Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

238 results about "Cobalt based alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt based materials are alloyed with chrome, nickel, and tungsten. Due to the high cost of these alloys, they are used where severe conditions prevail and require high temperature strength and hardness, excellent wear, galling, corrosion, and/or erosion resistance. Due to the high chromium content...

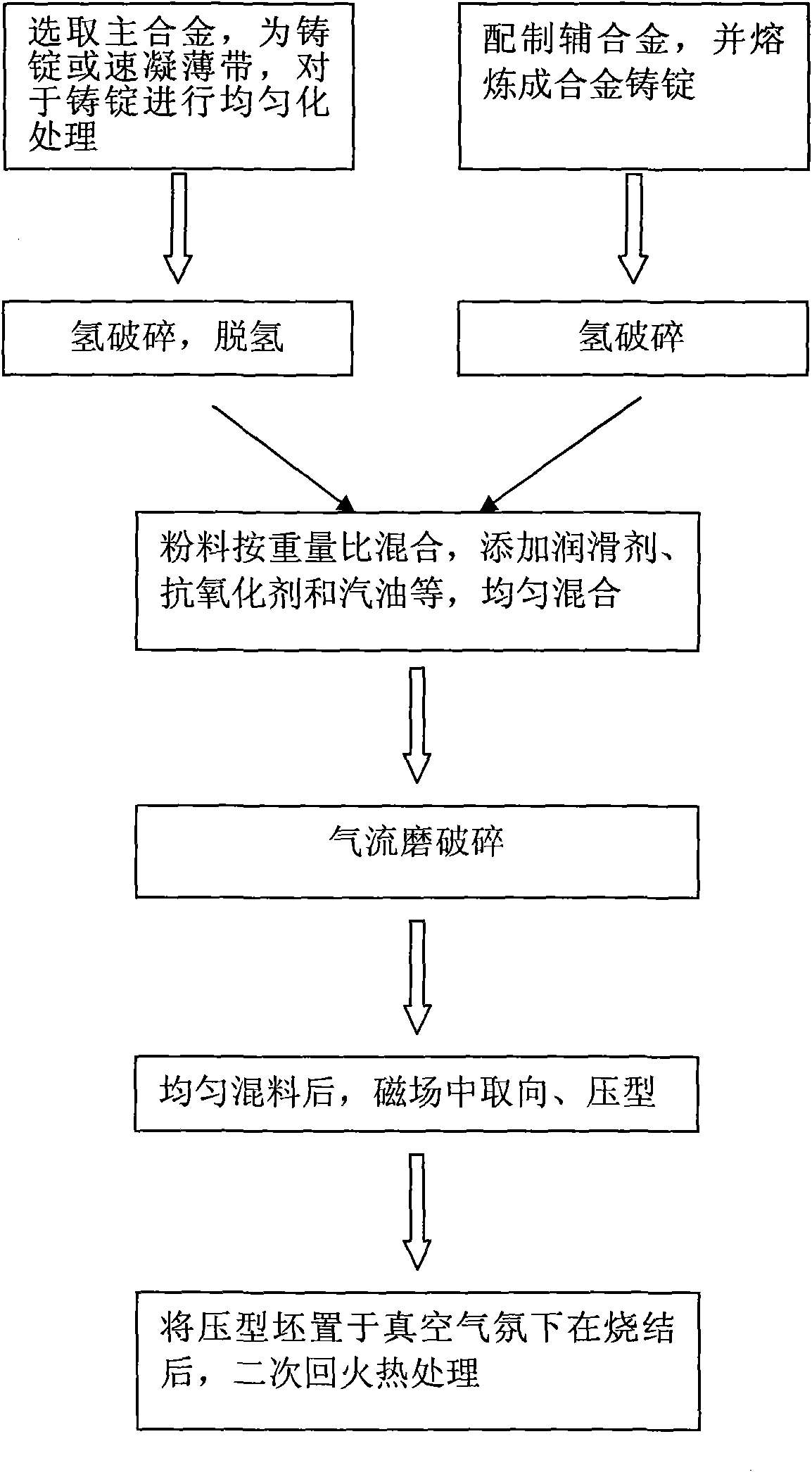

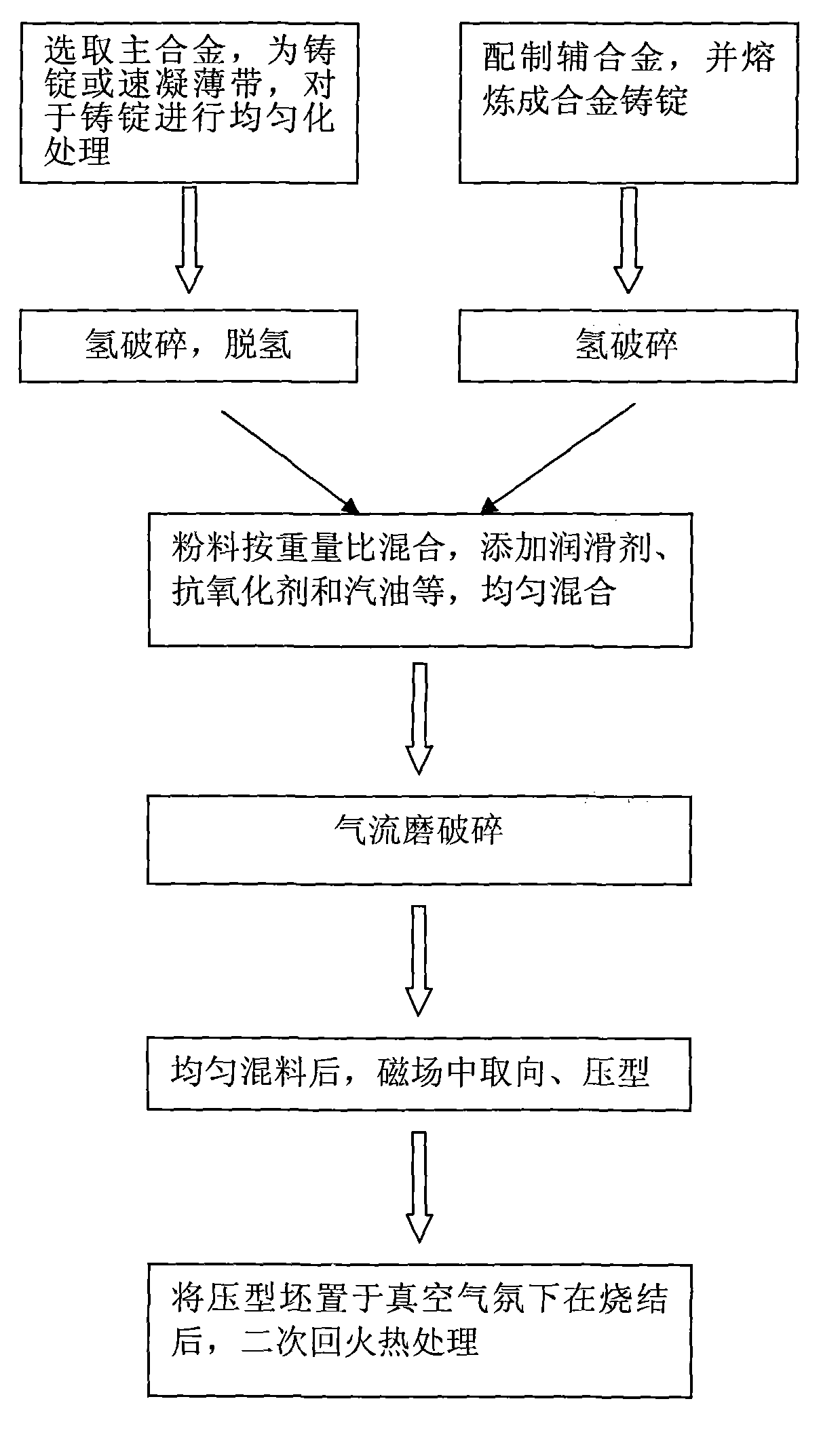

Method for preparing corrosion-resistant sintered neodymium iron boron (NdFeB) magnet

InactiveCN101958171AStrong resistance to electrochemical corrosionReduce weightlessnessInductances/transformers/magnets manufactureMagnetic materialsWeightlessnessRare earth

The invention discloses a method for preparing a corrosion-resistant sintered neodymium iron boron (NdFeB) magnet. In the method, an intergranular phase optimized design is used as a starting point on the basis of preparation technology of a double-alloy method, the high-cobalt content rare earth cobalt-based alloy which does not contain iron and boron is selected as an auxiliary alloy, and the melting point of the auxiliary alloy is ensured to be lower than 1,050 DEG C through component control so as to meet the liquid-phase sintering effect. By measuring the weightlessness condition of the material placed in an environment of the temperature of 120 DEG C, two atmosphere and 100 percent of humidity for 96 hours, results show that the weightlessness of the prepared sintered NdFeB magnet is only less than 1 / 3 of that of the sintered NdFeB magnet prepared by a single-alloy method and a conventional double-alloy method, and the sintered NdFeB magnet has excellent corrosion resistance. The method for preparing the corrosion-resistant sintered NdFeB magnet can be widely applied in the field of production of high-performance sintered NdFeB magnets.

Owner:WUXI NANLIGONG TECH DEV +2

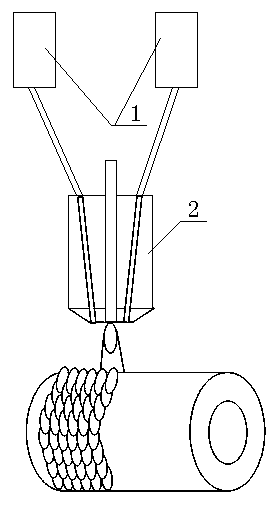

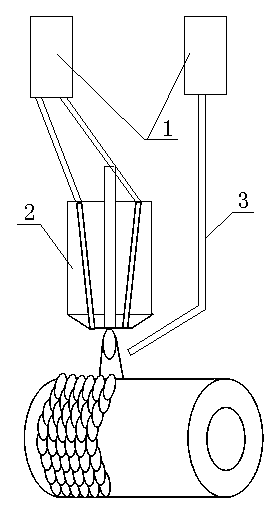

Laser cladding Co-based alloy powder for conductor roll

InactiveCN101187022ASolve repair problemsImprove performanceMetallic material coating processesChemical compositionAlloy substrate

Provided is cobalt-based alloy powder for laser cladding electricity conducting roller, the weight percentages of the chemical components of the material are that Cr is 24-30%, W is 6-10%, Mo is 3-6%, Ni takes 6-12%, Fe holds 2-10%, Mn is 0.5-2%, Si holds 0.2-2%, V is 0.1-0.6%, B takes 0.3-1.5%, C holds 0.5-2.5%, Y2O3 is 0-0.5%, Hf takes 0-0.5%, La2O3 holds 0-0.5%, Ce is 0-0.5%, and the rest is Co. The invention has the advantages that with multiple strengthened methods, the alloy substrate is strengthened and the crystal boundary quality is improved, which enables the alloy to achieve perfect combination property, thereby achieving medium rigidity and relatively high intensity of the alloy, simultaneously forming self-fluxing alloy and reducing alloy melting point, and increasing properties of oxidation resistance, abrasion resistance, corrosion resistance, and certain electricity conduction.

Owner:SHENYANG DALU LASER TECH

High abrasion-proof laser cladding cobalt-base alloy powder and preparation method thereof

InactiveCN102943266AImprove toughnessHigh hardnessMetallic material coating processesCarbideHardness

The invention relates to a high abrasion-proof laser cladding cobalt-base alloy powder and a preparation method of the alloy powder. The high abrasion-proof laser cladding cobalt-base alloy powder is characterized by comprising matrix alloy powder, hard carbide particles and a bonding agent; and the combined powder comprises 50-98% of matrix alloy powder, 1-45% of WC or TiC or mixed powder of WC and TiC, and 1-5% of bonding agent. The preparation method comprises the following steps of: preparing the matrix alloy powder, adding the carbide particles into the prepared matrix alloy powder, adding bonding agent into the mixture, stirring, ball milling, combining the powder, drying, crushing and screening. The high abrasion-proof laser cladding cobalt-base alloy powder not only is high in hardness and toughness, but also has excellent wear resistance and corrosion resistance, thus being especially suitable for laser cladding of parts with high impact resistance and high abrasion-proof property. Furthermore, the phenomenon of segregation caused by great differences among the specific gravities of all components in the processes of storage, transportation and using can be effectively prevented.

Owner:江苏新亚特钢锻造有限公司

High-temperature-stability gamma'-phase-reinforced cobalt-base high-temperature alloy and preparation method thereof

The invention belongs to the technical field of new materials, and relates to a gamma'-phase high-temperature-stability cobalt-base high-temperature alloy with gamma / gamma' two-phase structure, which is a candidate material for high-temperature hot end components of gas turbines for aviation, spaceflight, vessels, power generation and the like. The alloy comprises the following components in atomic percentage: 4-12% of Al, 4-12% of W, 1-4% of Ta, 1-6% of Ti, 0-10% of Cr, 0-3% of Mo, 0-2% of Hf, 0-1% of C, 0-1% of B and the balance of Co. The preparation method comprises the following steps: smelting in a vacuum induction furnace, carrying out solid solution heat treatment at 1250-1300 DEG C, and carrying out aging heat treatment at 1000-1100 DEG C. After carrying out L12-type gamma'-phase high-temperature reinforcement, the gamma' shape is cubic, the volume percent is higher than 60%, and the gamma'-phase is uniformly distributed in the gamma-phase. Compared with the traditional cobalt-base high-temperature alloy, the alloy provided by the invention has higher application temperature; and compared with the recently developed similar cobalt-base alloys, the alloy provided by the invention has higher gamma'-phase solution temperature and gamma / gamma' two-phase structure stable existence temperature.

Owner:UNIV OF SCI & TECH BEIJING

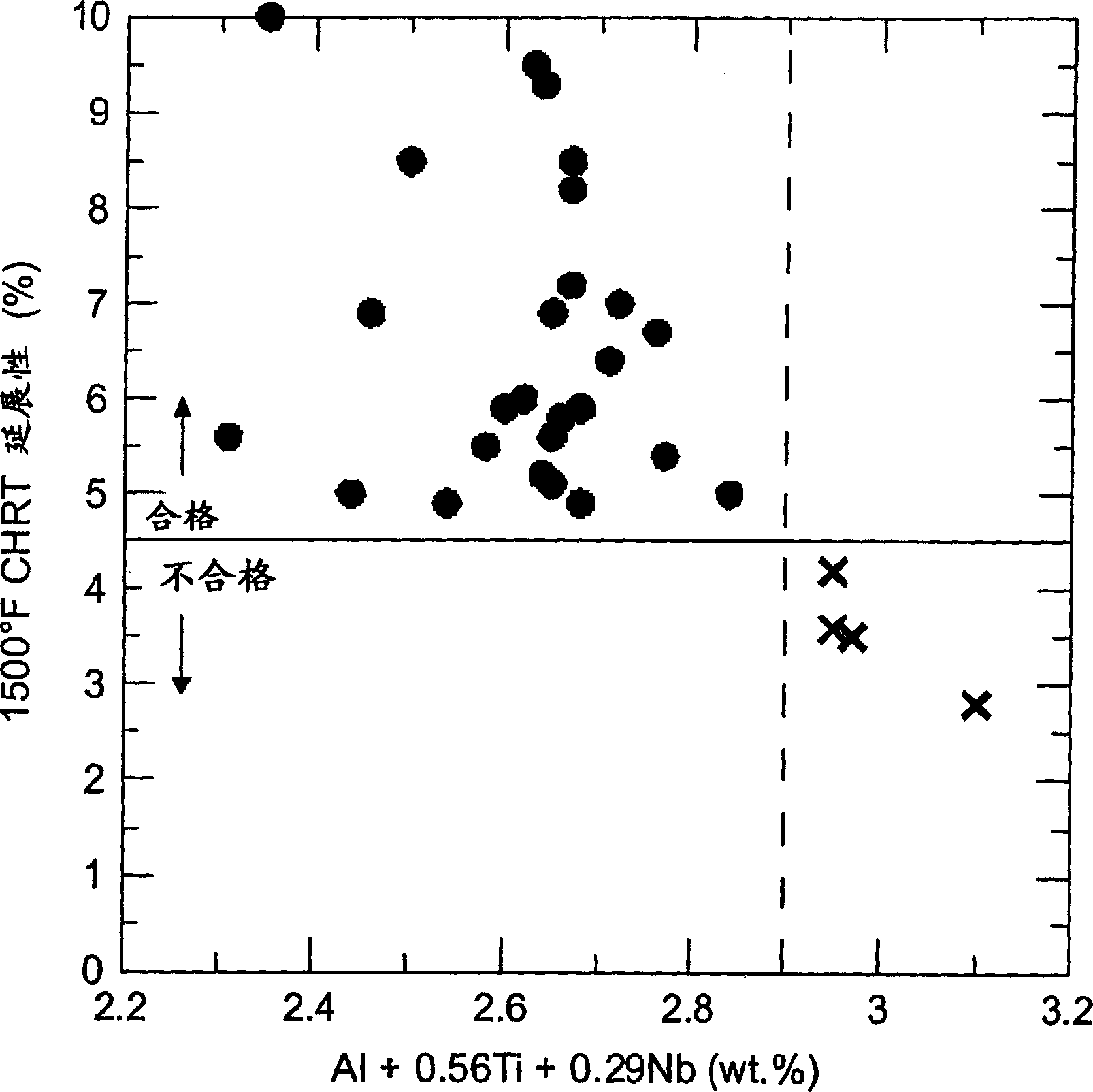

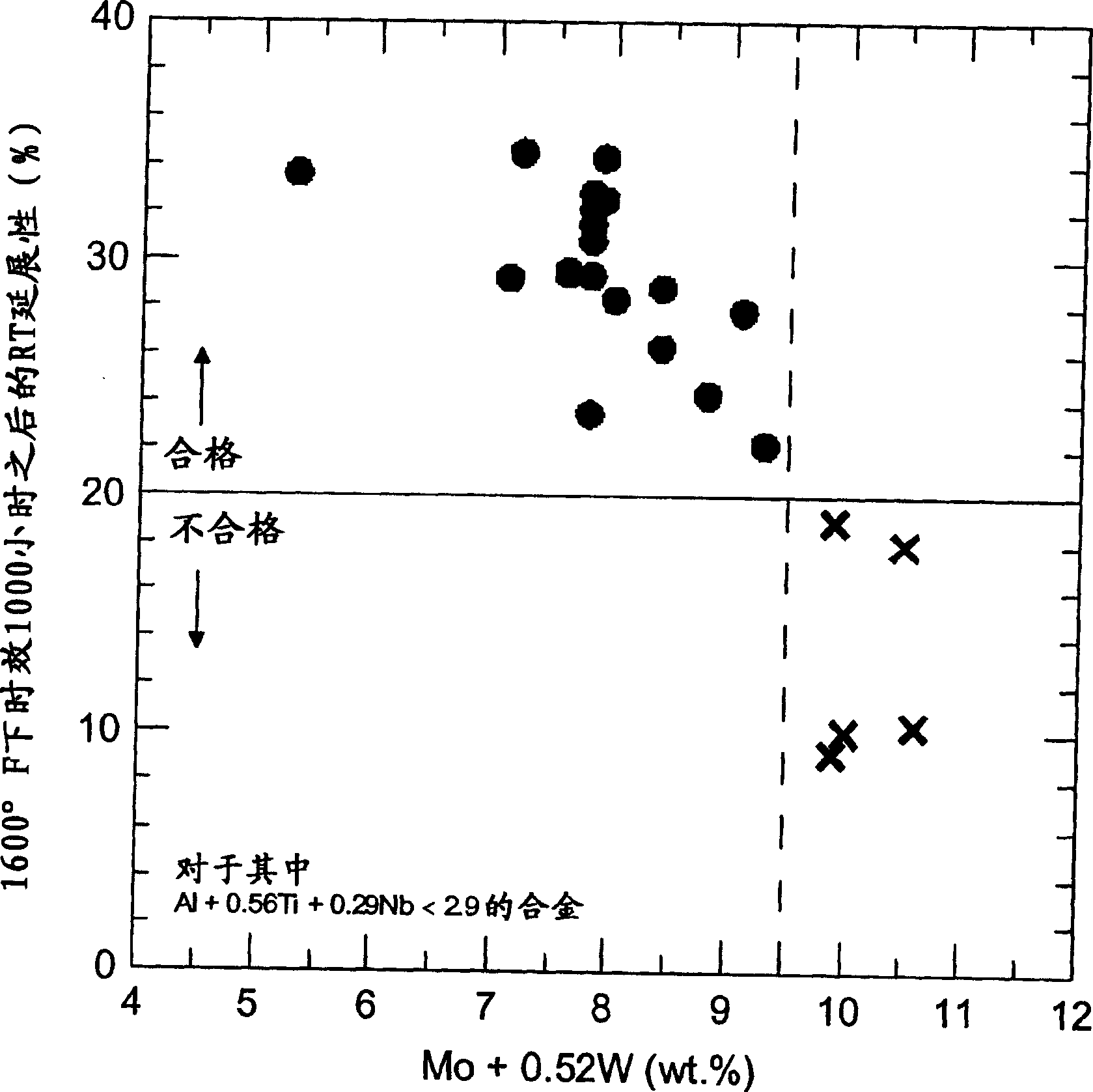

Ni-Cr-Co alloy for advanced gas turbine engines

Owner:HAYNES INTERNATIONAL

Laser fusion welding method of abrasion-proof heat-proof composite coating on surface of tuyeres of blast furnace port sleeve

InactiveCN101109026AImprove wear resistanceImprove corrosion resistanceMolten spray coatingTuyeresHigh power lasersWear resistant

The invention relates to a wear-resistant and heat-resistant complex coating laser fusion approach on the tuyere surface of a blast furnace. The high power laser quickly scans and welds the tuyere surface of the blast furnace and metallurgically combines with the substrate materials to form a good nickel-based toughness transition layer. The laser bandwidth clads the nickel-based toughness transition layer to produce a cobalt-based alloy with excellent effects of wear-resistant and heat-resistant. The technology process comprises the following steps: firstly the blast furnace tuyere is pre-treated; secondly the pre-deposited nickel-base alloy is coated with plasma; thirdly the nickel-based alloy is welded quickly by the high power laser; fourthly the cobalt-based alloy is clad by the high power laser bandwidth; finally is the following heat treatment. The invention can avoid the structure stress caused by the difference between the substrate material and the cladding material in the laser cladding process. In addition, the treatment to the copper substrate before and after laser cladding can decrease temperature gradient so as to prevent the cladding layer from cracking to a certain degree.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

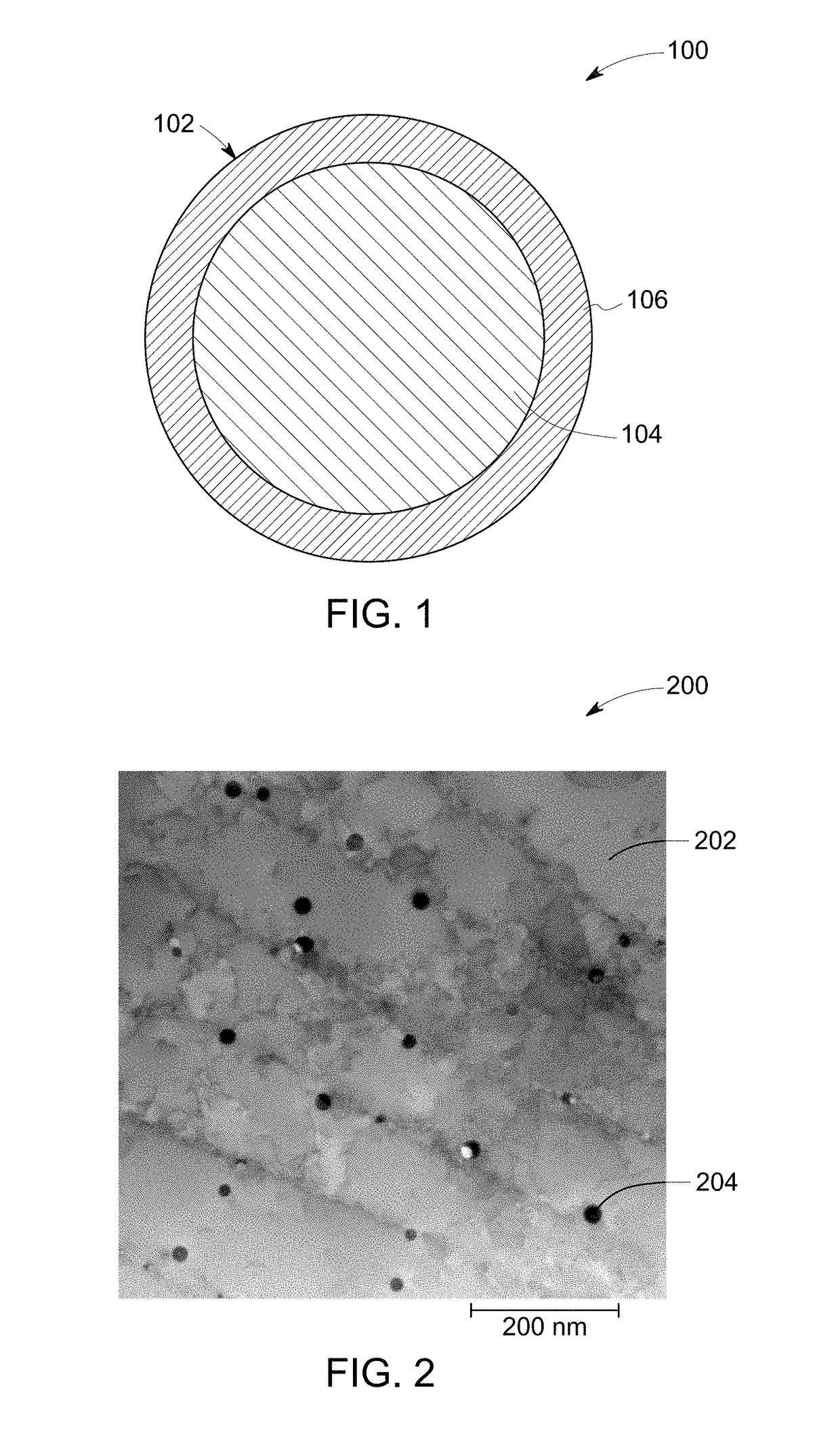

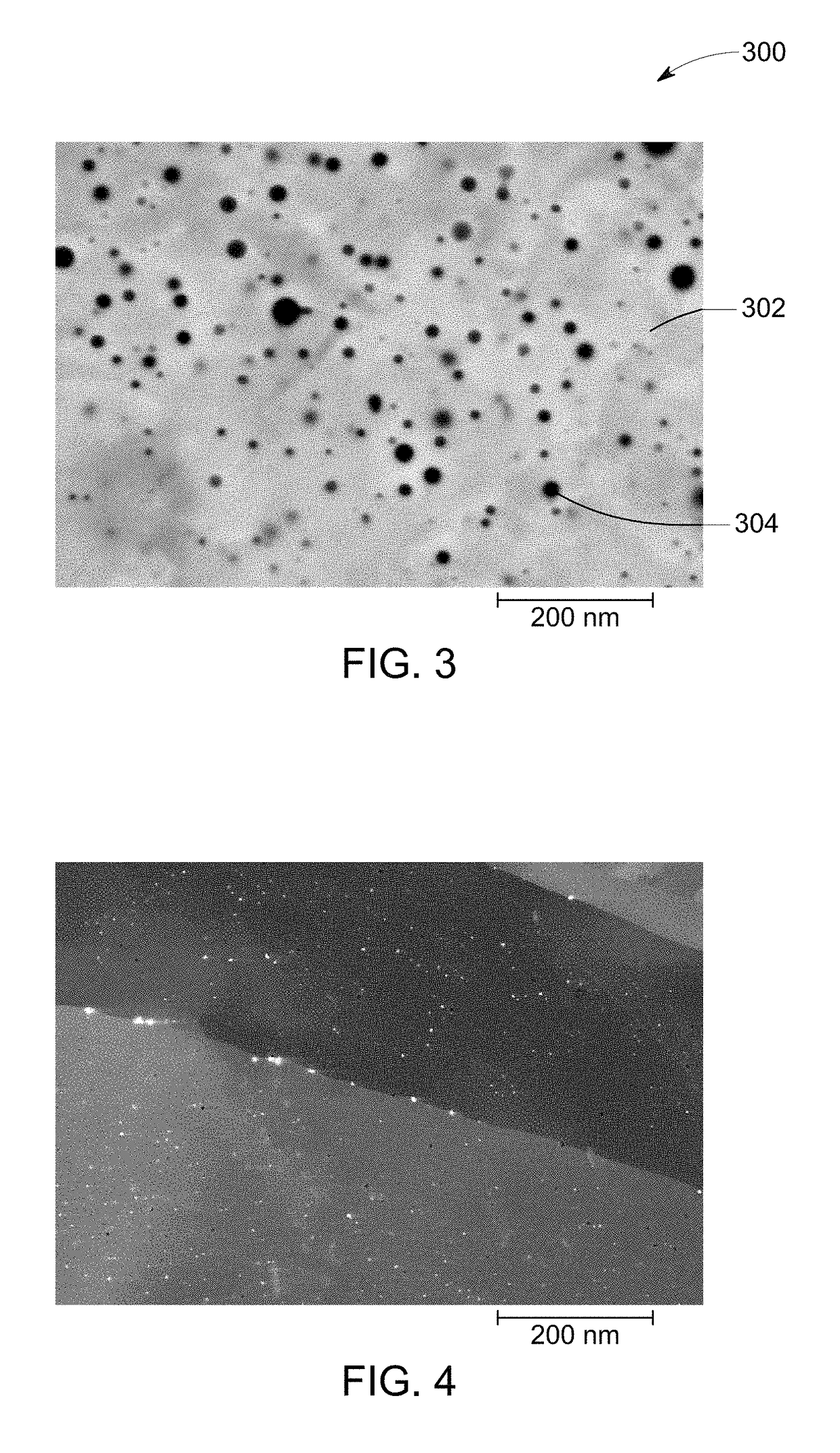

Additive manufacturing method and materials

PendingUS20180193916A1Additive manufacturing apparatusTransportation and packagingOxygen richAdditive layer manufacturing

A core-shell structured alloy powder for additive manufacturing, an additively manufactured precipitation dispersion strengthened alloy component, and a method for additively manufacturing the component are provided. The alloy powder comprises a plurality of particles, where one or more of the plurality of particles comprise an alloy powder core and an oxygen or nitrogen rich shell disposed on at least a portion of the alloy powder core. The alloy powder core comprises an alloy constituent matrix with one or more reactive elements, where the reactive elements are configured to react with oxygen, nitrogen, or both. The alloy constituent matrix comprises stainless steel, an iron based alloy, a nickel based alloy, a nickel-iron based alloy, a cobalt based alloy, a copper based alloy, an aluminum based alloy, a titanium based alloy, or combinations thereof. The alloy constituent matrix comprises reactive elements present in a range from about 0.01 weight percent to 10 weight percent of a total weight of the alloy powder.

Owner:GENERAL ELECTRIC CO

Cobalt-based alloy powder for laser cladding of steam turbine last-stage blade

InactiveCN102021559AImprove performanceHigh hardnessMetallic material coating processesHardnessWear resistance

The invention discloses cobalt-based alloy powder for the laser cladding of a steam turbine last-stage blade. The powder comprises Cr, W, Co, Zr and Hf and is characterized by also comprising Ni, Mn, Si and C, wherein the powder comprises the following components in percentage by mass: 0.4 to 0.9 percent of C, 24 to 30 percent of Cr, 6 to 10 percent of W, 8 to 14 percent of Ni, 0.3 to 0.8 percent of Mn, 0.5 to 1.0 percent of Si, 0.02 to 0.06 percent of Zr, 0.25 to 0.5 percent of Hf and the balance of Co. The powder is cladded on a disabled steam turbine last-stage blade by a laser cladding processing method to form a cobalt-based alloy coating with high hardness, oxidation resistance, corrosion resistance, erosive wear resistance, high strength and high cladding performance so as to solve the technical problem of the repair of the steam turbine last-stage blade.

Owner:成都大陆激光技术有限公司

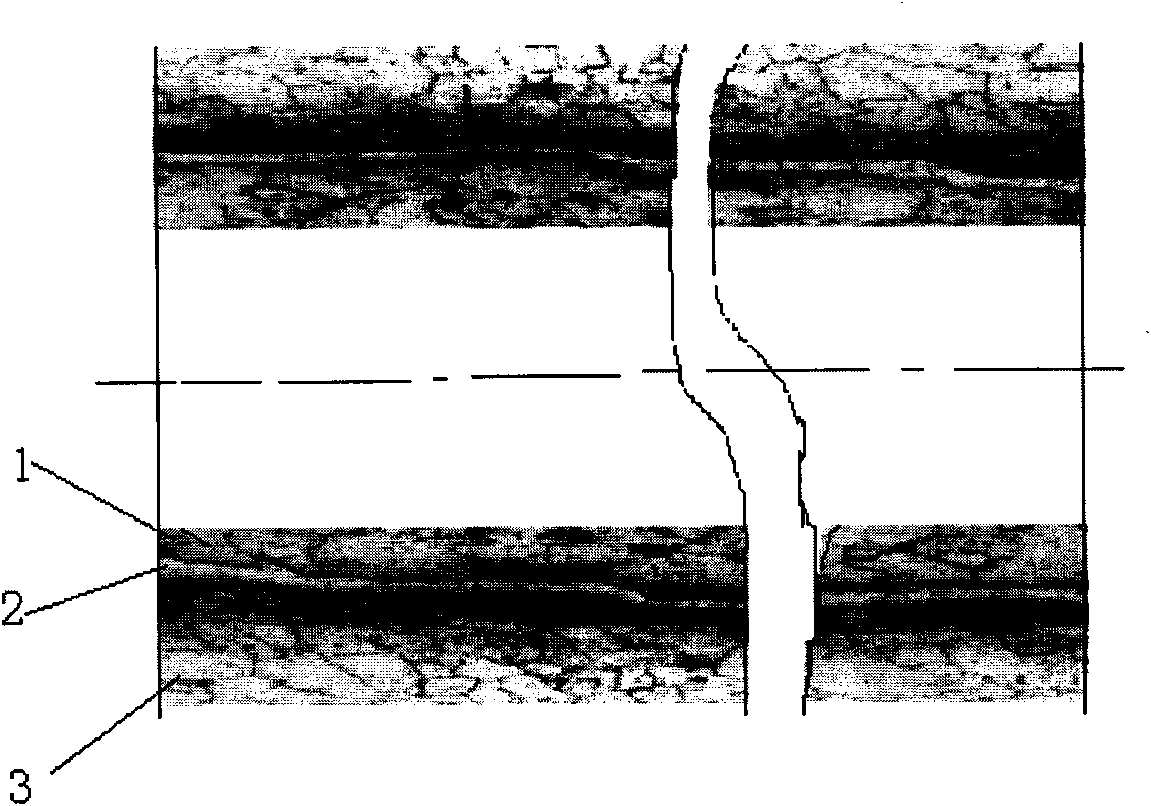

Target foil for use in the production of [18f] using a particle accelerator

InactiveUS20090052628A1High strengthConversion outside reactor/acceleratorsX-ray tube electrodesParticle acceleratorNiobium

The invention is directed to a novel foil for use as an entrance window foil during the production of [18F] by irradiation of [18O] using a particle accelerator. The foil is a high strength cobalt based alloy foil, thin film coated with an inert and refractory metal such as niobium.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA +1

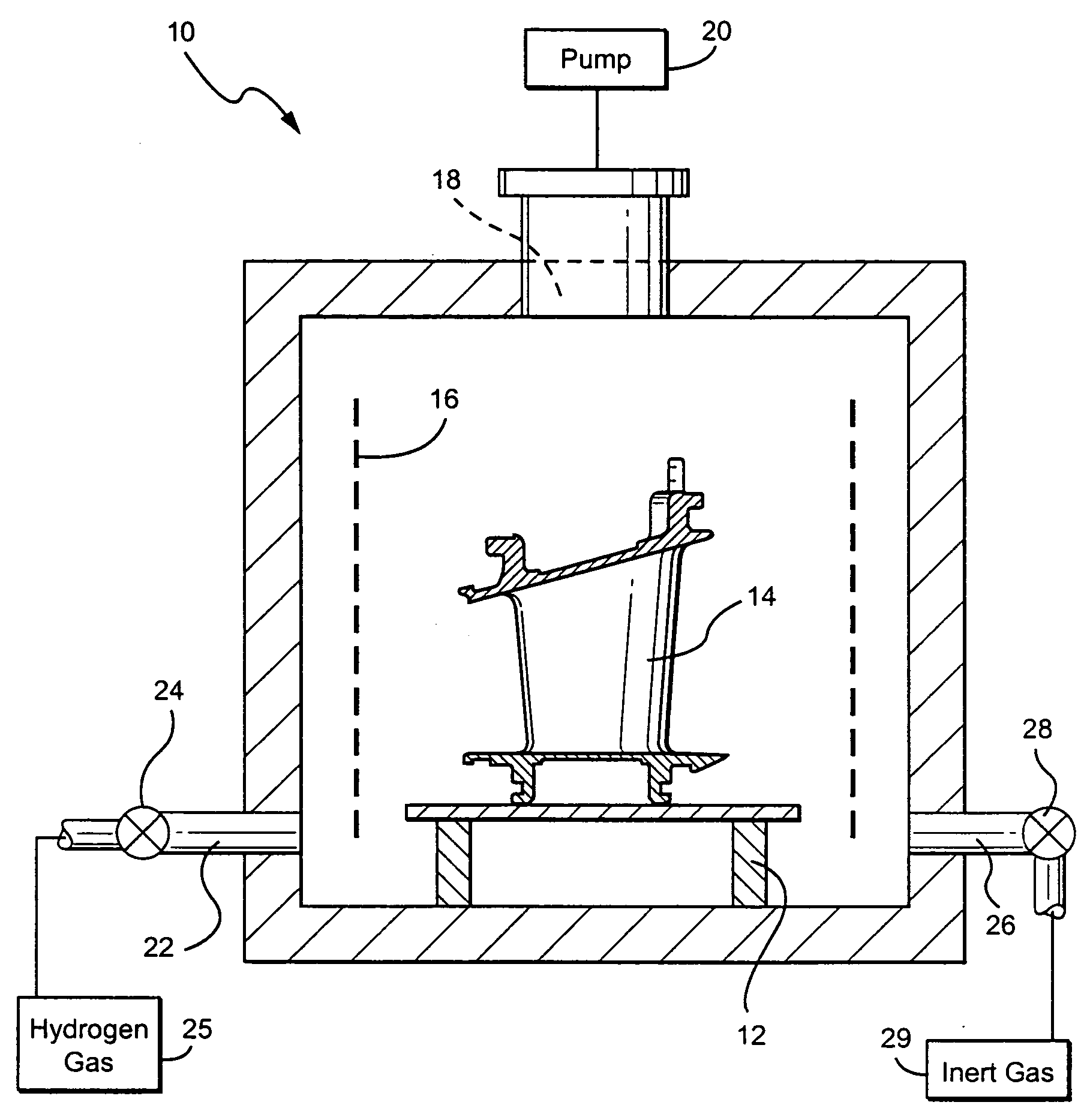

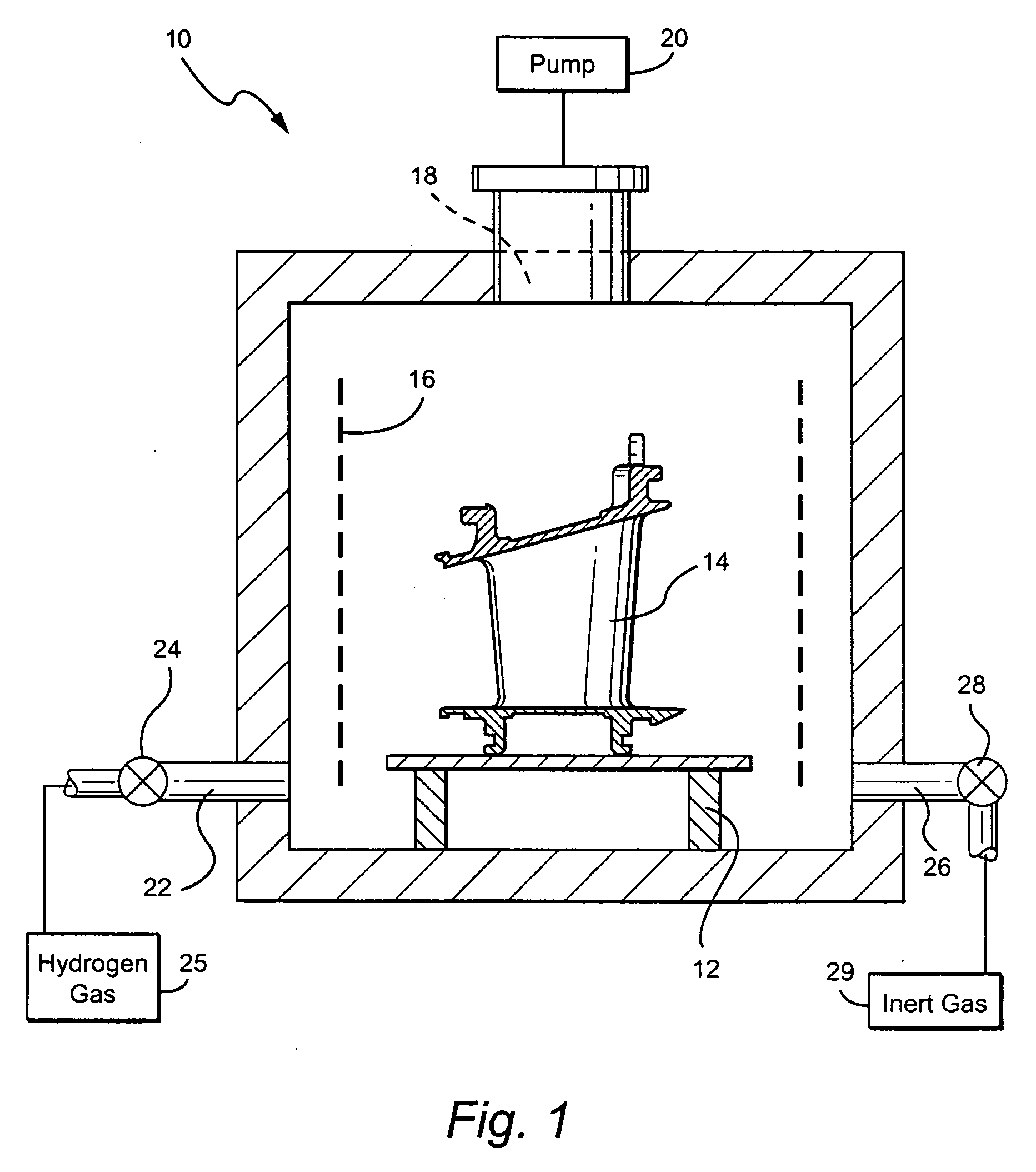

Methods of hydrogen cleaning of metallic surfaces

The pulsed partial pressure hydrogen cleaning of cobalt-based alloys in turbine components is achieved by disposing the component within a vacuum furnace and heating the component. Upon heating to about 1400° F., a partial pressure hydrogen gas and a vacuum are repetitively cycled within the furnace by supplying in each cycle a fresh supply of hydrogen gas, followed by removal of reaction products between the hydrogen gas and surface contaminants and substantially all residual hydrogen gas from within the furnace. The repetitious cycling renders the surfaces clean, enabling refurbishment thereof by activated diffusion healing repair.

Owner:GENERAL ELECTRIC CO

Preparation method for protective coating of zinc pan roller sleeves and bushes

ActiveCN104278268AExtended service lifeRealize independent powder feedingPlasma welding apparatusPressure inorganic powder coatingStrip steelHardness

The invention discloses a preparation method for a protective coating of zinc pan roller sleeves and bushes. The method comprise: cleaning and preheating surfaces of a roller sleeve and a bush, employing plasma built-up welding equipment to performing multi-layer powder built-up welding, selecting single cobalt-base alloy with relatively low hardness as a built-up welding combination bottom layer, and employing a cobalt-base alloy powder and a boron nitride powder as other layers of built-up welding powder materials, arranging two powder feeders respectively for putting the cobalt-base alloy powder and the boron nitride powder on the plasma built-up welding equipment, and respectively setting powder sending parameters, so as to realize independent sending of the two powders; and setting corresponding built-up welding parameters, keeping warm of the interior of a furnace after built-up welding and slowly cooling along with the furnace, and performing machining the built-up welded layer to obtain the protective coating with the thickness of 2.0-15 mm. By using the protective coating prepared by the method and used for the roller sleeve and the bush, the service life of the roller sleeve and the bush is effectively improved, the wear resistance and the lubrication performance are improved, strip steel is guaranteed to smoothly enter or get out of a zinc liquid system of a zinc pan, and the production efficiency of hot galvanized plates and strips is improved.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Method for detecting contents of titanium, manganese, Ferrum, nickel and tungsten in tantalum contained cobalt-base alloy

InactiveCN102914532AFast sample dissolutionShorten the dissolution timePreparing sample for investigationAnalysis by electrical excitationManganeseMaterial resources

The invention provides a method for detecting contents of titanium, manganese, ferrum, nickel and tungsten in a tantalum contained cobalt-base alloy. The analyzing steps are as follows: weighing a specimen; preparing a specimen solution; preparing a correcting solution; drawing a working curve; measuring concentrations of titanium, manganese, ferrum, nickel and tungsten in the specimen solution; and calculating measuring results so as to obtain the contents of titanium, manganese, ferrum, nickel and tungsten. According to the invention, problems that a sample is hard to dissolve, serious interference on spectral line measurement is caused and so on are overcome; the sample dissolving speed is greatly increased; spectral interferences of a matrix on measuring elements are eliminated through matrix matching; and the measuring accuracy is enhanced. The method for detecting the contents of titanium, manganese, ferrum, nickel and tungsten in the tantalum contained cobalt-base alloy, provided by the invention, has the advantages of speediness in sample dissolution and and measurement as well as simplicity and convenience in operation; and a great deal of manpower and material resources are saved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

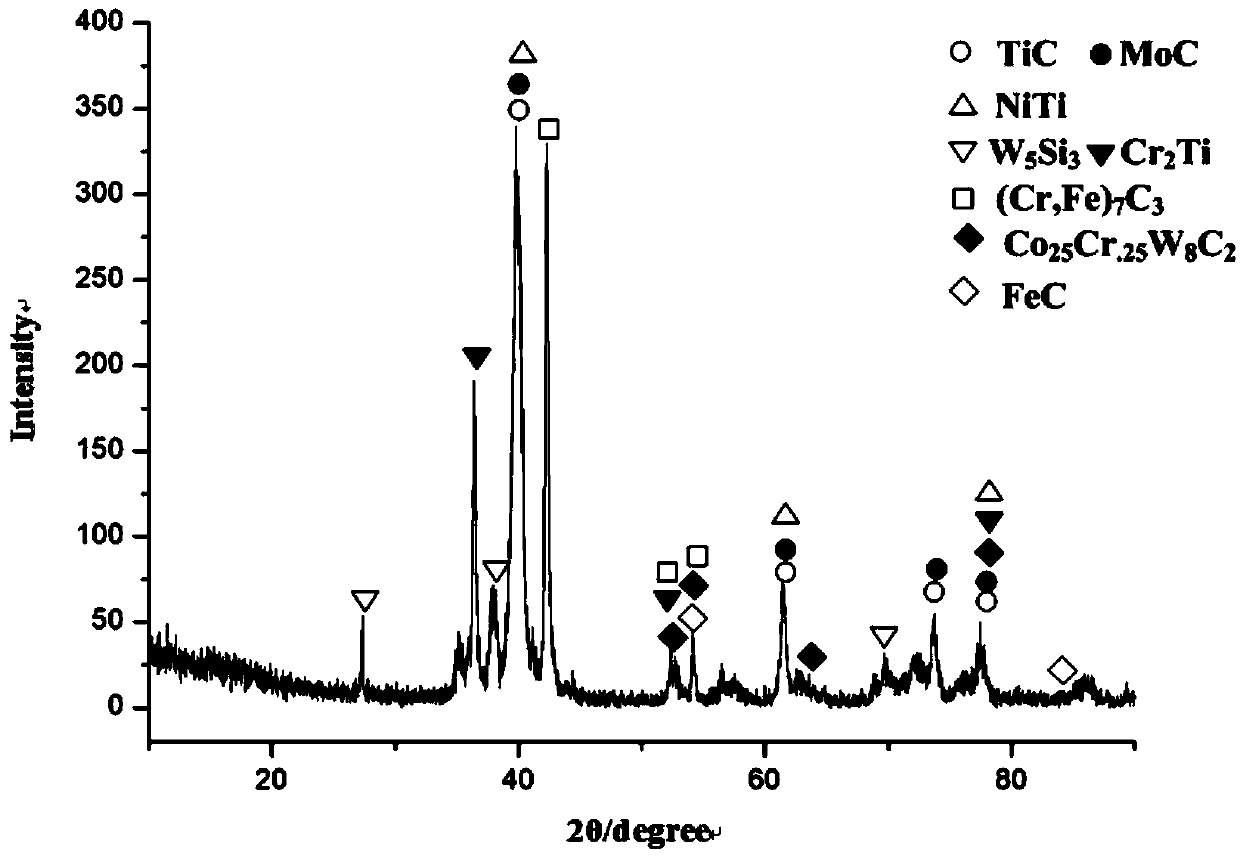

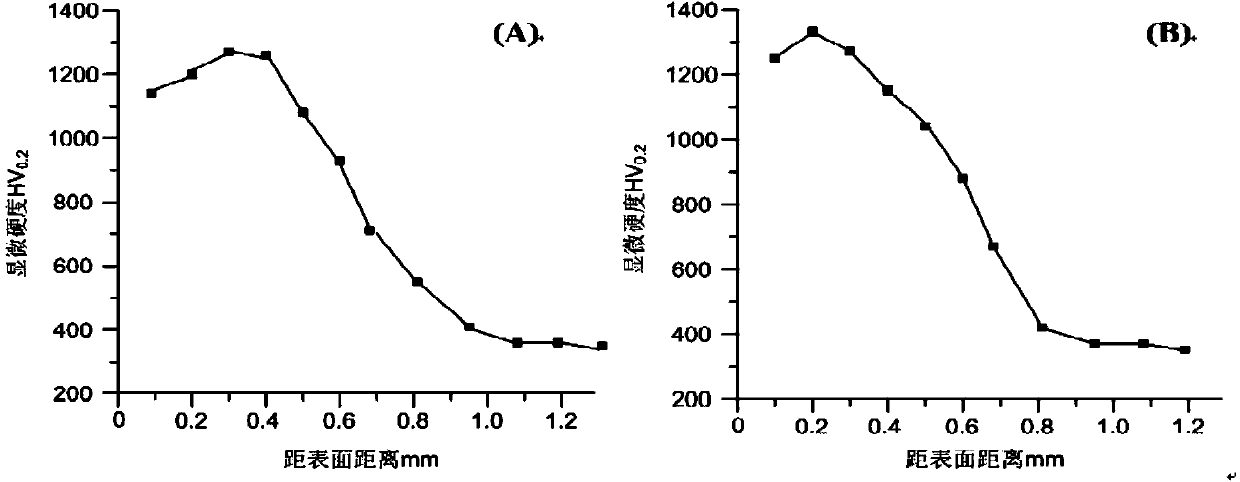

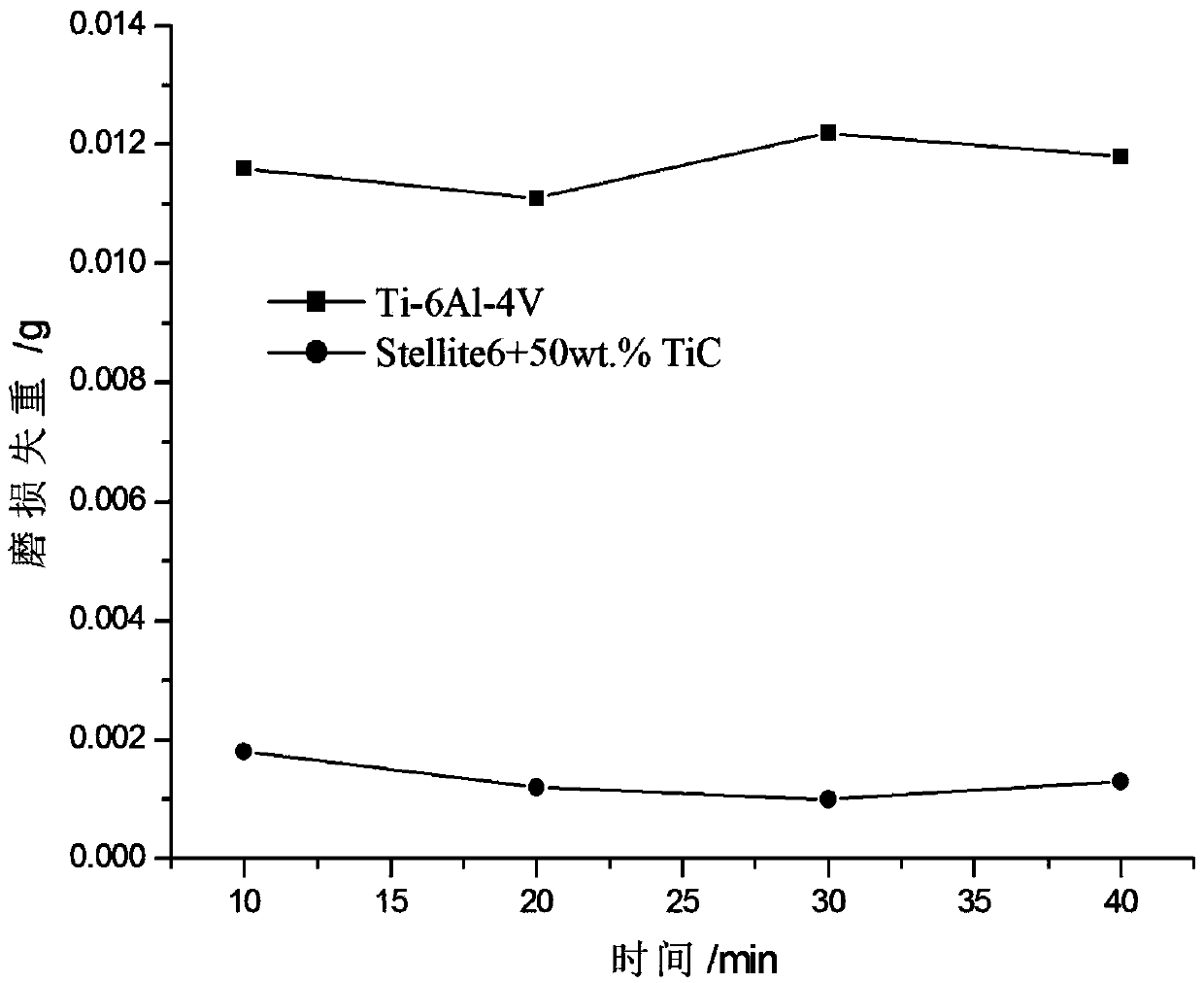

TiC-reinforced cobalt-based metal ceramic composite coating on titanium alloy surface and preparation process thereof

ActiveCN103614723AImprove wear resistanceMetallic material coating processesCeramic compositeTitanium alloy

The invention relates to a TiC-reinforced cobalt-based metal ceramic composite coating on a titanium alloy surface and a preparation process thereof. The preparation process comprises the following steps of uniformly mixing a cobalt-based alloy and a ceramic hard-phase TiC, and mixing into a paste form with a binder; uniformly applying the paste to the surface of the titanium alloy matrix, and drying in the air; performing laser cladding on the sample dried in the air, wherein the laser power is 800-1,200W, and the scanning speed of the laser is 2.5-7.5mm / s; blowing argon for protection, wherein the protection gas pressure is 0.2-0.4MPa, and the diameter of the light spot of the laser is fixed at 4mm. In the preparation process provided by the invention, the titanium alloy surface is subjected to laser cladding by adopting the composite system of the cobalt-based alloy and TiC as a cladding material, and the characteristics of corrosion resistance and good wettability of the cobalt-based alloy can be combined with the characteristics of high stability, high hardness, high wear resistance and the like of TiC, thereby being favorable for preparing a cladding layer with good toughness matching on the titanium alloy surface.

Owner:SHANDONG UNIV

Micro-nano oxide particle reinforced high abrasion resistance cobalt-based alloy powder and preparation method thereof

InactiveCN103526078AImprove toughnessHigh hardnessMetallic material coating processesMicro nanoHardness

The invention relates to micro-nano oxide particle reinforced high abrasion resistance cobalt-based alloy powder and a preparation method thereof. The micro-nano oxide particle reinforced high abrasion resistance cobalt-based alloy powder is combined powder and is characterized by comprising 50%-98% of matrix alloy powder, 1%-45% of micro-nano oxide particles and 1%-5% of a binding agent, wherein the micro-nano oxide particles are micro-nano Al2O3 or micro-nano mixed powder of one or more of micro-nano Cr3C2 and micro-nano ZrO2. The preparation method comprises the following processing steps: preparing the matrix alloy powder, adding the micro-nano oxide particles, adding the binding agent, stirring, ball-milling, combining the powder, drying, smashing and screening. The micro-nano oxide particle reinforced high abrasion resistance cobalt-based alloy powder has the advantages of high hardness and toughness, excellent abrasion resistance and corrosion resistance and capability of effectively preventing segregation due to wide proportion difference of the components in the storing, transporting and using processes and is particularly suitable for laser-clad high impact resistance and high abrasion resistance parts.

Owner:江苏盛伟模具材料有限公司

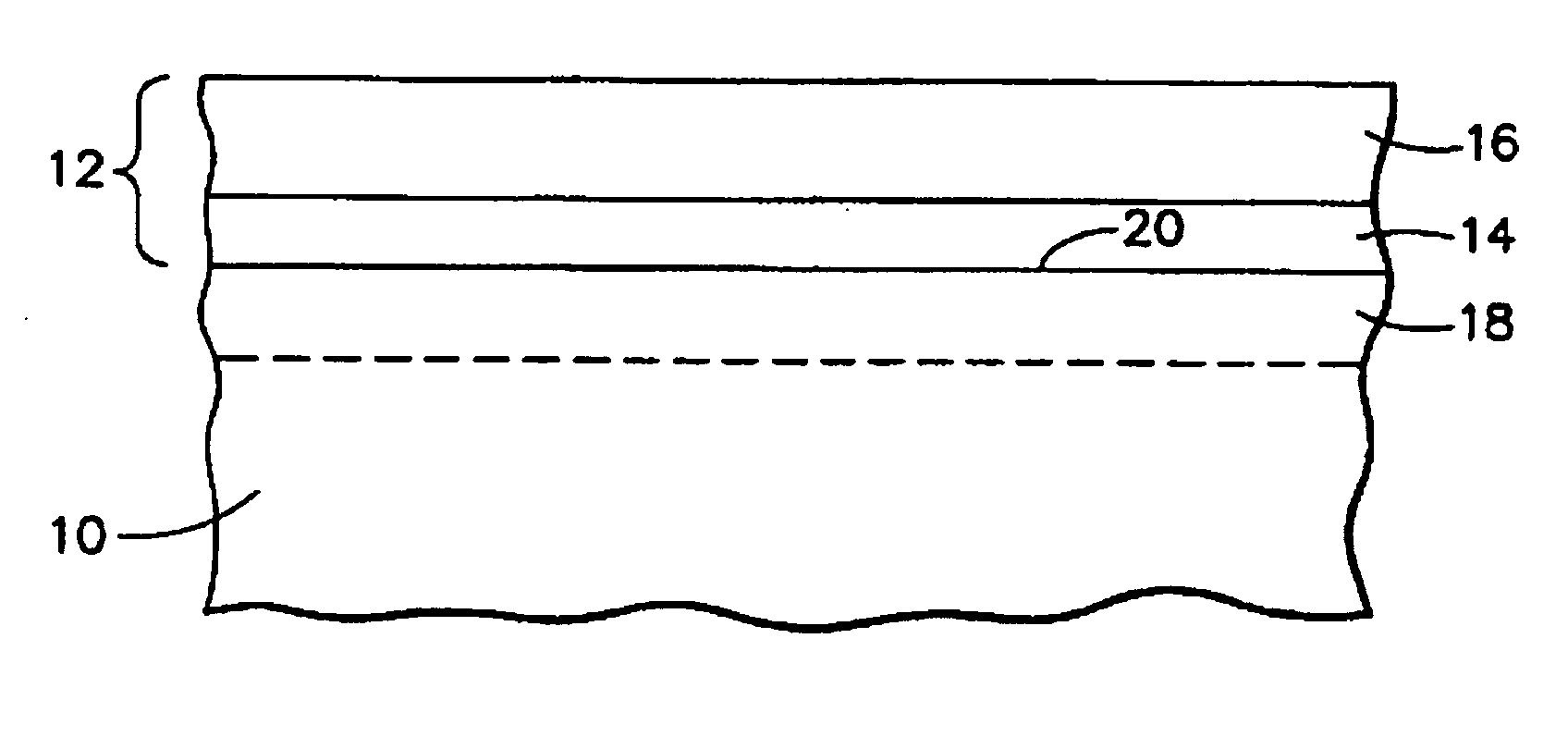

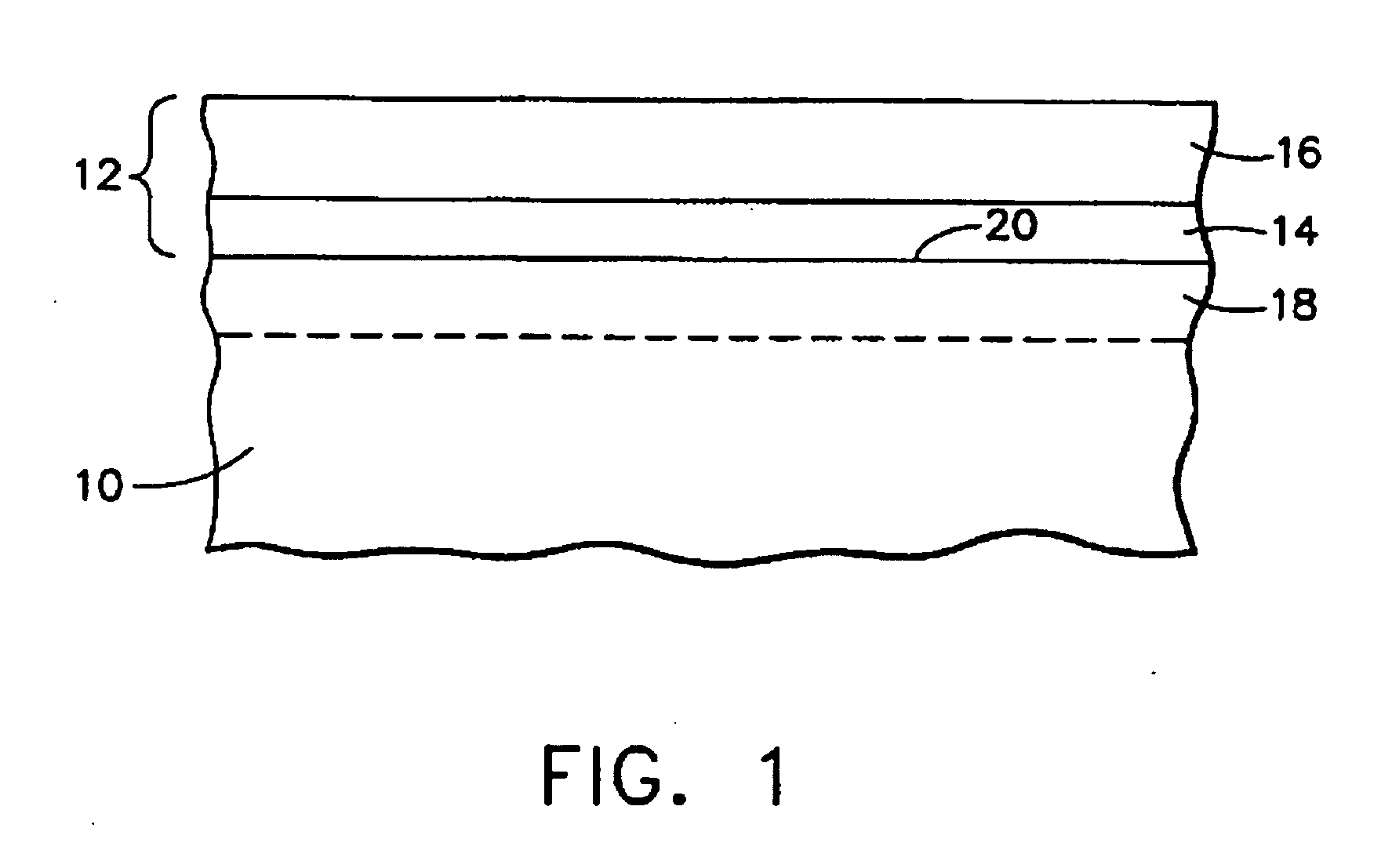

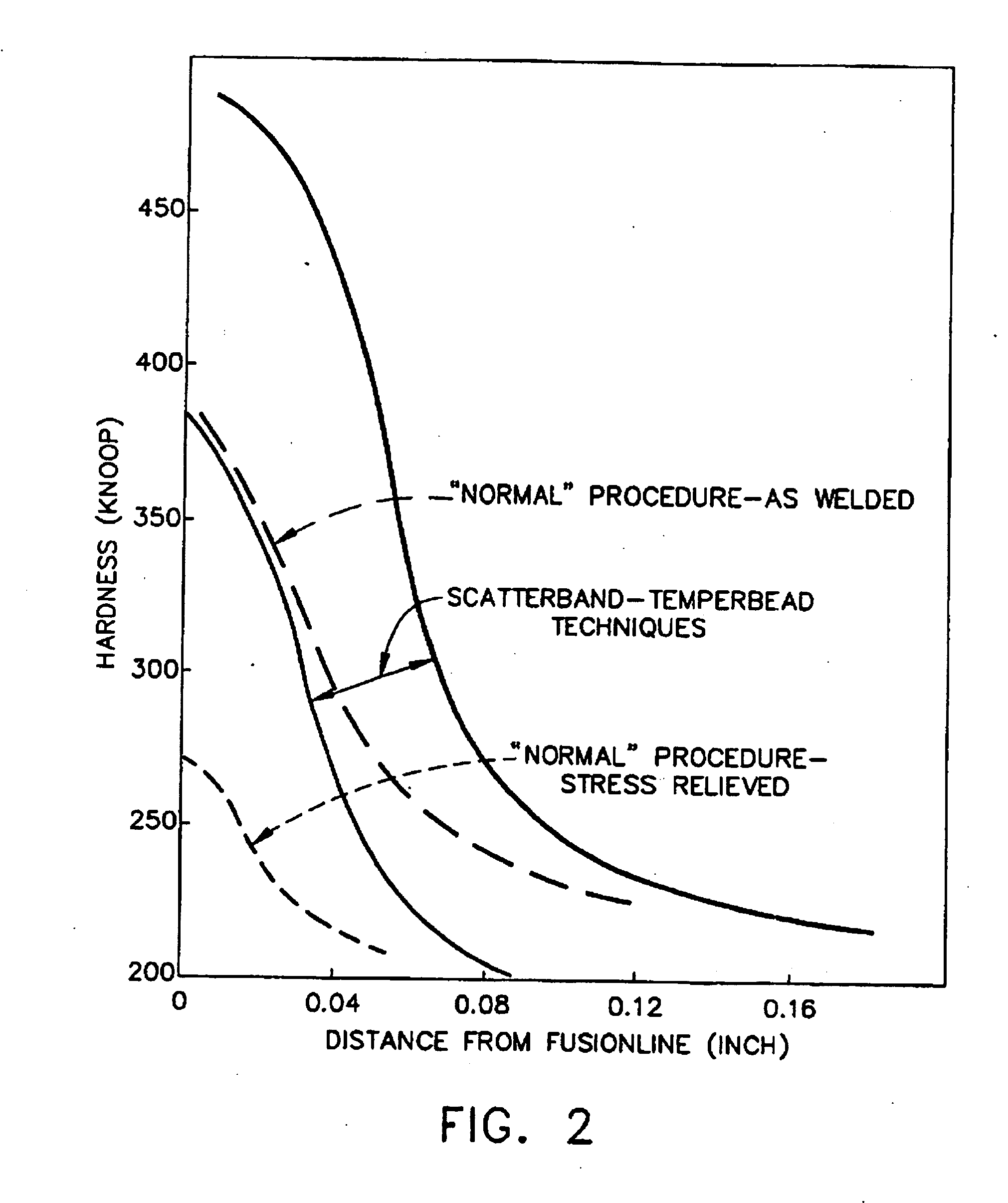

Weld repair process and article repaired thereby

A method for repairing a steel alloy article, and an article repaired thereby, is provided and comprises the steps of depositing at least a first weld repair layer on a surface of the article so as to form a heat affected zone in the article beneath the surface. Locally heat treating the first weld repair layer and at least a portion of the heat affected zone adjacent the first weld repair layer at a temperature above the critical A1 temperature of the steel alloy article. Depositing at least one additional weld repair layer on the first weld repair layer without forming additional heat affected zone in the surface of the article. The first weld repair layer and the at least one additional weld repair layer are comprised of a material chosen from the group consisting of nickel chromium—iron alloys, cobalt base alloys, ERNiCr-3, ENiCrFe-3, ERNiCrMo-3, ERNiFeCr-2, ERCoCr-A, ERCoCr-E, CrMo alloys and CrMoV alloys. The article can be placed in service without a post-weld heat treatment of the additional weld repair layer following the step of depositing the additional weld repair layer.

Owner:GENERAL ELECTRIC CO

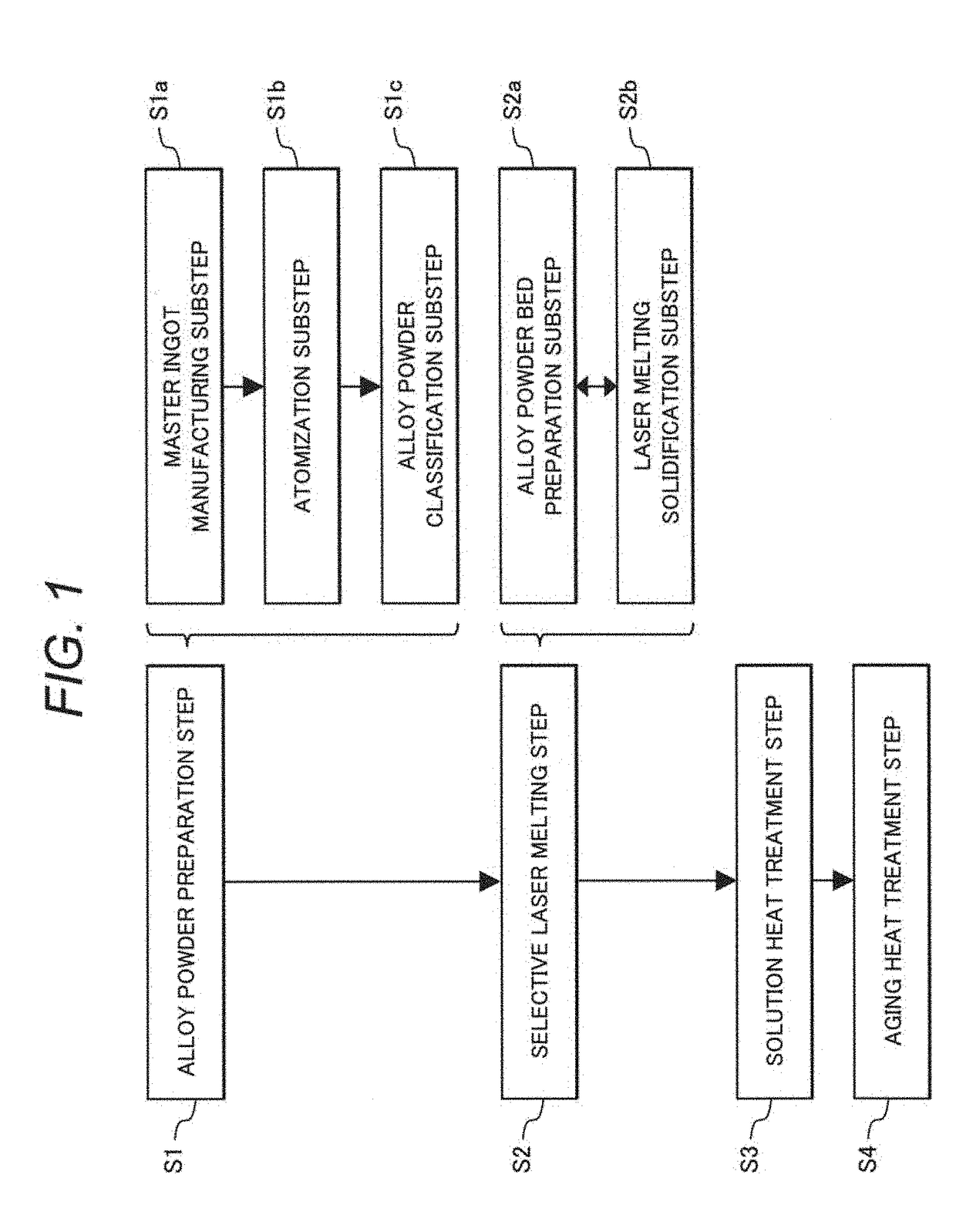

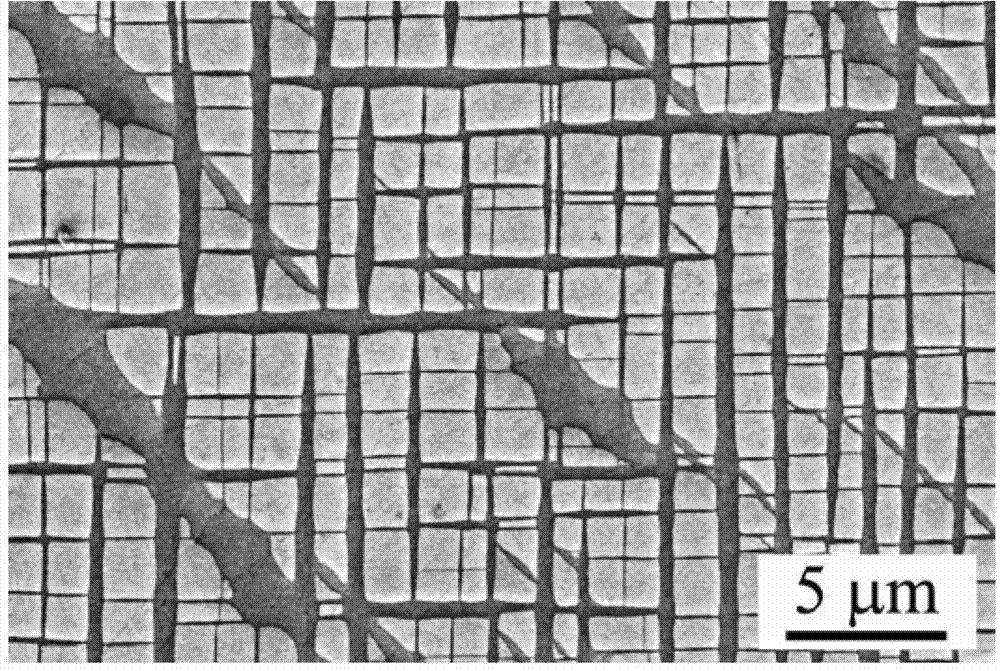

Cobalt based alloy additive manufactured article, cobalt based alloy product, and method for manufacturing same

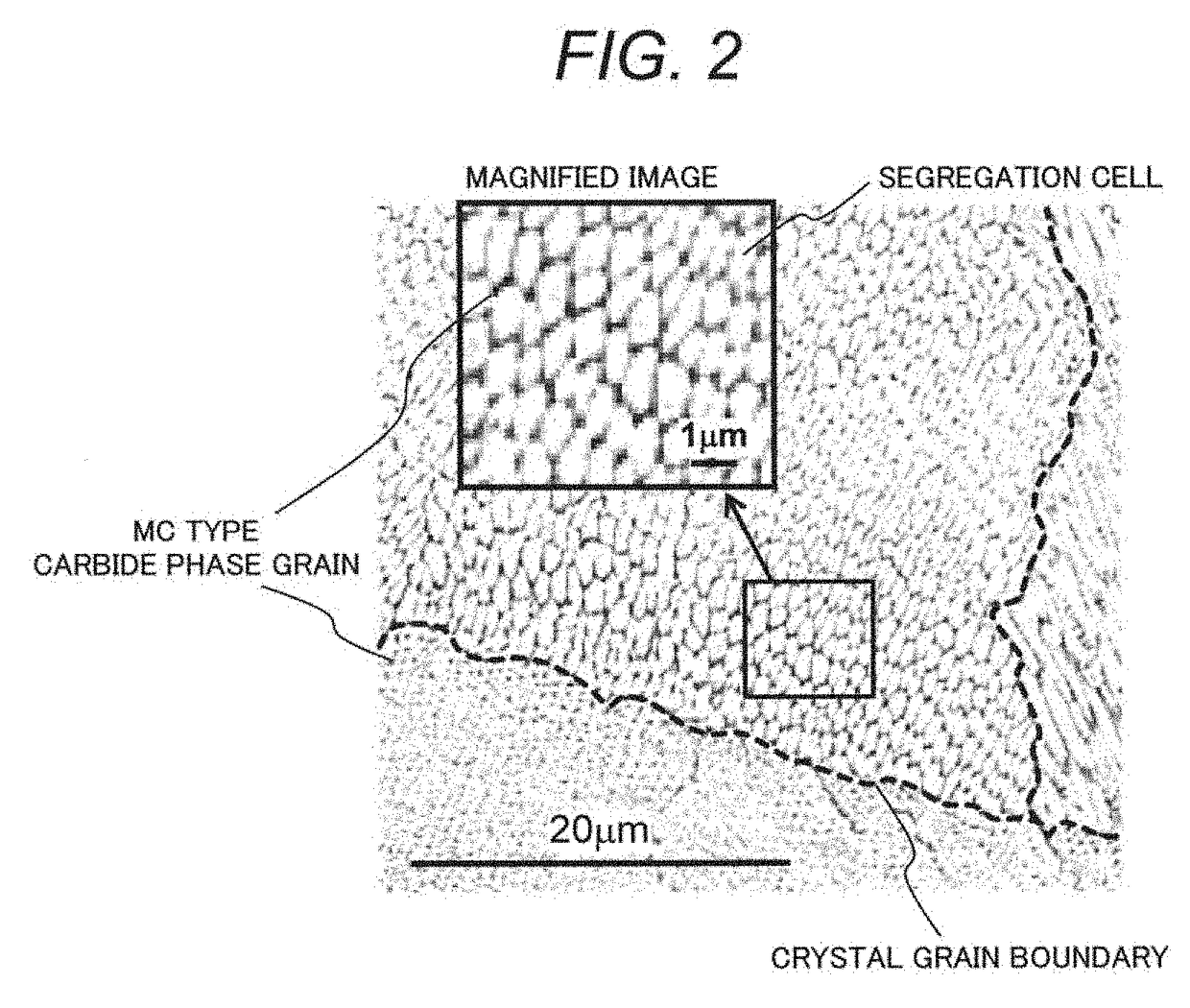

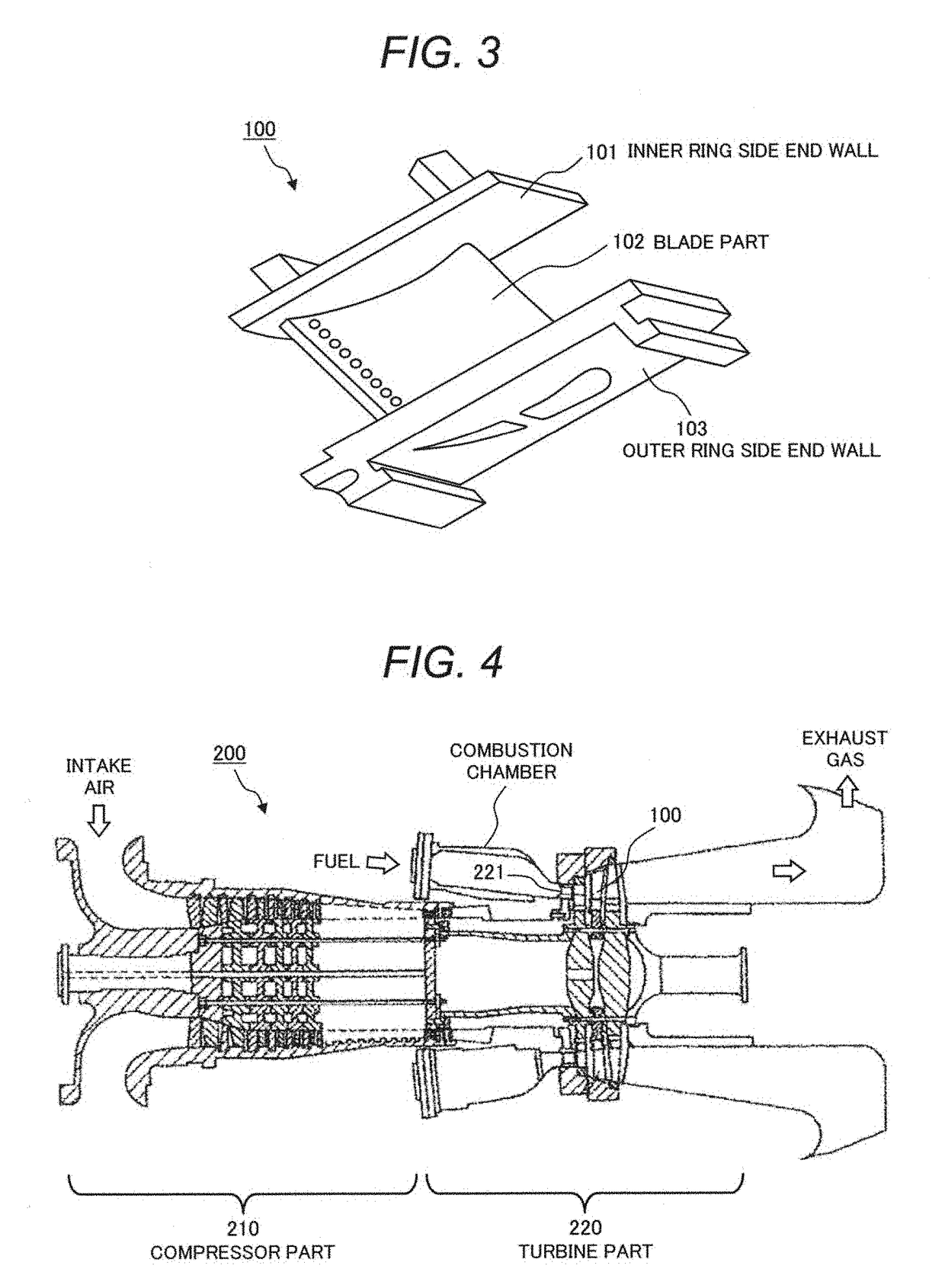

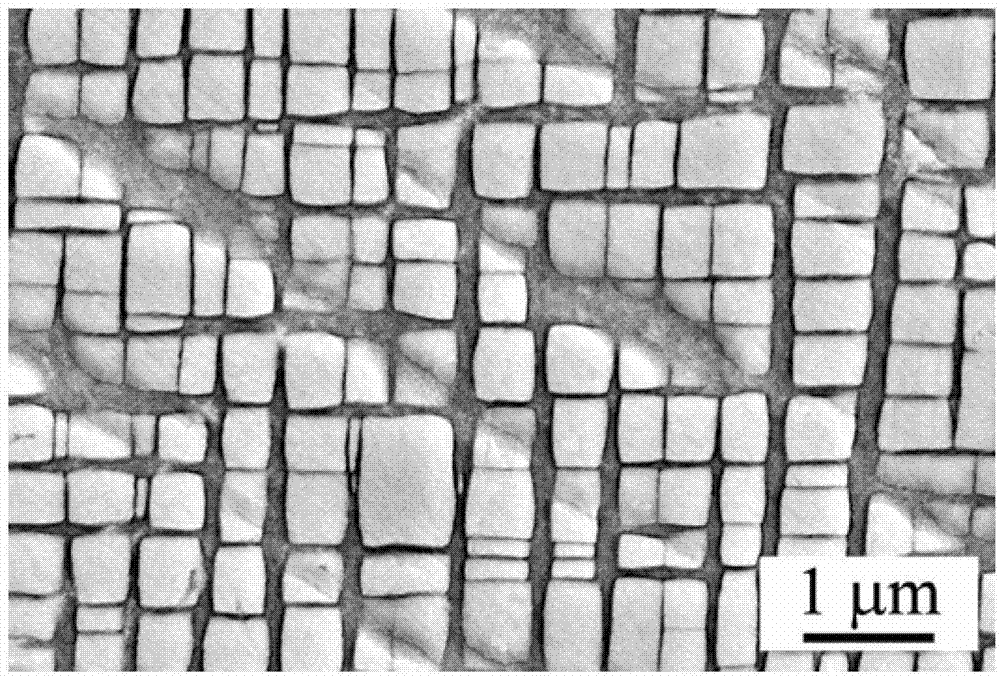

There is provided an additive manufactured (AM) article formed of a Co based alloy having a composition comprising: in mass %, 0.08-0.25% C; 0.1% or less B; 10-30% Cr; 30% or less in total of Fe and Ni, the Fe being 5% or less; 5-12% in total of W and / or Mo; 0.5-2% in total of Ti, Zr, Nb and Ta; 0.5% or less Si; 0.5% or less Mn; 0.003-0.04% N; and the balance being Co and impurities. The AM article comprises crystal grains with an average size of 10-100 μm. In the crystal grains, segregation cells with an average size of 0.15-1.5 μm are formed, in which components constituting an MC type carbide phase comprising the Ti, Zr, Nb and / or Ta are segregated in boundary regions of the cells, and / or grains of the MC type carbide phase are precipitated at an average intergrain distance of 0.15-1.5 μm.

Owner:MITSUBISHI POWER LTD

Nickel chromium alloy for sealing face of nuclear power valve

InactiveCN101629256ALess affected by heatHigh bonding strengthMetallic material coating processesPlasma jetNuclear power

The invention discloses a nickel chromium alloy for a sealing face of a nuclear power valve. The nickel chromium alloy comprises the following components in percentage by weight: 26.0-28.0 percent of chrome, 2.0-2.5 percent of silicon, 1.1-1.3 percent of boron, 4.5-5.5 percent of molybdenum, 3.0-4.0 percent of tungsten, 0.9-1.1 percent of carbon and the balance of nickel. Meanwhile, a coating layer is prepared by a laser cladding technology so as to obtain a sealing face coating layer of a nickel-based alloy nuclear power valve, which has the following relevant parameters: the rigidity is HRC 42-46 which is slightly higher than HRC39-43 of a Stellite-6 cobalt-based alloy coating layer; the tissue grain fineness number of the coating layer is 11-12 grades which is superior to 9-10 grades of a general plasma jet welding layer and 8-9 grades of a flame resurfacing welding layer; and the width of a combination band of the coating layer and a basal body is 10-30 micrometers which is superior to 80-120 micrometers of a plasma jet welding combination band and 200-300 micrometers of a flame resurfacing welding combination band.

Owner:SUZHOU UNIV

Cobalt-based high-temperature alloy wire and preparation method thereof

InactiveCN110983113ADecreased high temperature strengthImprove high temperature strengthDouble phaseOxidation resistant

The invention provides a cobalt-based high-temperature alloy wire which is prepared from the following chemical components in percent by mass: 0.06-0.12% of C, less than or equal to 0.3% of Si, 1-1.8%of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 19.2-20% of Cr, 9.5-10.5% of Ni, 14.2-15.5% of W, less than or equal to 2.8% of Fe, less than or equal to 0.4% of other impurities and the balance Co. By adding 19.2-20% of Cr, the cobalt-based high-temperature alloy wire has excellent corrosion resistance, and a condition that high-temperature strength is decreased as aresult of a double phase area as the content of Cr is too high to promote generation of an epsilon-Co phase and a sigma phase is avoided. Elements such as massive Co, 14.2-15.5% of W and 19.2-20% ofCr and the like in the cobalt-based alloy can reduce stacking fault energy, so that the high-temperature strength of the alloy is improved. The content of W is controlled at 19.2-20%, so that it is ensured that a condition of prominent work hardening of the alloy, difficulty in cold processing and poor stability as the too high W content is avoided. As the cobalt-based high-temperature alloy wirecontains 9.5-10.5% of Ni, the tissue stability of the alloy is improved favorably, and precipitation of a Co7W6 phase is reduced. By adding 1.1-1.8% of Mn, the oxidation resistance of a Ni-Cr alloy isimproved effectively.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

Nickel base alloy powder for intaking and exhausting valve sealing surface weld deposit of automobile

InactiveCN101342646ALow costImprove performanceWelding/cutting media/materialsSoldering mediaStellite alloyRoom temperature

The invention discloses nickel base alloy powder for overlaying welding of the sealing surface of the intake and outlet valve of automobiles. The nickel base alloy powder comprises the components with the following weight portions of 25-27 percent of Cr, 4-6 percent of Mo, 10-15 percent of Fe, 2-3 percent of Si, 1.5-2 percent of B, 0.65-0.75 percent of C and Ni for the rest. The beneficial effects of the invention are (1) low cost, (2) good technological properties and (3) high hardness. The nickel base alloy powder can take the place of cobalt base alloy powder and has low cost. The price of the nickel base alloy powder is one third of the price of the cobalt base alloy powder. The nickel base alloy powder is especially suitable for plasma overlaying welding technology and vacuum furnace melting technology of the sealing surface of the intake and outlet valve of automobiles and locomotives. Compared with Stellite No. 6 cobalt base alloy powder, the welding layer of the invention processed by the same plasma arc overlaying welding technology has a same volume loss (mm <3>) in wear test. By comparing the hardness of the nickel base alloy powder with the hardness of the Stellite No. 6 cobalt base alloy powder, the two powders have the same hardness HRC which is 43 after the powders are cooled to room temperature. The two powder after being welded have the same hardness under 400-700 centigrade temperature in the furnace, while the nickel base alloy powder has better red-hardness.

Owner:TIANJIN ZHUJIN METAL SURFACE ENG MATERIALTECH DEV

Particle-reinforced cobalt-based metal powder for ultra high speed laser cladding

InactiveCN108130530AImprove surface wear resistanceExtended service lifeTransportation and packagingMetal-working apparatusUltra high speedChemical composition

The invention provides a particle-reinforced cobalt-based metal powder for ultra high speed laser cladding. The particle-reinforced cobalt-based metal powder comprises the following components in proportion: 50-98% of cobalt matrix metal powder and 2-50% of oxide / carbide particles. A cobalt matrix comprises the following chemical components in percentage by mass: 0.1-2.0% of C, 20.0-40.0% of Cr, 1.0-20.0% of W, 1.0-10.0% of Mo, less than or equal to 1.5% of Si, less than or equal to 3.0% of Fe, less than or equal to 3.0% of Ni, less than or equal to 1.0% of Mn, less than or equal to 0.030% ofP, less than or equal to 0.030% of S, and the balance of Co and inevitable impurities. The particle size of the metal powder is 10-100 [mu]m, and the liquidity of the metal powder is 32-41 s / 100g. Through application of the particle-reinforced cobalt-based metal powder, a laser cladding technology is adopted, and is combined with different processes to reinforce and repair the surface of the matrix.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Method for measuring iron and nickel contents in cobalt-base alloy welding wire by flame atomic absorption method

InactiveCN101408506AImprove accuracyHigh precisionColor/spectral properties measurementsAbsorbanceSpectrometer

The invention relates to a method for determining the content of iron and nickel, in particular to a method for determining the content of iron and nickel in a cobalt base alloy welding wire by using a flame atomic absorption method. The method for determining the content of the iron and the nickel in the cobalt base alloy welding wire by using the flame atomic absorption method comprises the following steps: sampling, accurately weighing the welding wire sample, dissolving the sample with acid, diluting with hydrochloric acid to obtain concentration of absorbance which can be measured by using an atomic absorption spectrometer, preparing series of standard solution curve and measuring the absorbance of the solution by using air-acetylene flame. As the technical proposal is adopted, the rapid and effective method for determining the content of the iron and the nickel in the cobalt base alloy welding wire by using the flame atomic absorption method is established, and the accuracy and the precision of the analytic result are enhanced.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

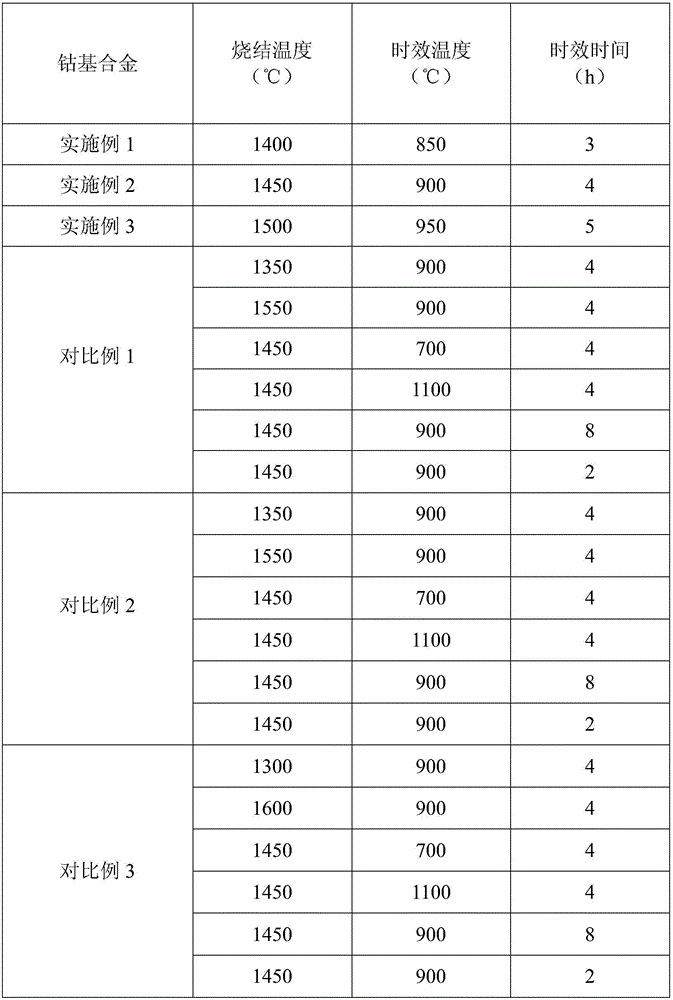

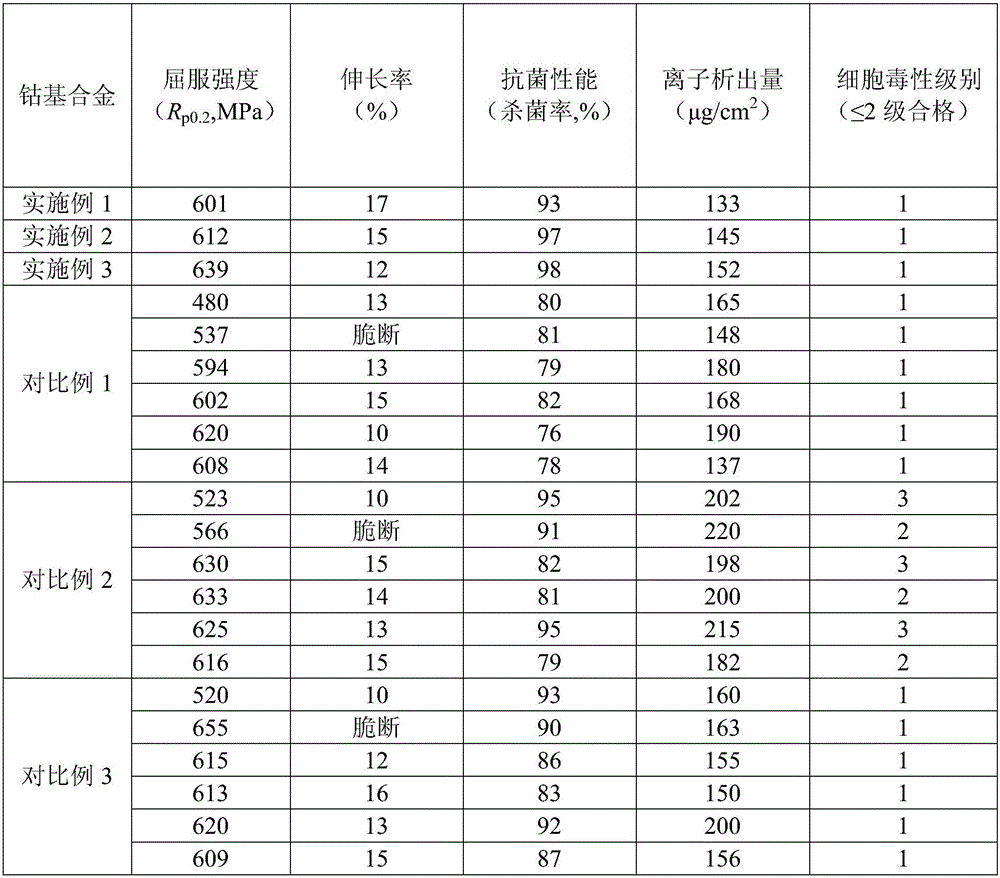

3D printing based method for preparing antibacterial cobalt based dental crown

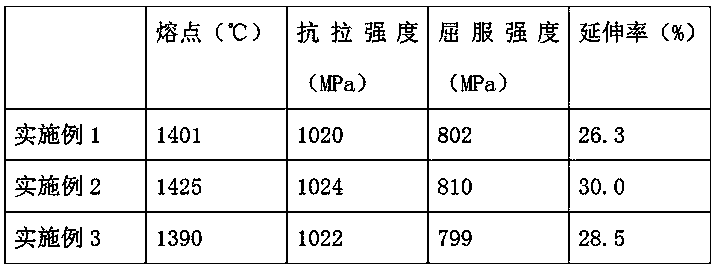

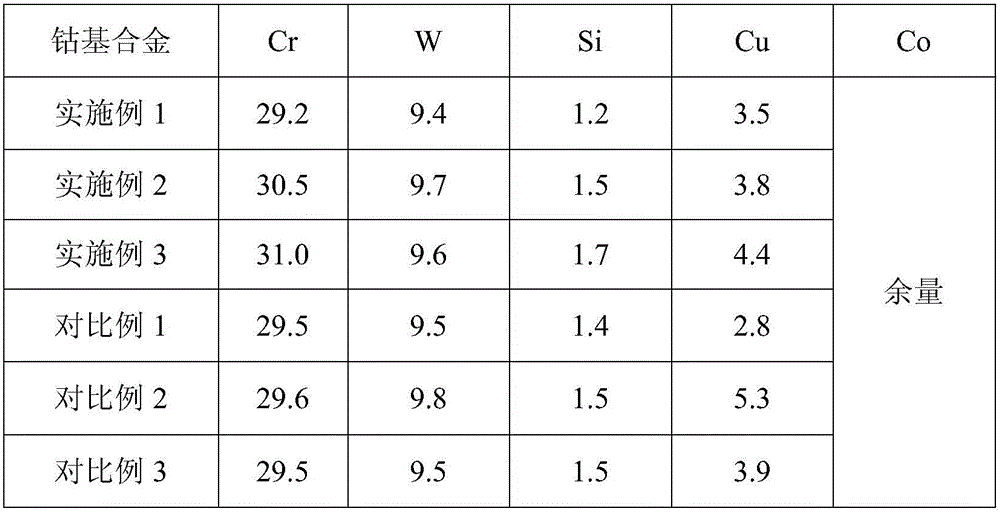

ActiveCN105838926ASolve the mechanical propertiesSolve excessive ion precipitationAdditive manufacturing apparatusIncreasing energy efficiencyCopperDental crowns

The invention provides a method for preparing antibacterial cobalt based alloy for a dental crown. The method comprises the following steps: 1), by a vacuum induction melting, adding an antibacterial metal copper into a cobalt based alloy to prepare the antibacterial cobalt based alloy; 2), using inert gas atomization to obtain a spherical antibacterial cobalt based alloy powder and sieving to prepare the antibacterial cobalt based alloy powder with average particle size of in 10-30 micron; 3), preparing a three-dimensional structure model of the cobalt based alloy dental crown product by using 3D printing equipment for printing; 4), sintering at high temperature of 1400 DEG to 1500 DEG C, and insulating for 4-5 hours; and 5), carrying out antibacterial heat treatment to obtain the antibacterial cobalt based dental crown products. The cobalt based alloy can significantly reduce the risk of bacterial infection of the existing cobalt based alloy for oral crown used in medical devices.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

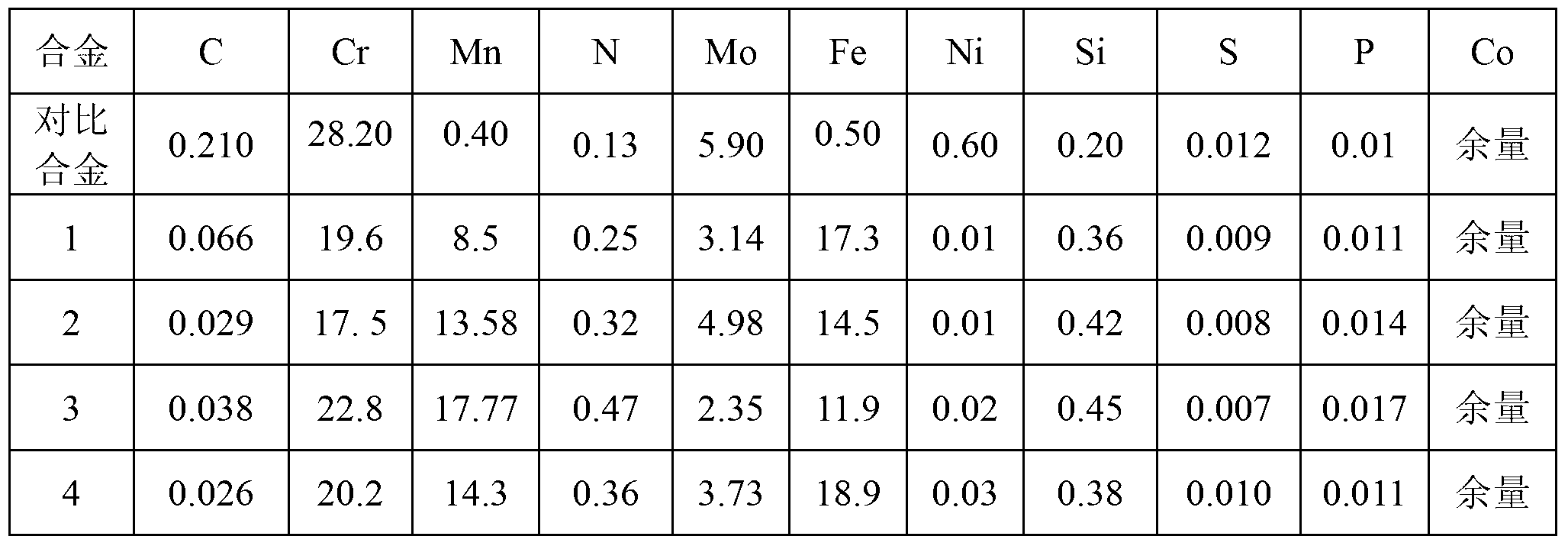

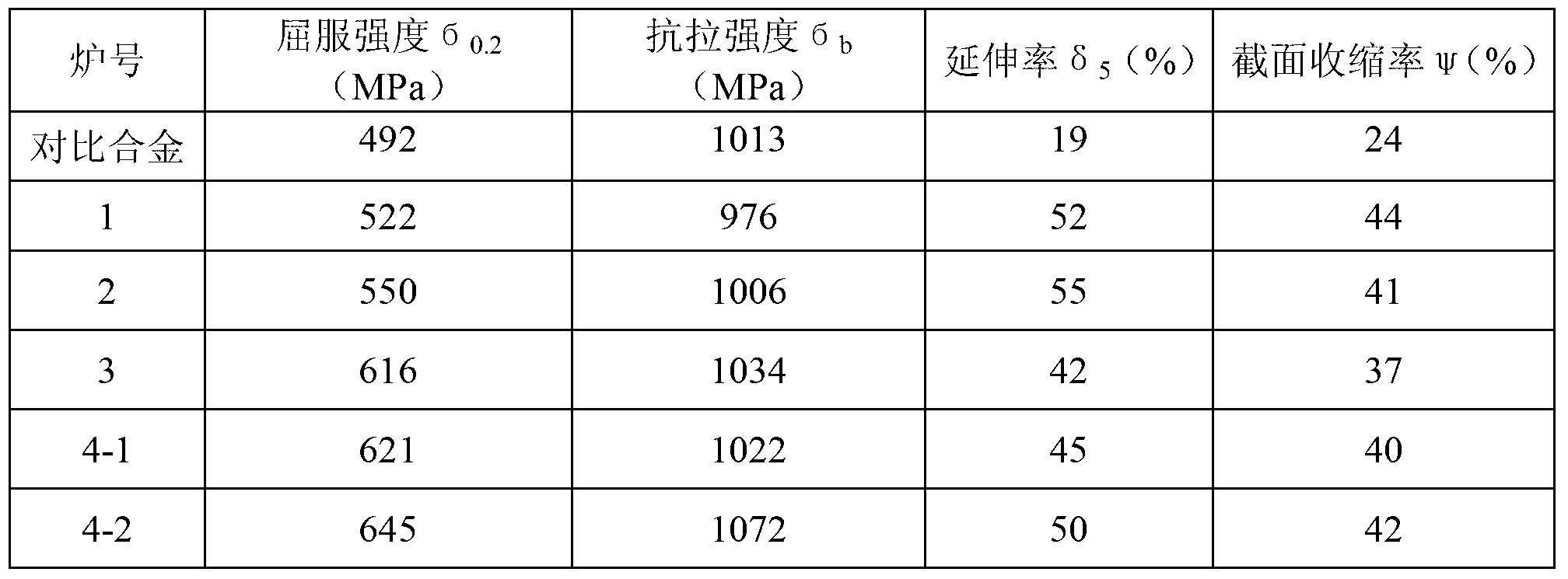

Novel cobalt-base alloy for surgical implant and application thereof

ActiveCN103215475AImprove mechanical propertiesImprove corrosion resistanceProsthesisChemical compositionNitrogen

The invention discloses a novel forgeable cobalt-base alloy for surgical implant and application through which the content of cobalt and chromium is reduced on the basis of the Co-Cr-Mo alloy and the mechanical property and corrosion-resistant property are optimized by adding a proper amount of iron and manganese elements and by adding the nitrogen element. The novel forgeable cobalt-base alloy is characterized by comprising the following chemical components by weight: less than or equal to 0.08 percent of C, 16-24 percent of Cr, 10-20 percent of Fe, 5-20 percent of Mn, 2-6 percent of Mo, 0.2-0.6 percent of N, less than or equal to 0.1 percent of Ni, less than or equal to 0.5 percent of Si, less than or equal to 0.01 percent of S, less than or equal to 0.02 percent of P and the balance of Co. The alloy has excellent mechanical property and corrosion-resistant property, can be used for avoiding the nickel damage and reducing the cost of the alloy, has excellent toughness combination and cold and hot working performance and has important social and economic significance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Cobalt-based alloy and cladding layer prepared from cobalt-based alloy

ActiveCN107326221AImproves abrasive wear resistanceBlock the path to rapid expansionMolten spray coatingChemical compositionMetallic materials

Provided are a cobalt-based alloy and a cladding layer prepared from the cobalt-based alloy. The cobalt-based alloy comprises Co, Ni, Cr, Fe, Si, W, C and Al. The cobalt-based alloy is specifically prepared from, by weight, 19-22.5% of Ni, 18-19.5% of Cr, 7.5-10.5% of Al, 0.8-1.1% of Fe, 0.7-1.0% of Si, 3.0-4.4% of W, 0.6-0.9% of C, and the balance Co and smaller than 0.1% of inevitable impurities, and the mass percent of Ni and Co is greater than 0.4 but smaller than 0.56, and the mass percent of Ni and Al is greater than 2 but smaller than 2.7. The cobalt-based alloy can be used for preparing the cladding layer with high abrasion resistance performance and heat fatigue resistance performance, and the cladding layer not only can be used for repairing and enhancing a friction layer of a brake disc, but also can be used as the friction layer of the brake disc and a protection layer on the surface of other metal materials needing to bear repeated heat impact and having friction abrasion in the environments like mold cavity linings, engine pistons and inner cylinders, petroleum pipeline valve inner walls.

Owner:SOUTHWEST JIAOTONG UNIV

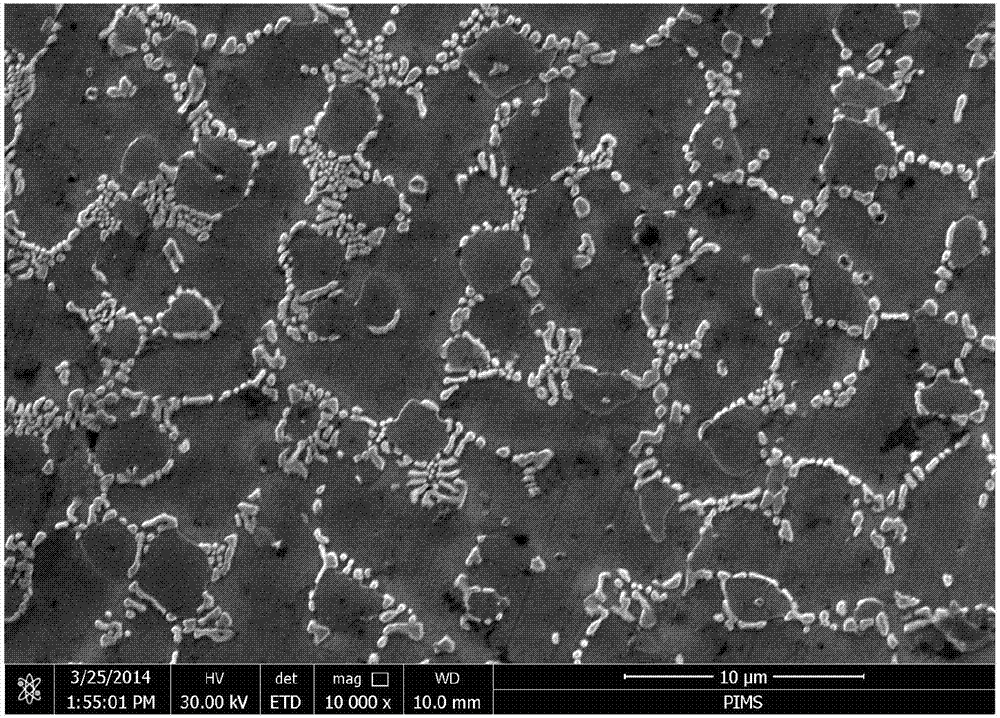

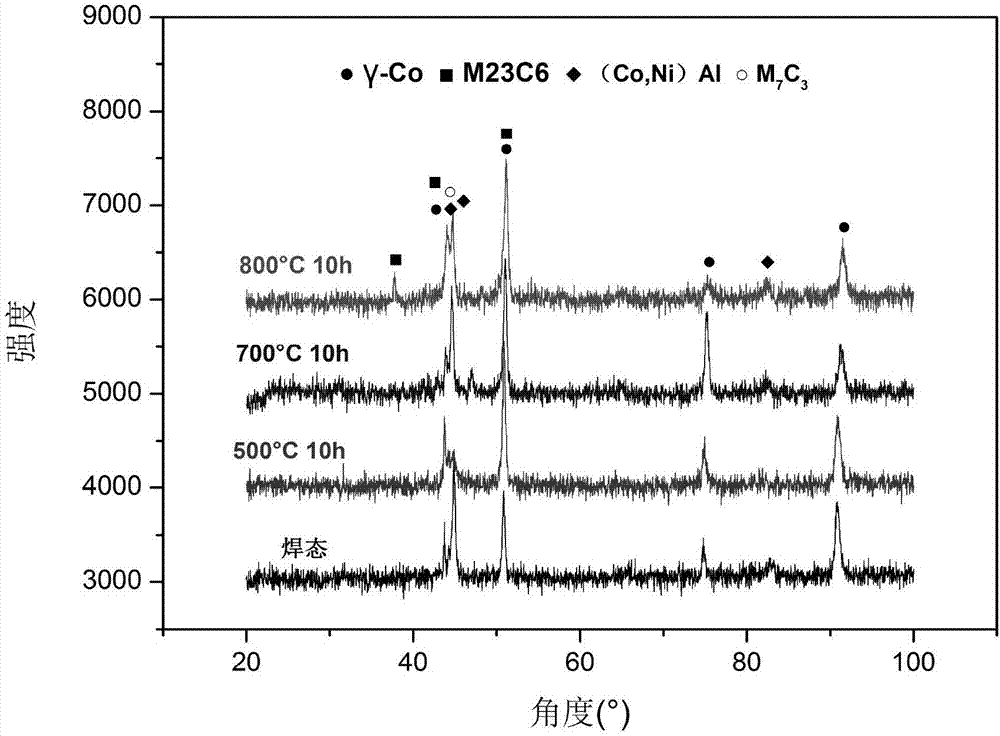

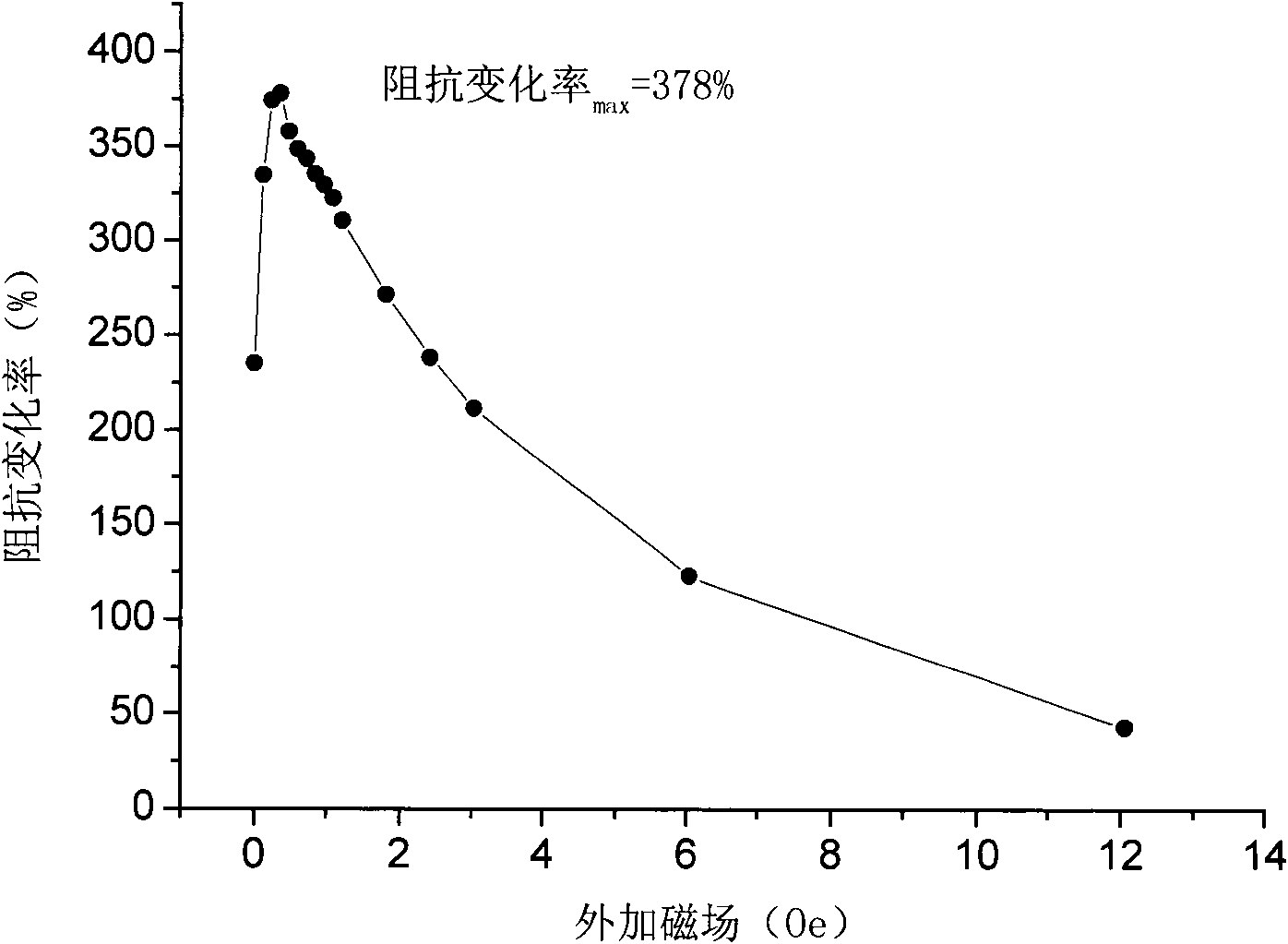

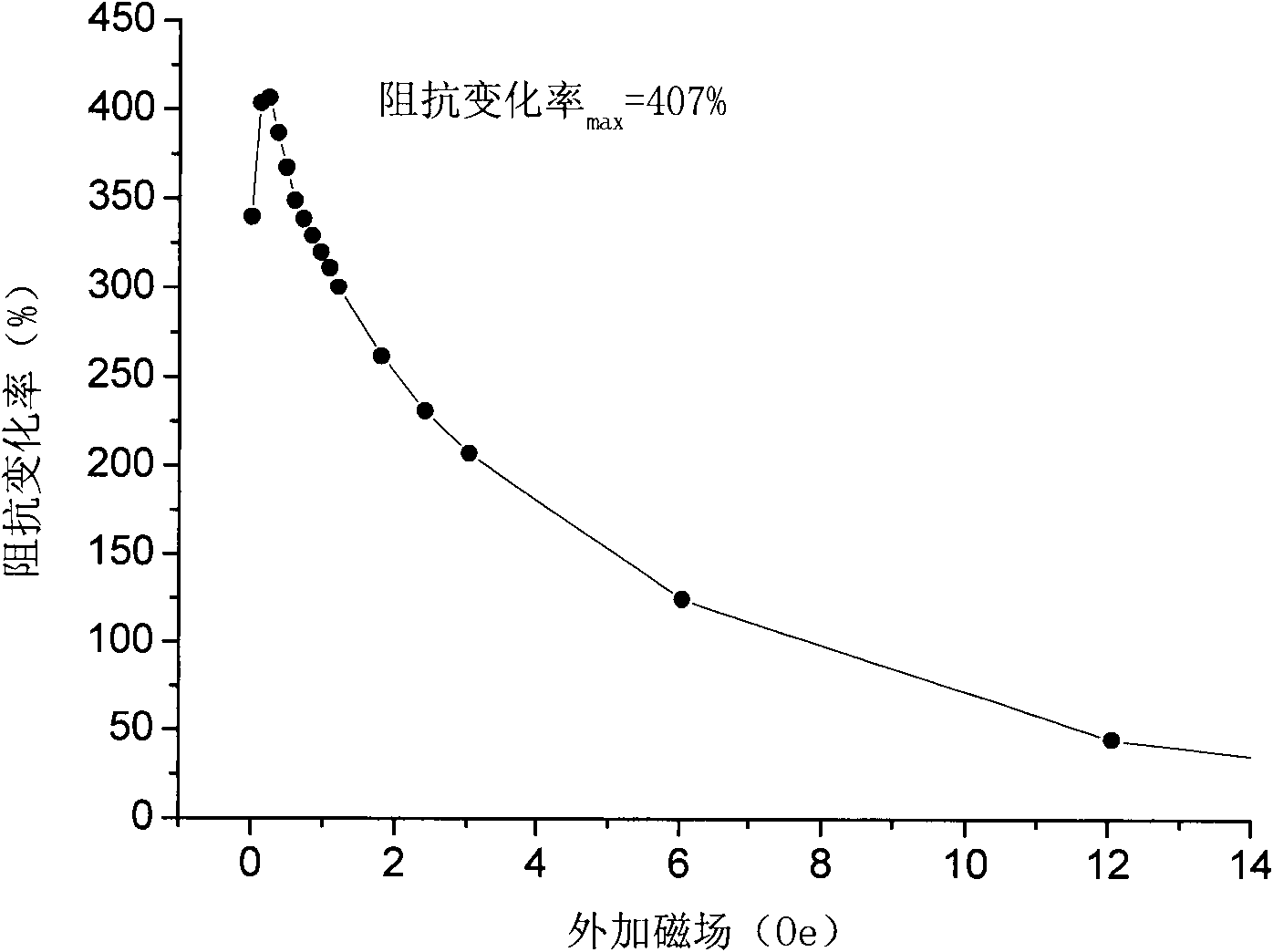

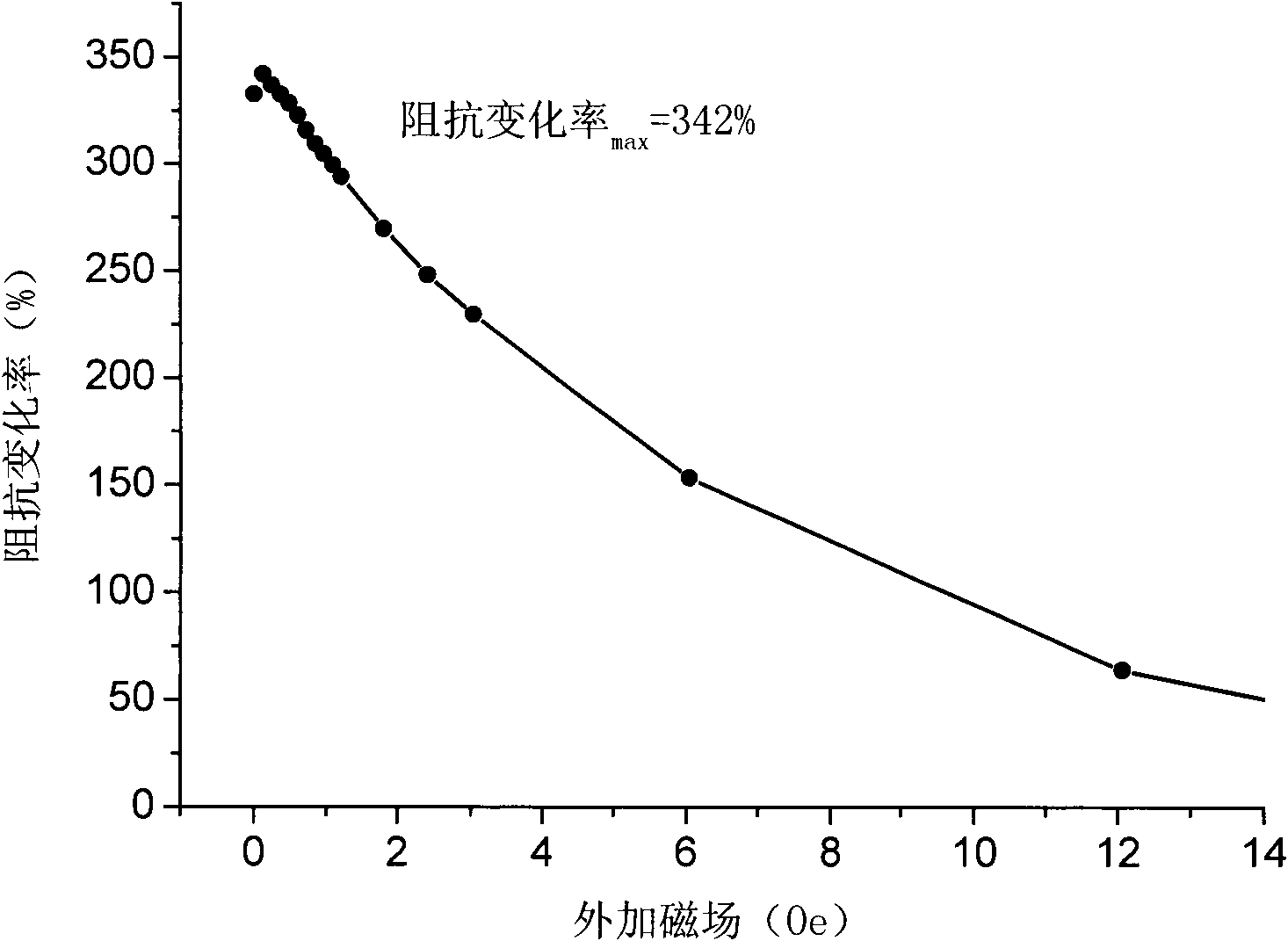

Cobalt-based amorphous giant magneto-impedance ribbon and preparation method thereof

ActiveCN102134691AExcellent soft magnetic propertiesImprove mechanical propertiesInorganic material magnetismPower flowProcessing cost

The invention discloses a cobalt-based amorphous giant magneto-impedance ribbon which is characterized in that the ribbon is made from a cobalt-based amorphous material as raw materials and obtained by taking the steps of orderly smelting, rapid quenching and current heating rapid annealing heat treatment, wherein a direct-current magnetic field is applied during the heat treatment, the expression of the components of the cobalt-based amorphous material is Co(alpha)Fe(beta)V(gamma)Si(delta)B(epsilon), beta is equal to 0-5, gamma is equal to 0-3, epsilon is equal to 12-20, delta is equal to 5-10, both beta and gamma are not equal to 0, and alpha plus beta plus gamma plus delta plus epsilon is equal to 100. The invention also discloses a preparation method of the giant magneto-impedance ribbon. Compared with the prior art, the cobalt-based amorphous giant magneto-impedance ribbon has the advantages that the cobalt-based alloy with excellent soft magnetic property and mechanical propertyis used as mother alloy and current heating rapid annealing treatment under magnetic field condition is carried out so that the processing cost is saved, the production efficiency is improved and theobtained material has higher giant magneto-impedance change rate and magnetic field sensitivity while having excellent soft magnetic property and flexibility.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Compound centrifugal manufacturing method for axial sleeve of bushing

InactiveCN101596583AImprove corrosion resistanceImprove wear resistanceHot-dipping/immersion processesSlagCentrifugal force

The invention discloses a compound centrifugal manufacturing method for an axial sleeve of a bushing, which comprises the following steps: smelting molten metal of an iron-based material and molten metal of a cobalt-base alloy in two smelting furnaces respectively; performing deslagging and deoxidation treatment after the melting down of the molten metal of the iron-based material and the molten metal of the cobalt-base alloy; performing centrifugal casting on the outer layer molten metal of the cobalt-base alloy first, and adding an acid slag protective agent along with the outer layer molten metal of the cobalt-base alloy when the outer layer molten metal of the cobalt-base alloy is cast to 20 to 30 percent of the gross weight of the outer layer molten metal of the cobalt-base alloy needing to be cast; passing 3 to 5 minutes after the outer layer molten metal is cast, and after solidifying the outer layer molten metal of the cobalt-base alloy, casting the inner layer molten metal of the iron-based material until finishing; and under the action of centrifugal force, cooling and solidifying the inner layer molten metal and the outer layer molten metal into a blank of a compound centrifugal axial sleeve of a bushing, and assembling and processing the blank.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

Powder metallurgical gear and forming method thereof

InactiveCN102935514AImprove toughnessHigh strengthPortable liftingGearing elementsCarbide siliconAl powder

The invention discloses a powder metallurgical gear which is prepared from powder metallurgical alloy powder, and the powder metallurgical alloy powder is prepared from the following materials in parts by weight: 20-30 parts of sintered aluminum power, 20-30 parts of nickel-molybdenum alloy power, 40-60 parts of iron-based alloy powder, 10-15 parts of cobalt-based alloy powder, 1-3 parts of silicon carbide, and 2-5 parts of lubricant. The invention also provides a method for forming the powder metallurgical gear. The powder metallurgical gear and forming method thereof disclosed by the invention have the beneficial effects that the raw material ratio is changed, the toughness and strength of the powder metallurgical gear can be enhanced, and the service life of the powder metallurgical gear can be prolonged; and in the method for forming the powder metallurgical gear, the pressure is lower than the existing commonly used pressure (500MPa), thereby lowering the demands on equipment and reducing the cost.

Owner:WUXI ZHONGCAI NEW MATERIAL

Axle bush and axle sleeve

InactiveCN101592187AWear hasAbrasive conditions, has corrosion resistance withBearing componentsSurface layerThermal expansion

The invention discloses an axle bush and an axle sleeve. Both the axle bush and the axle sleeve comprise a matrix and a working surface layer, wherein the working surface layer is made of a cobalt-base alloy, and the cobalt-base alloy comprises the following components in percentage by weight: 10 to 40 percent of Cr, 0.1 to 15 percent of Ni, 0.1 to 15 percent of W, 0.1 to 10 percent of Mo, 0.01 to 5.0 percent of V, 0.01 to 5.0 percent of Ti, 0.01 to 1.5 percent of C, 0.01 to 20 percent of Fe, 0.01 to 5.0 percent of Al, 0.1 to 3.0 percent of Mn, 0.01 to 5.0 percent of Nb, 0.1 to 3.0 percent of Si, and the balance of Co. The axle bush and the axle sleeve are operated under the conditions of hot-dip aluminum-zinc liquid, hot-dip zinc liquid, hot-dip zinc aluminum, hot-dip pure aluminum liquid and the like, and have good heat-resistant fatigue properties such as good durability, enough strength and elongation, low thermal expansion coefficient, low elastic modulus and the like so as to improve the service properties and prolong the service life.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

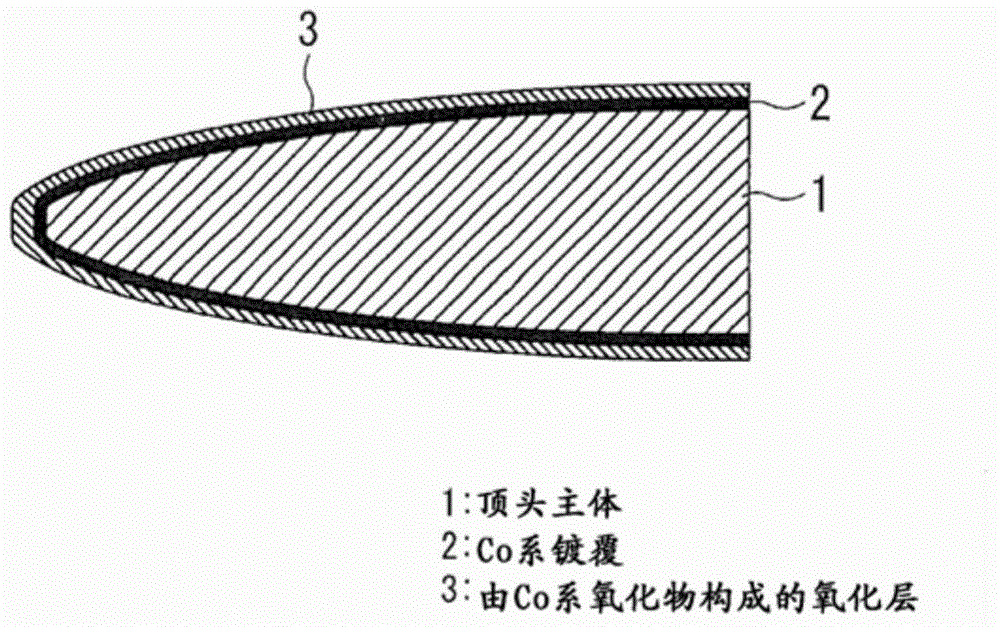

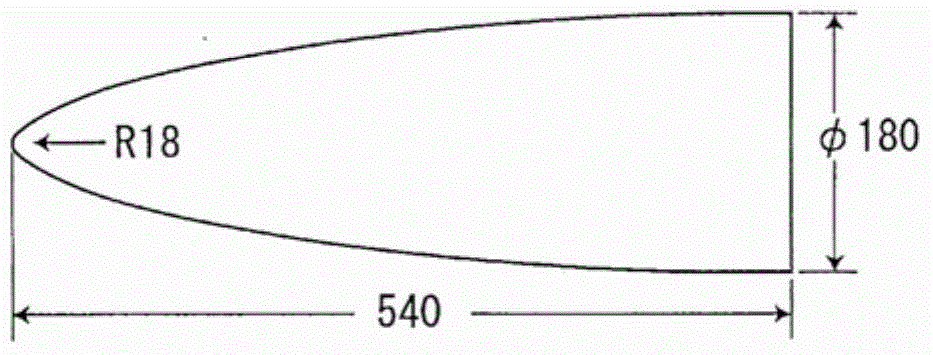

Plug for rolling seamless steel pipe, method for manufacturing said plug, and method for manufacturing seamless steel pipe in which said plug is used

Provided is a technique for significantly increasing the life of a plug used under severe conditions such as rolling of a seamless high-alloy steel pipe. Specifically, a plug for rolling of a seamless steel pipe, the plug having an oxide layer composed of a cobalt-base oxide on a surface of a coating layer formed by coating a surface of a base metal with cobalt or a cobalt-base alloy, a method for manufacturing the plug and a method for manufacturing a seamless steel pipe using the plug.

Owner:JFE STEEL CORP

Method for preparing hydroxylapatite coating by microplasma spraying

InactiveCN101591759AImprove biological activityImprove stabilityMolten spray coatingApatiteHydroxylapatite

The invention discloses a method for preparing a hydroxylapatite coating by microplasma spraying, which belongs to the field of implant processing and preparation in biomedical material engineering. The method adopts microplasma spraying equipment to spray dried hydroxylapatite powder onto a matrix of a biomedical implant metal material with the surface subjected to sand blasting treatment, thereby obtaining the hydroxylapatite coating with controllable crystallinity and good biological stability. The preparation of the coating by the method has simple process, and the hydroxylapatite powder has high deposition efficiency. The method can be used for depositing the hydroxylapatite coating on the surfaces of inert implant metal materials such as stainless steel, cobalt-based alloy, titanium and titanium alloy to make the surfaces of biologically inert metal matrixes biologically activated to prepare medical implant devices such as dental roots, artificial joints and the like.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

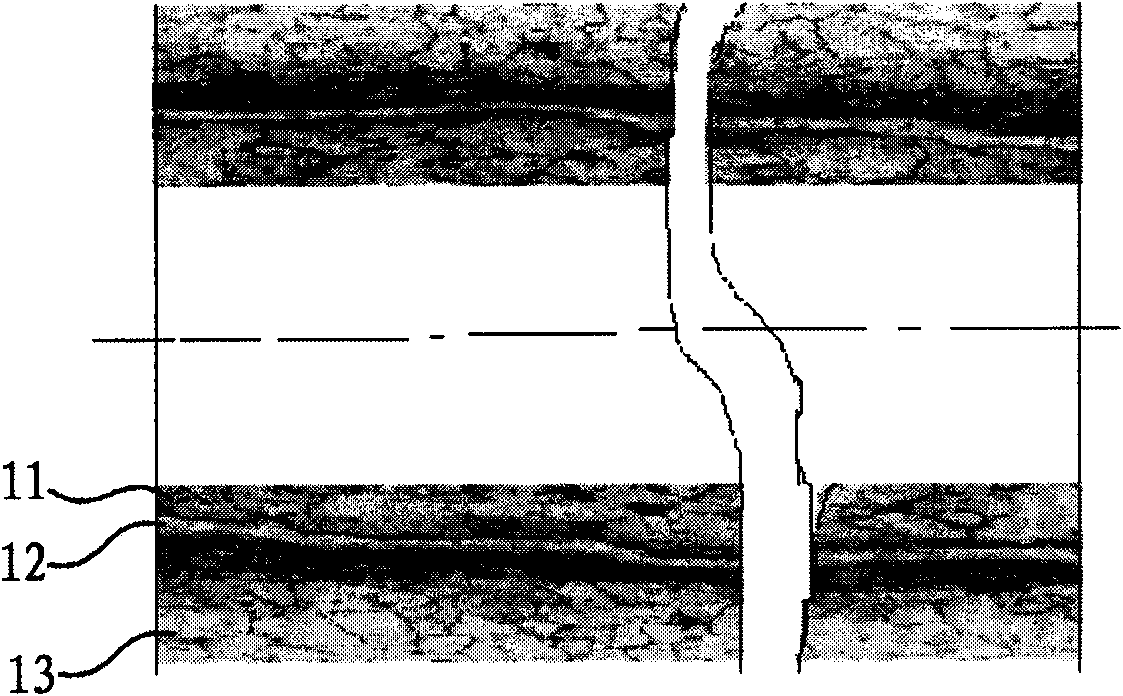

![Target foil for use in the production of [18f] using a particle accelerator Target foil for use in the production of [18f] using a particle accelerator](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/608e22dd-af99-4217-bcfe-89a8d80b969b/US20090052628A1-20090226-D00000.png)

![Target foil for use in the production of [18f] using a particle accelerator Target foil for use in the production of [18f] using a particle accelerator](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/608e22dd-af99-4217-bcfe-89a8d80b969b/US20090052628A1-20090226-D00001.png)

![Target foil for use in the production of [18f] using a particle accelerator Target foil for use in the production of [18f] using a particle accelerator](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/608e22dd-af99-4217-bcfe-89a8d80b969b/US20090052628A1-20090226-D00002.png)