Preheating device for chemical vapor deposition furnace

A chemical vapor deposition and preheating device technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of short heat conduction time, inability to form an effective gas field, and limited gas preheating capacity. , to achieve the effect of expanding the thermal radiation capacity, densifying the carbon disk column, and reducing the probability of axial backmixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

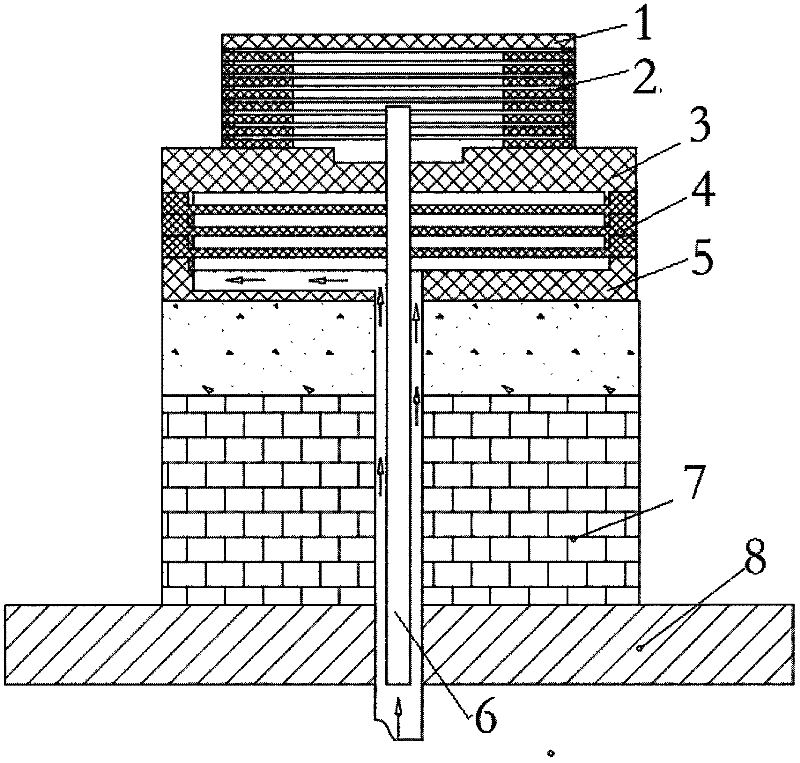

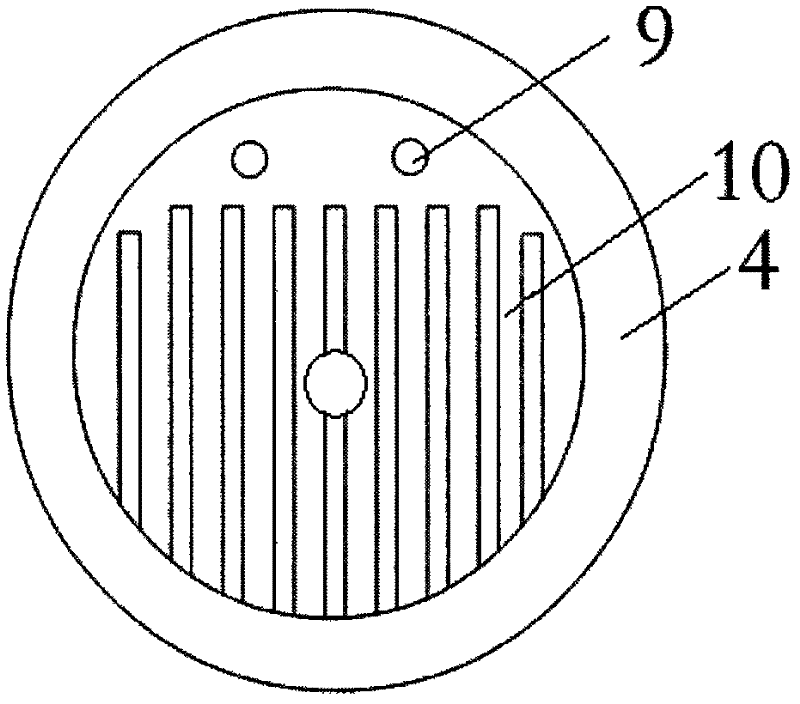

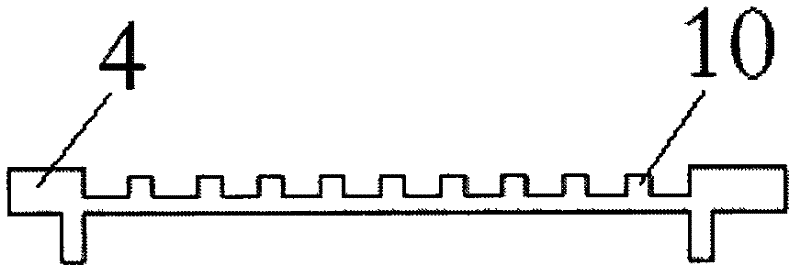

[0016] This embodiment is a chemical vapor deposition furnace preheating device, which includes a disturbance panel 3 , an air flow plate 4 and a base 5 .

[0017] The base 5 is placed on the upper surface of the base 7 . The air flow plates 4 are stacked layer by layer on the upper surface of the base 5, and the layers are staggered at 180°; the number of layers of the air flow plates 4 is proportional to the gas flow rate entering the deposition furnace, which is 2 to 5 layers. When the gas flow rate is ≤2000L / h, the number of layers of air flow plate 4 is 2 layers; when the gas flow rate is 2000L / h~3000L / h, the number of layers of air flow plate 4 is 3 layers; when the gas flow rate is ≥3000L / h , the number of layers of the airflow plate 4 is 4 layers or 5 layers. In this embodiment, the air flow plate 4 has three layers. The disturbance panel 3 is placed on the upper surface of the top airflow panel 4 . The prefabricated body 2 is placed on the upper surface of the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com