Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152results about How to "Reduce weightlessness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

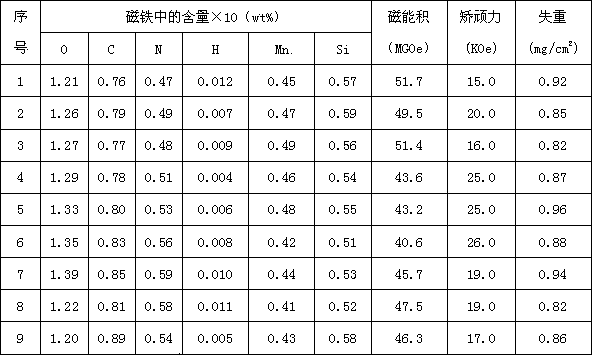

Sintered neodymium-iron-boron preparation method capable of improving intrinsic coercivity and anticorrosive performance

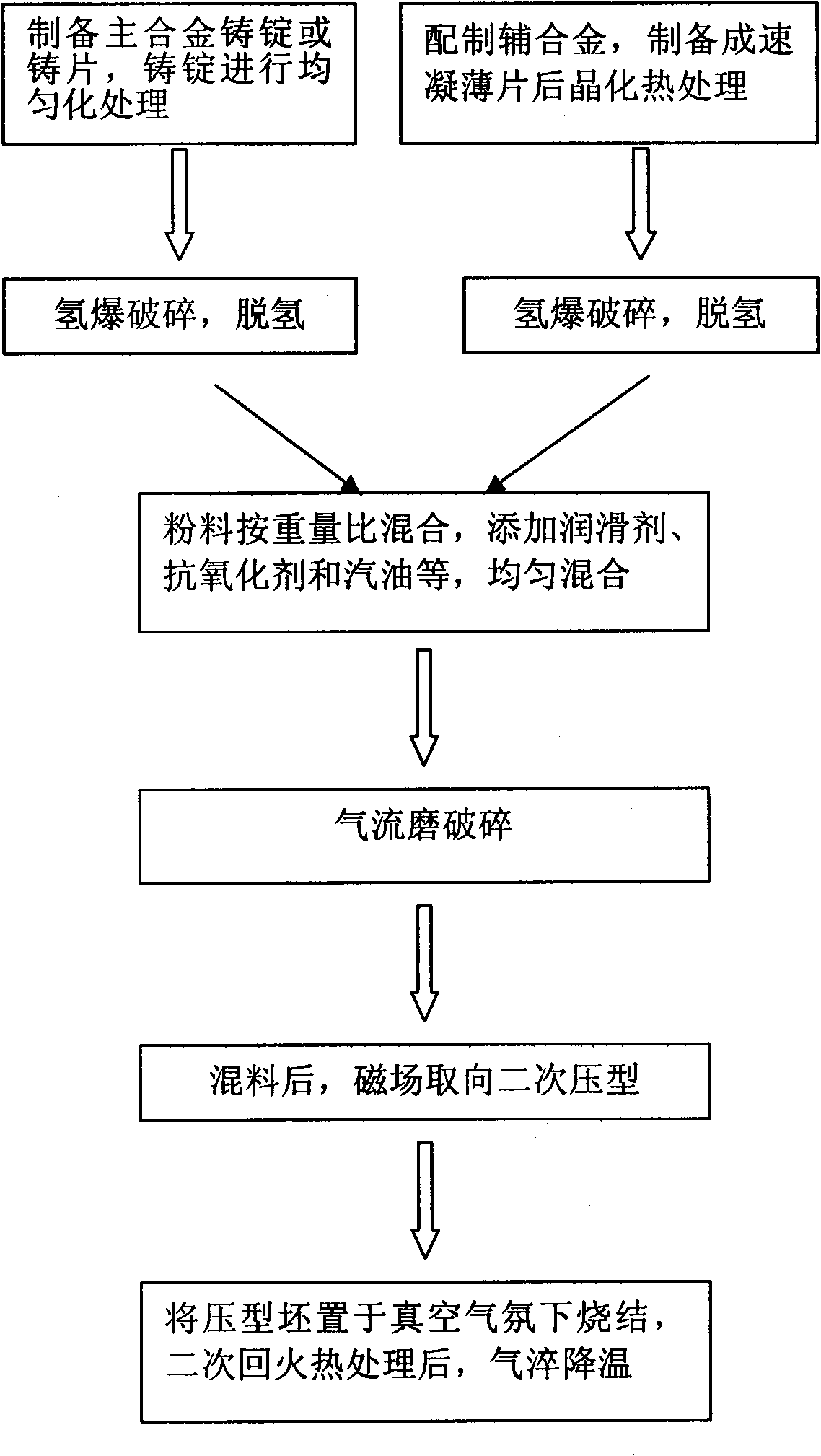

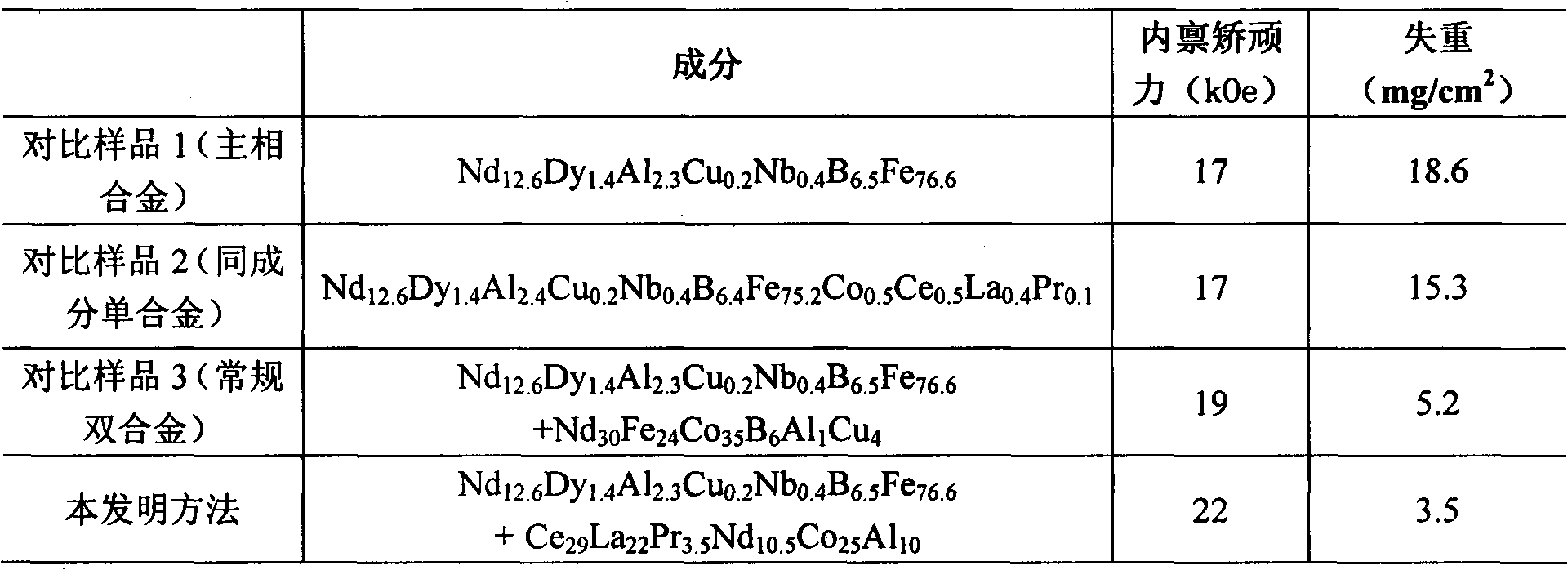

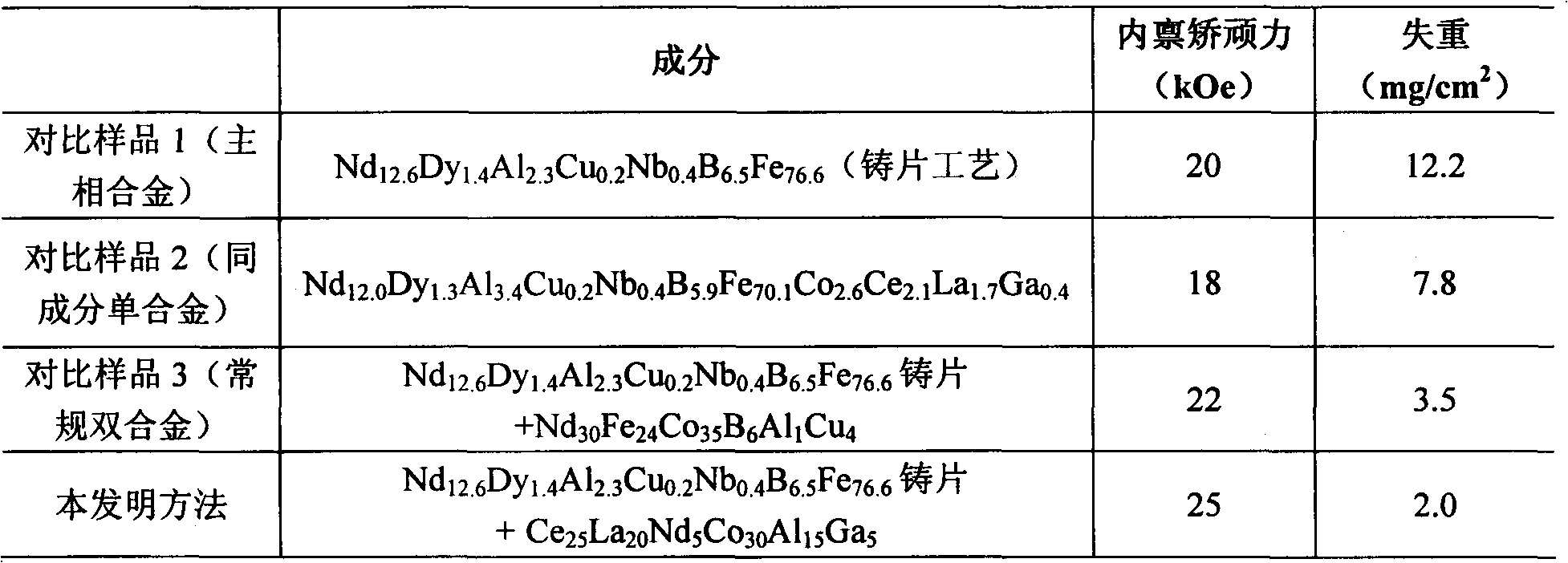

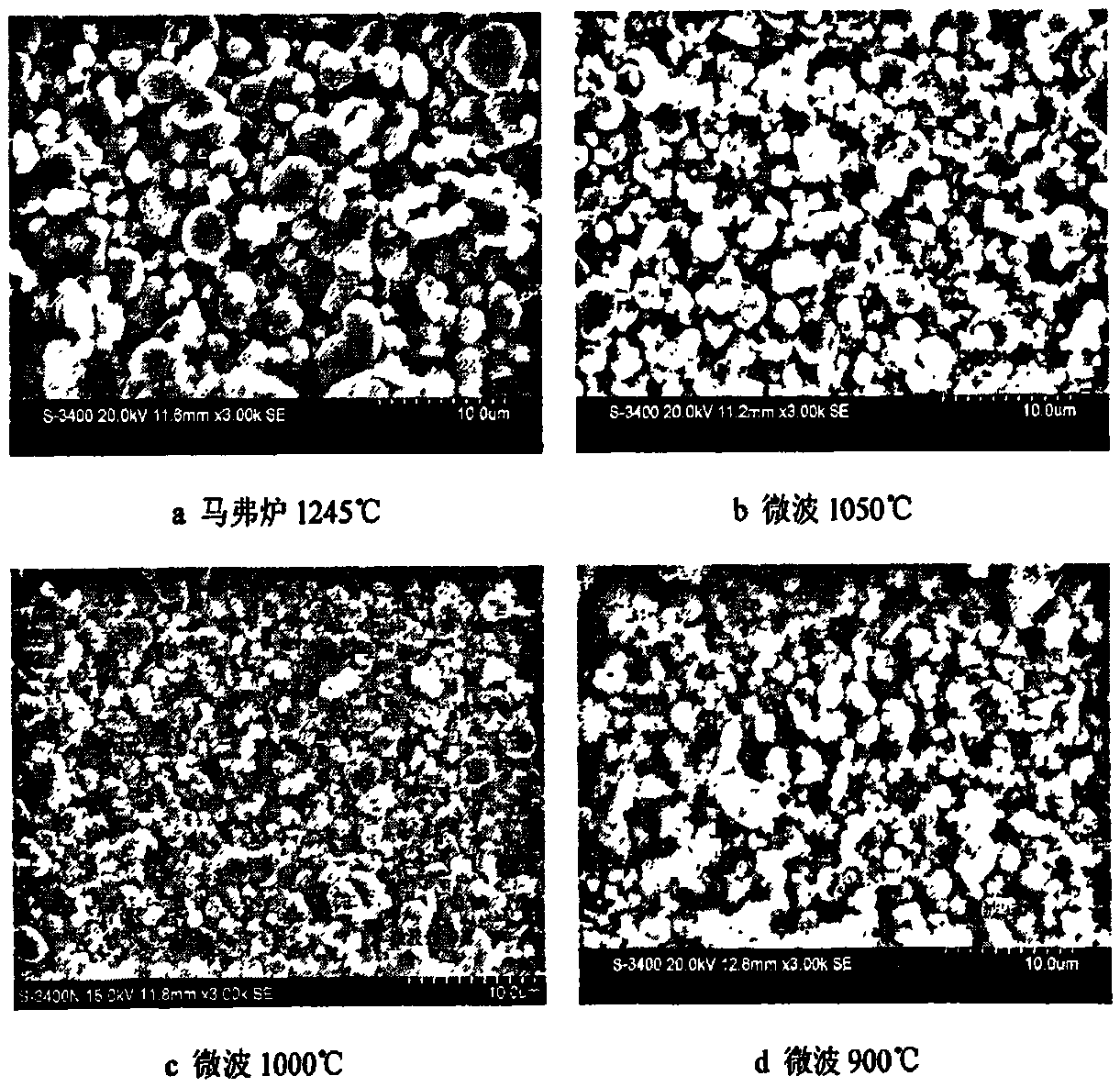

ActiveCN102220538ALow cooling rate requirementsEnhanced Amorphous Formation AbilityInorganic material magnetismAlloyGas quenching

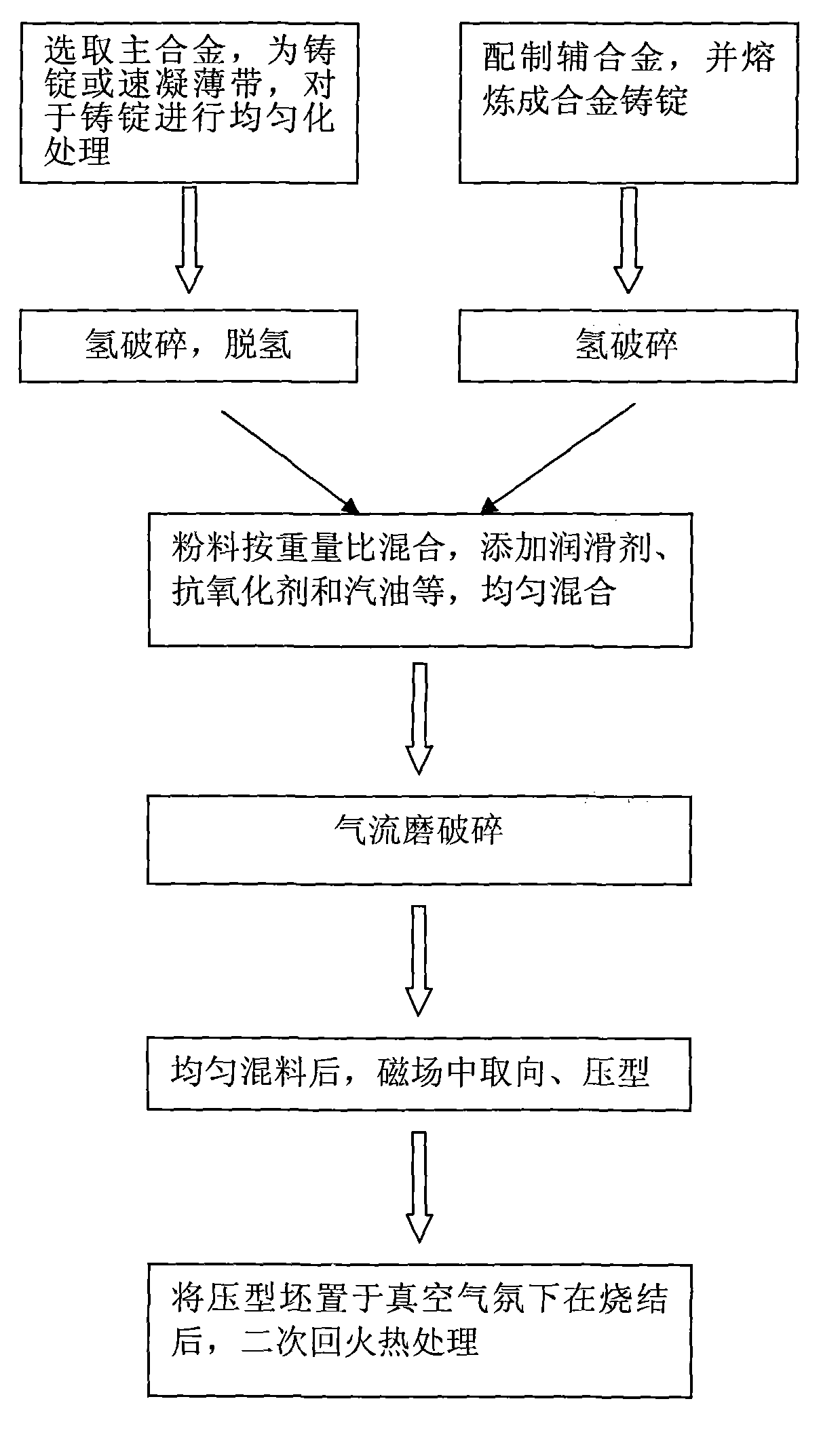

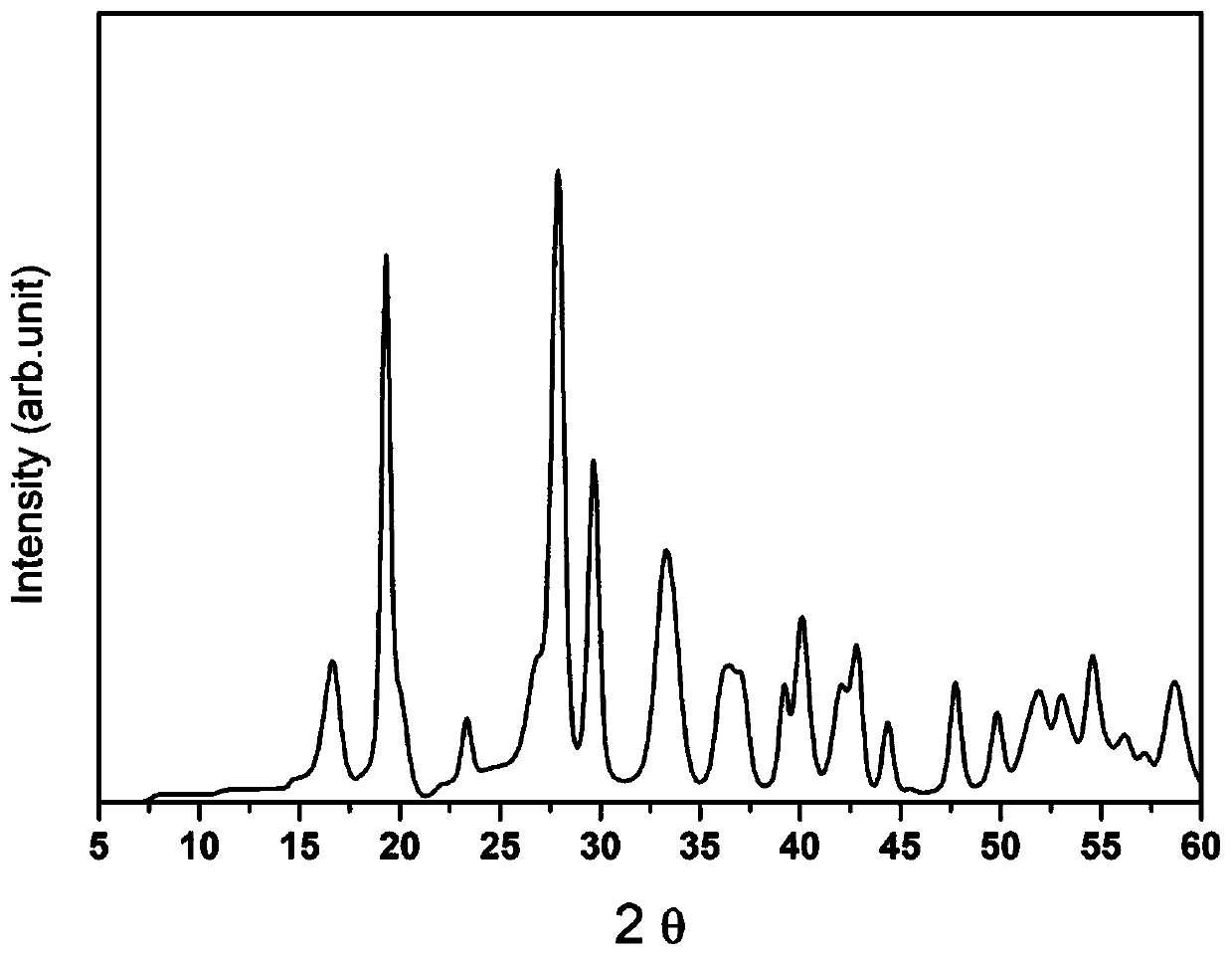

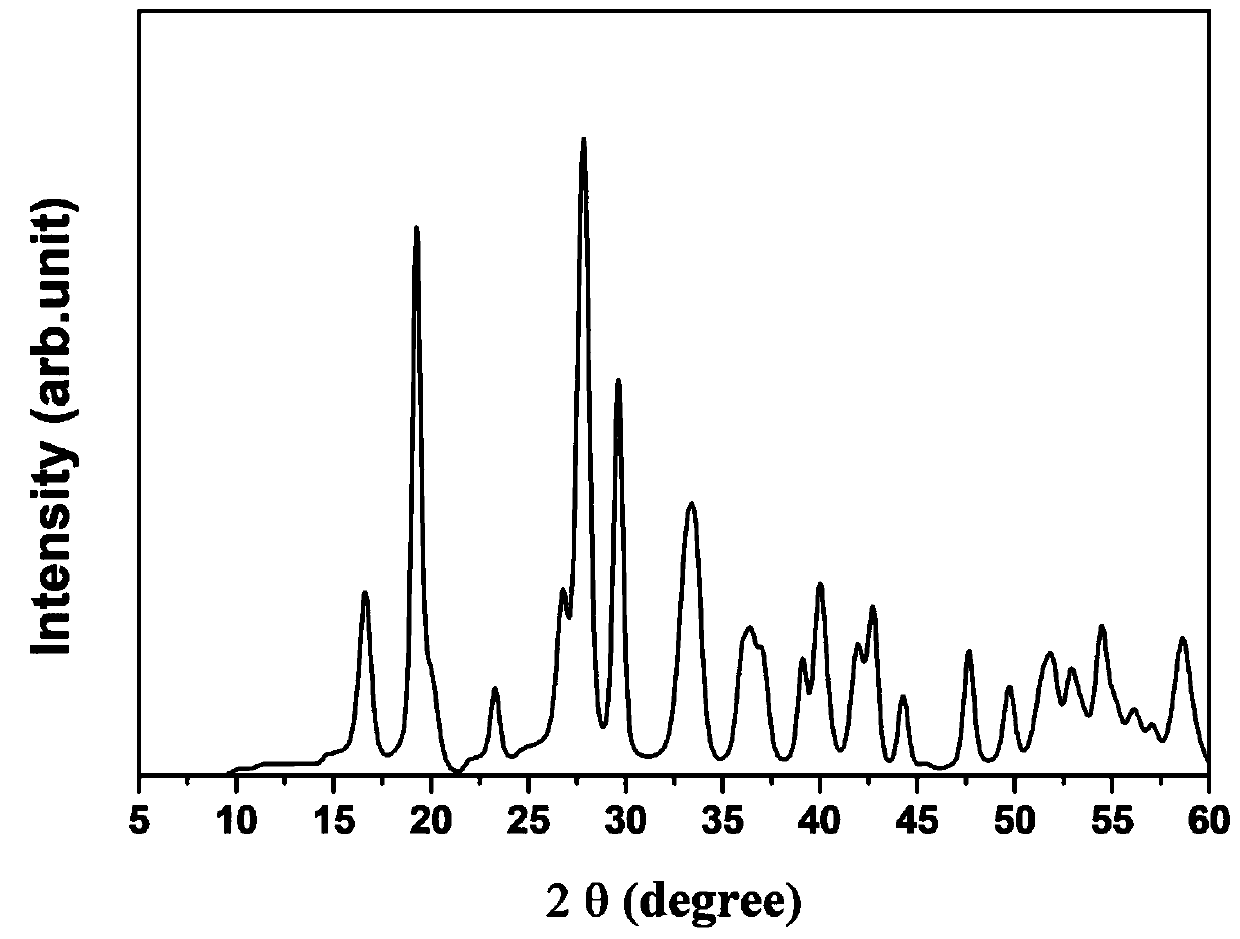

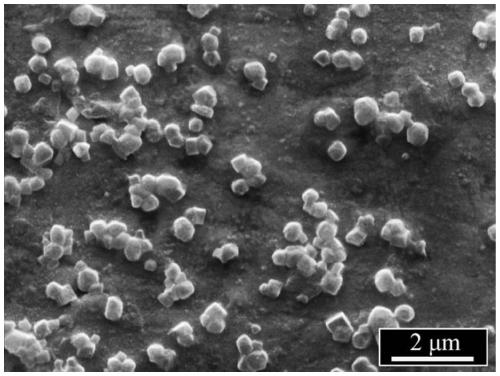

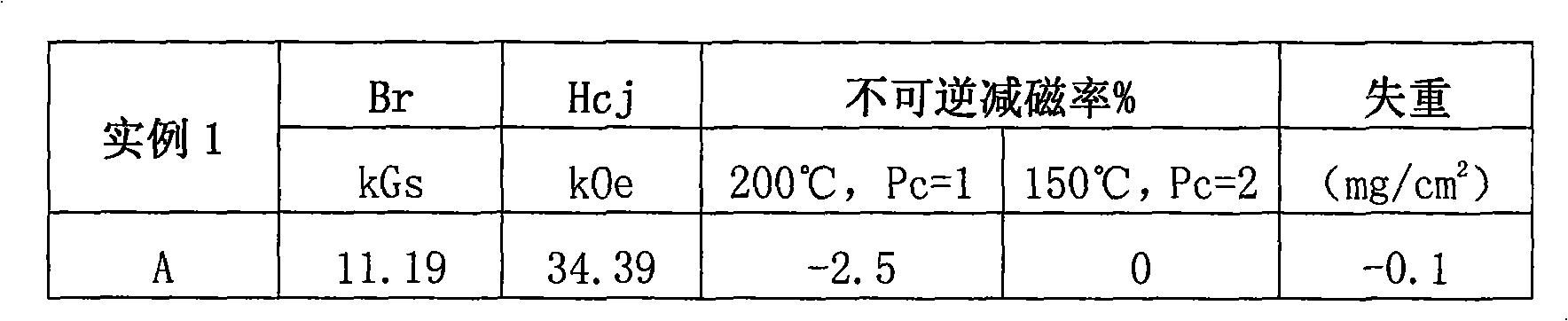

The invention discloses a sintered neodymium-iron-boron preparation method capable of improving intrinsic coercivity and anticorrosive performance. On the basis of a double-alloy preparation process, Ce-enriched multicomponent rare-based alloy with high amorphous forming ability is used as an auxiliary alloy, and the decrystallizatoin of crystal boundary phase structure is realized by gas quenching cooling in a sintering tempering process. In the invention, the intrinsic coercivity is obviously improved, the anticorrosive weight loss is greatly reduced, the magnetic performance and anticorrosive performance are high, and the method can be widely used in the field of production of high-performance anticorrosive sintered neodymium-iron-boron material.

Owner:NANJING UNIV OF SCI & TECH +1

Method for preparing corrosion-resistant sintered neodymium iron boron (NdFeB) magnet

InactiveCN101958171AStrong resistance to electrochemical corrosionReduce weightlessnessInductances/transformers/magnets manufactureMagnetic materialsWeightlessnessRare earth

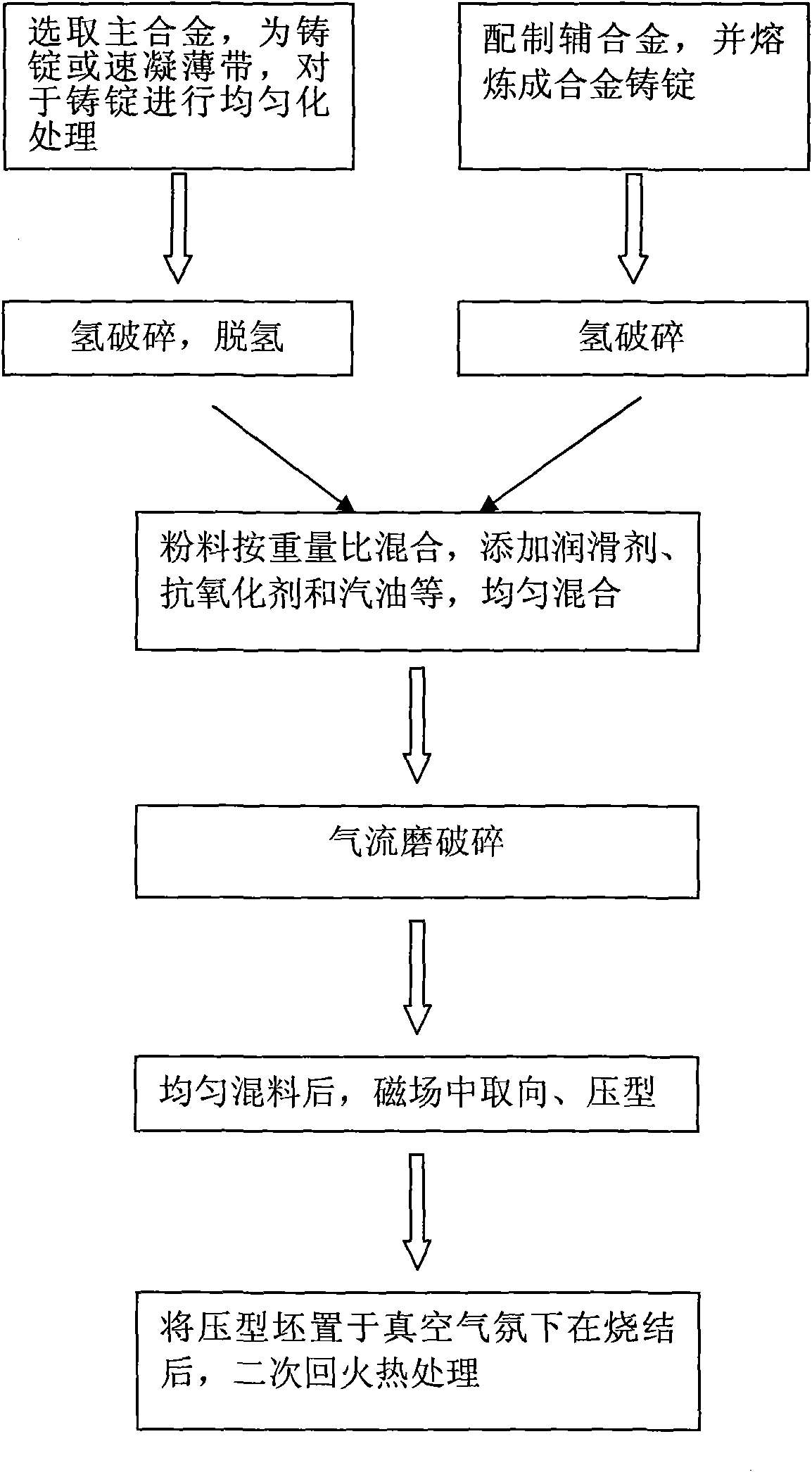

The invention discloses a method for preparing a corrosion-resistant sintered neodymium iron boron (NdFeB) magnet. In the method, an intergranular phase optimized design is used as a starting point on the basis of preparation technology of a double-alloy method, the high-cobalt content rare earth cobalt-based alloy which does not contain iron and boron is selected as an auxiliary alloy, and the melting point of the auxiliary alloy is ensured to be lower than 1,050 DEG C through component control so as to meet the liquid-phase sintering effect. By measuring the weightlessness condition of the material placed in an environment of the temperature of 120 DEG C, two atmosphere and 100 percent of humidity for 96 hours, results show that the weightlessness of the prepared sintered NdFeB magnet is only less than 1 / 3 of that of the sintered NdFeB magnet prepared by a single-alloy method and a conventional double-alloy method, and the sintered NdFeB magnet has excellent corrosion resistance. The method for preparing the corrosion-resistant sintered NdFeB magnet can be widely applied in the field of production of high-performance sintered NdFeB magnets.

Owner:WUXI NANLIGONG TECH DEV +2

Broad-spectrum disease resistance bacillus and application thereof

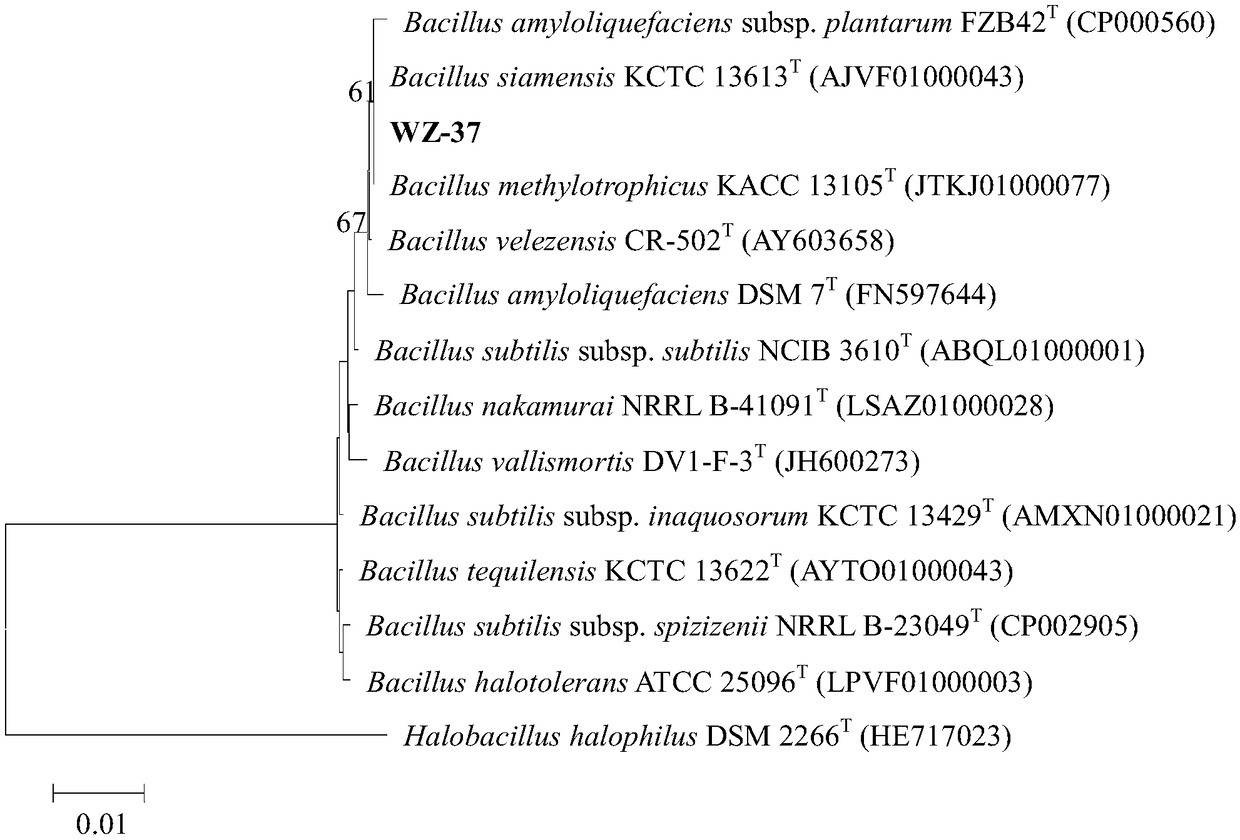

ActiveCN109022315ABroad antibacterial spectrumStrong antagonistic effectBiocidePlant growth regulatorsDiseaseUltraviolet

The invention belongs to the technical field of agricultural biocontrol, and especially relates to a broad-spectrum disease resistance bacillus and an application thereof. The biocontrol bacillus is classified and named as Bacillus velezensis, and the preservation number is CGMCC. No.15766. The Bacillus velezensis has the advantages of broad antibacterial spectrum, strong antagonistic effect, longlasting period, and effectiveness in inhibition of the growth of crop pathogenic fungi, and can be used in the fields of agricultural biocontrol to prevent and control crop diseases caused by gray mold, blight, anthracnose, stem rot, seedling blight, stalk break, gibberellic disease and other fungi. The Bacillus velezensis can also be used for promoting the growth of crop seeds and seedlings andthe preservation and fresh-keeping of fruits and vegetables. The Bacillus velezensis has the characteristics of strong resistance to ultraviolet and drought, simple preparation method and low cost, isa biocontrol strain with excellent performance, and has good development and application prospects.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Method for preparing corrosion resistance rare earth permanent-magnetic material

InactiveCN101026034AImprove corrosion resistanceReduce weightlessnessInorganic material magnetismInductances/transformers/magnets manufactureCorrosion resistantRare-earth magnet

This invention discloses a preparation method for anti-corrosion rare earth magnet material characterizing that it takes the optimized grain-boundary phase design as the starting point on the basis of a dual alloy method to select Nd base alloy with high crystal forming ability as the assist alloy and reduces the temperature of the press mold blank in a quartz container to room temperature from over grain-boundary phase melting point with the water extraction way to get enough cooling rate and guarantee the non-grain-boundary phase, compared with the material of the same composition prepared by ordinary method, the weightlessness of this invented material reduces over 30% after testing the weightlessness of the material by laying it for 96 hours under 121deg.C, 2 atmosphere and 100% humid environment to show the advanced performance of anti-corrosion.

Owner:NANJING UNIV OF SCI & TECH

Channel catfish ictalurus punctatus deepfreezed fillets and processing technique

InactiveCN101032337AIncrease incomeGreat tasteMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsLeiocassis longirostrisIce water

The present invention discloses one kind of fast frozen white delicious fish fillet of spotted forked-tail Leiocassis longirostris and its production process. The production process includes the steps of temporarily raising, killing to eliminate blood, slicing, eliminating skin, trimming, soaking to sterilize, loading into tray and quick freezing, grading, coating with ice, packing, etc. The production process features complete elimination of blood, low temperature of fish fillet in icy water at 0-4 deg.c, soaking fish fillet in ozone icy water and ultralow temperature quick freezing at below -35 deg.c. The production process has high fish fillet yield and less nutrient loss, and the produced fish fillet is white, translucent and delicious.

Owner:YIYANG YIHUA AQUATIC PRODS

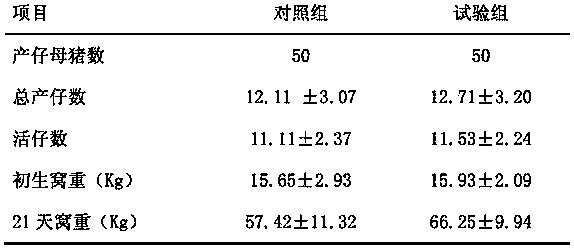

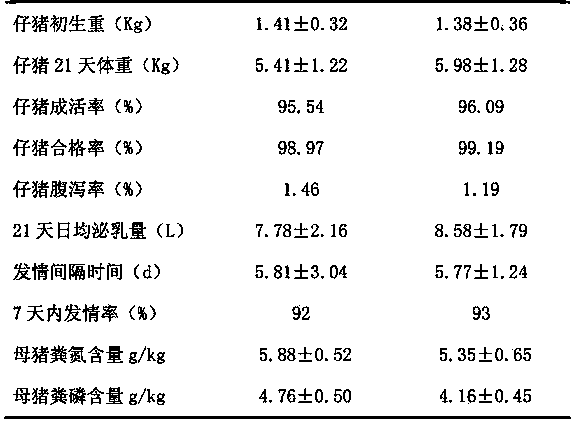

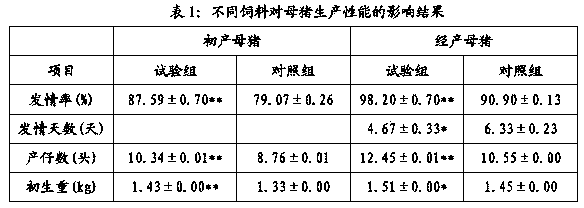

Efficient and environment-friendly compound feed for lactating sow and preparation method thereof

InactiveCN103976194AExtended shelf lifeIncrease in sizeAnimal feeding stuffAccessory food factorsAnimal scienceRoom temperature

The invention discloses an efficient and environment-friendly compound feed for lactating sow and a preparation method thereof. The compound feed is characterized by comprising the following raw materials in parts by weight: 40 to 50 parts of maize, 20 to 30 parts of wheat, 3 to 5 parts of wheat bran, 10 to 15 parts of peeled soybean meal, 1 to 2 parts of fish meal, 3 to 5 parts of biological soybean meal, 1 to 1.2 parts of rock powder, 1.2 to 1.4 parts of calcium hydrophosphate, 0.3 to 0.5 part of table salt, 1.5 to 2.5 parts of soybean oil, 0.4 to 0.45 part of lysine, 0.04 to 0.06 part of methionine, 0.1 to 0.12 part of threonine, 0.01 to 0.02 part of a complex enzyme preparation, 0.06 to 0.1 part of microecologics, 0.03 to 0.06 part of an emulsifier, and 1 to 1.5 parts of a compound premix. The preparation method comprises the following steps: weighing the various raw materials in a predetermined ratio; fine crushing maize, wheat, wheat bran, peeled soybean meal and biological soybean meal; directly adding to a horizontal twin-shaft paddle mixer in a ratio to mix; feeding the mixture to a granulating machine for granulating; processing at a temperature of 85 DEG C until the gelatinization degree is more than 90%; cooling till the temperature is not higher than room temperature by 5 DEG C after granulating; and then weighing, bagging and sealing through an automatic packing machine. The preparation method is mainly used for preparing the compound feed for lactating sow.

Owner:TANGRENSHEN GRP CO LTD

Sow mating feed and using method thereof

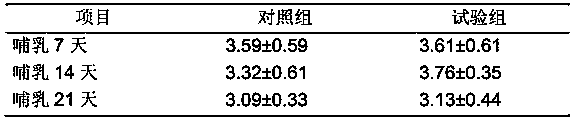

The invention discloses sow mating feed, and belongs to the technical field of pig raising feed. The sow mating feed is all-around in nutrition through scientific formulation, can meet needs of sows on various nutrients in a mating stage, promote metabolism, improve the immunity of a sow, reduce postpartum body weight loss of the lactating sow, promote rapid empathema of the sow to shorten the mating cycle, increase the number of piglets and the weight of a newborn piglet, increase the annual reproductive times and the reproductive performance of the sow; comparison tests show that the sow mating feed used in the mating period of the sow has a more significant effect than lactating sow feed, can improve the empathema rate, the litter size and the piglet birth weight of first-litter sows, can improve the empathema rate, the litter size and the piglet birth weight of multiparous sows and shorten the number of empathema days.

Owner:铁骑力士食品有限责任公司

Polybasic solid solution rare earth silicate ceramic powder and preparation method thereof

The invention relates to the technical field of ultrahigh temperature ceramic powder, in particular to polybasic solid solution rare earth silicate ceramic powder and a preparation method thereof. Thechemical formula of the polybasic solid solution rare earth silicate ceramic powder is (Y0.2Yb0.2Re'0.2Re'0.2La0.2)2Si2O7, wherein Re' and Re' are selected from any two of Nd, Ce, Sm, Er and Eu. Thepreparation method comprises the following steps: mixing raw materials by adopting a wet-mixing method, and drying; then placing the mixture in a high-temperature reaction furnace for reacting; performing wet milling and spray drying granulation to obtain the polybasic solid solution rare earth silicate ceramic powder. The polybasic solid solution rare earth silicate ceramic powder has high solidsolubility, excellent high temperature resistance, no decomposition at a high temperature and low thermal conductivity. The preparation method is simple and feasible.

Owner:淄博星澳新材料研究院有限公司

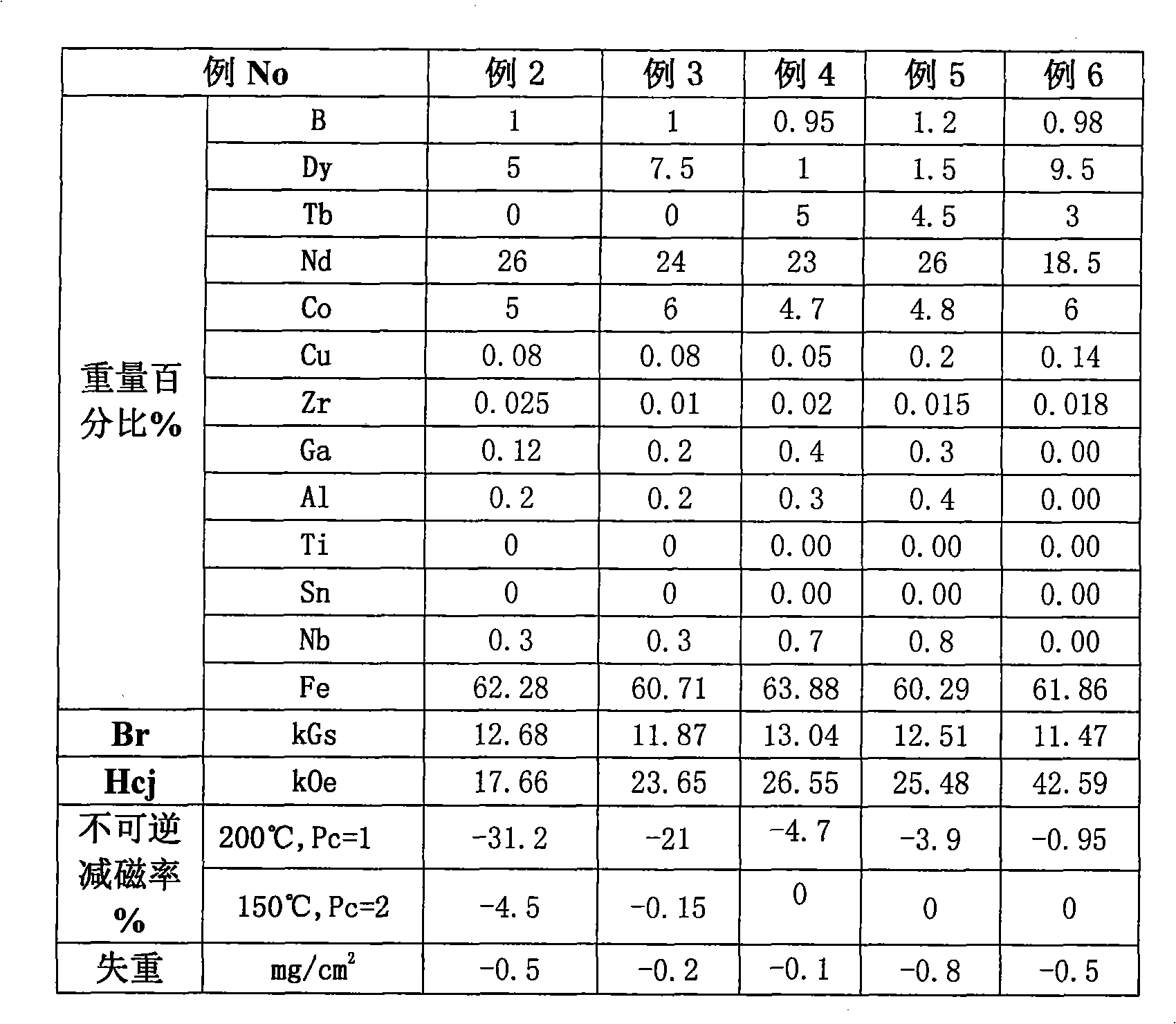

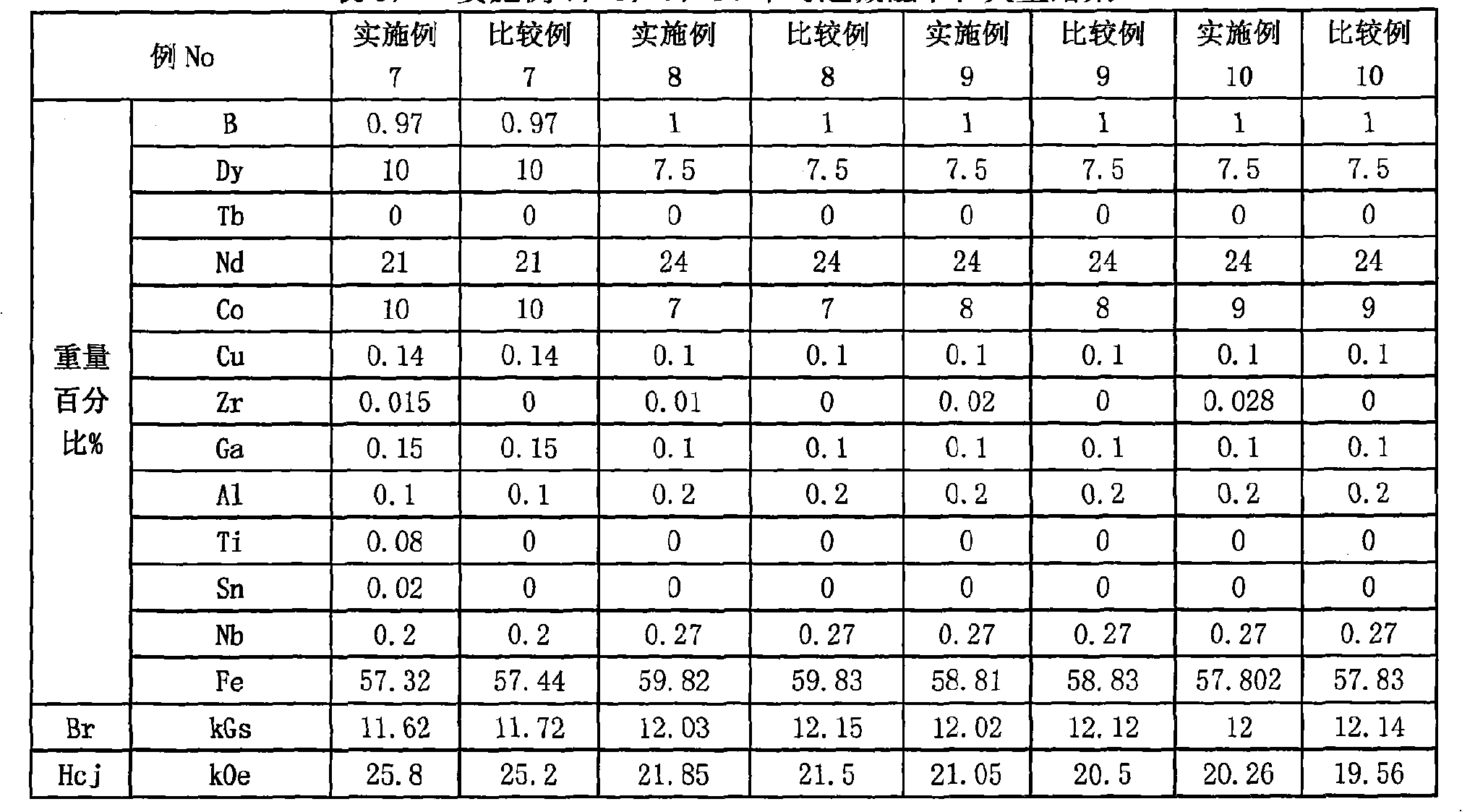

Fire resistant permanent magnet alloy and manufacturing method thereof

ActiveCN101315825AImprove matchImprove the disadvantages of poor temperature resistanceMagnetic materialsZirconium hydrideAdditive ingredient

The invention relates to a permanent magnet alloy with excellent heat resistance and a preparation method thereof, and the alloy consists of components according to the following formula: R29-32Al0-0.4Nb0-0.8(Ti+Sn)0-0.1Zr0.01-0.029Ga0-0.4B0.95-1.2Co4.5-10Cu0.05-0.2Fe remaining, wherein, R at least selects from one of Ce, Pr, Nd, Dy or Tb, Fe remaining is Fe and inevitable impurities. In the preparation method, Zr is added by a 10-30 nanometer zirconium oxide powder form when mixing fine powder; as the zirconium oxide disperses in crystal boundary phase of an NdFeB magnet and is of square crystal structure, oxygen content distribution of the magnet and microstructure are effectively improved. The permanent magnet alloy with excellent heat resistance optimizes the matching of elements, improves the shortcoming of bad heat resistance of sintered NdFeB material, expands the application range of the sinterable NdFeB, improves the performance of the sintered NdFeB in two aspects of ingredient and technique, and can make up the shortcoming of low use temperature of the sintered NdFeB.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Polyethylene gas-exchange fresh-keeping bag for fruit and vegetable, manufacturing process and application thereof

InactiveCN101012018ALow running costReduce rotEnvelopes/bags making machineryBagsEngineeringVolumetric Mass Density

The polythene bag fruit fresh keeping bag is made by adding ventilating mother granule into the polythene, blowing into barrel film, using smooth surface compressing the roller into 1mum-15mum micropore ventilating tubular film into film thickness 0.015mm-0.02mm, with micropore density of 500, 000-1, 000, 000 / m2, ventilating quantity of 15min-70min / (100mmX100mm.20g.1.013X105Pa) fresh keeping bag. It can exhaust Co2 and restraining O2, realizing air conciliation and moisture keeping. The air adjusting fresh keeping bag keeps freshness of food 7 days longer, freezing fresh keeping period longer than 1-2 months.

Owner:山西三水渗水膜科技发展中心

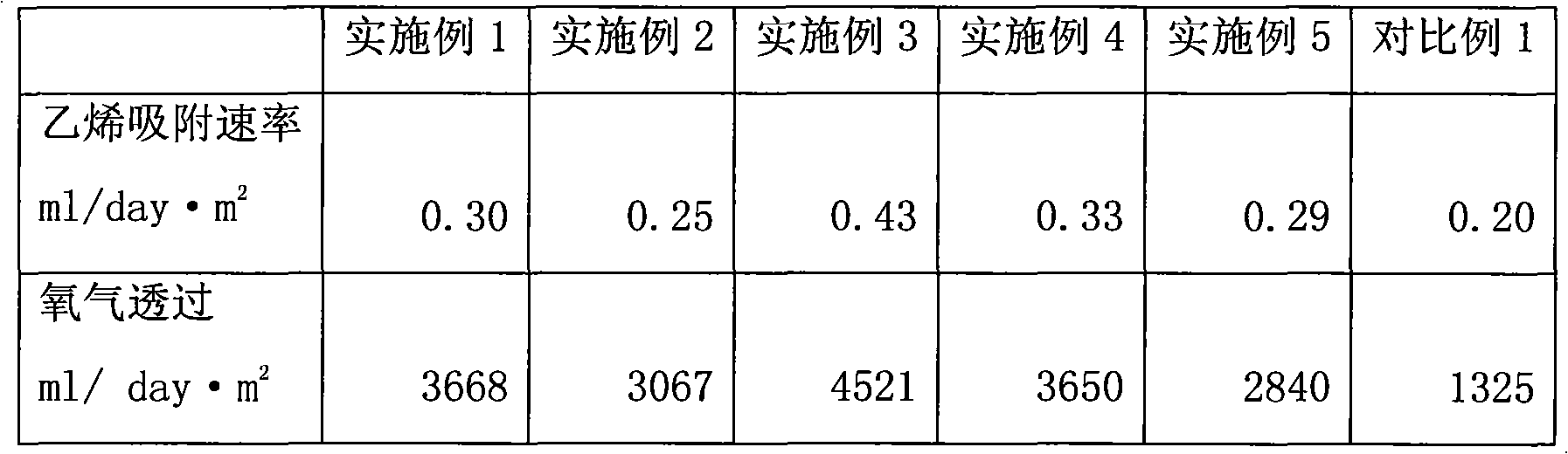

Fruit-preserving green packing material with ethylene adsorption function and preparation method thereof

ActiveCN101967245AAvoid knife woundsConsistent maturityFruit and vegetables preservationContainers preventing decayMolecular sieveGranularity

The invention discloses a fruit-preserving green packing material with an ethylene adsorption function and a preparation method thereof, belonging to the field of packing materials. The material comprises 100-90 parts of polyethylene or polypropylene resin by weight and 0.5-10 parts of aluminum silicate molecular sieve by weight, wherein the granularity of the aluminum silicate molecular sieve is 5-100 microns and the silica alumina ratio of the same is 5-100. The preparation method comprises the steps of: firstly preparing the aluminum silicate molecular sieve; then melting and blending the aluminum silicate molecular sieve and the polyethylene or polypropylene resin, and blowing to make thin films. The ethylene adsorption rate of the packing material in the invention reaches 0.25-0.43ml / day.m<2>, and the oxygen transmissivity reaches 1300-4600ml / day.m<2>, therefore, a banana shelf life is prolonged by 25-125%, and the weightlessness is reduced by more than 50%.

Owner:大家智合(北京)网络科技股份有限公司

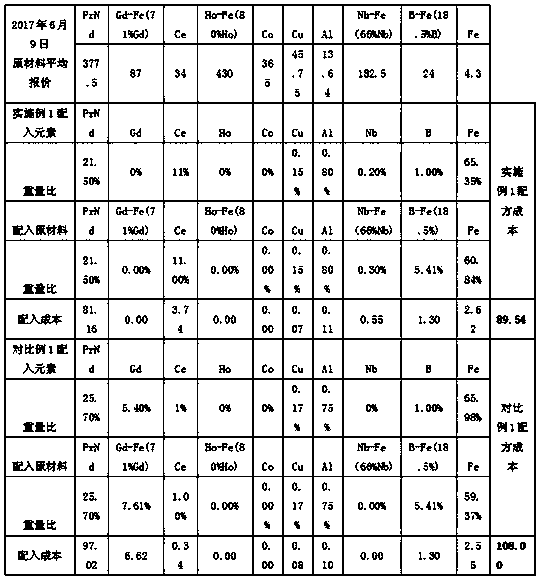

Low-cost N35 NdFeB magnet with high cerium content and sintering method thereof

InactiveCN107610858ALow costReduce consumptionInorganic material magnetismInductances/transformers/magnets manufactureNiobiumCerium

A low-cost N35 NdFeB magnet with high cerium content and a sintering method thereof belong to the technical field of powder metallurgy. The low-cost N35 NdFeB magnet is prepared from the following rawmaterials based on percent by weight according to a sintering process, 12-27% of praseodymium neodymium (Pr-Nd), 7-15% of cerium (Ce), 0-0.5% of niobium (Nb), 0-1% of aluminum (Al), 0-1% of copper (Cu), 0.9-1.1% of boron (B), 0-1.2% of cobalt (Co), 0-0.5% of zirconium (Zr) and 0-3% of gadolinium (Gd) with the balance being iron (Fe). In the scheme, a part of praseodymium neodymium (Pr-Nd) is substituted by cerium (Ce), the magnetic performance index reaches national standard of N35 mark sintering NdFeB, and the material cost can be reduced by 15-25 yuan during production of each kilogram of the corresponding mark magnet.

Owner:DONGYANG ZHONGYUAN MAGNETIC MATERIAL

Sintered neodymium iron boron permanent magnet based on crystal grain recombination and manufacturing method

ActiveCN104240888ACorrosion resistanceImprove performancePermanent magnetsInductances/transformers/magnets manufactureRare-earth elementHydrogen

The invention discloses a sintered neodymium iron boron permanent magnet based on crystal grain recombination and a manufacturing method. The permanent magnet has composite main phases that main phases with high heavy rare earth RH content are distributed around main phases with lower heavy rare earth RH content, and no continuous grain boundary phase exists in the composite main phases; average content of heavy rare earth RH on the periphery of the composite main phases is higher than content of heavy rare earth RH in the core part of the composite main phase, and the average crystal grain size of the composite main phases is 6-14mu m; heavy rare earth RH comprises more than one of Dy, Tb, Ho, Gd and Y elements. The manufacturing method comprises steps of first alloy smelting, second alloy smelting, hydrogen decrepitation, alloy plate mixing, jet mill powdering, magnetic field formation, vacuum sintering and aging; the step of first alloy smelting comprises a process of preparing first alloy plates containing Pr and Nd elements; the step of second alloy smelting comprises a process of preparing second alloy plates containing heavy rare earth RH elements.

Owner:SHENYANG GENERAL MAGNETIC

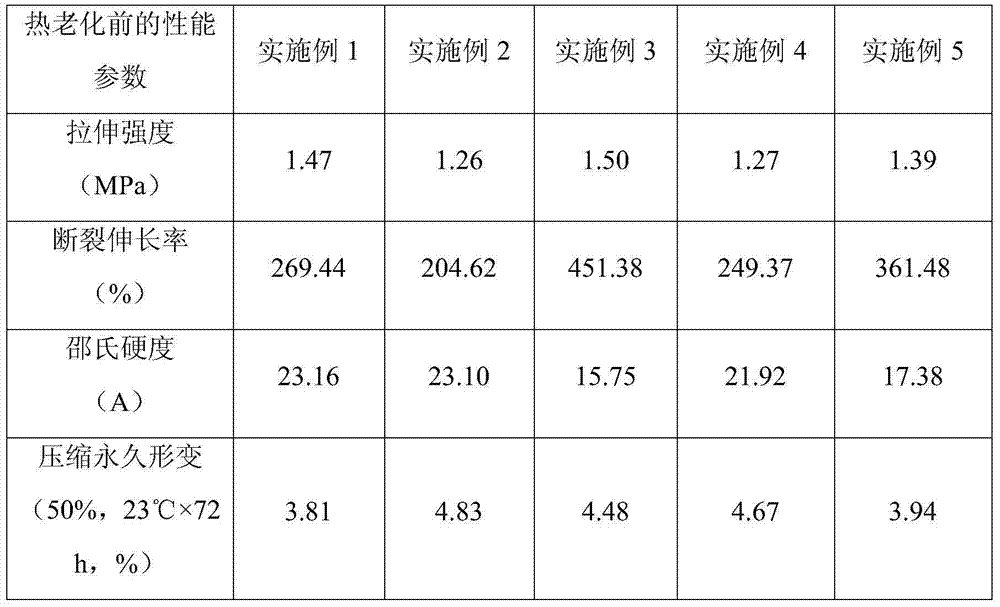

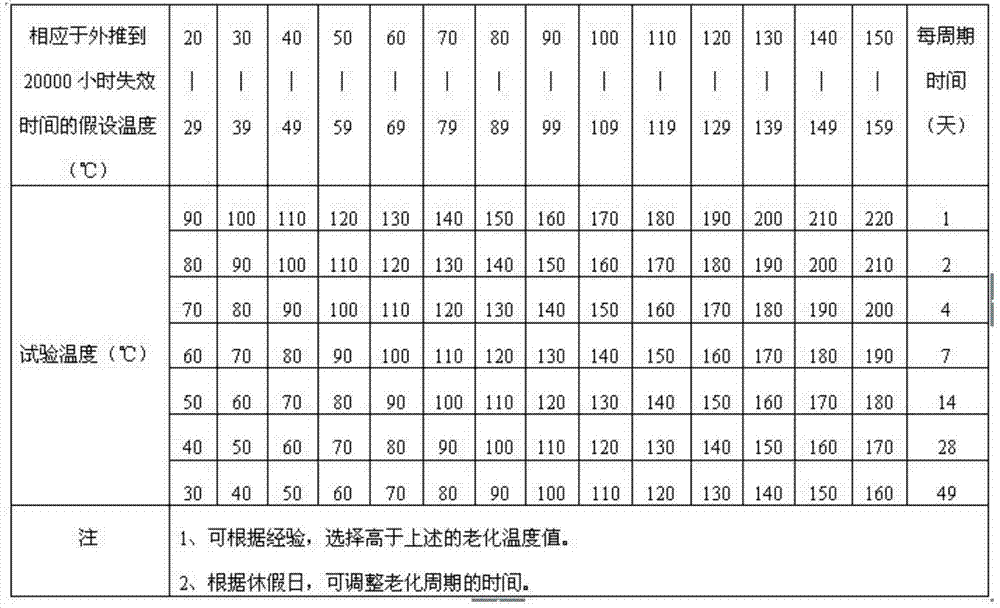

High-temperature-resistant silicone rubber foam material and preparation method thereof

The invention discloses a high-temperature-resistant silicone rubber foam material and a preparation method thereof. The preparation method of the high-temperature-resistant silicone rubber foam material is characterized by comprising the following steps: mixing 100 parts of silicone rubber base stock, 20-35 parts of a reinforcing agent, 2-3 parts of a structure controlling agent, 0-0.2 part of colour master batch, 60-150 parts of a pore-forming agent and 4-5 parts of a radiation sensitizer, moulding, crosslinking through gamma ray radiation, forming pores through subsection dissolving-out, and drying, so that the silicone rubber foam material which is resistant to high temperature of 250 DEG C and still maintains excellent performance after equivalent time of 20000 hours can be obtained. The preparation method of the high-temperature-resistant silicone rubber foam material has the advantages that radiation crosslinking and dissolving-out pore forming are combined, so that crosslinking is uniform, control is easy, energy conservation and environmental protection are realized, a technology is concise, reproducibility is good, and production efficiency is high; the high-temperature-resistant silicone rubber foam material still maintains high tensile strength, high weight loss, low longitudinal deformation and low surface hardness after the equivalent time of 20000 hours at the temperature of 250 DEG C, permanent compressive deformation is slightly increased, the high-temperature-resistant silicone rubber foam material does not become brittle or hard, and the high-temperature-resistant silicone rubber foam material can serve as filling and positioning, sealing cushion, cable insulation as well as buffer and vibration-absorptive materials or parts which are used in high-temperature environment.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

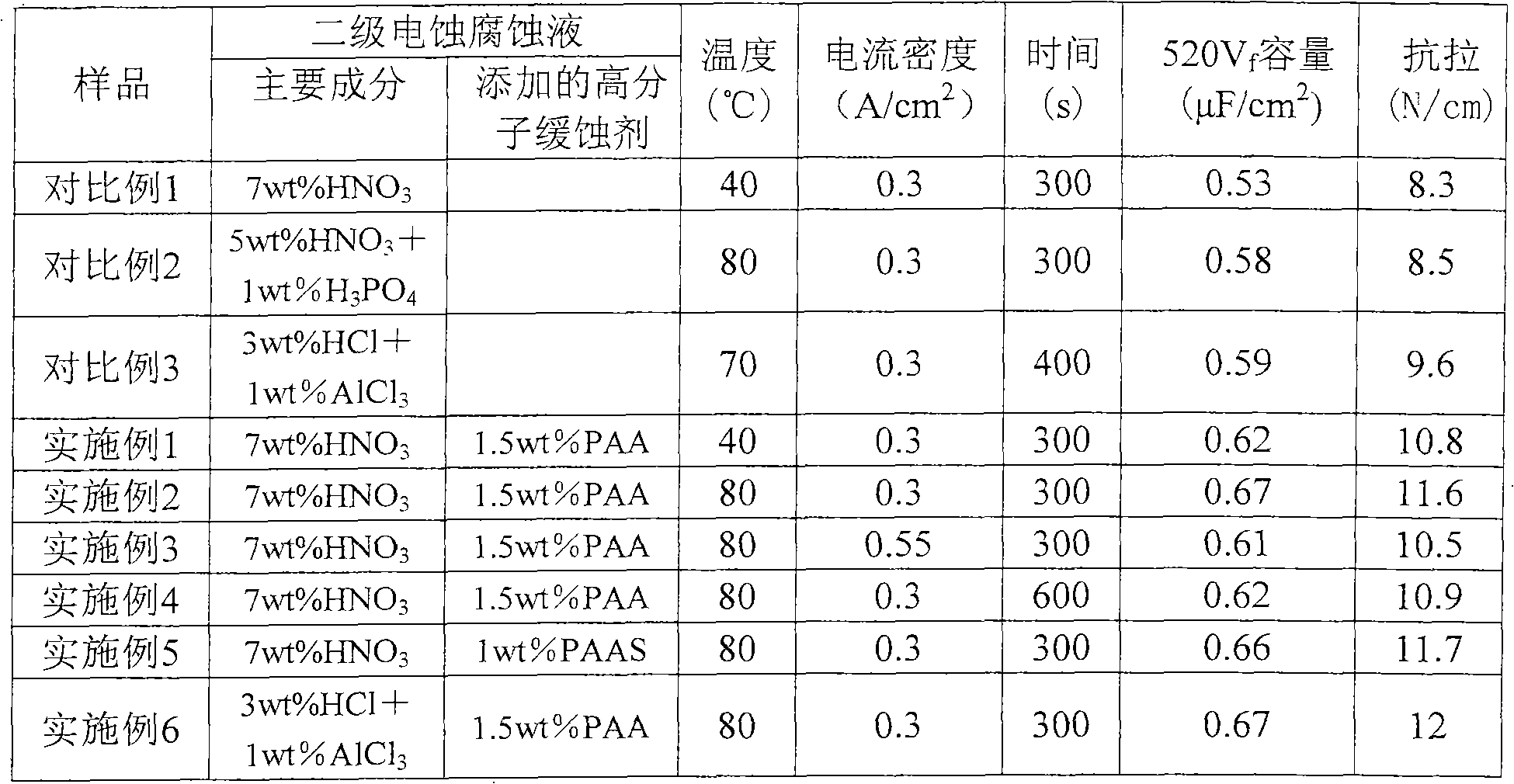

Anode foil corrosion technology of electrolytic capacitor

InactiveCN101345137AReduce weightlessnessHigh capacitanceElectrolytic capacitorsElectrolysisPolystyrene

The invention relates to an anode foil etching process of an electrolytic capacitor. The process comprises pre-processing, primary electrical erosion and secondary electrical erosion, wherein, high molecular weight inhibitor is added into the etching solution of the secondary electrical erosion; the inhibitor is one or more types out of linear PAA, PAAS and polystyrene sulfonic acid; the weight percentage of the inhibitor is 0.01 percent to 10 percent. According to the weight ratio, the inhibitor solution consists of one type out of 1 percent to 10 percent of H2SO4, H3PO4, HCl and HNO or the mixed solution of H3PO4 and HCl; the inhibitor solution is not restricted by the acids and the mixed solution of two or more acids and salts; when the temperature is 30-90 DEG C, the current density is restricted at 0.1A / cm<2> to 0.5A / CM<2>; the hole expanding time is controlled within 50s to 600s; subsequently, the post-processing is carried out. The process of the invention improves the static capacity of the anode aluminium foil and reduces the weightlessness.

Owner:深圳清研技术管理有限公司

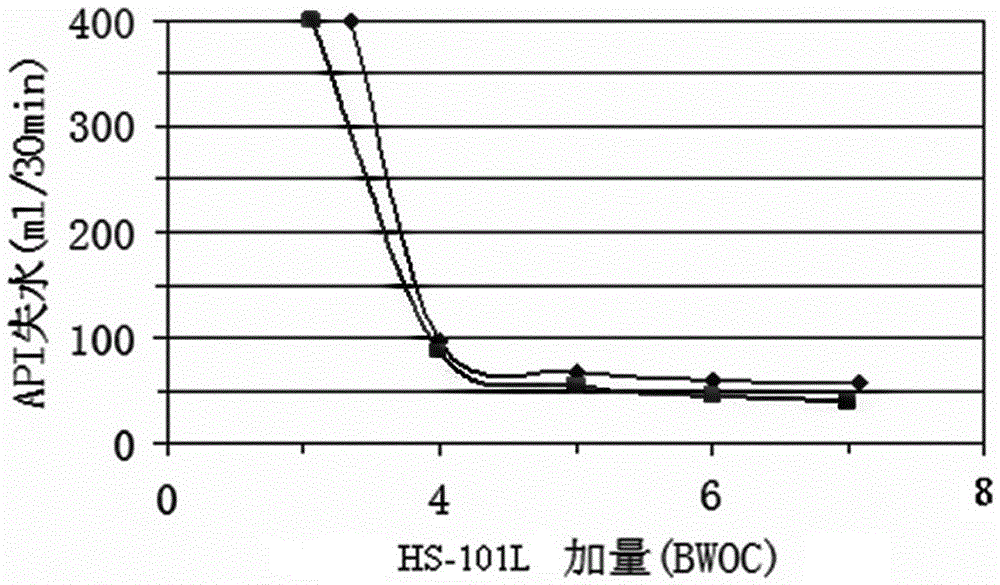

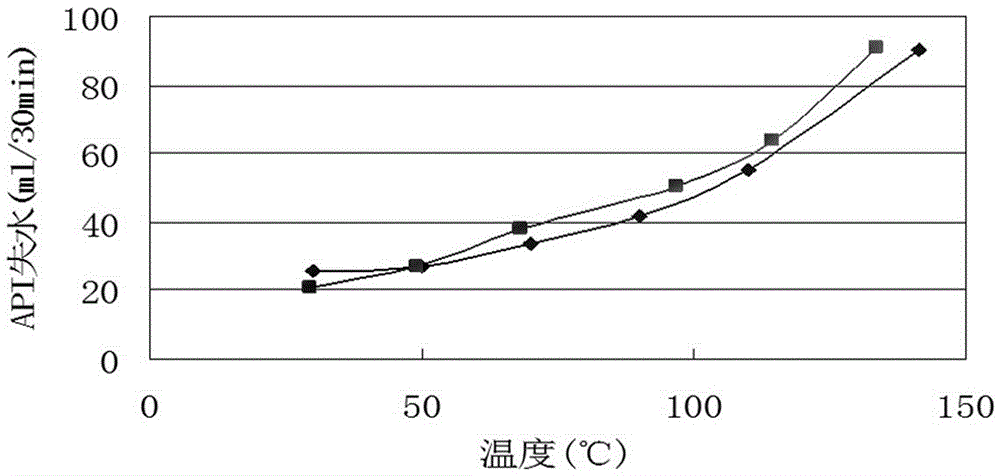

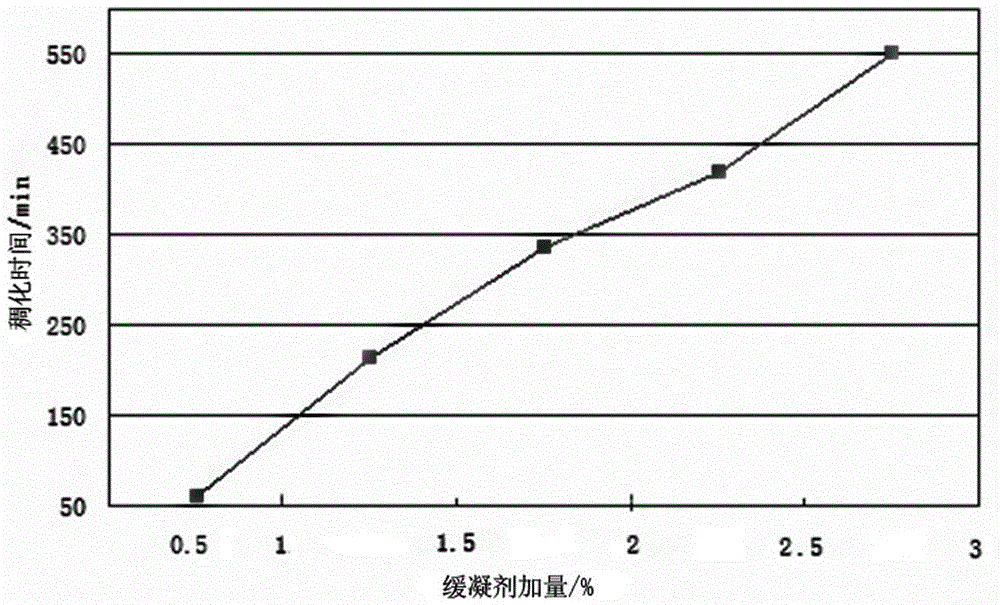

Preparation method of high-temperature-resistant great-temperature-difference cement paste for oilfield well cementing

The invention relates to a preparation method of a high-temperature-resistant great-temperature-difference cement paste for oilfield well cementing. The high-temperature-resistant great-temperature-difference cement paste for oilfield well cementing is prepared from the following raw materials in parts by weight: 600 parts of Grade-G oil well cement, 30-36 parts of HS101L water-loss control agent, 8-20 parts of HS201L retarder, 1.8 parts of HS-301S dispersing agent, 150 parts of quartz sand, 30 parts of silicon micropowder, 1.8 parts of HS-XF1S suspension stabilizer, 280-300 parts of water and 1 part of sodium bis(2-ethylhexyl)sulfosuccinate. The particle size of the quartz sand is 80-120 meshes; and the particle size of the silicon micropowder is 300-400 meshes, and the silicon dioxide content is 90% or above. The preparation method comprises the following steps: adding liquid-phase raw materials into a paste mixing vessel, and uniformly mixing; and adding solid-phase substances into a solid-phase vessel, stirring uniformly, adding the solid-phase mixture into the paste mixing vessel, finally adding a defoaming agent, and stirring uniformly. The cement paste prepared by the method can be used under the condition of 50-180 DEG C, has outstanding resistance to great temperature difference, and can effectively avoid the phenomenon of super slow setting caused by great temperature difference.

Owner:CHINA PETROCHEMICAL CORP +2

Neutral low-temperature refining enzyme and use thereof in pretreatment of fabrics

ActiveCN102154230AReduce pollutionImprove water absorptionBiochemical fibre treatmentEnzymesPectinaseCellulose

The invention relates to a neutral low-temperature refining enzyme and use thereof in pretreatment of fabrics. The neutral low-temperature refining enzyme comprises 15 to 50 weight parts of neutral cellulose, 30 to 70 weight parts of pectinase, 10 to 30 weight parts of xylanase, 5 to 30 weight parts of lipase and 10 to 15 parts of laccase. When the neutral low-temperature refining enzyme is used, cotton seed hulls, pectic substances, waxiness and the like can be removed effectively, the water absorptivity, fiber strength and dyeing property of cotton fabrics can be improved, dye can be saved, process time can be reduced and the production efficiency can be improved. A green processing method which is low in carbon content, environment-friendly and energy-efficient can be realized actually in the fabric dyeing industry.

Owner:沧州夏盛酶生物技术有限公司

Processing liquid and processing process for ultralow-temperature scouring and bleaching of cotton knitted fabric

ActiveCN103306129AReduce energy consumptionReduced fabric weight lossBleaching apparatusVegetal fibresChemistryComposite material

The invention provides processing liquid for ultralow-temperature scouring and bleaching of cotton knitted fabric. The processing liquid comprises the following components according to concentration range: 0.2-10.0g / L of a scouring agent, 0.5-20.0g / L of solid sodium hydroxide (NaOH), 0.5-30.0g / L of hydrogen peroxide (H2O2) and 0.1-20.0g / L of a hydrogen peroxide activating agent. According to a processing process provided by the invention, the scouring and bleaching processing temperature of the cotton knitted fabric is decreased from 98 DEG C to 60 DEG C, at least 53.7% of energy can be saved, the weight loss of the fabric is lowered by 20%, the discharging of residual liquid COD (Chemical Oxygen Demand) is reduced by 8%, and the scouring and bleaching processing is carried out on the pure cotton knitted fabric in an energy-saving and environment-friendly manner in the premise that the processing quality is guaranteed.

Owner:DYMATIC CHEM

Physical honey peach storage method

ActiveCN103609666AReduce decay rateImprove sensory qualityFruits/vegetable preservation by freezing/coolingHeat shockCO2 content

The invention belongs to the technical field of fruit and vegetable fresh keeping and in particular relates to a physical honey peach storage method. The physical honey peach storage method mainly comprises the following steps: (1) selecting peaches and dissipating heat in a room at the temperature of 20 to 25 DEG C after the honey peaches are picked within 5 hours; (2) performing heat shock treatment on the selected honey peaches at the temperature of 53 to 55 DEG C for 8-12 minutes, and rapidly taking the honey peaches subjected to heat shock treatment out; (3) dissipating heat of the honey peaches subjected to the heat shock treatment in an indoor environment at the temperature of 20 to 25 DEG C; (4) performing unsealed package on the honey peaches by using polyamide film and polyethylene film composite bags; and (5) storing the packaged honey peaches in an air-conditioned cold store at the temperature of 8 to 10 DEG C, regulating the temperature of the air-conditioned cold store to be 2 to 4 DEG C after adapting to a low temperature, and continuously performing cold storage, wherein the volume rate of gas in the air-conditioned cold store is as follows: the N2 content is 86 percent, the O2 content is 4 percent and the CO2 content is10 percent, and the humidity is controlled to be 80-90 percent. The invention aims to provide the physical honey peach storage method which is convenient to operate, safe, high-efficiency, good in storage effect and long in storage time.

Owner:ZHEJIANG JIAXING AGRI SCI ACADEMY INST

Special surface treating agent for neodymium iron boron and application method of special surface treating agent

InactiveCN104451635AReduce weightlessnessHarm reductionMetallic material coating processesPhosphateStrong acids

The invention relates to a special surface treating agent for neodymium iron boron. The special surface treating agent is prepared from raw materials including zinc dihydrogen phosphate, manganese dihydrogen phosphate, nickel nitrate, sodium fluoride, sodium nitrate, phosphoric acid, citric acid, phosphotungstic acid and sodium molybdate. According to the special surface treating agent disclosed by the invention, all components are mixed with deionized water to obtain a finished product. When the special surface treating agent is in use, a neodymium iron boron magnetic material is put into an ultrasonic roller and is sequentially subjected to oil removal, washing, surface conditioning, treatment by the special surface treating agent for the neodymium iron boron, sealing and drying, wherein micro-rust on the surface is firstly removed; a uniform and compact protective film is formed on the surface; the treated neodymium iron boron magnetic material is small in weight loss; a saline soaking test proves that the treated neodymium iron boron magnetic material is better in corrosion resistance, and harms caused by acid pickling of a strong acid to the environment and operators are reduced.

Owner:泰伦特生物工程股份有限公司

Antifungal protein separated and purified from bacillus subtilis J18, protein product, preparation method and application

InactiveCN103045704AInhibition of reproductionGrowth inhibitionBiocideNon-fibrous pulp additionDiseaseAntifungal protein

The invention relates to an antifungal protein separated and purified from bacillus subtilis J18, a protein product, a preparation method and an application. A strain serial number of the bacillus subtilis J18 is CGMCC No.3665, and a strain name is the bacillus substilis J18. The preparation method of the protein product comprises the following steps of: mixing the J18 antifungal protein with 1 percent of acetic acid to form a chitosan solution with a pH value of 6.0, compositing the chitosan solution to form a film coating reagent which has the concentration of 0.05mg / mL and is used for soaking a fruit, and also coating a mixture which is formed by mixing the J18 antifungal protein solution with an oxidized starch solution on a preservative paper to prepare an antifungal preservative paper used for wrapping the fruit. The antifungal protein has remarkable control effect to fruit and crop diseases and particularly black spot diseases of pears after picking and is an antagonistic strain with broad spectrum and high efficiency.

Owner:BIOLOGY INST OF HEBEI ACAD OF SCI

Pretreatment process of linen fabric

InactiveCN104611936ASoft touchImprove the fabric gradePhysical treatmentBiochemical fibre treatmentEnvironmental geologyManufacturing engineering

The invention discloses a pretreatment process of a linen fabric. The pretreatment process comprises the steps of checking bad products, sewing in an overturning manner, singeing, carrying out low-temperature plasma treatment, desizing, refining by scouring enzyme, carrying out acid washing, carrying out chlorine bleaching, carrying out oxygen bleaching, carrying out deoxidized enzyme washing, washing and drying. After the pretreatment process is adopted, the use amount of a chemical reagent is reduced, little pollution is caused, energy is saved, the emission is reduced, the difficulty of wastewater pollution control is reduced, the production efficiency is improved, the treated linen fabric is soft in hand feeling, the brightness of the linen fabric is improved, and the fabric quality is improved.

Owner:SUZHOU CHENHENG WEAVING

Feeding method for sows from pregnancy to parturition

InactiveCN106922603AHeating fastAvoid heat stressFood processingAnimal feeding stuffWeaningWeightlessness

The invention relates to a feeding method for sows from pregnancy to parturition. The method comprises the following steps: preparing feed for sows from pregnancy to parturition and preparing nursing sow feed and restricting feed to pregnant sows; feeding in all following stages including weaning and breeding, feeding in a short term (estrualization), 7days after breeding, 7-100 days after breeding, 95 days after pregnancy to 112 days and sow delivery. The feeding method for sows from pregnancy to parturition has the following beneficial effects: by preparing dedicated feeds for pregnant sows and nursing sows, the sows are processed in different periods; special-purpose microecologics and preventative heat stress can effectively prevent constipation; feed with high content of energy, proteins and unsaturated fatty acid enable sow milk to be sufficient; full nutrition and reduction in weightlessness of a lactation period help promote oestrus of sows; by the method for feeding, a sow can deliver more than 10 piglets weighted average at 1.5 kilograms; after 28 days of weaning, the individual weight of each sow can be up to 8 kilograms; and estrus rate of the piglets within 5 days of sows is up to more than 90%.

Owner:株洲市良强饲料科技有限公司

Low-voltage anode foil pretreatment

InactiveCN101030485AReduce weightlessnessHigh mechanical strengthElectrolytic capacitorsCapacitor manufactureLow voltageWeightlessness

The invention is concerned with the preliminary treatment method for the low voltage anodic foil, includes the following steps: (1) processes the heating treatment to the low voltage foil that is not annealing in 300-600deg.Cfor 0.5-3 minutes; (2) processes the anodic foil at the temperature of 20-70deg.Cfor 30-90 seconds in the mixing liquor of 0.5-10wt% of the sodium hydroxide and 1-5wt% of the dodecyl benzene sulfonic acid sodium; (3) processes the anodic foil at the temperature of 20-70deg.Cfor 30-90 seconds in the mixing liquor of 1-10wt% of the hydrochloric acid; (4) processes the first level erosion, the middle processing, the second level erosion, and the post processing, in order to get the low voltage anodic foil that is small weightlessness, high specific volume, and better machinery intensity.

Owner:DONGGUAN HEC CONDENSER CO LTD

Water-saving dyeing process of cheese

InactiveCN103806308ASoft touchThe color difference between the inner and outer layers is not obviousDyeing processYarnElectricity

The invention provides a water-saving dyeing process of cheese, and the cheese is dyed by yarn pretreatment, dyeing and dyeing postprocessing. According to the water-saving dyeing process of the cheese, a refining agent is chosen to replace caustic soda and hydrogen peroxide of a traditional process for the yarn pretreatment, and the refining agent can ensure that yarn is soft in hand feeling, is unconspicuous in inner and outer-layer color difference, and is basically free of reparation and broken end phenomenon, a woven fabric is smooth, the weight loss rate is reduced to about 3%, acid pickling is not needed, the time is short, and is shortened by 30 minutes to 1 hours compared with that of the traditional process, so that the water, electricity and time are saved, the bleaching consumption is low, the dyeing quality is good, and the comprehensive cost is low. At the same time, in the water-saving dyeing process of the cheese, a neutral electrolyte is added for accelerating the dying in a diffusion stage, the dye uptake of the cheese is ensured, and the problems of dyeing defects, deep and shallow strips, great inner and outer-layer difference and the like can be avoided.

Owner:WUHU FUCHUN DYEING & WEAVING

Sintered NdFeB permanent magnet based on particle combination adjustment and production method of sintered NdFeB permanent magnet

ActiveCN104252937ACorrosion resistanceImprove performanceInductances/transformers/magnets manufactureMagnetic materialsRare earthYttrium

The invention discloses a sintered NdFeB permanent magnet based on particle combination adjustment and a production method of the sintered NdFeB permanent magnet. The permanent magnet comprises a composite principal phase in which a principal phase with high heavy rare earth RH content surrounds a principal phase with low heavy rare earth RH content. Continuous grain boundary phase does not exist in the composite principal phase. The content of heavy rare earth RH on the periphery of the composite principal phase is higher than the content of heavy rare earth RH at the center of the composite principal phase. The average grain size of the composite principal phase is 6-14 micrometers. The heavy rare earth RH contains one or more of Dy (dysprosium), Tb (terbium), Ho (holmium), Gd (gadolinium) and Y (yttrium). The production method includes the processes of preparation of first alloyed powder, preparation of second alloyed powder, mixing of the alloyed powder, forming of magnetic fields, and vacuum sintering and aging. The first alloyed powder contains Pr (praseodymium) and Nd (neodymium). The second alloyed powder contains the heavy rare earth RH. The average grain size of the second alloyed powder is 1.1-2.9 micrometers.

Owner:SHENYANG GENERAL MAGNETIC

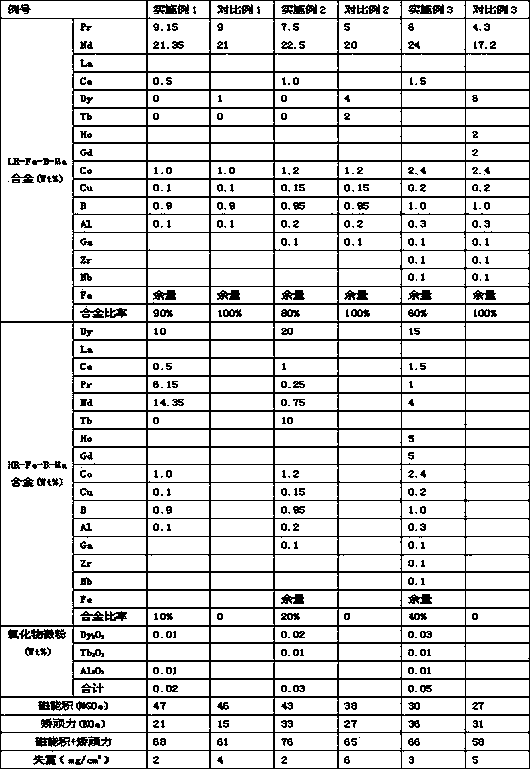

Manufacturing method for Ce-containing NdFeB rare earth permanent magnet

ActiveCN103996522AImprove antioxidant capacityReduce dosageInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementHydrogen

The invention discloses a manufacturing method for a Ce-containing NdFeB rare earth permanent magnet. The Ce-containing NdFeB rare earth permanent magnet is made of Ce-LR-Fe-B-Ma alloy, Ce-HR-Fe-B-Mb alloy and metal oxide micro-powder, wherein LR represents two or more rare-earth elements which do not contain Ce but contain Nd and Pr; HR represents one or more rare-earth elements which do not contain Ce but contain Dy or Tb; Ma represents one or more elements of Al, Co, Nb, Ga, Zr, and Cu; Mb represents one or more elements of Al, Co, Nb, Ga, Zr, Cu and Mo. The manufacturing method for the Ce-containing NdFeB rare earth permanent magnet comprises the following working procedures of smelting the Ce-LR-Fe-B-Ma alloy, smelting the Ce-HR-Fe-B-Mb alloy, performing hydrogen decrepitation on the alloy, performing surface adsorption on the metal oxide micro-powder and pulverization, performing magnetic field forming, performing sintering and performing aging. In this way, the NdFeB rare earth permanent magnet is manufactured.

Owner:SHENYANG GENERAL MAGNETIC

Colla corii asini sow feed

InactiveCN103141695APromote absorptionReduce weightlessnessAnimal feeding stuffColla corii asiniAbortion

Owner:株洲市良强饲料科技有限公司 +1

Coating preservative for fruits and vegetables and preparation method of coating preservative

InactiveCN107223708AHigh strengthReduce rotFruits/vegetable preservation by coatingFood ingredient for microbe protectionVegetable oilGlycerol

The invention provides a coating preservative for fruits and vegetables and a preparation method of the coating preservative. The coating preservative is prepared from the following raw materials: starch, pectin, lecithin, vegetable oil, protein, citric acid, cinnamon essential oil, phytic acid, sodium erythorbate, glycerol, emulsifier and water. The preparation method of the coating preservative comprises the following steps: firstly, adding the starch, the pectin and the citric acid into water with four fifth usage; heating, preserving heat, adding the glycerol, the vegetable oil and the protein, stirring and cooling to obtain a mixed solution A; adding the phytic acid and the sodium erythorbate into water with residual usage, and stirring to obtain a mixed solution B; adding the mixing solution B, the cinnamon essential oil, the lecithin and the emulsifier into the mixed solution A obtained in the first step under the condition of stirring, dispersing, heating, preserving heat and cooling to obtain a finished product. According to the coating preservative, rotting and weight loss of the fruits and the vegetables can be reduced, appearance of the fruits and the vegetables is kept, and the storage period of the fruits and the vegetables is prolonged; in addition, the coating preservative is easily washed by water and can be naturally degraded, so that residues of a chemical preservative are reduced; the coating preservative has no toxin or harm to a human body and is high in safety.

Owner:土山土水生态农业江苏有限公司

Permanent-magnet material resistant to high temperature and with high magnetic performance

The invention discloses a permanent-magnet material resistant to high temperature and with high magnetic performance. The mass of the permanent-magnet material comprises 100 parts of Nd2Fe14B magnetic powder, 0.1-0.3 part of ferrocene magnetic powder, 0.1-5 parts of titanate coupling agent, 1-10 parts of bisphenol A epoxy resin and 0.2-3 parts of graphene oxide powder, and a cured material is formed after uniformly mixing the raw materials in a composite environment of a temperature field with a constant temperature being 20-200 DEG C and an orientation field with field magnetic intensity being 0.5-3T. With the permanent-magnet material provided by the invention, the defect of unfavorable temperature resistance of a bonded NdFeB material is improved, the application range of the bonded NdFeB material is expanded, the defect of low application temperature of the bonded NdFeB material can be made up, the magnetic performance of the magnet under high temperature is greatly improved, the weight loss of the magnet can be effectively reduced, and the corrosion resistance of the magnet is improved.

Owner:JIANGSU PULONG MAGNETIC ELECTRICITY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com