Method for producing diaphragm of super capacitor

A supercapacitor and diaphragm technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of large diaphragm resistance and electrode short circuit, and achieve the effects of good temperature resistance, strong electrochemical corrosion resistance, and simple film production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

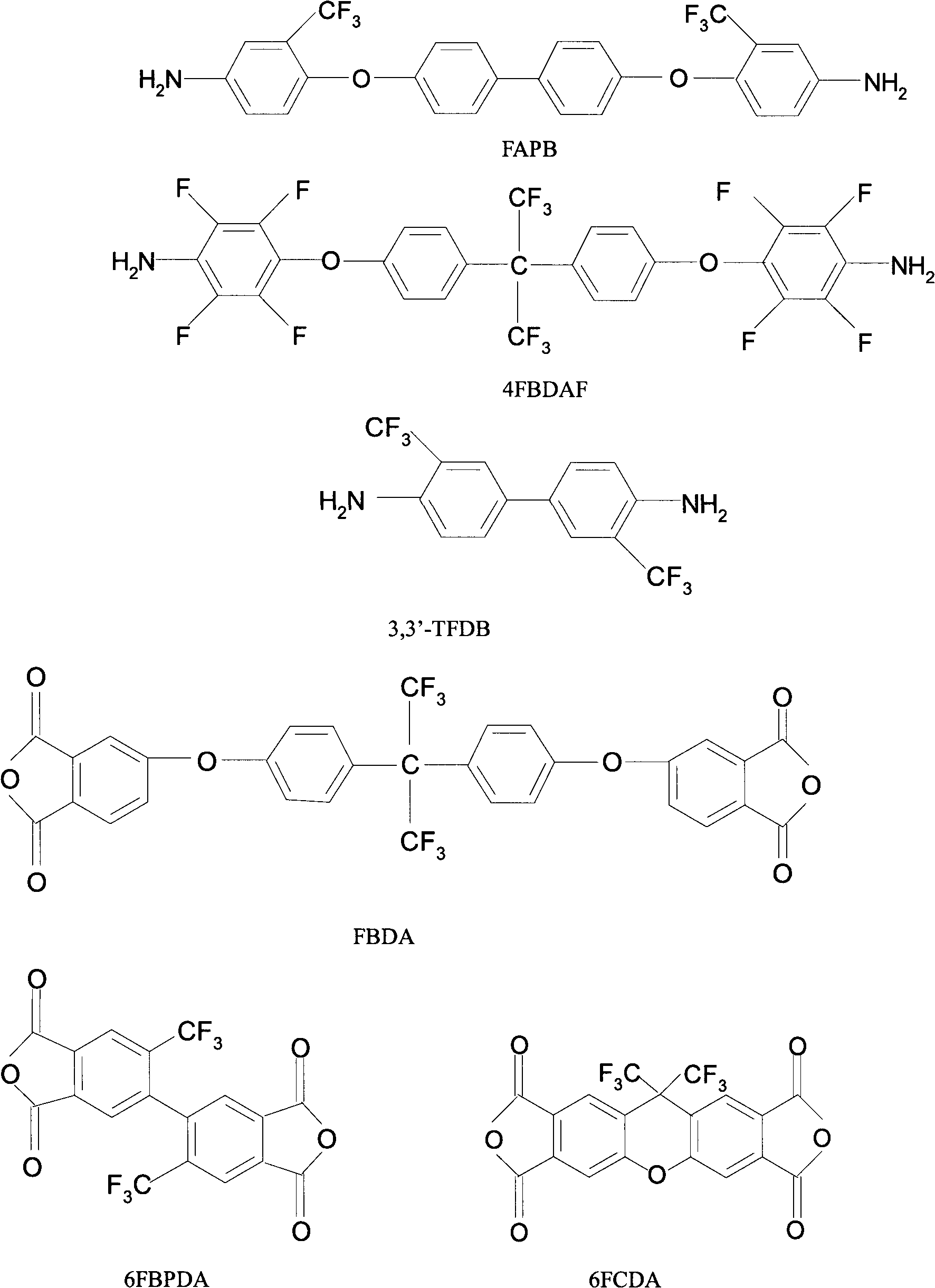

[0028] Put 20g of soluble polyimide (FBDA-FAPB) and 120g of solvent dimethylacetamide in a three-necked flask, stir at room temperature for 2 hours, then add 8g of hybrid materials and 0.1ml of concentrated hydrochloric acid, and continue to heat up to 100°C Stir for 48 hours. After the solution is completely mixed, let it cool and stand for 2 hours, and cast it on a clean glass plate to form a 100-micron film. After the solvent evaporates, peel off the film from the glass plate and dry it at 100°C for 4 hours. hours, a 60-micron supercapacitor diaphragm was obtained.

Embodiment 2

[0030] Place 20g of soluble polyimide (6FBPDA-3,3'-TFDB) and 180g of solvent dimethylformamide in a three-necked flask, stir at room temperature for 2 hours, then add 15g of hybrid material and 0.3ml of concentrated hydrochloric acid, and heat up Continue to stir for 48 hours at 100°C. After the solution is completely mixed, cool and let it stand for 2 hours, and cast it on a clean glass plate to form a 120-micron film. After the solvent evaporates, peel off the film from the glass plate. Dry at 150° C. for 4 hours to obtain a 85-micron supercapacitor diaphragm.

Embodiment 3

[0032] Put 30g of soluble polyimide (6FDA-2,2'-DTFODA) and 250g of solvent N methylpyrrolidone into a three-necked flask, heat and stir at 50°C for 2 hours, then add 20g of hybrid material and 0.5ml of concentrated hydrochloric acid, Raise the temperature to 120°C and continue to stir for 72 hours. After the solution is completely mixed, cool and stand for 2 hours. Cast a 200-micron film on a clean glass plate. After the solvent evaporates, peel off the film from the glass plate. Dry at 180°C for 12 hours to obtain a 150 micron supercapacitor separator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com