On-line detection system and method of trace dissolved gas in organic oil

A technology of dissolved gas and detection system, applied in general control systems, control/regulation systems, measuring devices, etc., can solve the problems of small separation, long oil and gas balance time, large volume, etc., to achieve easy installation and maintenance, meet real-time requirements The effect of degassing, simplifying the number of channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1. System composition

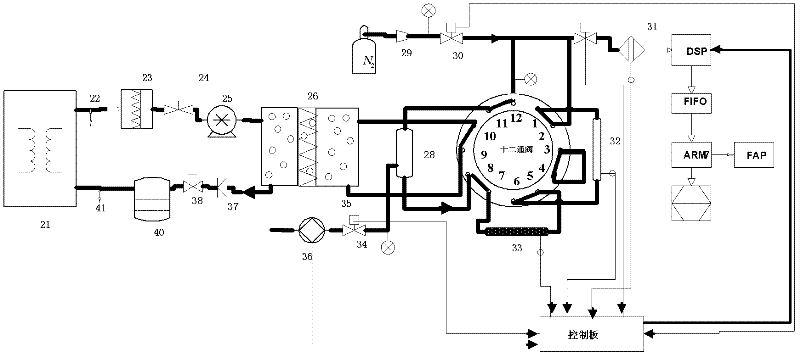

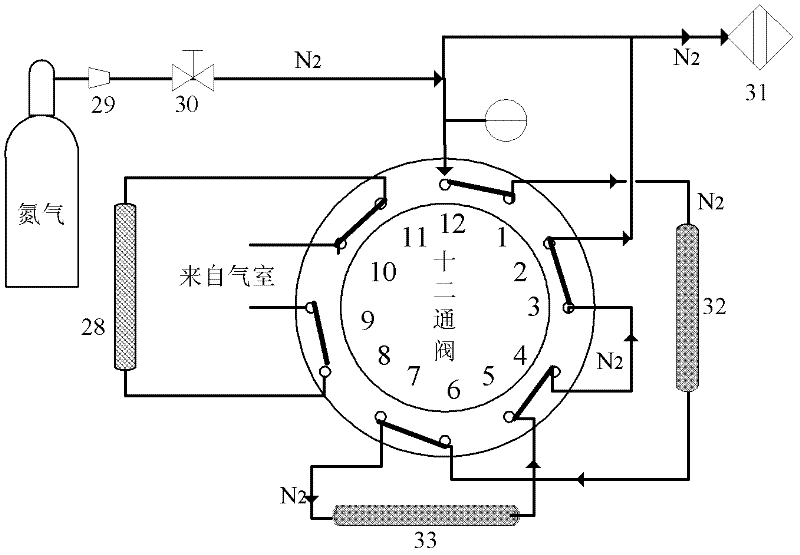

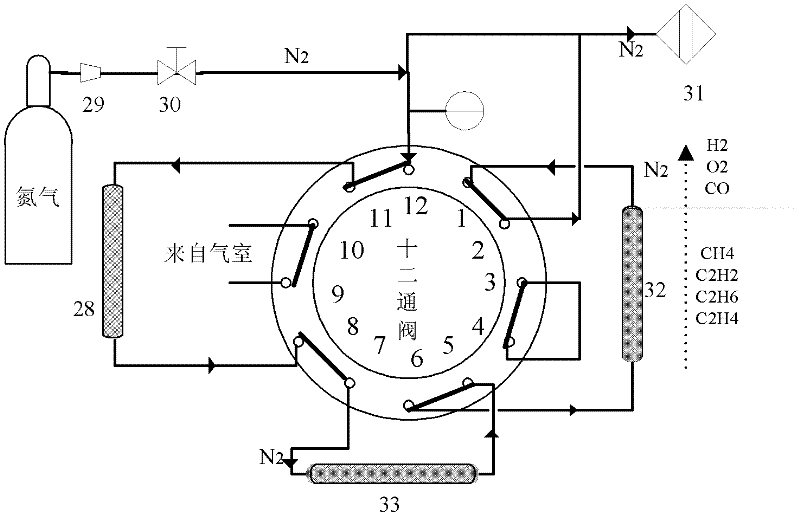

[0049] Refer to attached figure 1 , The system integration invention includes an oil-gas separation unit, a gas detection unit, and a control unit. The oil-gas separation unit includes organic oil pretreatment, oil-gas separation chamber part, and oil circulation buffer; the gas detection unit includes a carrier gas unit, a 12-way valve sampling module, a double-column mixed gas separation module, and a trace amount of combustible gas Sensor module; the control unit includes a motor control module, a temperature control module, a signal acquisition and data processing module, a status indication and fault processing module, and a data transmission module.

[0050] The oil-gas separation chamber part includes a micro-magnetic oil pump, a micro-air chamber, a Teflon PTFE fast degassing membrane, a check valve and a gas vacuum pump: the micro-magnetic oil pump pumps the pretreated organic oil at an appropriate speed under the control of the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com