Processing liquid and processing process for ultralow-temperature scouring and bleaching of cotton knitted fabric

A technology of cotton knitted fabric and treatment liquid, which is applied in the field of scouring and bleaching of cotton knitted fabric, can solve the problems of unsatisfactory processing effect, low hydrogen peroxide oxidation capacity, and inability to bleach fabrics, and achieve energy saving, fabric weight loss reduction, The effect of ensuring the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

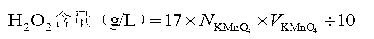

Examples

Embodiment 1

[0058] In this embodiment, the treatment solution for ultra-low temperature scouring and bleaching of cotton knitted fabrics includes the following components, and the concentration of each component is:

[0059] Scouring agent 1.0g / L;

[0060] Solid sodium hydroxide (NaOH) 5.0g / L;

[0061] 100% hydrogen peroxide (H 2 o 2 ) 4.5g / L;

[0062] Hydrogen peroxide activator 3.0g / L.

[0063] Wherein, the scouring agent is selected from the high-concentration scouring agent DM-1361 produced by Guangdong Demei Fine Chemical Co., Ltd.;

[0064] The hydrogen peroxide activator is selected from the hydrogen peroxide activator DM-1430 produced by Guangdong Demei Fine Chemical Co., Ltd.;

[0065] The hydrogen peroxide and solid sodium hydroxide are commercially available conventional reagents.

[0066] In this embodiment, the processing steps of ultra-low temperature scouring and bleaching of cotton knitted fabrics are as follows:

[0067] (1) Configure the treatment solution accordi...

Embodiment 2

[0073] In this embodiment, the treatment solution for ultra-low temperature scouring and bleaching of cotton knitted fabrics includes the following components, and the concentration of each component is:

[0074] Scouring agent 0.5g / L;

[0075] Solid sodium hydroxide (NaOH) 2.5g / L;

[0076] 100% hydrogen peroxide (H 2 o 2 ) 2.5g / L;

[0077] Hydrogen peroxide activator 1.7g / L.

[0078]The selection of reagents and the treatment process are the same as in Example 1.

Embodiment 3

[0080] In this embodiment, the treatment solution for ultra-low temperature scouring and bleaching of cotton knitted fabrics includes the following components, and the concentration of each component is:

[0081] Scouring agent 1.5g / L;

[0082] Solid sodium hydroxide (NaOH) 7.5g / L;

[0083] 100% hydrogen peroxide (H 2 o 2 ) 7g / L;

[0084] Hydrogen peroxide activator 4.7g / L.

[0085] The selection of reagents and the treatment process are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com