Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

351 results about "Element space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

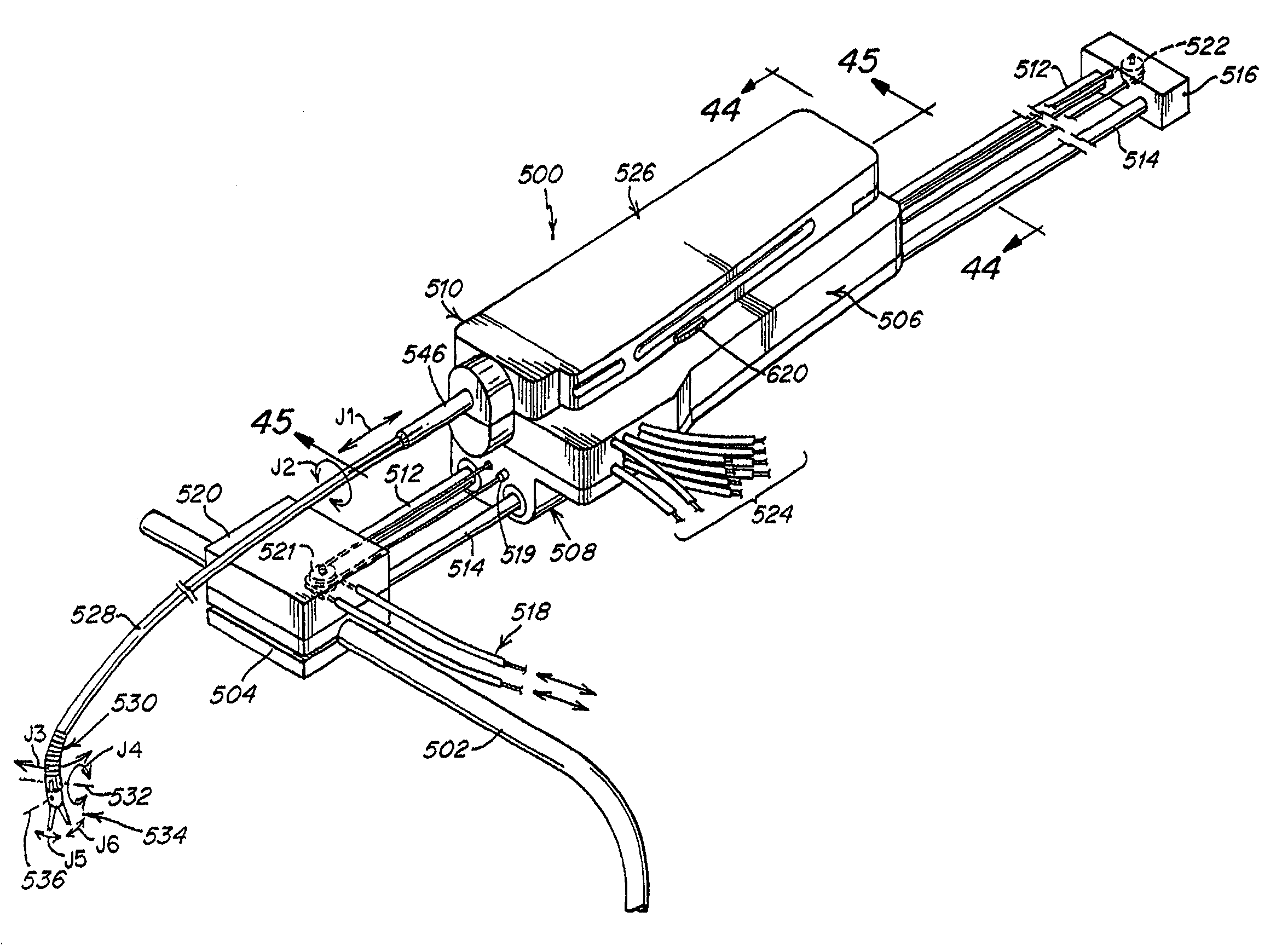

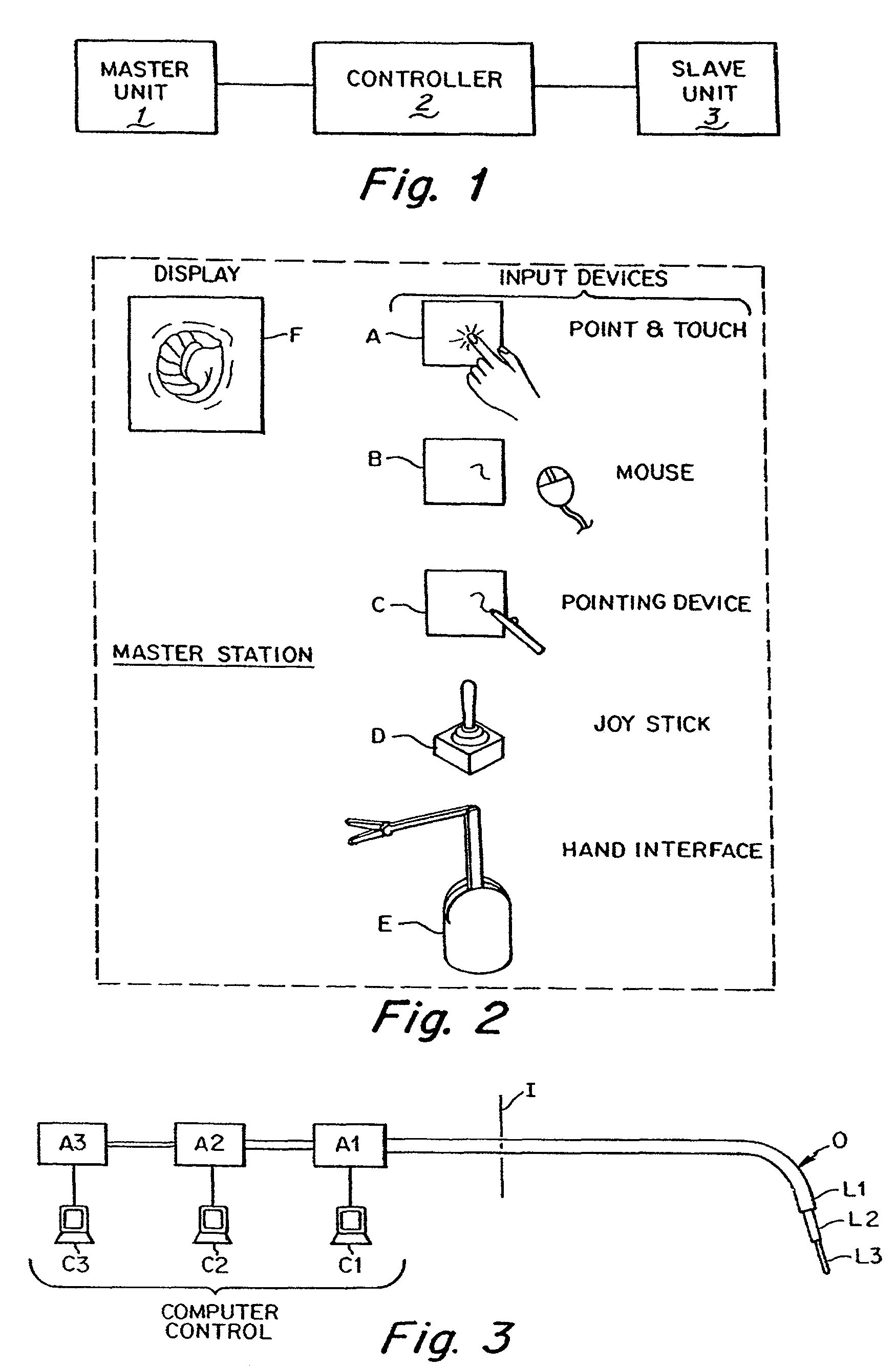

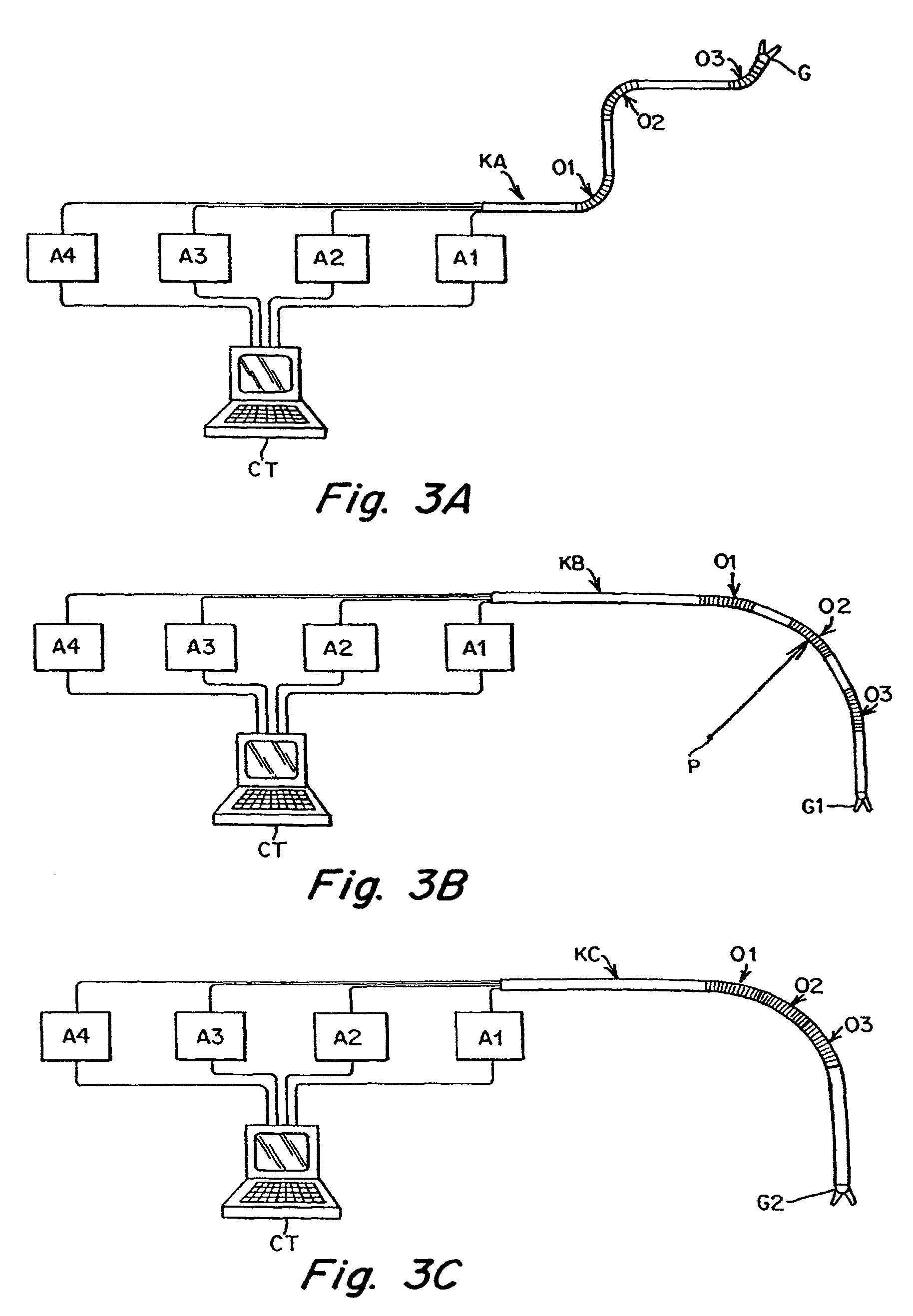

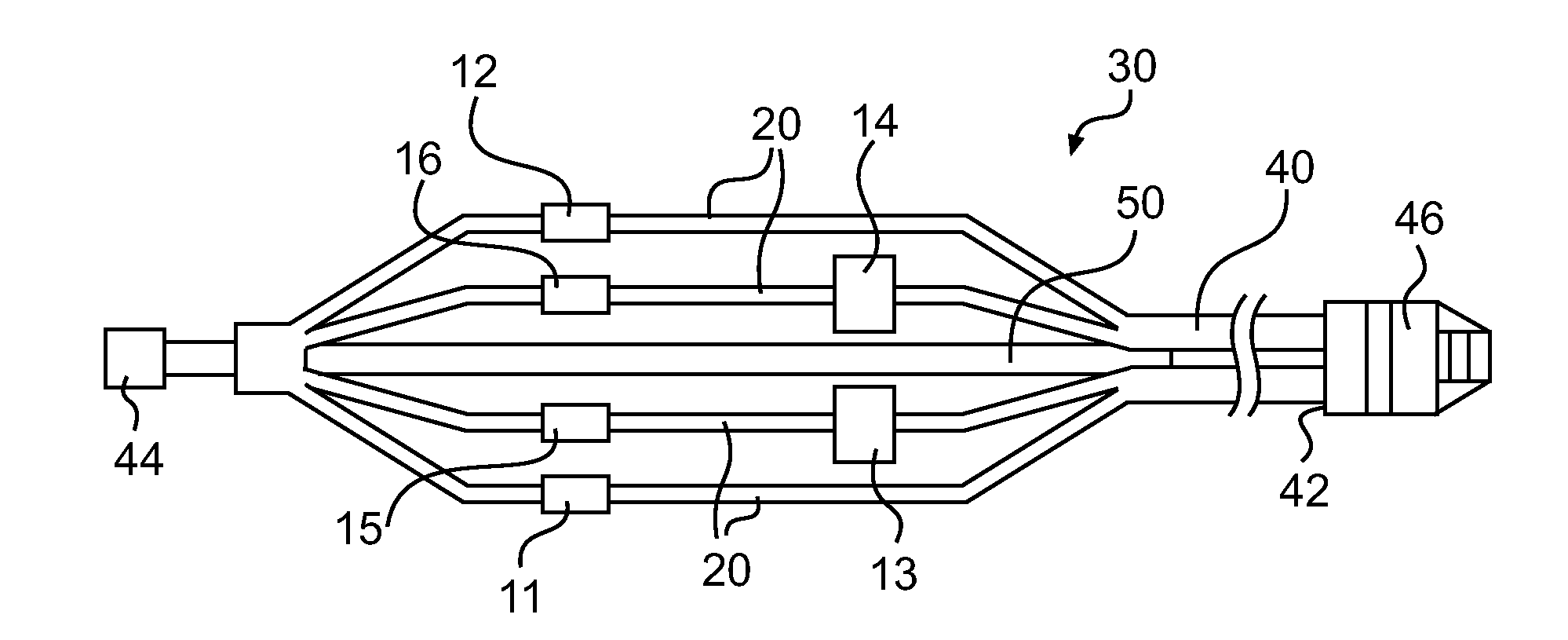

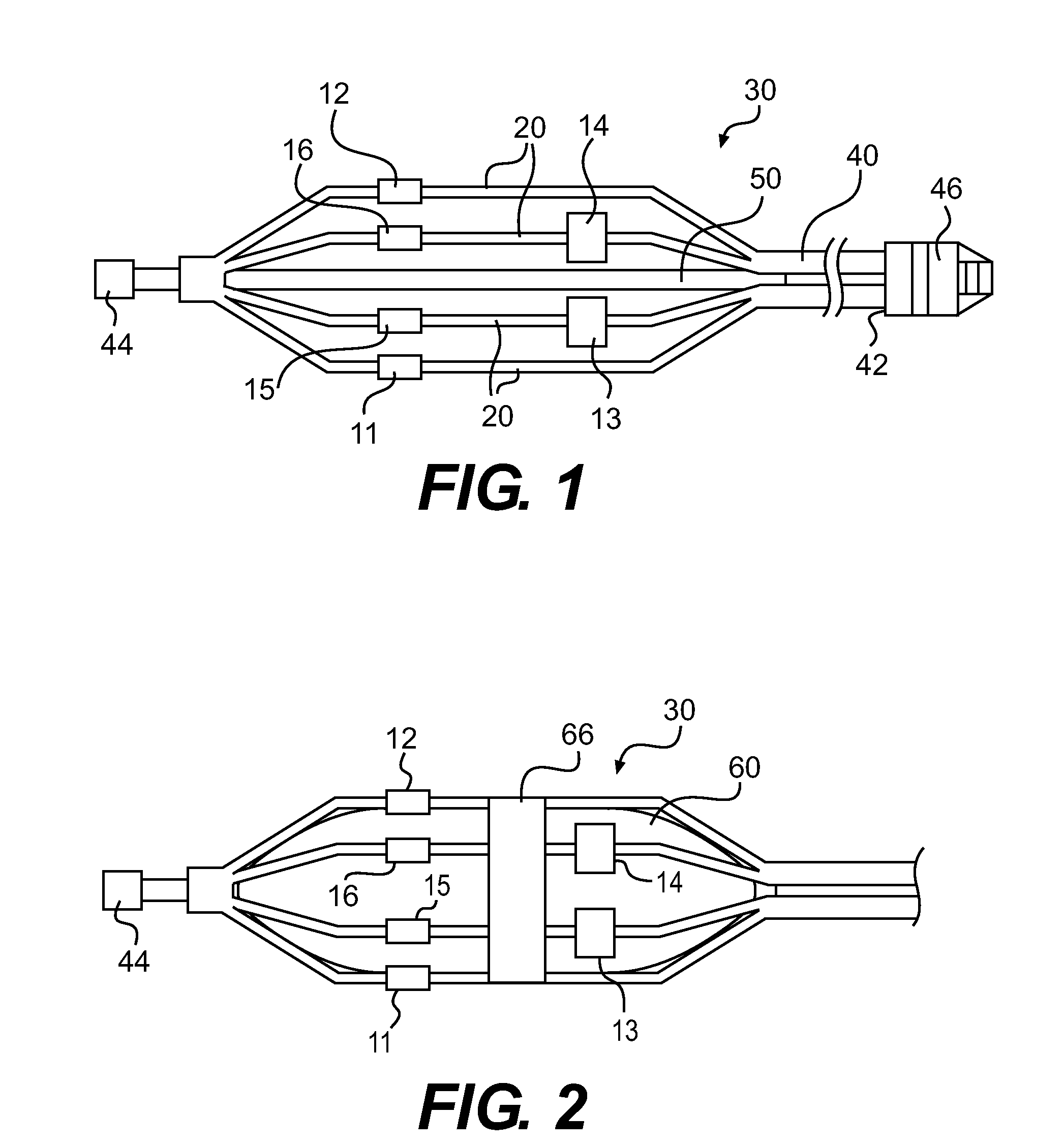

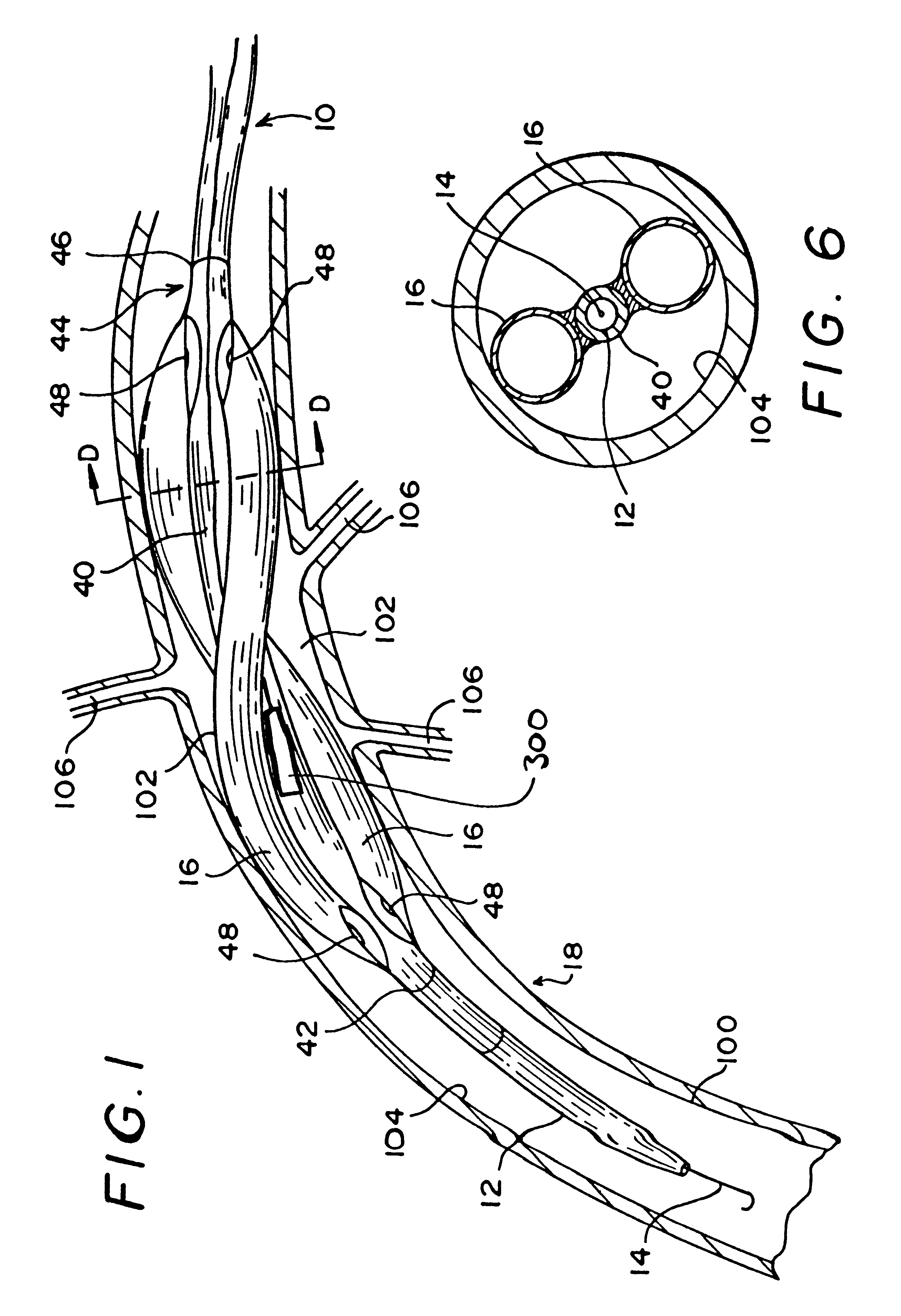

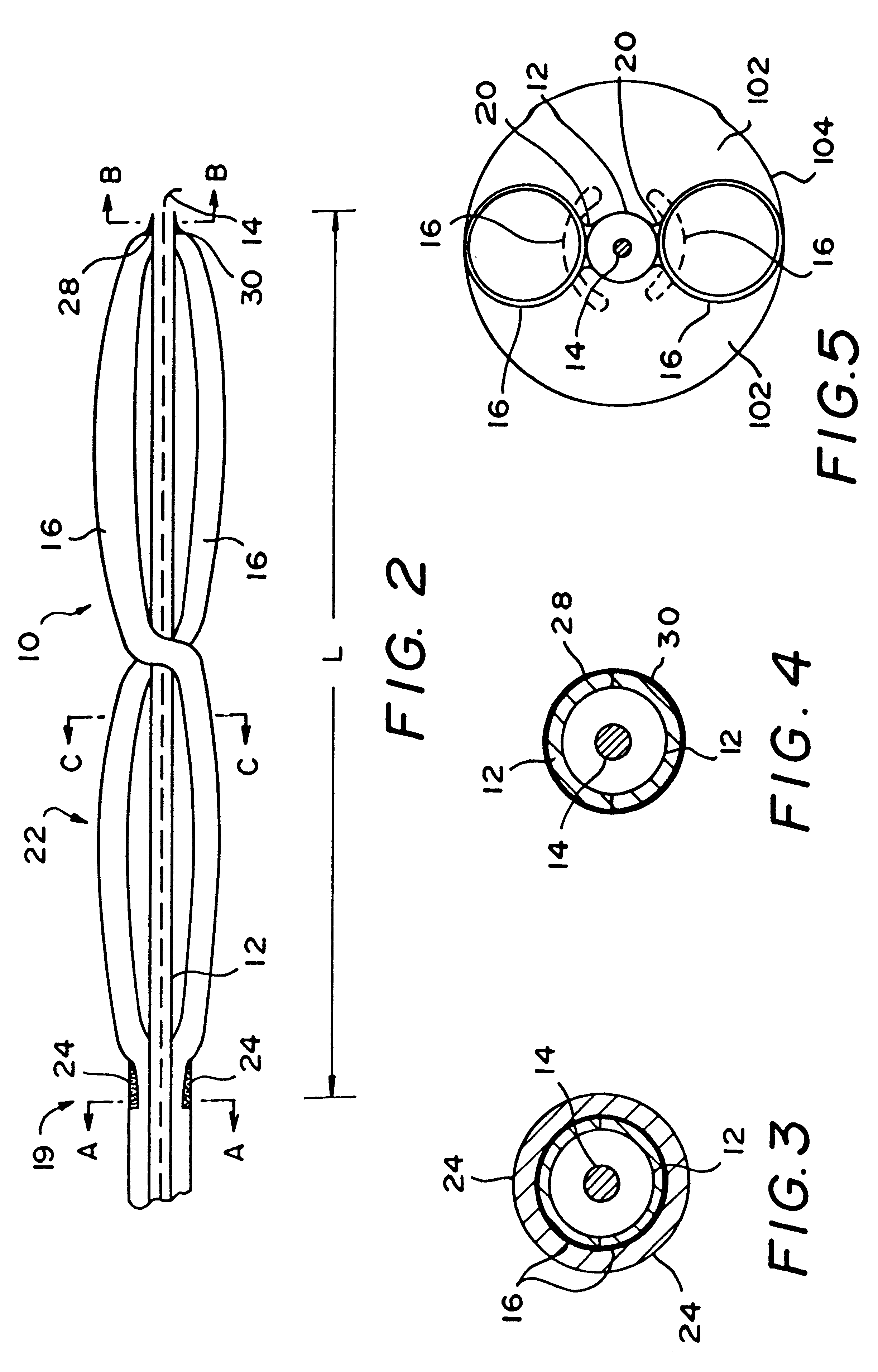

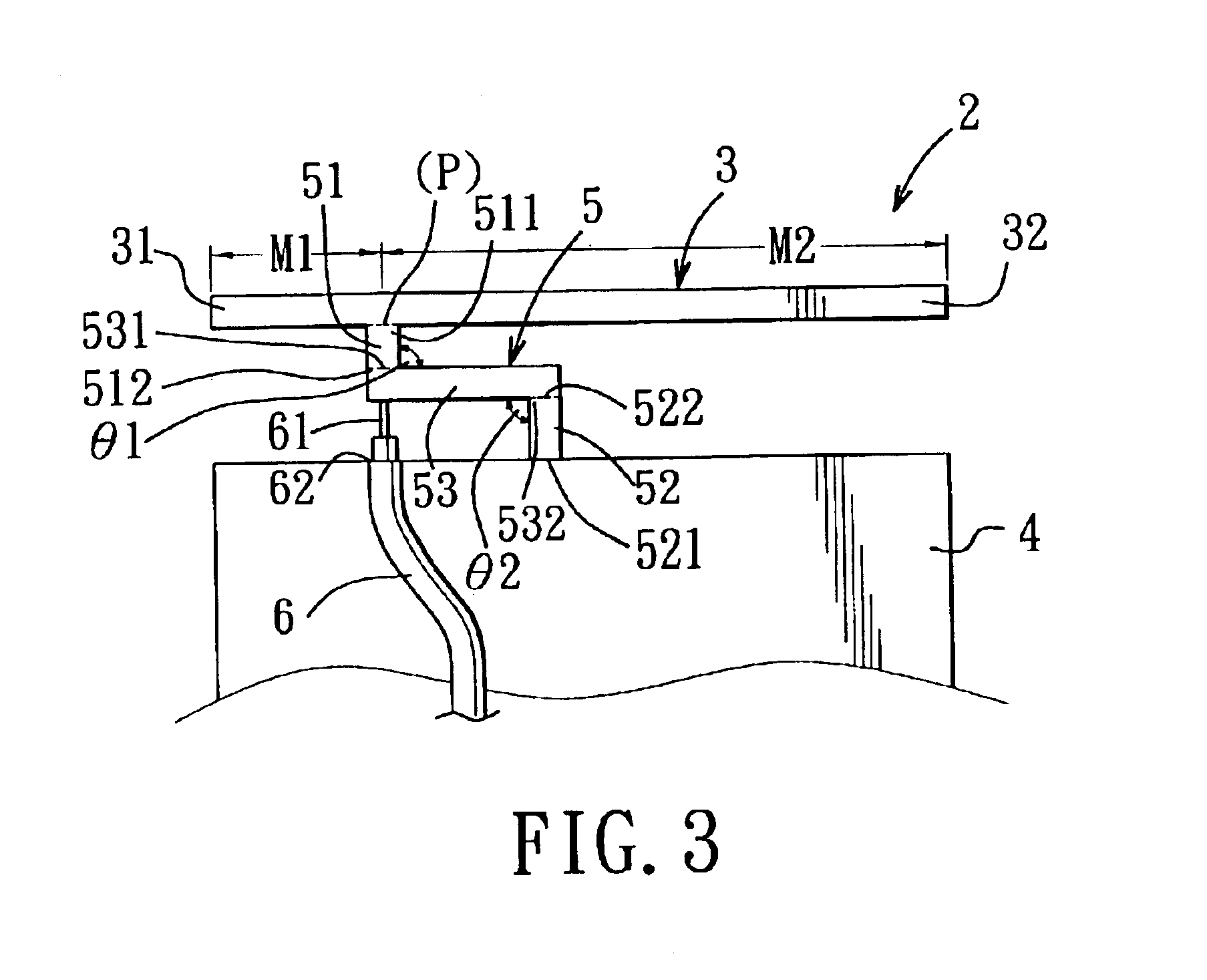

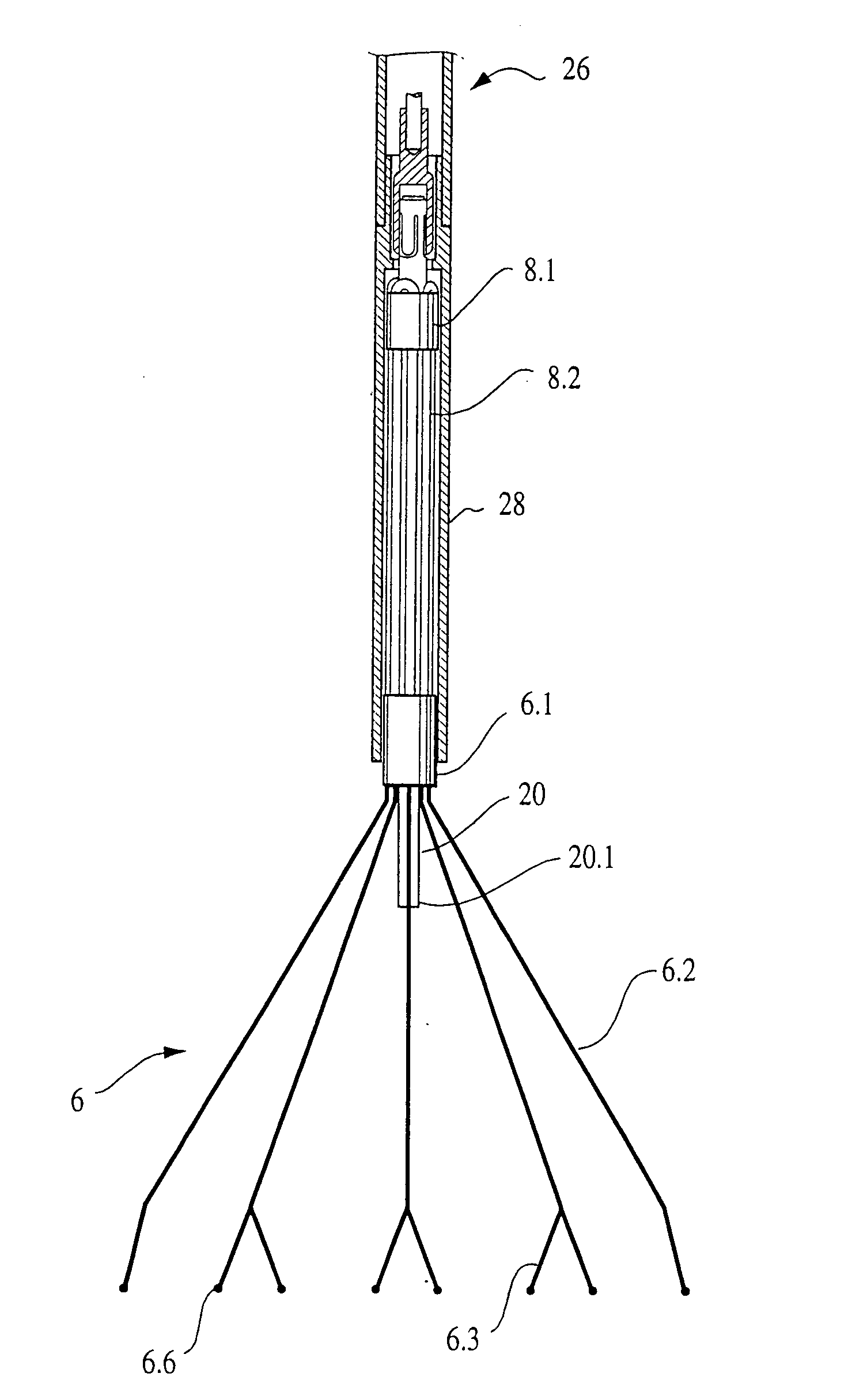

Flexible instrument

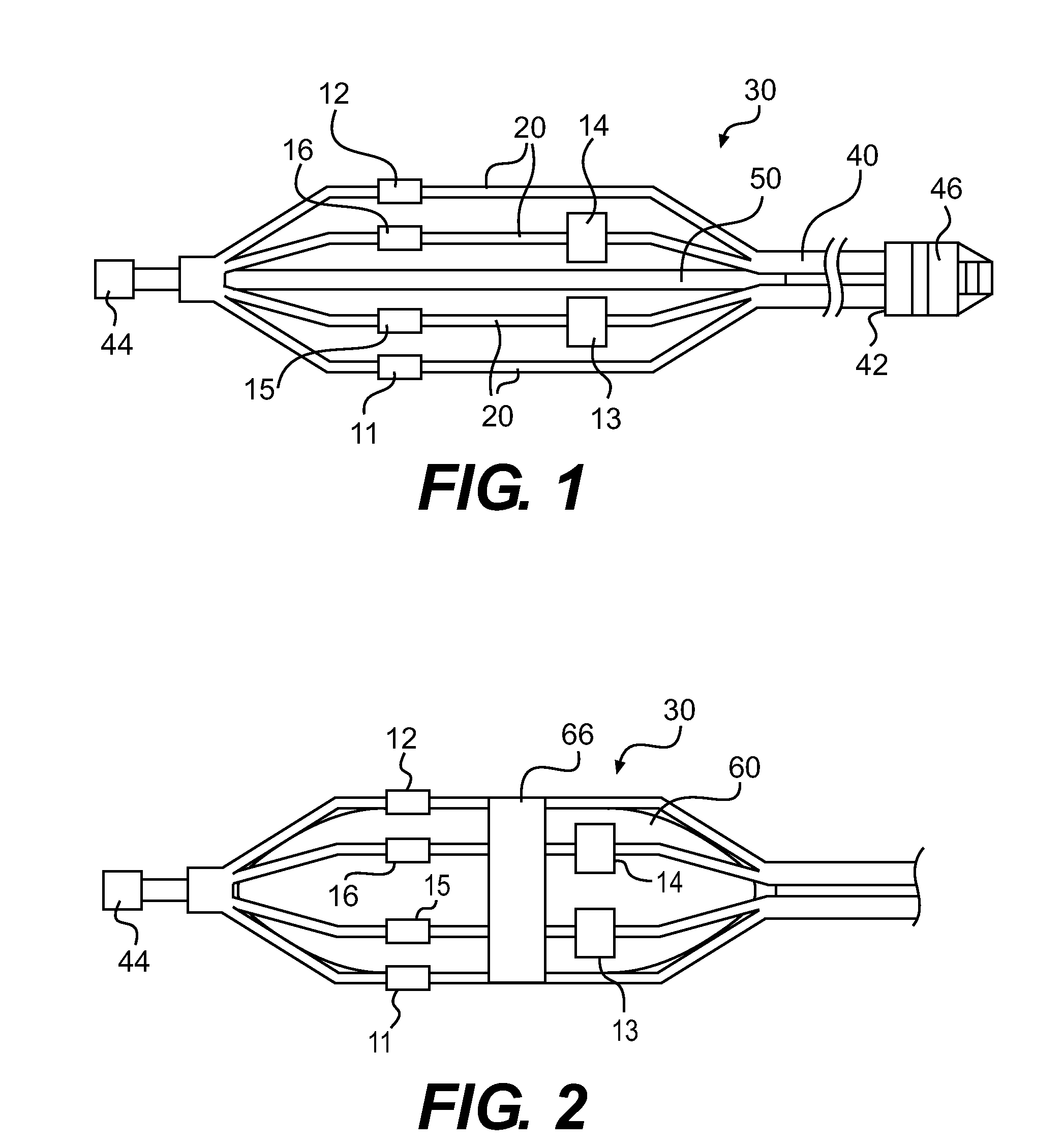

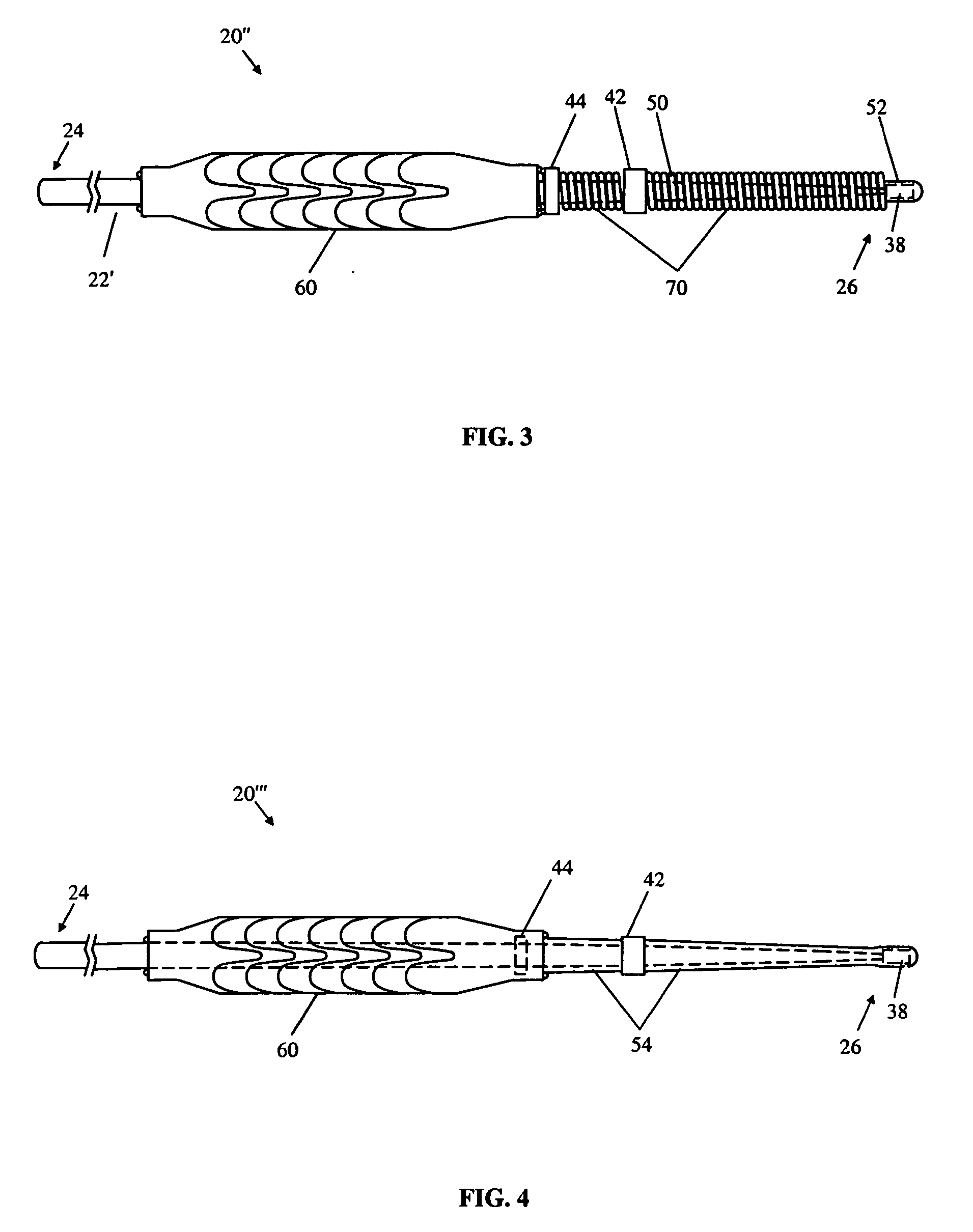

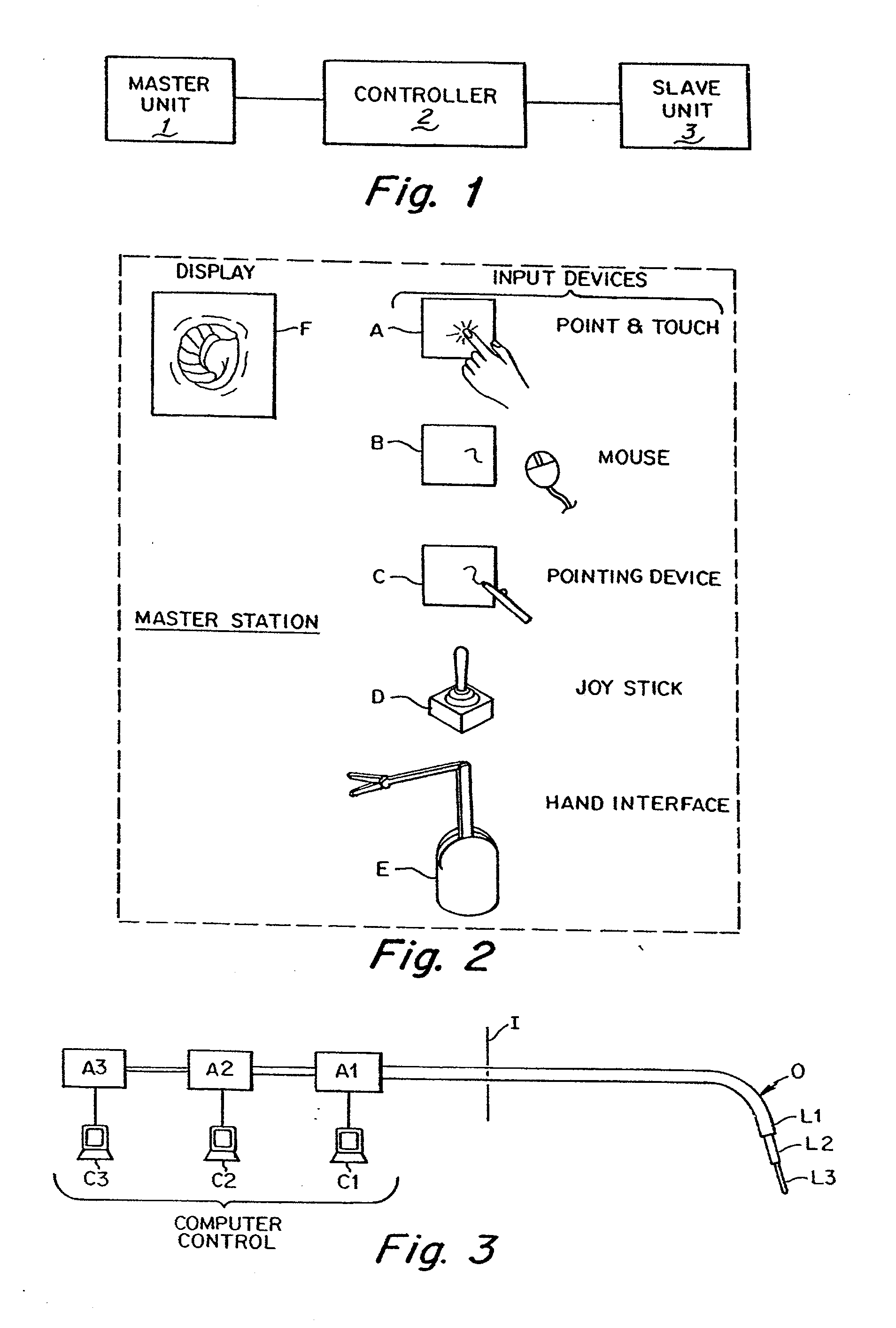

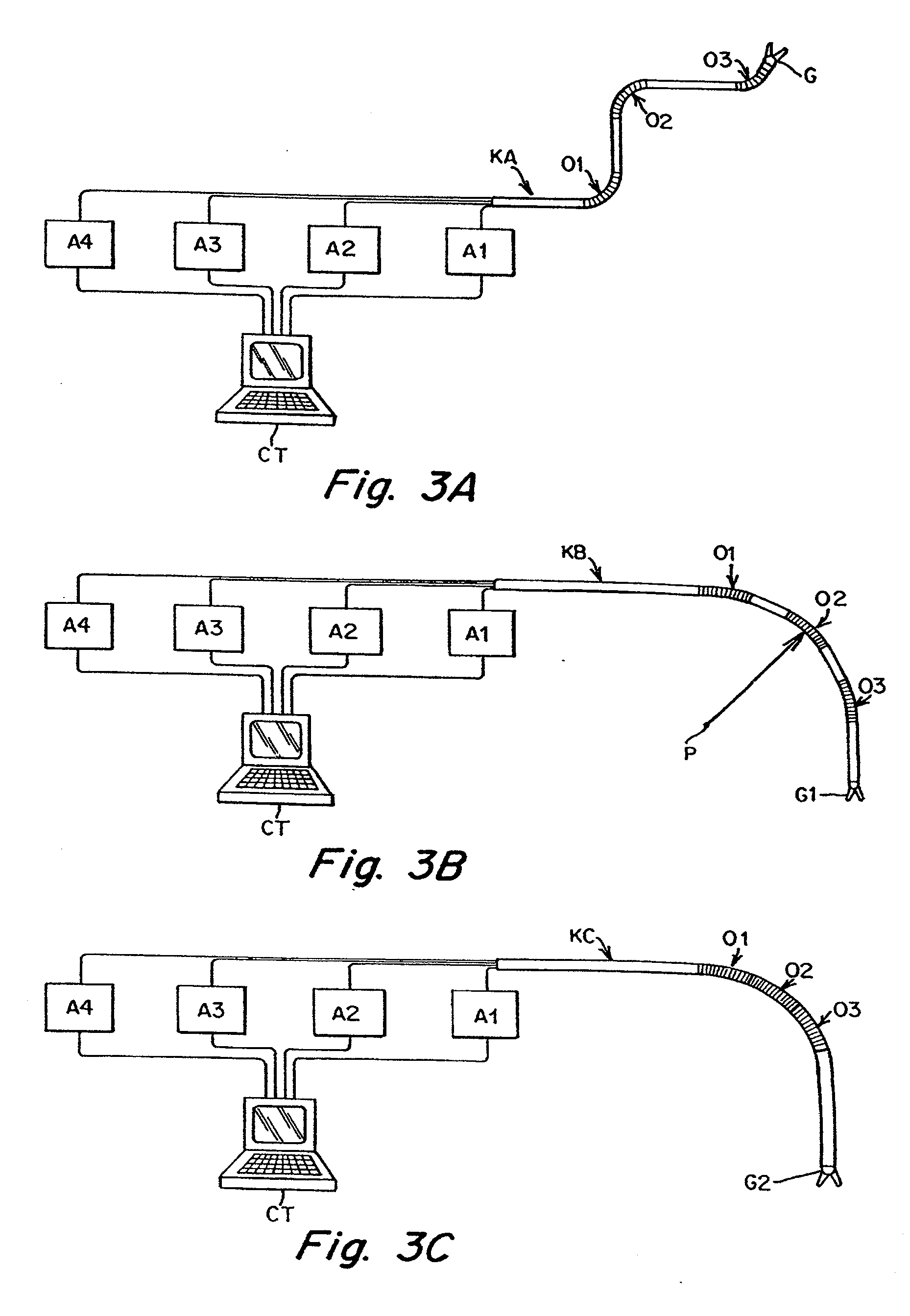

InactiveUS7775972B2Suture equipmentsProgramme-controlled manipulatorElement spaceBiomedical engineering

A medical probe and medical system are provided. The medical probe comprises an elongated shaft, a plurality of electromagnetic elements spaced along the elongated shaft, and a plurality of wires extending through the elongated shaft and configured for energizing the electromagnetic elements that actuate a controlled bending of the elongated shaft. The medical system may comprise the medical probe and a controller configured for energizing the electromagnetic elements via the wires to actuate the controlled bending of the elongated shaft. The medical system may optionally comprise a user interface configured for conveying commands to the controller, in which case, the controller will be configured for energizing the electromagnetic elements via the wires to actuate a controlled bending of the elongated shaft in response to the commands.

Owner:HANSEN MEDICAL INC

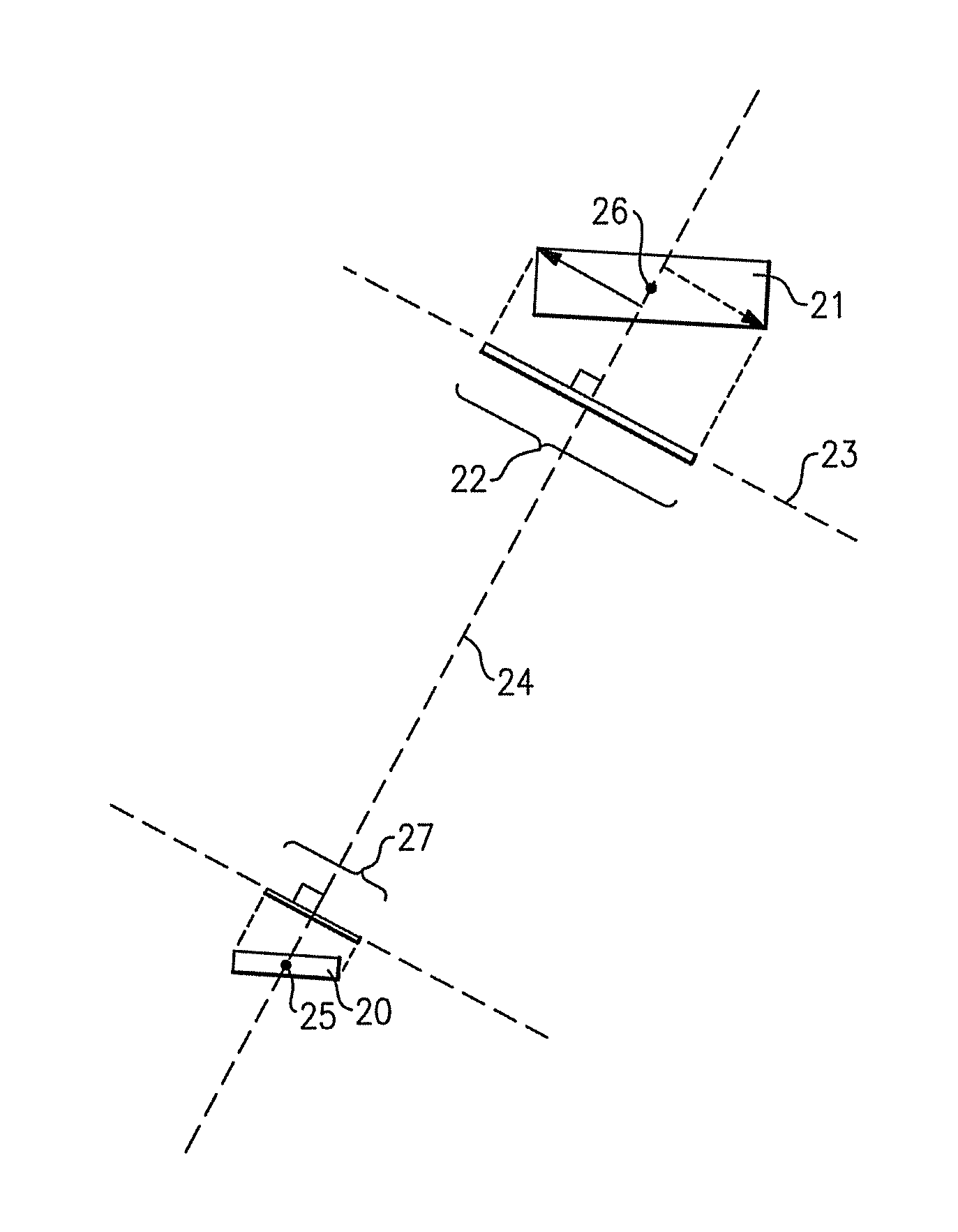

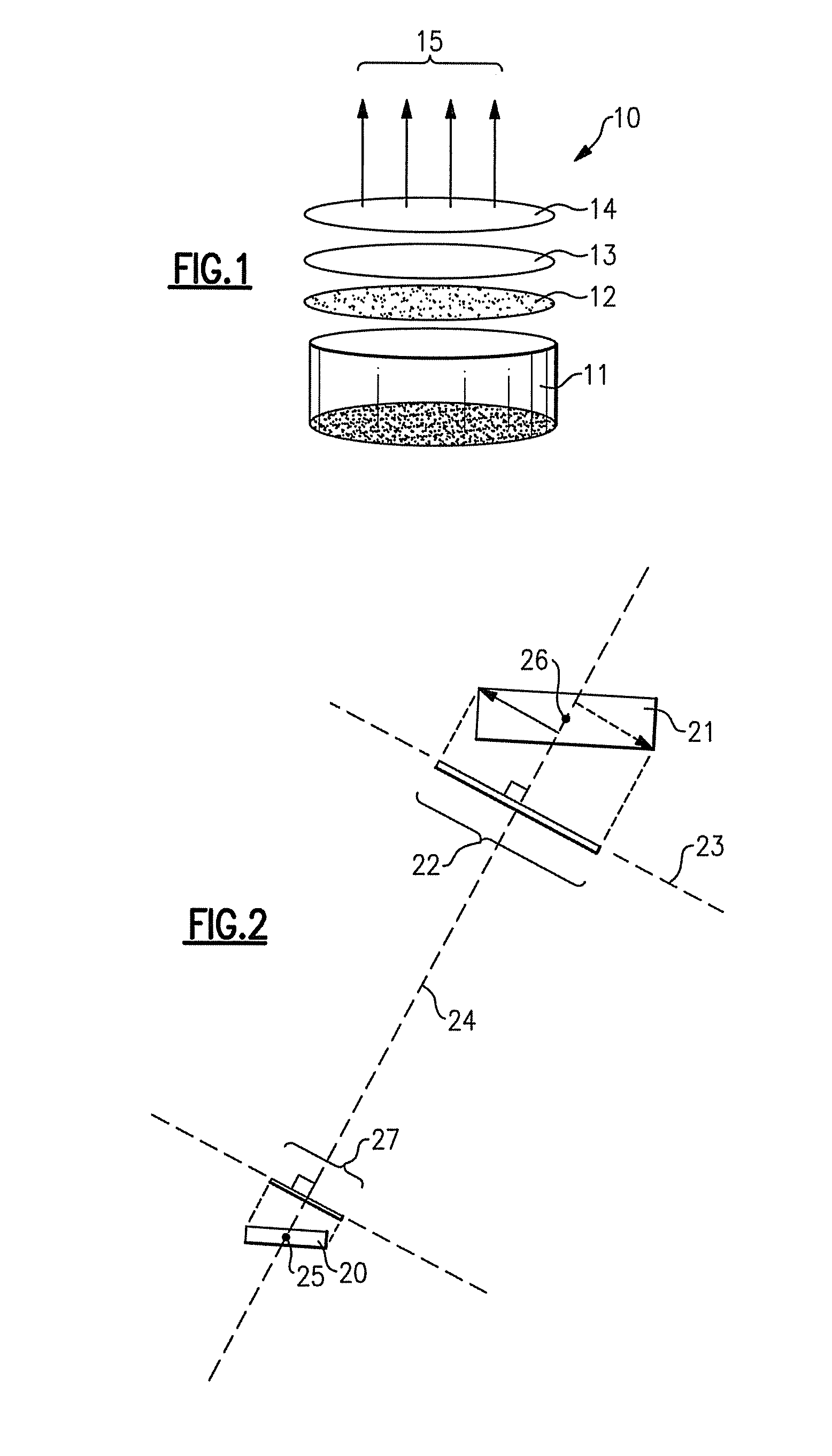

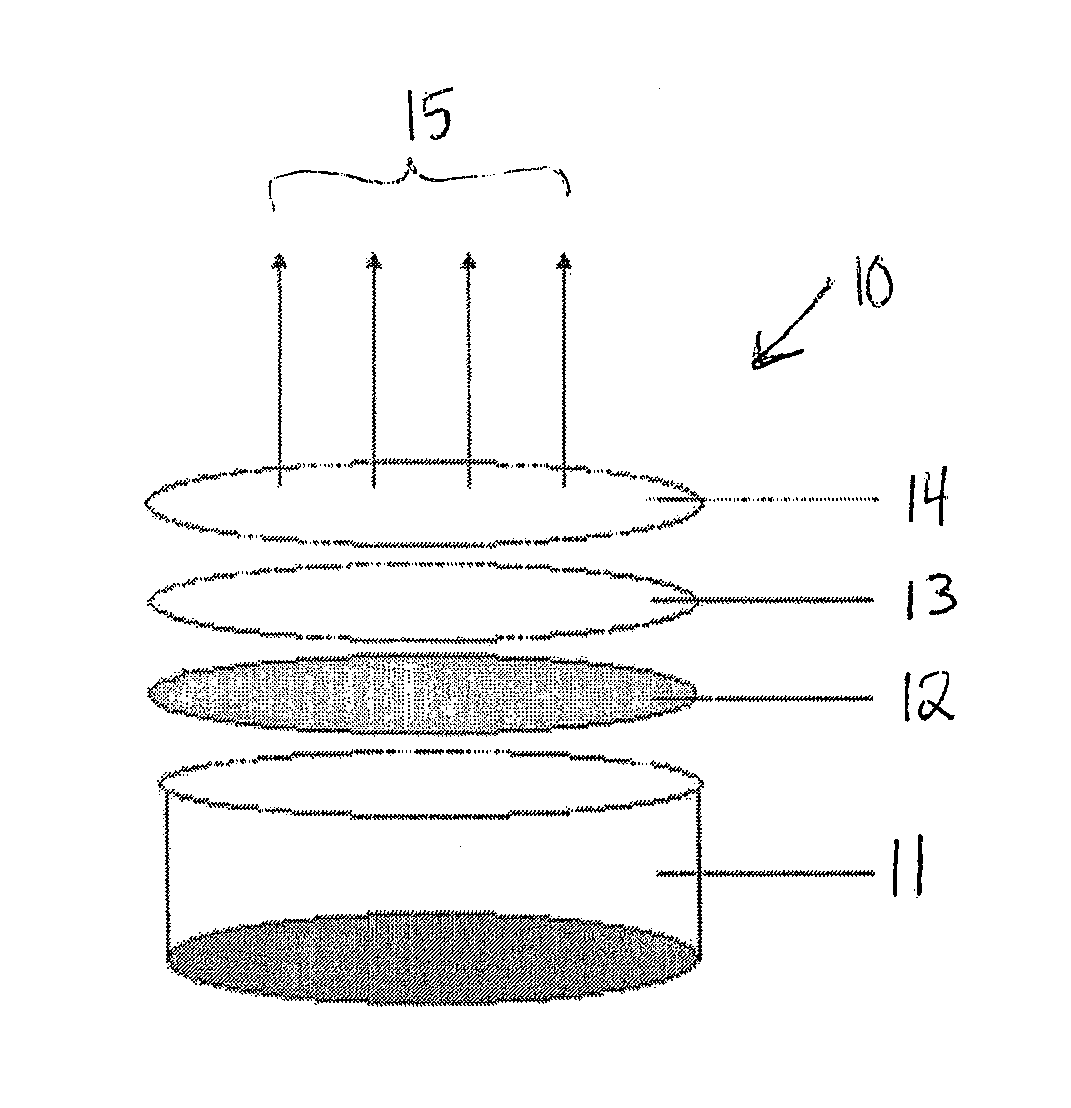

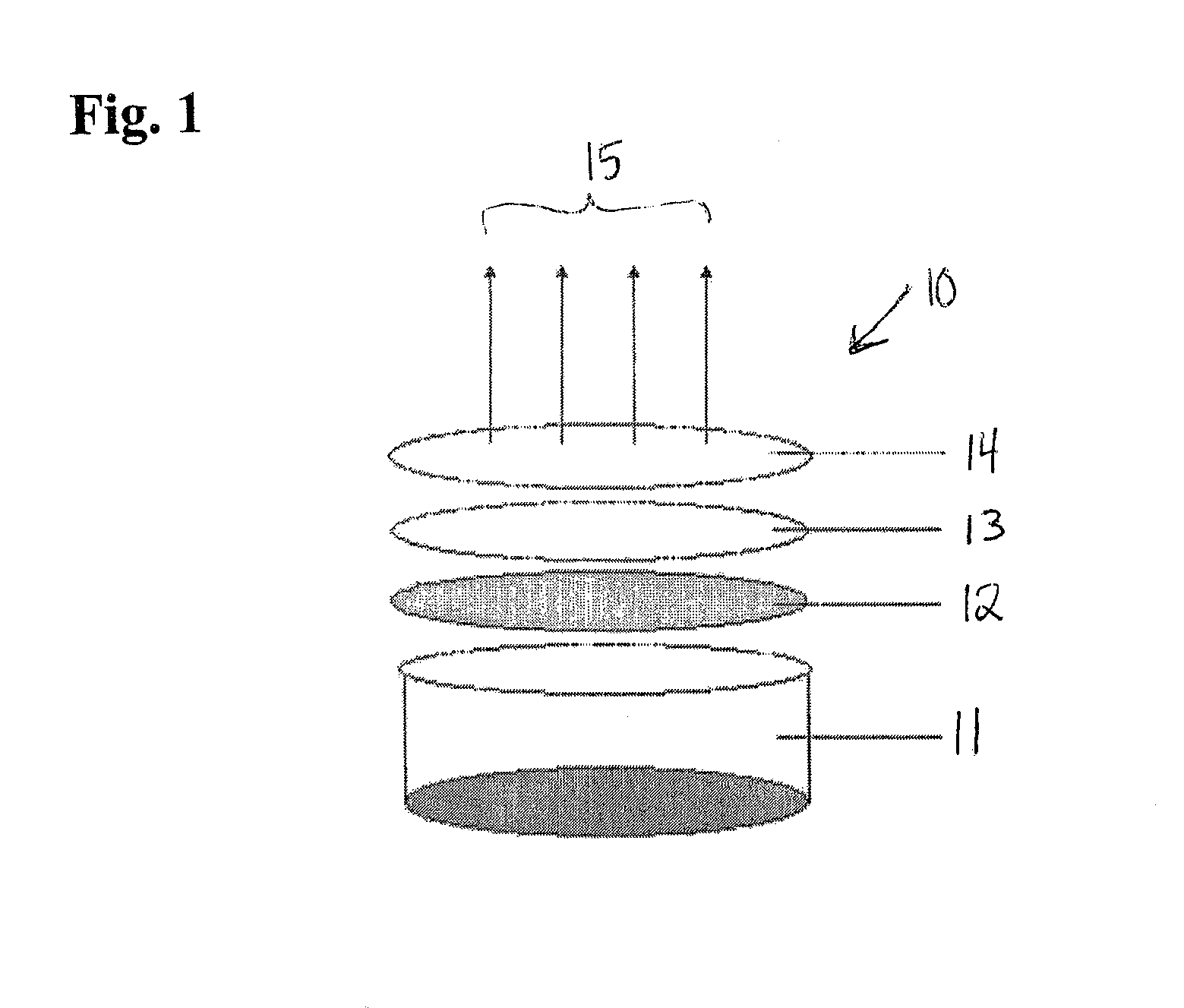

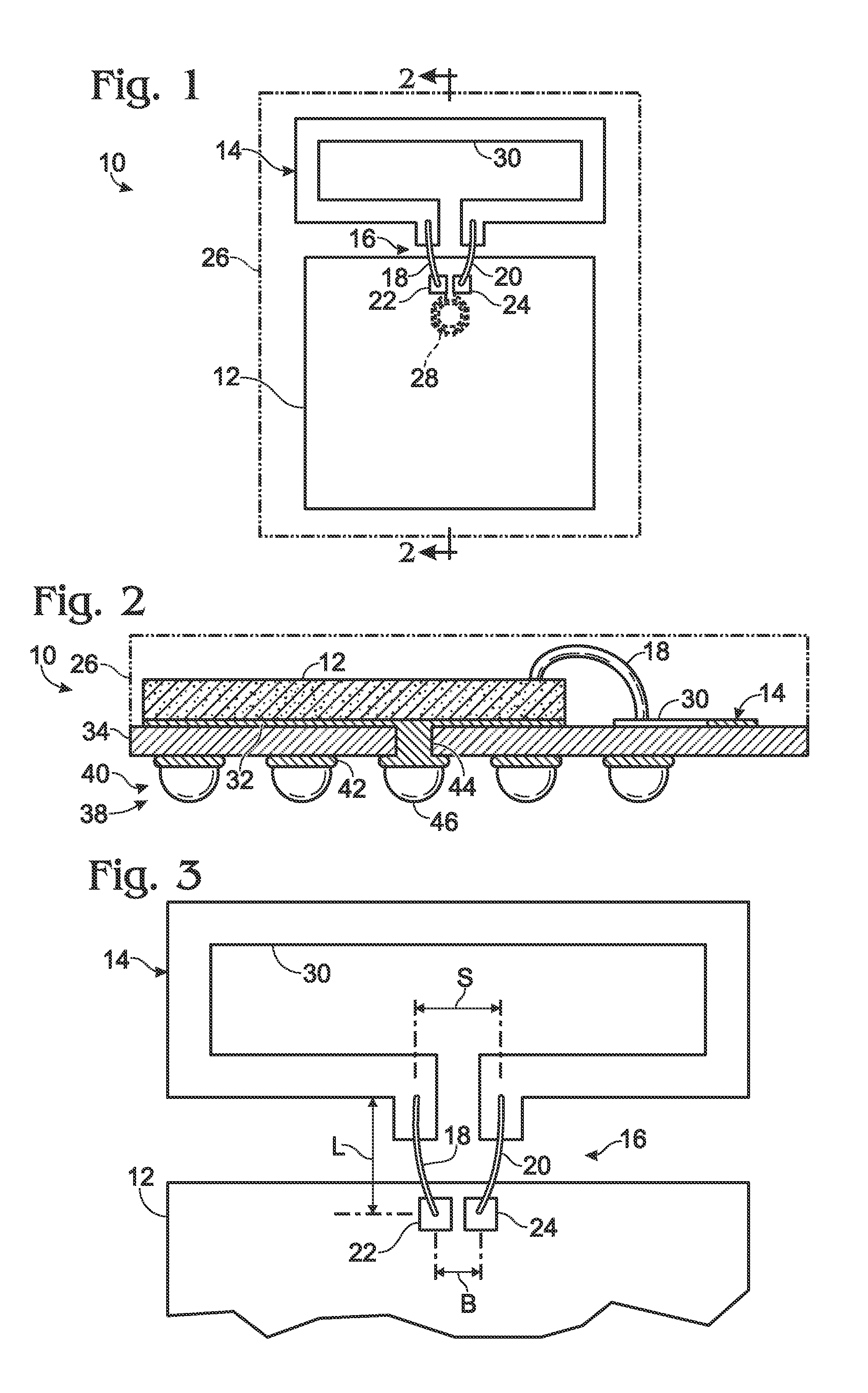

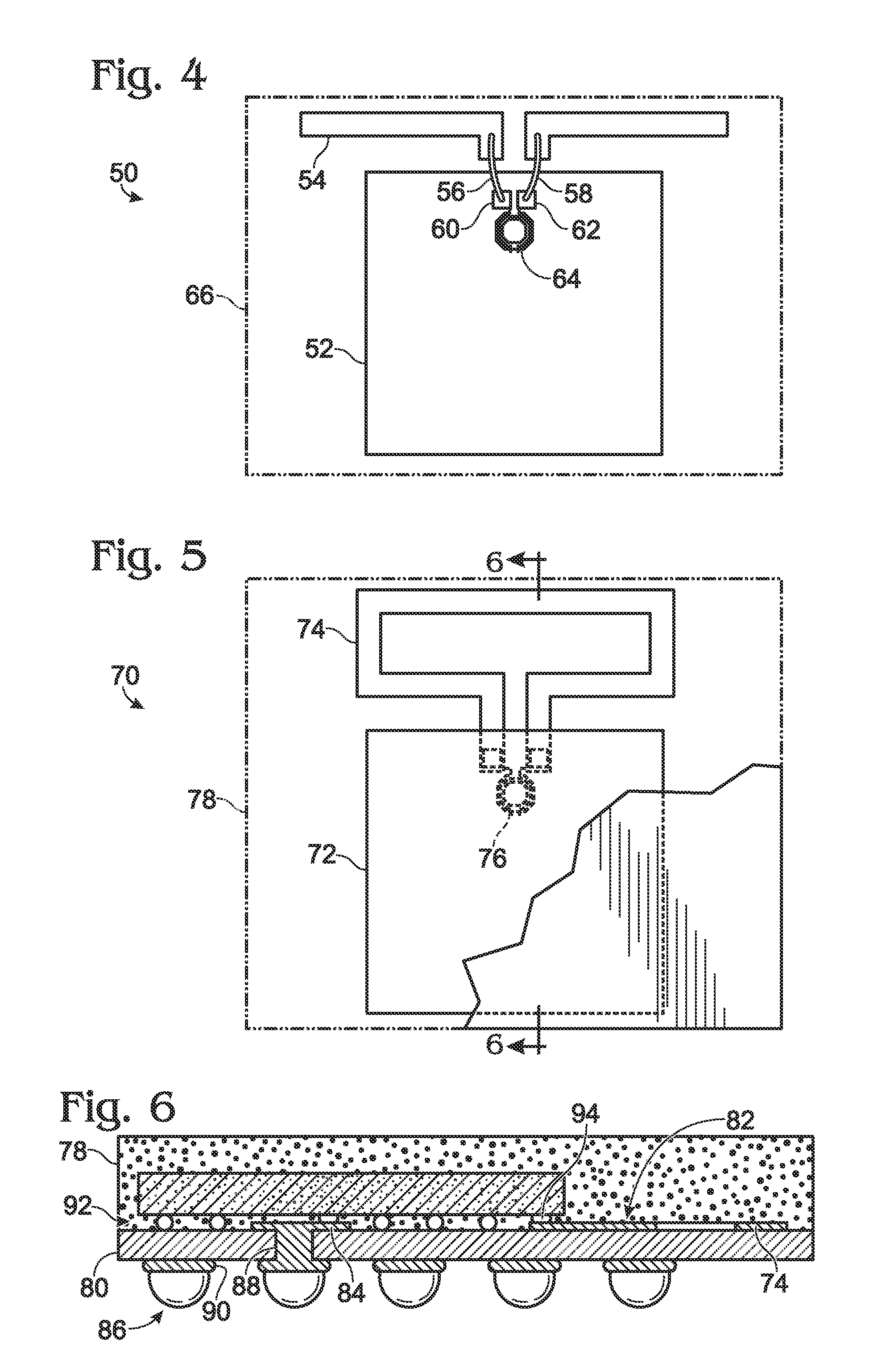

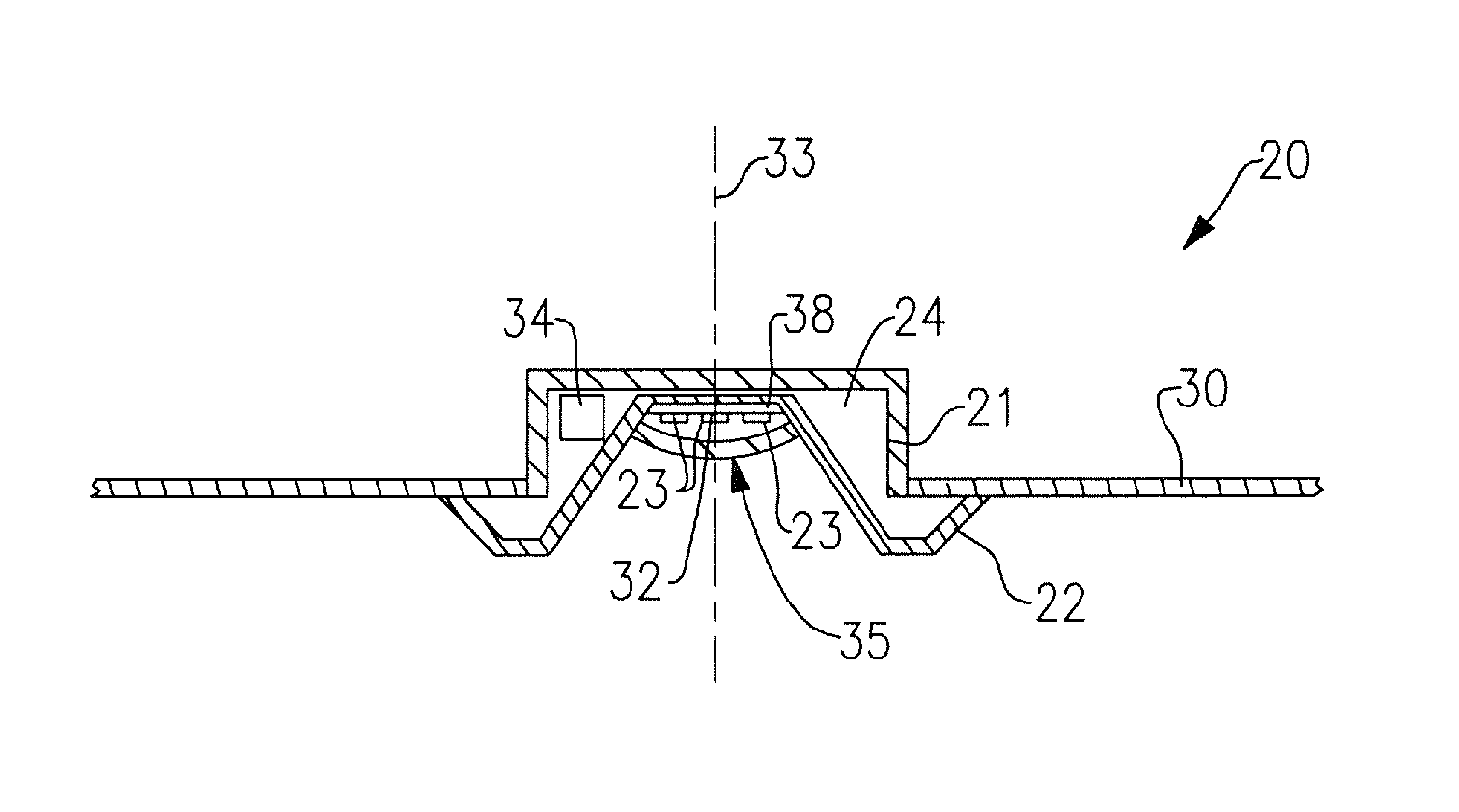

Lighting device

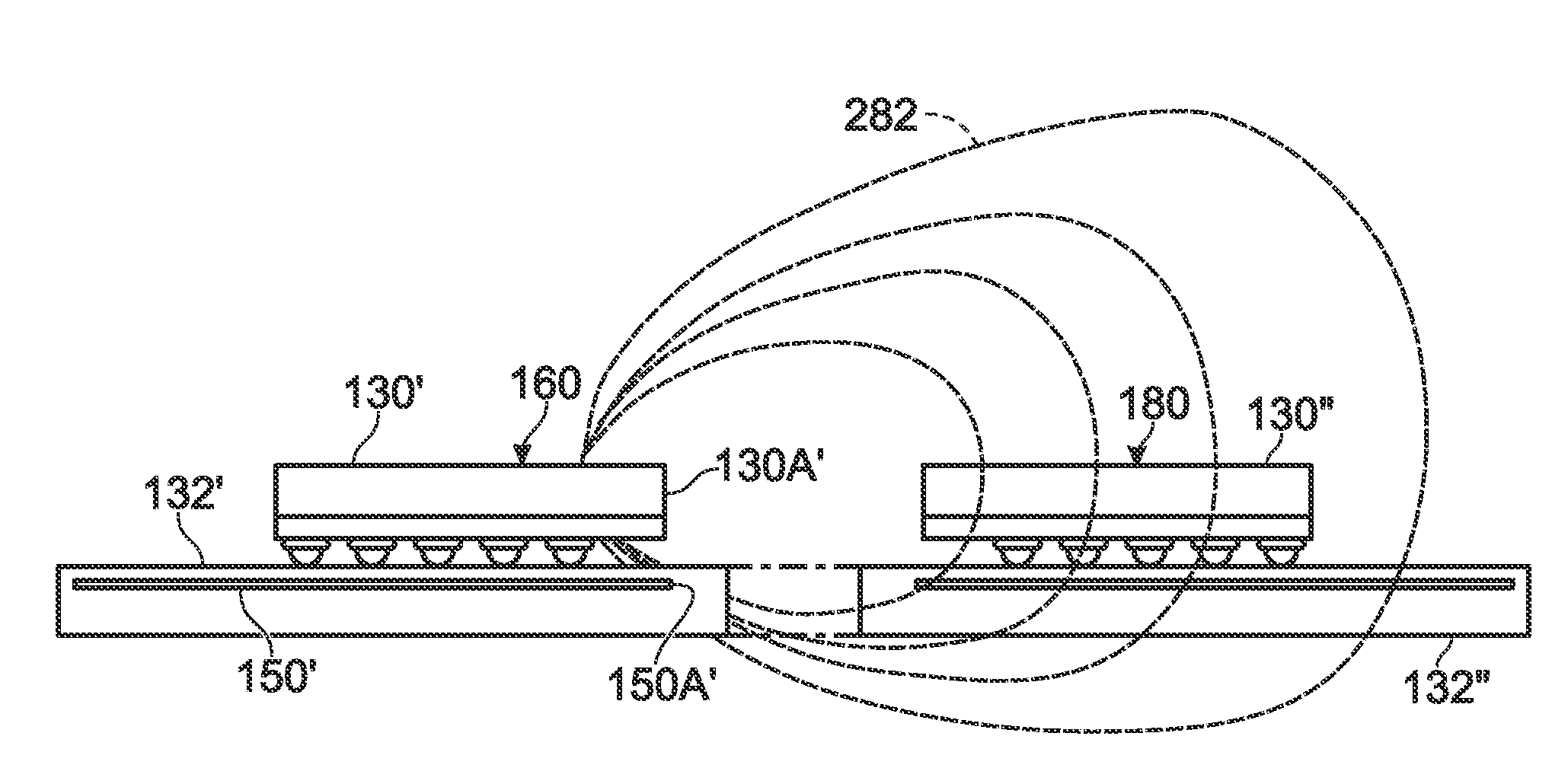

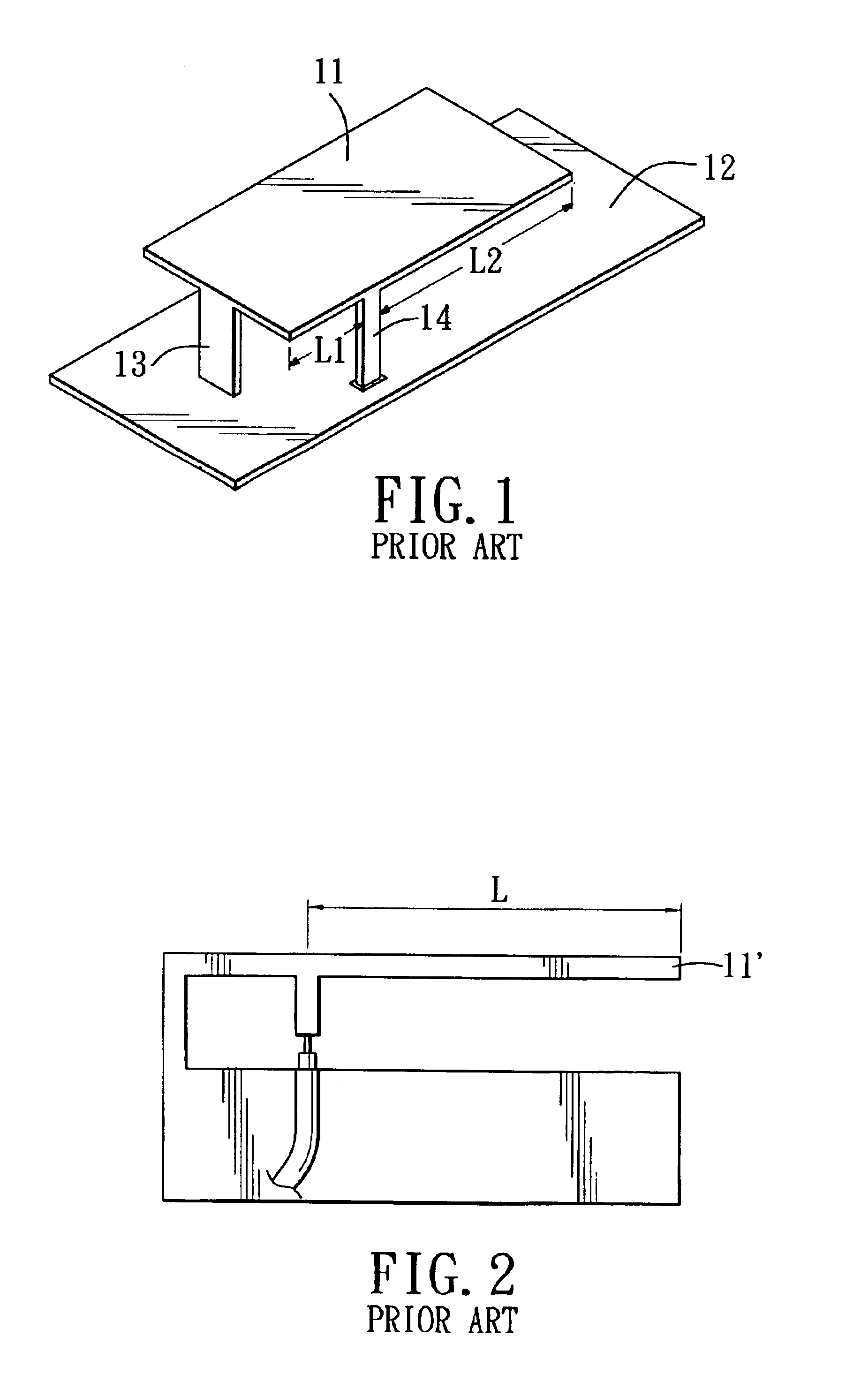

ActiveUS7614759B2Maximizing light extractionReduce probabilityPoint-like light sourceLighting elementsElement spaceEffect light

A lighting device comprising at least one solid state light emitter and at least one luminescent element spaced from the light emitter, a surface of the luminescent element being at least twice as large as the illumination surface of the light emitter. Also, a lighting device comprising at least one solid state light emitter and at least one luminescent element spaced from the light emitter, a surface of the luminescent element surface being at least twice as large as and substantially parallel to the illumination surface of the light emitter. Also, a lighting device comprising at least one solid state light emitter and at least one luminescent element spaced from the light emitter, a surface area of a projection of the luminescent element being at least twice as large as a surface area of a projection of the light emitter.

Owner:CREELED INC

Lighting device

ActiveUS20070236911A1Improve extraction efficiencyReduce probabilityPoint-like light sourceLighting heating/cooling arrangementsElement spaceEffect light

A lighting device comprising at least one solid state light emitter and at least one luminescent element spaced from the light emitter, a surface of the luminescent element being at least twice as large as the illumination surface of the light emitter. Also, a lighting device comprising at least one solid state light emitter and at least one luminescent element spaced from the light emitter, a surface of the luminescent element surface being at least twice as large as and substantially parallel to the illumination surface of the light emitter. Also, a lighting device comprising at least one solid state light emitter and at least one luminescent element spaced from the light emitter, a surface area of a projection of the luminescent element being at least twice as large as a surface area of a projection of the light emitter.

Owner:CREELED INC

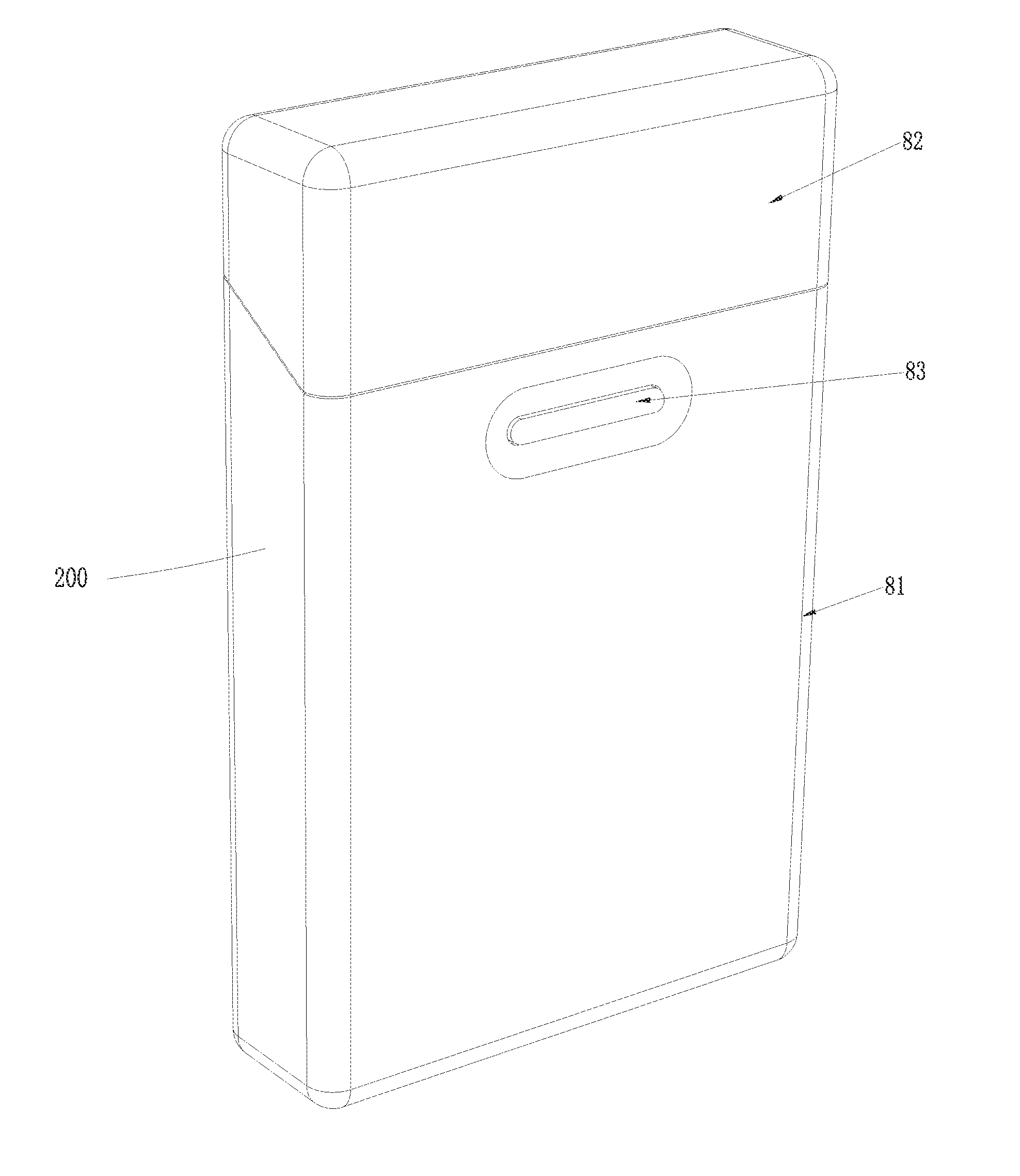

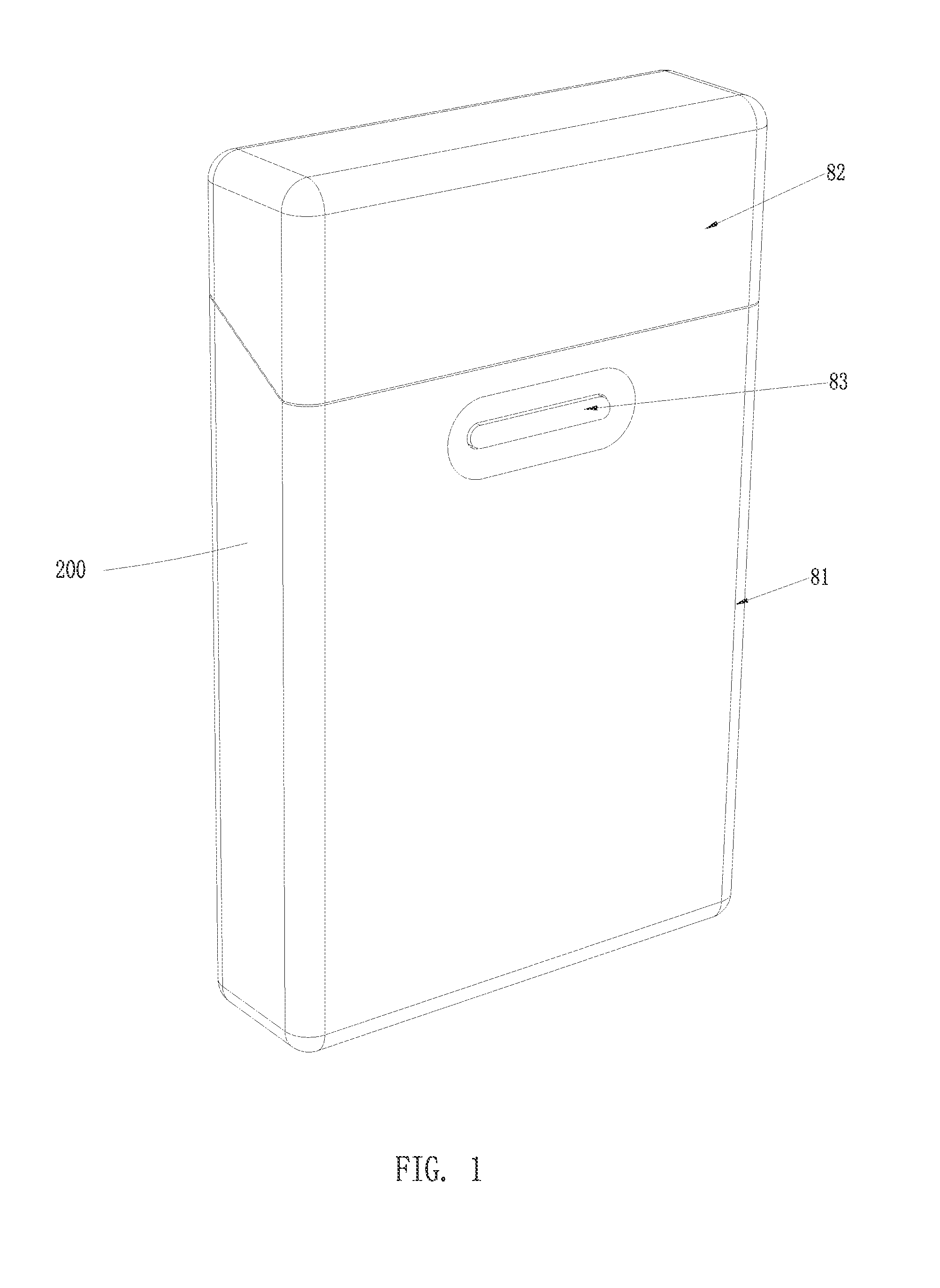

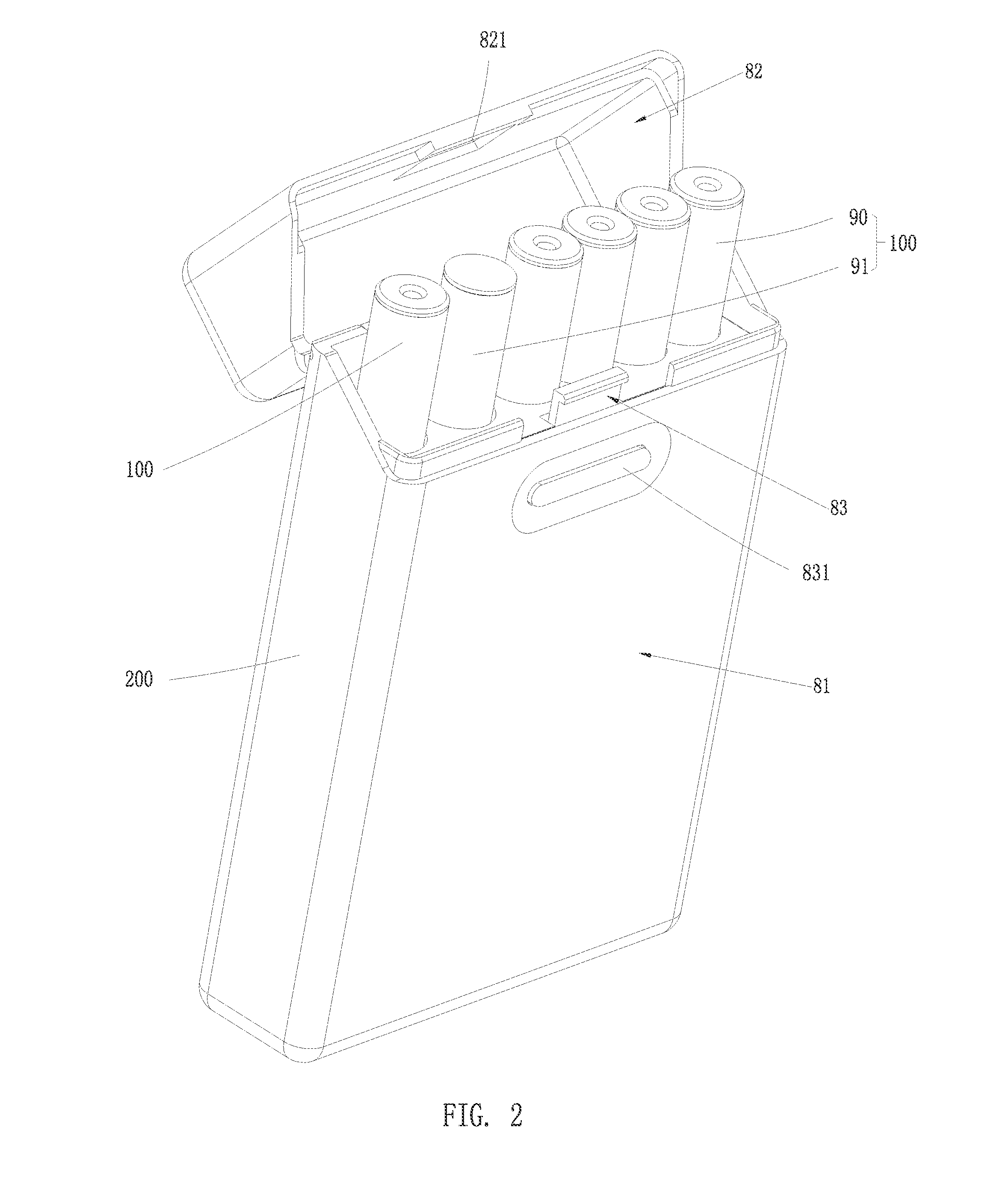

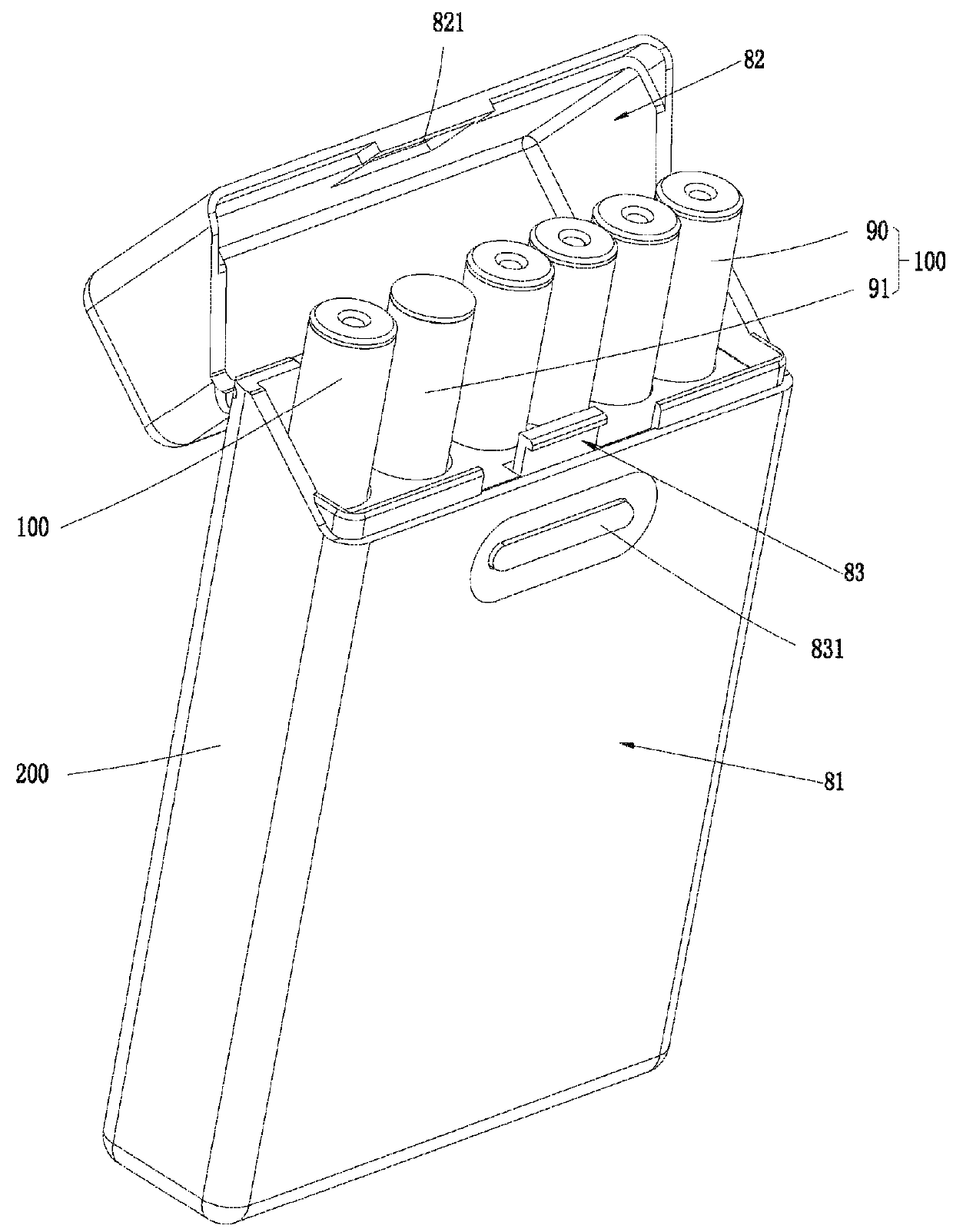

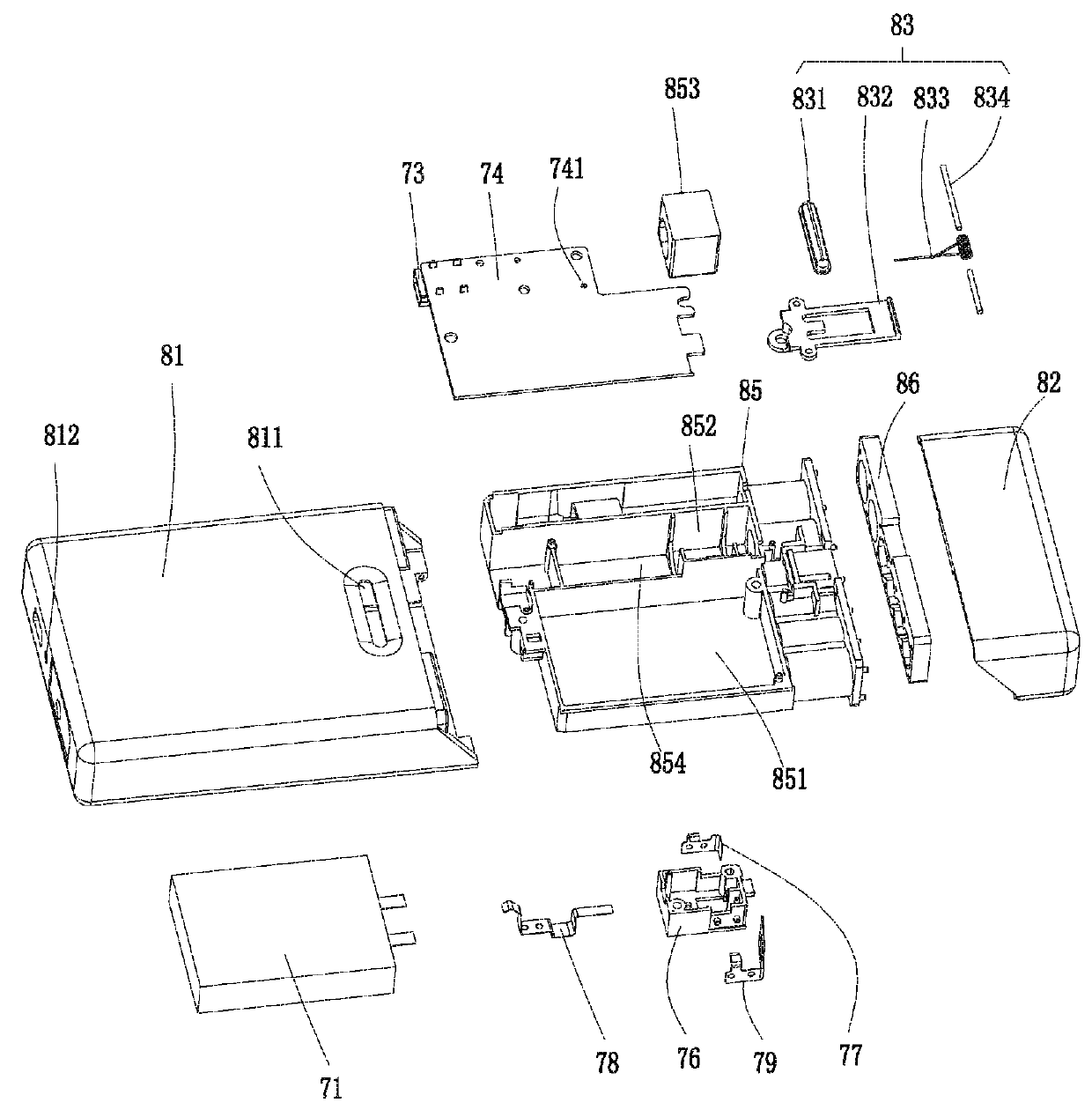

Electronic Cigarette Case

InactiveUS20130342157A1Ensure electrical connection reliabilitySimple manufacturing processBatteries circuit arrangementsTobacco pipesElement spaceElectricity

The present invention relates to an electronic cigarette case, includes a case body, a charging device disposed in the case body for charging electronic cigarettes. The charging device includes a charging base, a rechargeable battery, and a control circuit board integrated with a circuit processing unit. The charging base has an electrode support where first and second electrode elements, and a trigger element spaced apart from the second electrode element are all disposed on the electrode support. The second electrode element is flexibly deformable when one of the electronic cigarettes is inserted into the case body to create a charging circuit. The circuit processing unit automatically controls the rechargeable battery for charging the electronic cigarette being inserted until it is full of power, whereby the electronic cigarette case is readily to be assembled and to sue, and has a reliable electrical connection with an outer power source.

Owner:HUIZHOU KIMREE TECH

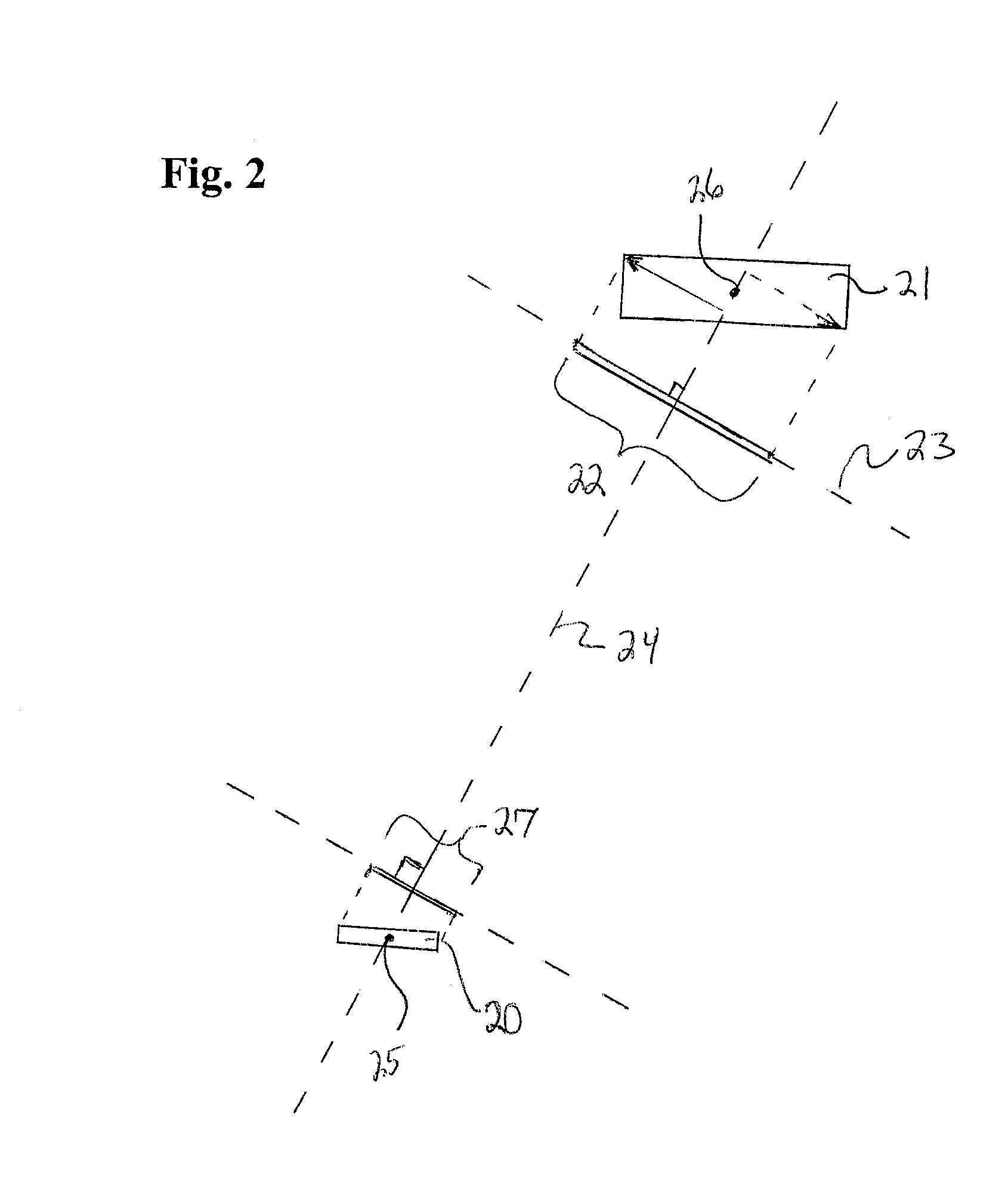

Integrated circuit with electromagnetic communication

ActiveUS20120263244A1Baseband system detailsModulated-carrier systemsElement spaceElectrical conductor

A system for transmitting or receiving signals may include an integrated circuit (IC), a transducer operatively coupled to the IC for converting between electrical signals and electromagnetic signals; and insulating material that fixes the locations of the transducer and IC in spaced relationship relative to each other. The system may further include a lead frame providing external connections to conductors on the IC. An electromagnetic-energy directing assembly may be mounted relative to the transducer for directing electromagnetic energy in a region including the transducer and in a direction away from the IC. The directing assembly may include the lead frame, a printed circuit board ground plane, or external conductive elements spaced from the transducer. In a receiver, a signal-detector circuit may be responsive to a monitor signal representative of a received first radio-frequency electrical signal for generating a control signal that enables or disables an output from the receiver.

Owner:MOLEX INC

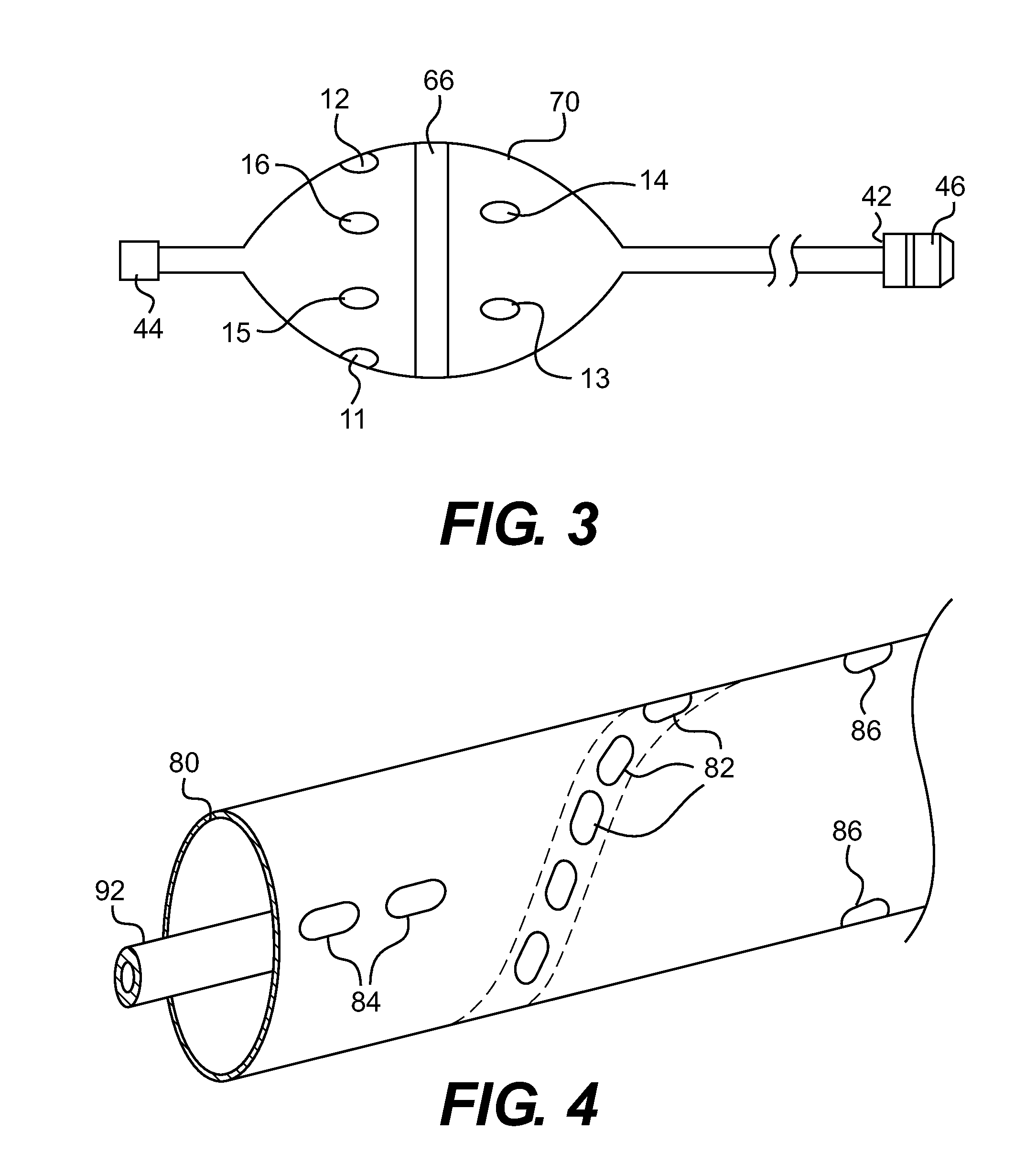

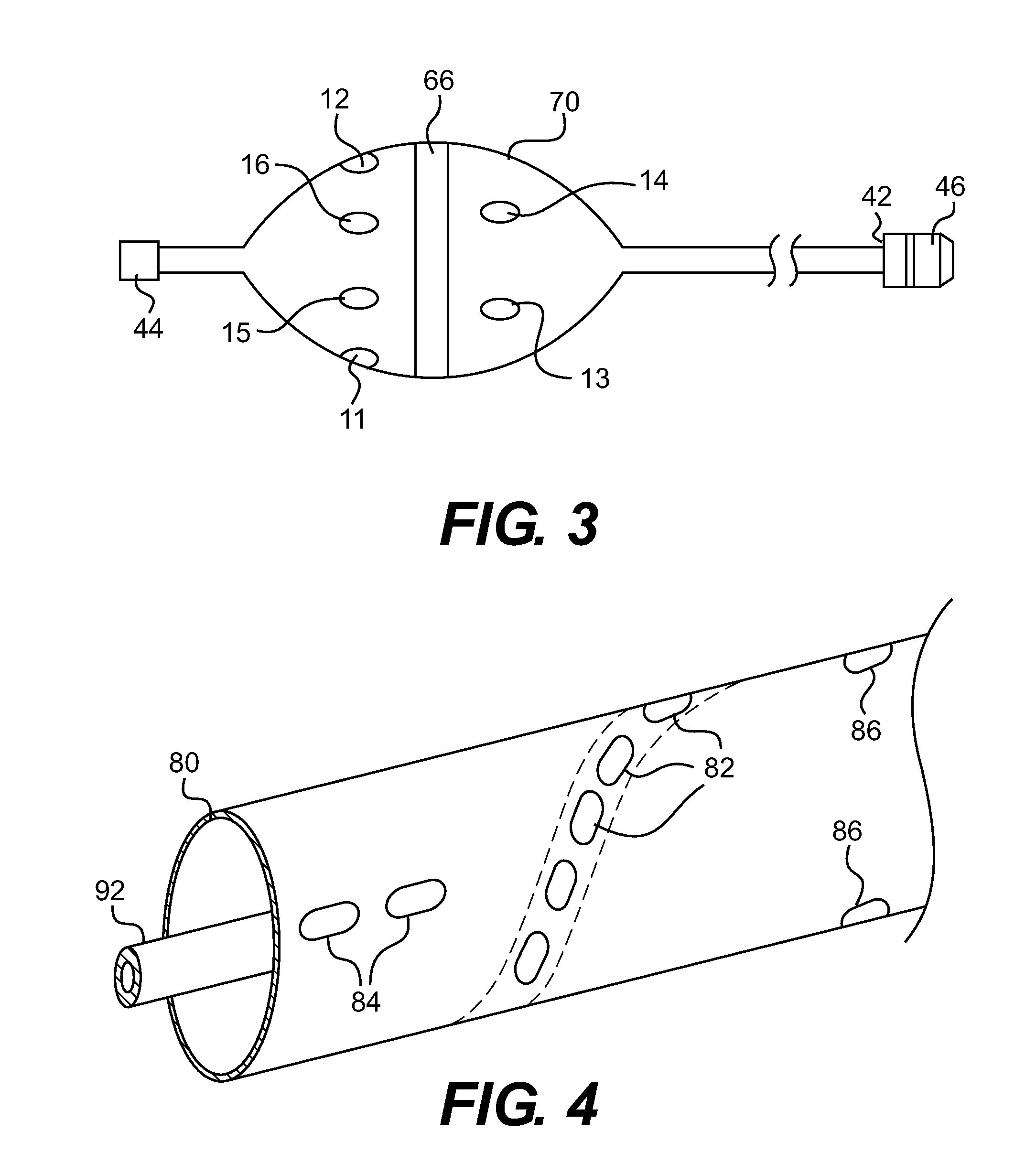

Apparatus and method of assessing transvascular denervation

ActiveUS20120296329A1Smooth connectionEnhanced signalCatheterSurgical instrument detailsElement spaceDenervation

A catheter apparatus for assessing denervation comprises: an elongated catheter body; a deployable structure coupled to the catheter body, the deployable structure being deployable outwardly from and contractible inwardly toward the longitudinal axis of the catheter body; one or more ablation elements disposed on the deployable structure to move outwardly and inwardly with the deployable structure; one or more stimulation elements spaced from each other and disposed on the deployable structure to move with the deployable structure, the stimulation elements being powered to supply nerve stimulating signals to the vessel; and one or more recording elements spaced from each other and from the stimulation elements, the recording elements being disposed on the deployable structure to move with the deployable structure, the recording elements configured to record response of the vessel to the nerve stimulating signals.

Owner:ST JUDE MEDICAL

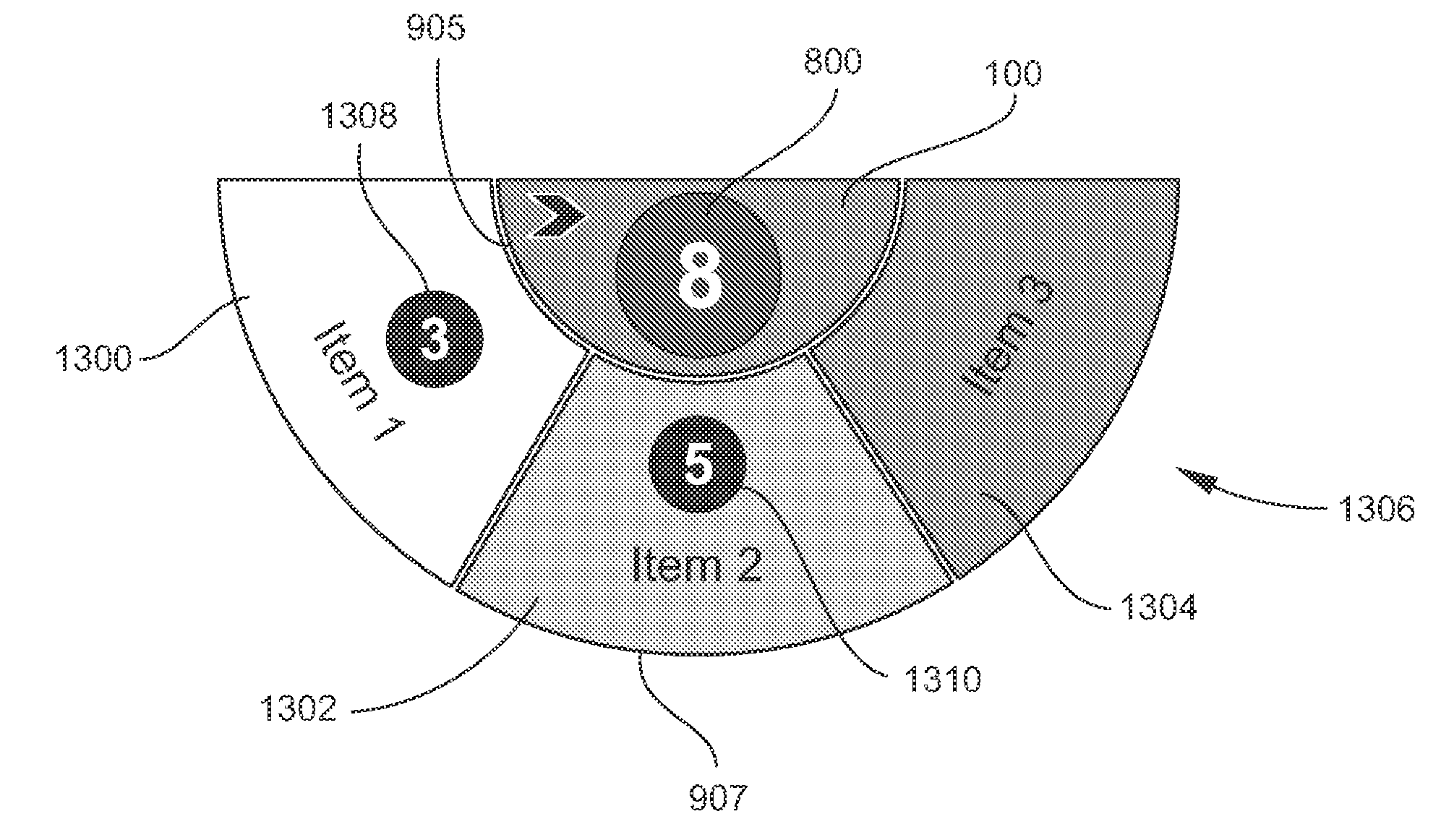

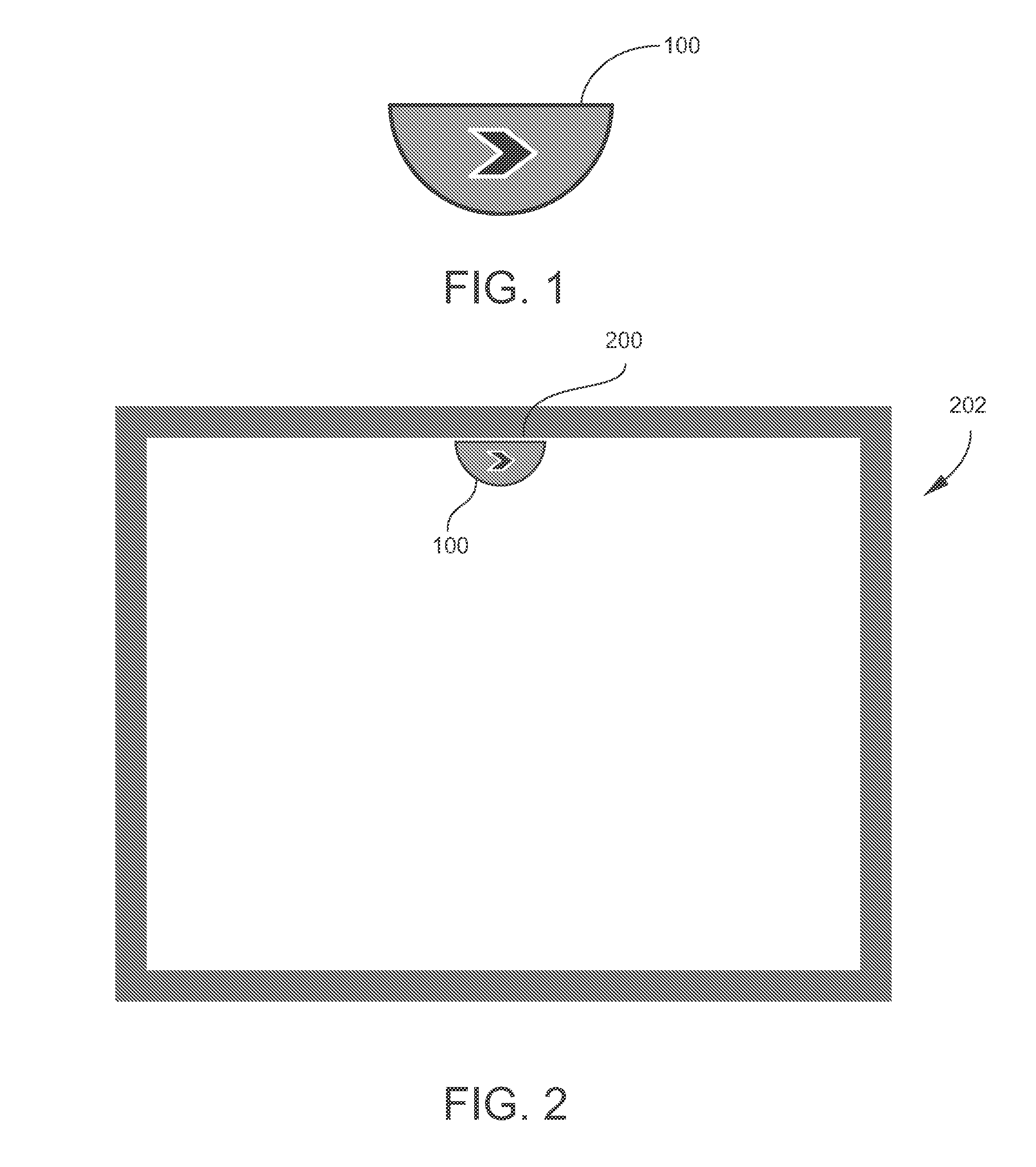

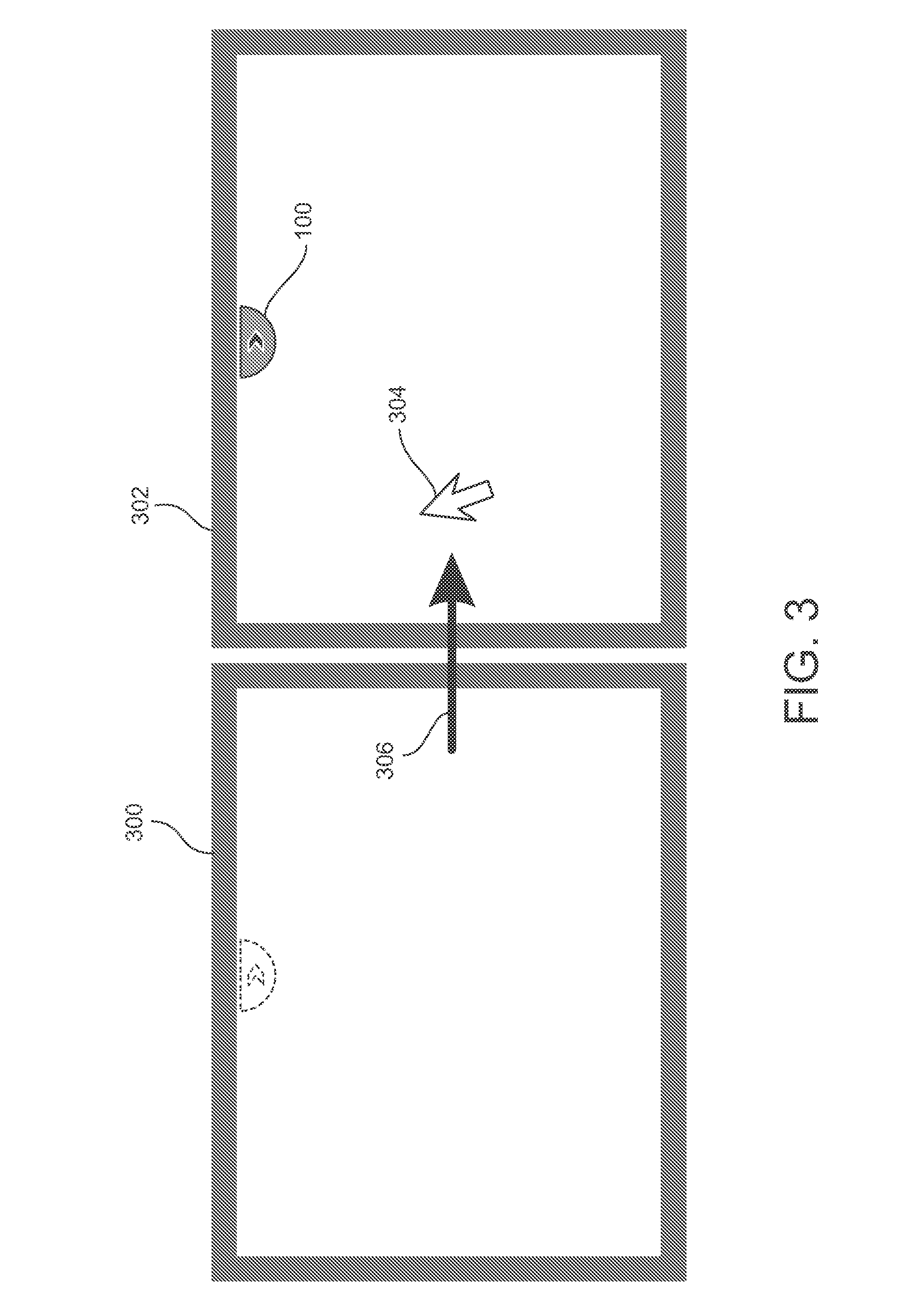

Methods and Systems for Managing a Graphical Interface

Methods and systems for managing a graphical user interface involve, for example, one or more processors displaying on a display screen a visualization of a hub element defined in part by an arc-shaped boundary portion and defining a badge element within the visualization of the hub element. Thereafter, a radial menu element may be animated by the one or more processors for rotation to a position adjacent and extending radially from the arc-shaped boundary portion of the hub element and defined in part by an arc-shaped boundary portion of the radial menu element spaced apart from the arc-shaped boundary portion of the hub element.

Owner:CITIBANK

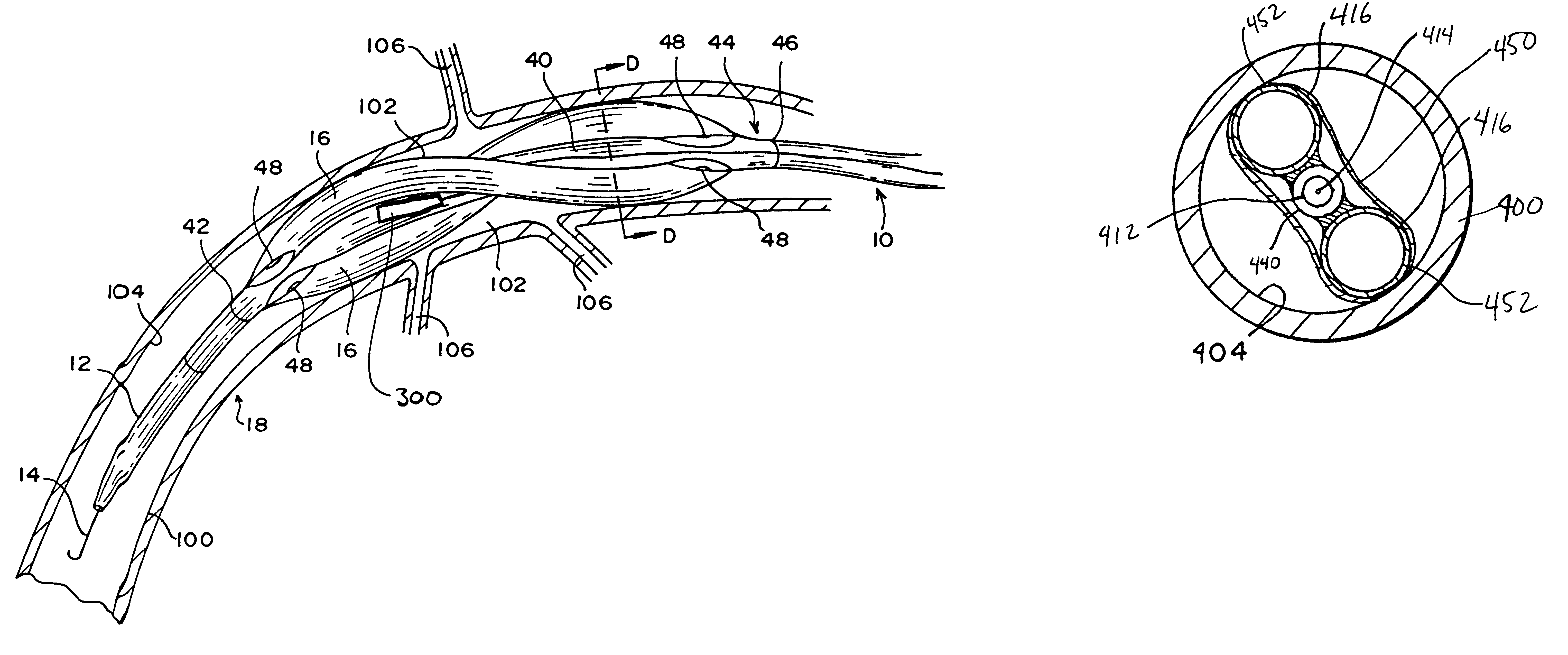

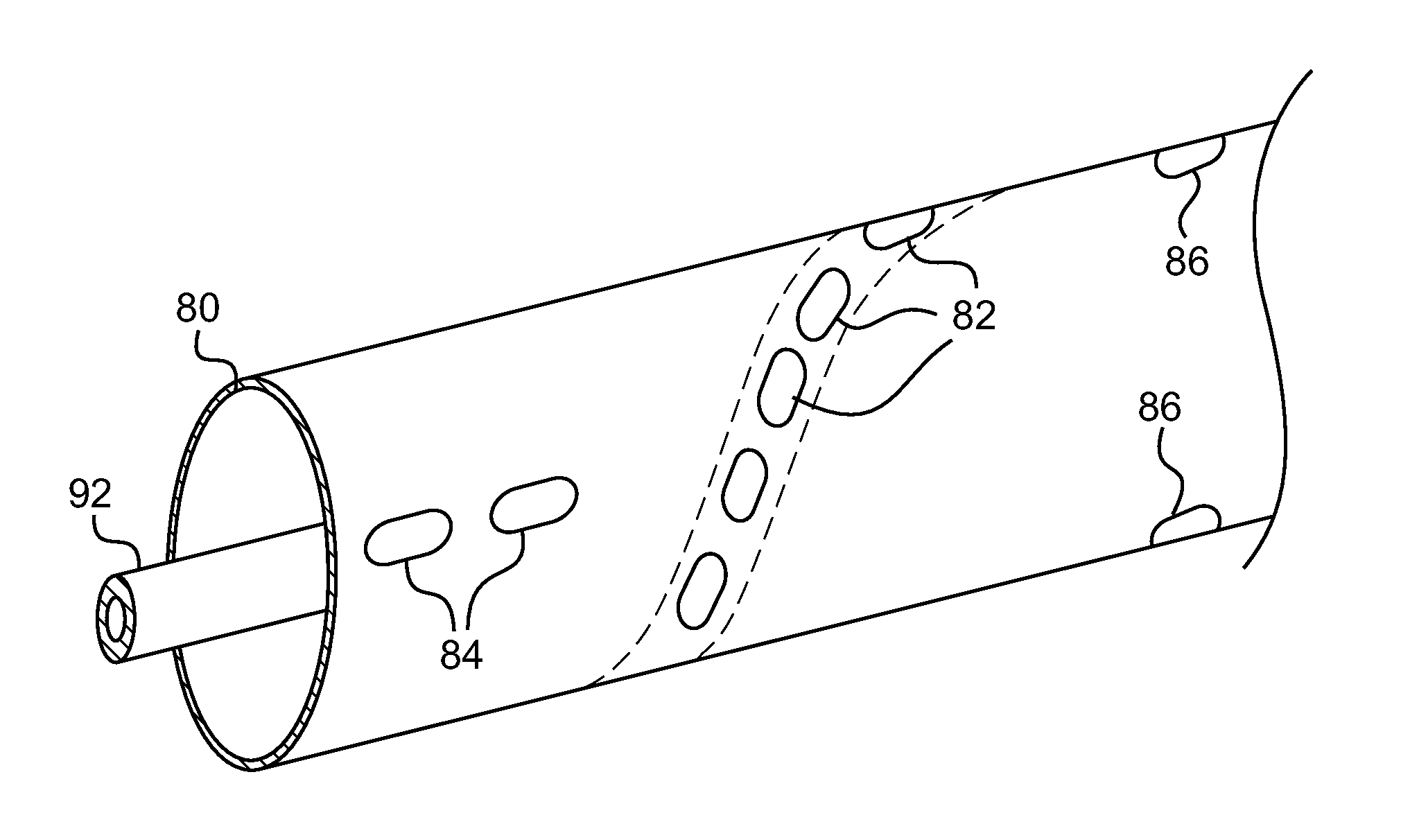

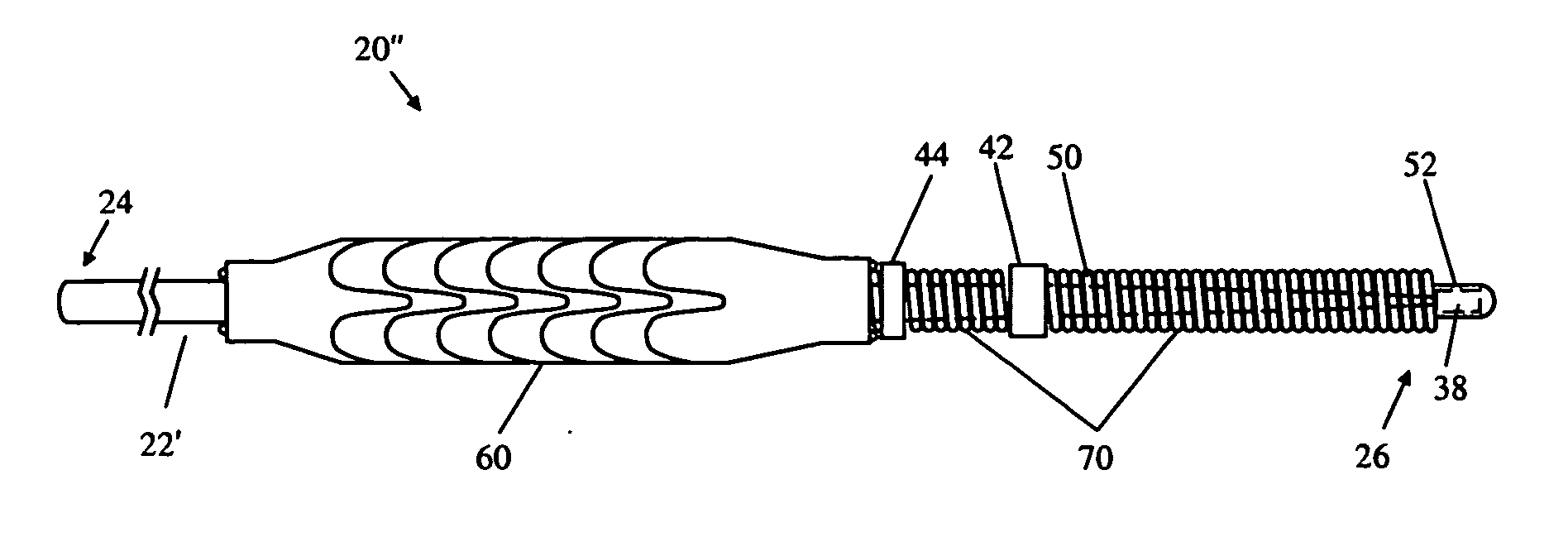

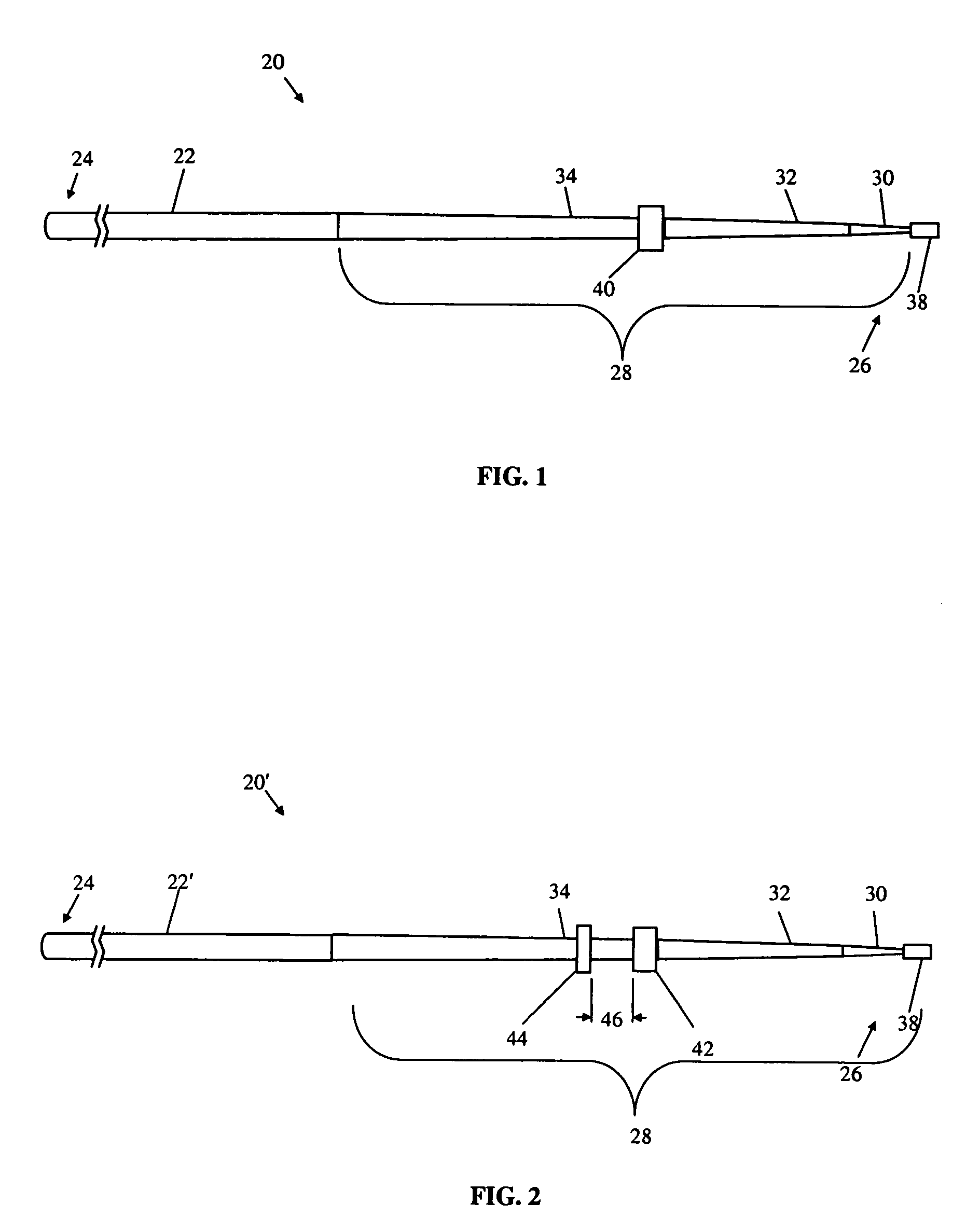

Helical spiral balloon catheter

A balloon catheter device designed to be especially well suited for use in providing medical treatment within a blood vessel, and a method for conducting such medical treatment are provided, wherein the balloon catheter has a central support tube or lumen, and has, near a distal end of the catheter, a plurality of inflatable balloon elements extending along the catheter in helical patterns, with the balloon elements spaced equidistantly around the central support tube. The catheter thus provides the ability to apply pressure, by way of the inflated balloon elements, to center the central support tube in the blood vessel, while at the same time preserving blood flow in the blood vessel past the catheter as well as in side branch blood vessels extending from the blood vessel under repair.

Owner:BERSIN ROBERT M

Multifrequency inverted-F antenna

InactiveUS6861986B2Simultaneous aerial operationsAntenna supports/mountingsElement spaceRadiating element

A multifrequency inverted-F antenna includes a radiating element having opposite first and second ends, a grounding element spaced apart from the radiating element, and an interconnecting element extending between the radiating and grounding elements and including first, second, and third parts. The first part is connected to the radiating element at a feeding point between the first and second ends. The second part is offset from the first part in a longitudinal direction, and is connected to the grounding element. The third part interconnects the first and second parts. A feeding line is connected to the interconnecting element.

Owner:WISTRON NEWEB

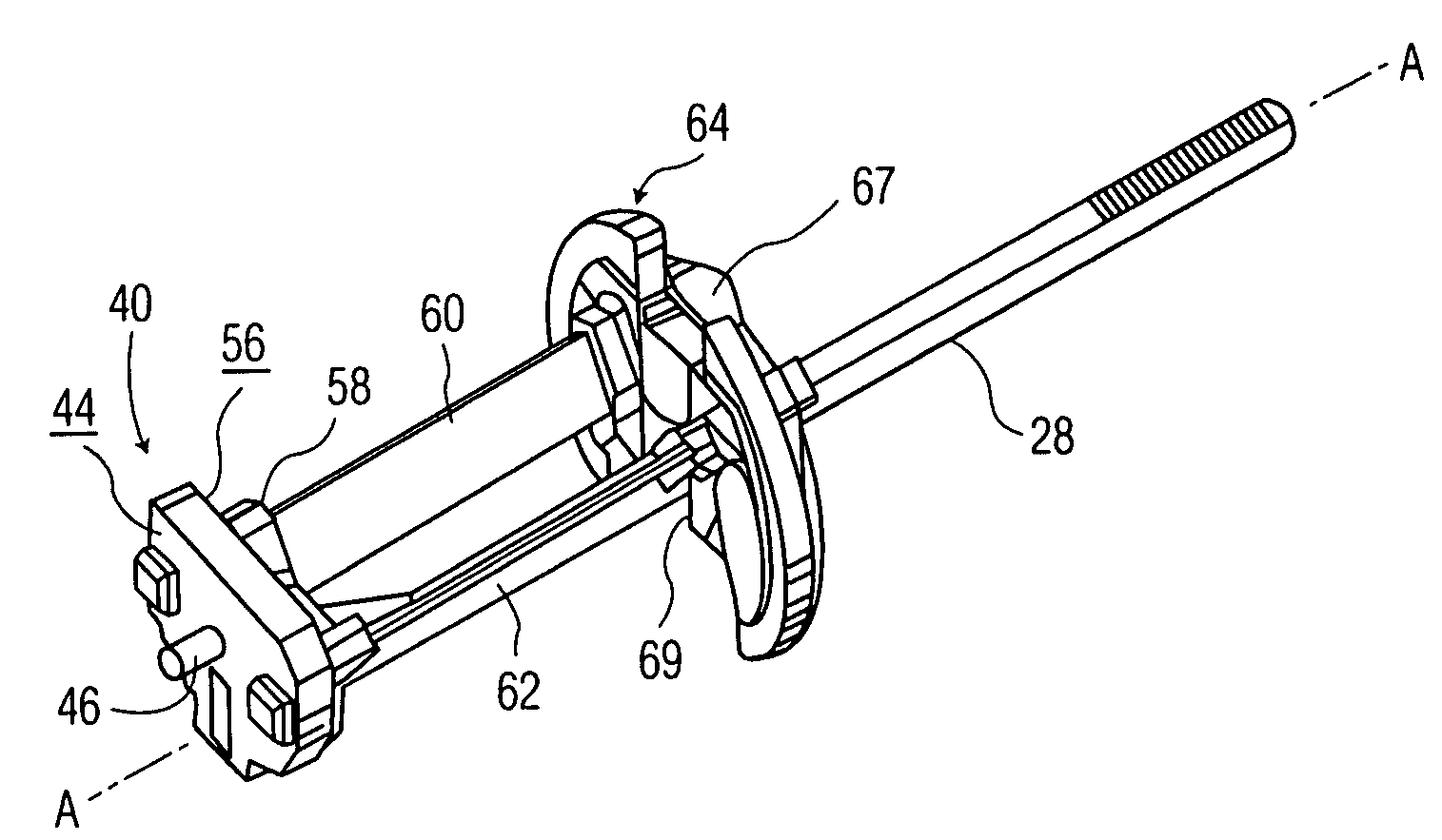

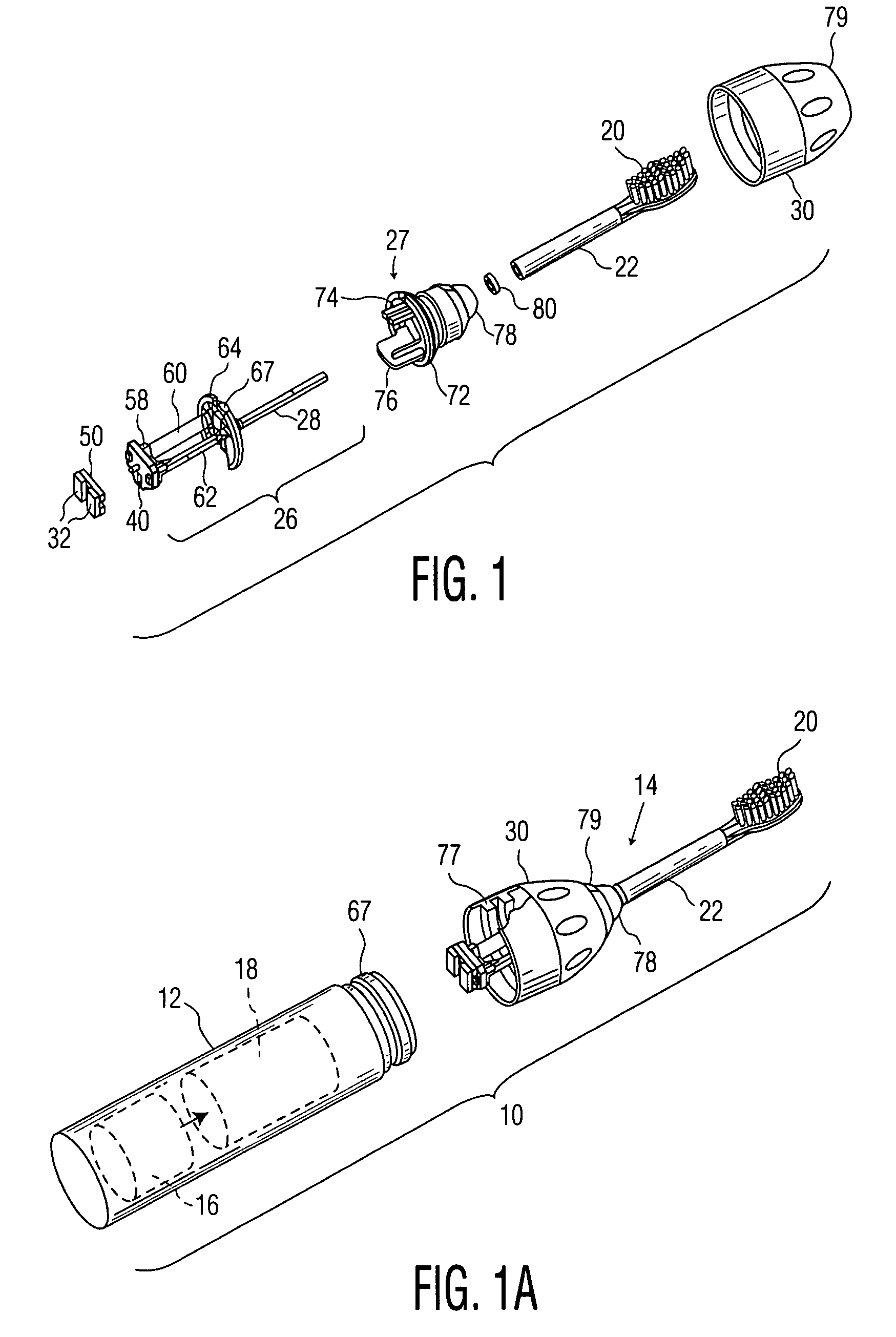

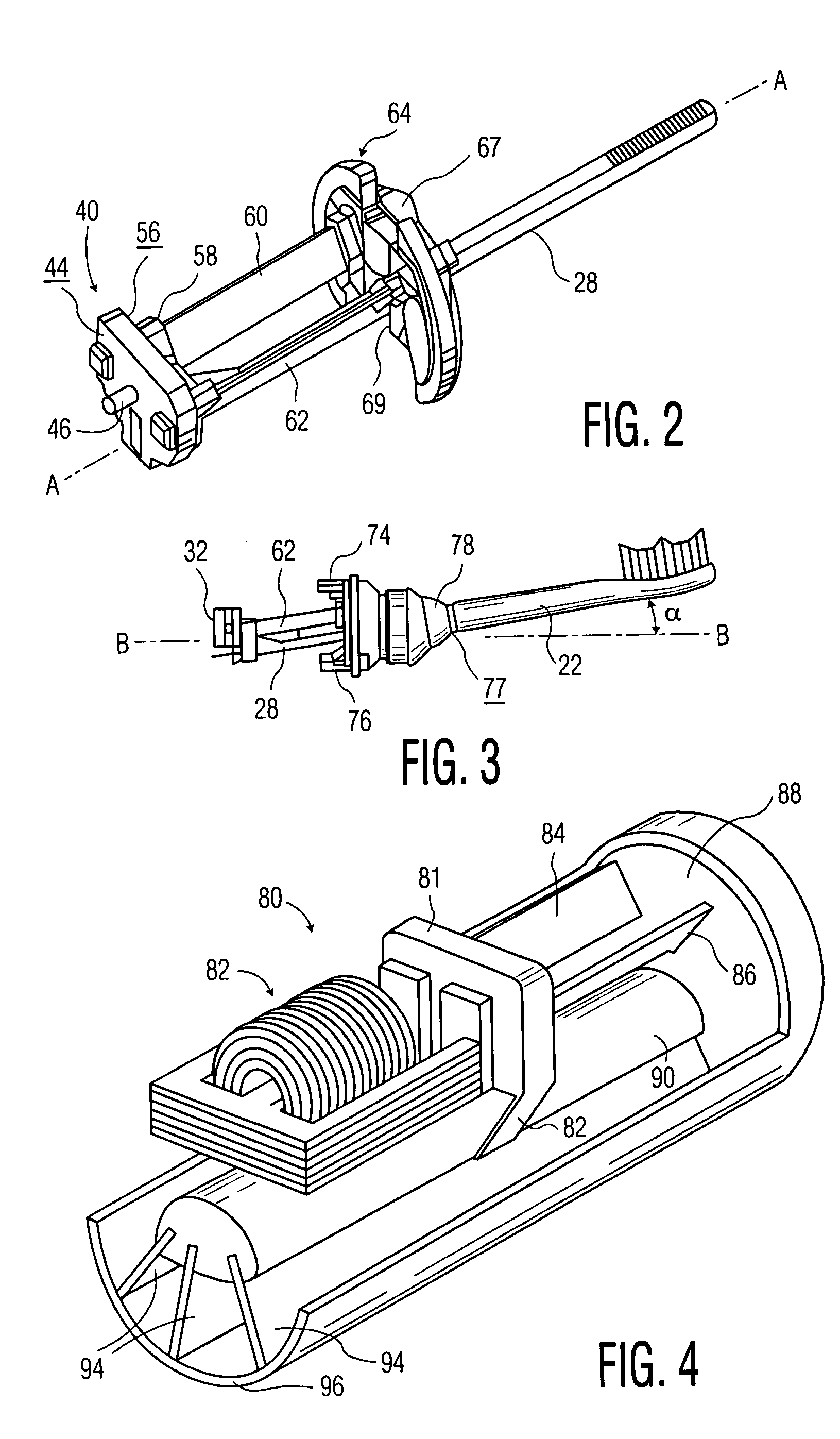

Apparatus for converting side-to-side driving motion to rotational motion with a spring assembly and system for tuning the spring assembly

The apparatus for converting side-to-side to rotational motion for a workpiece includes a spring assembly with a movable base mounting element which is driven in a slightly arcuate reciprocal side-to-side motion and a fixed mounting element spaced apart from the base element and mounted in the appliance so that it does not rotate or move in operation of the apparatus. A spring member, such as two planar leaf springs positioned at an angle to each other, is mounted between the movable base element and the fixed mounting element. A drive shaft member extends from the movable base element through the fixed mounting element and beyond. A workpiece such as a brushhead is mounted on the distal end of the drive shaft. The spring member is configured so that it is substantially less resistant to twisting action than bending action, such that the side-to-side motion of the base element results in rotation of the workpiece.A method for tuning resonant spring assembly systems used in appliances such as power toothbrushes, particularly leaf spring systems, includes the step of measuring the frequency-dependent amplitude of the appliance workpiece, and then removing a portion of the spring member so as to decrease its spring rate sufficiently that the resonant frequency of the spring member closely approximates the drive frequency of the appliance.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

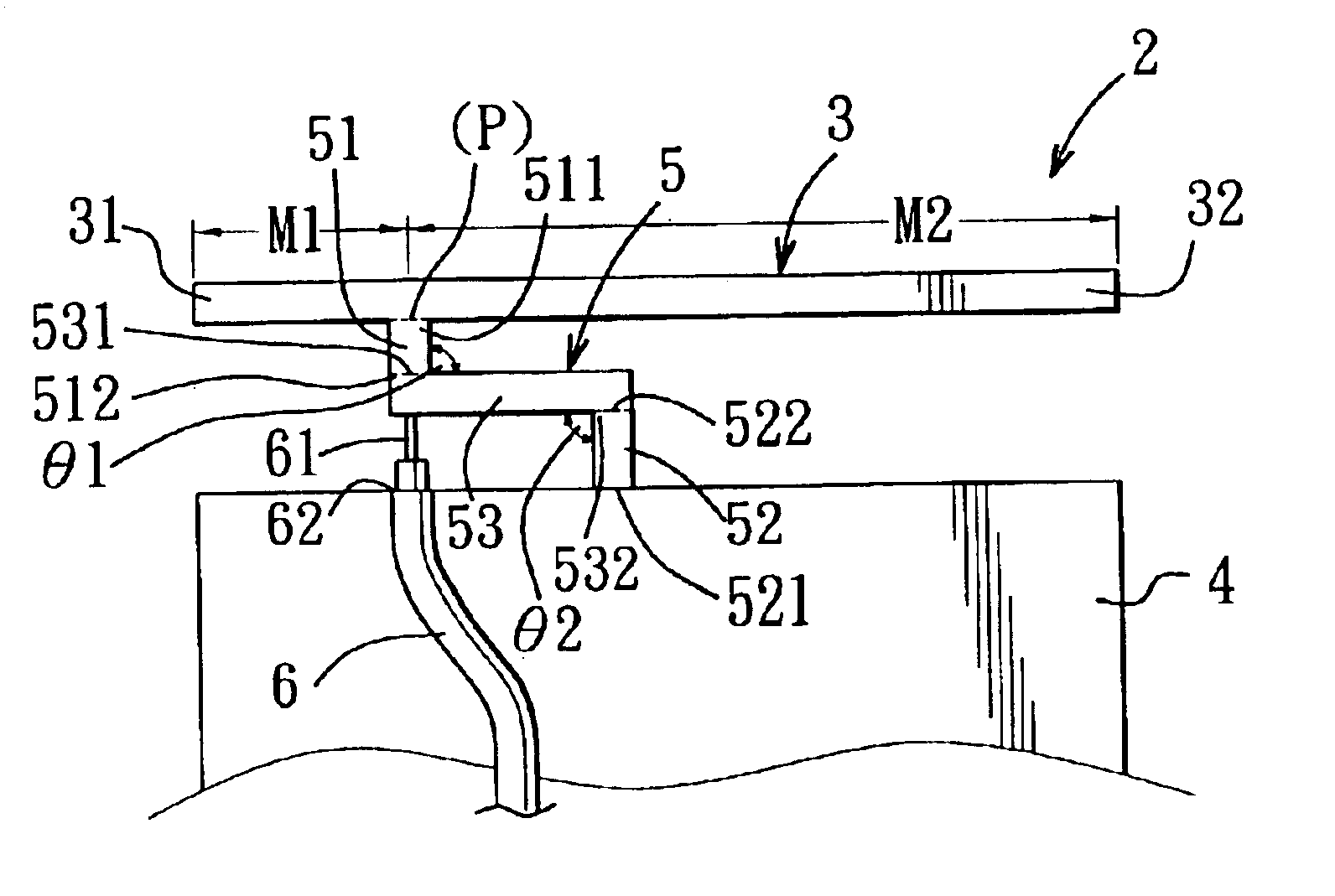

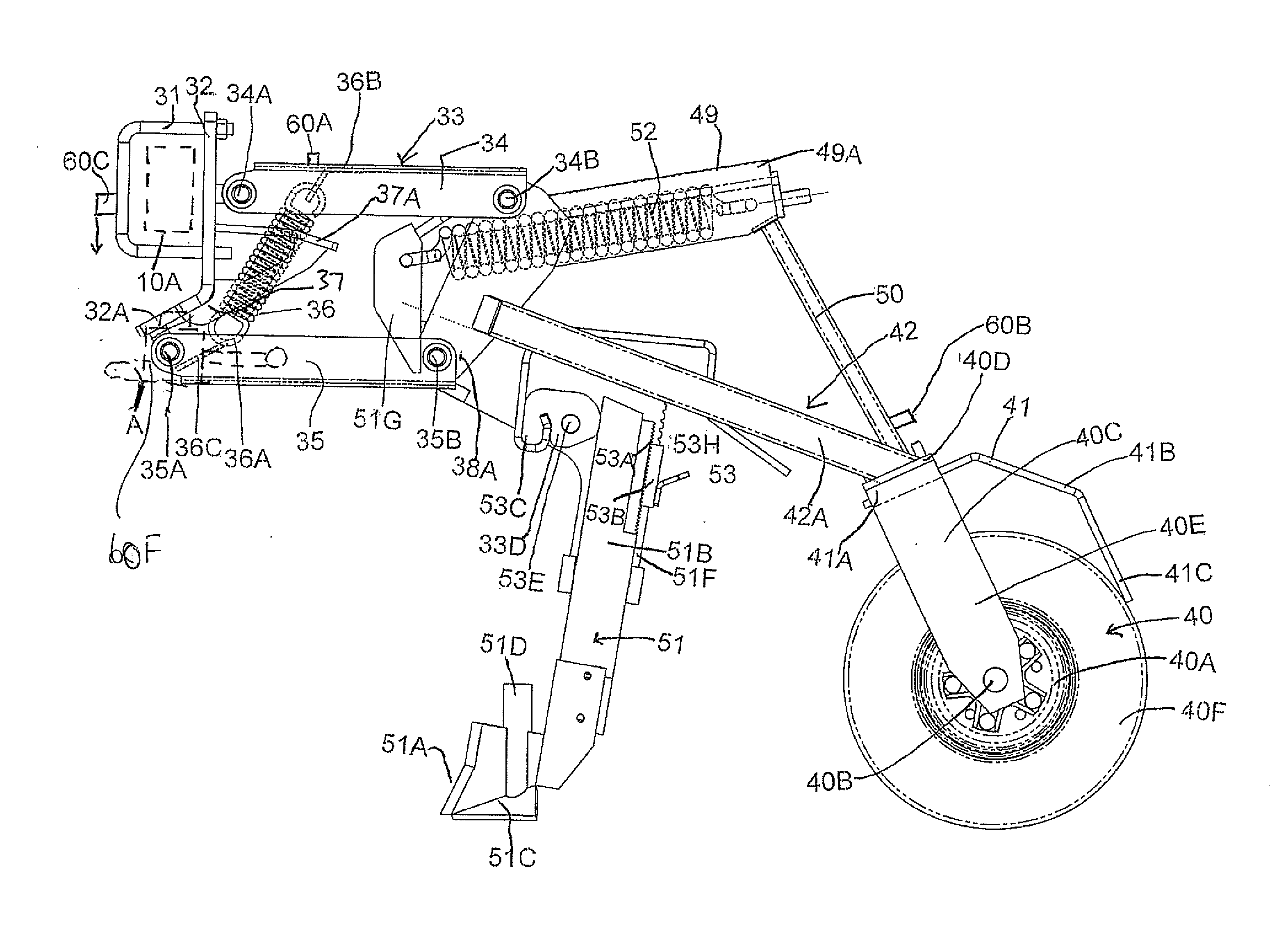

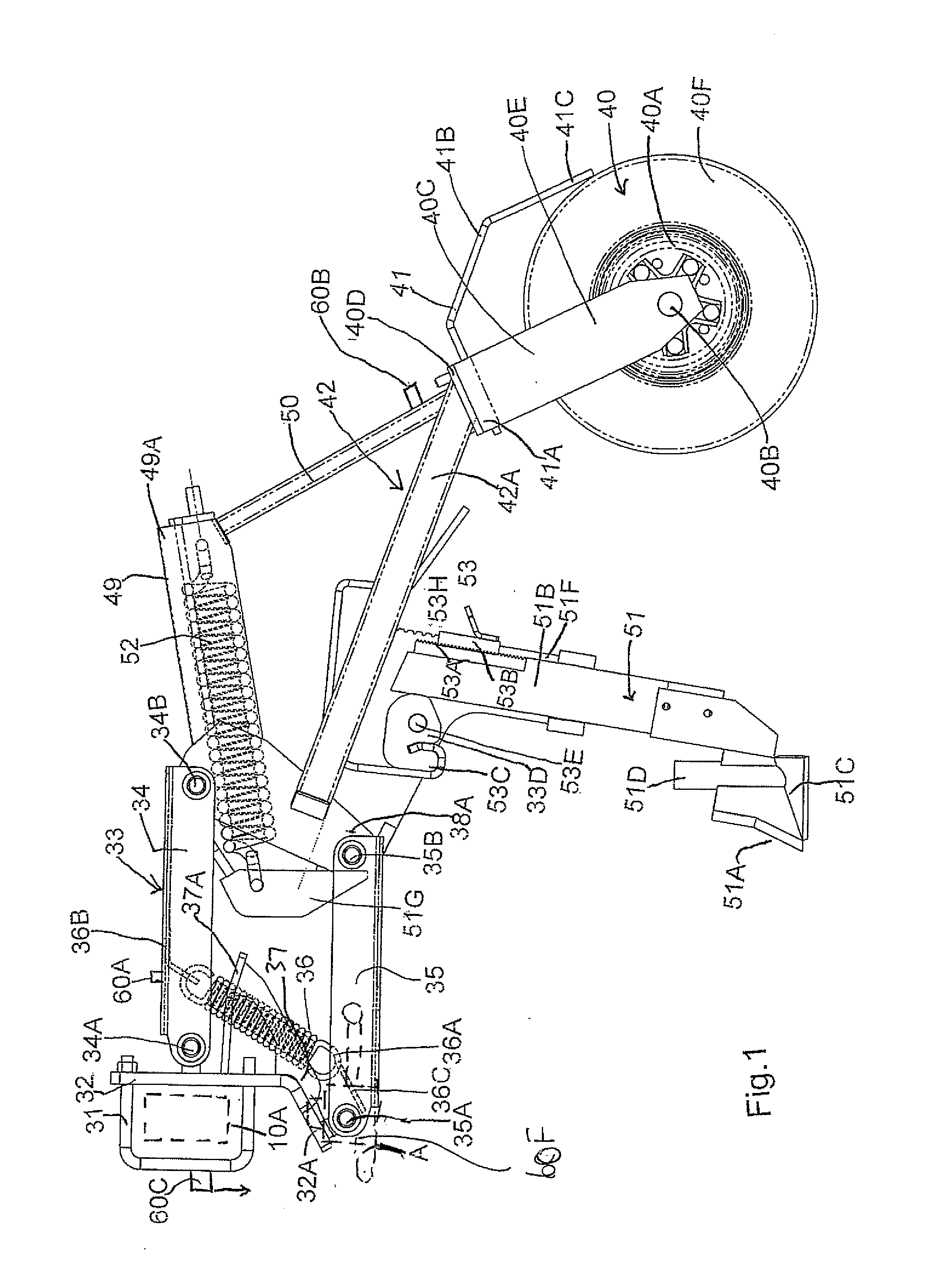

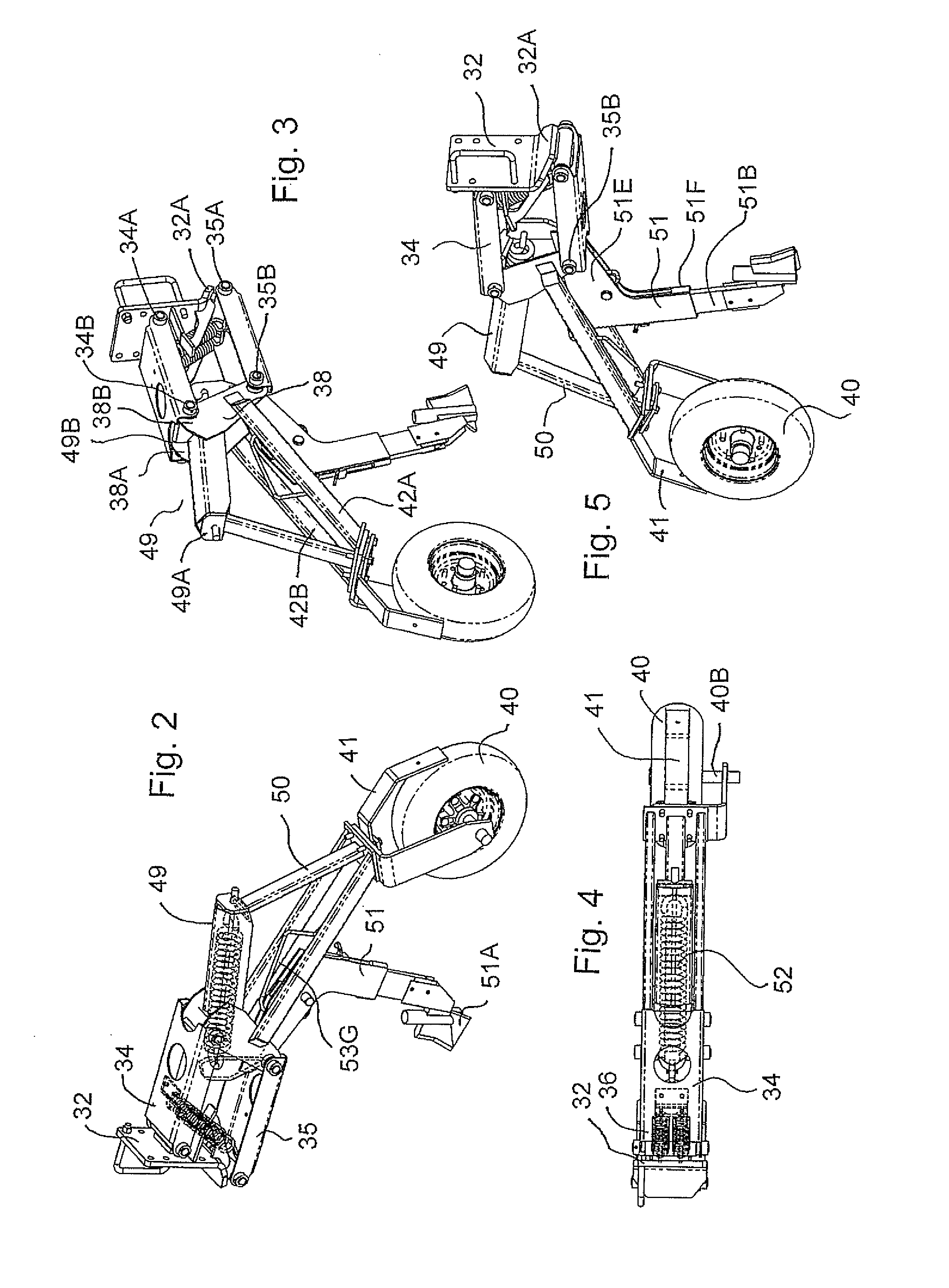

Tool Control System for Agricultural Seeders

A seeder includes a frame on ground wheels defining tool bars for seeding elements spaced across the frame. Each element includes a pair of parallel arms connected to the tool bar bracket forming a parallel linkage for up and down movement of a support arm connected at a rear end and carrying the packer wheel. A spring applies a downward spring force on the parallel linkage to apply a downward force on the packer wheel so that the spring force increases as the parallel arms pivot upwardly and decreases as the parallel arms pivot downwardly. A control device is arranged to raise and lower the tool bar in response to a detected value of a sensor so as to change the angle of the parallel linkage and change the spring force. A cam controlled double rack adjustment of the height of the opener allows the user to change seeding depth.

Owner:BUHLER EZEE ON

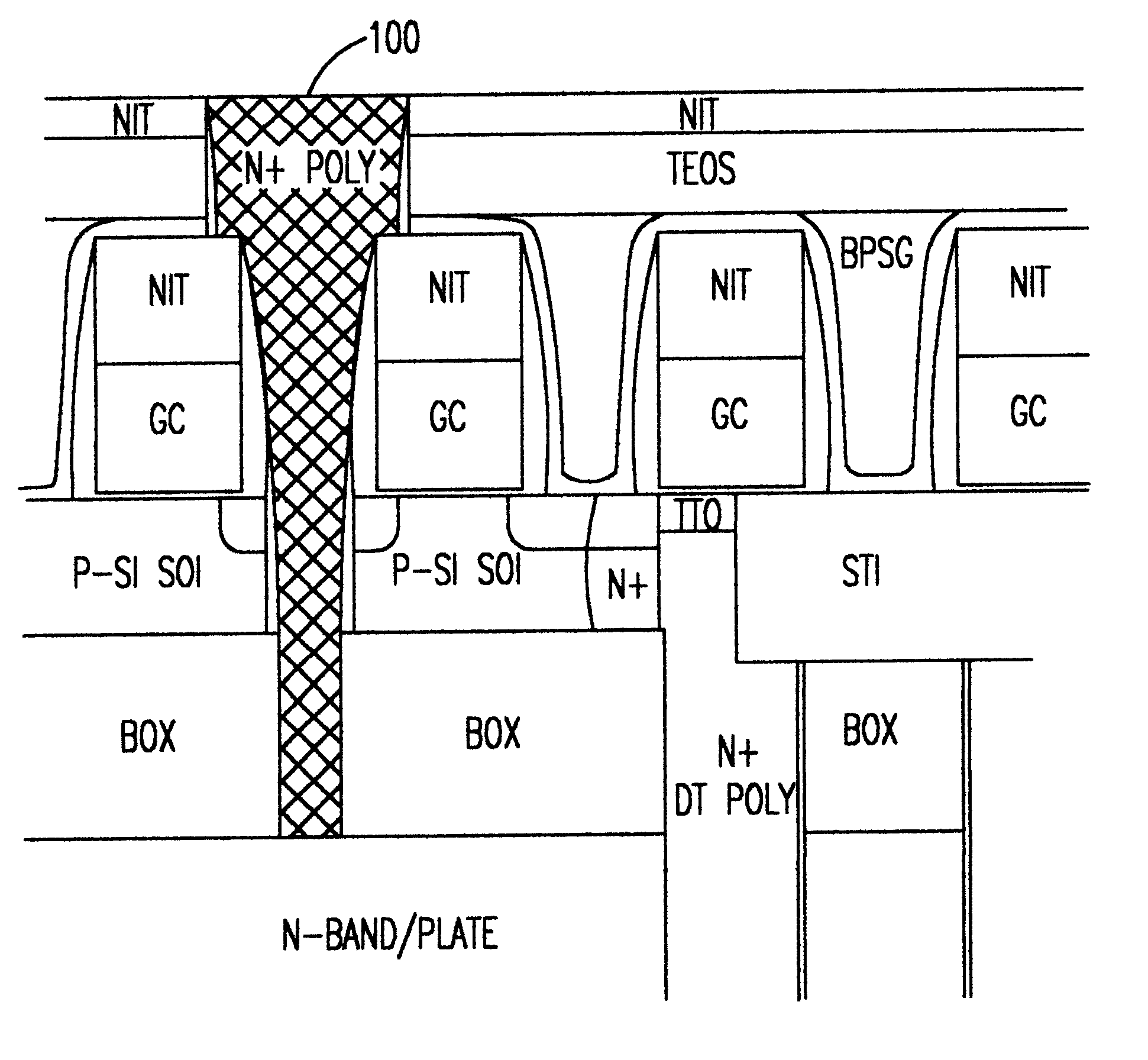

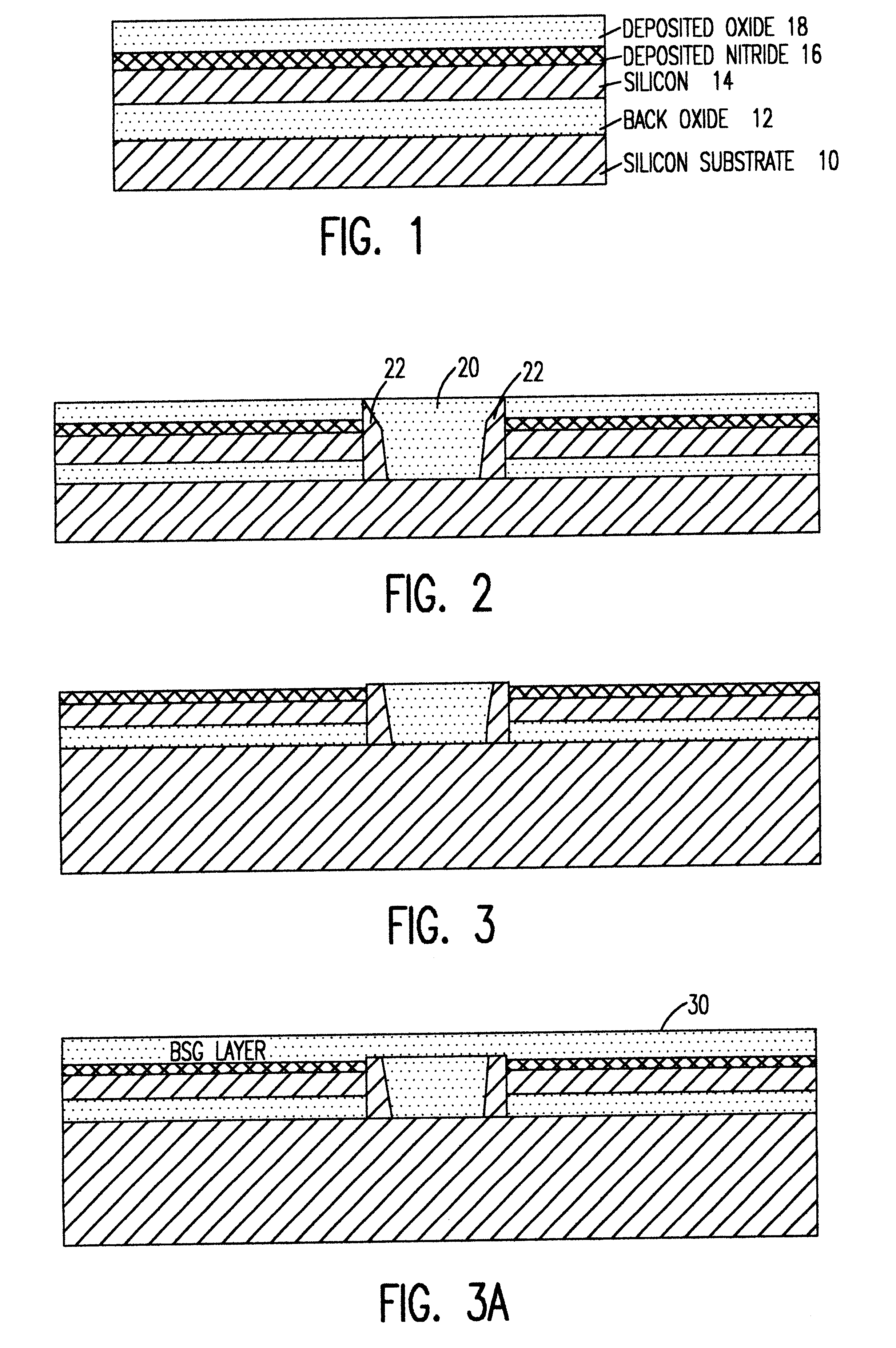

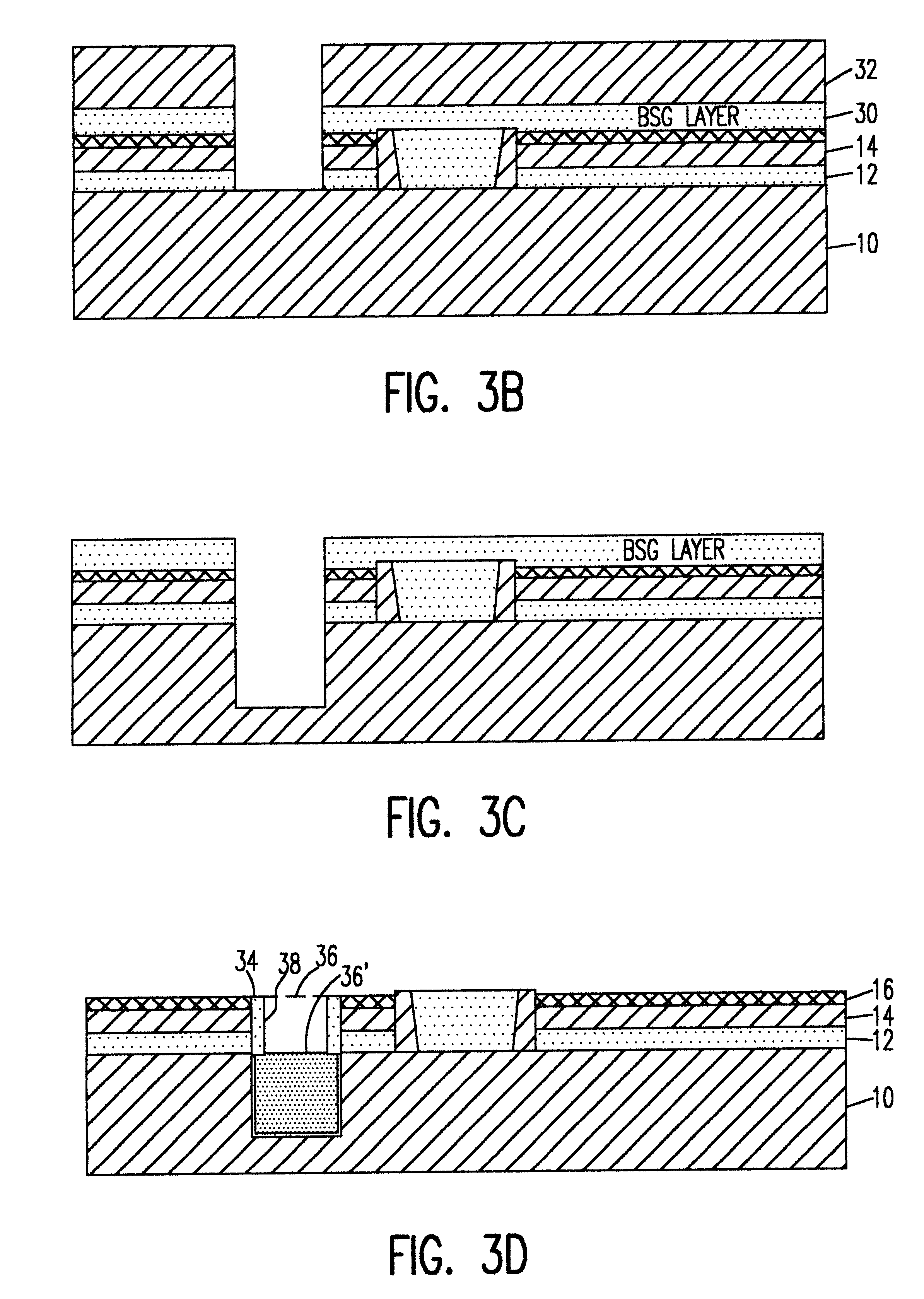

Structures and methods of anti-fuse formation in SOI

InactiveUS6396121B1Low programming voltage and currentReduce thermal effectsTransistorSemiconductor/solid-state device detailsDielectricElement space

An anti-fuse structure that can be programmed at low voltage and current and which potentially consumes very little chip spaces and can be formed interstitially between elements spaced by a minimum lithographic feature size is formed on a composite substrate such as a silicon-on-insulator wafer by etching a contact through an insulator to a support semiconductor layer, preferably in combination with formation of a capacitor-like structure reaching to or into the support layer. The anti-fuse may be programmed either by the selected location of conductor formation and / or damaging a dielectric of the capacitor-like structure. An insulating collar is used to surround a portion of either the conductor or the capacitor-like structure to confine damage to the desired location. Heating effects voltage and noise due to programming currents are effectively isolated to the bulk silicon layer, permitting programming during normal operation of the device. Thus the potential for self-repair without interruption of operation is realized.

Owner:IBM CORP

Apparatus and method of assessing transvascular denervation

A catheter apparatus for assessing denervation comprises: an elongated catheter body; a deployable structure coupled to the catheter body, the deployable structure being deployable outwardly from and contractible inwardly toward the longitudinal axis of the catheter body; one or more ablation elements disposed on the deployable structure to move outwardly and inwardly with the deployable structure; one or more stimulation elements spaced from each other and disposed on the deployable structure to move with the deployable structure, the stimulation elements being powered to supply nerve stimulating signals to the vessel; and one or more recording elements spaced from each other and from the stimulation elements, the recording elements being disposed on the deployable structure to move with the deployable structure, the recording elements configured to record response of the vessel to the nerve stimulating signals.

Owner:ST JUDE MEDICAL

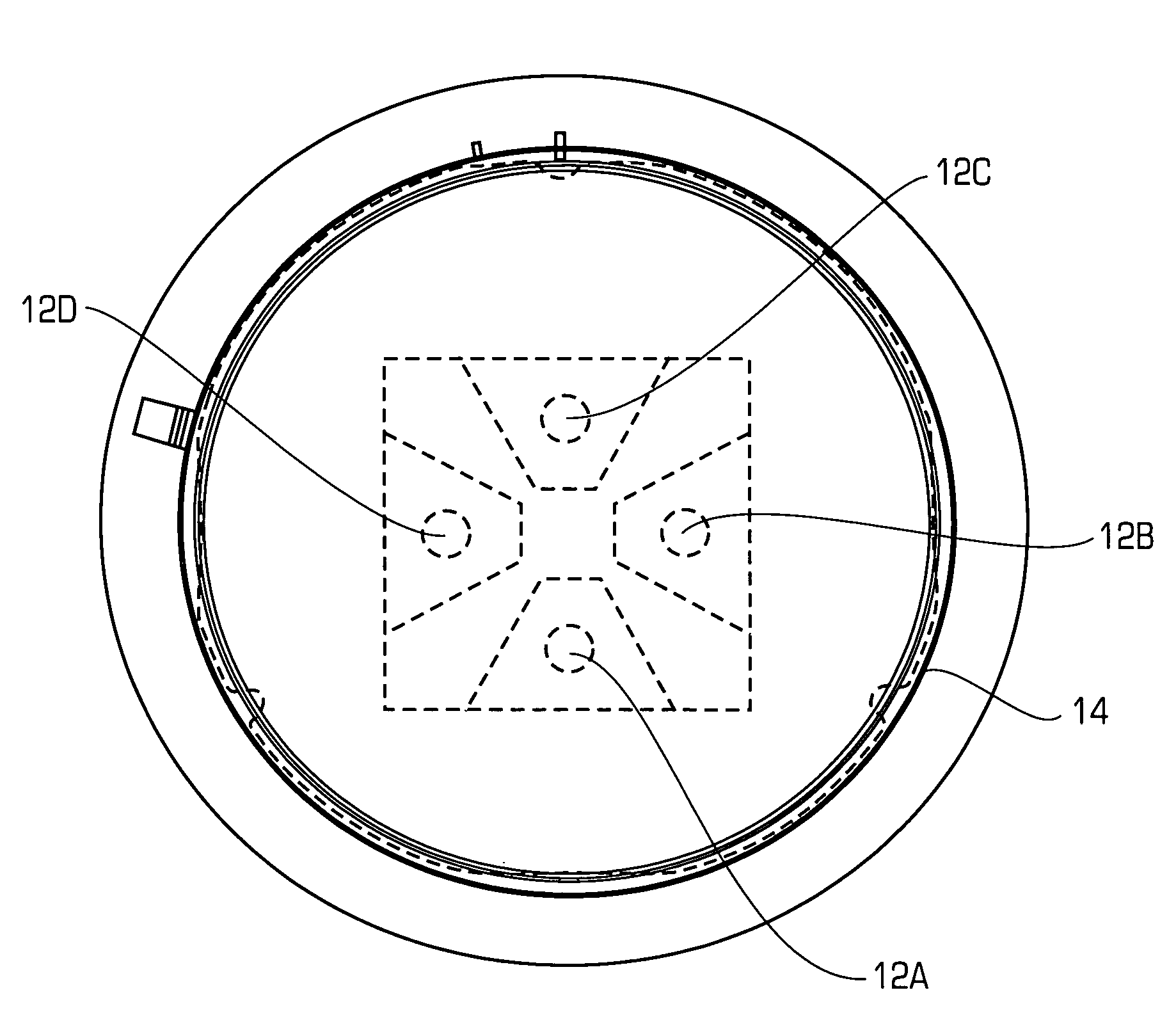

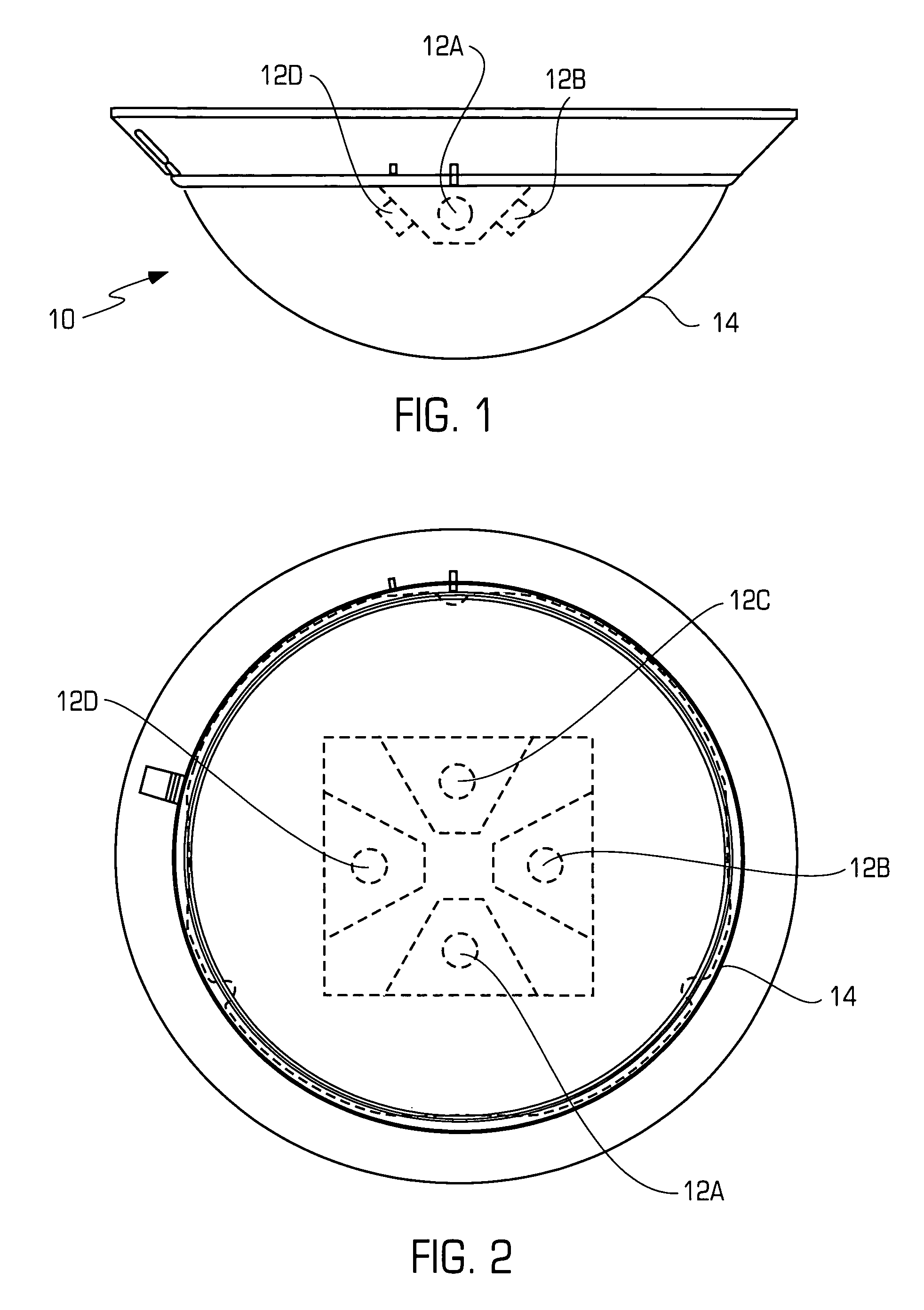

Lighting device and method of installing light emitter

ActiveUS9151457B2Reduce and eliminate needImprove energy efficiencyNon-electric lightingPoint-like light sourceElement spaceEffect light

A lighting device comprising a junction box, a trim element and a solid state light emitter, at least a portion of a space defined by regions of the trim element within a space defined by regions of the junction box, the light emitter within the trim element space. A lighting device comprising a trim element (with at least two regions) and a solid state light emitter, in which at least a first part of the first region can be positioned in a first space with the second region outside the first space, the light emitter within the first part. A lighting device, comprising a trim element (which comprises at least two regions), part of an exterior of which defines a first space, at least a first part of the first region within the first space, a solid state light emitter within the first part. Methods of installing a light emitter.

Owner:IDEAL IND LIGHTING LLC

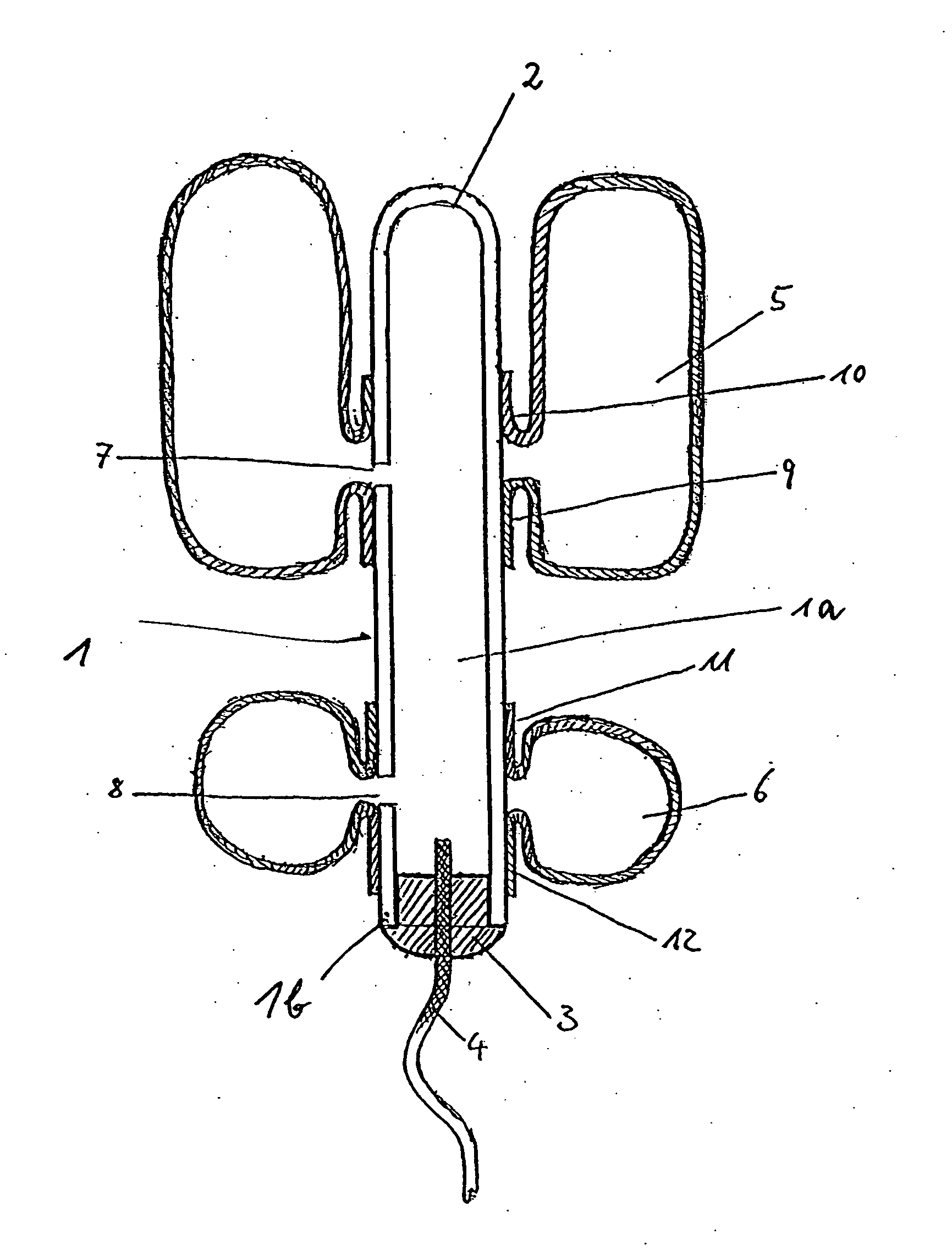

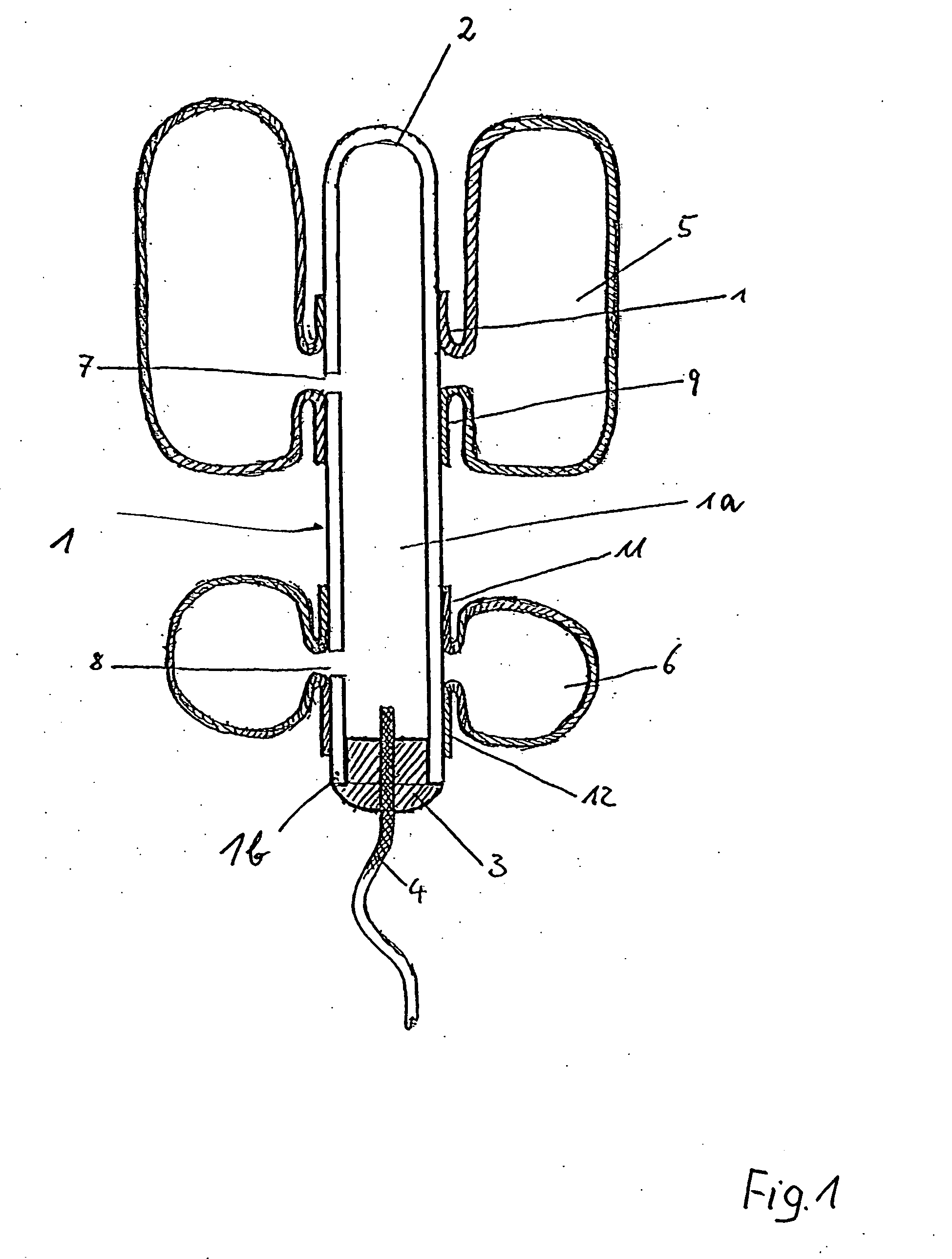

Closure system for managing rectal or anal incontinence

InactiveUS20070213661A1Reduce riskAvoid it happening againAnti-incontinence devicesSurgeryElement spaceButtress

A closure system for managing rectal or anal incontinence, having a shaft element, with a distal end and a proximal end and at least one lumen. An inflatable intrarectal balloon includes a flexible, extensible plastic material with a distal end and a proximal end, each of which is attached to the shaft element in a securely bonded and sealed fashion. The intrarectal balloon communicates with the at least one lumen via a perforation in the wall of the shaft element and can be acted on with a filling medium via the lumen. An anchoring element serves as a buttress, which is attached to the shaft element spaced apart from the intrarectal balloon on its proximal side, in the direction toward the proximal end of the shaft element. The distal end of the intrarectal balloon is attached to the shaft element, the balloon being invaginated in the direction toward the proximal end of the balloon in such a way that the intrarectal balloon attached with its two ends to the shaft element, as it is filled with a filling medium, executes a rolling motion from the distal end of the shaft element toward the proximal end of the shaft element.

Owner:KIMBERLY-CLARK WORLDWIDE INC

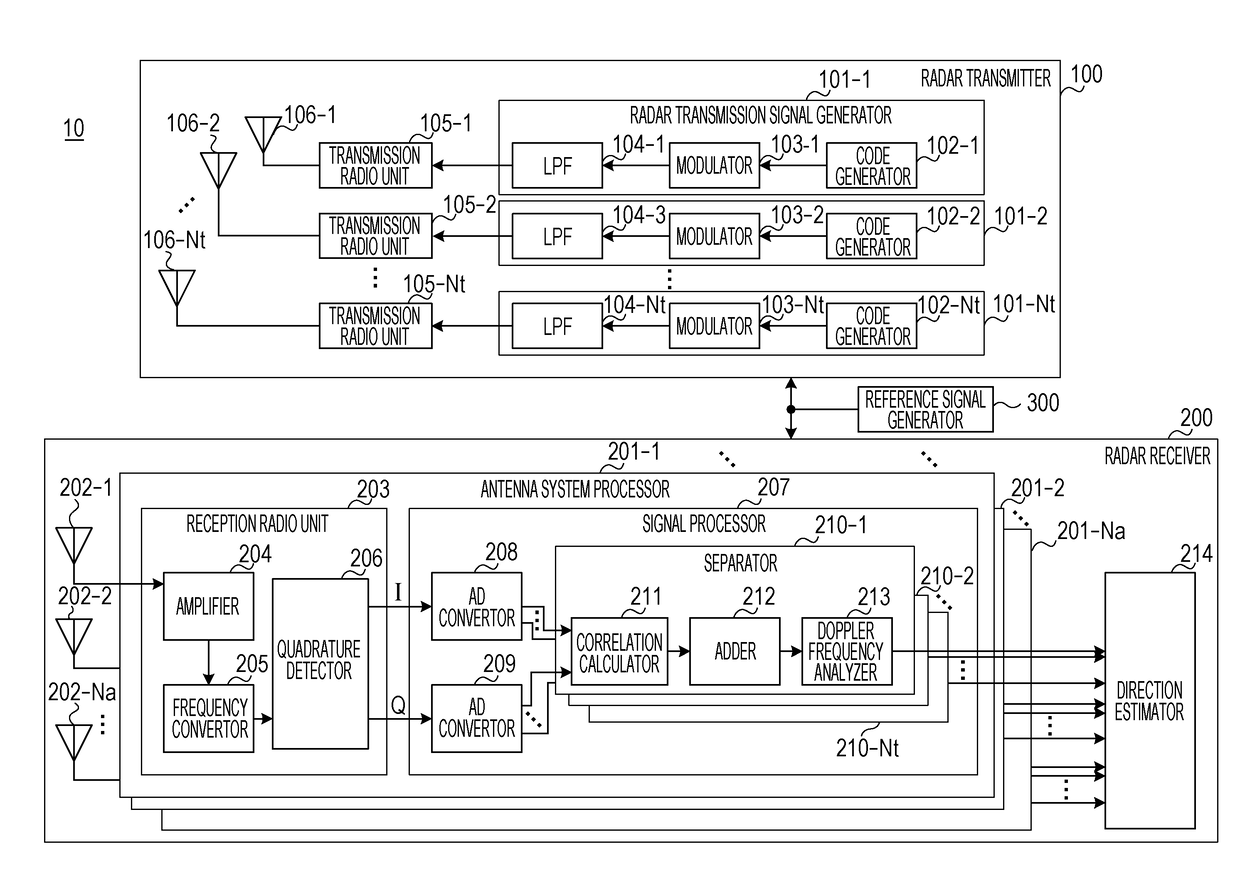

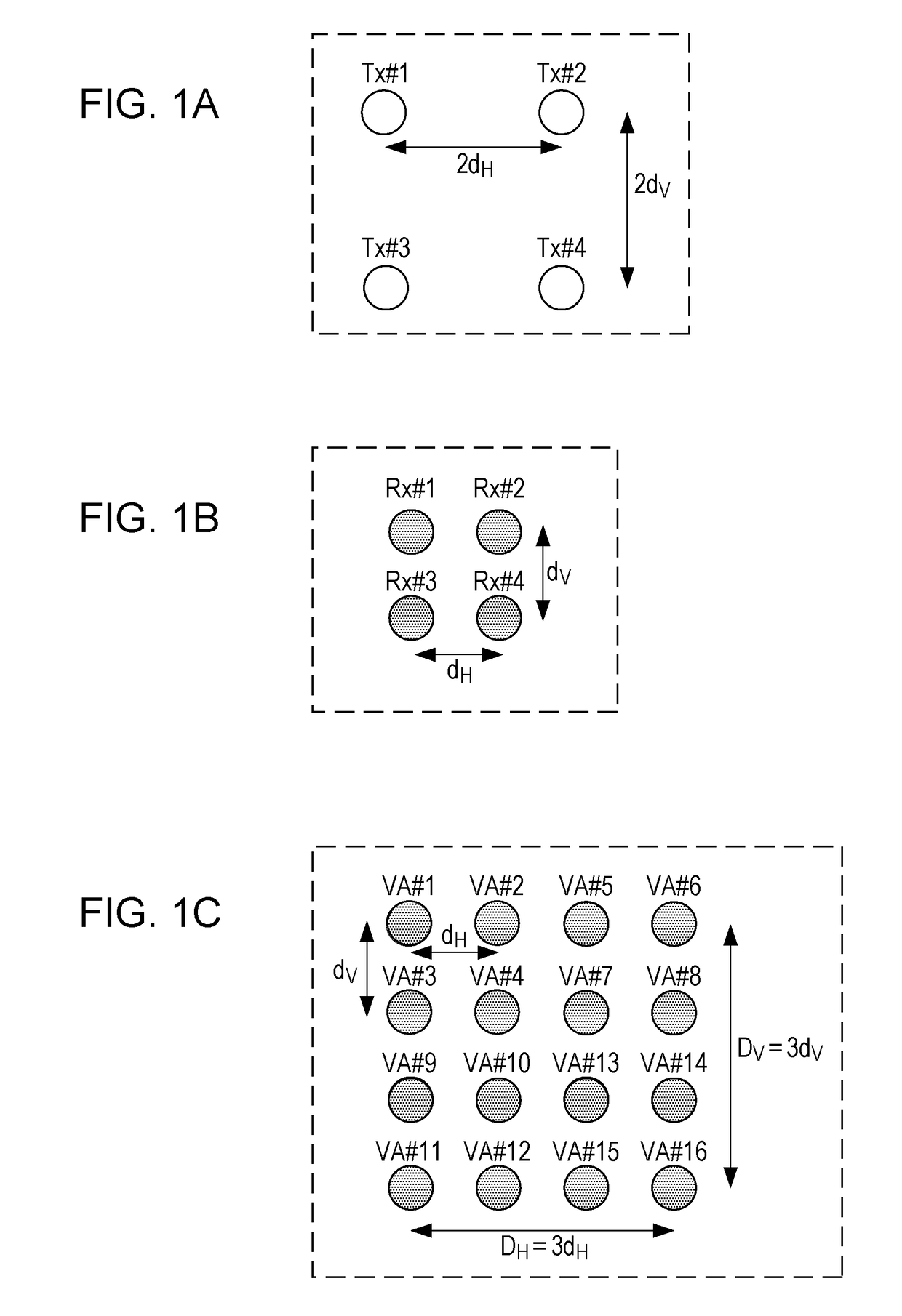

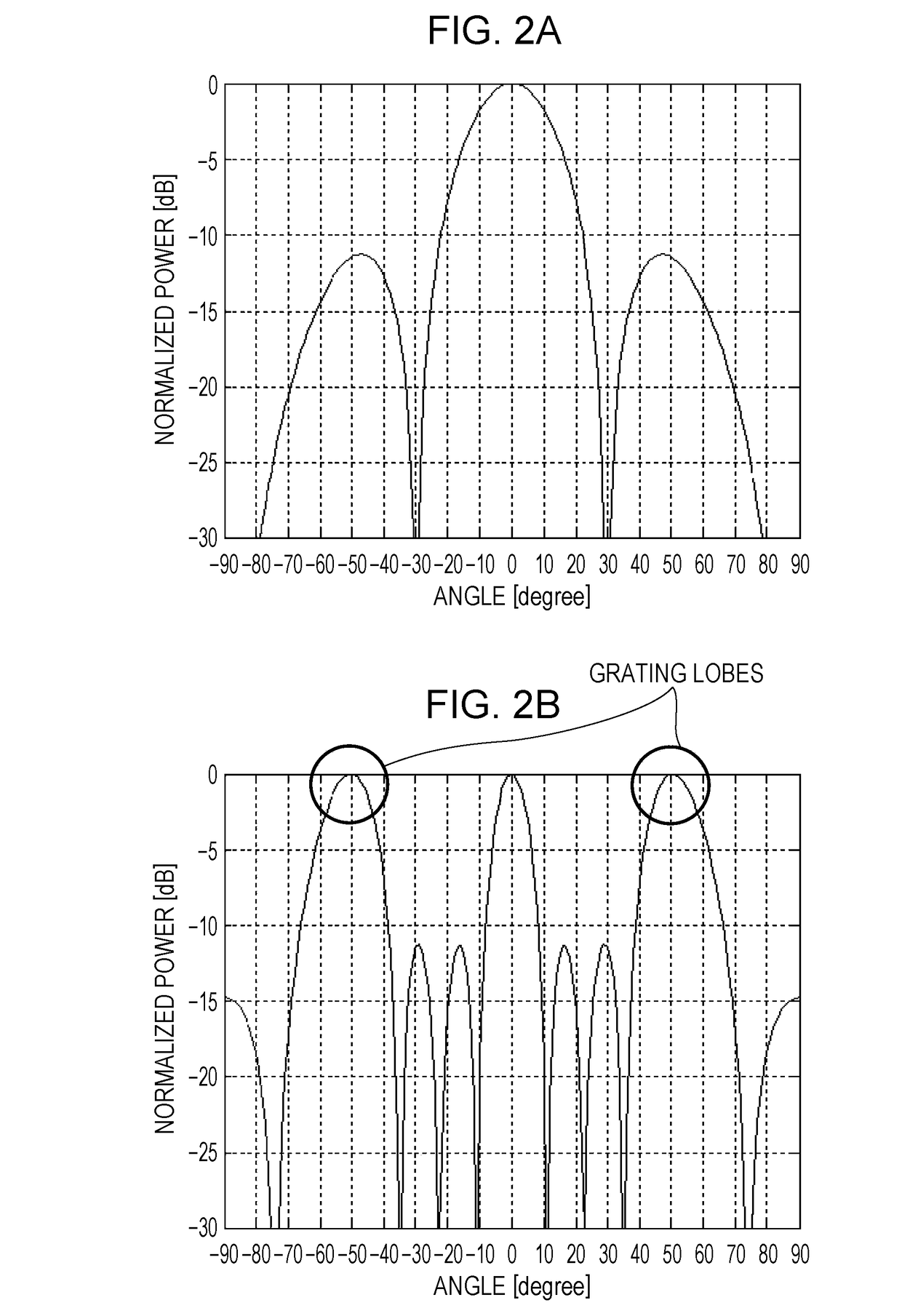

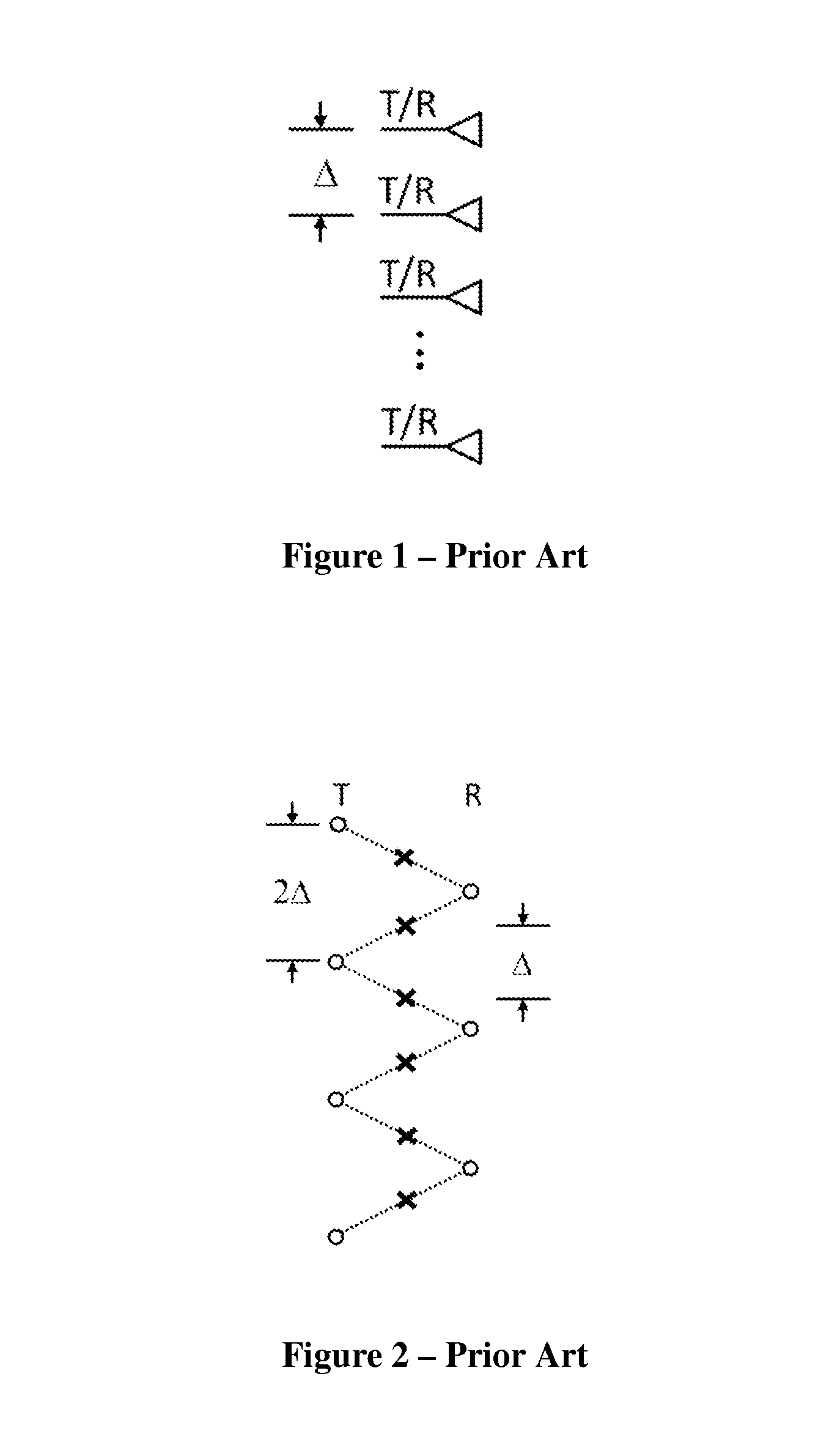

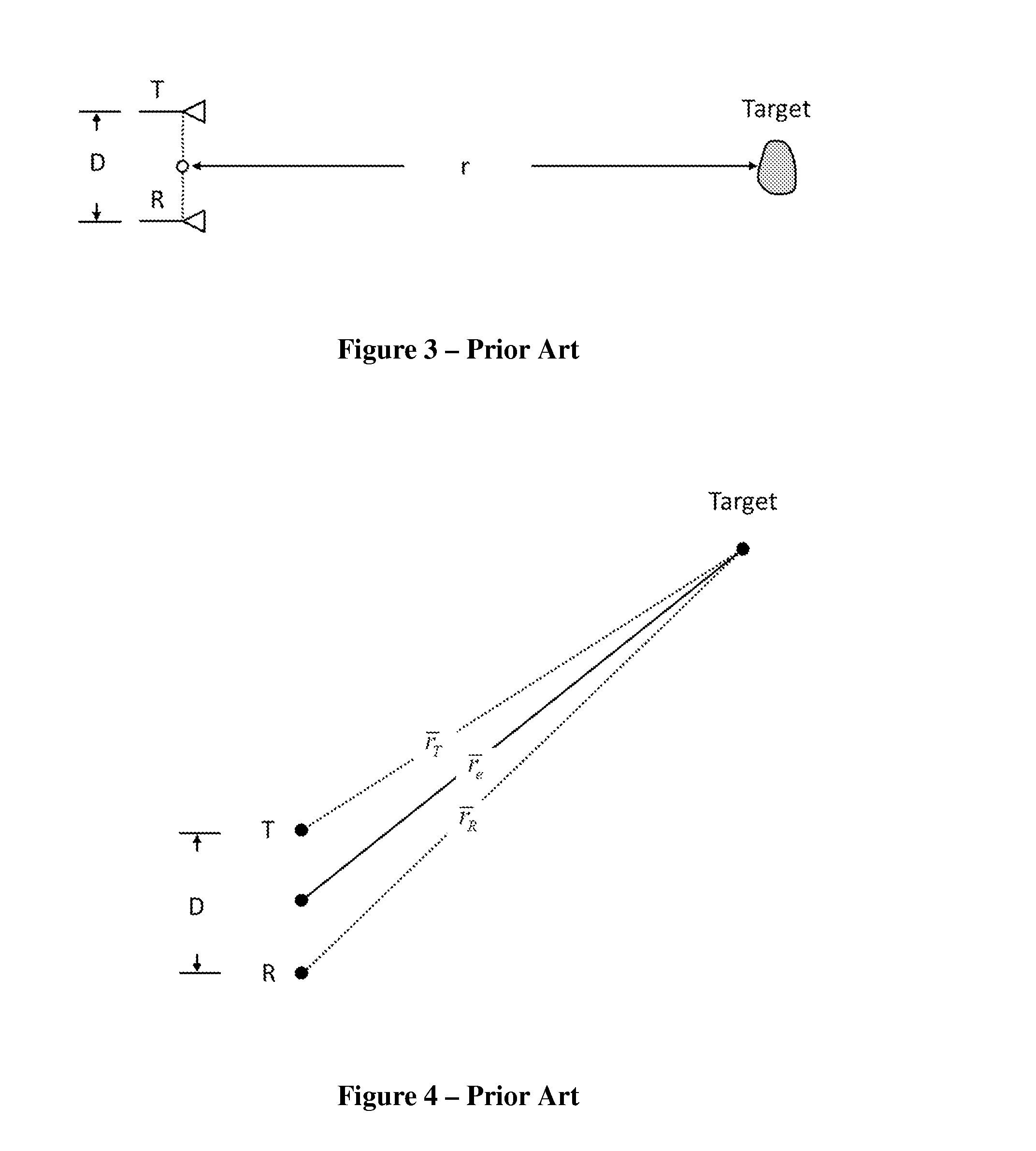

Radar device

ActiveUS20170082730A1Increase aperture lengthIncrease the lengthAntenna arraysRadiating elements structural formsElement spaceRadar

A plurality of transmission antennas include Nt1 transmission antennas arranged in a first direction and Nt2 transmission antennas arranged in a second direction orthogonal to the first direction, a plurality of reception antennas include Na1 reception antennas arranged in the first direction and Na2 reception antennas arranged in the second direction. In the first direction, an inter-element space between any two of the Nt1 transmission antennas and an inter-element space between any two of the Na1 reception antennas are each a value which is a product of a first space and an integer and are all values different from each other, and in the second direction, an inter-element space between any two of the Nt2 transmission antennas and an inter-element space between any two of the Na2 reception antennas are each a value which is a product of a second space and an integer and are all values different from each other.

Owner:PANASONIC HLDG CORP

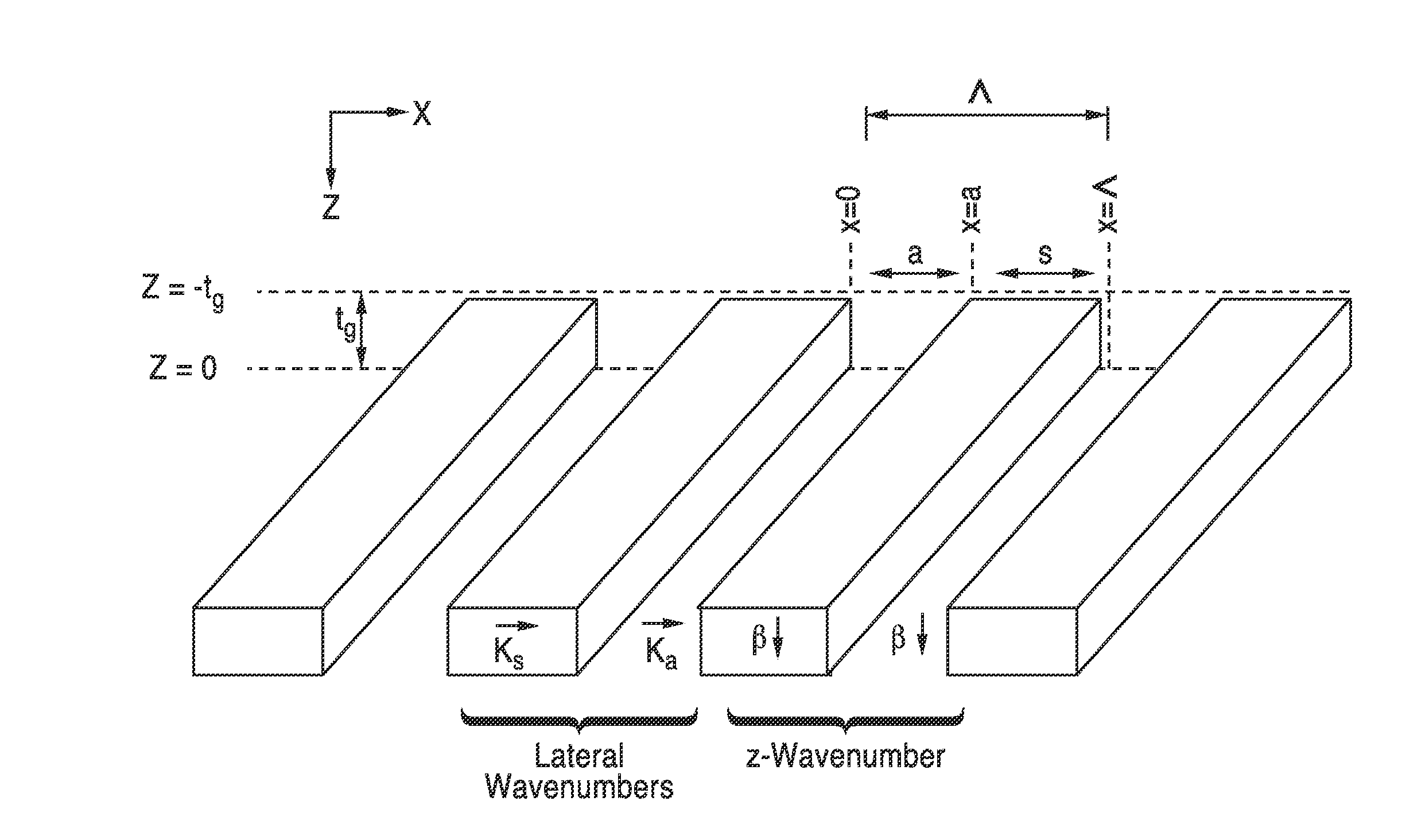

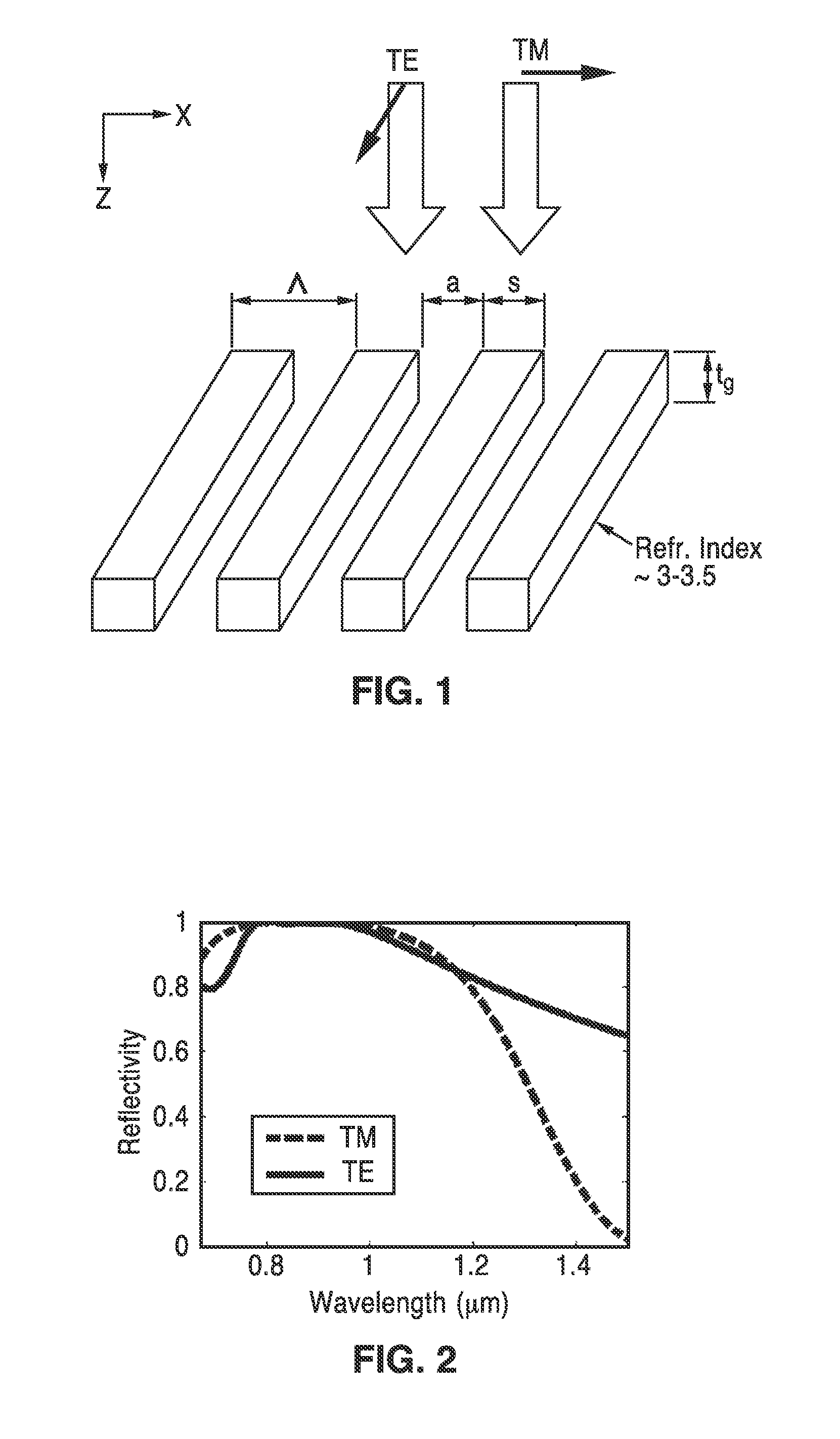

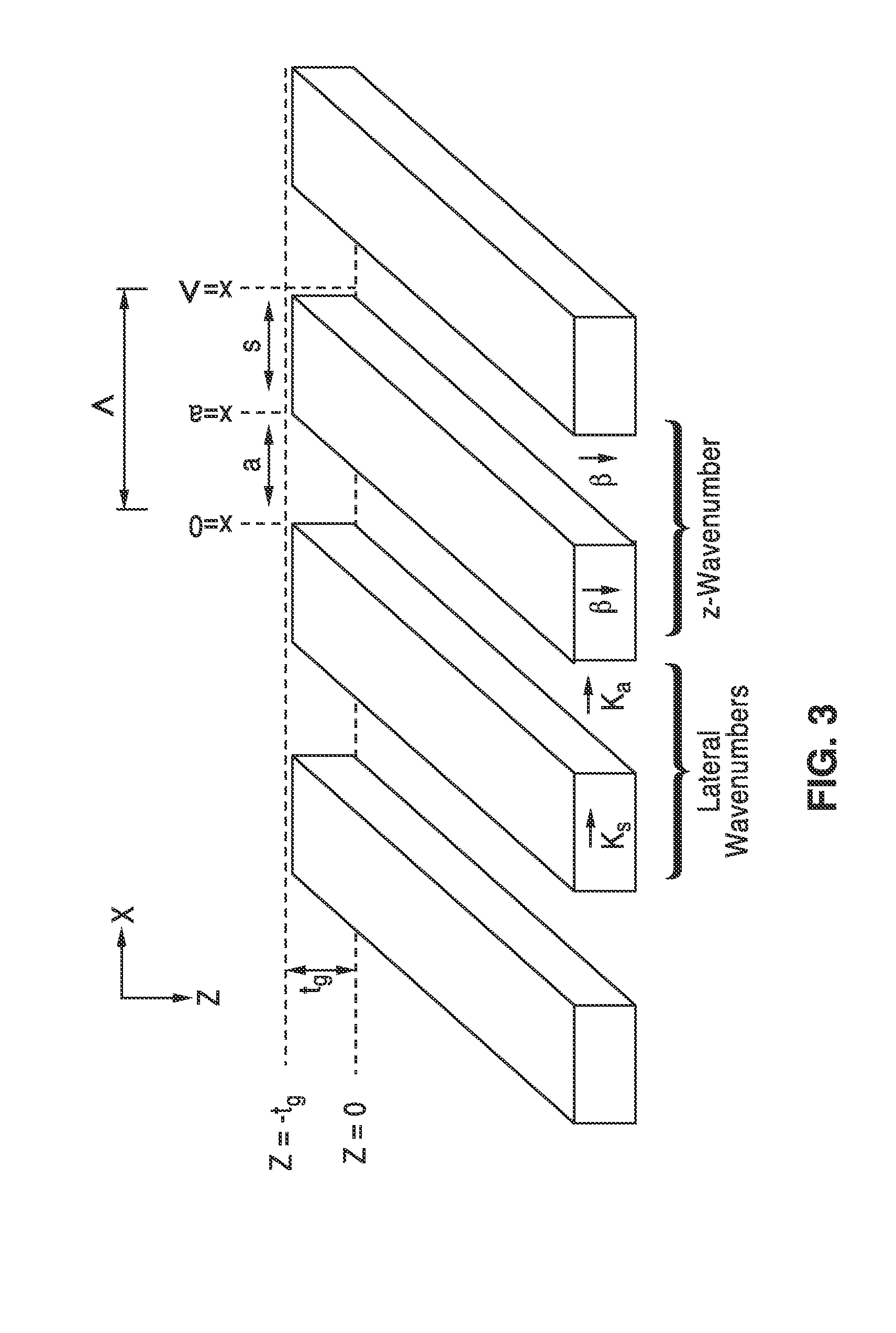

Planar, high na, low loss transmitting or reflecting lenses using sub-wavelength high contrast grating

ActiveUS20130058370A1Minimizing energy leakageSmall sizeLaser detailsNanoopticsHigh contrastElement space

Planar lenses and reflectors are described comprising subwavelength high-contrast gratings (HCG) having high index of refraction grating elements spaced apart from one another in straight and / or curved segments and surrounded by low index material. The high-contrast grating is configured to receive an incident wave which excites multiple modes within the high-contrast grating and is focused for reflection and / or transmission by said high contrast grating. The width of the high contrast grating bars vary along a distribution direction of the grating bars which is perpendicular to the length of the grating bars and / or varies along the length of one or more grating bars to focus said reflection and / or transmission. The HCG is configured to provide double focusing, whose use is exemplified within a vertical cavity surface emitting laser (VCSEL) structure using focusing HCG structures for both the top and bottom mirrors.

Owner:RGT UNIV OF CALIFORNIA

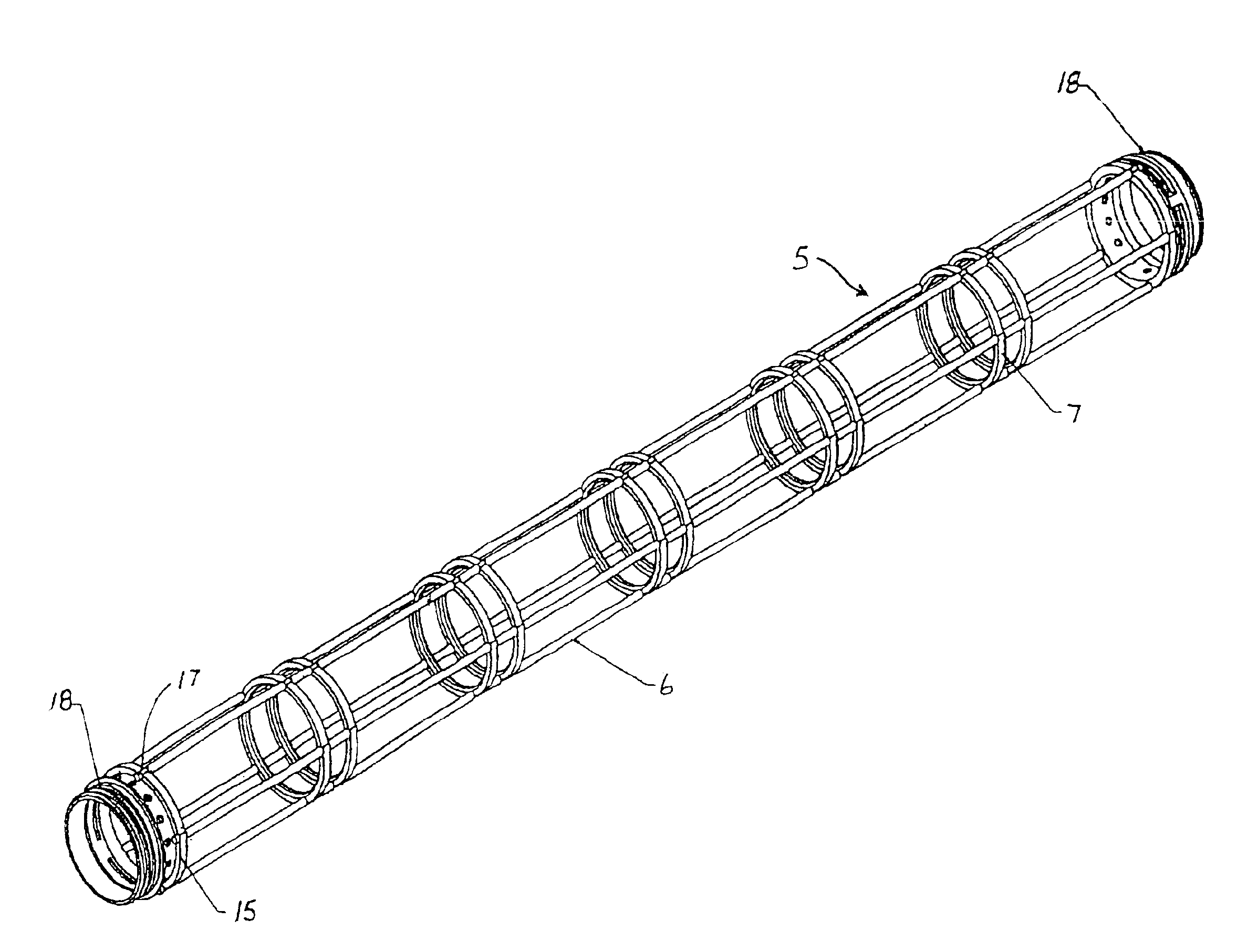

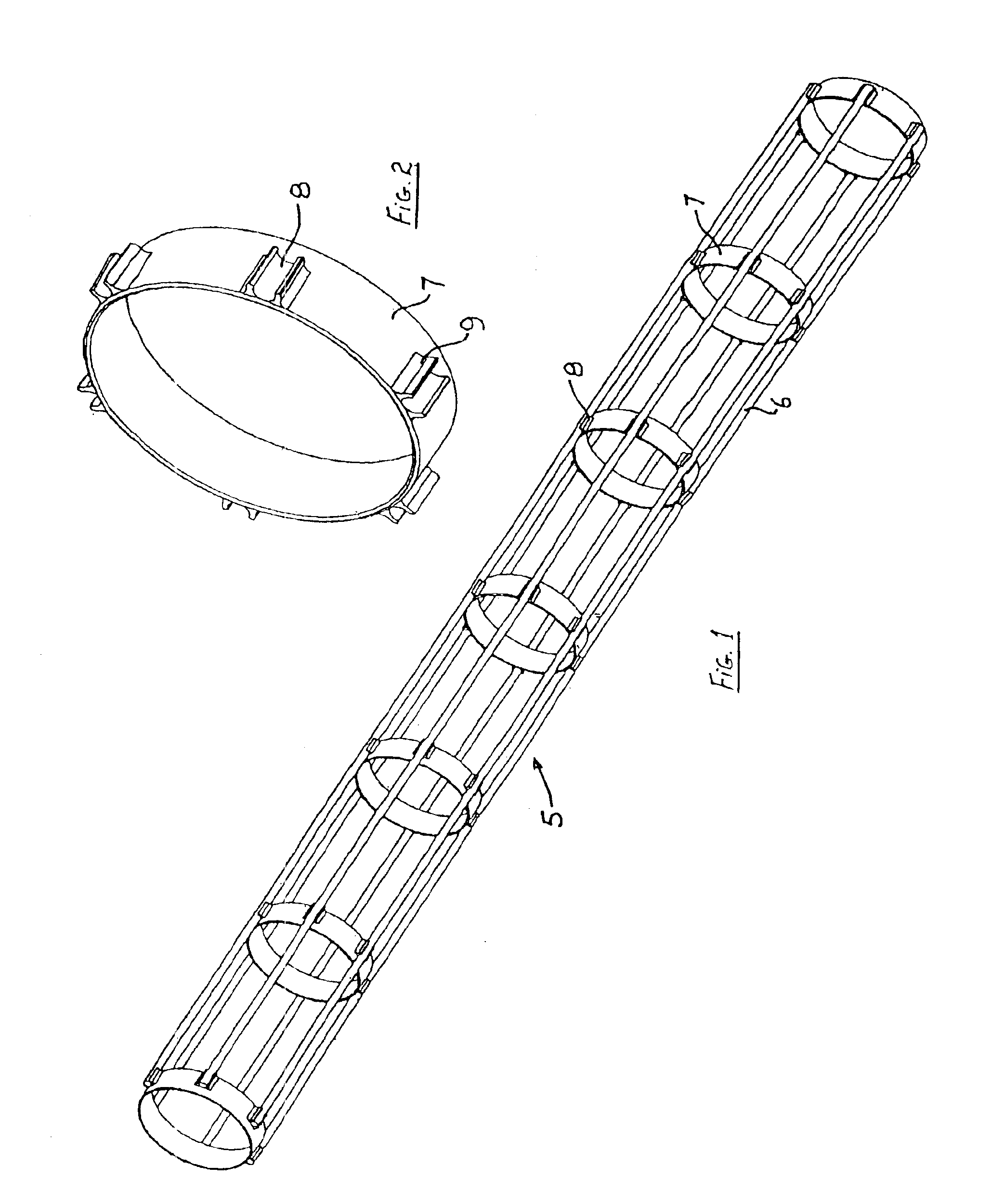

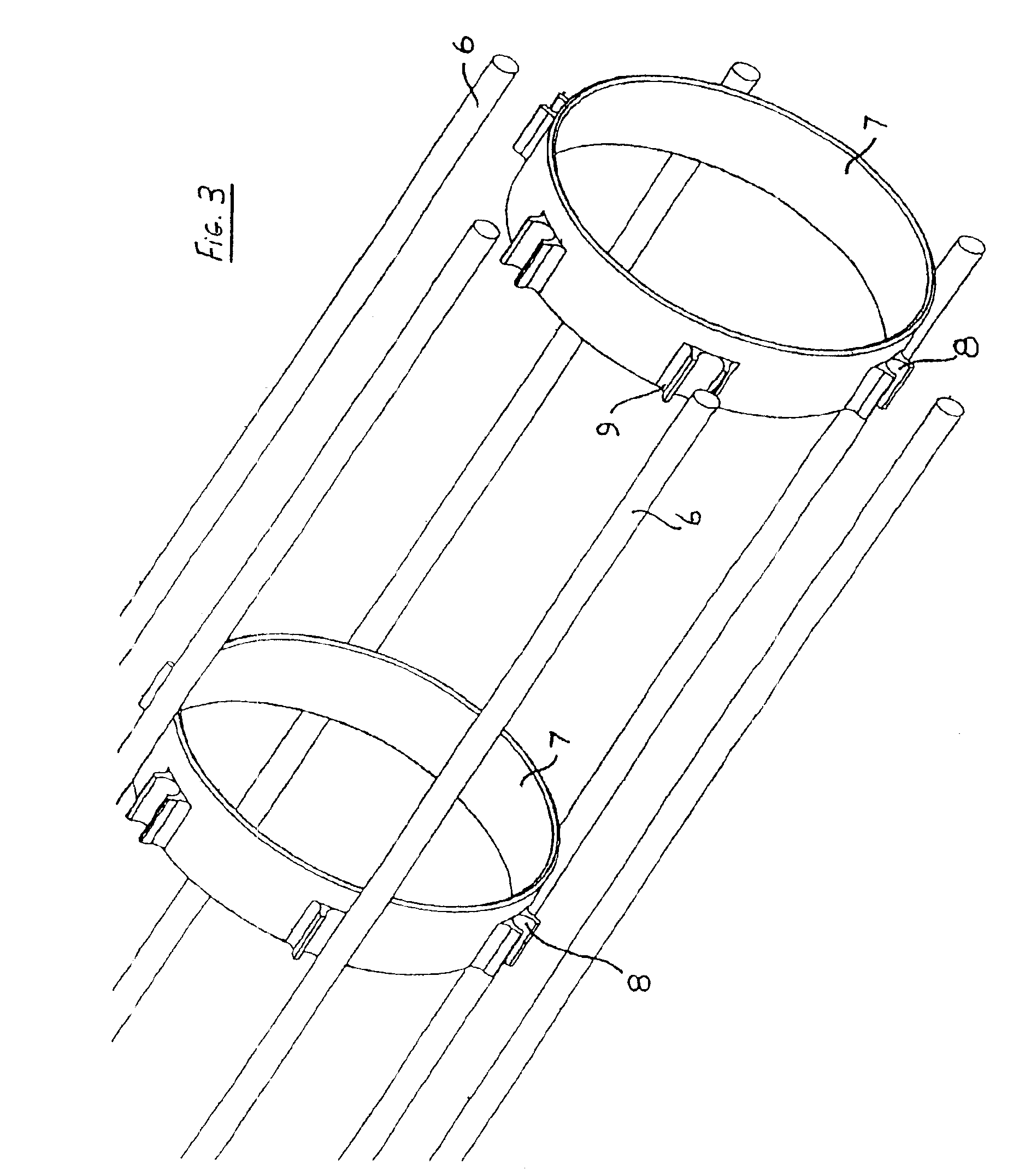

Hollow fiber restraining system

A restraining system for hollow fibers is provided. The restraining system includes a plurality of longitudinally extending elements spaced from one another and supported by a number of discrete spacer elements, each spacer element extending generally transverse of said longitudinal elements, such that in combination with said longitudinal elements they define a cage-like structure.

Owner:EVOQUA WATER TECH LLC

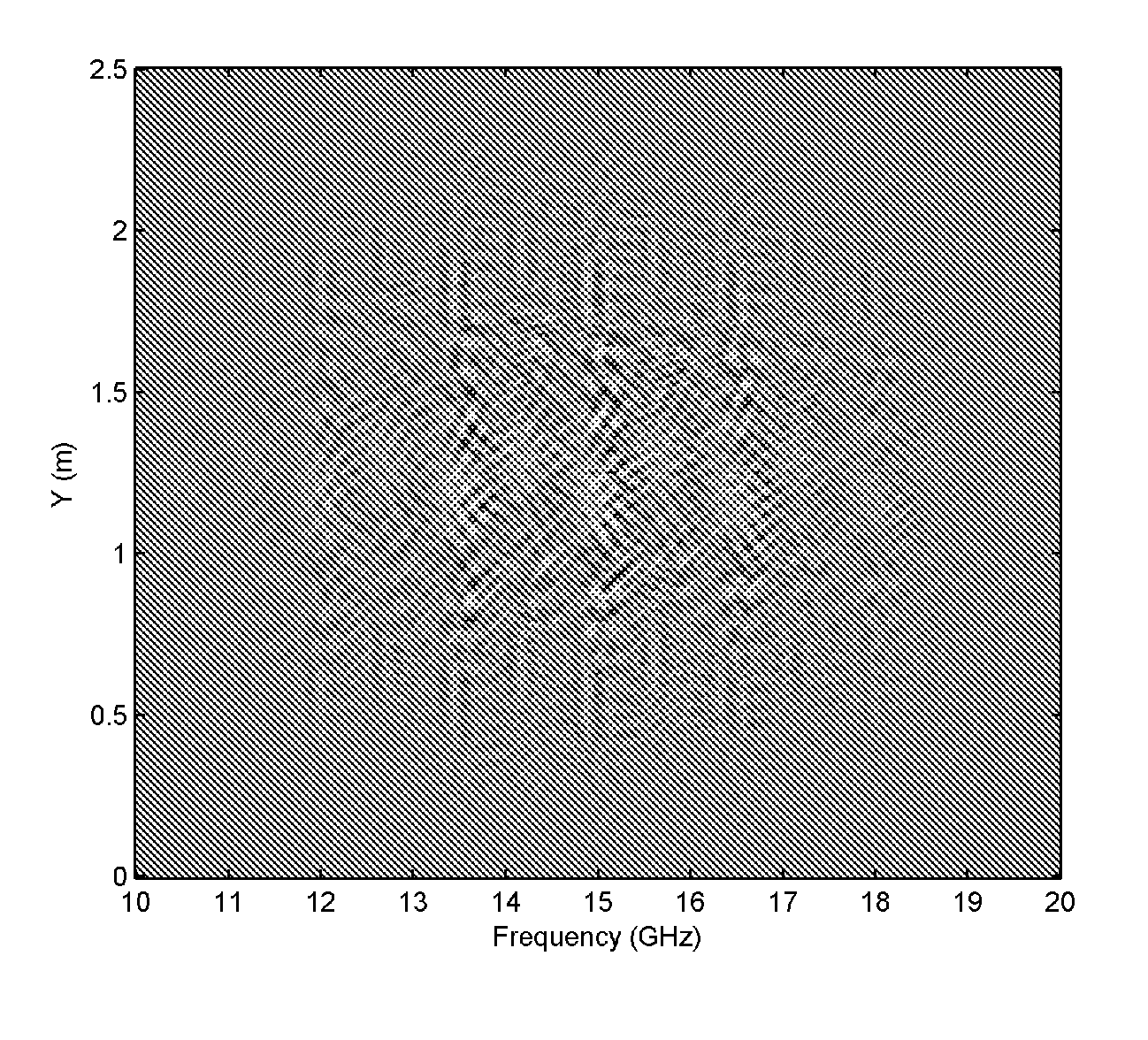

Apparatus for synthetic imaging of an object

An apparatus for synthetic imaging of an object is disclosed. The apparatus includes a plurality of transmitter elements spaced apart by a first distance in a first column and a plurality of receiver elements spaced apart by a second distance in a second column. The first distance and the second distance are different. The plurality of transmitter elements is a non-integer multiple of the plurality of receiver elements, and the plurality of receiver elements is a non-integer multiple of the plurality of transmitter elements.

Owner:BATTELLE MEMORIAL INST

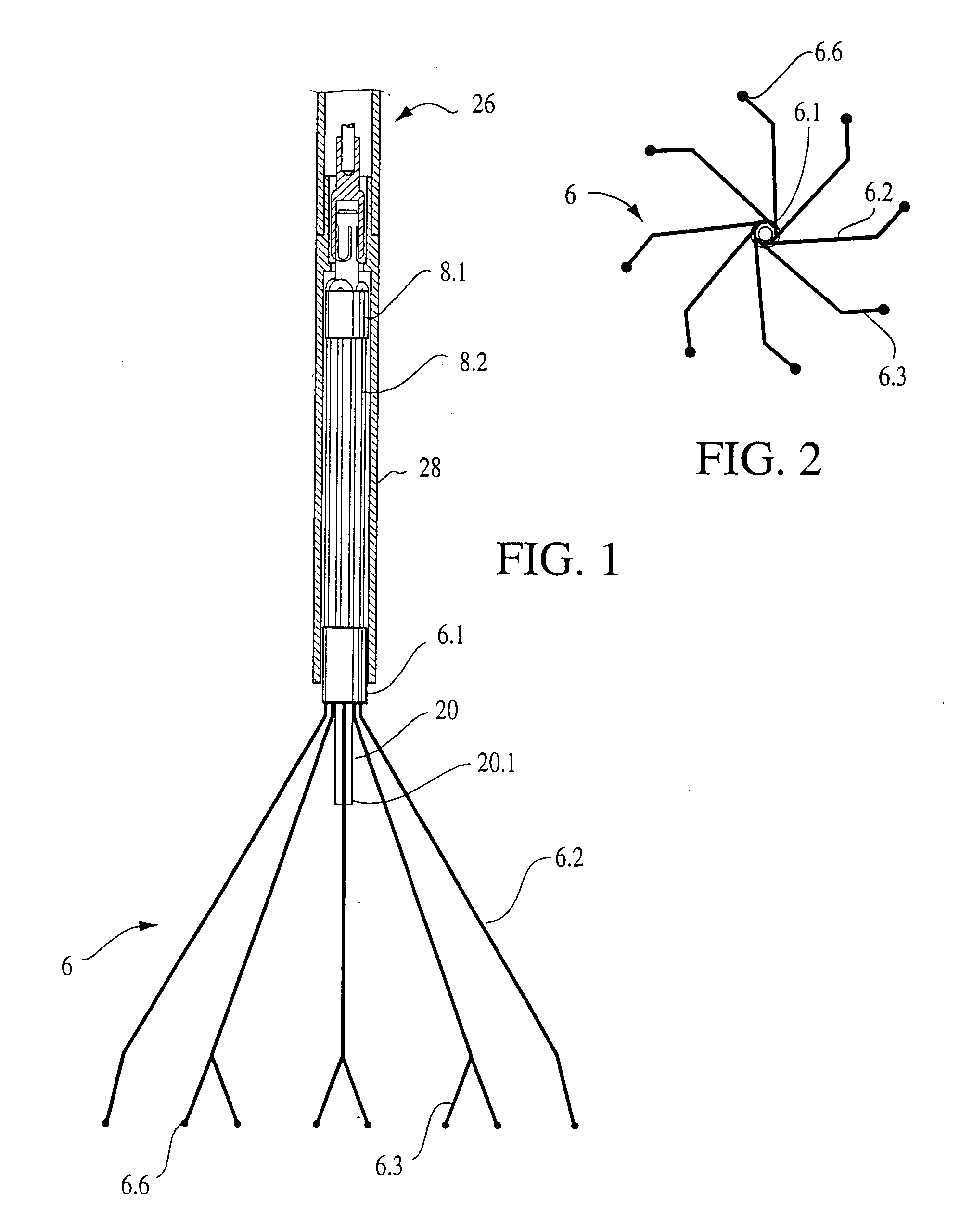

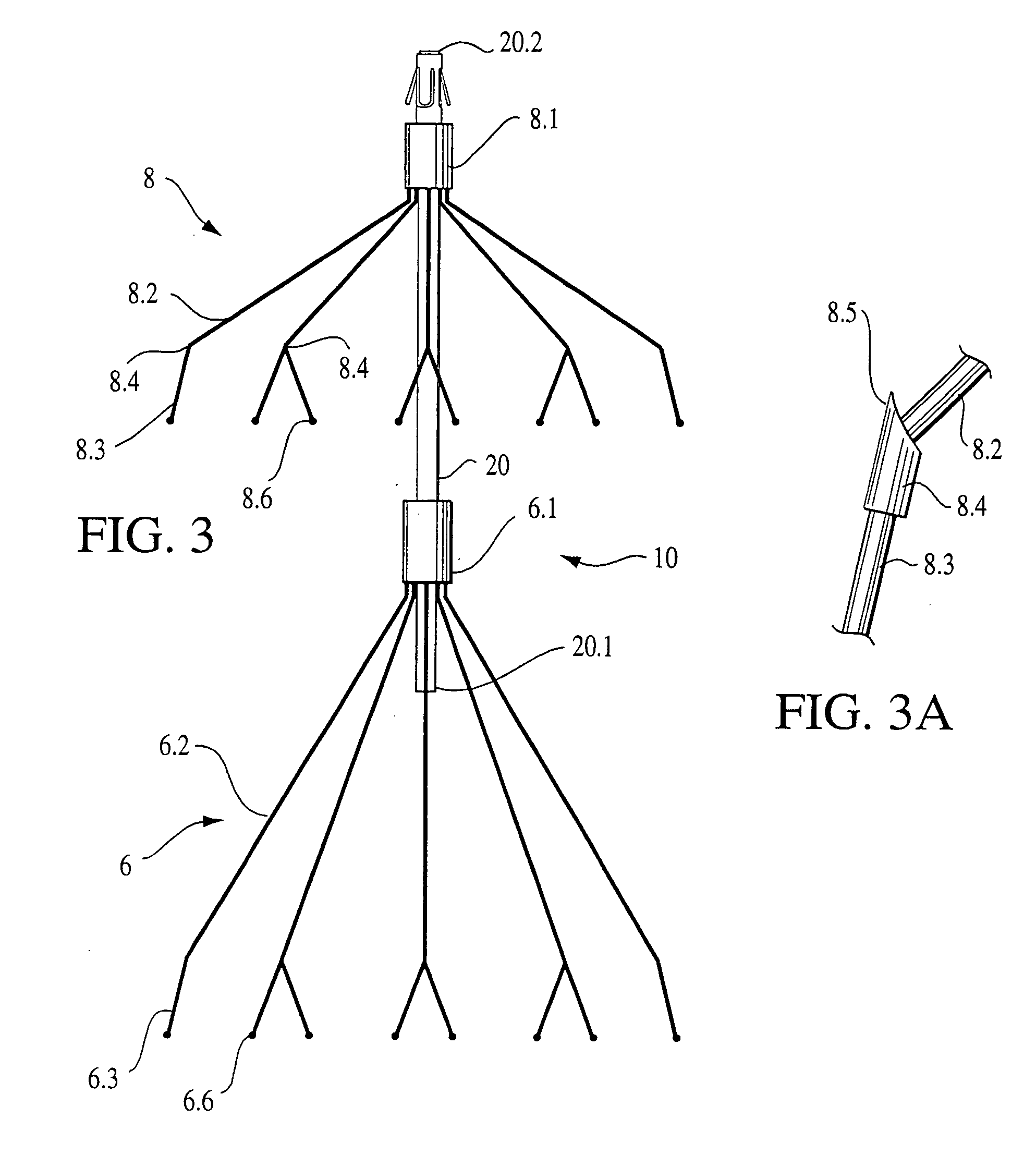

Body vessel filter

A catheter-deliverable filter assembly for deploying a filter element in a vessel of the body, comprising an elongated support having proximal and distal ends, the proximal end of the elongated support comprising a hook, separate filter and anchoring elements spaced axially along said support and each comprising a core carried by the support and a plurality of flexible, resilient wires having proximal portions attached to the core and distal portions extending distally of the core and configured to expand into resilient contact with walls of a vessel, said wires converging proximally toward their respective cores to define apices of the respective elements, said filter element being spaced distally of said anchoring element, and said anchoring element alone including gripping elements carried by distal portions of said wires and adapted to grip the walls of the vessel to anchor the filter assembly in the vessel.

Owner:EV3

Stent delivery guide wire

Owner:STEREOTAXIS

Electronic cigarette case

InactiveUS9357802B2Firmly connectedCost of manufactureBatteries circuit arrangementsTobacco pipesElement spaceElectricity

The present invention relates to an electronic cigarette case, includes a case body, a charging device disposed in the case body for charging electronic cigarettes. The charging device includes a charging base, a rechargeable battery, and a control circuit board integrated with a circuit processing unit. The charging base has an electrode support where first and second electrode elements, and a trigger element spaced apart from the second electrode element are all disposed on the electrode support. The second electrode element is flexibly deformable when one of the electronic cigarettes is inserted into the case body to create a charging circuit. The circuit processing unit automatically controls the rechargeable battery for charging the electronic cigarette being inserted until it is full of power, whereby the electronic cigarette case is readily to be assembled and to sue, and has a reliable electrical connection with an outer power source.

Owner:HUIZHOU KIMREE TECH

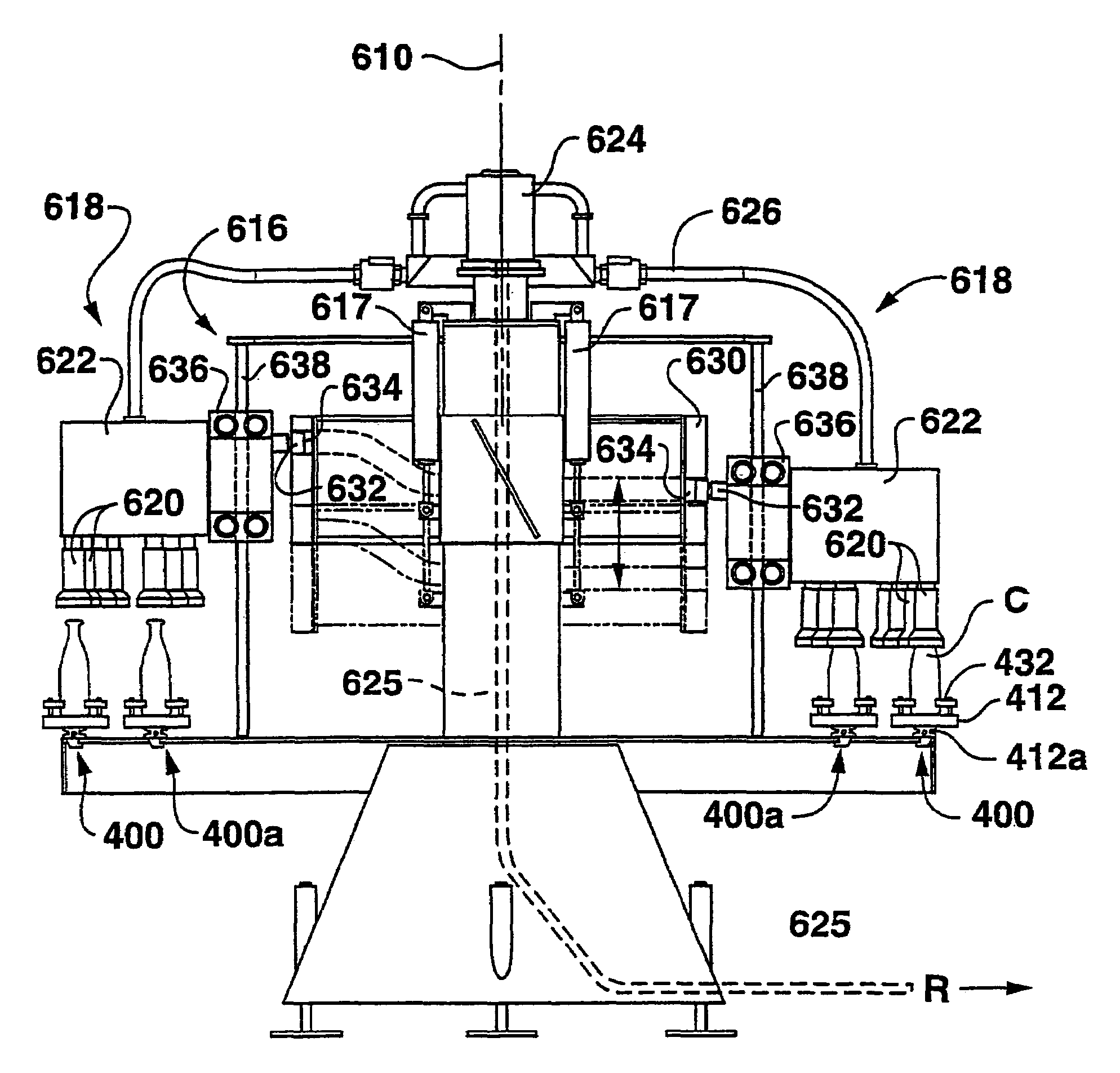

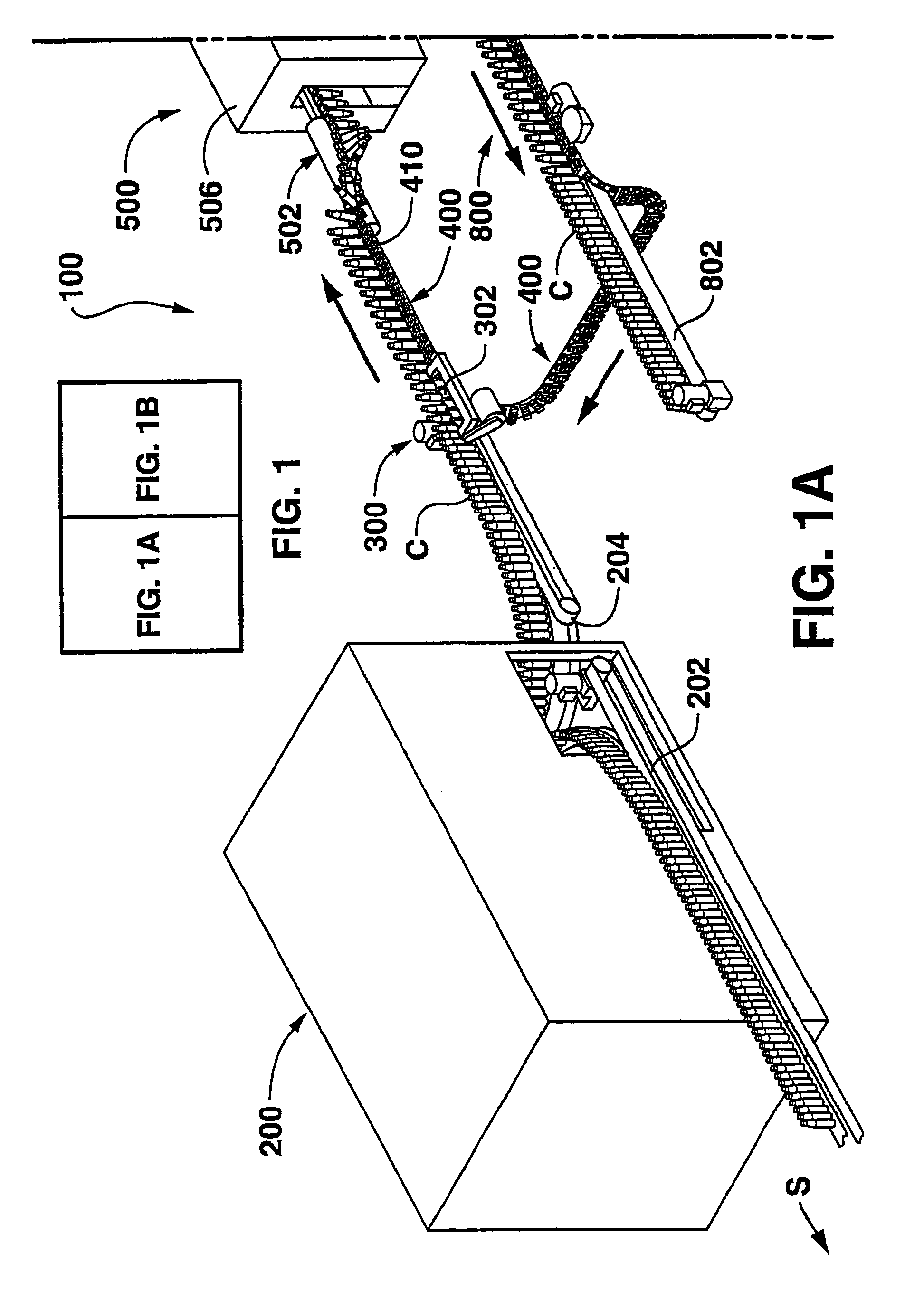

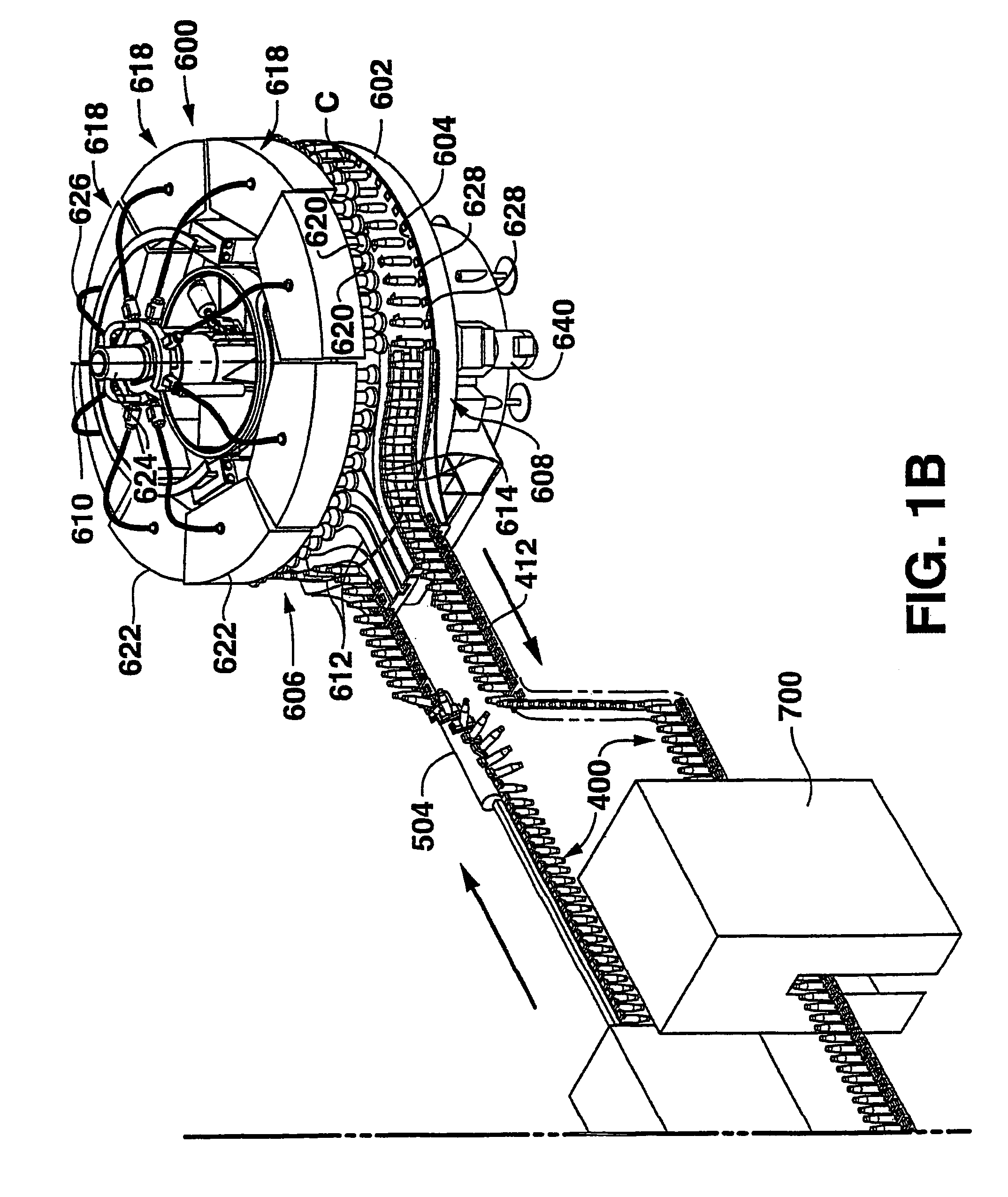

System for securely conveying articles and related components

A system is disclosed for conveying articles for processing, the system including a conveyor configured to convey articles to the processing station. The conveyor includes a plurality of links, each link including at least one movable gripper for gripping an article, articles being gripped by adjacent links so as to achieve a predetermined spacing between the articles. A processing station is disposed along the conveyor, the conveyor being driven so as to move the articles through the processing station maintaining the predetermined spacing via the movable grippers, the processing station including mating elements spaced according to the predetermined spacing for processing the articles. The articles may be containers, and the processing station may be a filler or other container processing elements.

Owner:ILLINOIS TOOL WORKS INC

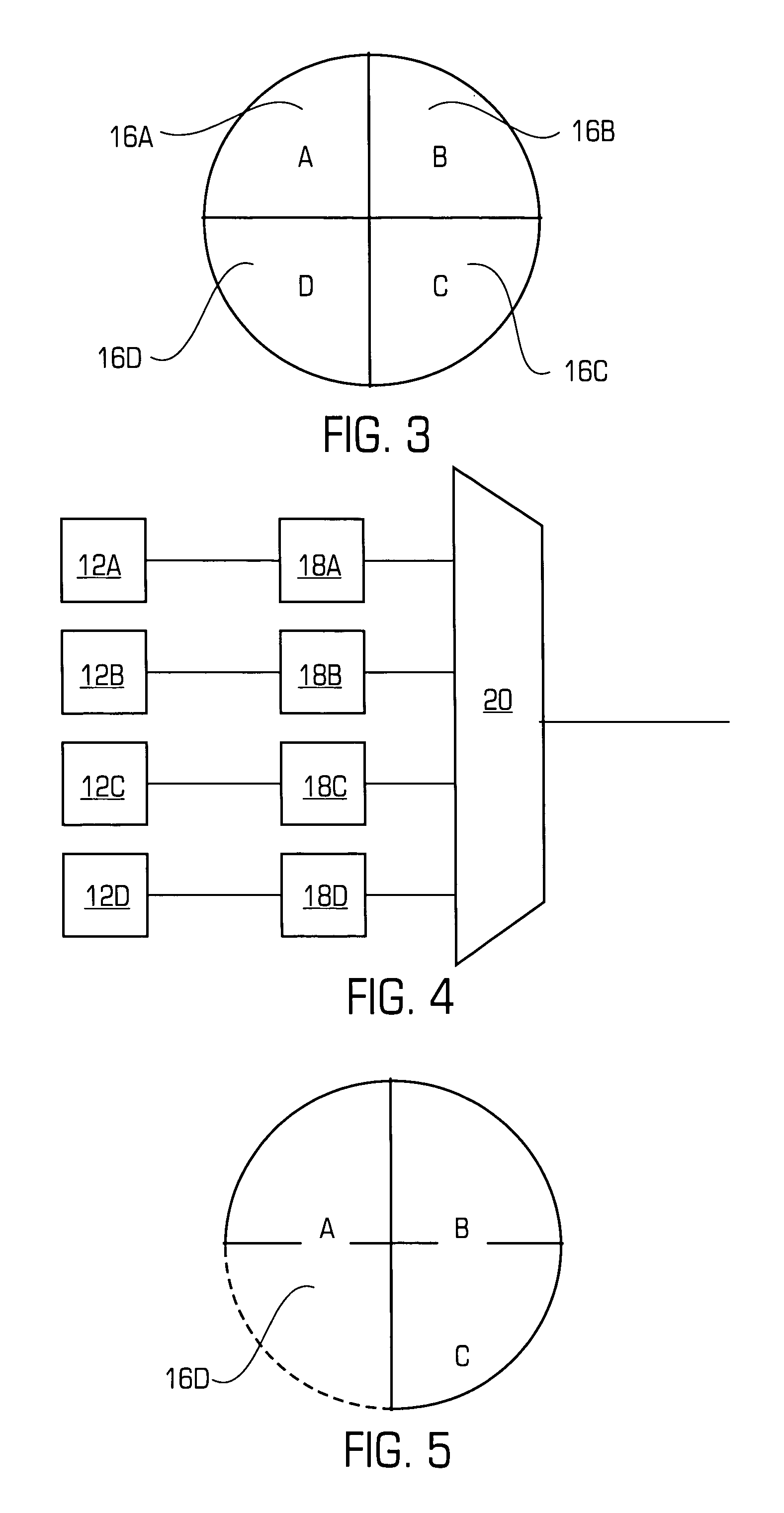

Field coverage configurable passive infrared radiation intrusion detection device

Owner:INET CONSULTING

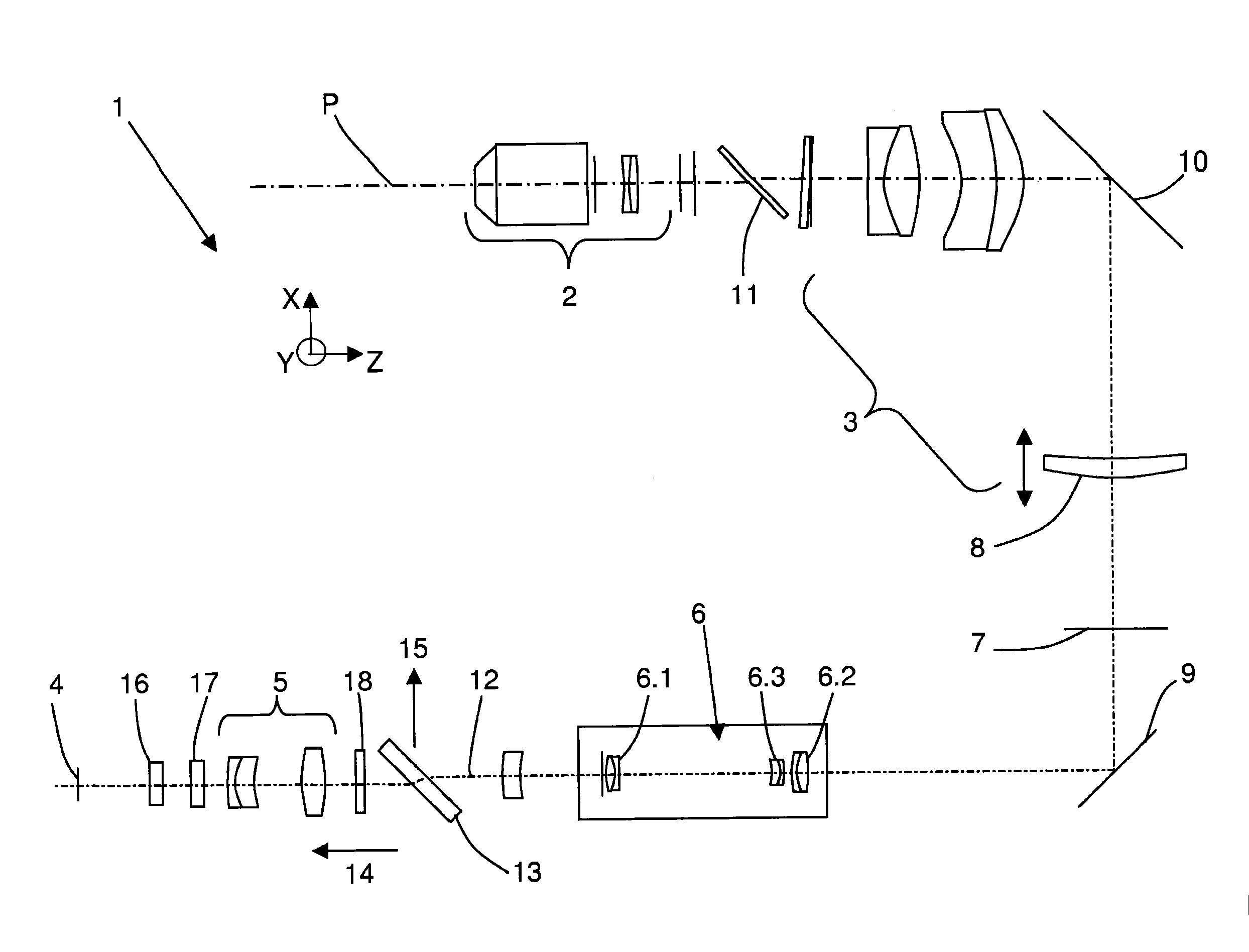

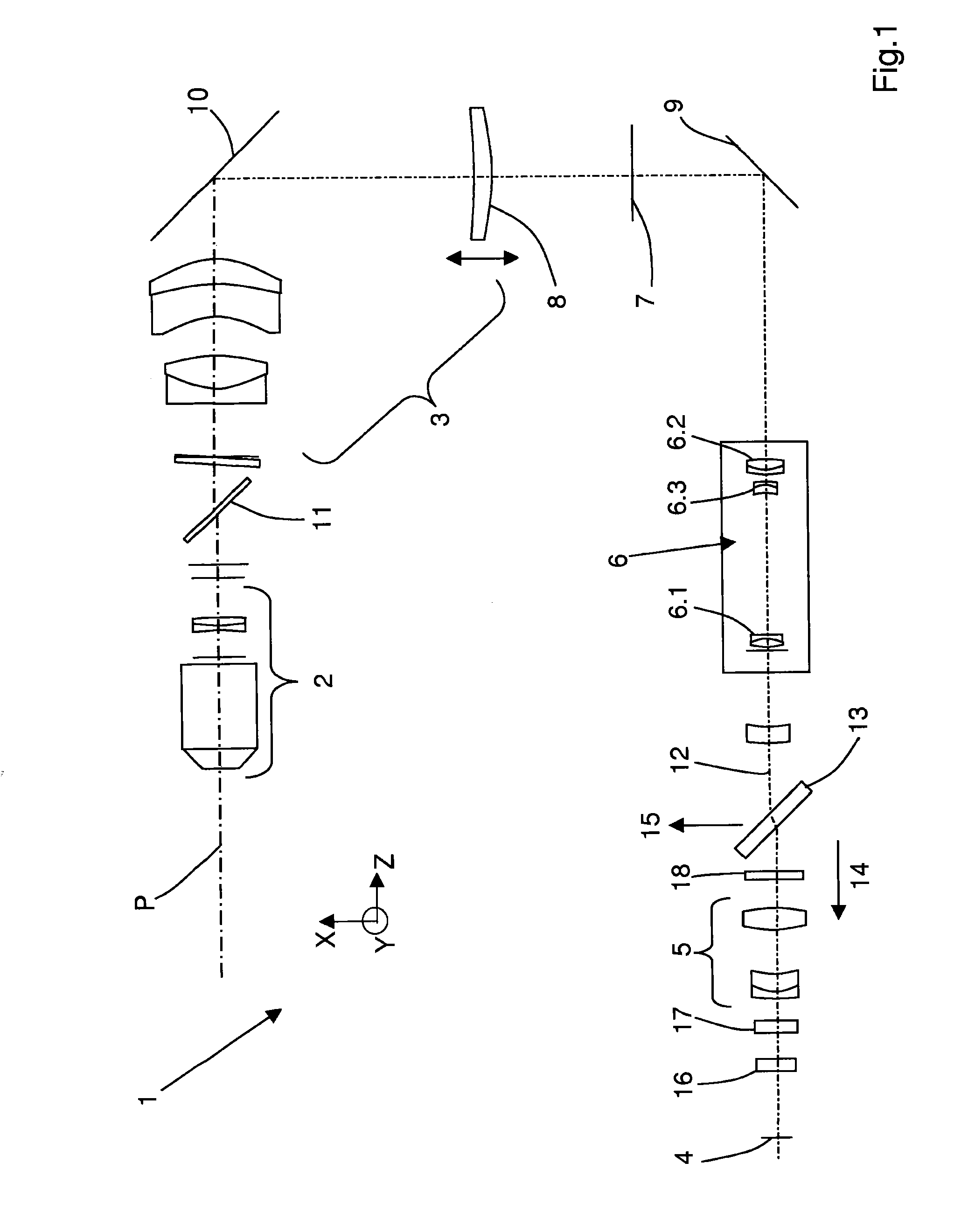

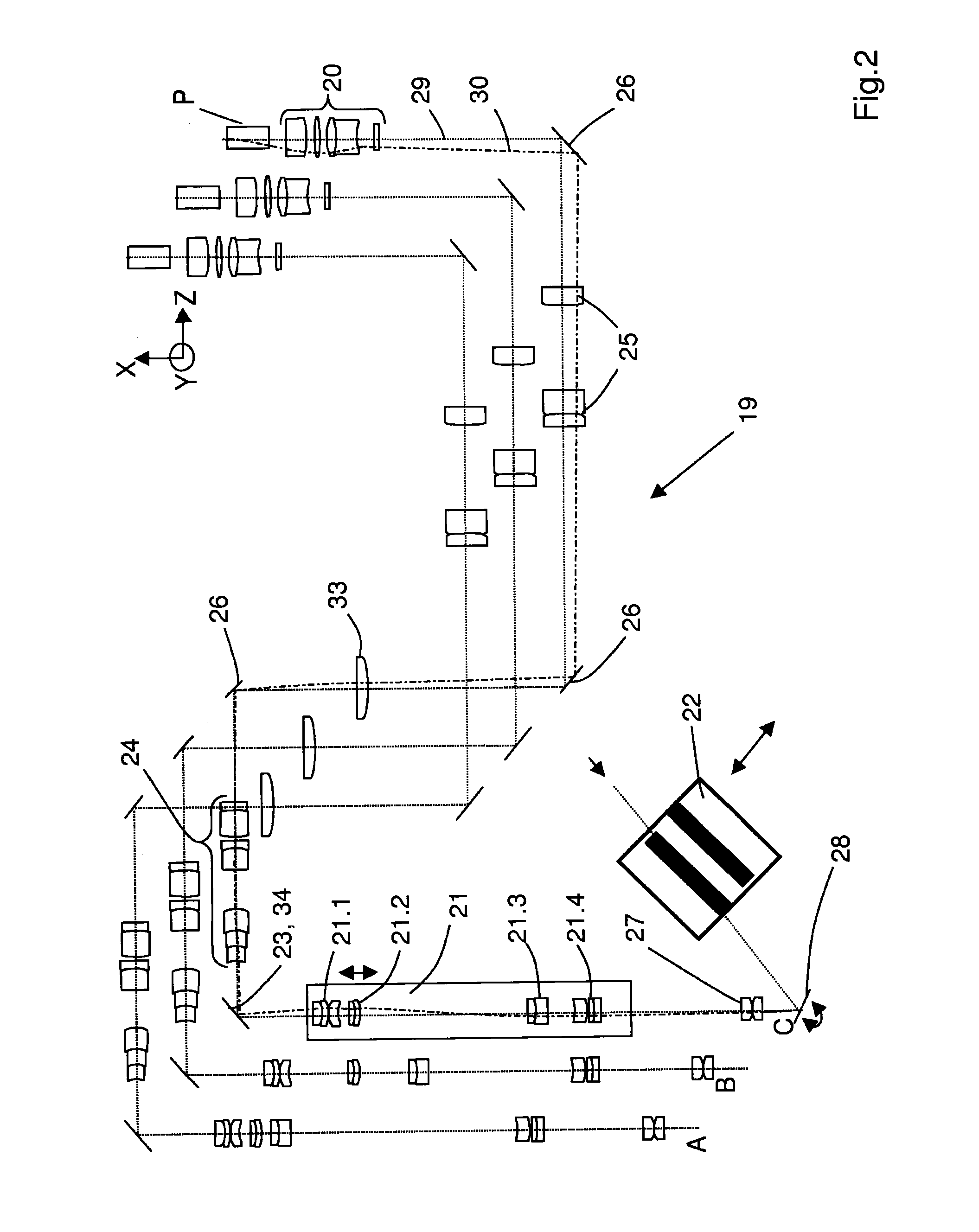

Microscope with a sheet of light

ActiveUS20120200693A1Color television detailsClosed circuit television systemsElement spaceTransverse axis

A family of microscopes with illumination systems directing a sheet of light having an approximately planar extension in an illumination axis of an illumination beam path and in a transverse axis orthogonally oriented to the illumination axis. The microscopes have detection devices used to detect light that is emitted by a sample region. The detection devices including a detection lens system disposed in the detection beam path and an optical detection element spaced from a front lens of the detection lens system and independently adjustable thereof. The optical detection element continuously varies the size of a detection image field and / or continuously displaces a focal plane of detection in the P-region.

Owner:CARL ZEISS MICROSCOPY GMBH

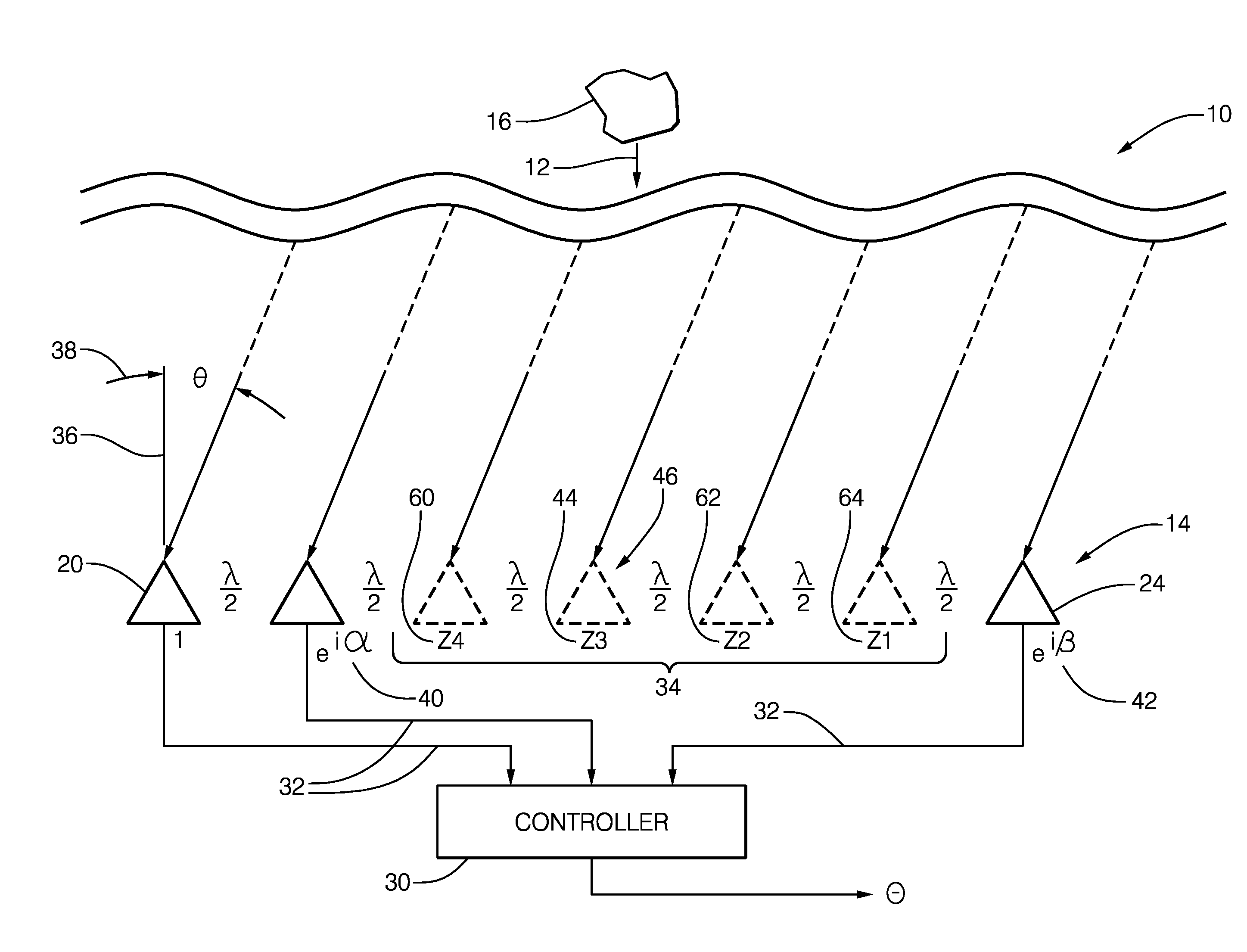

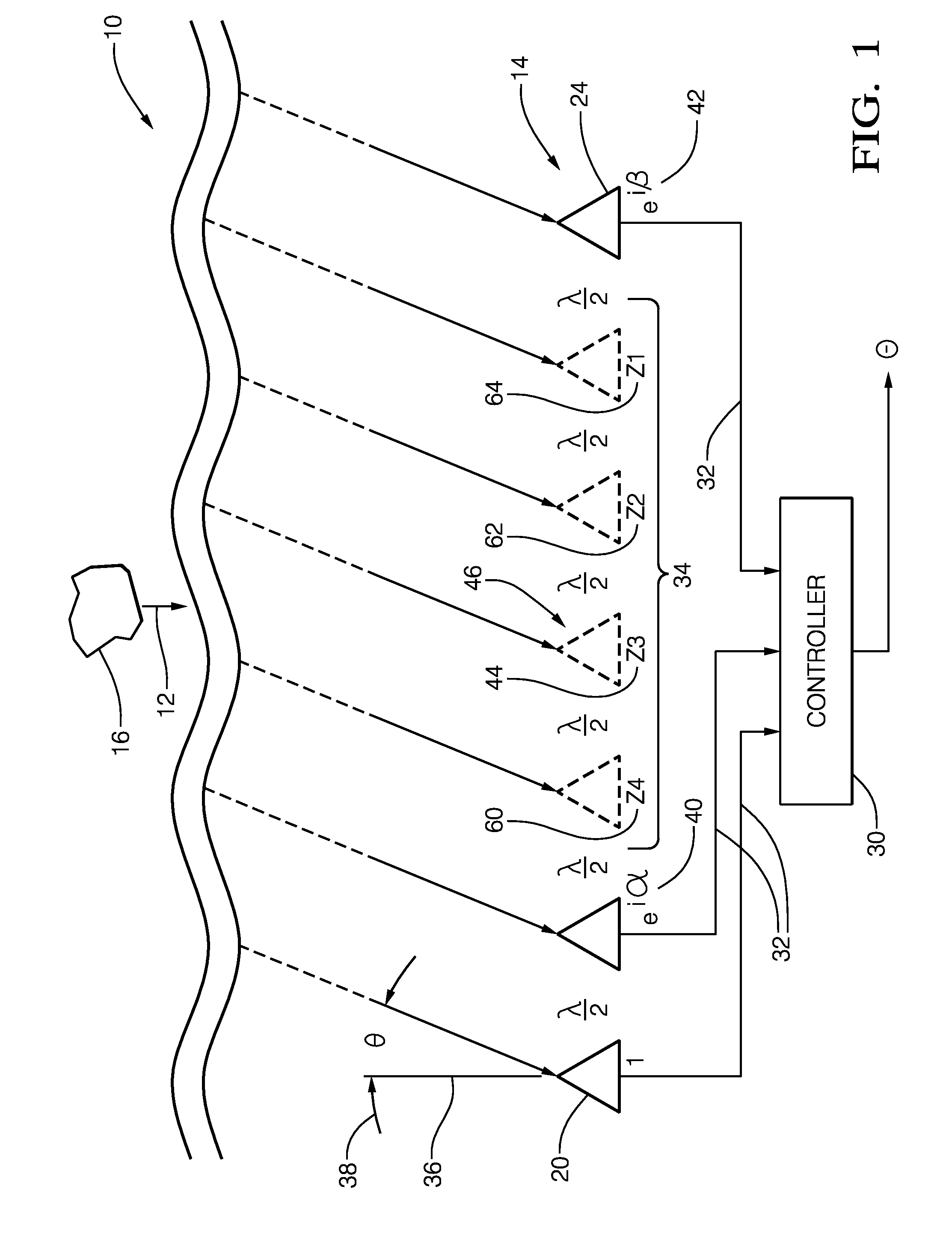

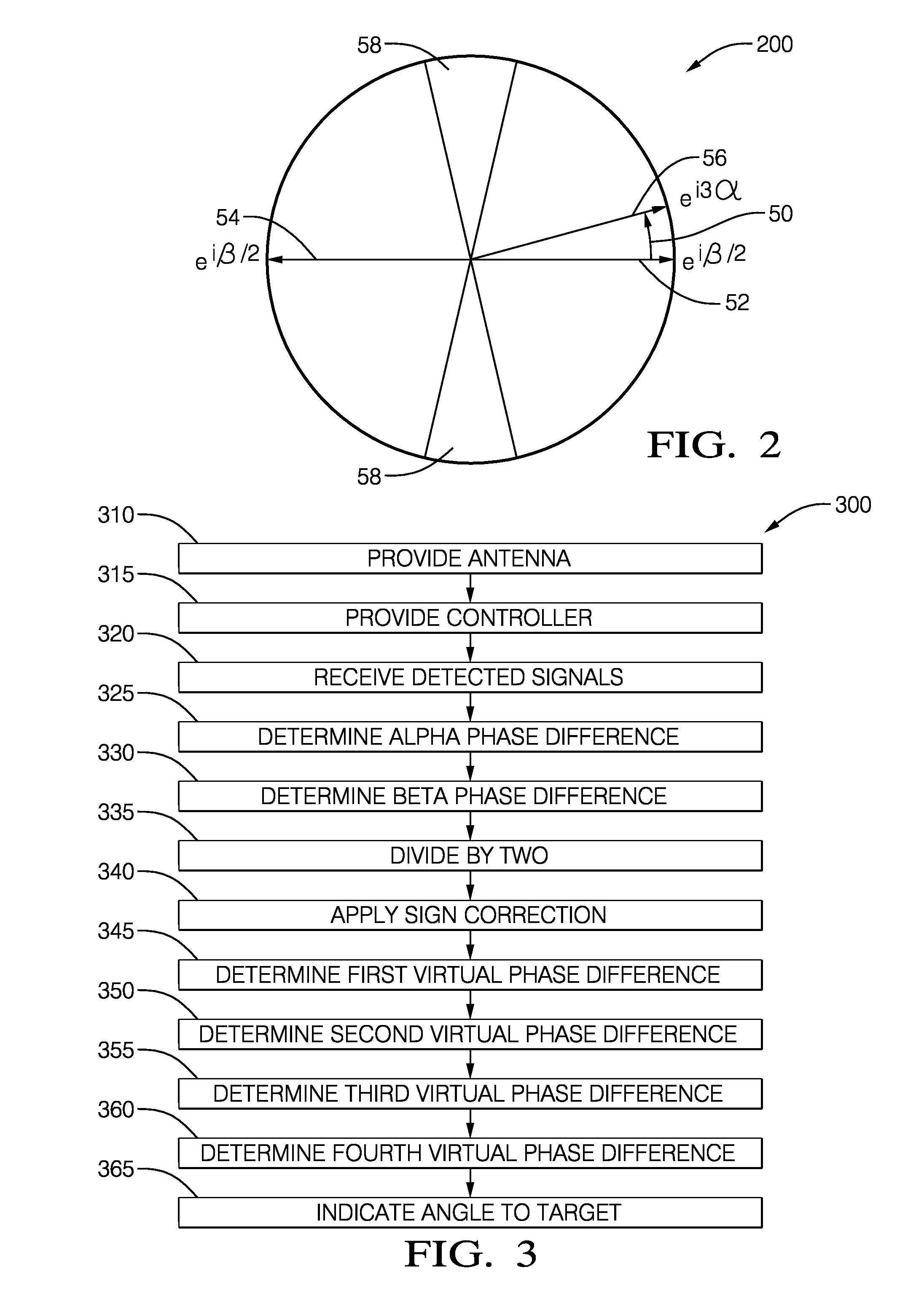

Radar system and method for virtual antenna signals

A radar system includes a radar antenna and a controller. The antenna includes a reference element, an alpha element spaced apart from the reference element by one half-wavelength of the reflected signal, and a beta element spaced apart from the reference element by an even number of half-wavelengths of the reflected signal. The controller is configured to determine an alpha phase difference between detected signals from the reference element and the alpha element, determine a beta phase difference between detected signals from the reference element and the beta element, and determine a first virtual phase difference that corresponds to the reflected signal expected to be detected by a first virtual element located halfway between the reference element and the beta element. The first virtual phase difference is based on the beta phase difference divided by two.

Owner:APTIV TECH LTD

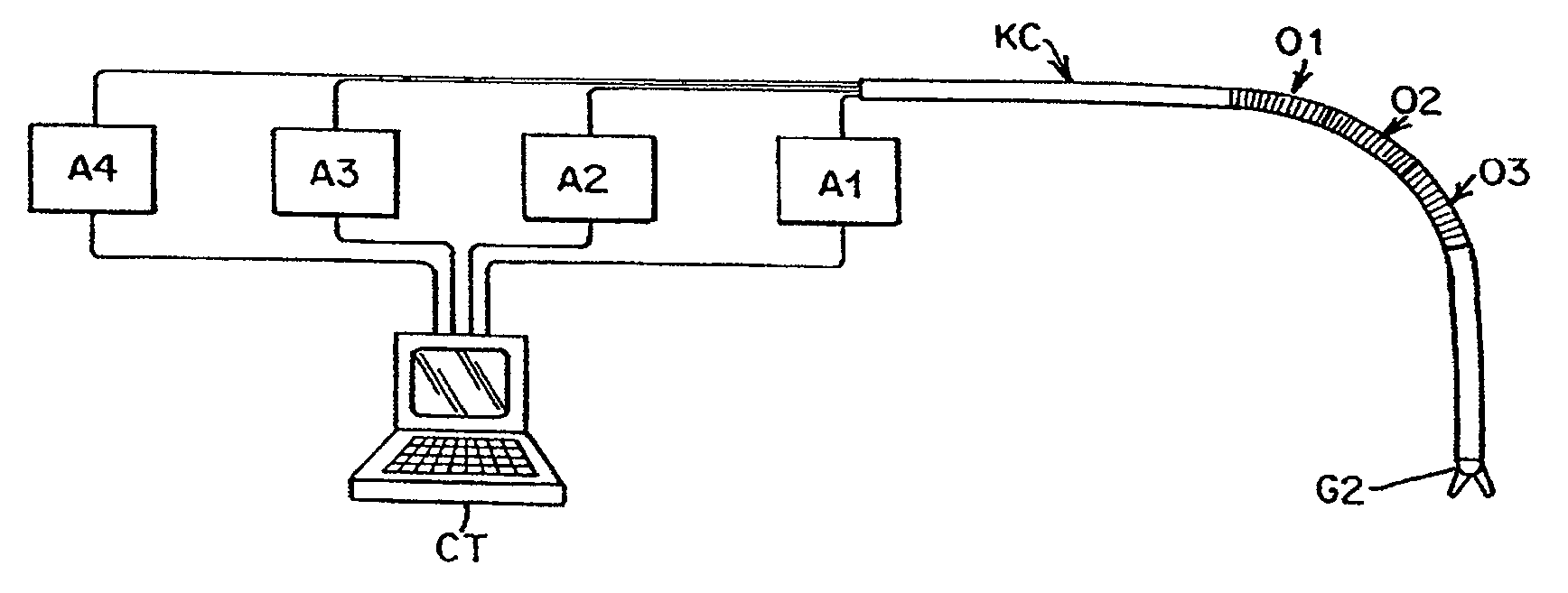

Flexible instrument

InactiveUS20070239170A1Suture equipmentsProgramme-controlled manipulatorElement spaceBiomedical engineering

A medical probe and medical system are provided. The medical probe comprises an elongated shaft, a plurality of electromagnetic elements spaced along the elongated shaft, and a plurality of wires extending through the elongated shaft and configured for energizing the electromagnetic elements that actuate a controlled bending of the elongated shaft. The medical system may comprise the medical probe and a controller configured for energizing the electromagnetic elements via the wires to actuate the controlled bending of the elongated shaft. The medical system may optionally comprise a user interface configured for conveying commands to the controller, in which case, the controller will be configured for energizing the electromagnetic elements via the wires to actuate a controlled bending of the elongated shaft in response to the commands.

Owner:HANSEN MEDICAL INC

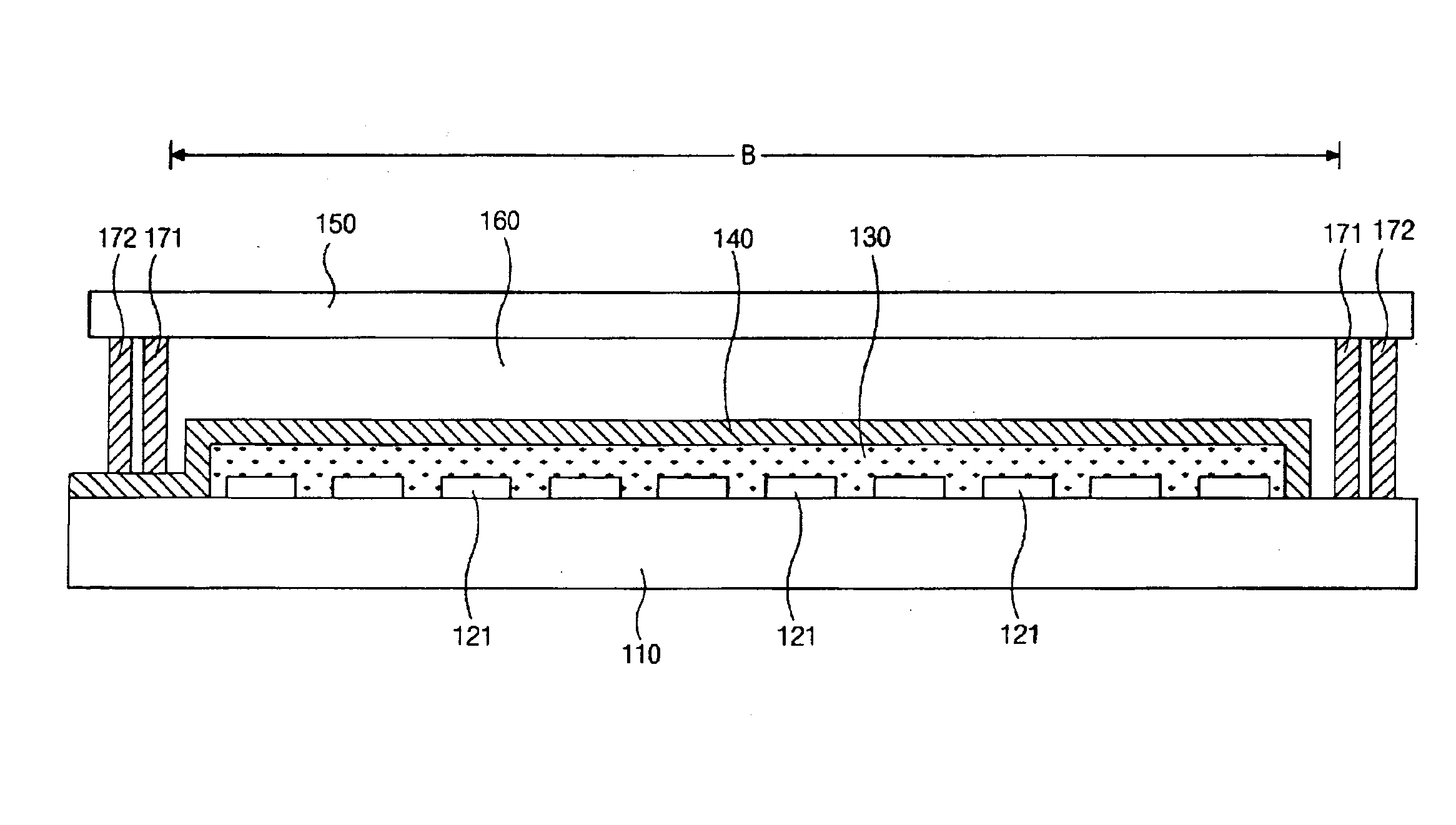

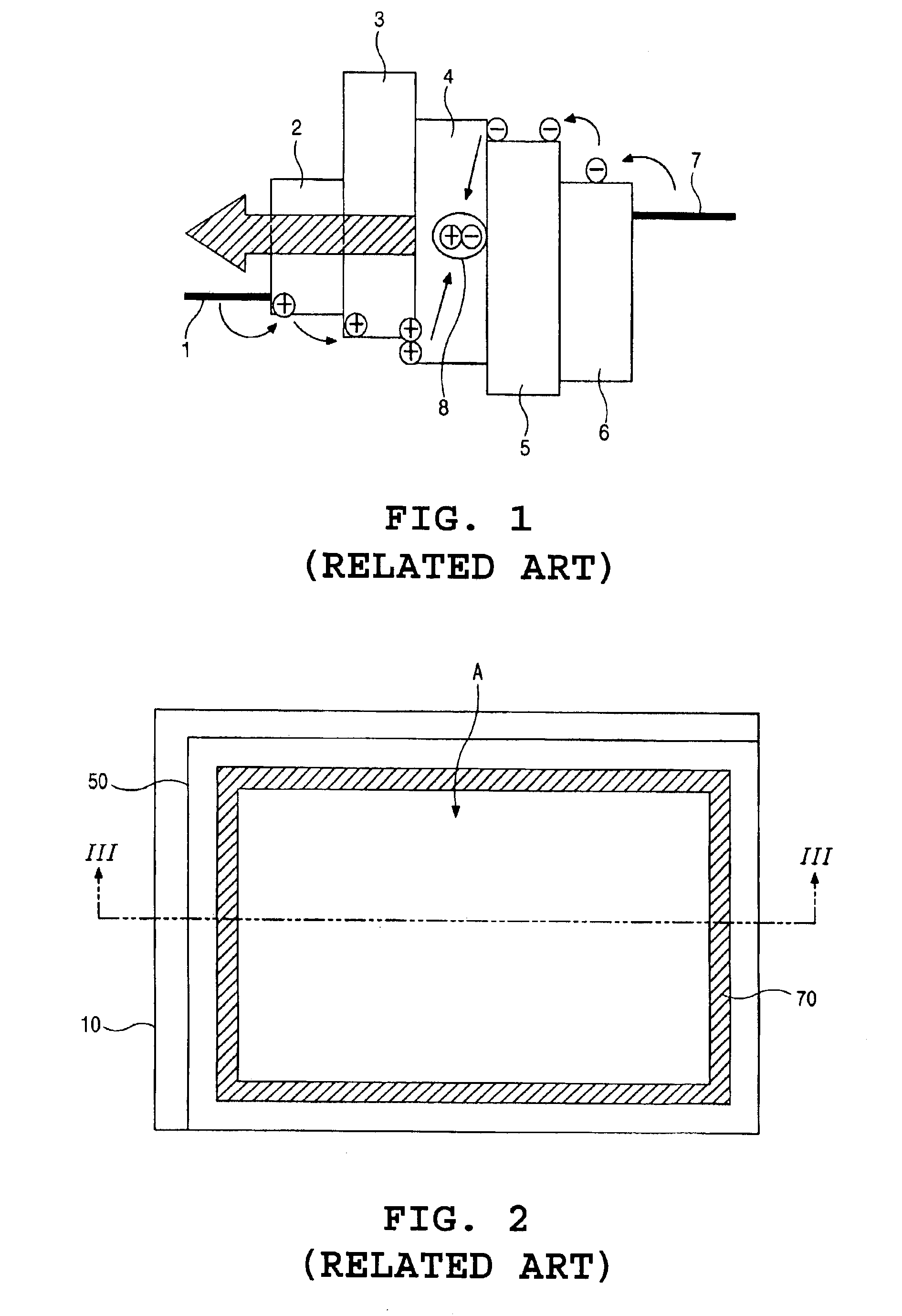

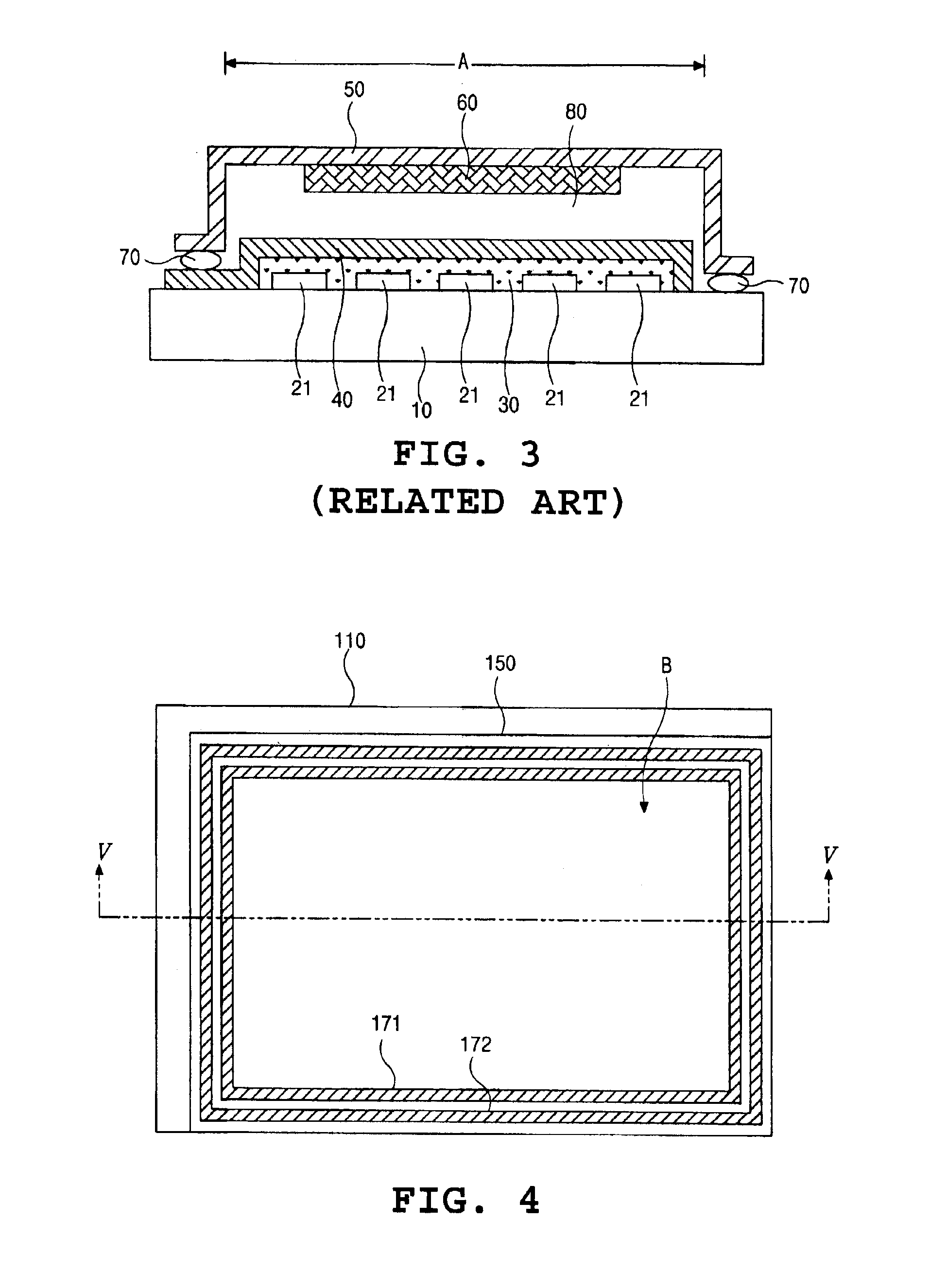

Organic electroluminescence display device having sealing structure and method of fabricating the same

InactiveUS6861801B2Long life-timeLong lastingDischarge tube luminescnet screensElectroluminescent light sourcesElement spaceDisplay device

An organic electroluminescence display device and a method of fabricating the same are disclosed in the present invention. The organic electroluminescence display device includes a substrate, a sealing element spaced apart from the substrate, a first sealant disposed between the substrate and the sealing element, the first sealant defining an array region and an airtight space between the substrate and the sealing element, a second sealant disposed between the substrate and the sealing element, the second sealant surrounding the first sealant, a first electrode in the array region on an inner surface of the substrate, an emissive layer on the first electrode, and a second electrode on the emissive layer.

Owner:LG DISPLAY CO LTD

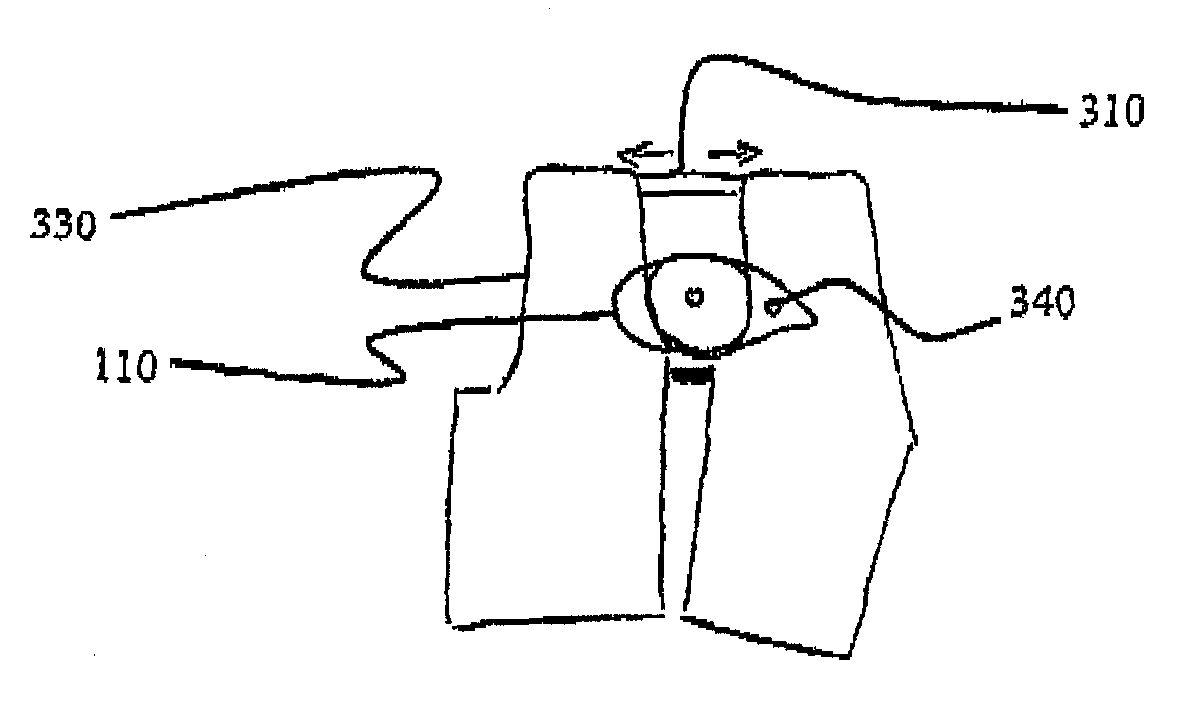

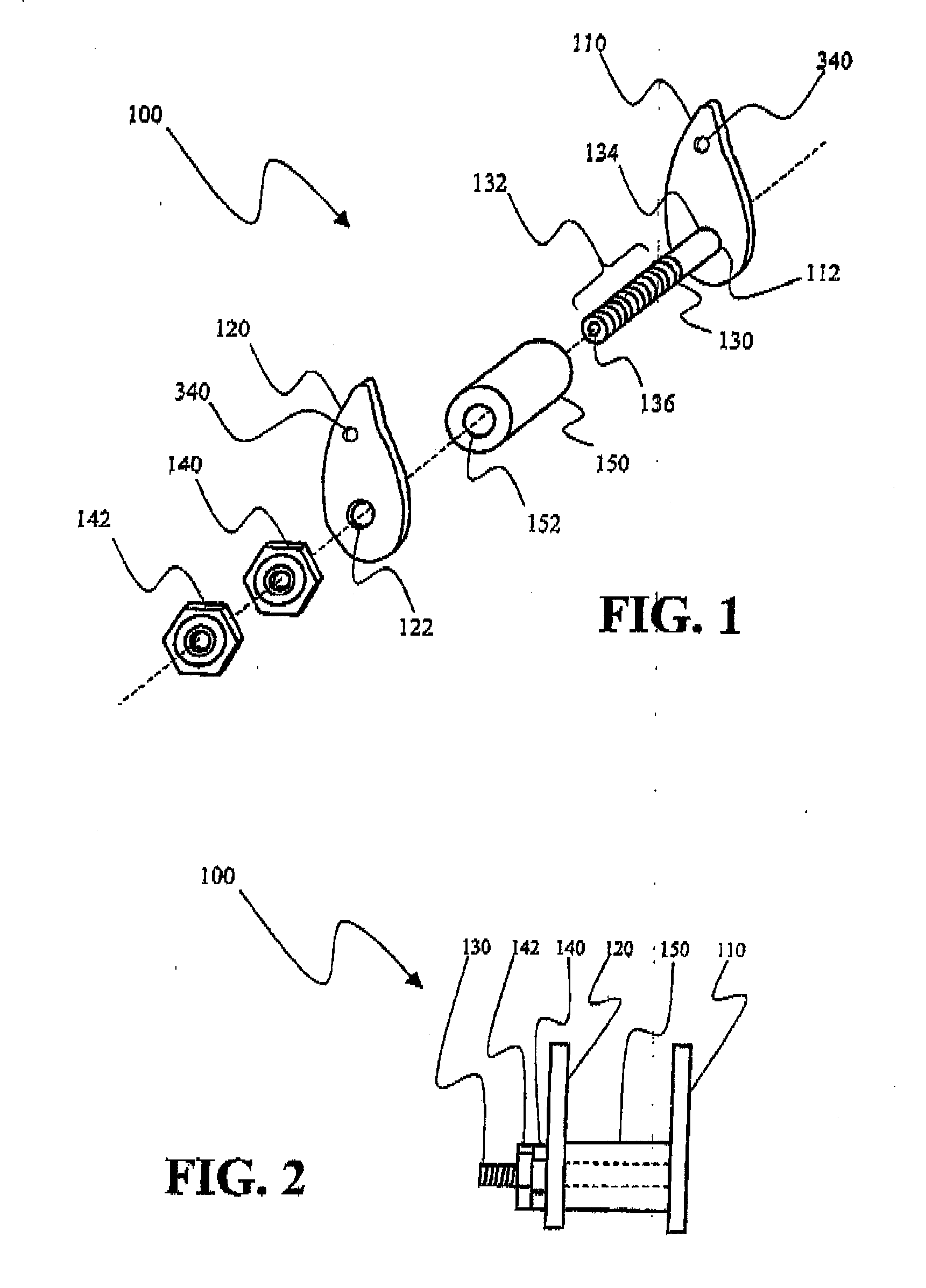

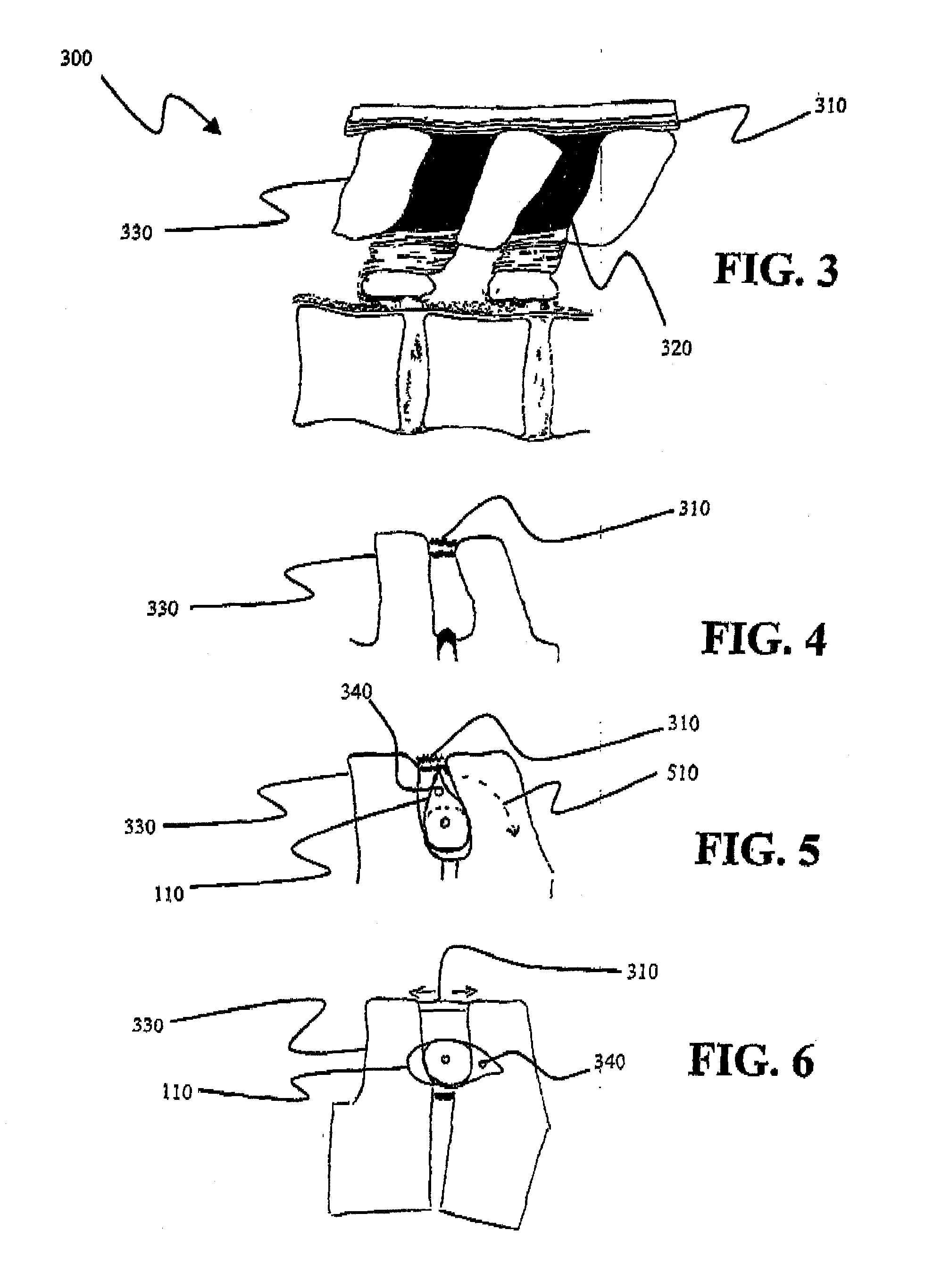

Interspinous Internal Fixation/Distraction Device

ActiveUS20100241166A1Improved interspinous fixationIncreased distractionInternal osteosythesisJoint implantsElement spaceDistraction

Disclosed are an apparatus for an interspinous fixation and / or distraction of vertebrae and a methodology for minimally invasive implantation of the apparatus in the spine of a patient. The apparatus corresponds to a pair of teardrop shaped lateral wing elements spaced apart by a central core element that may be selectively sized during the implantation process. The wings and central core are held together by a single threaded bolt and locking nut configuration resulting in a simple structure that may be easily implanted with minimal patient discomfort.

Owner:GLOBUS MEDICAL INC

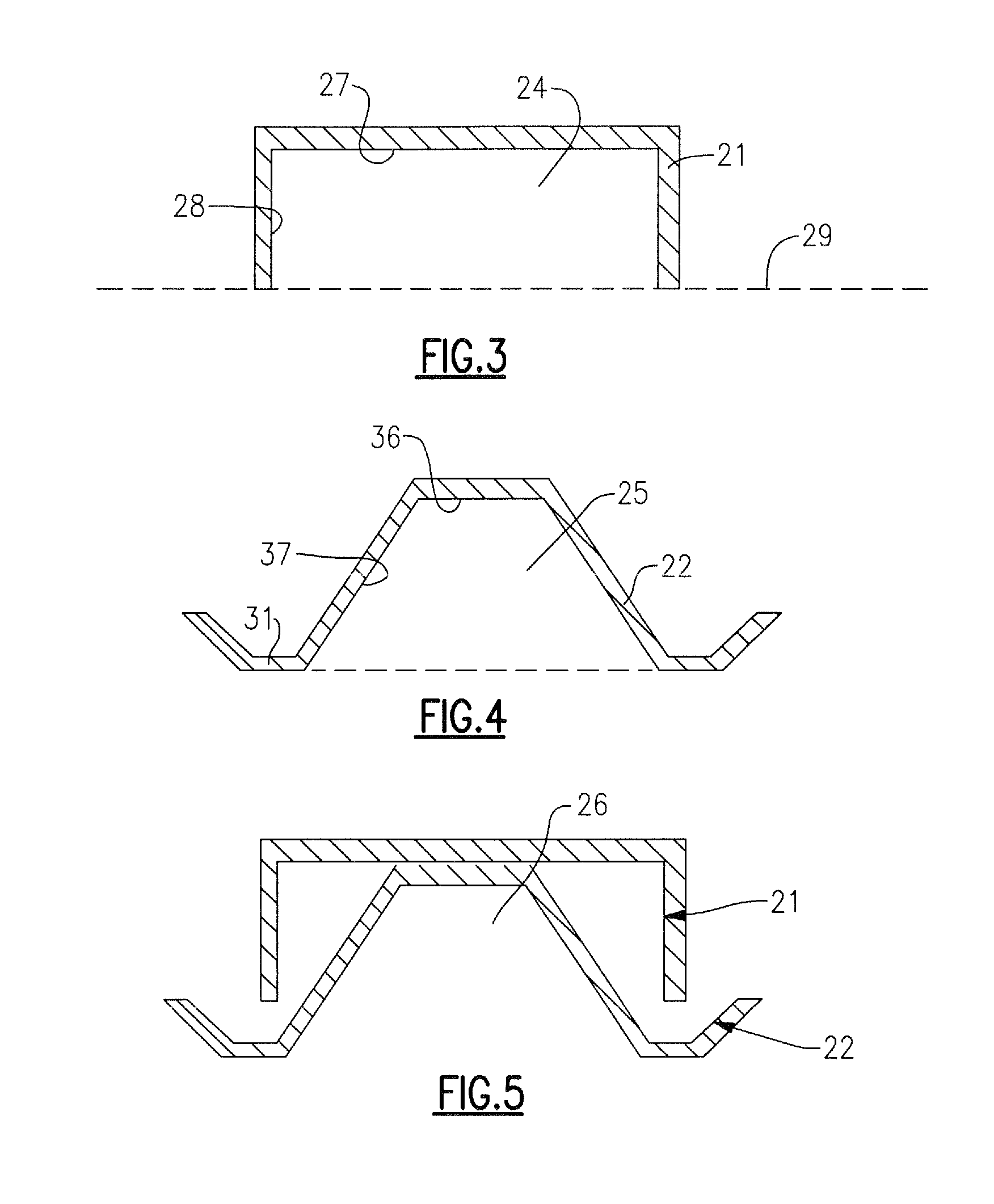

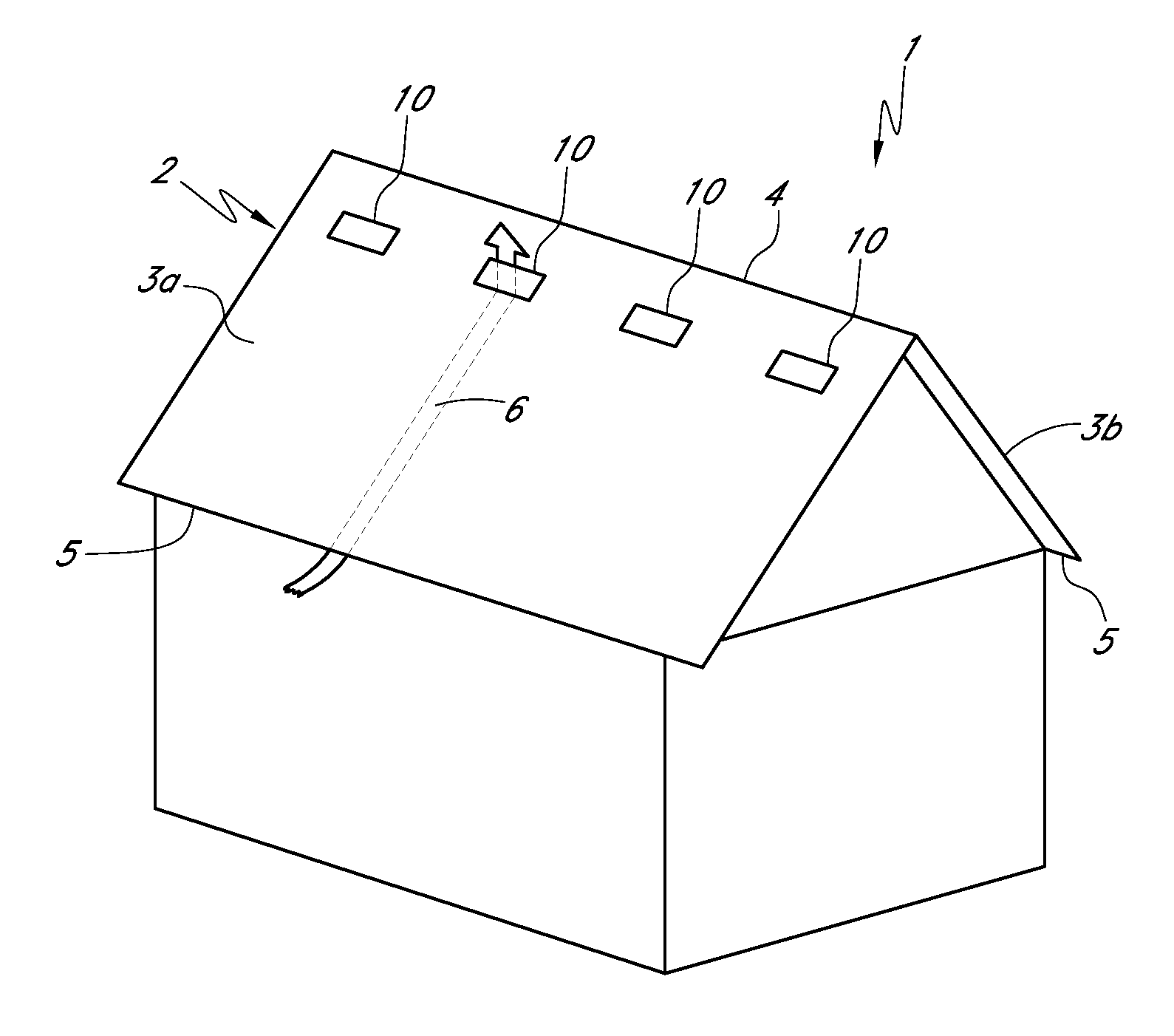

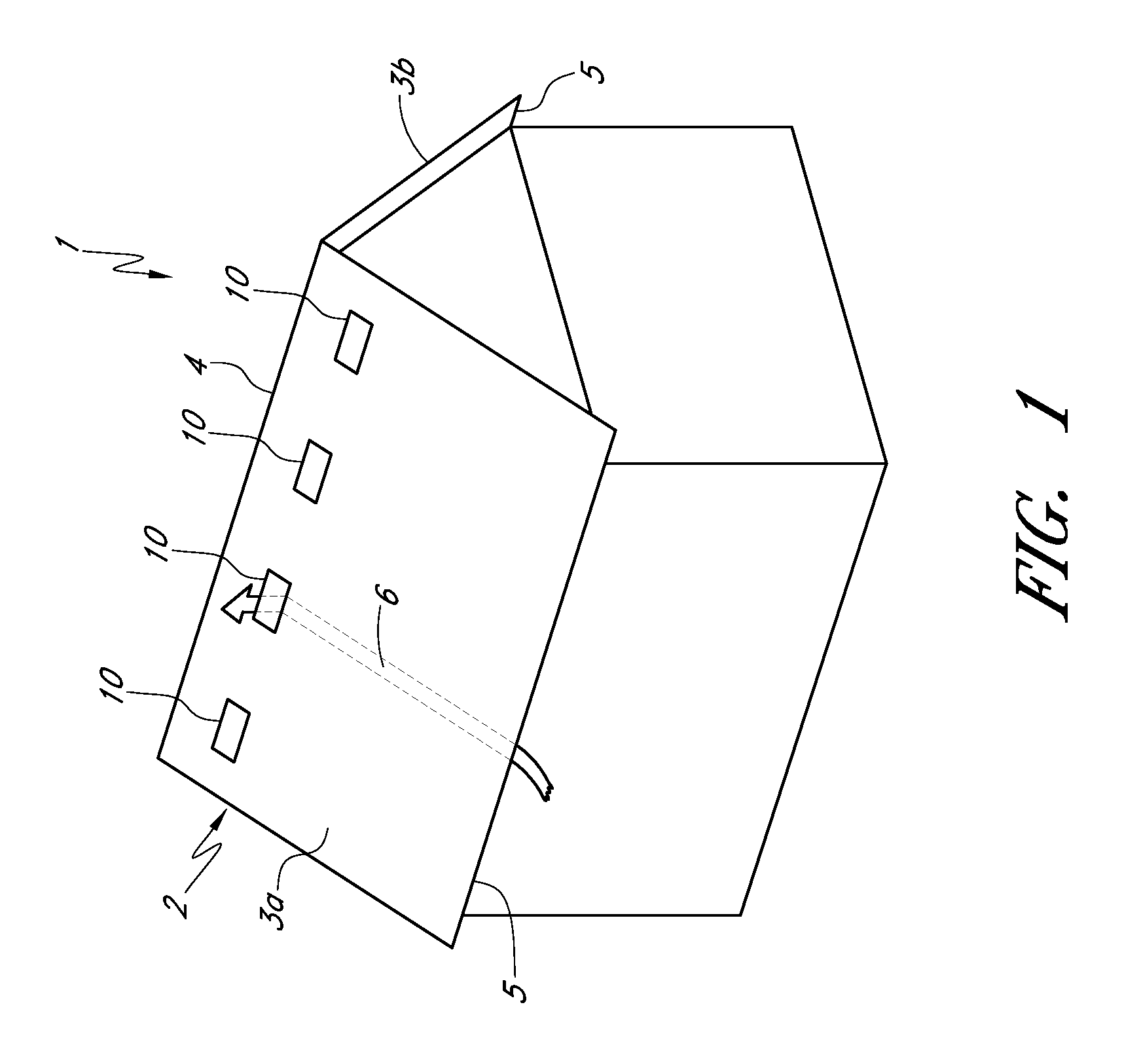

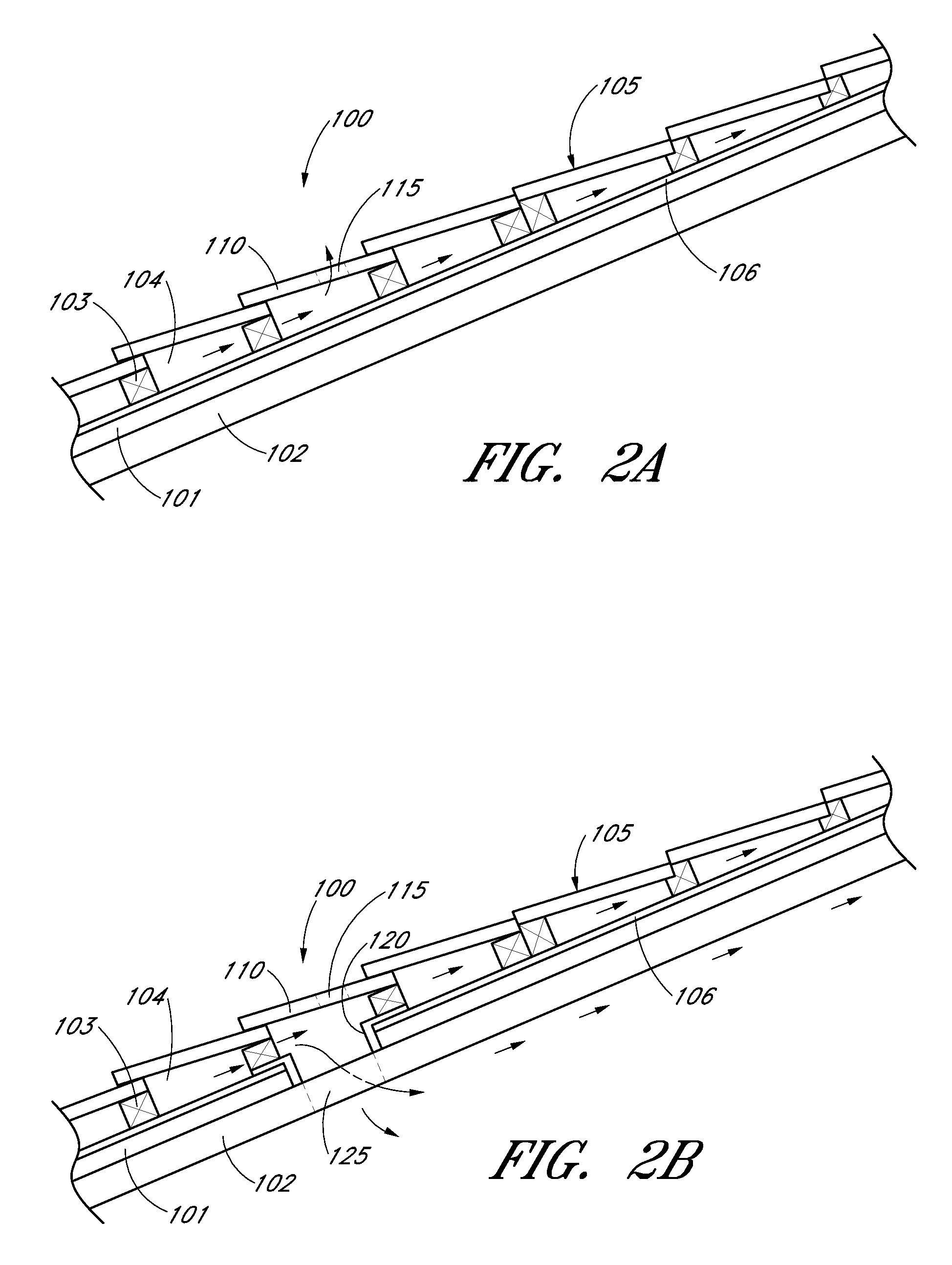

Above sheathing ventilation system

A roof structure and a vented eave riser are described. A vented eave riser can include a barrier wall with one or more air flow openings, and an ember impedance structure positioned proximate to the barrier wall. A roof structure may comprise a roof deck and a layer of roof cover elements spaced above the roof deck to form an air layer between the roof deck and the roof cover elements. The roof structure may also comprise one or more vent members each replacing and mimicking an appearance of one or more roof cover elements of the layer of roof cover elements, and / or at least one vented eave riser positioned at an eave between the roof deck and the layer of roof cover elements. The vent members and / or the vented eave riser may further include an ember impedance structure, such as a fire-resistant mesh material or a baffle structure.

Owner:ODANIELS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com