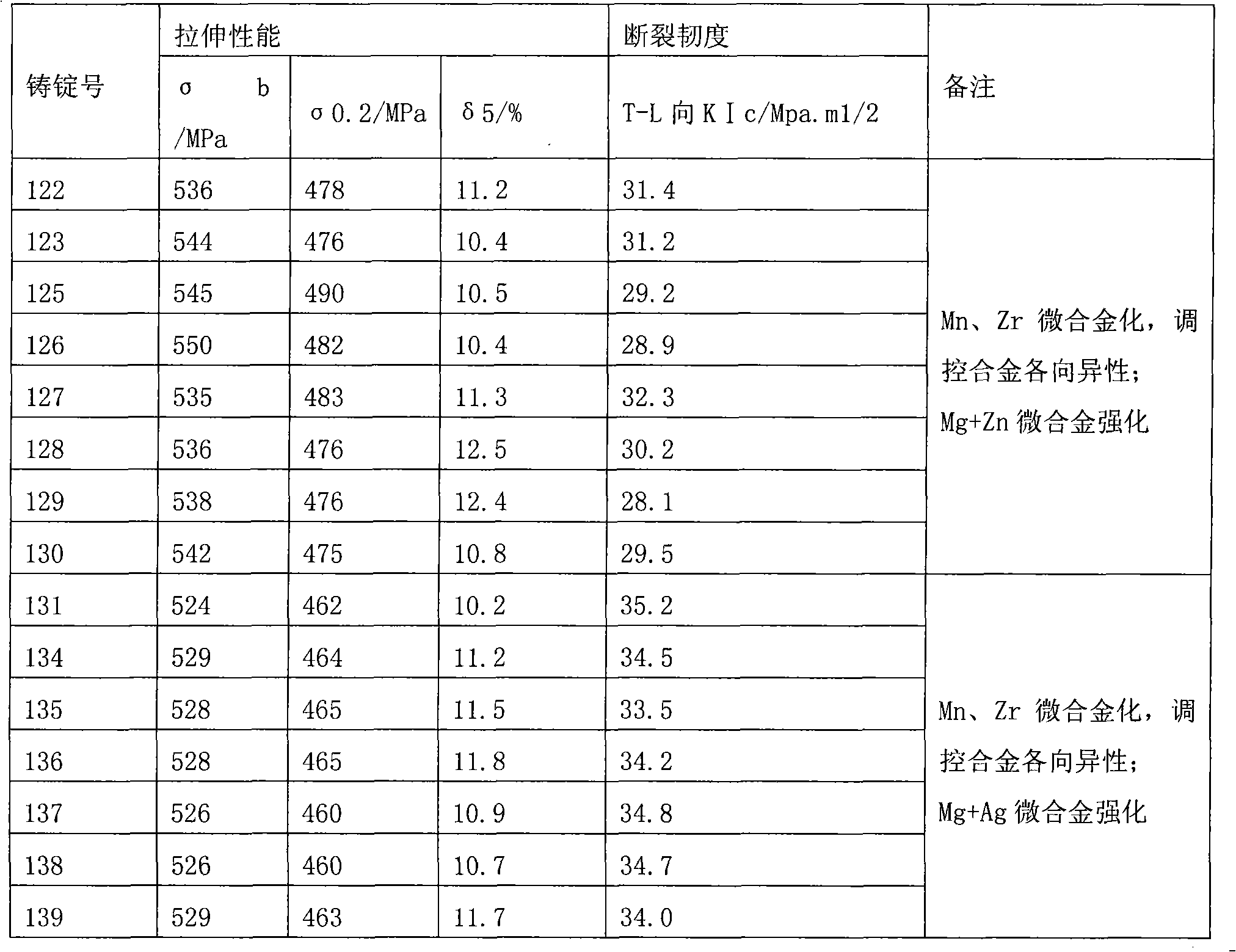

[0031] The technical solution of the present invention will be further described in detail below with reference to the accompanying drawings and embodiments:

[0032] Table 1 shows examples of the chemical composition and weight percentage of the new high-strength and toughness aluminum-lithium alloy proposed by the present invention.

[0033] Table 1: Chemical composition and weight percentage of new ultra-high-strength aluminum-lithium alloy

[0034] Ingot number

Cu

Li

Mn

Zn

Zr

Mg

Ag

Ti

Fe

Si

122

3.2

1.6

0.3

0.2

0.10

0.4

-

<0.12

<0.10

<0.10

123

3.2

1.5

0.2

0.4

0.12

0.5

-

<0.12

<0.10

<0.10

125

3.4

1.8

0.4

0.2

0.18

0.8

-

<0.12

<0.10

<0.10

126

3.5

1.3

0.4

0.6

0.15

0.6

-

<0.12

<0.10

<0.10

127

3.5

1.4

0.3

0.3

0.14

0.5

-

<0.12

<0.10

<0.10

128

4.0

1.6

0.5

0.4

0.15

0.6

-

<0.12

<0.10

<0.10

129

3.8

1.7

0.5

0.4

0.20

0.2

-

<0.12

<0.10

<0.10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com