Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Strong resistance to electrochemical corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

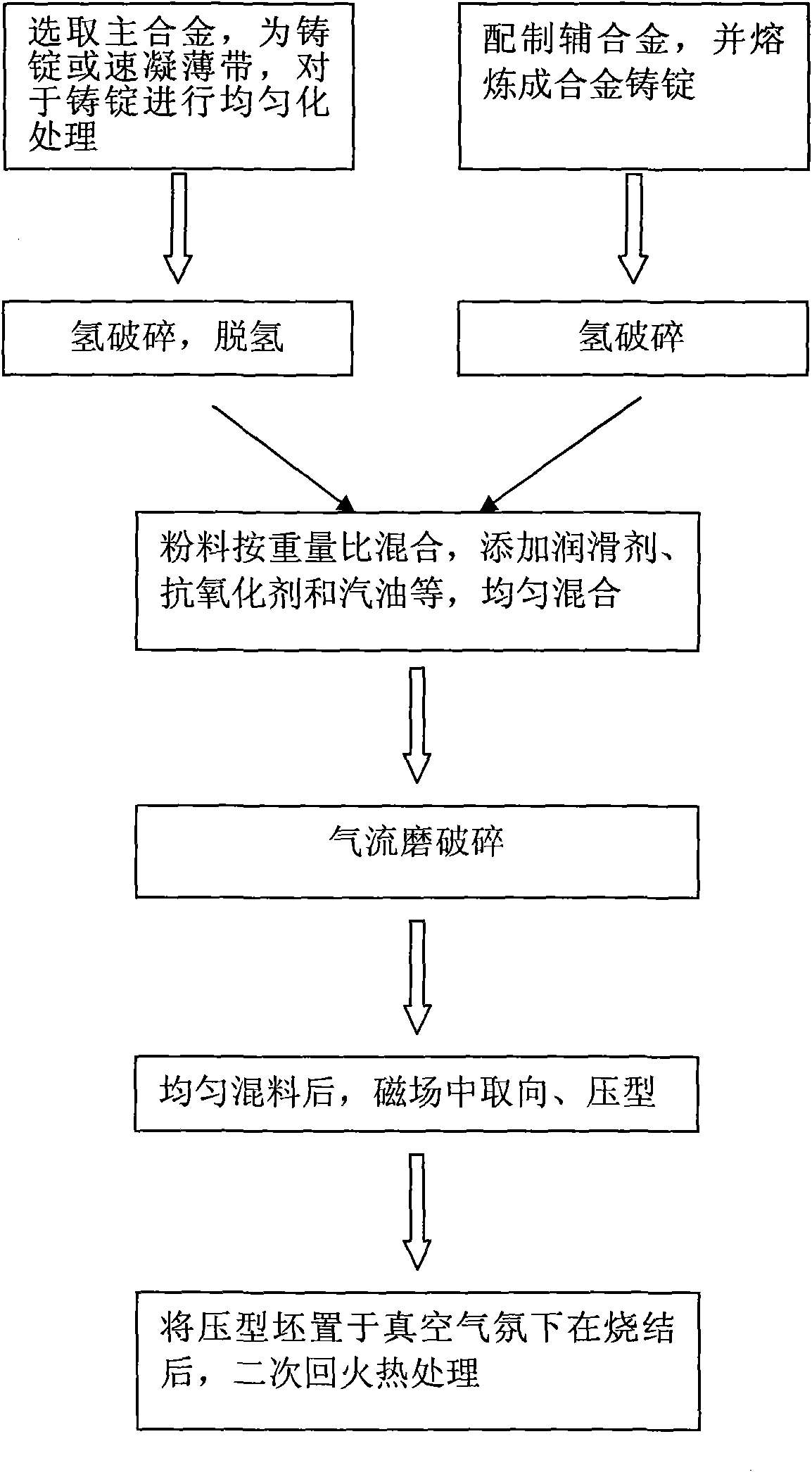

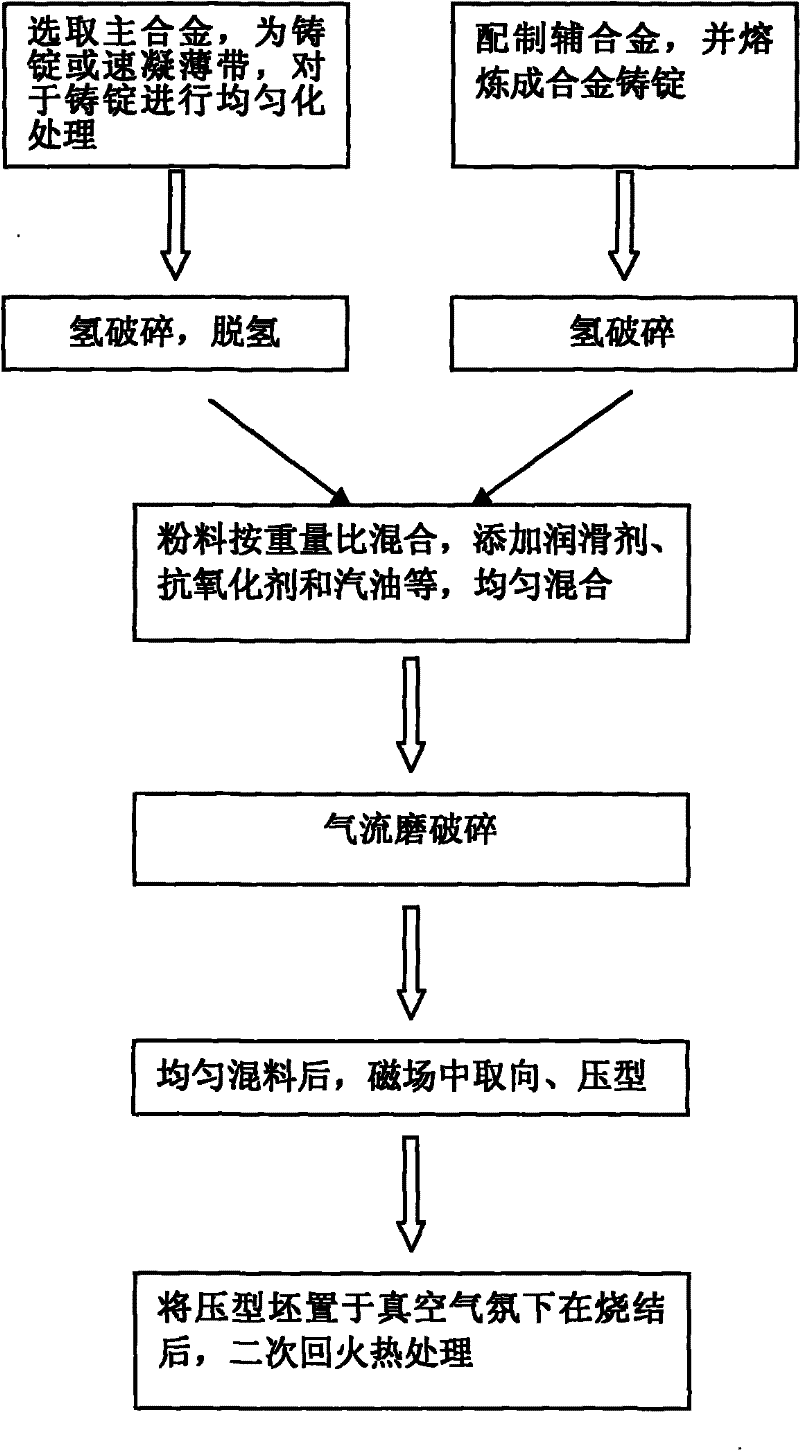

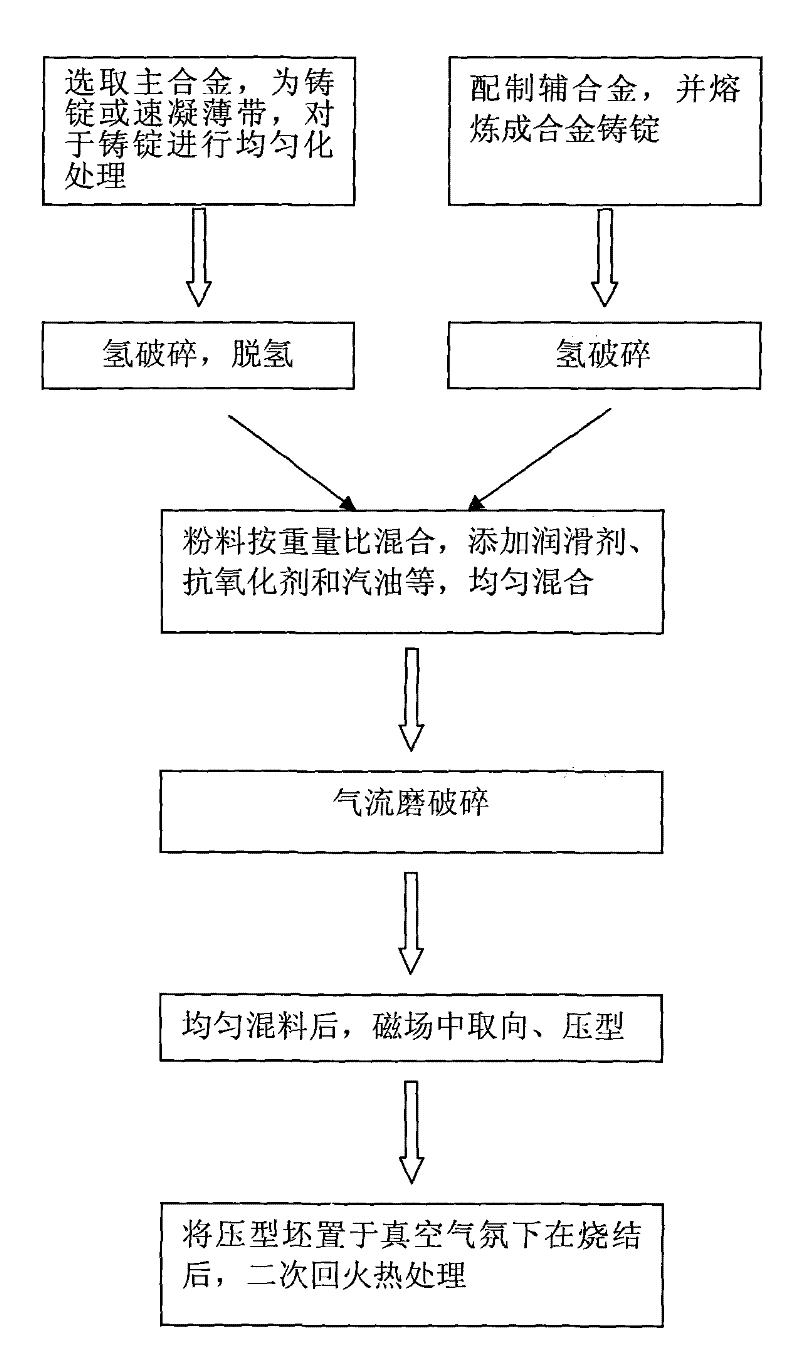

Method for preparing corrosion-resistant sintered neodymium iron boron (NdFeB) magnet

InactiveCN101958171AStrong resistance to electrochemical corrosionReduce weightlessnessInductances/transformers/magnets manufactureMagnetic materialsWeightlessnessRare earth

The invention discloses a method for preparing a corrosion-resistant sintered neodymium iron boron (NdFeB) magnet. In the method, an intergranular phase optimized design is used as a starting point on the basis of preparation technology of a double-alloy method, the high-cobalt content rare earth cobalt-based alloy which does not contain iron and boron is selected as an auxiliary alloy, and the melting point of the auxiliary alloy is ensured to be lower than 1,050 DEG C through component control so as to meet the liquid-phase sintering effect. By measuring the weightlessness condition of the material placed in an environment of the temperature of 120 DEG C, two atmosphere and 100 percent of humidity for 96 hours, results show that the weightlessness of the prepared sintered NdFeB magnet is only less than 1 / 3 of that of the sintered NdFeB magnet prepared by a single-alloy method and a conventional double-alloy method, and the sintered NdFeB magnet has excellent corrosion resistance. The method for preparing the corrosion-resistant sintered NdFeB magnet can be widely applied in the field of production of high-performance sintered NdFeB magnets.

Owner:WUXI NANLIGONG TECH DEV +2

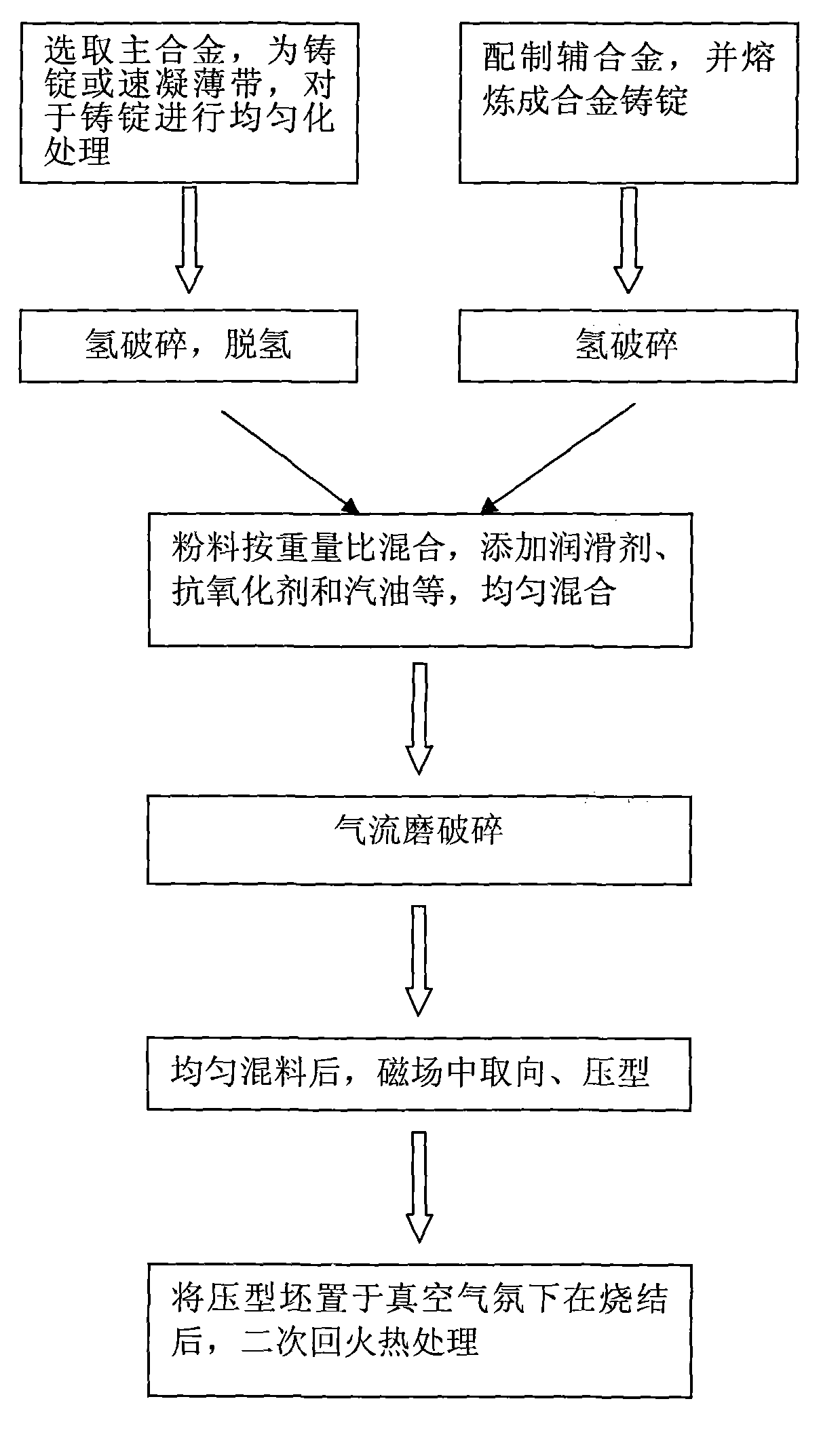

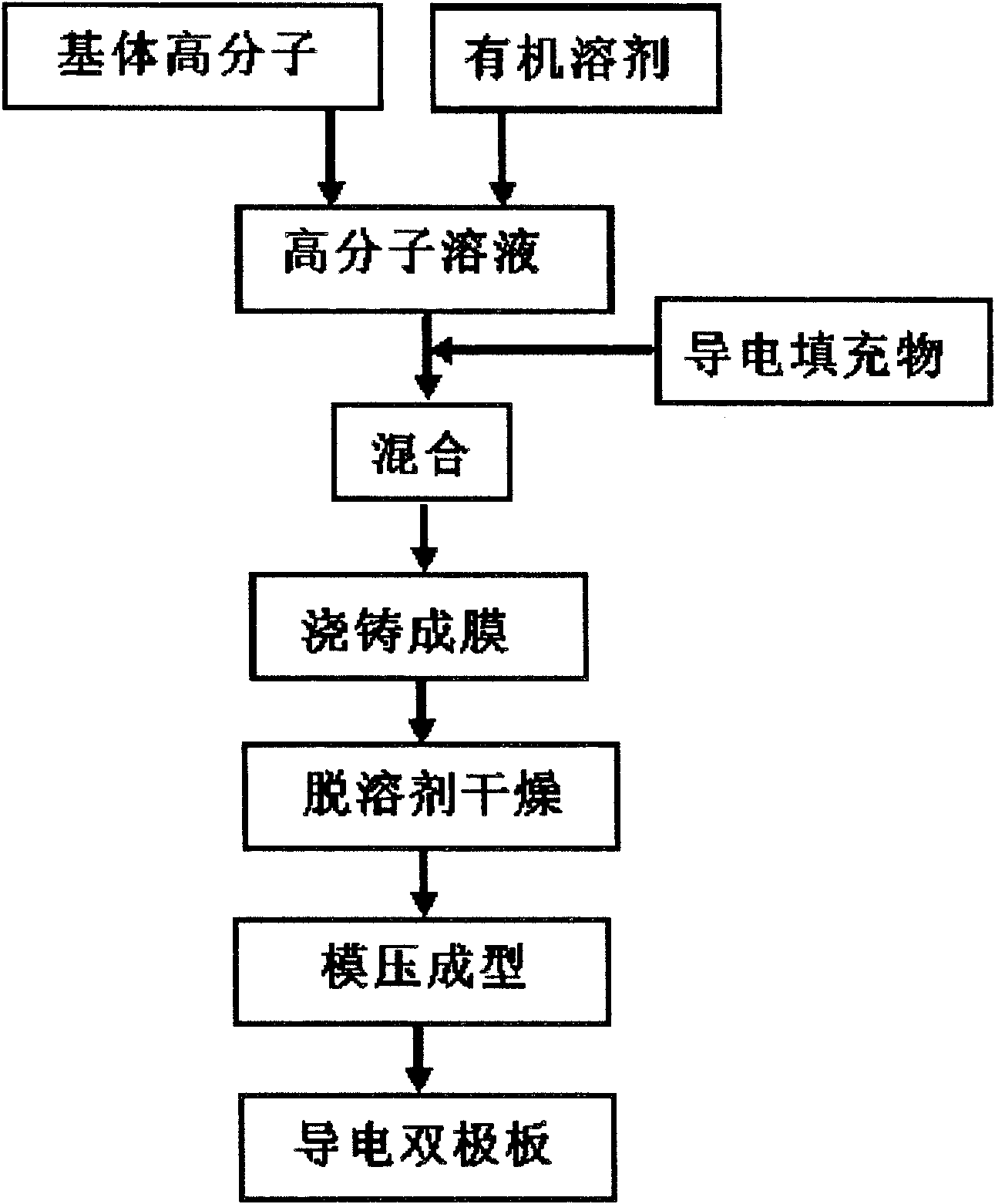

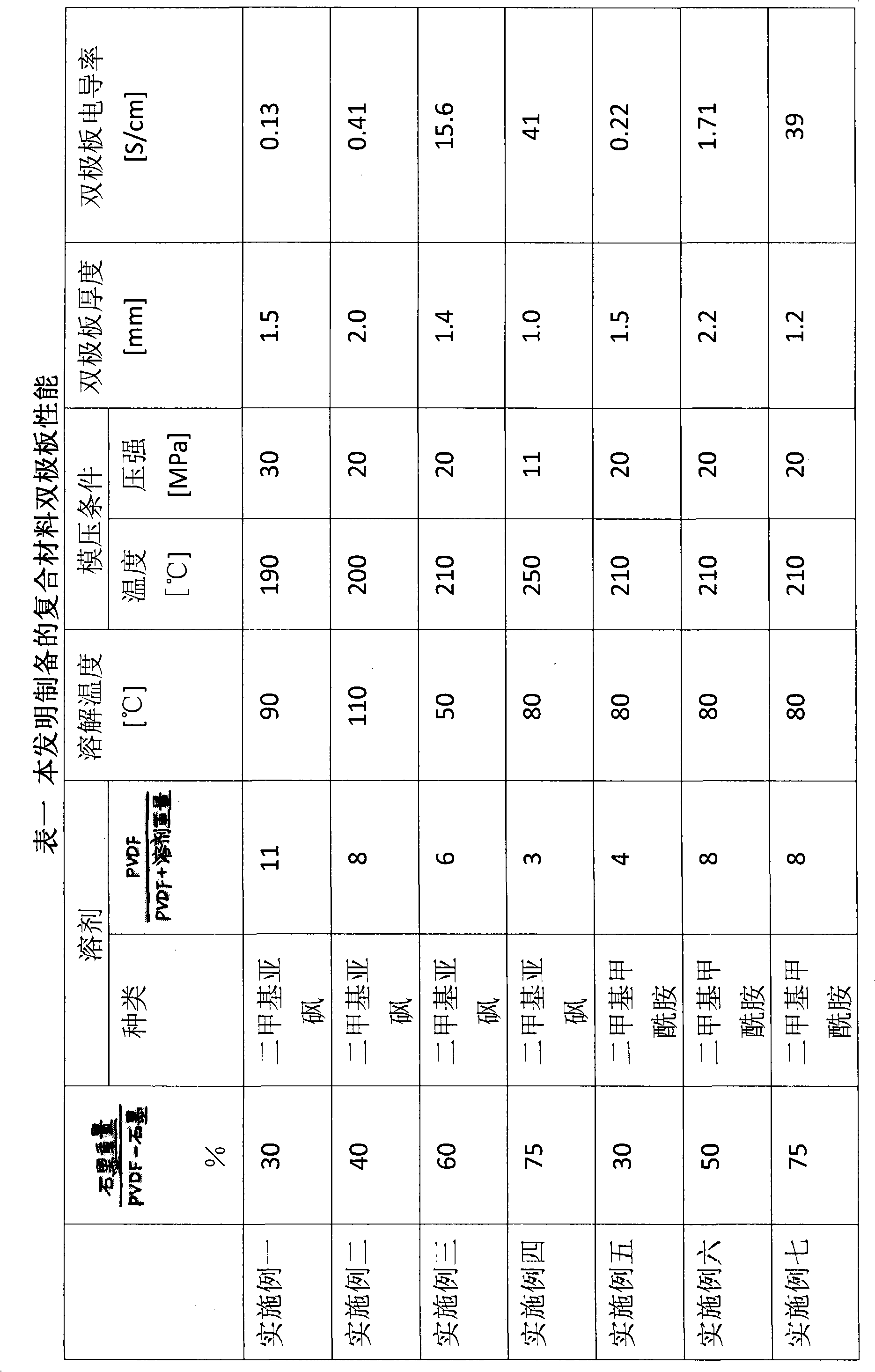

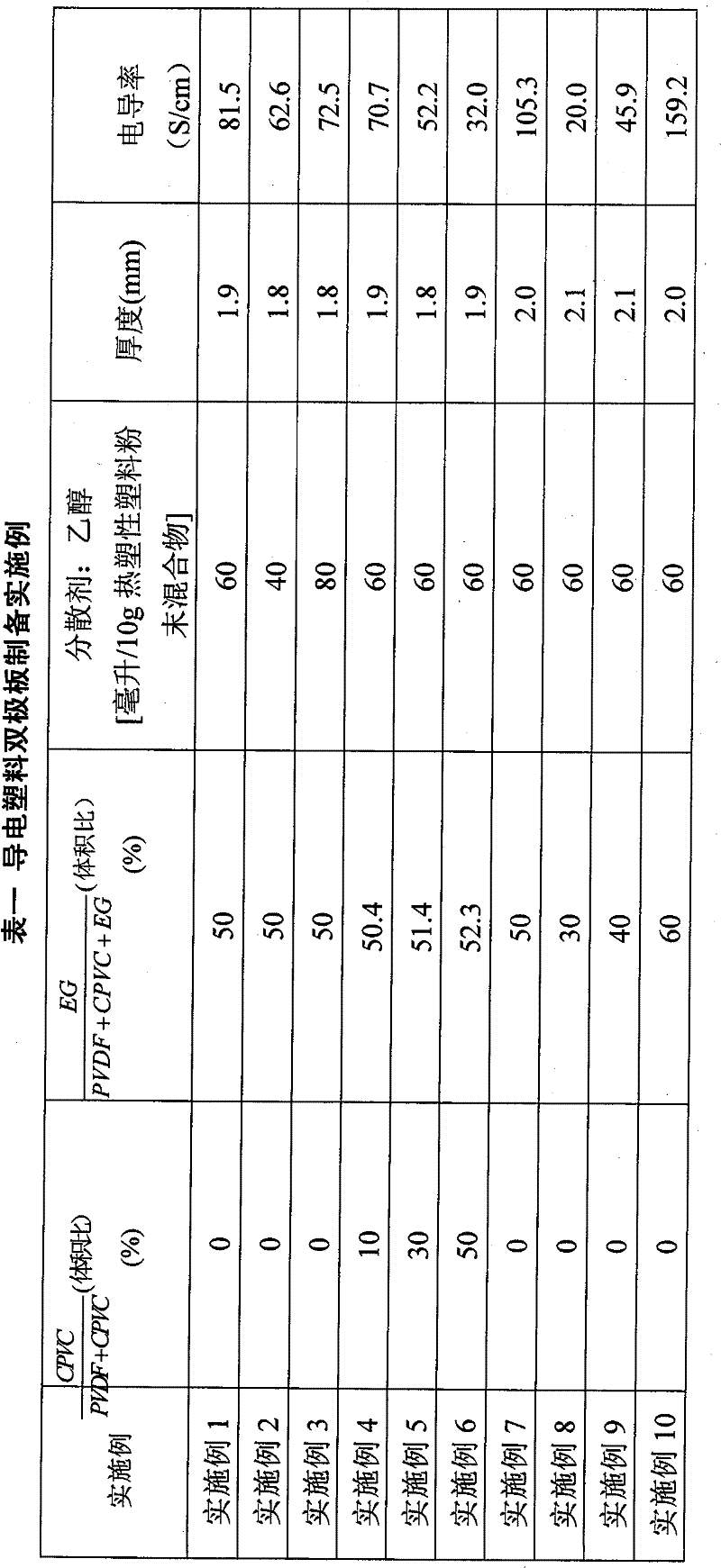

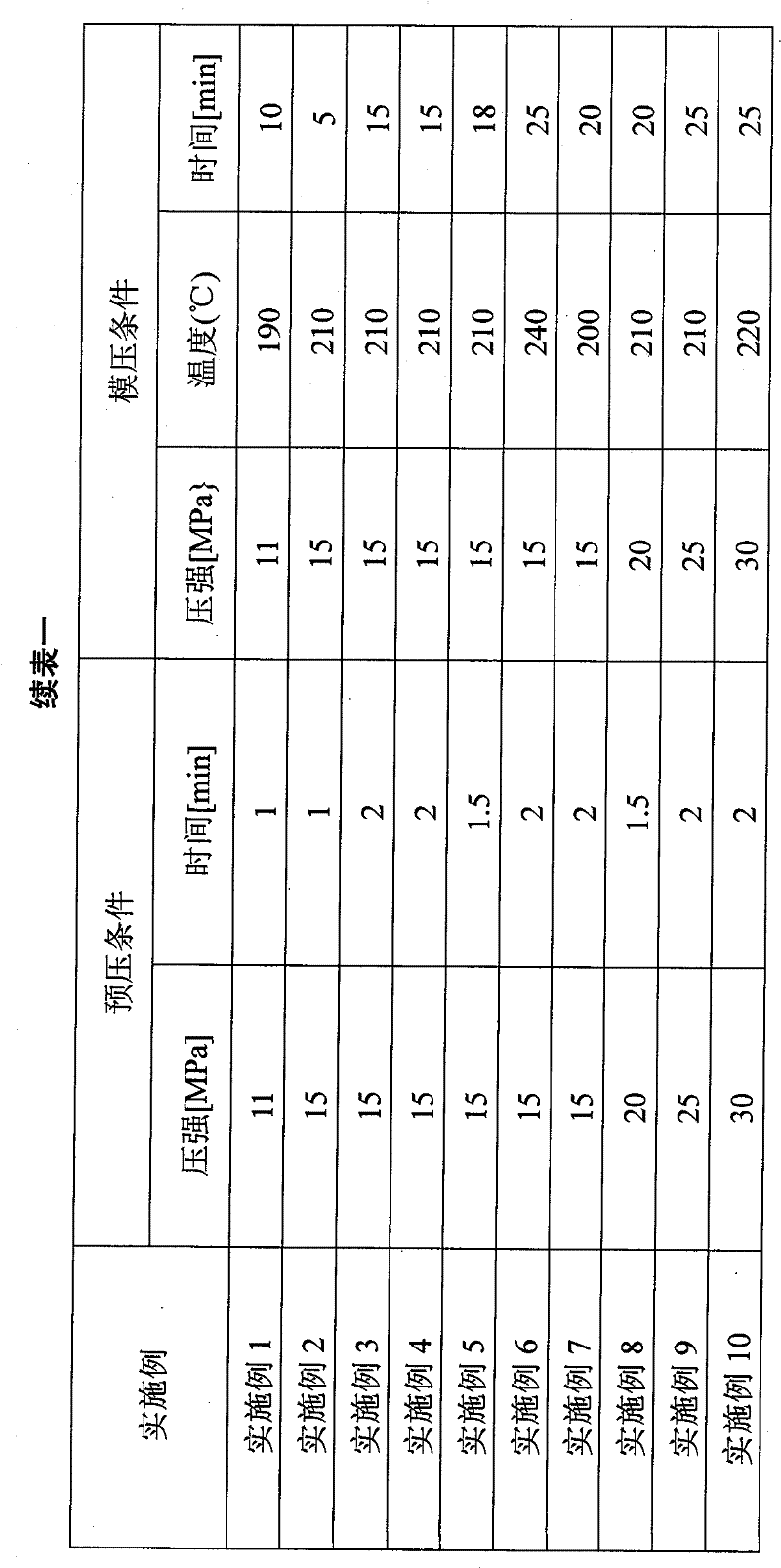

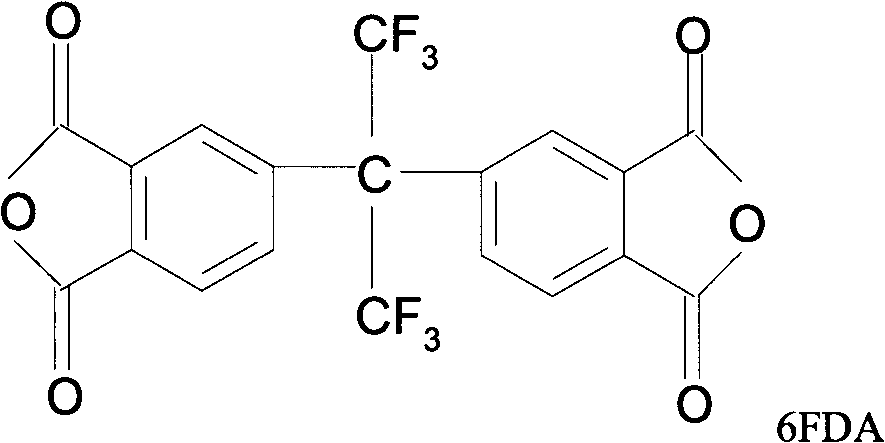

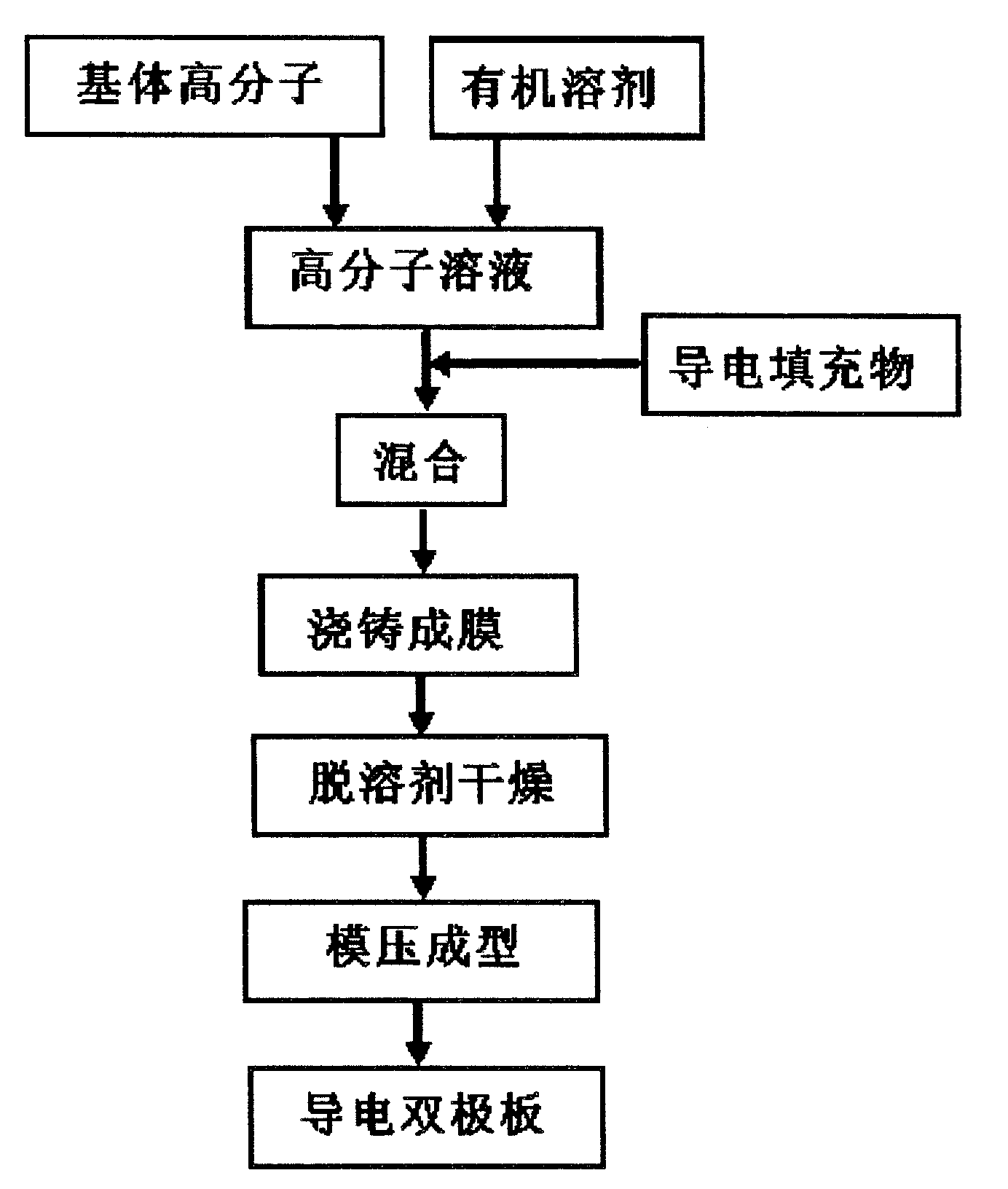

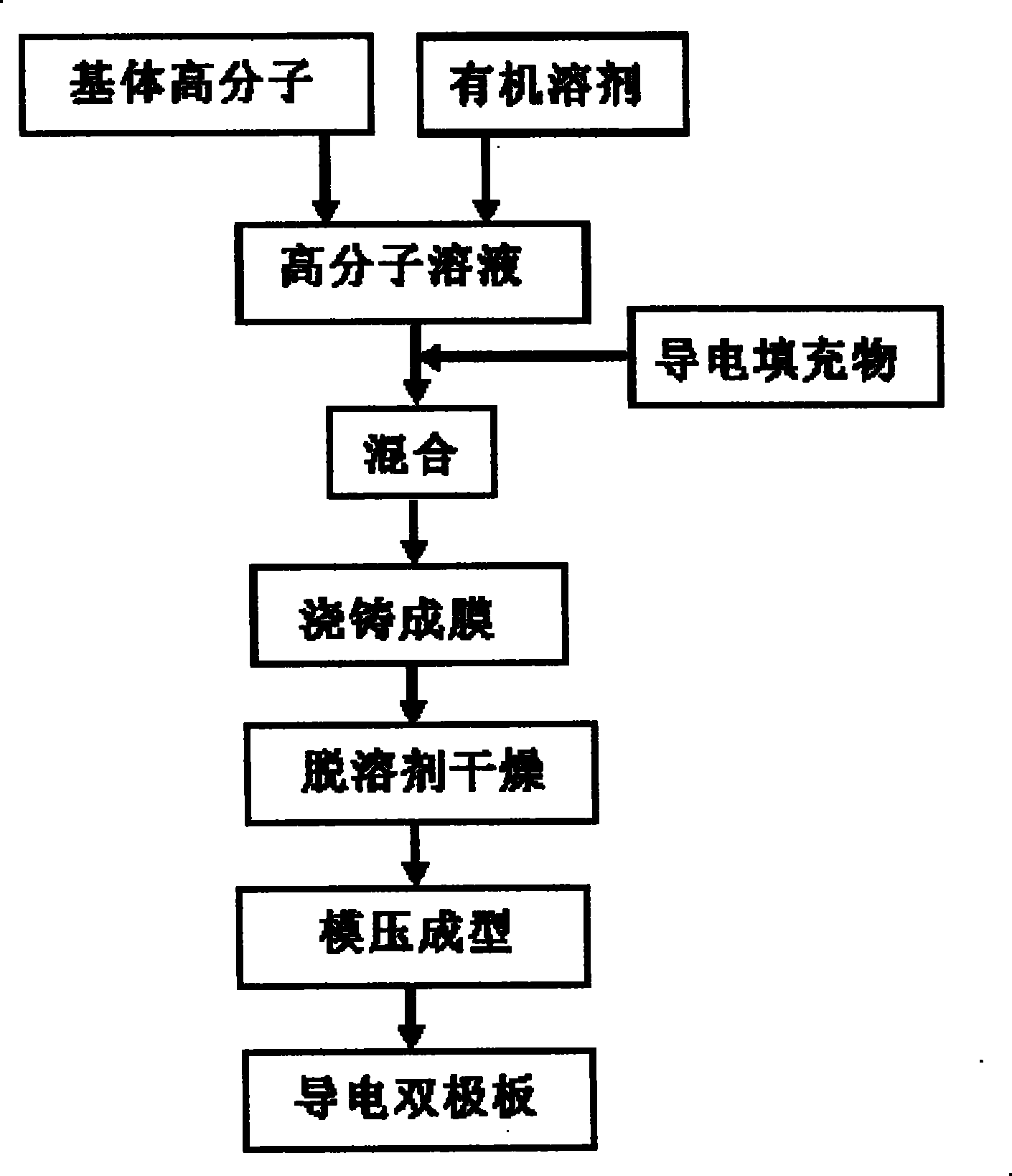

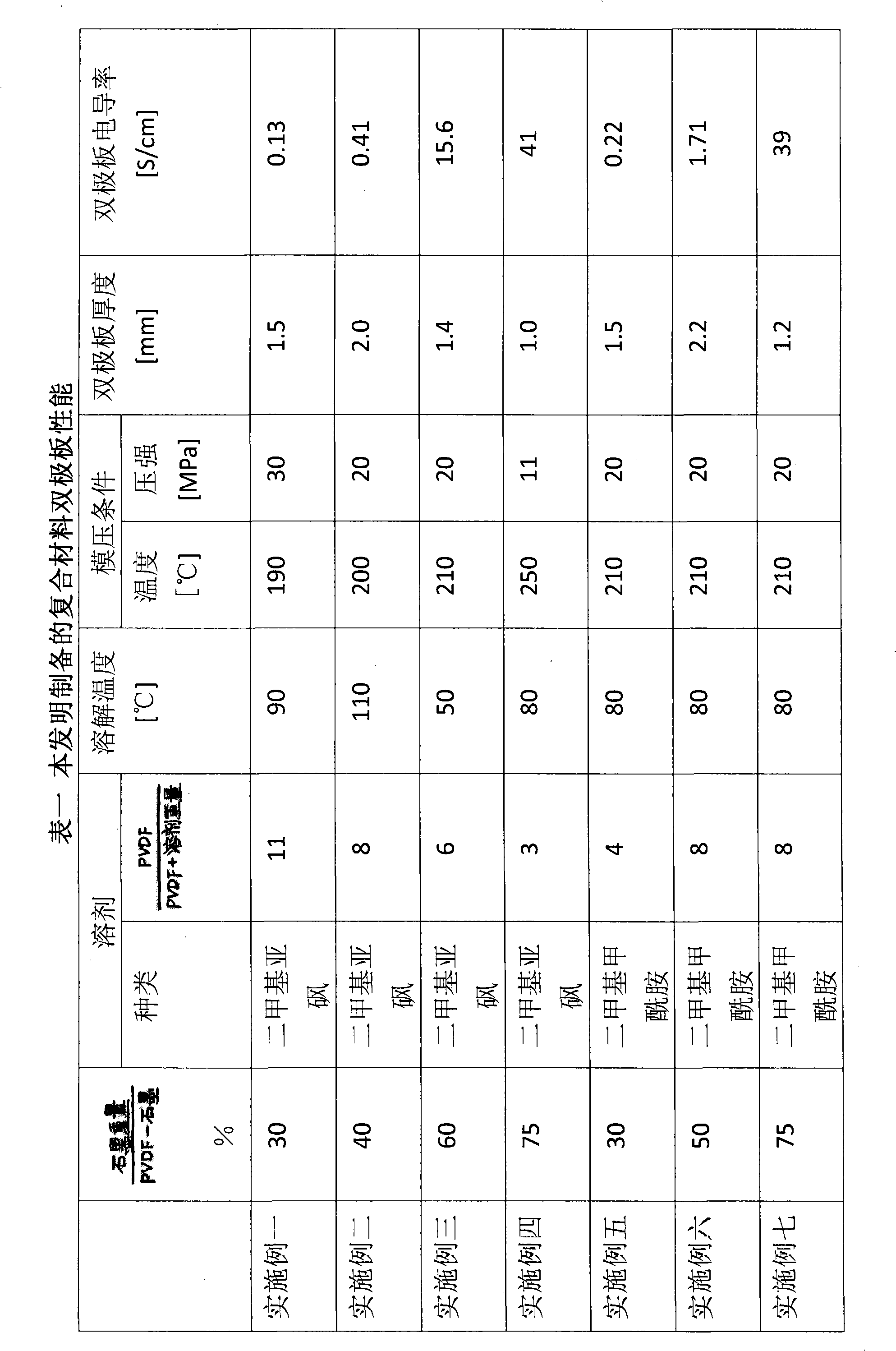

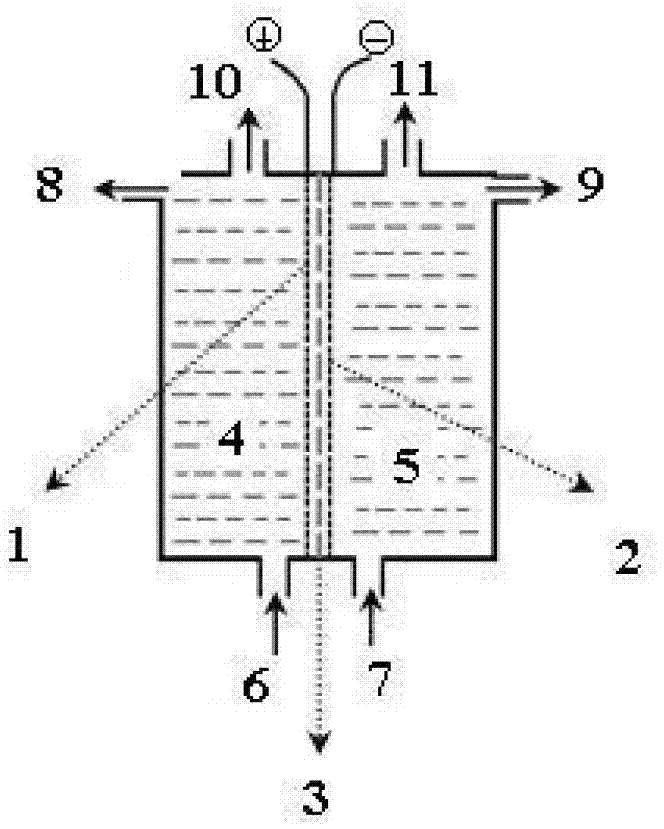

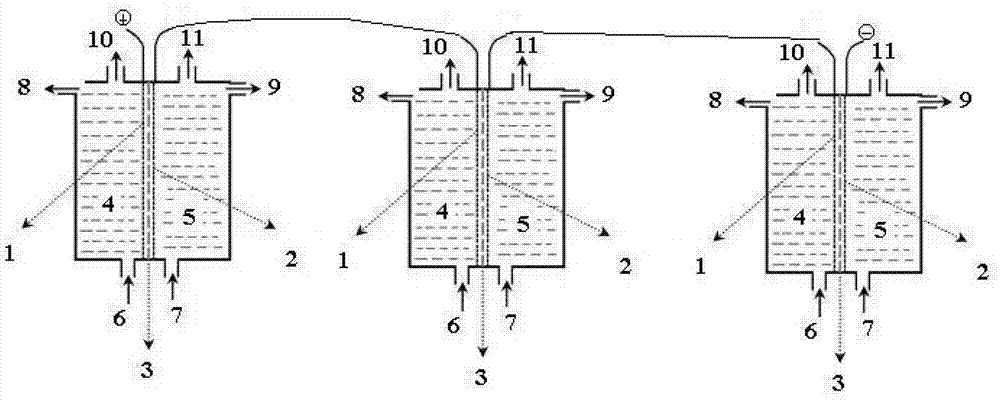

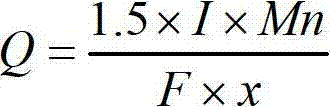

Preparation method of liquid flow battery composite material bipolar plate

InactiveCN101567452AEasy to prepare in batchesImprove conductivityCell electrodesFuel cell detailsCompression moldingThin layer

The invention relates to a preparation method of a liquid flow battery composite material bipolar plate, belonging to the technical field of liquid flow battery bipolar plate preparation. The preparation method of the liquid flow battery bipolar plate comprises three steps of using a solution method for mixing, using a tape casting method for casting and using a compression molding method for molding successively. The weight percentage of graphite powder / (graphite powder plus polyvinylidene fluoride) is 30% to 75%, and the dissolving temperature is 50 DEG C to 110 DEG C. The thin-layer thickness of a solution casted by the tape casting method is 0.2mm to 5mm, the compression molding temperature is 190 DEG C to 250 DEG C, and the pressure is 11MPa to 30MPa. The composite material bipolar plate made by using the method has the thickness of 1.0mm to 2.2mm and the electrical conductivity of 0.13S / cm to 41S / cm. The invention is easy for organizing large-scale and low-cost production process so as to overcome the shortcomings of complex processing and poor electrical conductivity of the prior liquid flow battery bipolar plate, thus laying the foundation for developing the chemical power technology used in large-scale energy conversion and storage.

Owner:TSINGHUA UNIV

Electrolytic solution for differential arc oxidization surface treatment of magnesium aluminum alloy in aluminates system

InactiveCN1737210ABroad marketHigh electrochemical impedanceAnodisationElectrolysisPlasma electrolytic oxidation

The invention relates to an electrolytic solution used to oxygenize surface of aluminum-magnesium alloy work-piece by differential arc. Said electrolytic solution comprises 4-40g / L of sodium aluminate, 0-10g / L of caustic soda and other assistants. The invention can generate a ceramic film with smooth surface, strong resistance to soiling, corrosion resistance and great mechanical behavior.

Owner:JILIN UNIV

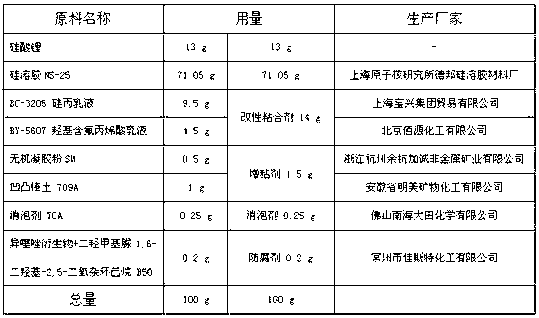

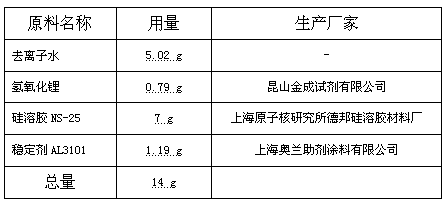

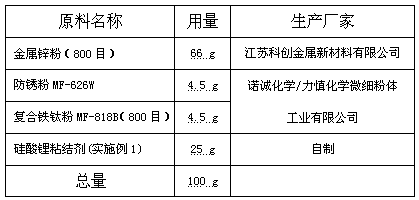

Modified inorganic lithium silicate binder, and preparation method and use thereof

InactiveCN103305129AReduce pollutionSave energyMacromolecular adhesive additivesAnti-corrosive paintsWater basedLithium hydroxide

The invention relates to a modified inorganic lithium silicate binder, and in particular relates to a water-based binder containing lithium silicate, silica soil and auxiliaries. More specifically, the modified inorganic lithium silicate binder comprises 10-25 parts of lithium silicate, 60-75 parts of silica soil and 10-15 parts of modified binder and 0.6-3 parts of auxiliaries, wherein the lithium silicate is prepared from 3-10 parts of de-ionized water, 0.5-1.5 parts of lithium hydrate, 5-12 parts of silica soil and 1-2 parts of stabilizer through a reaction; the modified binder is organic fluorine and / or an organic silicon modified acrylic emulsion. The binder provided by the invention is environment-friendly and free of pollution; the content of SiO2 of the modified inorganic lithium silicate binder does not exceed 20%; and the binder is low in viscosity, short in drying time; as a result, the formed dry film is insoluble in water, and excellent in bonding strength, flexibility and impact resistance; the binder is used for preparing an anticorrosion water-based inorganic zinc rich paint, and the combination properties of the paint film are improved; especially, the paint film is excellent in corrosion resistance, high in bonding strength, tough and wear resistant, and also excellent in crazing resistance, oil resistance, organic solvent resistance, weather fastness and high / low temperature resistance; the paint film has the welding performance with paint and has a function of protecting steel structures against corrosion for a long time.

Owner:JIUQING PAINT SHANGHAI

Anti-corrosion conductive ceramic electrode material for sewage and sludge treatment and preparation method thereof

ActiveCN105523761AGood for anodizingUnique electrochemical performanceWater/sewage treatment by electrochemical methodsElectrochemical sludge treatmentFiberEpoxy

The invention discloses an anti-corrosion conductive ceramic electrode material for sewage and sludge treatment and a preparation method of the anti-corrosion conductive ceramic electrode material. The anti-corrosion conductive ceramic electrode material is characterized in that carbon is used as aggregate; the anti-corrosion conductive ceramic electrode material is prepared from artificial graphite, graphitized mesocarbon microbeads, a reinforcement binder, graphitized carbon fiber and E-44 epoxy resin. The preparation method comprises the following steps of adding a Ti4O7 functional additive having strong electrode performance, simultaneously adding one or several of ceramic anti-wear-corrosion components of TiB2, TiO2, TiC, B2O3, SiO2 and SiC, carrying out solidification, compression molding and high-temperature sintering after adding a mixing solvent and completely mixing the mixture, and finally preparing the anti-corrosion conductive ceramic electrode material. According to the anti-corrosion conductive ceramic electrode material and the preparation method, disclosed by the invention, aiming at an actual working situation of a sewage and sludge treatment environment, unique anti-corrosion components are added while low specific resistance of the anti-corrosion conductive ceramic electrode material is ensured, not only are wearing resistance and corrosion resistance of traditional ceramics obtained, but also excellent conductivity and excellent electrochemical performance are obtained, and the service life is up to more than 3500 hours.

Owner:JIANGSU UNITED CERALLOY MATERIALS TECH

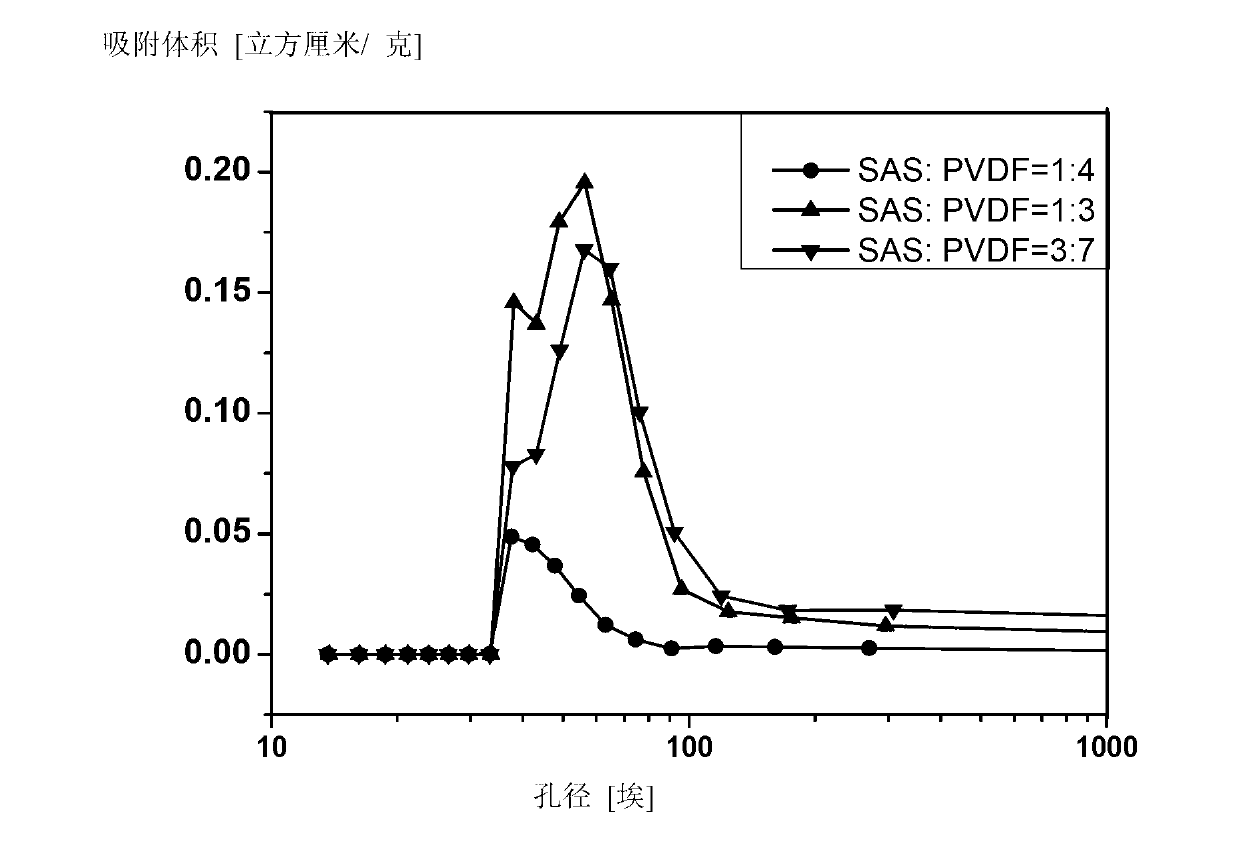

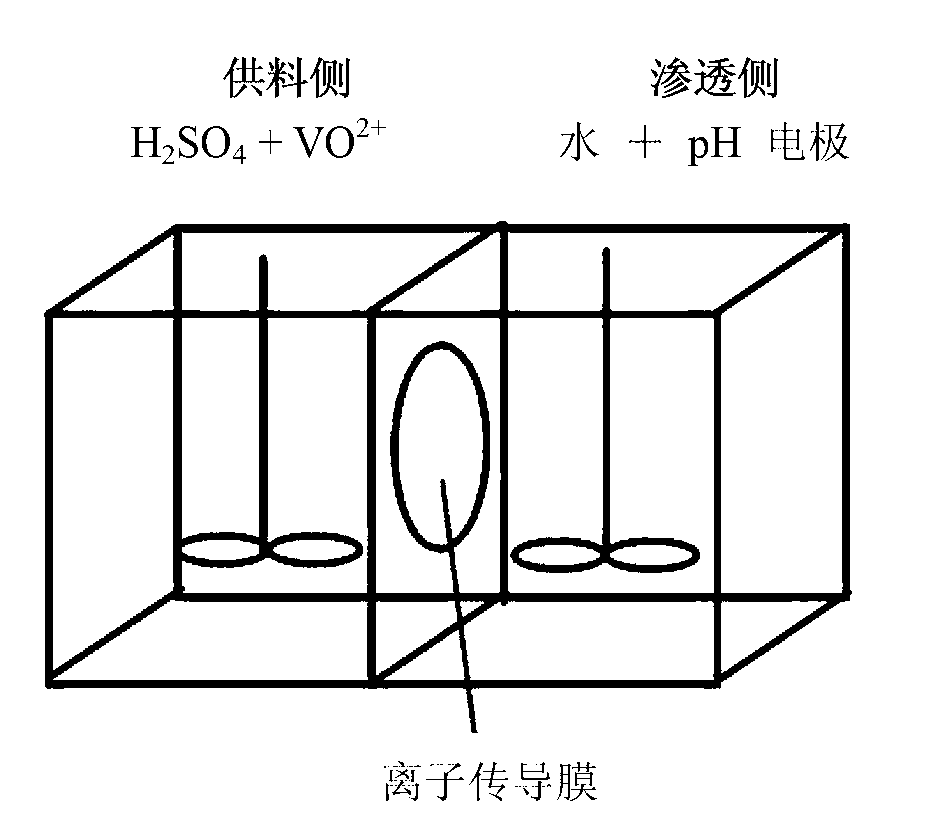

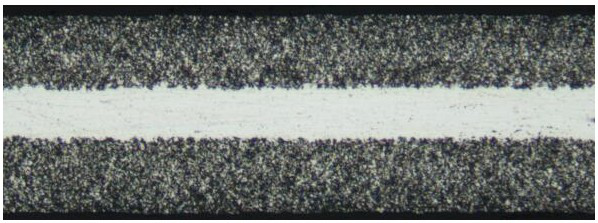

Porous membrane with nanometer aperture and preparation method thereof

InactiveCN102983301AHigh ion conductivityStrong resistance to electrochemical corrosionCell component detailsDouble bondElectrochemistry

The invention discloses a porous membrane with nanometer aperture and a preparation method thereof. The preparation method comprises the following steps of: (1) dissolving a polymerization monomer containing hydrophilic radical groups and double bonds and polyvinylidene fluoride in an organic solvent, so as to obtain a casting film solution; (2) carrying out curtain coating on the casting film solution by using a casting film method to form a thin film; (3) carrying out polymerization reaction on the polymerization monomer inside the thin film to generate low-molecule polymers, so that the organic solvent inside the thin film is evaporated and removed; and further arranging the thin film in an outer electric field, so that the polymerization monomer is subjected to the polymerization reaction under the effect of the outer electric filed; and (4) placing the thin film processed in the step (3) for impregnation in a water solution, and removing all the low-molecule polymers, so as to obtain the porous membrane with the nanometer aperture. The porous membrane with the nanometer aperture is suitably used as a membrane in an electric chemical device, and further can be used in a separation process and a matter conversion process under the driving of the electric field. With the adoption of the preparation method provided by the invention, the complicated processes of normally using a sulfonating agent in the conventional preparation ion conduction film, executing a plurality of preparation steps and the like can be avoided. The preparation method is simple, and the industrial amplification production can be easily realized.

Owner:TSINGHUA UNIV

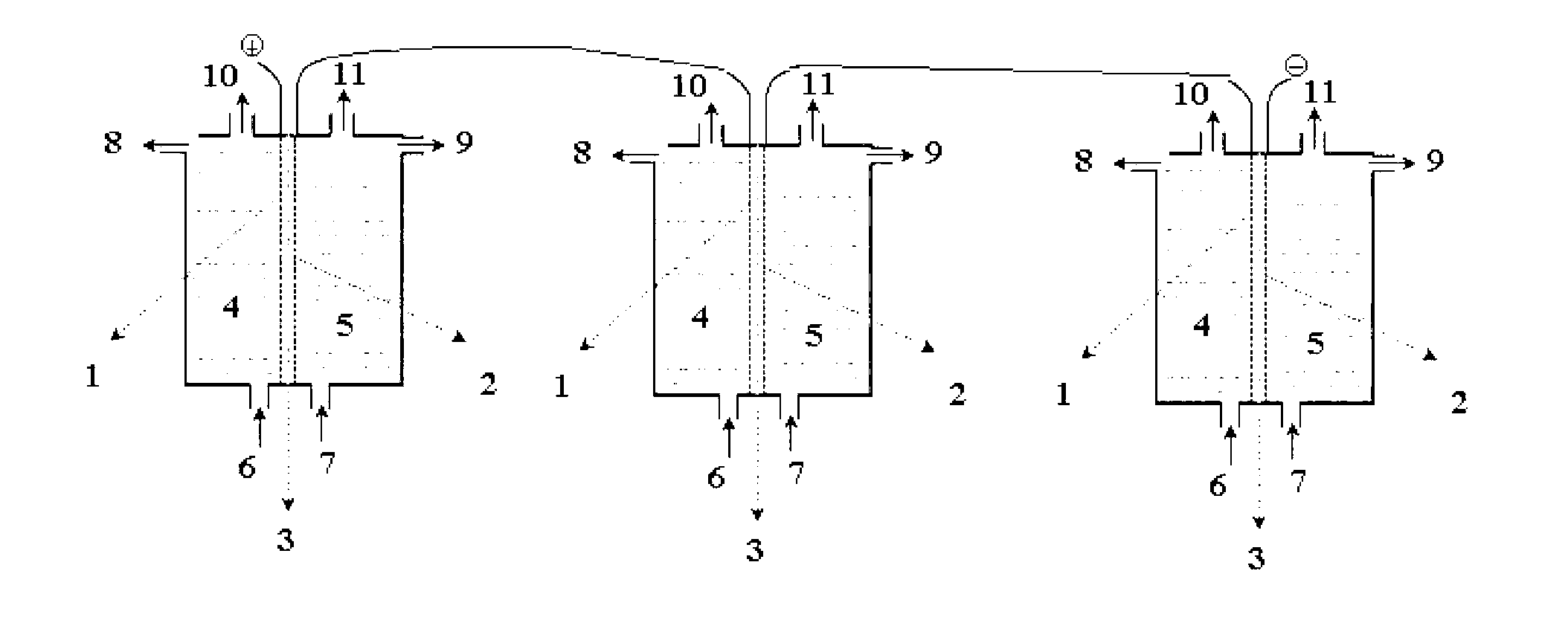

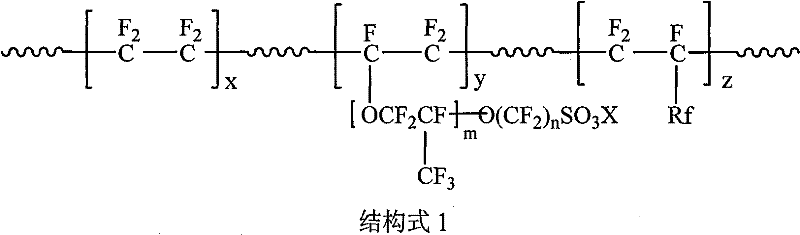

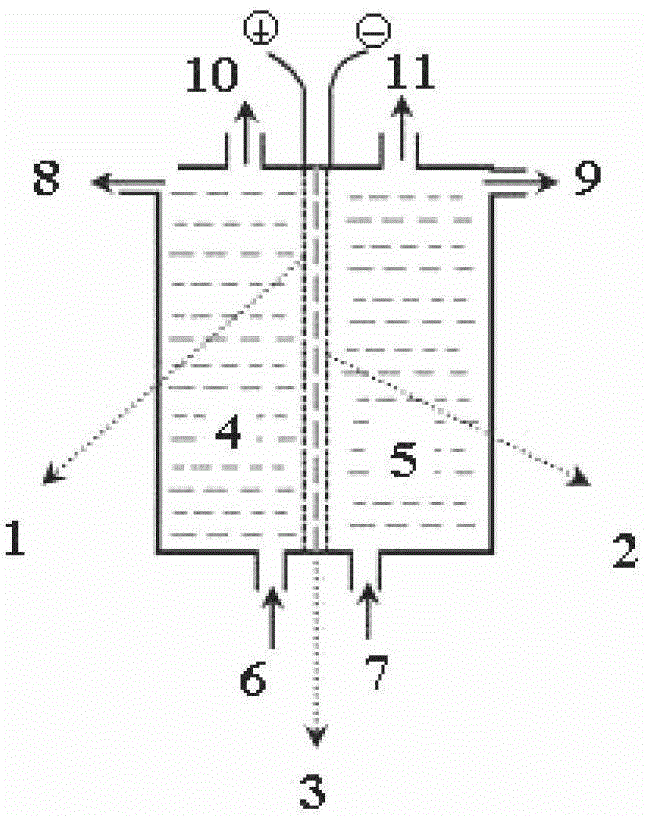

Method for preparing organic acid by electrolyzing organic acid salt on basis of chlor-alkali perfluor ion exchange membrane

ActiveCN102839383ANo pollution in the processNon-toxicElectrolytic organic productionDiaphragmsElectrolysisHydrogen ion

The invention relates to a method for preparing an organic acid by electrolyzing an organic acid salt on the basis of a chlor-alkali perfluor ion exchange membrane. According to the method, an electrolytic bath which is equipped with a perfluor ion exchange membrane between electrodes and is mainly composed of an anode chamber, an anode, the perfluor ion exchange membrane, a cathode and a cathode chamber is adopted. The method comprises the following steps: respectively supplying an anode solution and a cathode solution to the anode chamber and the cathode chamber of the electrolytic bath and performing electrochemical ion exchange, wherein the anode solution is an aqueous solution of the organic acid salt and the cathode solution is an alkali solution corresponding to cations in the organic acid salt; applying a direct current to the electrolytic bath so as to perform constant current electrolysis, and combining the anions in the organic acid salt solution enriched in the anode chamber with hydrogen ions generated by the anode chamber, thereby generating the organic acid; and collecting discharged solution containing the organic acid enriched in the anode chamber, concentrating and crystallizing, thereby obtaining the high-purity organic acid. The method has the advantages of simple process, easiness in industrial amplification, high current efficiency, and the like, and can realize the industrial preparation for the high-purity organic acid.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

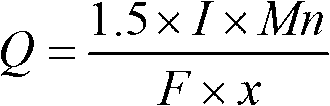

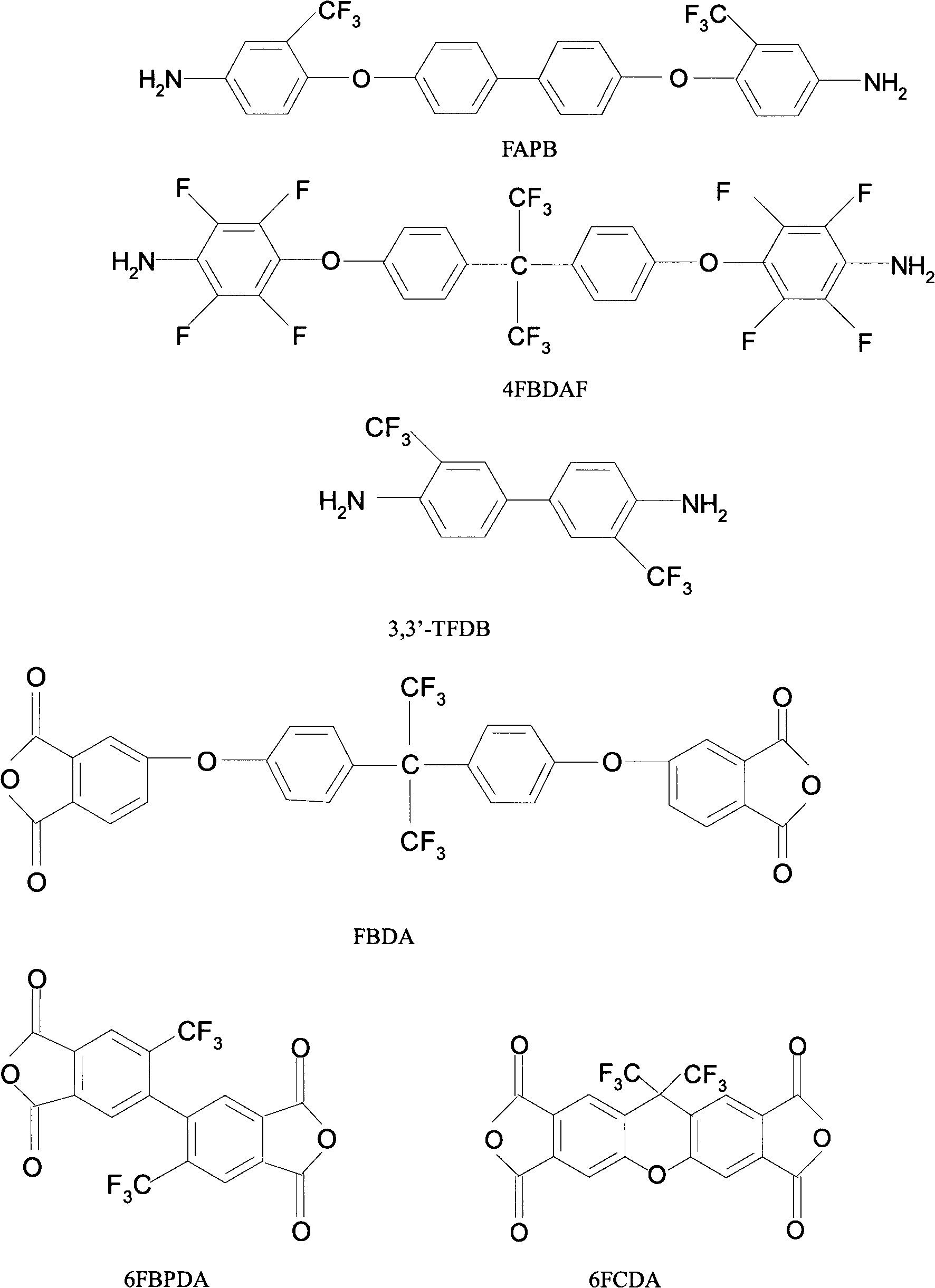

Method for producing diaphragm of super capacitor

ActiveCN102629519AEasy and quick passStrong resistance to electrochemical corrosionElectrolytic capacitorsPorosityEngineering

A method for producing a diaphragm of a super capacitor belongs to the technical field of ion channel membranes. The method is characterized in that dimethylacetamide is used for dissolving soluble polyimide and hybrid materials having ion channels; the tape casting method is used for forming a film on a smooth solid surface; and the film is heated, so that the hybrid materials are subjected to a sol-gel reaction to form iron transmission channels, and the hybrid materials and the polyimide form the diaphragm of the super capacitor. The novel diaphragm, which has good ion transmission performance and small resistance, of the supper capacitor can be obtained through the method, and the defect of high porosity of present diaphragms is eliminated. The method has the advantages of being simple in producing process and easy to magnify.

Owner:INST OF CHEM CHINESE ACAD OF SCI

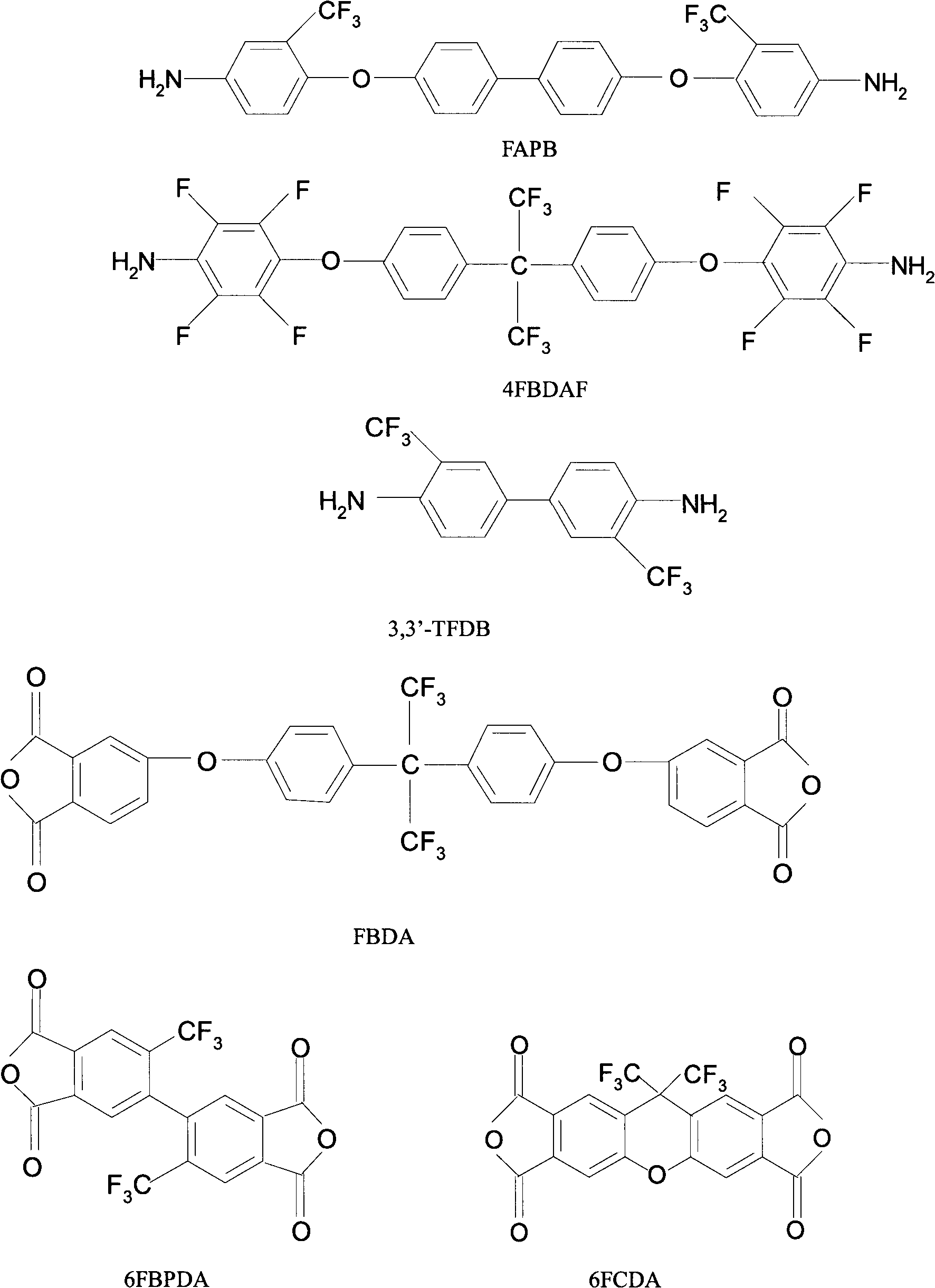

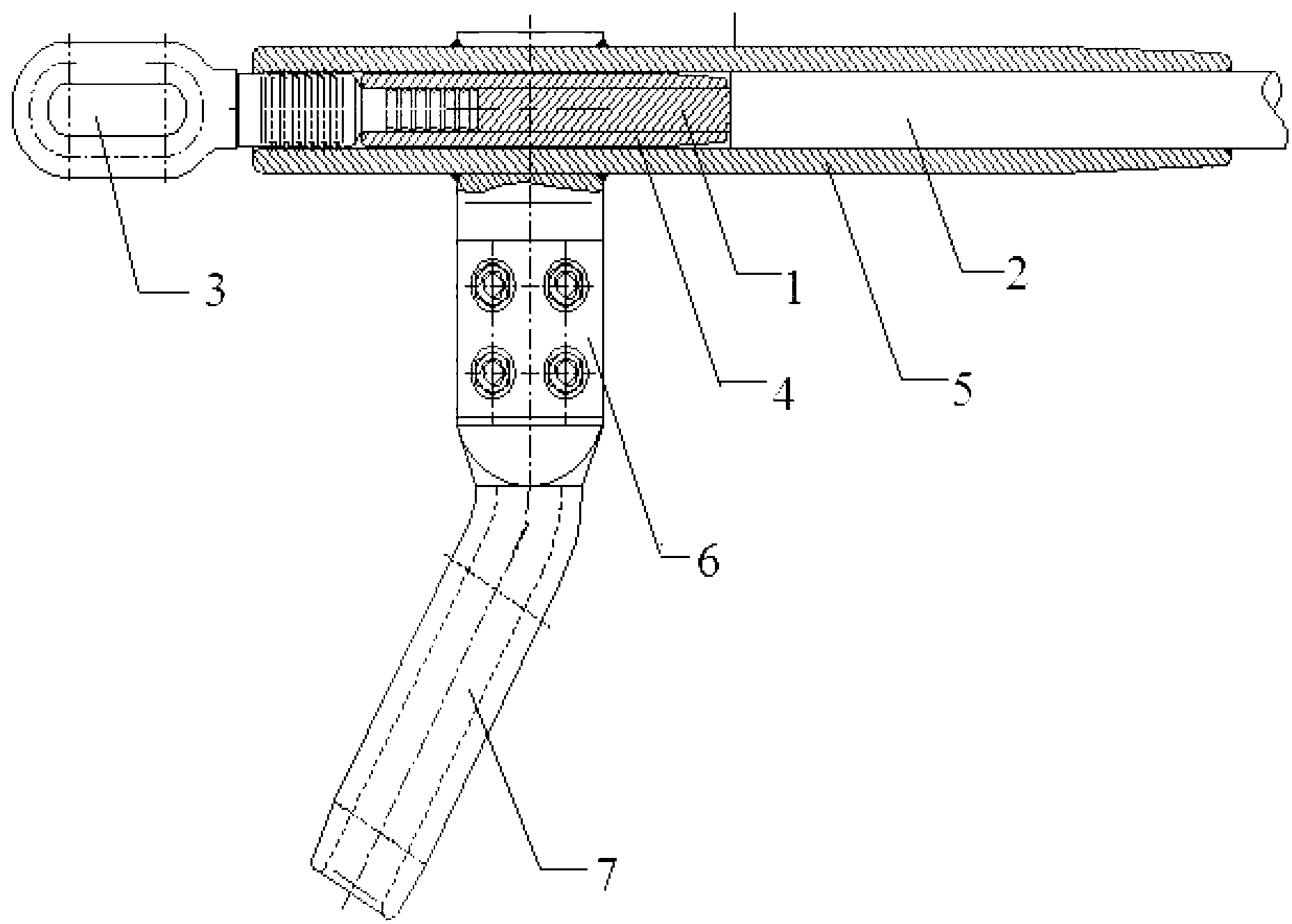

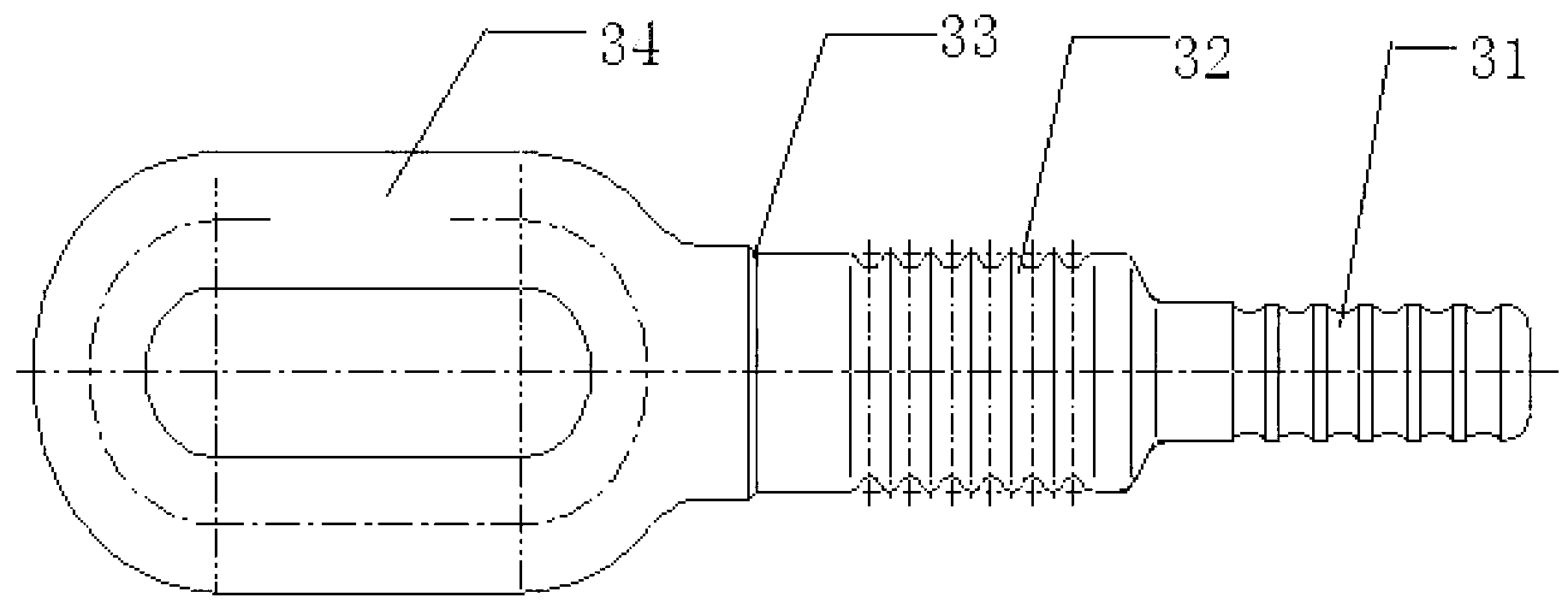

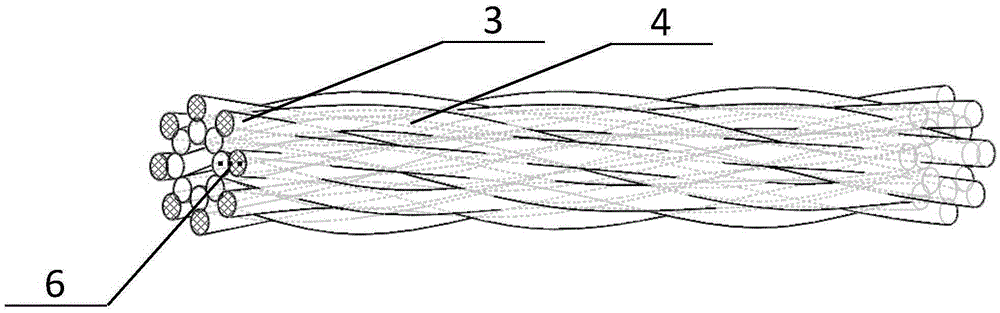

Strain clamp for aluminum alloy core aluminum stranded wire

InactiveCN103326296AThe crimping process is matureReduce on-site constructionAdjusting/maintaining mechanical tensionMechanical propertyCorrosion

The invention provides a strain clamp for an aluminum alloy core aluminum stranded wire. The strain clamp comprises a drainage plate 6, a drainage wire clip 7 which is connected with the drainage plate 6, a strain steel anchor 3, and an aluminum alloy tube 4 and a strain aluminum 5 which are orderly sleeved outside the strain steel anchor 3. Sleeve crimped parts are an anchor head 31 and a middle connecting part 32 of the strain steel anchor 3. One end which is not crimped of the aluminum alloy tube 4 is contained with a cavity for containing an inner core 1 of the aluminum alloy core aluminum stranded wire. One end which is not crimped of the strain aluminum 5 is provided with a cavity for containing a stranded wire 2. The middle part of the strain aluminum 5 is provided with the drainage plate 6. The aluminum alloy core aluminum stranded wire, the strain steel anchor 3, the aluminum alloy tube 4 and the strain aluminum 5 are coaxially arranged. The strain steel anchor 3 and the aluminum alloy tube 4 are pressed in advance. According to the strain clamp, mature hydraulic technology pressing is employed, the strain steel anchor and the aluminum alloy tube are pressed in a factory, the field construction is reduced, parts are few, an operation is convenient, the pressing quality is easy to be ensured, the corrosion resistance performance is good, high quality materials are selected, the installation is simple, the construction is facilitated, mechanical properties and electrical properties are good, and the quality is stable.

Owner:STATE GRID CORP OF CHINA +2

Preparation of proton conduction membrane

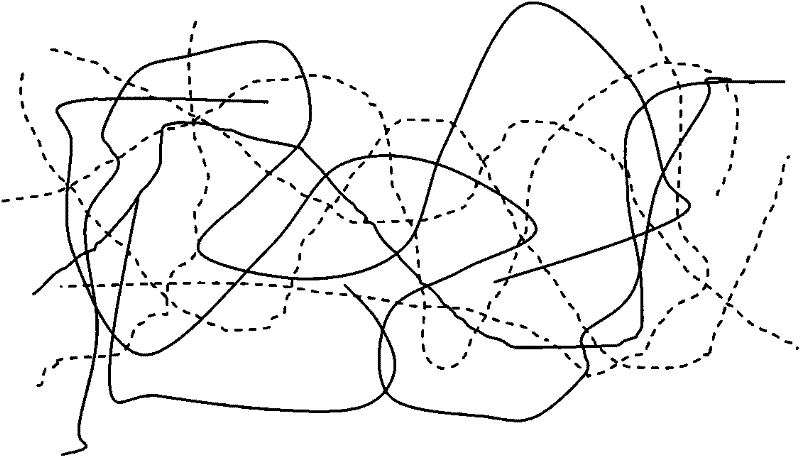

ActiveCN101475699BImprove conductivityStrong resistance to electrochemical corrosionCell component detailsProtonNetwork structure

The invention relates to a preparation method for a proton-conducting membrane, and belongs to the technical field of ion exchange membranes. The preparation method is characterized in that dimethyl sulfoxide is adopted to dissolve polyvinylidene fluoride and sodium allylsulfonate monomer containing proton conducting functional group; a flow casting method is adopted to form a membrane on a smooth solid surface through flow casting; the sodium allylsulfonate monomer is initiated to carry out polyreaction; and the products of the polyreaction and polyvinylidene fluoride molecular chain are formed into the proton-conducting membrane of macromolecular interpenetrating network structure. The preparation method can obtain an ion exchange membrane material with ideal proton conductibility, and overcomes the disadvantage that the prior melting mould pressing process cannot prepare homogeneous phase ion exchange membranes; moreover, the preparation method has the advantages of simple technological process, easy industrial scaling up and the like.

Owner:TSINGHUA UNIV

Corrosion resistant copper-nickel alloy

InactiveCN107653399AGood corrosion resistanceStrong resistance to electrochemical corrosionCorrosion resistantCopper nickel alloy

The invention discloses a corrosion resistant copper-nickel alloy. The corrosion resistant copper-nickel alloy comprises the following raw material components of, by weight, 55-68 parts of Ni, 20-30 parts of Cu, 0.5-1.5 parts of Fe, 0.05-0.3 part of C, 0.25-1.6 parts of Si, 0.3-1 part of Mn, 0.3-1 part of Ti and 0.5-2.5 parts of Al. The copper-nickel alloy is good in corrosion resistant effect, strong in anti-cavitation and electrochemical corrosion capacity, meanwhile quite high in strength and toughness and high in tensile strength.

Owner:TAICANG JIEGONG PRECISION METAL MATERIALS CO LTD

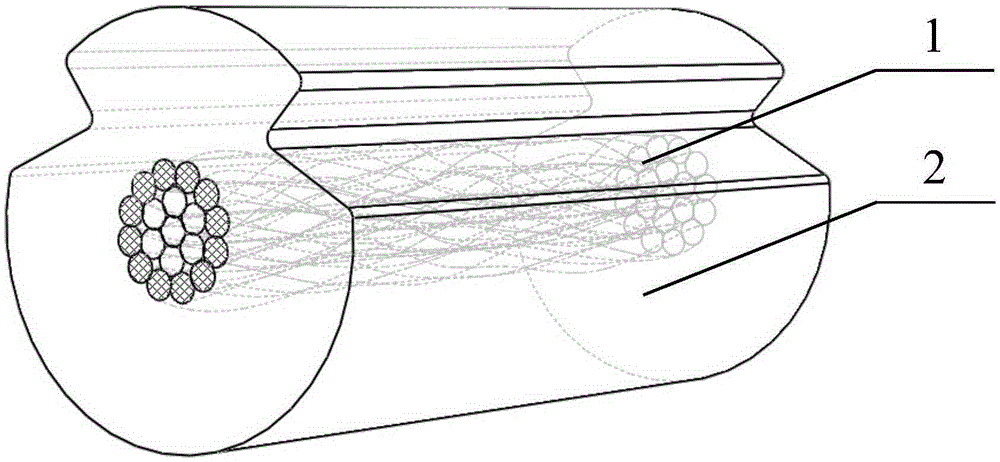

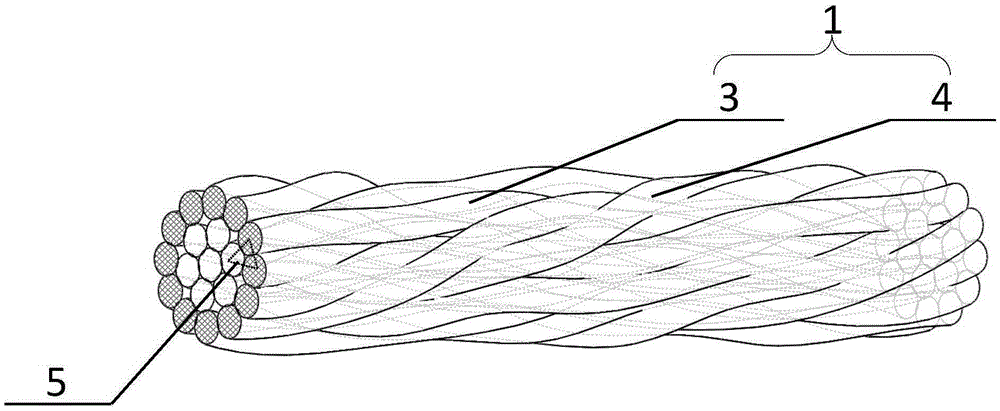

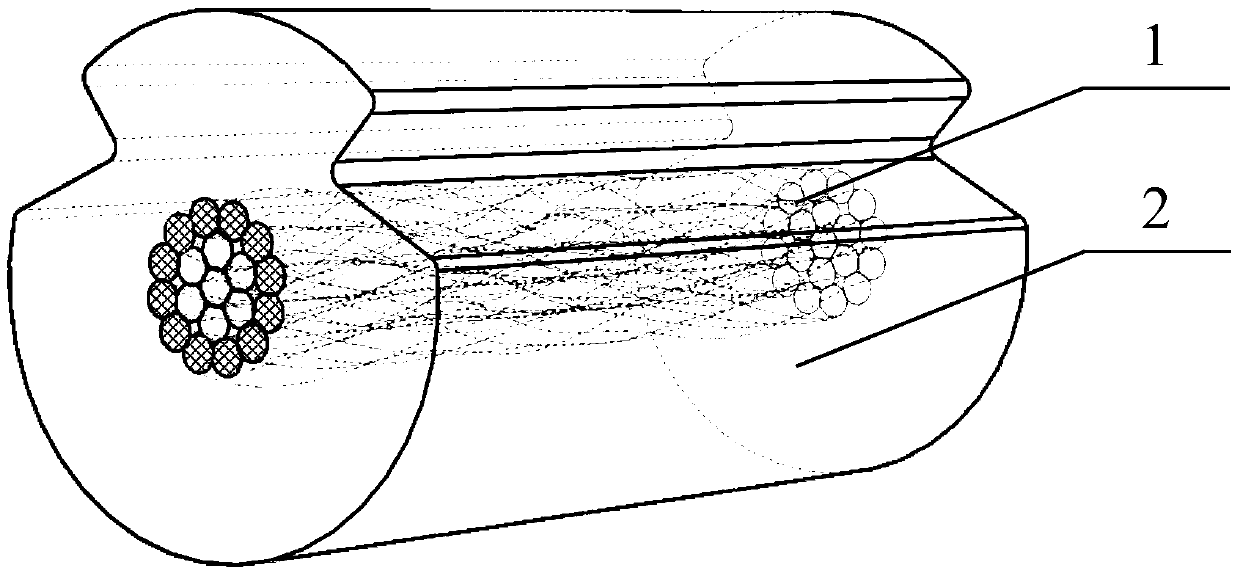

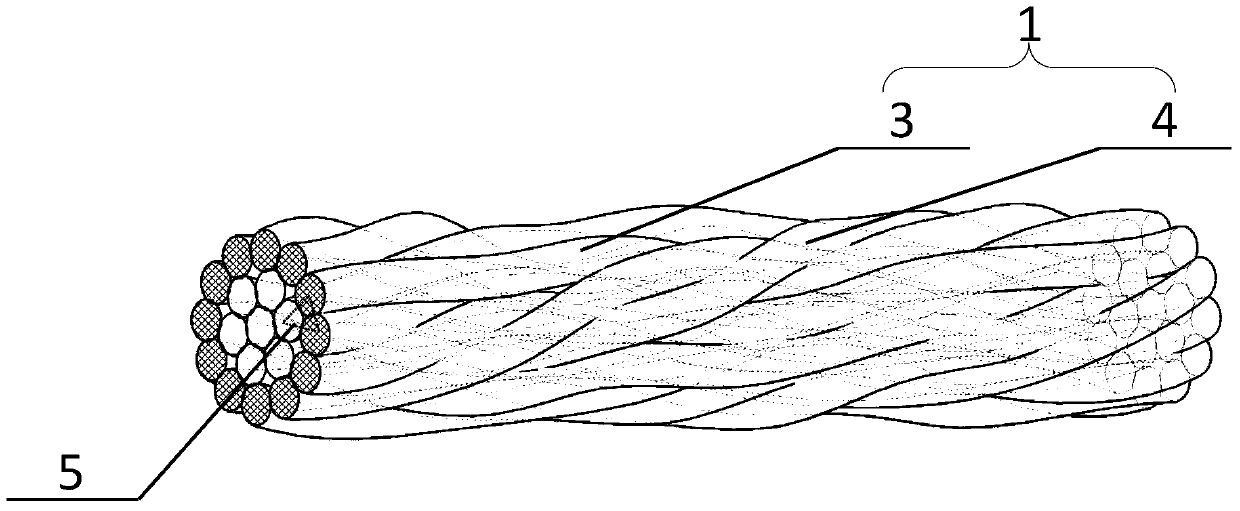

Enhancement core of fiber-reinforced copper-based composite material contact line

The embodiment of the invention provides an enhancement core of a fiber-reinforced copper-based composite material contact line. The enhancement core is composed of copper alloy wires and carbon fiber bundles. The enhancement core axially comprises a plurality of repeated feature circulation segments. The radial section of each feature circulation segment comprises a substructure formed by arranging one or more carbon fiber bundles and one or more copper alloy wires in a staggered manner. Due to the fact that the carbon fiber has the beneficial effects of being large in tensile strength, high in modulus and the like, the enhancement core has the larger tensile strength, potential difference does not exist between the carbon fiber and copper or between the carbon fiber and added alloy elements, the whole corrosion resistance of the contact line can be improved, and the enhancement core has the higher electrochemical corrosion resistance performance.

Owner:CHINA RAILWAYS CORPORATION +2

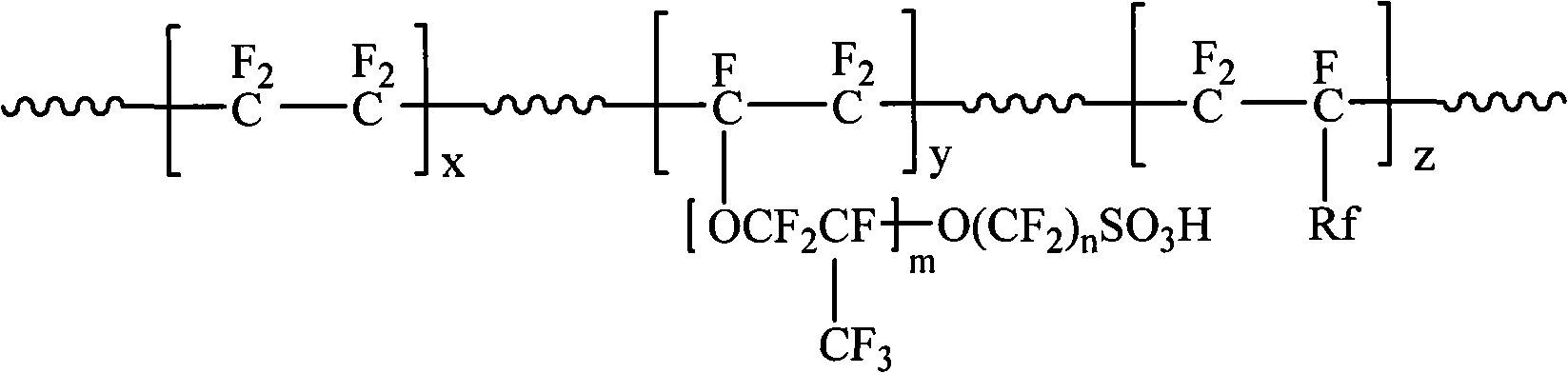

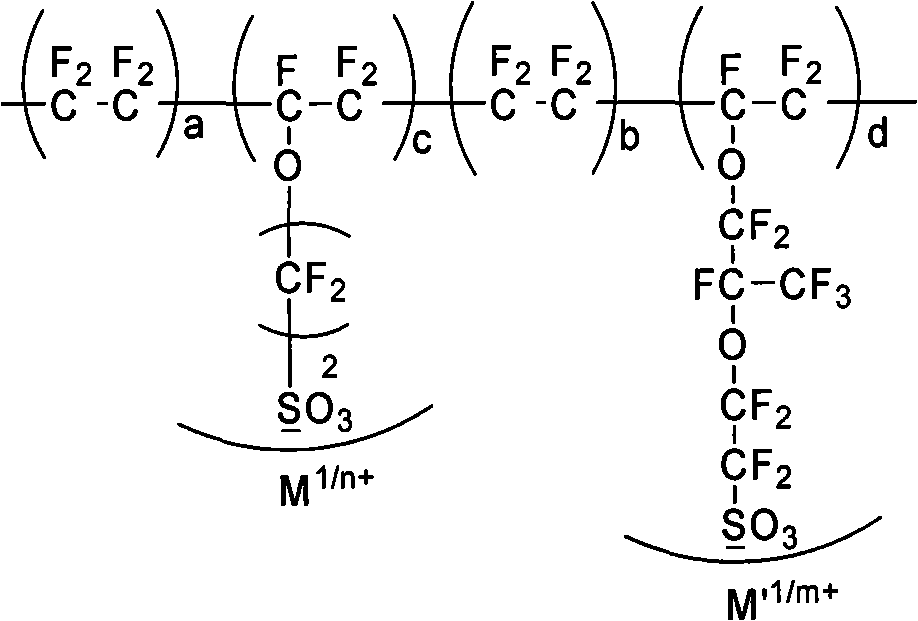

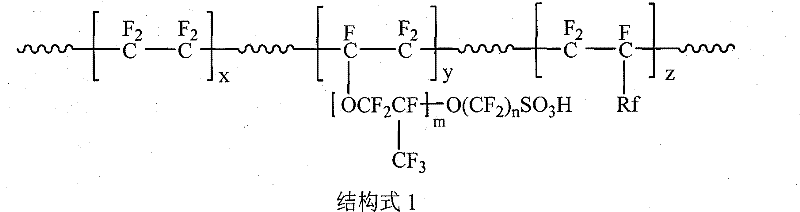

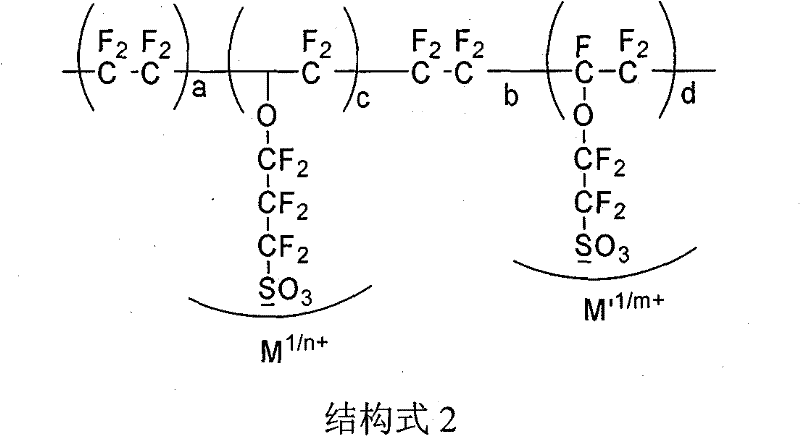

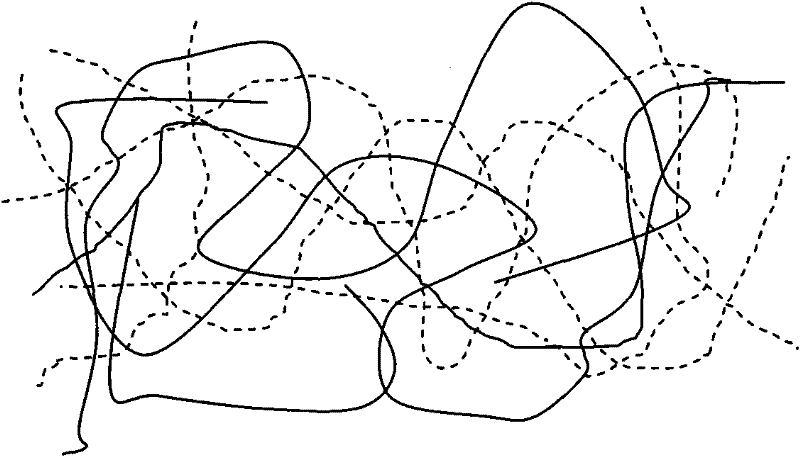

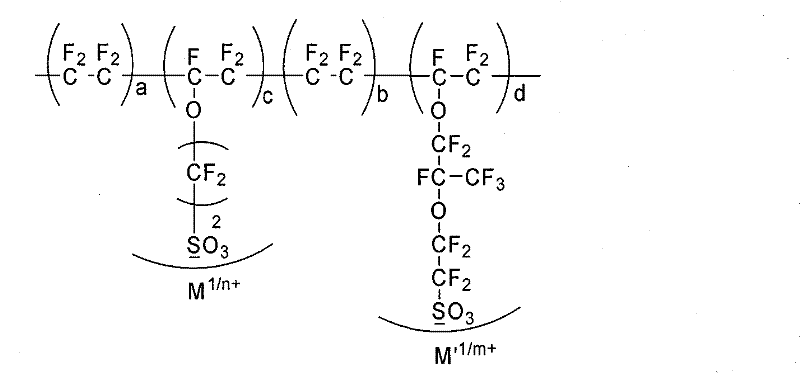

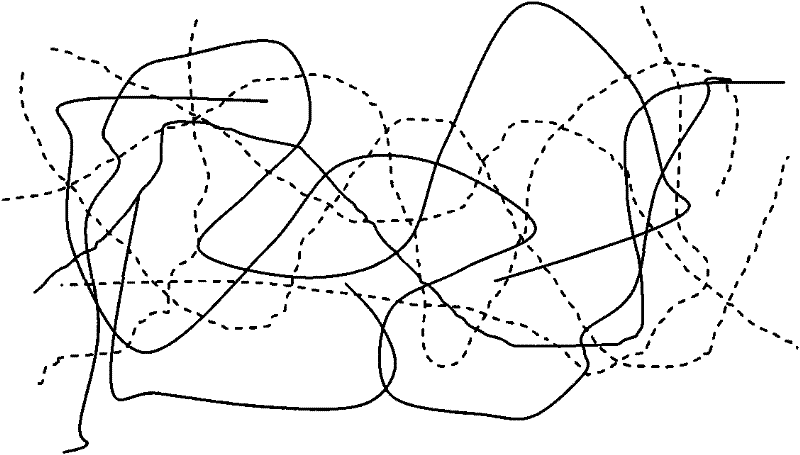

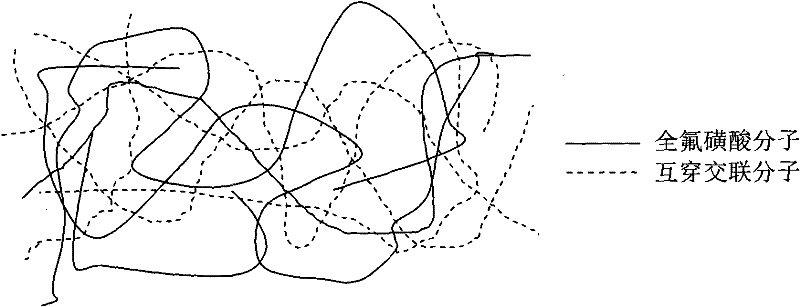

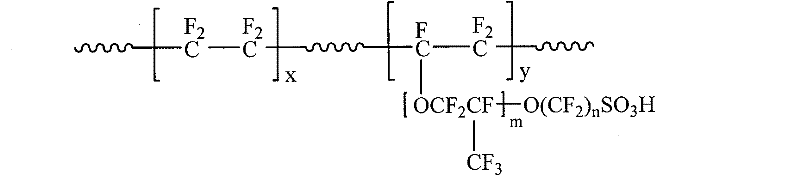

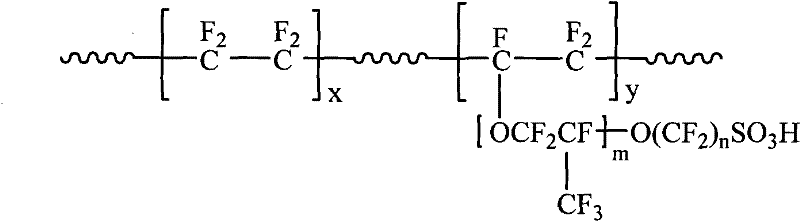

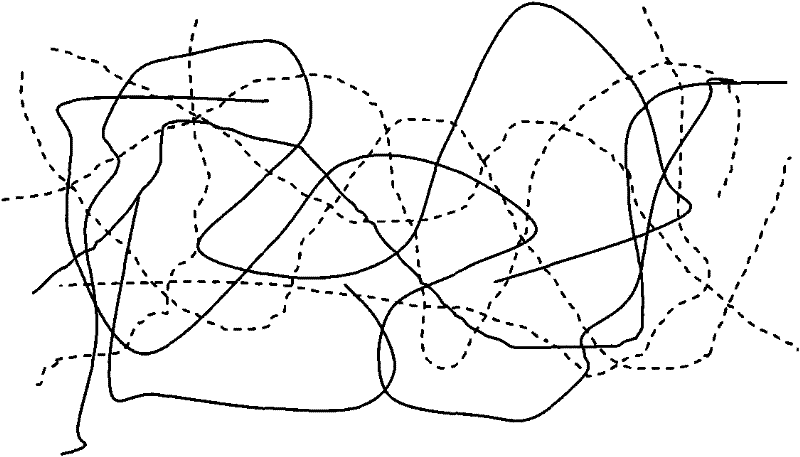

Ion exchange membrane of interpenetrating network structure and preparation method thereof

ActiveCN101794888AImprove conductivityStrong resistance to electrochemical corrosionCell electrodesOrganic solventHydrogen

The invention relates to an ion exchange membrane of interpenetrating network structure and a preparation method thereof. The preparation method is characterized by dissolving a hydrogen type perfluorosulfonic acid ion exchange resin and a salt type perfluorosulfonic acid ion exchange resin with a polar organic solvent; casting the solution on the smooth solid surface; and then forming the membrane under heating condition, wherein the molecular chains of the hydrogen type perfluorosulfonic acid ion exchange resin and the salt type perfluorosulfonic acid ion exchange resin form the macromolecular ion exchange membrane of interpenetrating network structure. The ion exchange membrane with good mechanical performance can be obtained by the method, thus overcoming the defect that the homogeneous crosslinked ion exchange membranes can not be prepared in the existing fusing and molding processes, and the method has the advantages of simple technological process, easy industrial scale-up, etc.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

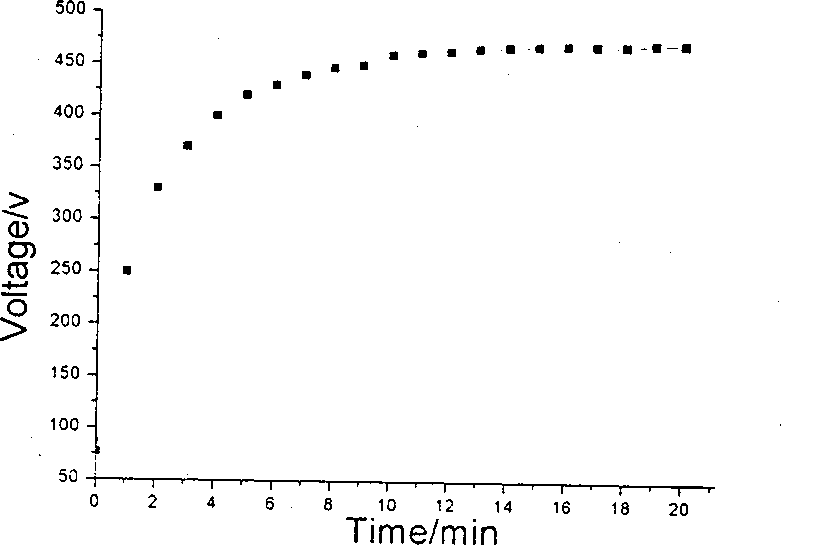

Manufacturing method of light edge controllable electrode foil for solid aluminum electrolytic capacitor

PendingCN114420457AHigh mechanical strengthStrong resistance to electrochemical corrosionSolid electrolytic capacitorsElectrolytic capacitor manufactureAluminum electrolysisAluminum electrolytic capacitor

The invention relates to a method for manufacturing a light edge controllable electrode foil for a solid aluminum electrolytic capacitor. The method comprises the following steps of: performing oil removal operation on the surface of an aluminum foil; performing local coating operation on the aluminum foil; performing curing treatment on the coating layer; performing electrochemical corrosion operation on the aluminum foil; the aluminum foil is placed in pure water to be washed; the aluminum foil is placed in a chemical cleaning solution to be subjected to post-treatment cleaning; and finally carrying out post-processing operation on the aluminum foil. Therefore, on one hand, the electrochemical corrosion process of the aluminum foil has definite directivity and controllability, and it is ensured that the formed corrosion foil has good mechanical strength; and on the other hand, no matter under any electrochemical corrosion condition, the'smooth edge 'on the aluminum foil can be prevented from being corroded, a good foundation is laid for reducing the width of the'smooth edge' as much as possible, the phenomenon that a large amount of aluminum foil raw materials are wasted is effectively eliminated, and the possibility is provided for more thorough corrosion of a non-coating area of the aluminum foil.

Owner:NANTONG HAIXING ELECTRONICS +2

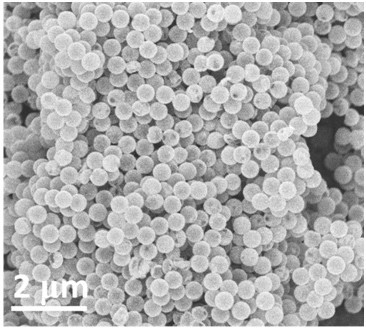

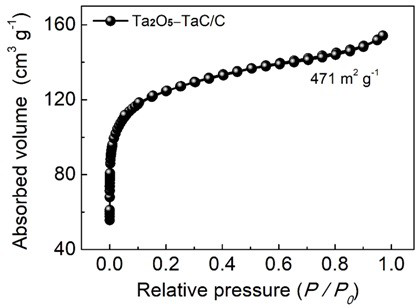

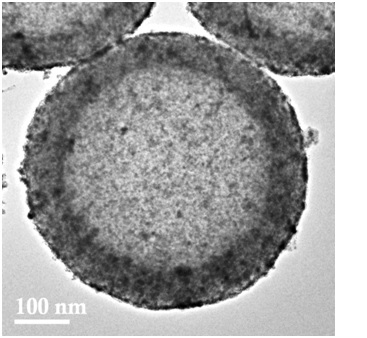

A kind of catalyst carrier, precious metal catalyst and its preparation method and application

ActiveCN110961162BRich anchor pointsLarge specific surface areaCatalyst carriersElectrochemical responsePtru catalyst

The invention relates to a catalyst carrier, a precious metal catalyst and a preparation method and application thereof. Using cross-linked polystyrene microspheres as sacrificial templates, transition metal compound-coated hollow carbon microspheres were prepared by combining solvothermal and one-step carbonization methods, and used as carriers to load precious metal nanoparticles through wet chemical reduction. It is uniformly anchored on the surface of transition metal compound-coated hollow carbon microspheres. The catalyst has the advantages of strong electrochemical corrosion resistance and large specific surface area, and shows excellent catalytic performance in electrochemical reactions such as oxygen reduction, hydrogen evolution, and methanol oxidation.

Owner:BEIJING UNIV OF CHEM TECH

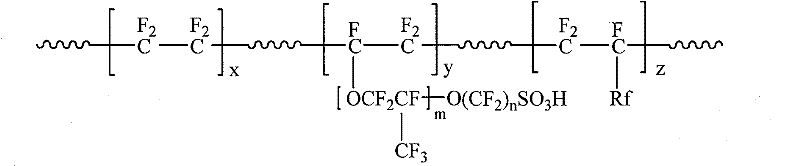

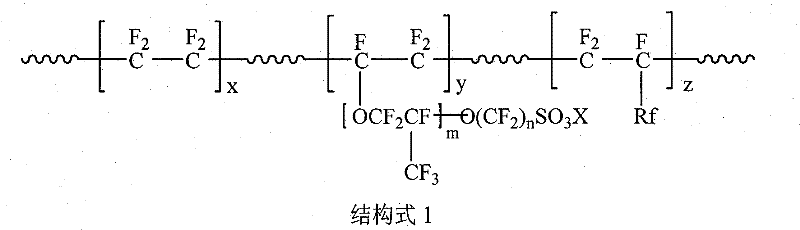

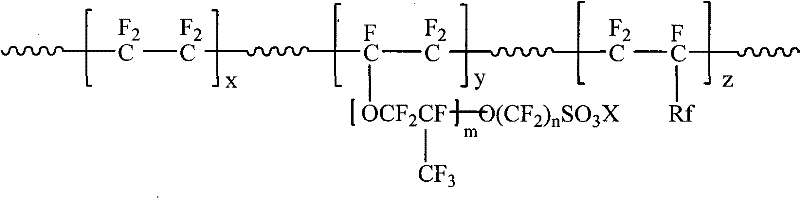

Perfluoro ion exchange membrane with interpenetrating network structure and preparation method thereof

InactiveCN101733021BImprove conductivityStrong resistance to electrochemical corrosionSemi-permeable membranesFinal product manufactureOrganic solventNetwork structure

Owner:SHANDONG DONGYUE POLYMER MATERIAL

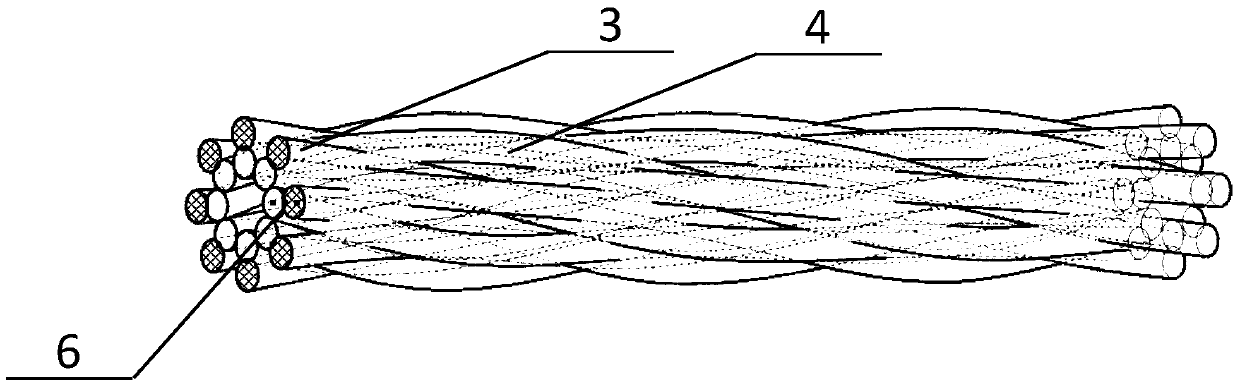

Reinforcing core of fiber-reinforced copper matrix composite contact wire

Owner:CHINA RAILWAYS CORPORATION +2

Electrolytic solution for differential arc oxidization surface treatment of magnesium aluminum alloy in aluminates system

InactiveCN100537851CHigh electrochemical impedanceStrong resistance to electrochemical corrosionAnodisationOxide ceramicPlasma electrolytic oxidation

The invention belongs to the surface modification technology of magnesium and aluminum alloys, and in particular relates to an electrolytic solution for micro-arc oxidation surface treatment of magnesium and aluminum alloy parts. The electrolytic solution includes sodium aluminate and various auxiliary components: according to the ratio of weight to total volume: it includes 4-40 g / L of sodium aluminate and 0-10 g / L of sodium hydroxide. The purpose of the present invention is to provide an aluminate system micro-arc oxidation treatment electrolyte that can significantly improve the corrosion resistance and mechanical properties of magnesium and aluminum alloy parts. The surface of the magnesium and aluminum alloy micro-arc oxidation ceramic layer prepared by the invention is smooth and fine, and has good stain resistance, corrosion resistance and good mechanical properties.

Owner:JILIN UNIV

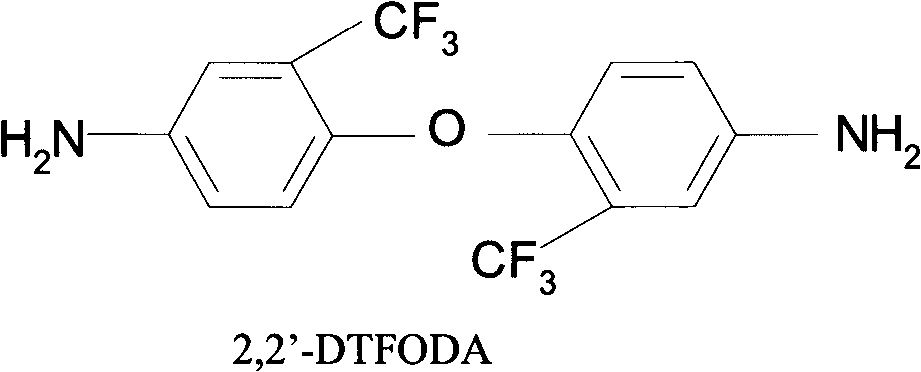

Preparation method of fluororesin-containing conductive plastic bi-polar plate

ActiveCN101814605BImprove conductivityGood chemical stabilityCell electrodesFuel cell detailsThermoplasticGram

Owner:TSINGHUA UNIV +1

Method for producing diaphragm of super capacitor

ActiveCN102629519BEasy and quick passStrong resistance to electrochemical corrosionElectrolytic capacitorsPorosityEngineering

A method for producing a diaphragm of a super capacitor belongs to the technical field of ion channel membranes. The method is characterized in that dimethylacetamide is used for dissolving soluble polyimide and hybrid materials having ion channels; the tape casting method is used for forming a film on a smooth solid surface; and the film is heated, so that the hybrid materials are subjected to a sol-gel reaction to form iron transmission channels, and the hybrid materials and the polyimide form the diaphragm of the super capacitor. The novel diaphragm, which has good ion transmission performance and small resistance, of the supper capacitor can be obtained through the method, and the defect of high porosity of present diaphragms is eliminated. The method has the advantages of being simple in producing process and easy to magnify.

Owner:INST OF CHEM CHINESE ACAD OF SCI

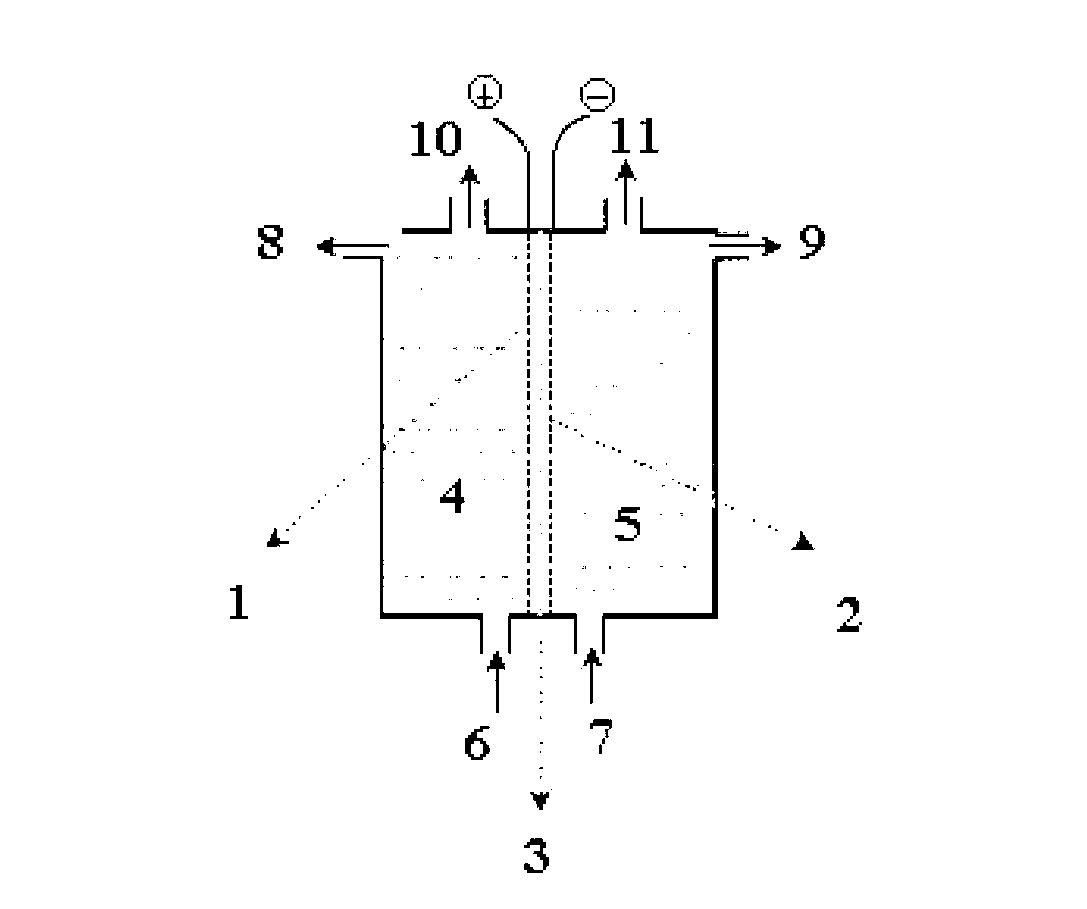

Preparation method of liquid flow battery composite material bipolar plate

InactiveCN101567452BEasy to prepare in batchesImprove conductivityCell electrodesFuel cell detailsCompression moldingElectrical battery

The invention relates to a preparation method of a liquid flow battery composite material bipolar plate, belonging to the technical field of liquid flow battery bipolar plate preparation. The preparation method of the liquid flow battery bipolar plate comprises three steps of using a solution method for mixing, using a tape casting method for casting and using a compression molding method for molding successively. The weight percentage of graphite powder / (graphite powder plus polyvinylidene fluoride) is 30% to 75%, and the dissolving temperature is 50 DEG C to 110 DEG C. The thin-layer thickness of a solution casted by the tape casting method is 0.2mm to 5mm, the compression molding temperature is 190 DEG C to 250 DEG C, and the pressure is 11MPa to 30MPa. The composite material bipolar plate made by using the method has the thickness of 1.0mm to 2.2mm and the electrical conductivity of 0.13S / cm to 41S / cm. The invention is easy for organizing large-scale and low-cost production processso as to overcome the shortcomings of complex processing and poor electrical conductivity of the prior liquid flow battery bipolar plate, thus laying the foundation for developing the chemical powertechnology used in large-scale energy conversion and storage.

Owner:TSINGHUA UNIV

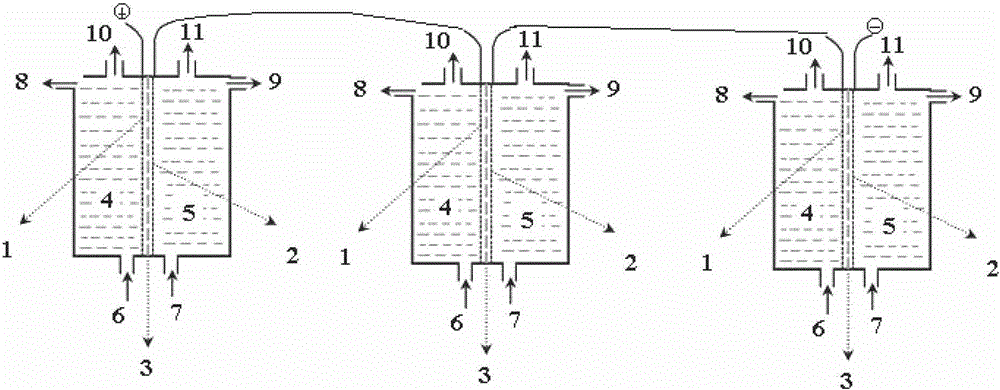

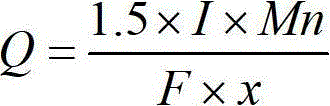

Method for preparing high-purity peroxysulphate based on electrolytic oxidation through ion-exchange membrane electrolyzer for chlor-alkali production

ActiveCN102877085BSimple methodEasy to scale up industrial productionCellsOrganic diaphragmsSulfate radicalsElectrolysis

The invention relates to a method for preparing high-purity peroxysulphate based on electrolytic oxidation through an ion-exchange membrane electrolyzer for chlor-alkali production. According to the method, a perfluorinated ion exchange membrane is arranged between electrodes, and the electrolyzer comprises an anode compartment, an anode, the perfluorinated ion exchange membrane, a cathode and a cathode compartment. The method comprises the following steps: an anolyte sulfate aqueous solution and a catholyte alkali solution are respectively supplied to the anode compartment and the cathode compartment of the electrolyzer to conduct electrochemical ion exchange, the electrolyzer is charged with direct current to conduct constant current electrolysis, sulphate ions in the sulphate solution are enriched in the anode compartment because of not passing through the ion-exchange membrane, and are migrated on the anode in the anode direction to discharge to generate sulfate radicals, the sulfate radicals are combined with M<+> to generate sulfate, and the anode out-of-electrolyzer solution is subjected to after treatment to obtain high-purity peroxysulphate. The method overcomes the defects that in the prior art, the energy consumption is high, and the current efficiency is low, is simple in process, achieves high current efficiency and low energy consumption, and is easy to realize industrial production.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Ion exchange membrane of interpenetrating network structure and preparation method thereof

ActiveCN101794888BImprove conductivityStrong resistance to electrochemical corrosionCell electrodesHydrogenOrganic solvent

The invention relates to an ion exchange membrane of interpenetrating network structure and a preparation method thereof. The preparation method is characterized by dissolving a hydrogen type perfluorosulfonic acid ion exchange resin and a salt type perfluorosulfonic acid ion exchange resin with a polar organic solvent; casting the solution on the smooth solid surface; and then forming the membrane under heating condition, wherein the molecular chains of the hydrogen type perfluorosulfonic acid ion exchange resin and the salt type perfluorosulfonic acid ion exchange resin form the macromolecular ion exchange membrane of interpenetrating network structure. The ion exchange membrane with good mechanical performance can be obtained by the method, thus overcoming the defect that the homogeneous crosslinked ion exchange membranes can not be prepared in the existing fusing and molding processes, and the method has the advantages of simple technological process, easy industrial scale-up, etc.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

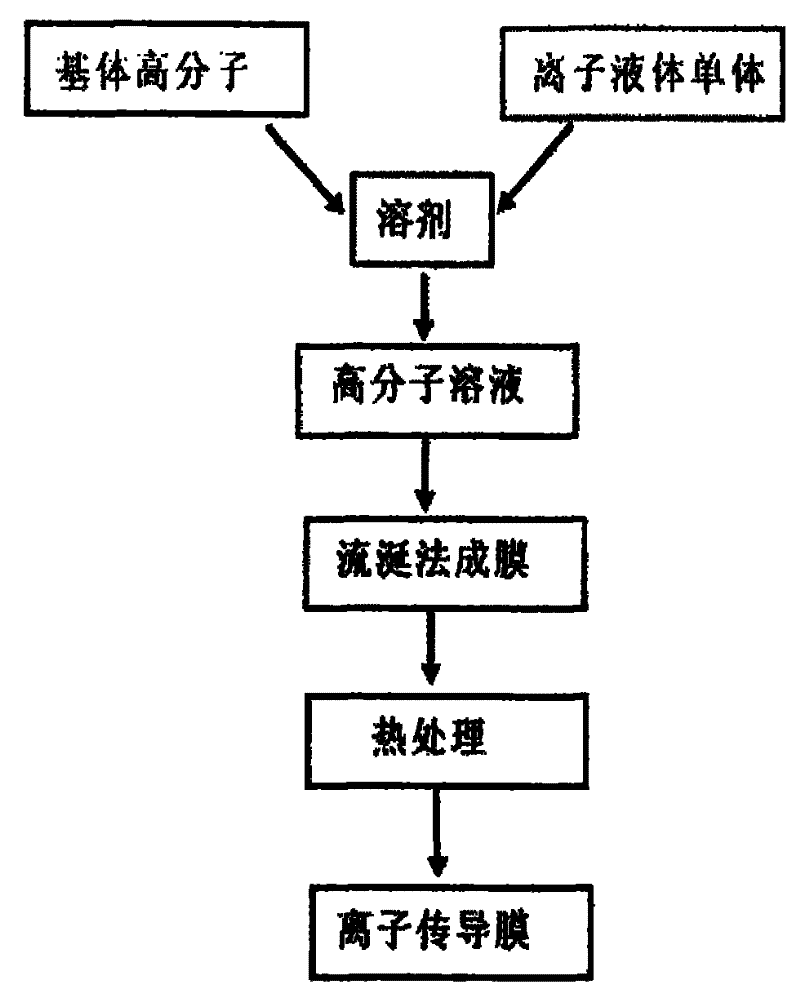

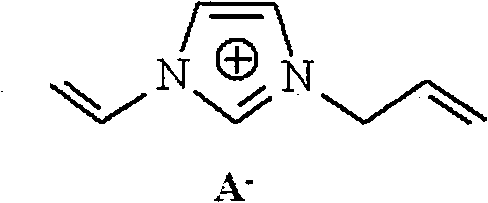

Method for preparing interpenetrating network type conducting film of polyion liquid

InactiveCN101613481BImprove conductivityStrong resistance to electrochemical corrosionDouble bondSolvent

The invention provides a method for preparing an interpenetrating network type conducting film of polyion liquid, belonging to the technical field of production of a high polymer conducting film. The method is characterized in that a polyvinylidene fluoride with stable chemical property as a substrate material is dissolved in strongly polar solvent with an ion liquid monomeric compound containingcarbon-carbon double bonds, such as 1-allyl-3-vinyl imidazole chloride, so as to prepare uniform solution after mixing; a film is prepared by a salivation method; and after heat treatment, the film triggers a monomer to perform a polymerization reaction, and forms the ion conducting film of the interpenetrating network with substrate high molecules. The conducting film can play a role of ionic conduction in electrodialysis, diffusion dialysis and electrochemical sensors. The conducting film material has simple preparation process, avoids using sulfonating agent and other strong oxidation substances in the preparing process, is advantageous to environmental protection, and simultaneously solves the problem that a homogeneous ionic conducting film cannot be obtained by the fusion method of ionic exchange resin.

Owner:TSINGHUA UNIV

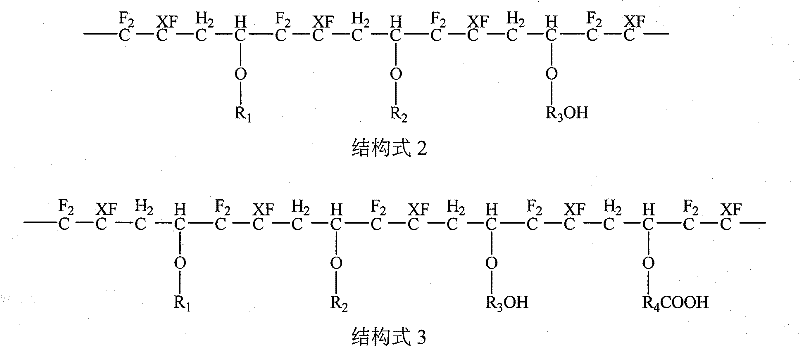

Fluorine-containing network structure ion exchange membrane based on fluoroethyl vinyl ether polyalcohol and preparation method thereof

InactiveCN101791526BImprove conductivityStrong resistance to electrochemical corrosionSemi-permeable membranesSecondary cellsVinyl etherCross-link

The invention relates to a fluorine-containing network structure ion exchange membrane based on fluoroethyl vinyl ether polyalcohol and preparation method thereof. Polar organic solvent is adopt to dissolve perfluorinated sulfonic acid resin and anhydrous poly isocyanate as well as anhydrous fluoroethyl vinyl ether (FEVE) polyalcohol; tape casting is adopted to form a membrane on smooth solid surface; then heating is carried out and poly isocyanate and anhydrous FEVE take polymerization, and products of the polymerization and perfluorinated sulfonic acid molecule chain form ion exchange membrane in macromolecule interpenetrating network structure. The membrane preparation method can obtain fluorine-containing ion exchange membrane material with favourable proton commutativity, overcomes the defect that the existing fusion mould pressing process can not prepare homogeneous cross linking ion exchange membrane and has the advantages of simple technological process and easy industrial scale-up.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Ion exchange membrane with interpenetrating network structure and preparation method thereof

ActiveCN101764235BGood effectImprove conductivityFinal product manufactureCell component detailsCross-linkIndustrial scale

The invention relates to an interpenetrating network structure ion-exchange membrane and a preparation method thereof. The preparation method comprises the following steps: a perfluorinated sulfonic acid exchange resin and a polymerizable monomer containing proton exchange functional groups are dissolved by using a polar organic solvent; and casting film is formed on the smooth surface of a solidby using the tape casting method; the polymerizable monomer containing the proton exchange functional groups is initiated to generate polymerization reaction, and the products of the polymerization reaction and perfluorinated sulfonic acid molecular chains form the ion exchange membrane with the interpenetrating network structure. The preparation method of the ion exchange membrane can obtain ionexchange membrane materials with very good proton exchange property, overcomes the defects that the homogeneous cross-linked ion exchange membrane can not be prepared in the existing melt molding process, and has the advantages of simple technological process, easy industrial scale-up and the like.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Method for preparing corrosion-resistant sintered neodymium iron boron (NdFeB) magnet

InactiveCN101958171BStrong resistance to electrochemical corrosionReduce weightlessnessInductances/transformers/magnets manufactureMagnetic materialsAlloyCobalt

The invention discloses a method for preparing a corrosion-resistant sintered neodymium iron boron (NdFeB) magnet. In the method, an intergranular phase optimized design is used as a starting point on the basis of preparation technology of a double-alloy method, the high-cobalt content rare earth cobalt-based alloy which does not contain iron and boron is selected as an auxiliary alloy, and the melting point of the auxiliary alloy is ensured to be lower than 1,050 DEG C through component control so as to meet the liquid-phase sintering effect. By measuring the weightlessness condition of the material placed in an environment of the temperature of 120 DEG C, two atmosphere and 100 percent of humidity for 96 hours, results show that the weightlessness of the prepared sintered NdFeB magnet is only less than 1 / 3 of that of the sintered NdFeB magnet prepared by a single-alloy method and a conventional double-alloy method, and the sintered NdFeB magnet has excellent corrosion resistance. The method for preparing the corrosion-resistant sintered NdFeB magnet can be widely applied in the field of production of high-performance sintered NdFeB magnets.

Owner:WUXI NANLIGONG TECH DEV +2

Long-service-life electrode boiler electrode bar and preparation method thereof

InactiveCN111363979AGood resistance to electrochemical corrosionExtended service lifeManganeseElectrochemical corrosion

The invention aims to provide a long-service-life electrode boiler electrode bar and a preparation method thereof. The long-service-life electrode boiler electrode bar is remarkably prolonged in service life because of high electrochemical corrosion resistance. The long-service-life electrode boiler electrode bar is composed of, by weight, equal to or smaller than 0.0015% of oxygen, equal to or smaller than 0.05% of carbon, 0.16% to 0.26% of silicon, 0.29% to 0.40% of manganese, 0.018% of phosphorus, 0.0015% of sulfur, 0.001% to 0.002% of aluminum, and the balance iron. The ferritic structurein the long-service-life electrode boiler electrode bar is no smaller than 85%, and the surface smoothness of the long-service-life electrode boiler electrode bar is N5 or higher. The service life ofthe long-service-life electrode boiler electrode bar can be ten years or more. An electrode bar in the prior art is seriously corroded after being used for three years and needs to be replaced. Therefore, the long-service-life electrode boiler electrode bar has the characteristic of being remarkably prolonged in service life because of high electrochemical corrosion resistance.

Owner:北京火龙升腾科技有限公司

Interpenetrating network ion exchange membrane based on polyurethane and preparation method thereof

ActiveCN101794889BImprove conductivityStrong resistance to electrochemical corrosionCell electrodesCross-linkIndustrial scale

The invention relates to an interpenetrating network ion exchange membrane based on polyurethane and preparation method thereof. Polar organic solvent is adopted to dissolve perfluorinated sulfonic acid resin and anhydrous poly isocyanate as well as anhydrous polyalcohol; tape casting is adopted to form a membrane on smooth solid surface; then heating is carried out and poly isocyanate and anhydrous polyalcohol take polymerization, and products of the polymerization and perfluorinated sulfonic acid molecule chain form ion exchange membrane in macromolecule interpenetrating network structure. The membrane preparation method can obtain ion exchange membrane material with favourable proton commutativity, overcomes the defect that the existing fusion mould pressing process can not prepare homogeneous cross linking ion exchange membrane and has the advantages of simple technological process and easy industrial scale-up.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Method for preparing organic acid by electrolyzing organic acid salt on basis of chlor-alkali perfluor ion exchange membrane

ActiveCN102839383BSimple methodEasy to scale up industrial productionElectrolytic organic productionDiaphragmsOrganic acidHydrogen ion binding

The invention relates to a method for preparing an organic acid by electrolyzing an organic acid salt on the basis of a chlor-alkali perfluor ion exchange membrane. According to the method, an electrolytic bath which is equipped with a perfluor ion exchange membrane between electrodes and is mainly composed of an anode chamber, an anode, the perfluor ion exchange membrane, a cathode and a cathode chamber is adopted. The method comprises the following steps: respectively supplying an anode solution and a cathode solution to the anode chamber and the cathode chamber of the electrolytic bath and performing electrochemical ion exchange, wherein the anode solution is an aqueous solution of the organic acid salt and the cathode solution is an alkali solution corresponding to cations in the organic acid salt; applying a direct current to the electrolytic bath so as to perform constant current electrolysis, and combining the anions in the organic acid salt solution enriched in the anode chamber with hydrogen ions generated by the anode chamber, thereby generating the organic acid; and collecting discharged solution containing the organic acid enriched in the anode chamber, concentrating and crystallizing, thereby obtaining the high-purity organic acid. The method has the advantages of simple process, easiness in industrial amplification, high current efficiency, and the like, and can realize the industrial preparation for the high-purity organic acid.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com