Noble metal doped particles and metallic oxide film integrated gas sensor and preparation method thereof

A technology of oxide thin film and gas sensor, which is applied in metal material coating process, gaseous chemical plating, material electrochemical variables, etc., can solve the problems of plasma instability, inclusion of impurities, and easy cracking of products, so as to improve sensitivity and stability, high ethanol sensitivity, and the effect of improving film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

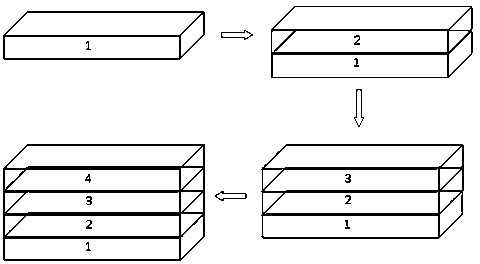

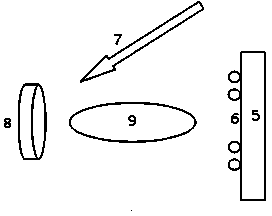

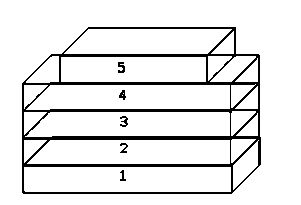

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Preparation of Pd-ZnO thin film gas sensor

[0050] The first step, the preparation of detection electrode-heating electrode substrate

[0051] (1) Substrate cleaning: for SiO 2 Material-covered Si substrates were treated with acetone, ethanol, and deionized water sequentially on SiO 2 - The Si substrate was ultrasonically cleaned for 5 minutes, then blown dry with nitrogen gas, and set aside.

[0052] (2) Photolithographic heating electrode pattern: the photoresist uses Suzhou Ruihong’s RZJ-304 positive resist. First, the cleaned substrate is spin-coated with photoresist. The low speed is 500rpm, the rotation time is 5s, and the high speed is 4000rpm , the rotation time is 20s, then pre-baked at 100°C for 2min, then install the mask plate corresponding to the heating electrode on the ABM lithography machine, expose for 9s, the light intensity is 15mw / cm2, develop for 11s after exposure, and then at 100°C After hard drying for 5 minutes, after hard dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com