Flooring panel

a technology of floor panels and panels, applied in the field of panels, can solve the problems of high production costs, high production costs, and difficult to meet the needs of customers, and achieve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

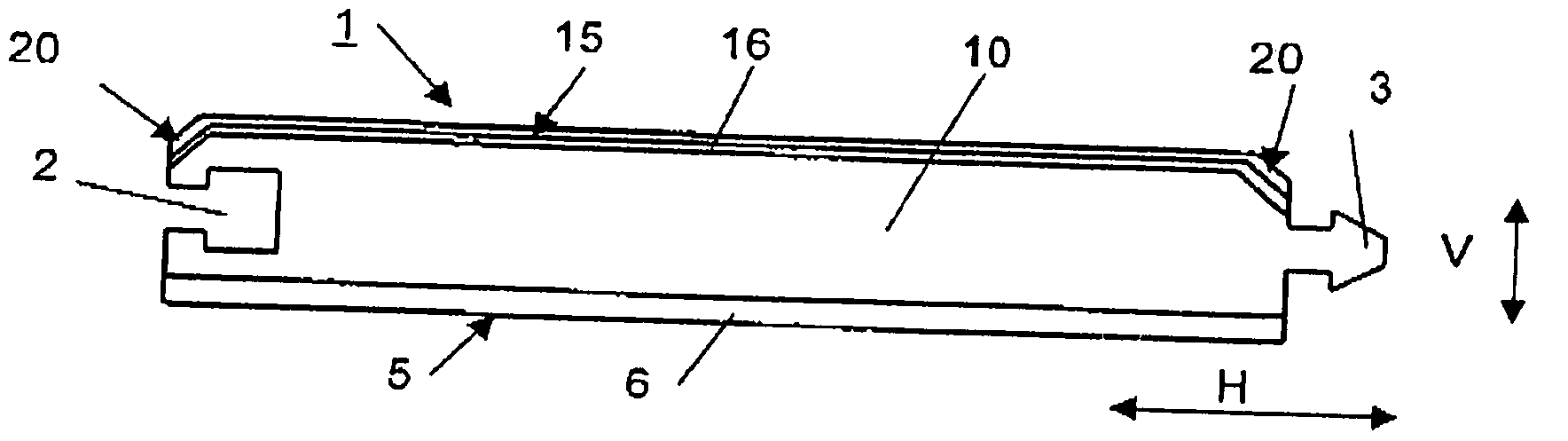

[0013]FIG. 1 shows a panel 1 in a cross-sectional view which is coated on an upper side 15 with a decorative layer 16 and on an under side 5 with a so-called counteracting layer 6. The core 10 of the panel 1 is made of an MDF or HDF material and is compressed at high pressure during production. The decorative layer 16 and the counteracting layer 6 serve as a stabilizing film and give the panel 1 a durable surface. The form-fitting elements 2, 3 arranged on the lateral edges are used to lock several panels to one another and lock the panels both in the horizontal direction H and in the vertical direction V. In addition to the embodiment shown, laying profiles or pivot profiles can also be available on the lateral edges.

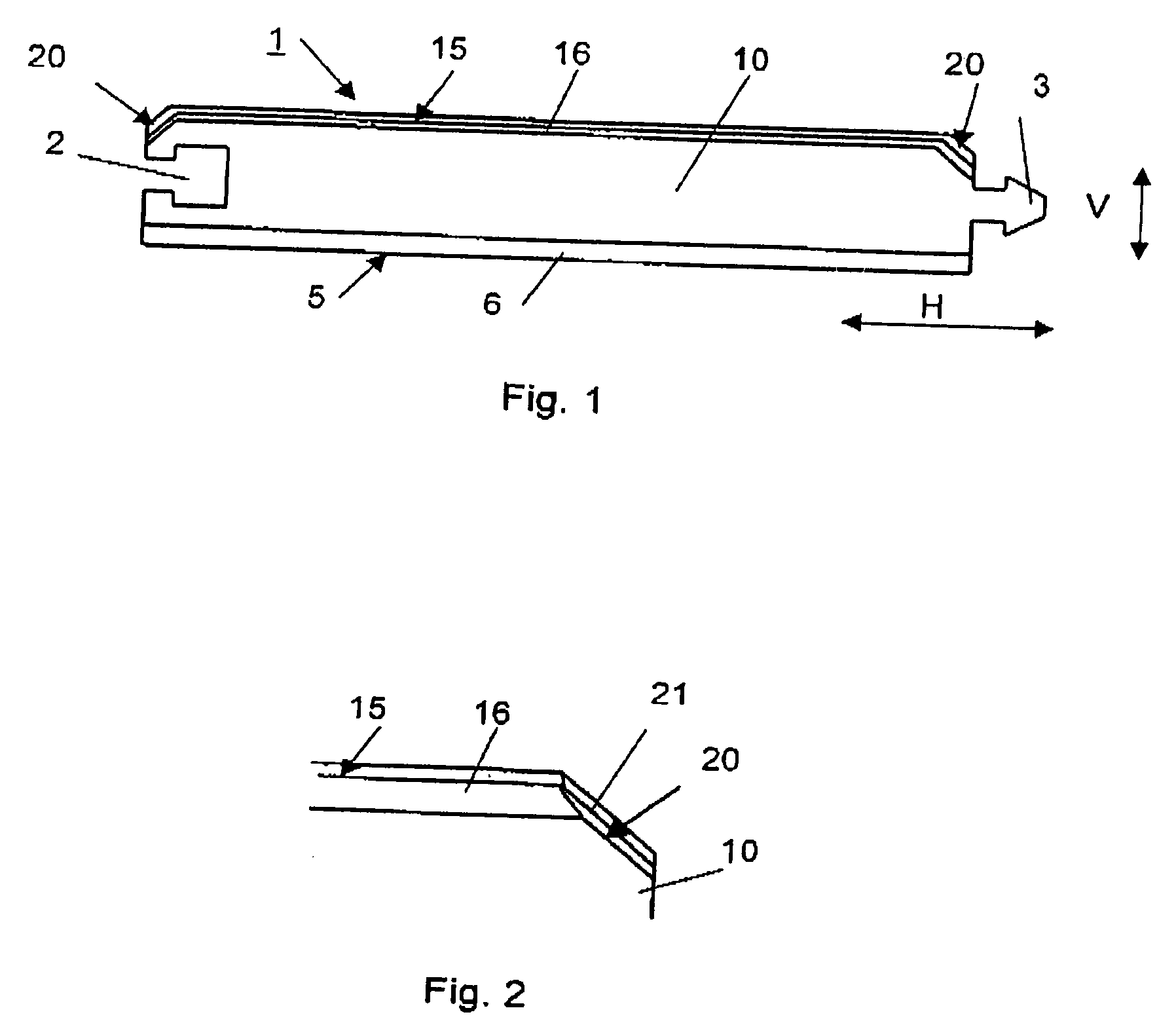

[0014] Alternatively to the use of fiberboards as core 10, OSB materials, chipboard or laminated wood can be used. Starting from the upper side 15, one chamfer 20 each is milled out on both lateral edges, which chamfers in the locked state form a V-shaped vertical joi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Color | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com