Forming window for high-speed continuous photocuring 3D printing

A 3D printing and 3D printer technology, which is applied in the field of high-speed continuous light-curing 3D printing forming windows, can solve the problem that oxygen-permeable and ultraviolet-permeable Teflon materials are expensive, and it is difficult to realize large-scale and high-efficiency manufacturing of solid parts. Rapid supply of resin materials and other issues to achieve the effect of expanding the range of process use, improving printing efficiency, and increasing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

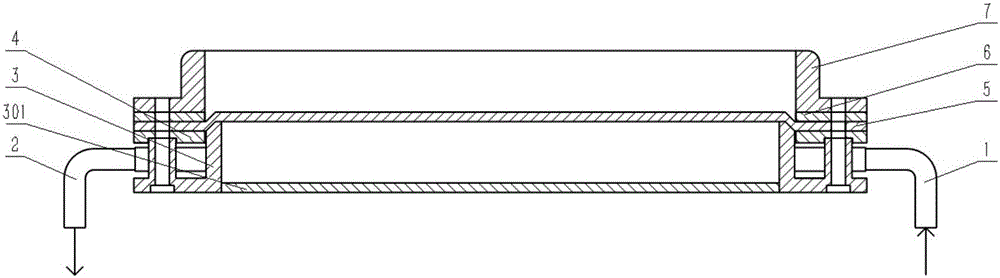

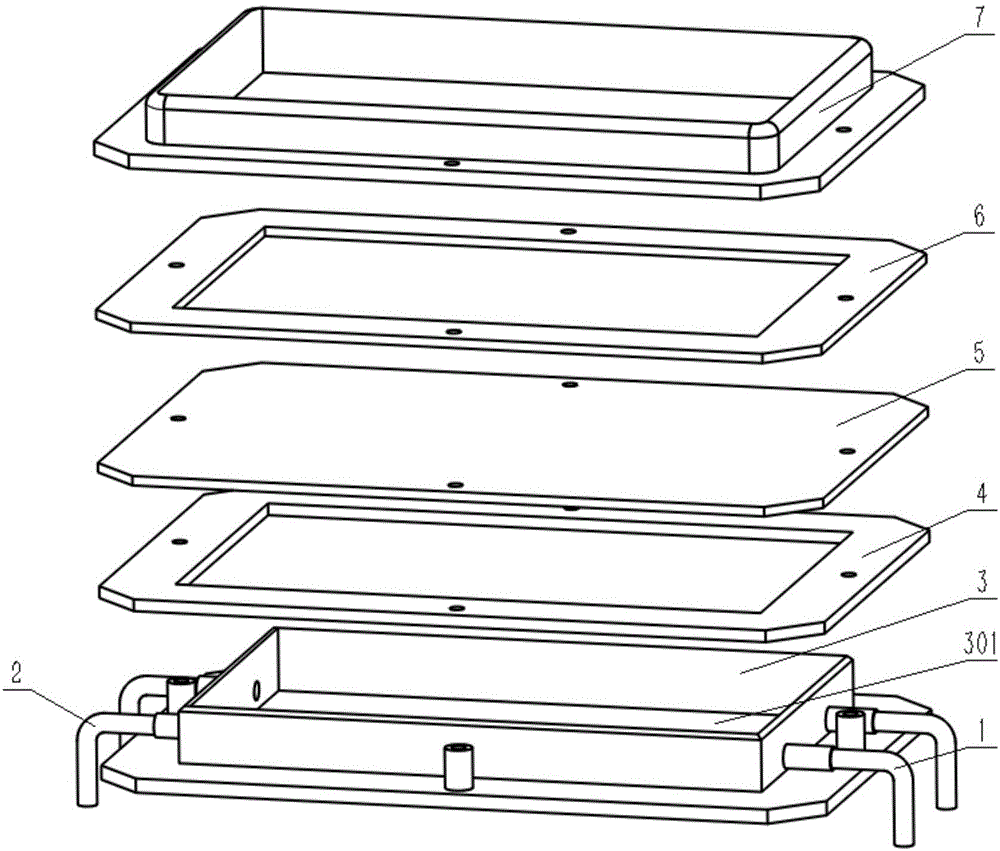

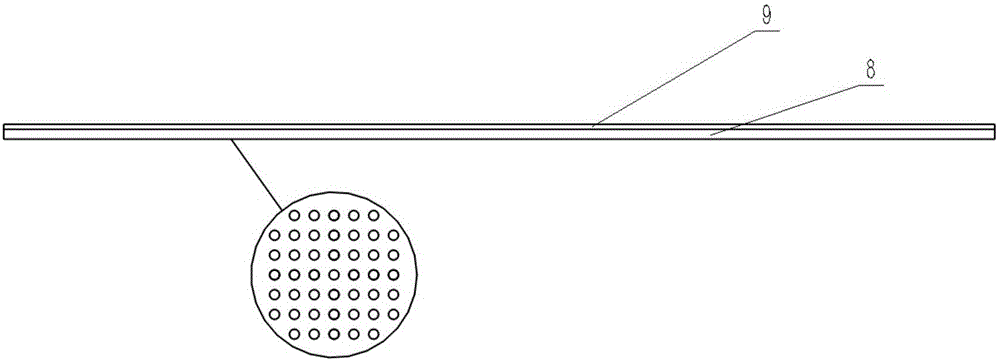

[0063] figure 1 It is a schematic diagram of the structural principle of the forming window for high-speed continuous photocuring 3D printing in Example 1 of the present invention, figure 2 It is a schematic exploded view of the forming window for high-speed continuous photocuring 3D printing in Example 1 of the present invention. Embodiment 1 The molding window includes: cooling air intake pipeline 1, cooling air outlet pipeline 2, oxygen supply cooling chamber 3, transparent quartz plate 301, pressure plate 4, composite oxygen-enriched membrane 5, sealing gasket 6, and liquid storage tank 7. The oxygen supply cooling chamber 3, the pressing plate 4, the composite oxygen-enriched membrane 5, the sealing gasket 6, and the liquid storage tank 7 are provided with holes through up and down, wherein the oxygen supply cooling chamber 3, the pressing plate 4, and the upper holes of the liquid storage tank 7 are Threaded holes, one side of the oxygen supply cooling chamber 3 has a ...

Embodiment 2

[0072] Example 2 The schematic diagram of the structure of the forming window for high-speed continuous light-curing 3D printing is as follows Figure 4As shown, on the basis of the molding window in Embodiment 1, a liquid level auxiliary pressure application module is added, including the upper chamber 10 of the chassis and the pressurized intake pipeline 11 . The printing device is divided into upper and lower chambers with the middle partition of the fixed window box as the boundary. The upper chamber 10 of the chassis has good airtightness, and the oil-free air compressor increases the gas pressure of the upper chamber through the pressurized intake pipeline 11 . During printing, high-pressure gas exerts pressure on the liquid surface of photosensitive resin to accelerate the flow of resin to the "dead zone" and curing area, and realize rapid resin reflow and replenishment.

Embodiment 3

[0074] As another embodiment, the cooling outlet pipeline 2 is connected to a vacuum pump, and the vacuum pump pumps air to promote the gas flow in the closed chamber formed by the oxygen supply cooling chamber 3 and the composite oxygen-enriched membrane 5, thereby improving the cooling efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com