Method for preparing interpenetrating network type conducting film of polyion liquid

An interpenetrating network type, polyionic liquid technology, used in the field of polymer conductive film material preparation, can solve the problems of inability to guarantee film stability and loss, and achieve reduced ion conduction resistance, strong electrochemical corrosion resistance, and electrical conductivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

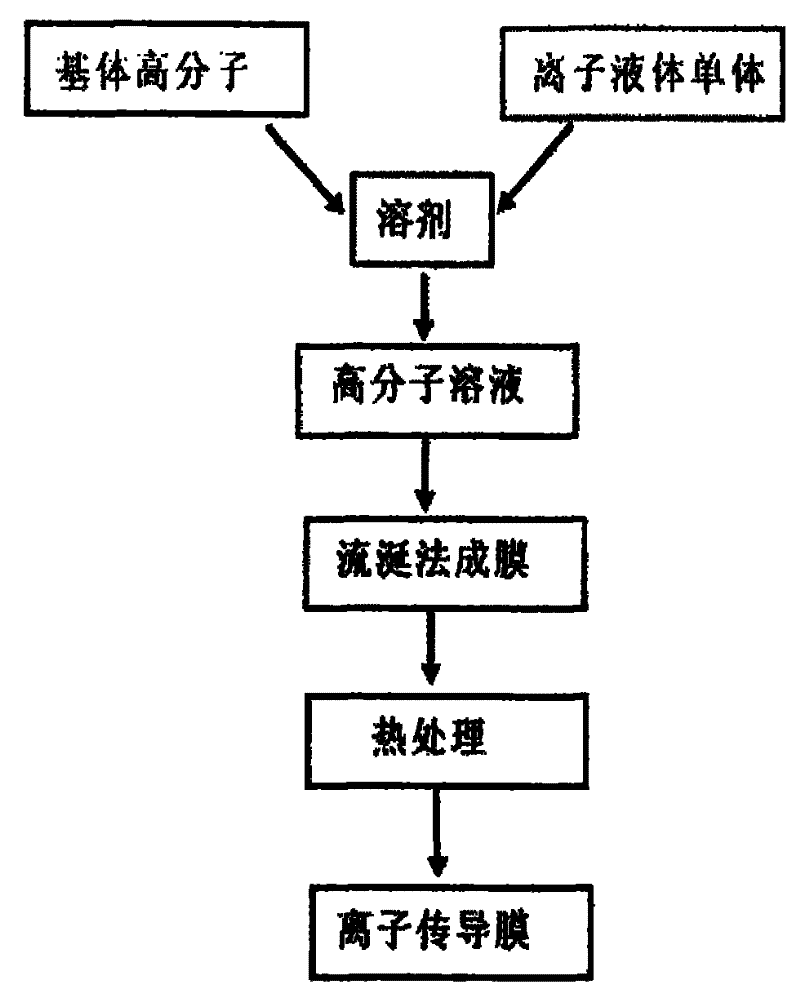

Method used

Image

Examples

Embodiment 8

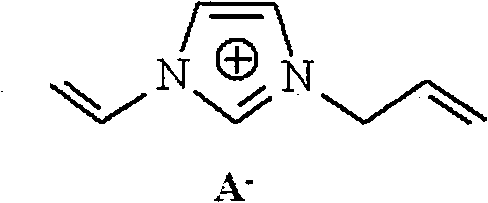

[0032] Embodiment 8: In order to further verify the method proposed by the present invention, the ionic liquid was replaced with 1-allyl-3-vinylimidazolium bromide ionic liquid, and its molecular structure is as follows.

[0033]

[0034]Add 1-allyl-3-vinylimidazole bromide ionic liquid into dimethyl sulfoxide (DMSO) according to the ratio of (ionic liquid weight / PVDF weight) = 0.2, 0.3, 0.4, 0.6, fully dissolve and pour Put it into the weighed polyvinylidene fluoride, mix thoroughly with a glass rod, then place it in a constant temperature water bath at 60°C, and stir it with an electric stirrer for 1 hour until it is fully dissolved and a uniform transparent solution is obtained. After dissolving, if there are many bubbles in the solution, it can be placed in a dry box for a while to eliminate bubbles. If there are no bubbles or few bubbles, this step can be omitted. After removing the air bubbles, pour the film-casting solution on a clean glass plate and scrape it into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com