Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

256results about How to "Fully warmed up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

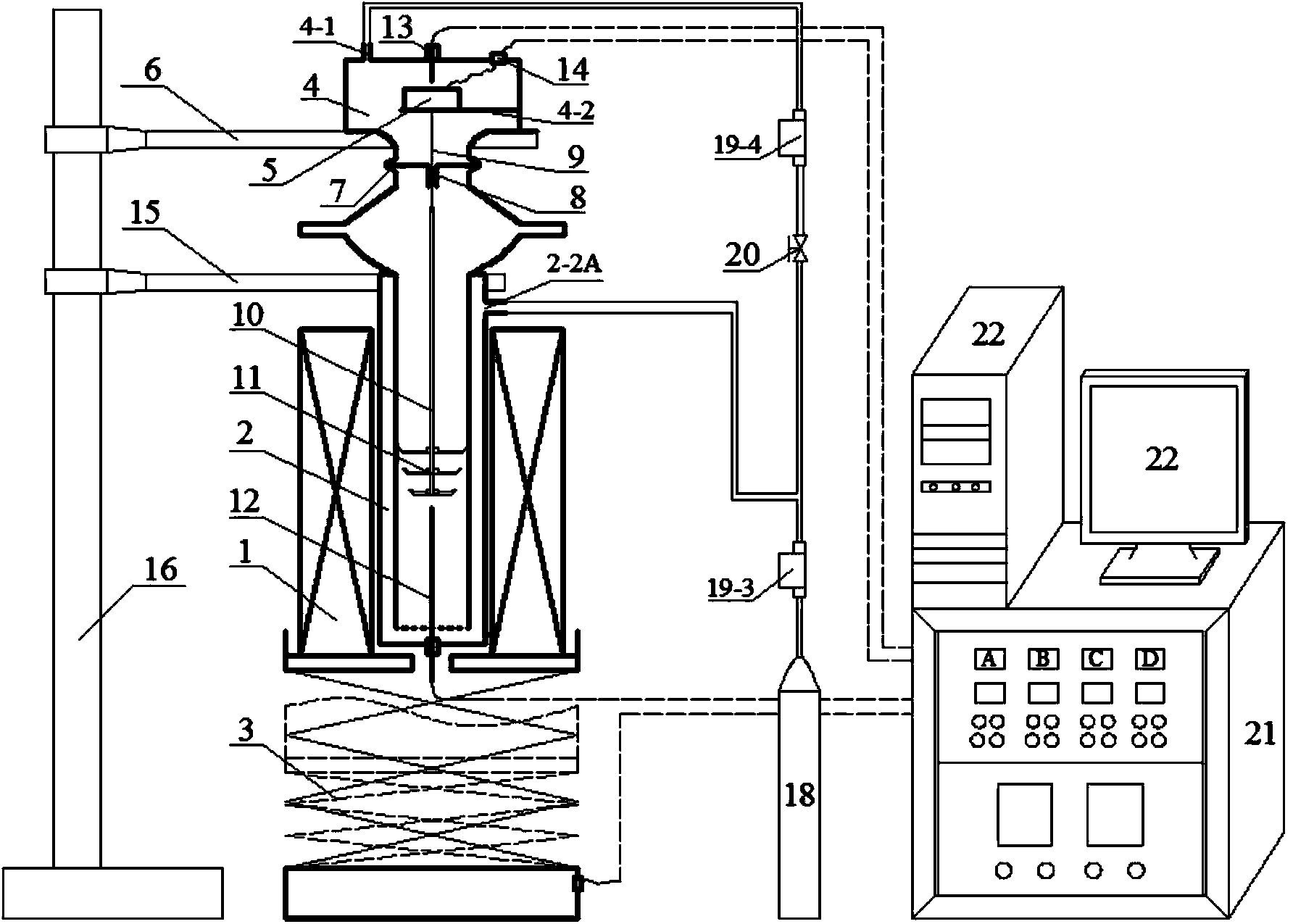

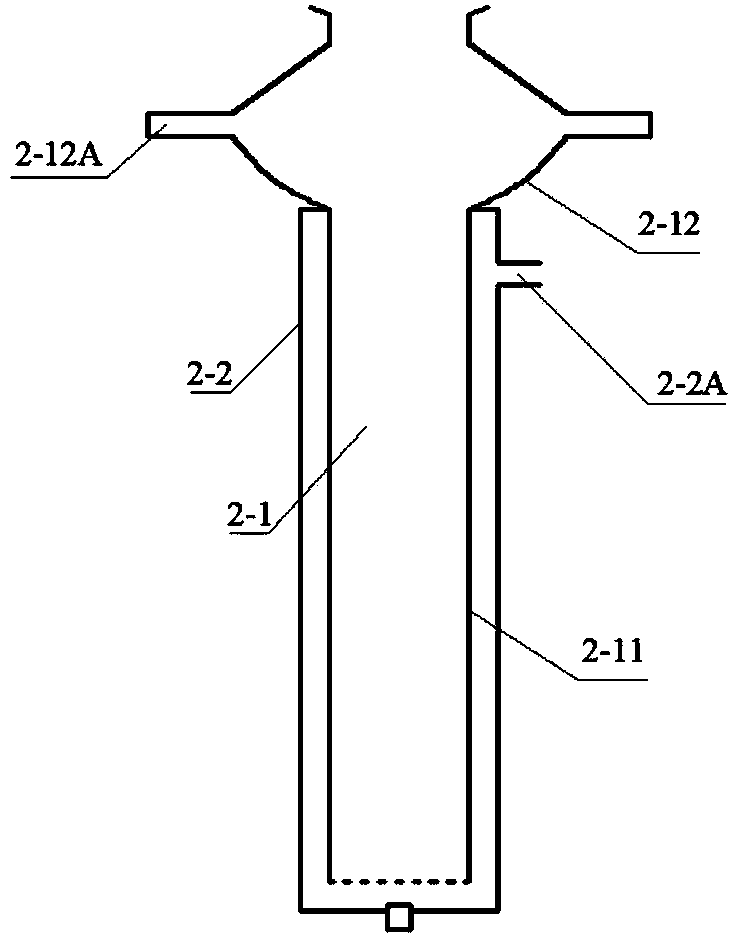

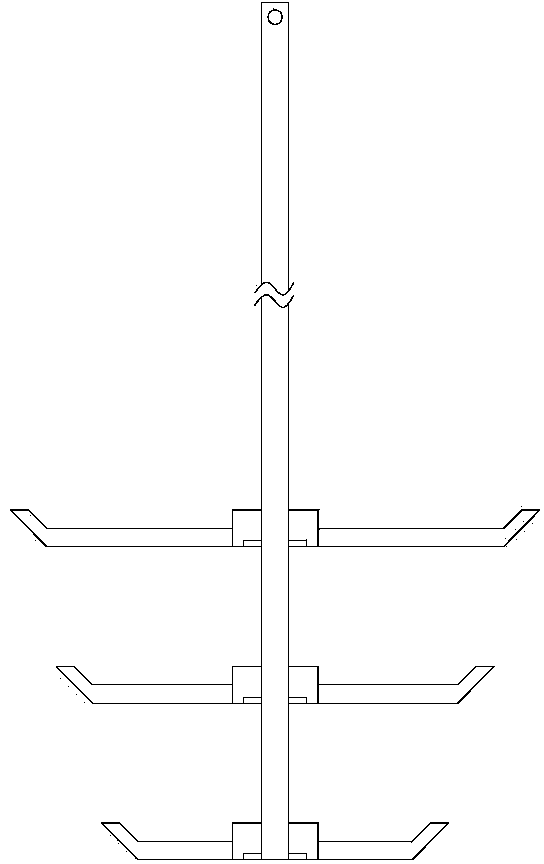

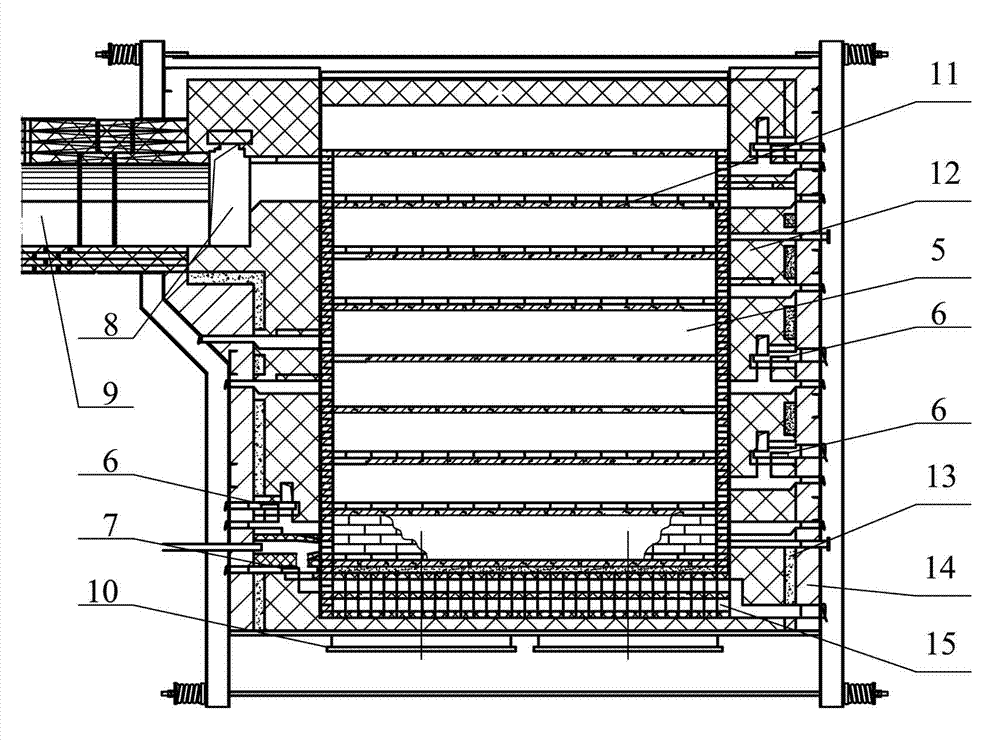

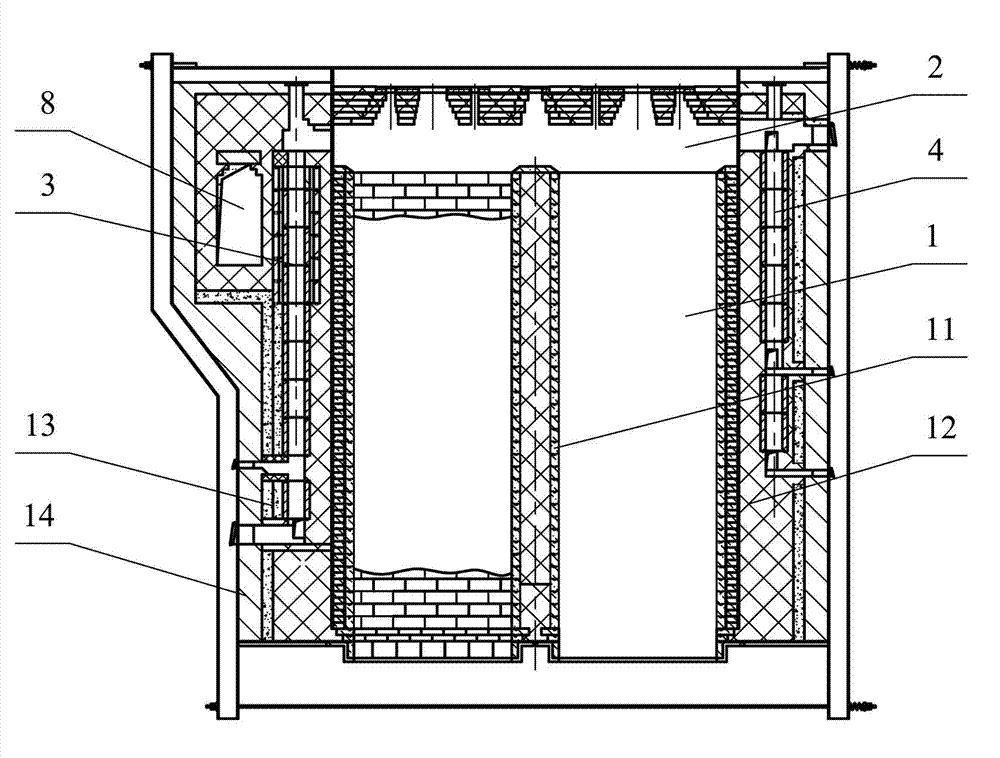

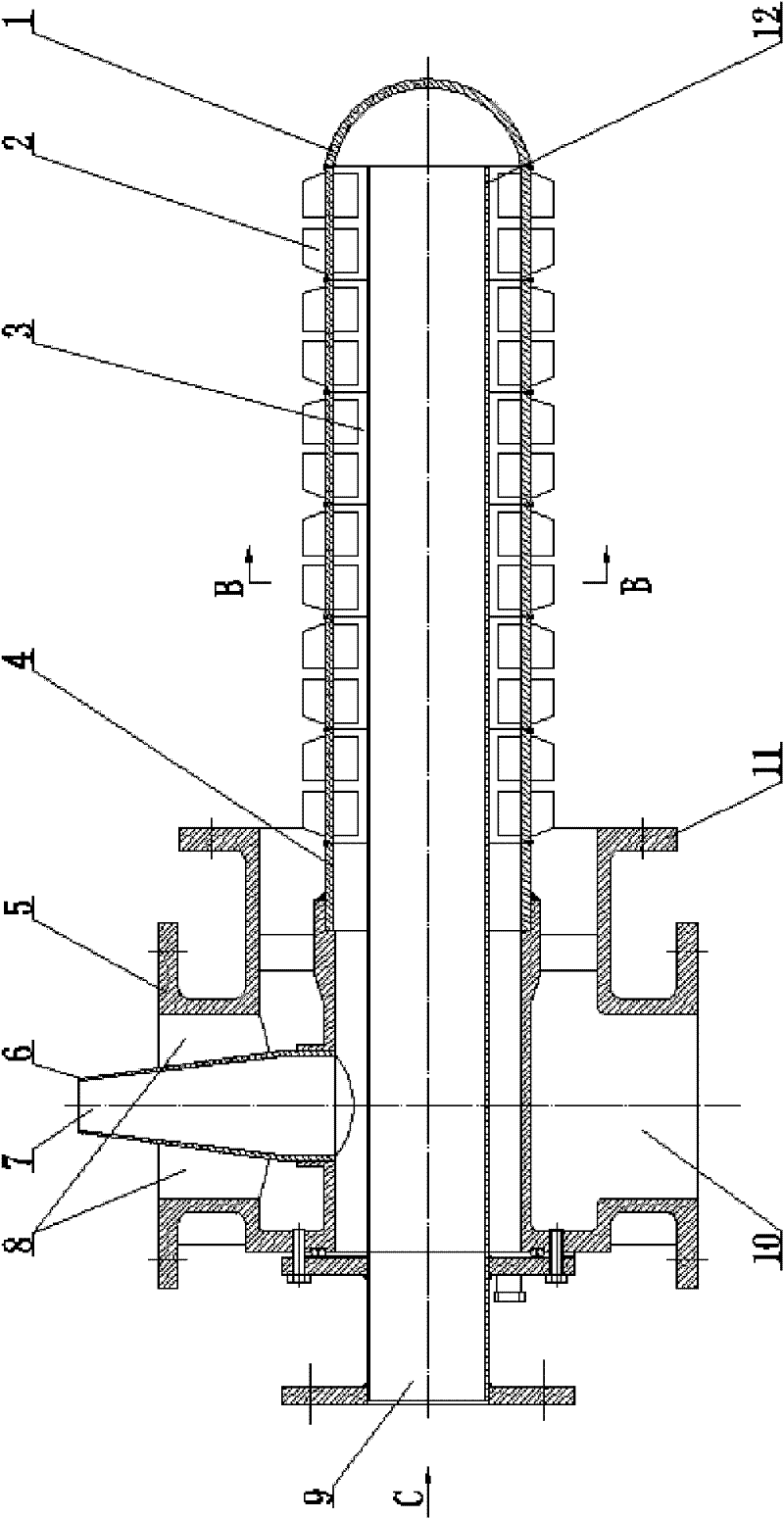

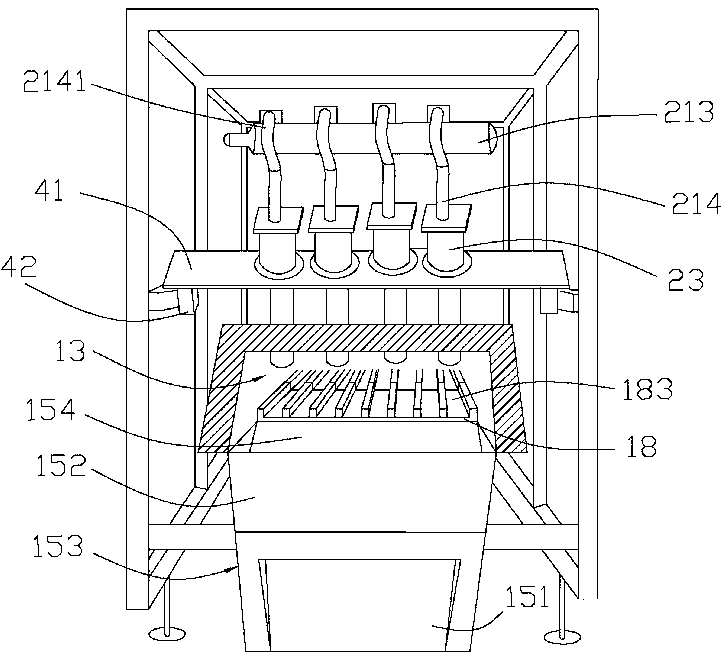

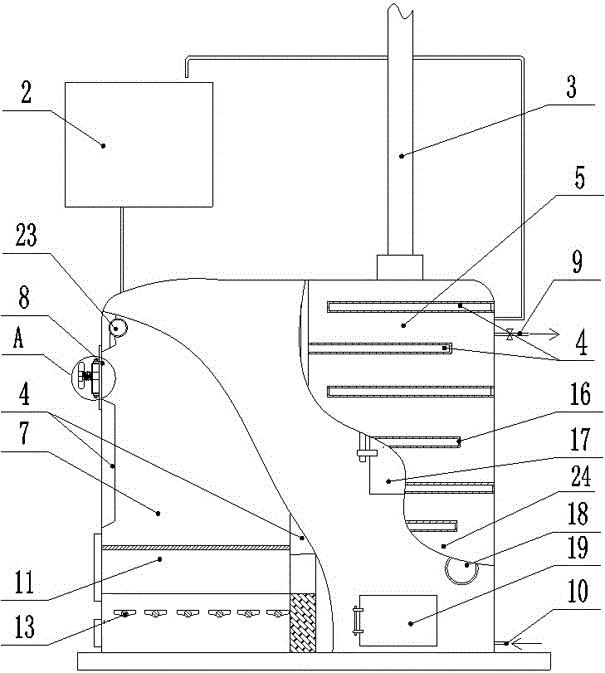

Thermal gravimetrical reactor applied to bulk specimen testing

The invention discloses a thermal gravimetrical reactor applied to bulk specimen testing, belonging to testing equipment for performing thermo gravimetric analysis on specimens and aiming to solve the problems that small-mass and small-sized specimens are required and a sample vessel is unbeneficial to gas-solid reactions in the conventional thermo gravimetric analyzer. Through a high-temperature reactor, reaction gas is preheated fully, so that mass measuring errors caused by temperature change of the reaction atmosphere are avoided; two types of hanging baskets are specific to different specimens respectively, so that the diffusion resistance during the reactions of bulk specimens is reduced effectively, and complete reactions and measuring accuracy are ensured; the height of an electric heating furnace is adjusted through a hydraulic lifting platform, so that samples can be heated at constant temperature under a high-accuracy condition. The thermal gravimetrical reactor can be used for dynamically measuring the mass changes of bulk specimens at various heating rates or under a constant-temperature condition, and is more consistent with the requirements of scientific research production than the conventional thermal gravimetrical analyzer.

Owner:HUAZHONG UNIV OF SCI & TECH

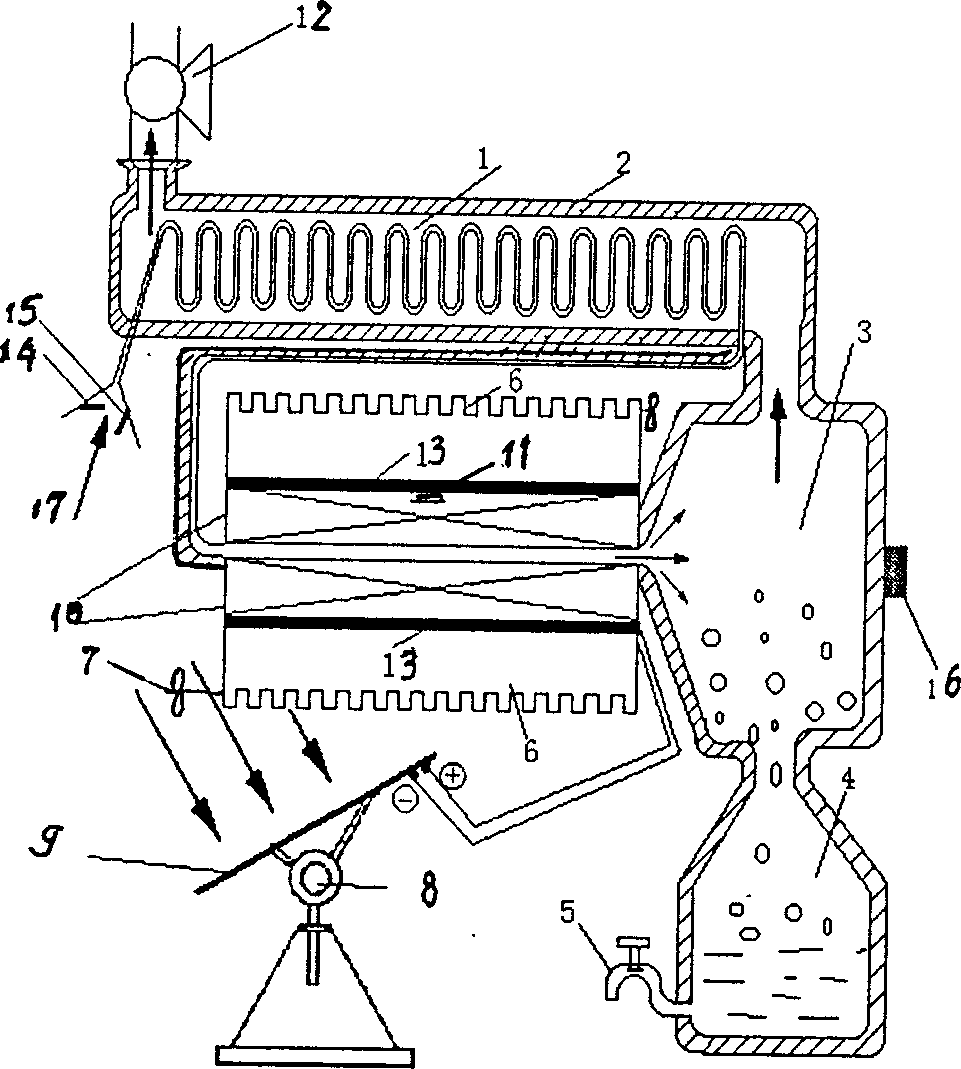

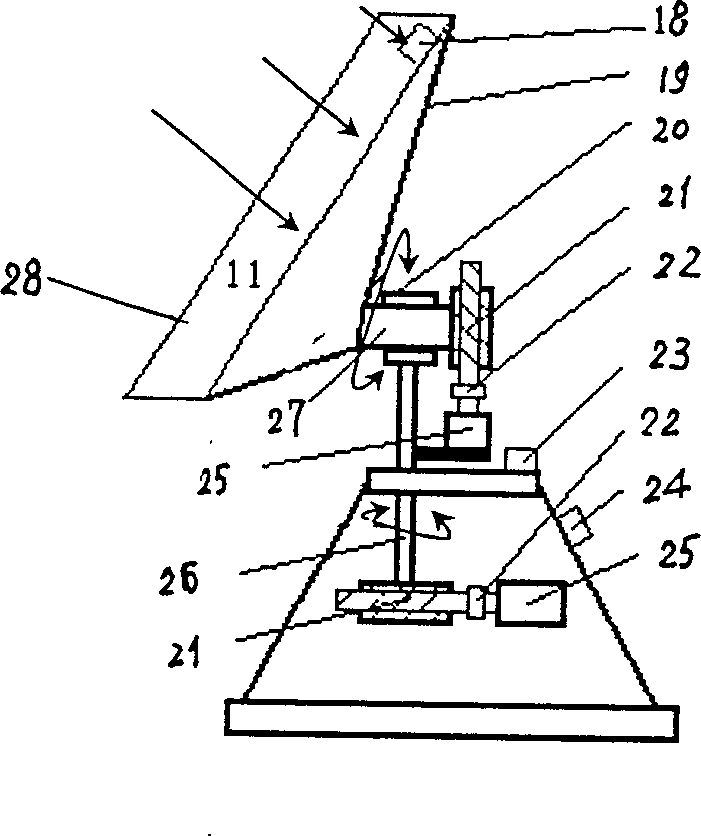

Water gaining apparatus of refrigerating and condensing air with semiconductor powered by solar energy

InactiveCN1485506ATo achieve the purpose of fetching waterImprove utilization efficiencySolar heat devicesMachines using electric/magnetic effectsMicrocontrollerInsulation layer

The invention relates to a water collecting apparatus through solar energy semi-conductor refrigeration moisture condensation method, which comprises a heat regenerator, a heat insulation layer, a water condensation chamber, a water collection device, a water discharge valve, a radiating fin, a draught fan, a two-dimensional turntable, a solar cell panel, a cold plate, a thermoelectric stock, a temperature and humidity transducer and a single chip system, wherein the battery plate is fixed on the turntable, a plate regenerator is arranged to increase the water collection ratio, the solar cellpanel is used for current supply for semi-conductor refrigeration, the natural air is driven by the draught fan to flow through the cold plate continuously, aqueous vapor in the air is condensed intowater drops, and flows into the water collector through the water condensing chamber, thus realizing refrigeration, cooling, condensation of moisture and water collection. The advantages of the invention are small volume, light weight, high water collection efficiency and convenience in carrying.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

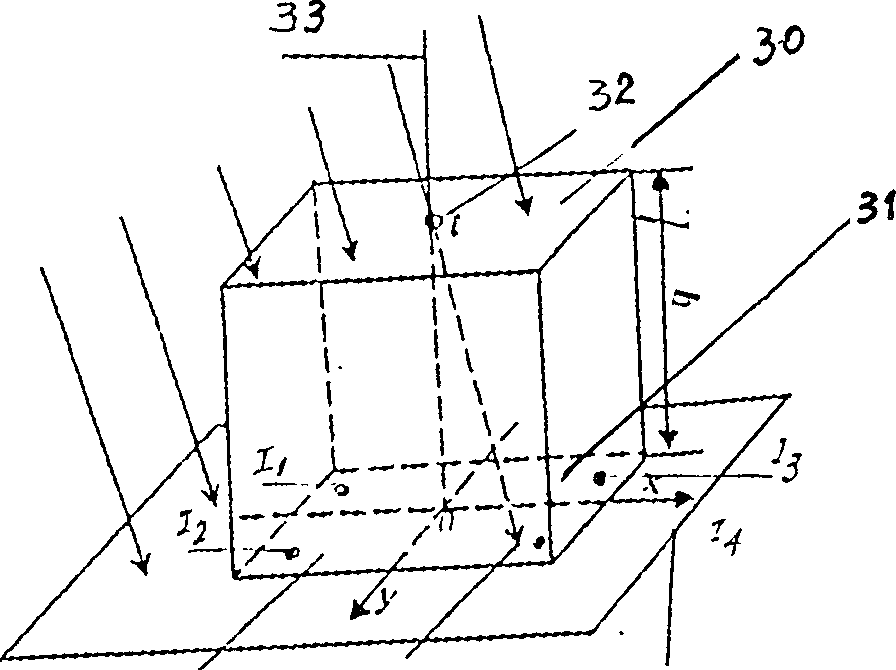

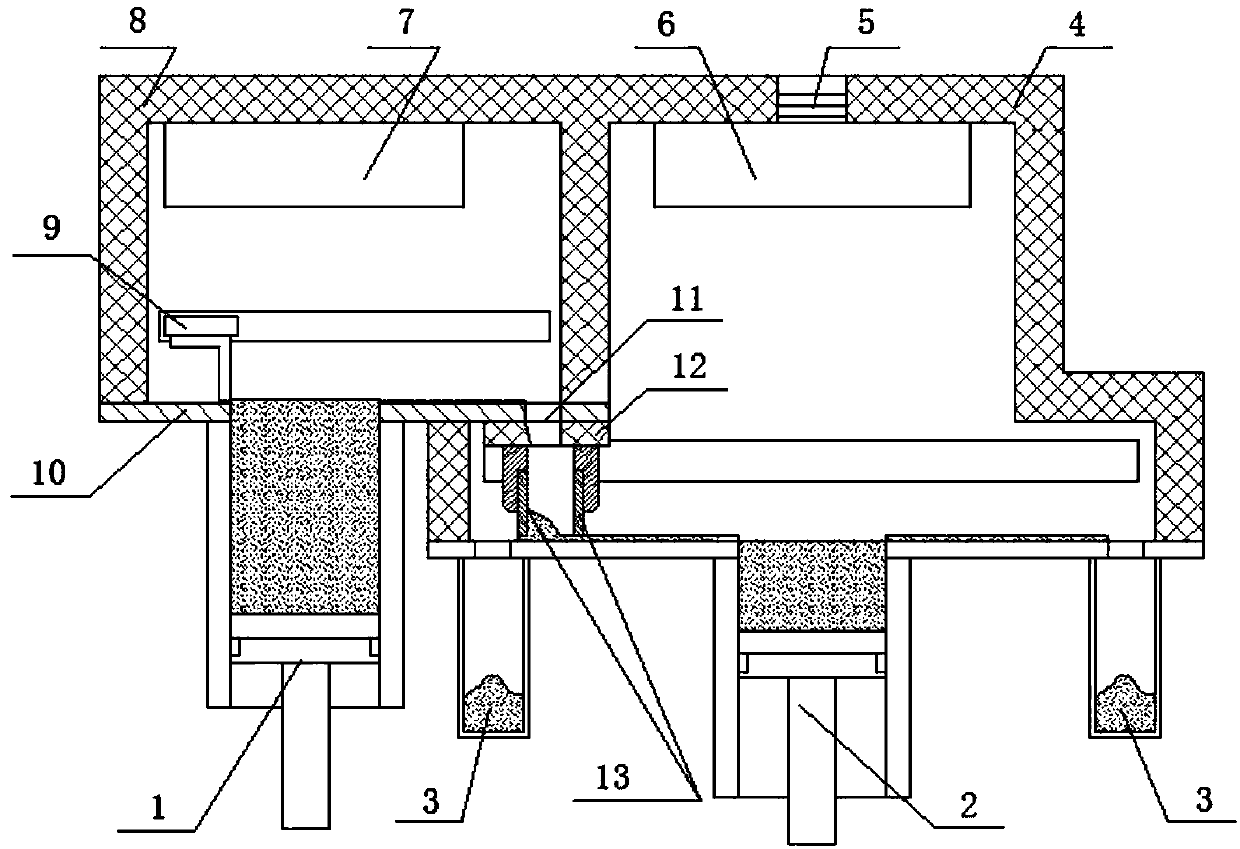

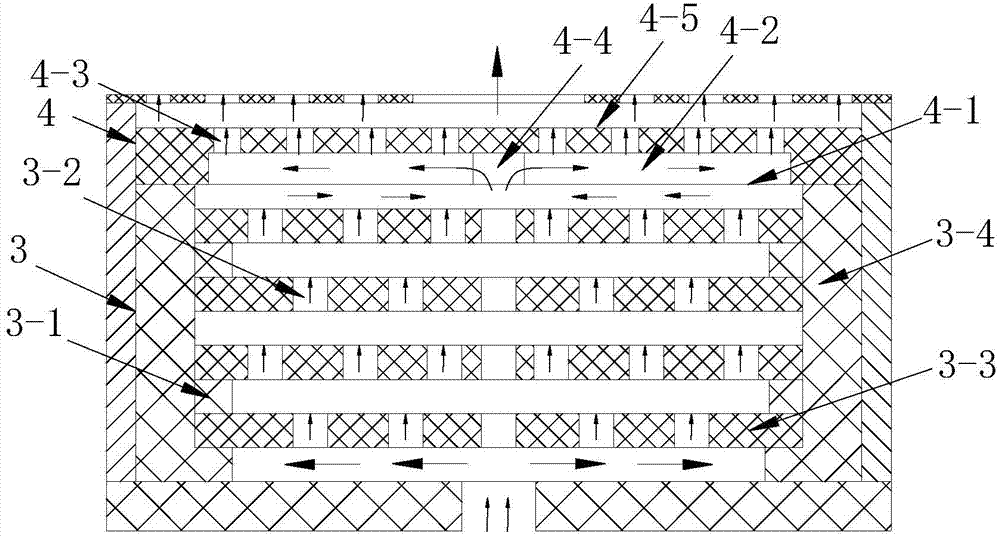

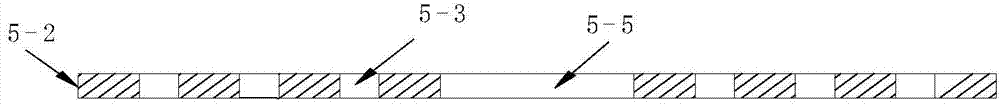

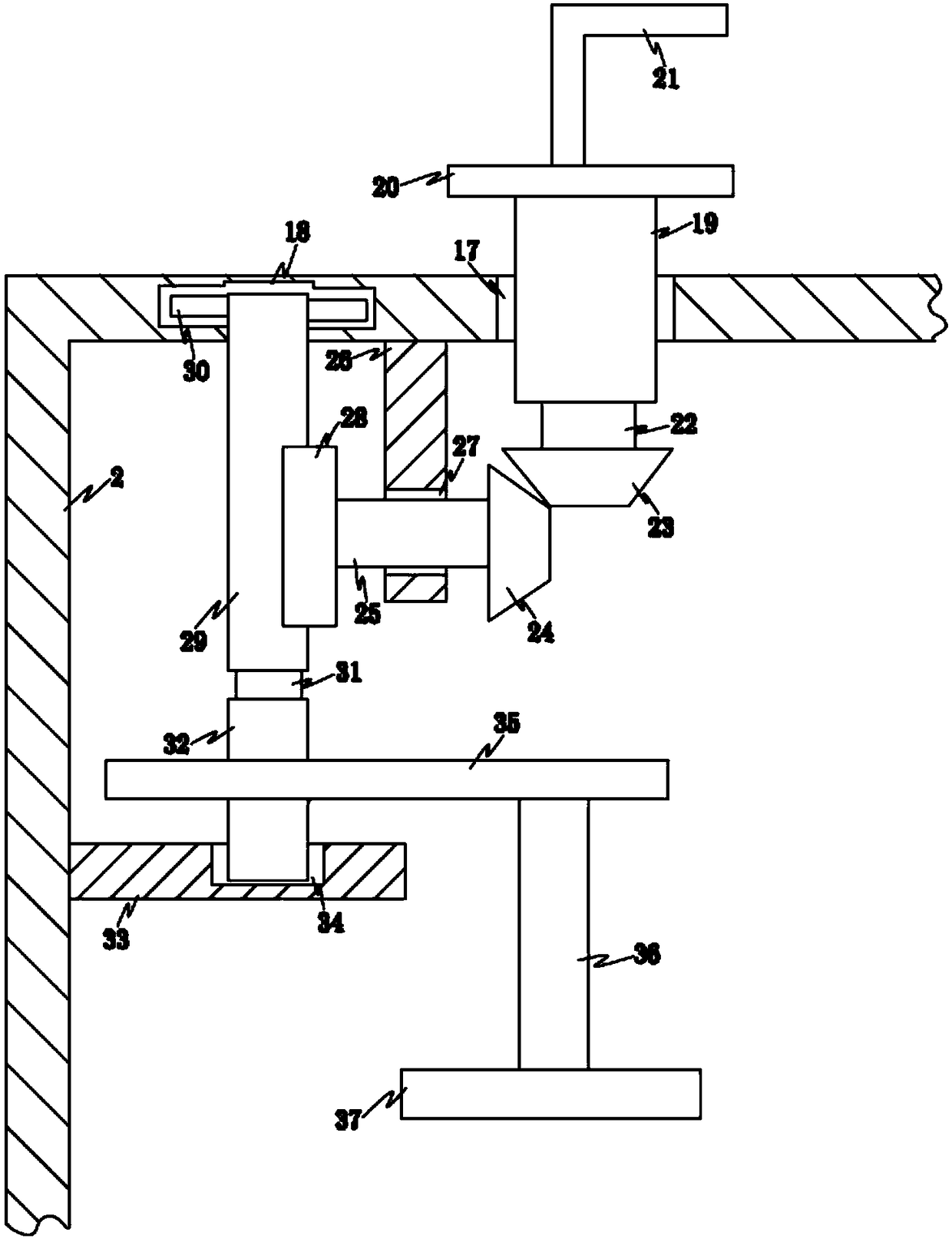

Novel rapid molding device and powder feeding and spreading method thereof

ActiveCN107745517AAccurate powder supplyGuaranteed smoothAdditive manufacturing apparatusIncreasing energy efficiencyRapid prototypingPiston

The invention discloses a novel rapid molding device and a powder feeding and spreading method thereof. The novel rapid molding device comprises a powder feeding cylinder, a molding cylinder, an overflow powder cylinder, a laser window, a powder feeding scraper plate and a bucket type double-scraper plate powder spreading mechanism, and also comprises a powder feeding cylinder heat preservation chamber, a powder feeding cylinder heater, a molding cylinder heat preservation chamber, a molding cylinder heater and a powder feeding cylinder working panel, the powder feeding scraper plate linearlymoves from the left to the right and pushes powder extruded through the lifting of the piston of the powder feeding cylinder to a powder falling opening at the right end of the powder feeding cylinderheat preservation chamber, the powder freely falls into two bucket scraper plates from top to bottom, and the bucket scraper plates horizontally move from the left to the right to push the powder tothe molding cylinder, spread the powder on the molding cylinder and send superfluous powder outside the two bucket scraper plates into the overflow powder cylinder in order to complete one-time powderspreading. The novel rapid molding device and the powder feeding and spreading method thereof have the advantages of effective improvement of the powder feeding and spreading manner, improvement of the powder spreading quality, reduction of material wastes, and improvement of the 3D printing quality and the printing efficiency.

Owner:武汉华科三维科技有限公司

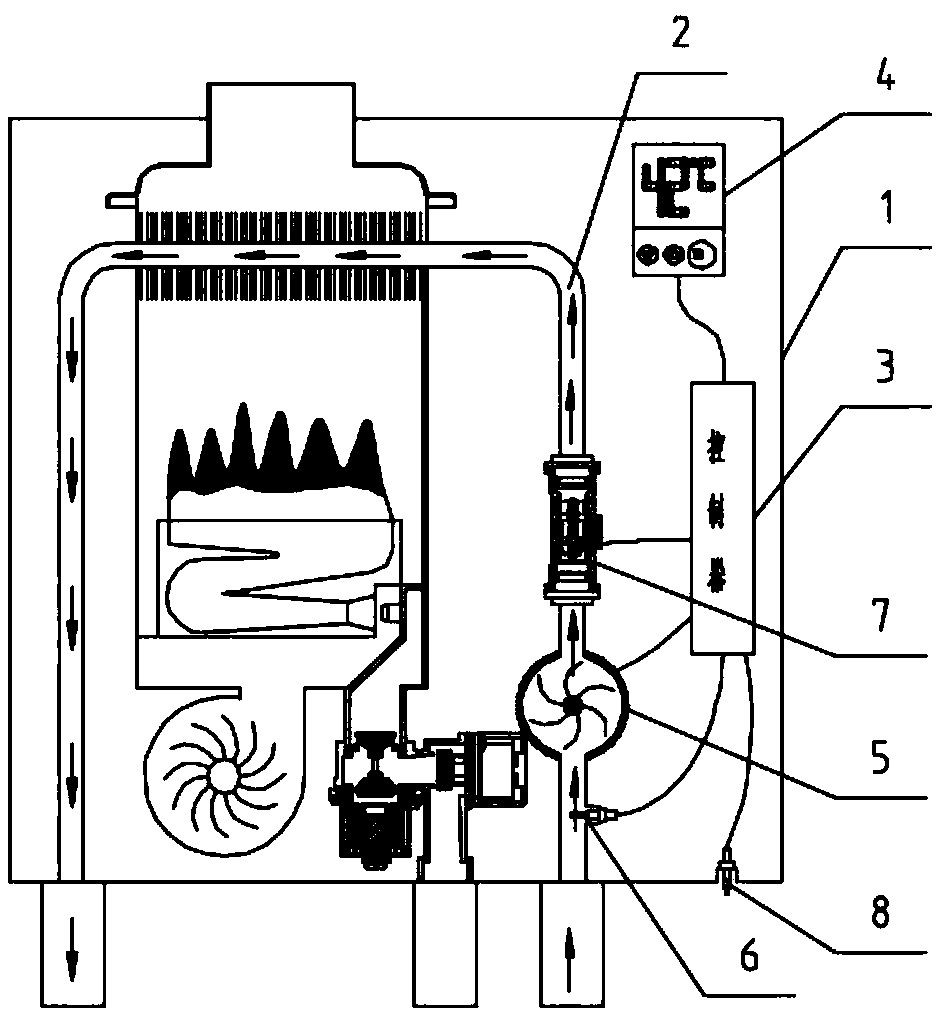

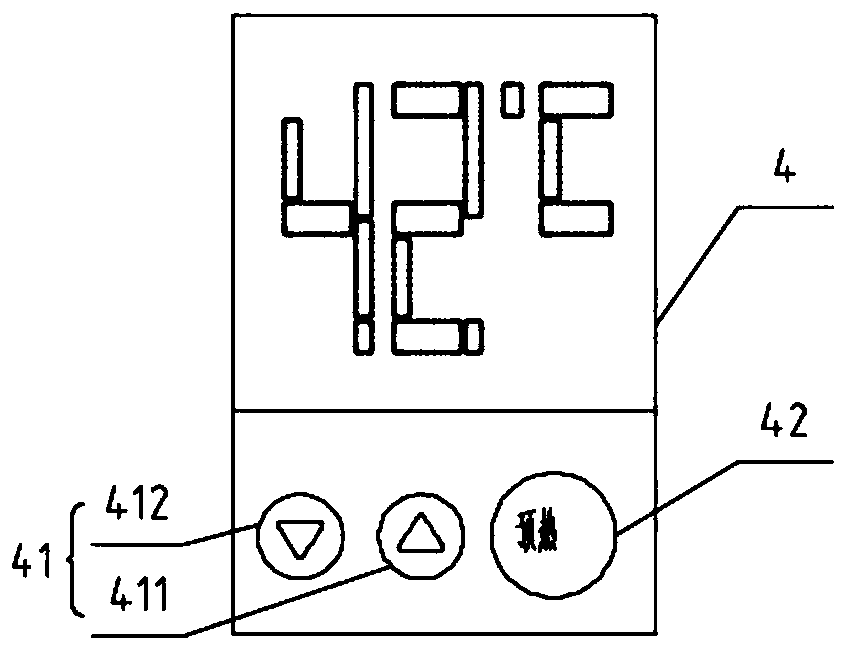

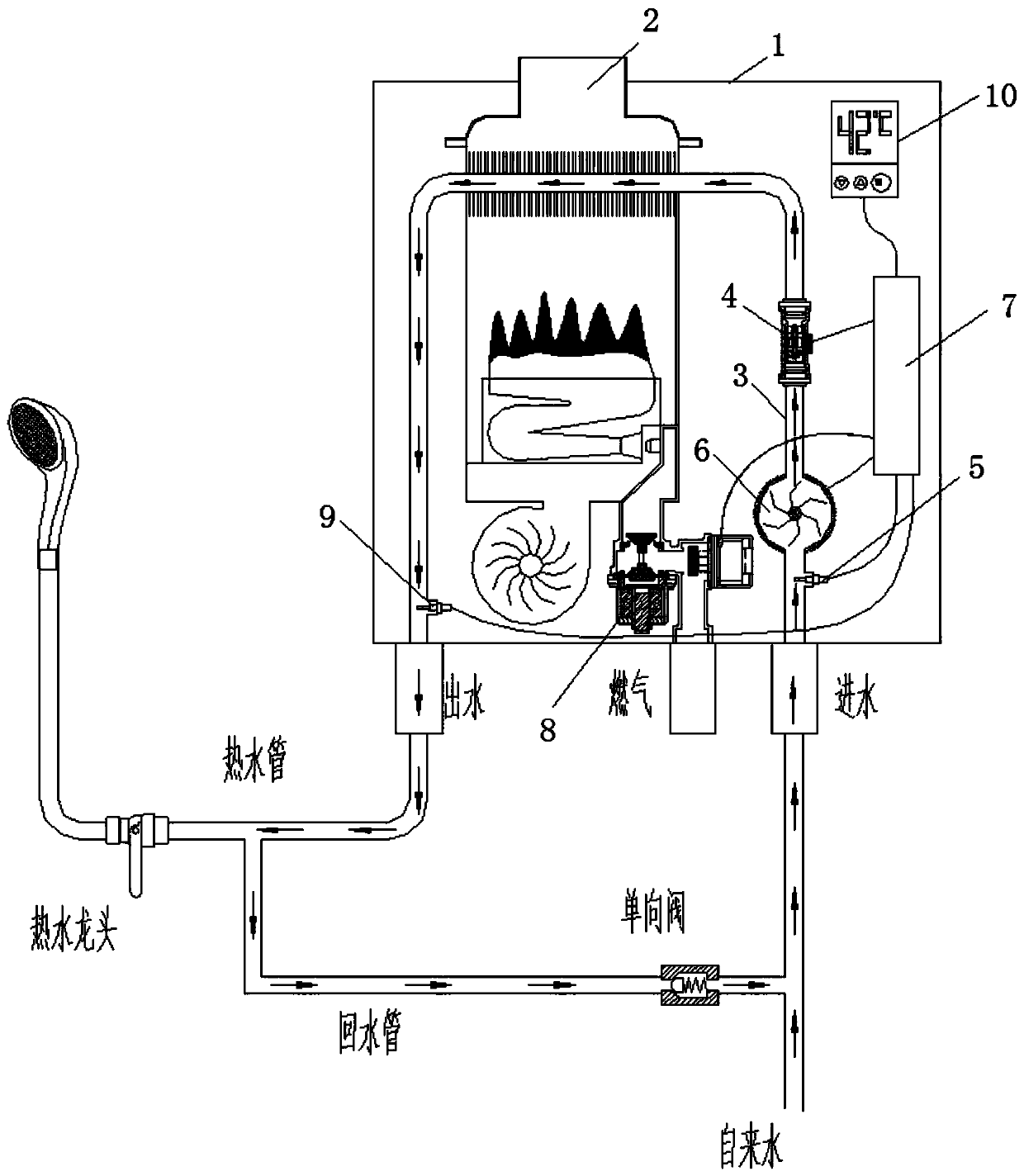

Gas water heater and control method

The invention discloses a gas water heater comprising a water heater body, a water inlet pipe and a controller. The water inlet pipe is arranged in the water heater body, an operating device electrically connected with the controller is further included, the operating device is provided with a temperature setting button and a pre-heating function key, and the controller is used for automatically matching a preheating temperature difference according to the preset temperature when the pre-heating function key is started. Meanwhile, a control method for using the gas water heater is also disclosed. The invention has the following advantages that the preheating temperature difference can be automatically matched according to the preset temperature, so that the water heater can automatically adapt to different use occasions, and the intelligent degree is high; the gas water heater can automatically adjust the heat temperature difference according to the circulating water flow rate and / or the ambient temperature, and the self-adaptive ability of the water heater is further improved; and the advantages that circulating water is fully preheated in summer, and the preheating time of the circulating water is shortened and energy consumption is low in winter are achieved, and the user experience is increased.

Owner:VATTI CORP LTD

Countercurrent-tank-type calcining furnace

ActiveCN103086348AHeating law is obviousIncrease production capacityEnergy inputCrucible furnacesEngineeringWater jacket

The invention relates to a countercurrent-tank-type calcining furnace comprising material tanks, fire paths provided on two sides of the material tanks, a front wall, and a back wall. A volatile content centralization channel is arranged above the material tanks. A front wall volatile content vertical channel is arranged in the front wall. A back wall volatile content vertical channel is arranged in the back wall. The front wall volatile content vertical channel communicates the volatile content centralization channel and bottom-layer fire paths. Volatile content drawing boards are arranged at the inlet ports of the bottom-layer fire paths. The back wall volatile content vertical channel communicates the volatile content centralization channel and last-but-two-layer fire paths and middle-part fire paths. Volatile content drawing boards are arranged at inlet ports of the last-but-two-layer fire paths and the middle-part fire paths. A preheated air channel is arranged below the bottom-layer fire paths. A preheated air drawing board is arranged at the inlet port of the preheated air channel. The preheated air channel and the bottom-layer fire paths are communicated at the front wall. First-layer fire paths are communicated with a flue. A cooling water jacket is arranged below the material tanks. With the furnace provided by the invention, maximal calcining temperature can be increased, such that product quality can be improved.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

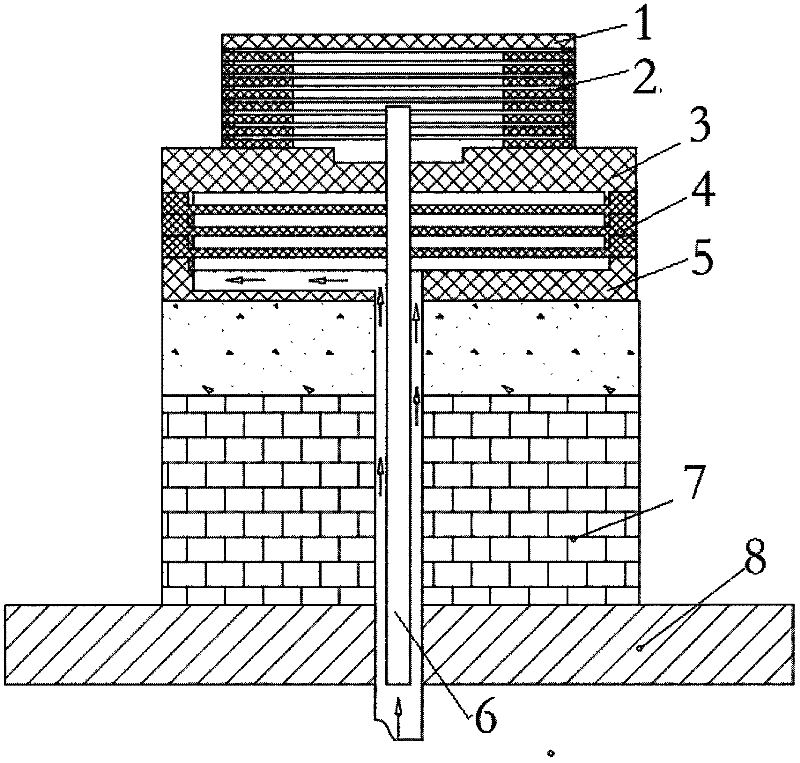

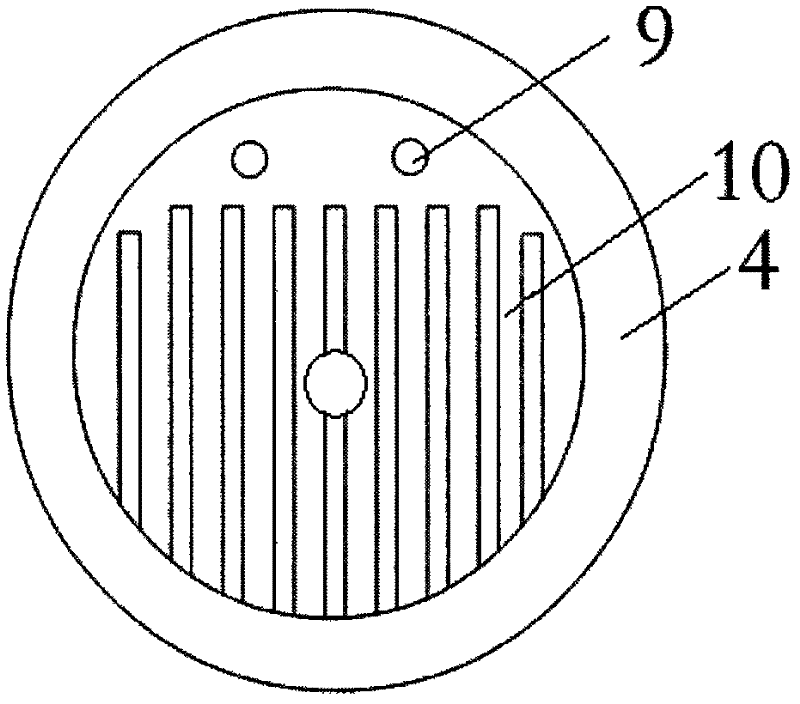

Preheating device for chemical vapor deposition furnace

ActiveCN102363878ASimple processExtend heating timeChemical vapor deposition coatingEngineeringChemical vapor deposition

The invention discloses a preheating device for a chemical vapor deposition furnace. Air flow plates which are arranged in parallel so as to increase air processes and prolong heating time, and beams are arranged simultaneously so as to improve heat radiation capacity; therefore, the aims of fully and uniformly preheating organic air can be fulfilled. An outlet is provided with disturbance holes which are positioned on the same circumference; and a certain included angle is formed between the axial direction of the disturbance holes and a horizontal plane; after preheated air enters the disturbance holes, the preheated air is forced to be sprayed along the axial direction of the disturbance holes to form strong rotation air flow under the collision action of disturbance walls, and organic air which is decomposed in advance forms macromolecules under the actions of centrifugal force and polymerization along with the rising of the rotation air flow; and the macromolecules preferentially enter the bottom of a stock column under the double actions of inertia force and centrifugal force, so axial back mixing probability is reduced, the macromolecules are diffused and deposited in a prefabrication body to achieve the effect of densifying the bottom, the air which is not decomposed rises continuously to ensure that top pressure and air pressure are reduced, and finally the aims of densifying the whole carbon disc stock column can be fulfilled.

Owner:XIAN AVIATION BRAKE TECH

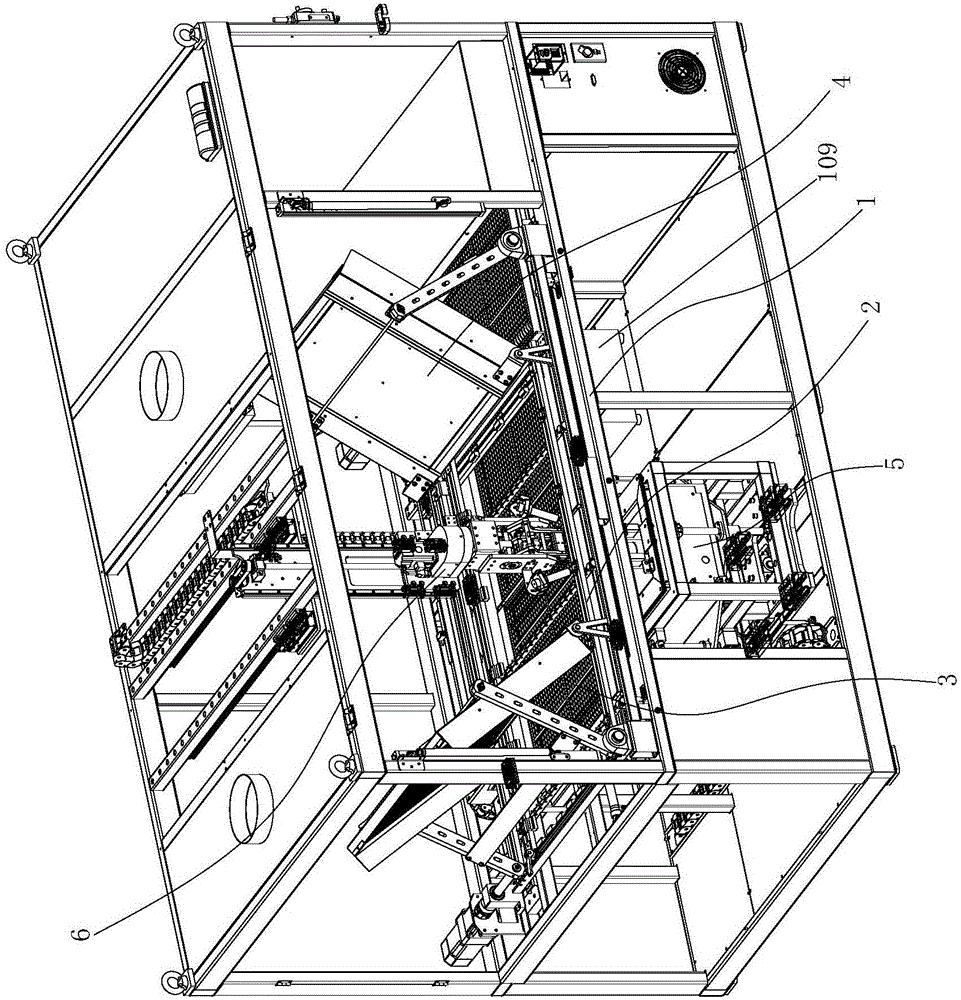

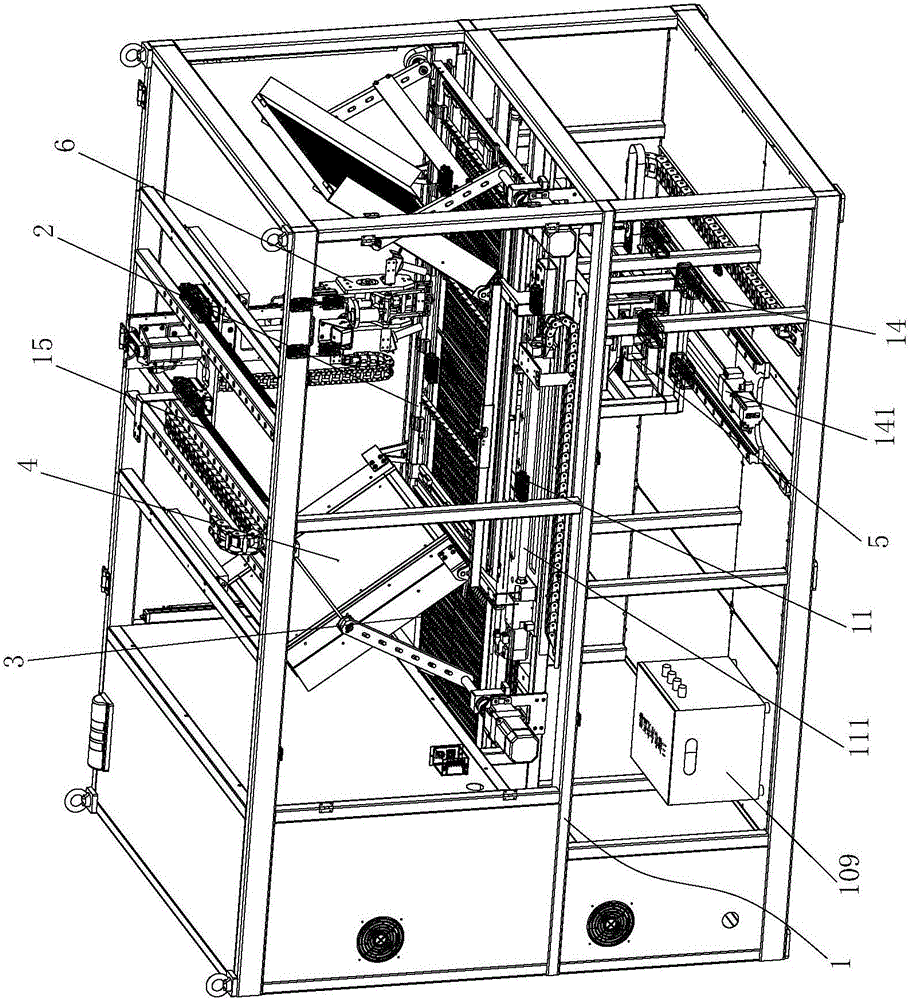

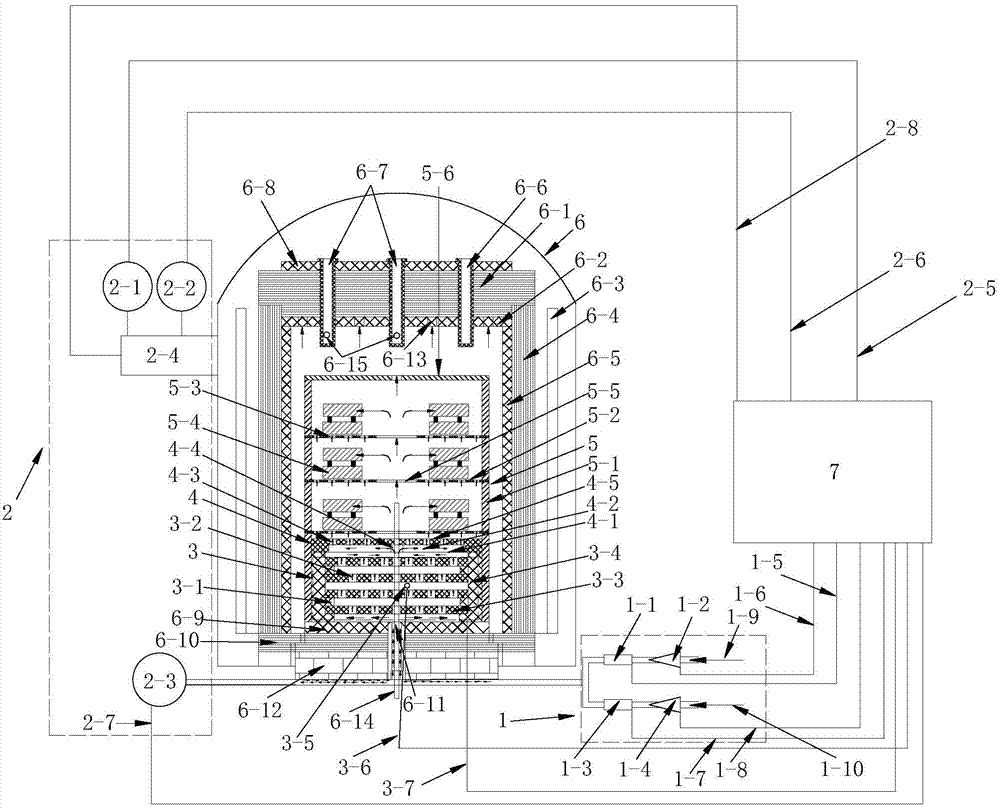

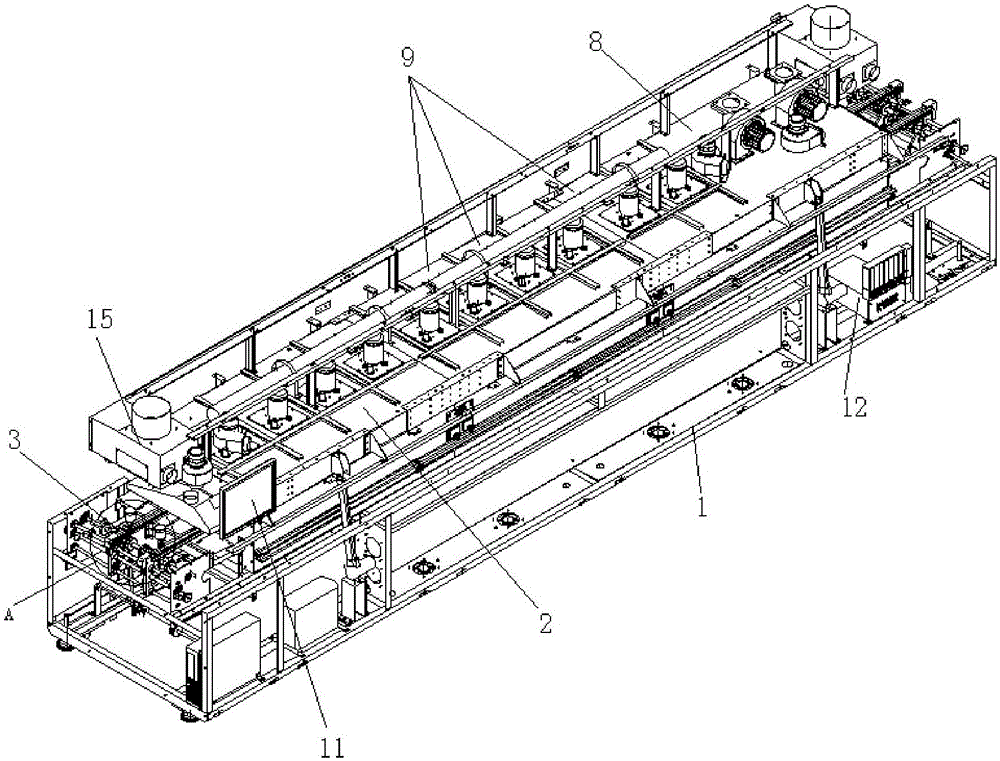

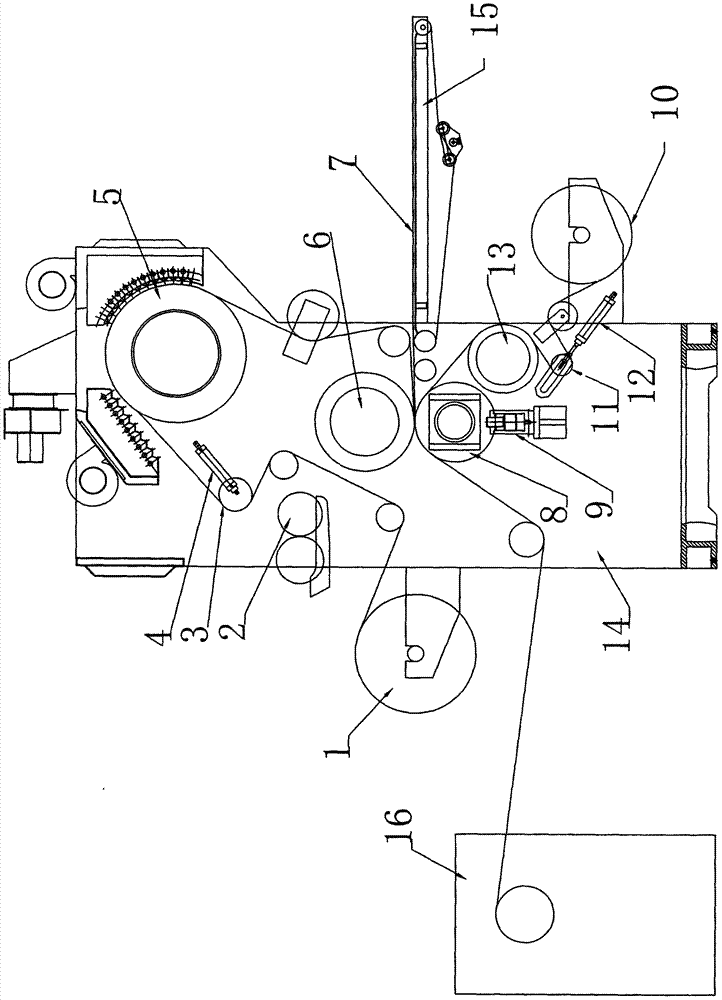

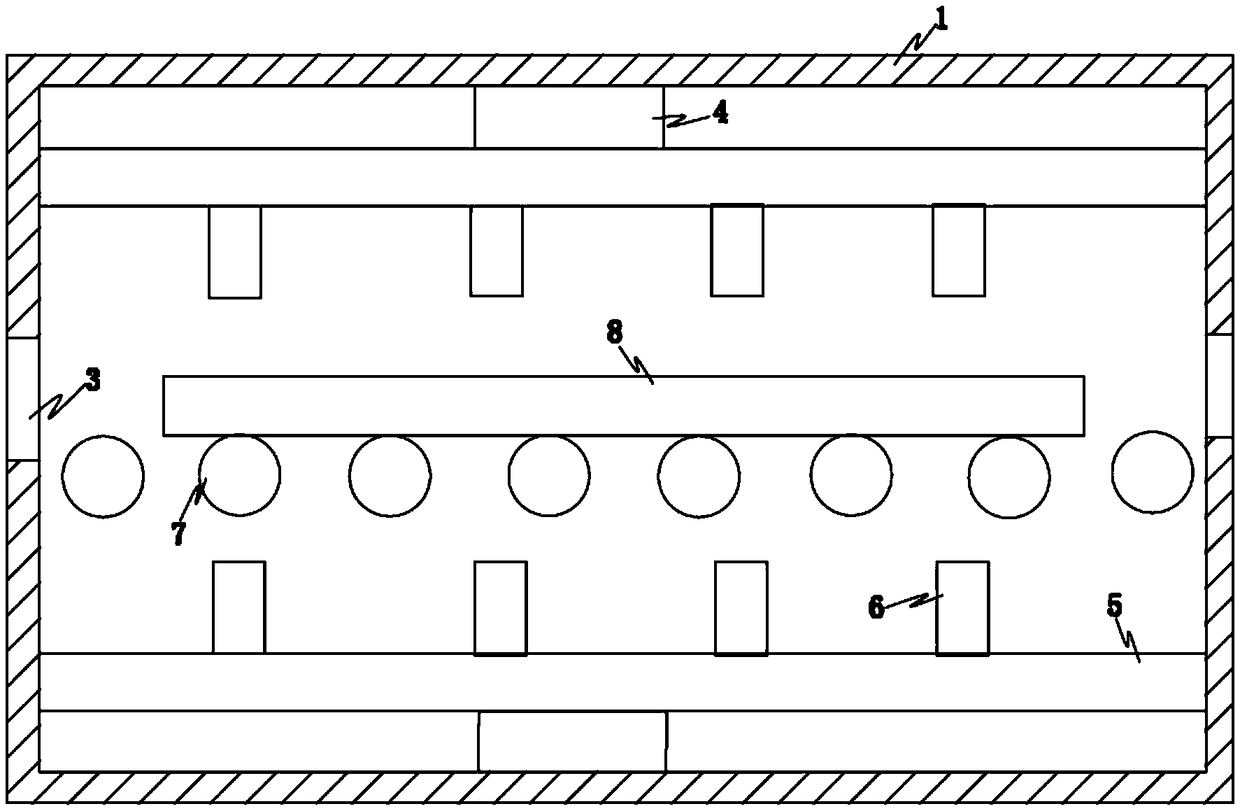

Improved automatic repair machine for PCBA through hole direct insertion device

PendingCN106793546AFully warmed upWarm up evenlyPrinted circuits repair/correctingEngineeringHeat losses

The invention relates to an improved automatic repair machine for a PCBA through hole direct insertion device. The automatic repair machine is provided with a main rack, and a PCBA fixing fixture is installed in the middle of the main rack; two lower heating assemblies and lower heating assembly driving cylinders are installed below the PCBA fixing fixture; two upper heating assemblies are erected above the PCBA fixing fixture, each connected with a swing frame and driven by a first y-direction servo motor; a flow jet tin furnace assembly is installed below the PCBA fixing fixture, and a manipulator device is installed in the area above the PCBA fixing fixture. According to the automatic repair machine, a preheating device of the repair machine is formed by the two movable lower heating assemblies and the two movable upper heating assemblies to fully and uniformly preheat a PCBA, a preheating area and disassembling, soldering and workpiece taking and inserting areas are located at the same position, therefore, a circuit board does not need to leave from the preheating area during working, heat losses are reduced, energy is saved, the tin immersion time is shortened, and the repair quality is improved; automatic workpiece extraction operation is conducted through the manipulator device, and therefore the workpiece insertion operation precision is improved.

Owner:东莞市崴泰电子有限公司

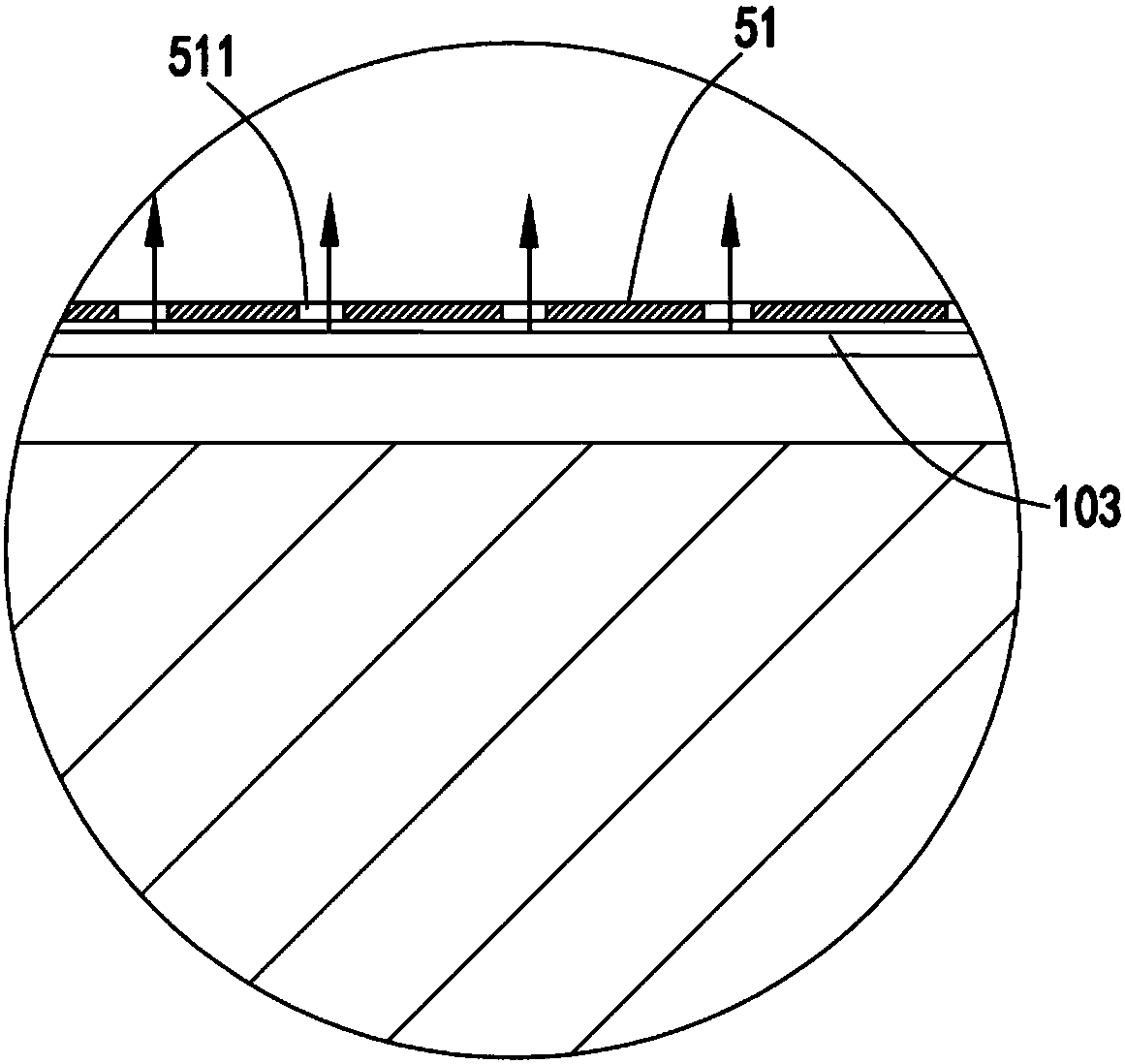

Carbon/carbon composite component chemical vapor infiltration device

ActiveCN104498891AWell mixedIncrease profitChemical vapor deposition coatingPressure controllerCarbon composites

The invention brings forward a carbon / carbon composite component chemical vapor infiltration device and aims to provide a device for solving problems of low reactant gas utilization rate and low infiltration efficiency existing by chemical vapor infiltration in the prior art. The invention is realized by the following technical scheme: a gas mixing and preheating device for primary control of reactant gas diversion direction and a temperature sensor for monitoring preheating temperature of reactant gas are arranged below a deep gas-mixing and outgassing device connected with a sealed infiltration chamber; the regulated and controlled reactant gas enters a gas mixing and preheating device from the bottom of a chemical vapor deposition furnace body through a gas supply device, and a controller automatically regulates electric power on a heater to obtain required preheating temperature; and the preheated reactant gas enters the sealed infiltration chamber and passes through a porous graphite liner plate to infiltrate through a composite preform placed inside the sealed infiltration chamber, and chemical vapor infiltration is performed under constant values by pressure control of a furnace pressure controller and temperature control of a temperature control sensor.

Owner:PLA NO 5719 FACTORY

Air injecting and backflow flue gas entraining heat exchanger for radiant tube combustion device

InactiveCN102418936AGuaranteed validityIncrease the heat exchange areaCombustion processIndirect carbon-dioxide mitigationPollutantFlue gas

The invention relates to the technology of a heat exchanger, in particular to an air injecting and backflow flue gas entraining heat exchanger for a radiant tube combustion device. The heat exchanger comprises a heat exchanger shell with a four-way structure, wherein the heat exchanger shell is connected with an inner core tube, a heat exchange tube and a high-temperature air injection tube; the high-temperature air injection tube has a conical reducing tube structure and is used for forming an air injection channel; the air injection nozzle end of the heat exchanger shell is connected with a main combustion nozzle through a corrugated pipe; and the flue gas inlet end of the heat exchanger shell is communicated with a radiant tube. In the heat exchanger, a conical reducing air injection pipe is added, negative pressure zone entrainment flue gas is formed, and the flue gas is mixed with preheated air; on the basis of effective heat exchange of the heat exchange tube, the preheating temperature of air is increased effectively; after the flue gas is mixed with the air, the oxygen concentration in a combustion zone is reduced, the generation amount of NOx is reduced, and the discharge amount of pollutants is reduced; fin structures arranged on the outer and inner sides in a staggered way increase a heat exchange area, and the turbulence scale of the flue gas and the air, improve a heat exchange effect, and utilize the flue gas afterheat efficiently; and the components are easy to assemble and disassemble.

Owner:WISDRI WUHAN WIS IND FURNACE

Through hole reflow soldering device and control method thereof

InactiveCN105772886AReduce energy consumptionEnergy savingPrinted circuitsMetal working apparatusReflow solderingEngineering

The invention discloses a through hole reflow soldering device. The through hole reflow soldering device comprises a reflow soldering machine platform. A soldering machine platform cover which can be opened and closed is arranged at the back edge of the upper plane of the reflow soldering machine platform. The upper plane of the reflow soldering machine platform is provided with a product conveying line adjustable in width. The reflow soldering machine platform is internally provided with first lower furnace pipes and second lower furnace pipes from left to right in sequence. A first warm area upper furnace pipe used for air draft is arranged in the position, corresponding to each first lower furnace pipe, of the interior of the soldering machine platform cover. A second warm area upper furnace pipe blowing cold air downwards is arranged in the position, corresponding to each second lower furnace pipe, of the interior of the soldering machine platform cover. Each first warm area upper furnace pipe and the corresponding first lower furnace pipe form a first warm area. Each second warm area upper furnace pipe and the corresponding second lower furnace pipe form a second warm area. Air blocking curtains which are used for separating the cold air from hot air and can be stretched or shortened are arranged in the positions, located between the first warm areas and the second warm areas, of the product conveying line. The reflow soldering machine platform is provided with a man-machine control interface and further provided with a cooling area. The through hole reflow soldering device is suitable for soldering of through holes of PCBs, the soldering temperature is convenient to control, and the soldering effect is better.

Owner:东莞市创威自动化科技有限公司

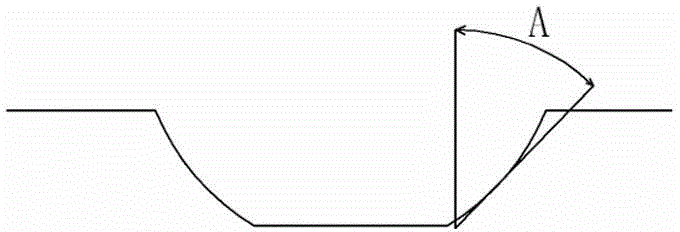

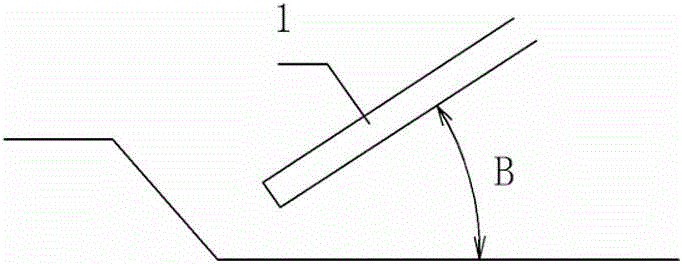

Repair method for transversal cracks of welding seams of thick-wall submerged arc welded pipe

InactiveCN102744553AAppropriate method of operationReal insulationArc welding apparatusStructural engineeringThick wall

The invention discloses a repair method for the transversal cracks of the welding seams of a thick-wall submerged arc welded pipe, comprising the following steps of: confirming defects, preheating before gouging, performing air gouging, grinding, performing MT (magnetic particle test), eliminating the residual liquids of PT (penetration flaw test), preheating before welding, welding, eliminating hydrogen after welding, and performing NDT (nondestructive test). By virtue of the repair method disclosed by the invention, the defects of the cracks in the welding seams or base metal can be completely removed after the lengths and positions of the defects of the cracks are determined. According to the invention, the preheating is performed in the initial stage of the air gouging, the operation method of the air gouging is proper, the range of the air gouging is 50 mm at the both ends of each crack, the both ends of each gouged groove are smoothly and flatly transited, and the included angle A between the transition surface and a vertical line is at least greater than 45 degrees, so that crater cracks are not easy to occur during the arc striking or arc stopping of the welding. In the repair method disclosed by the invention, thorough removal for the cracks is confirmed by virtue of magnetic particles, the preheating is adequately performed before the welding, the welding is rapidly performed in strict accordance with a small current, and heat input and welding bead widths are strictly controlled; a welding rod barrel is electrified, so that welding rods in the welding rod barrel can be really insulated, and a heat-insulating and slow-cooling measure is adopted after the welding is finished.

Owner:上海中油天宝巴圣钢管有限公司

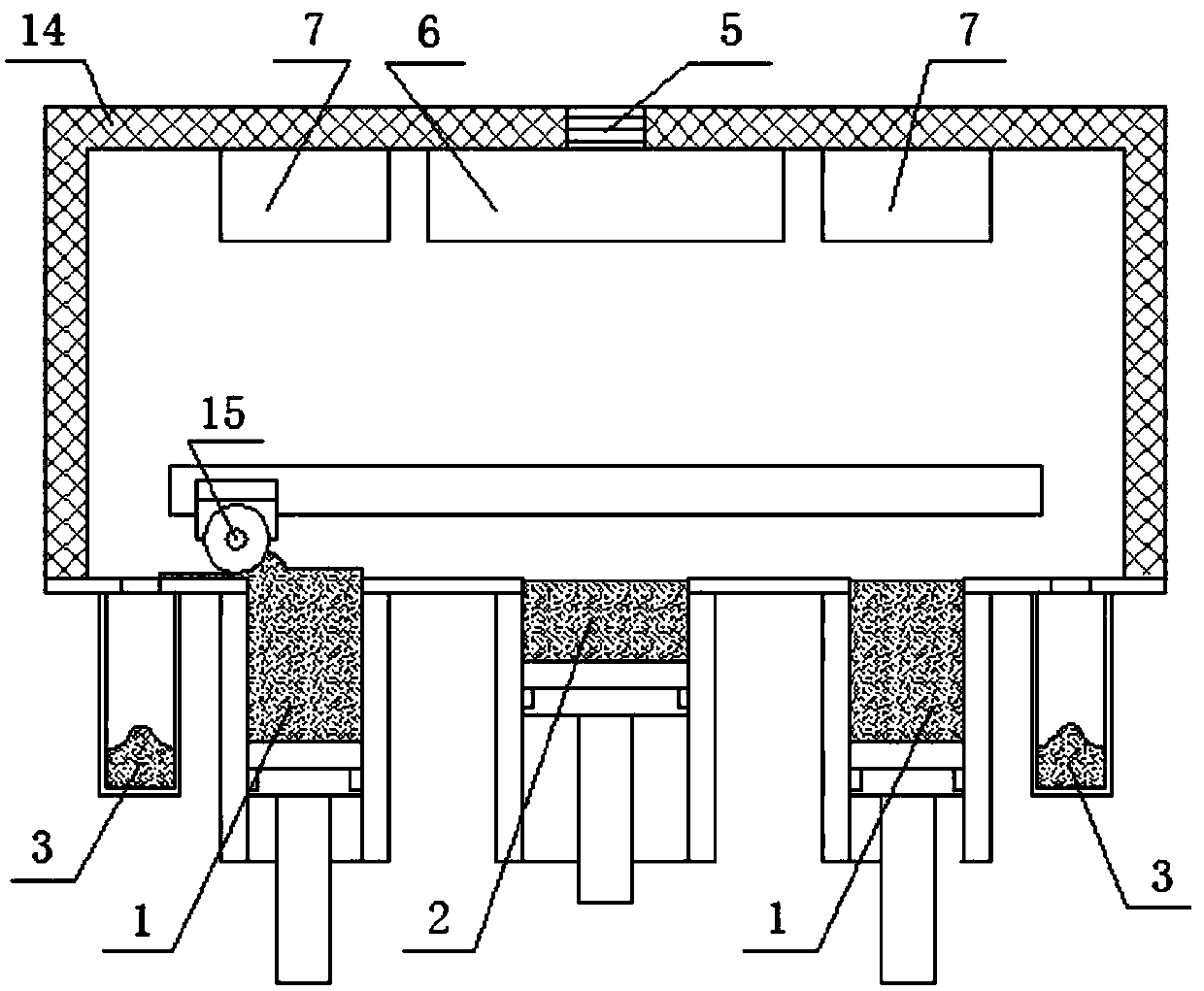

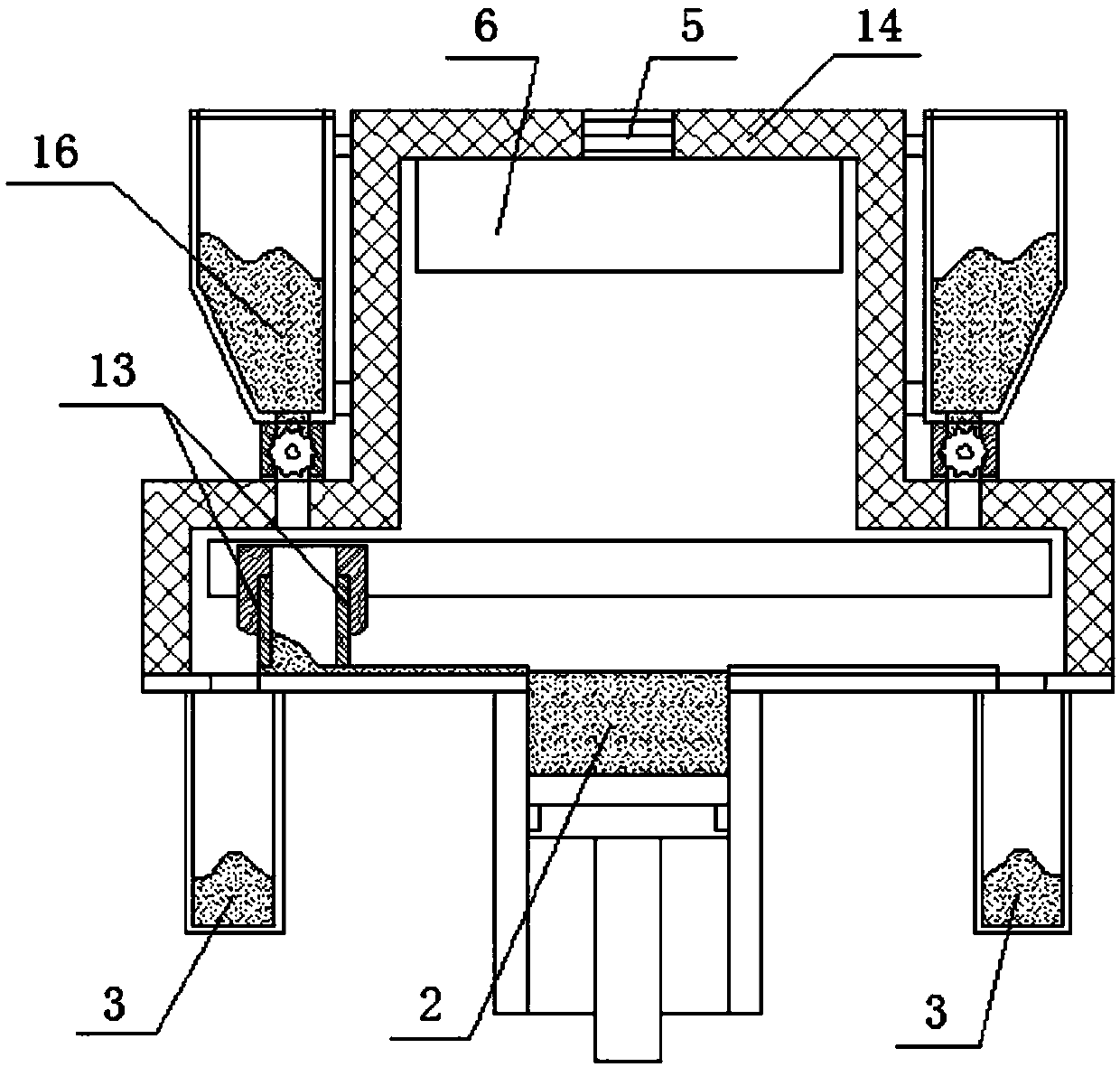

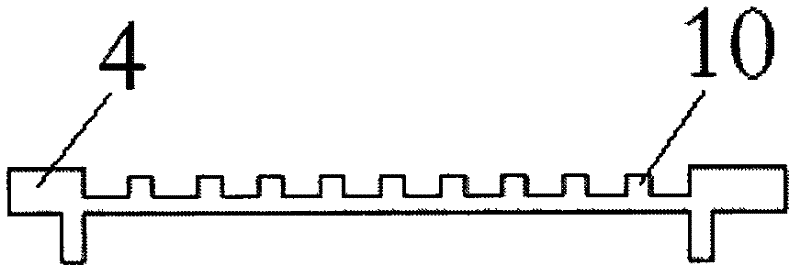

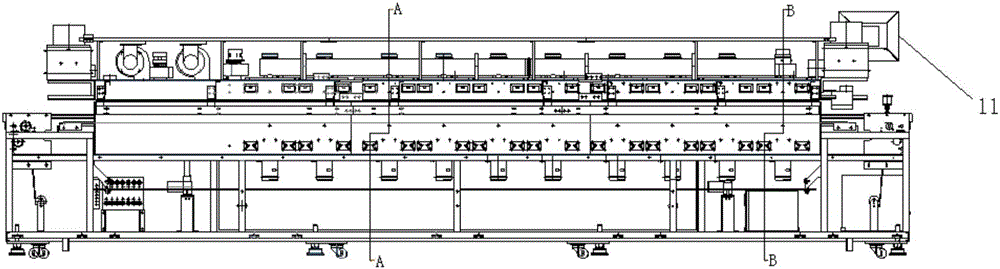

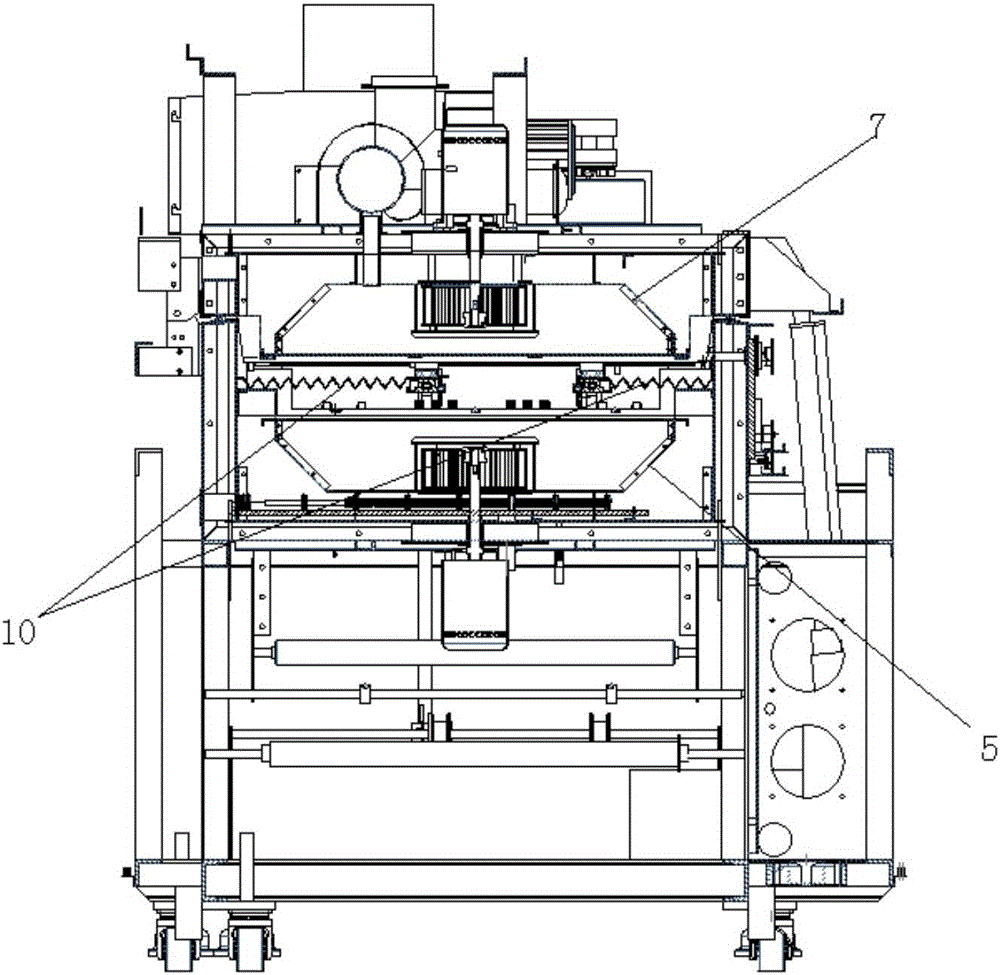

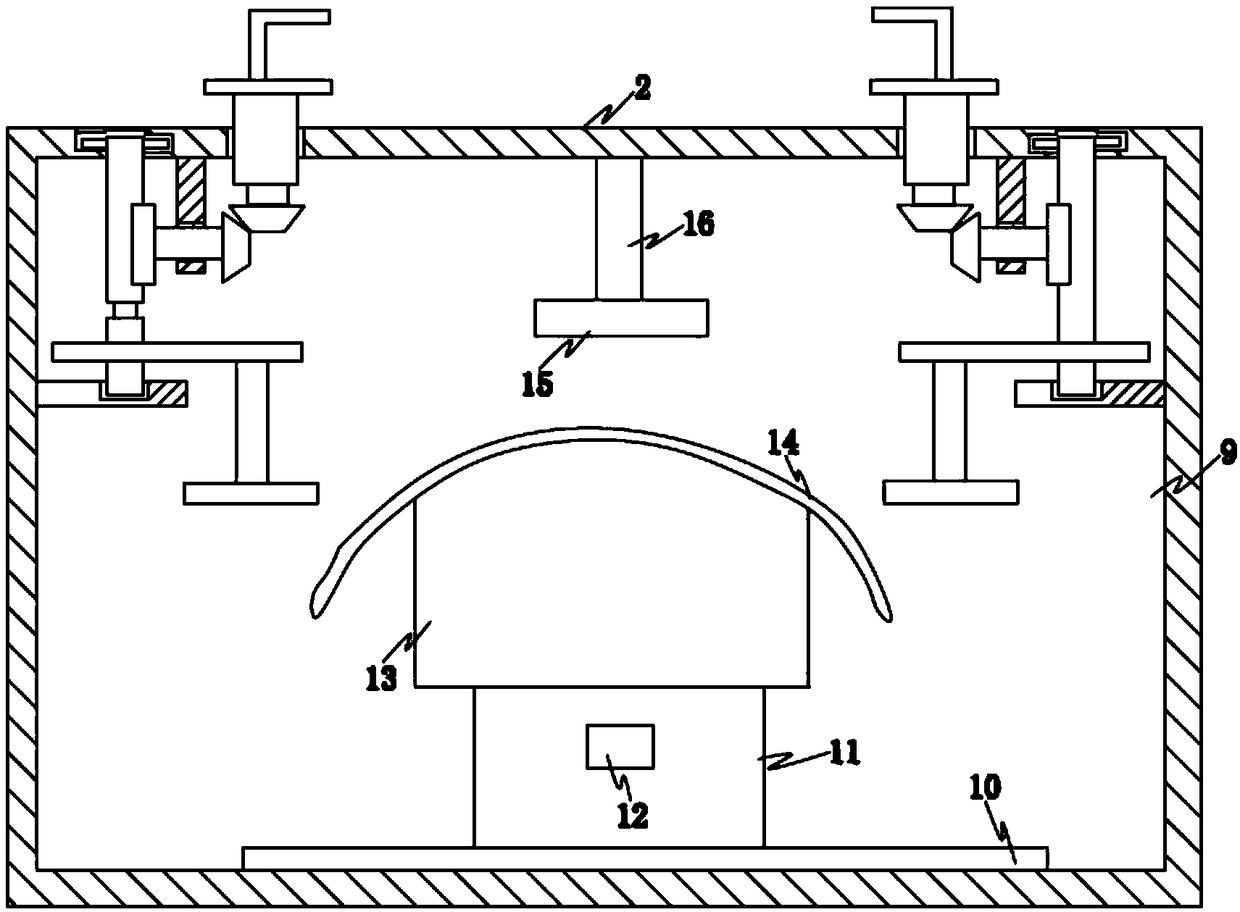

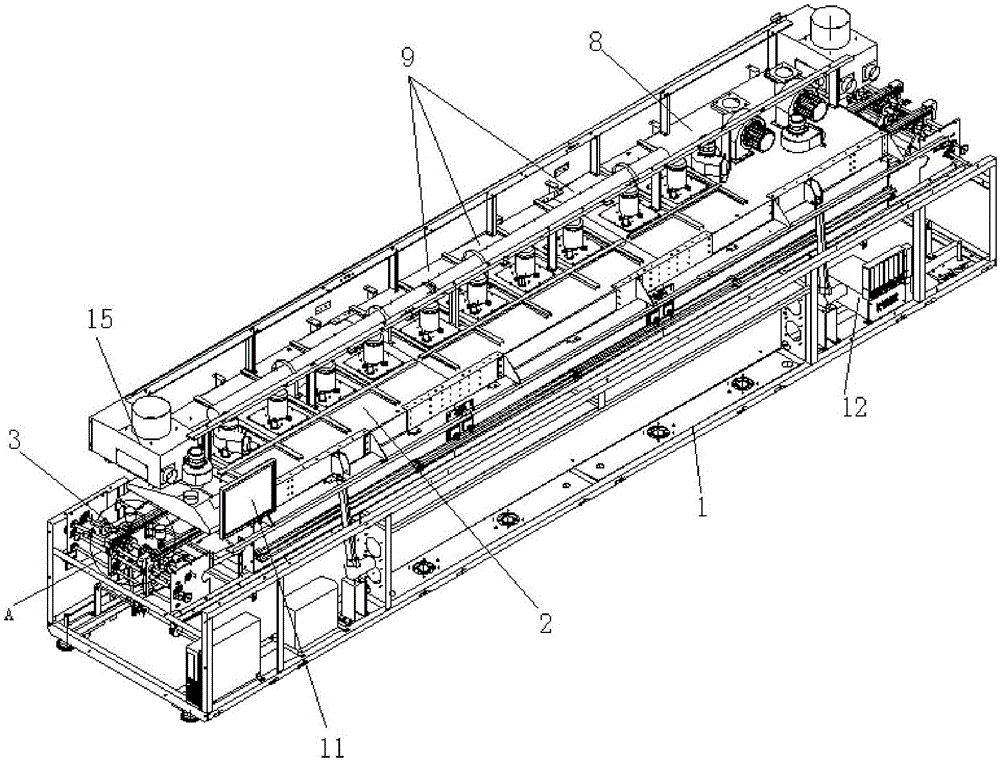

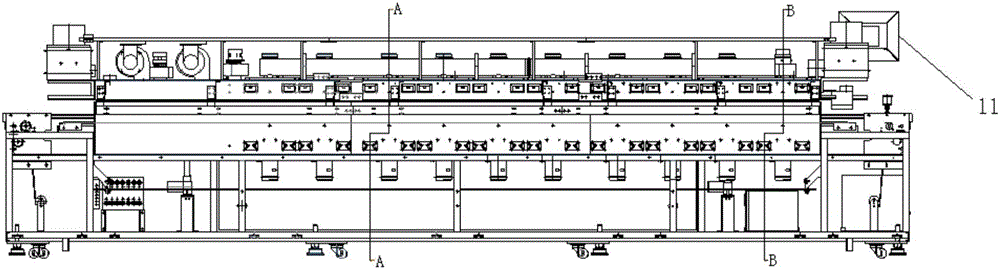

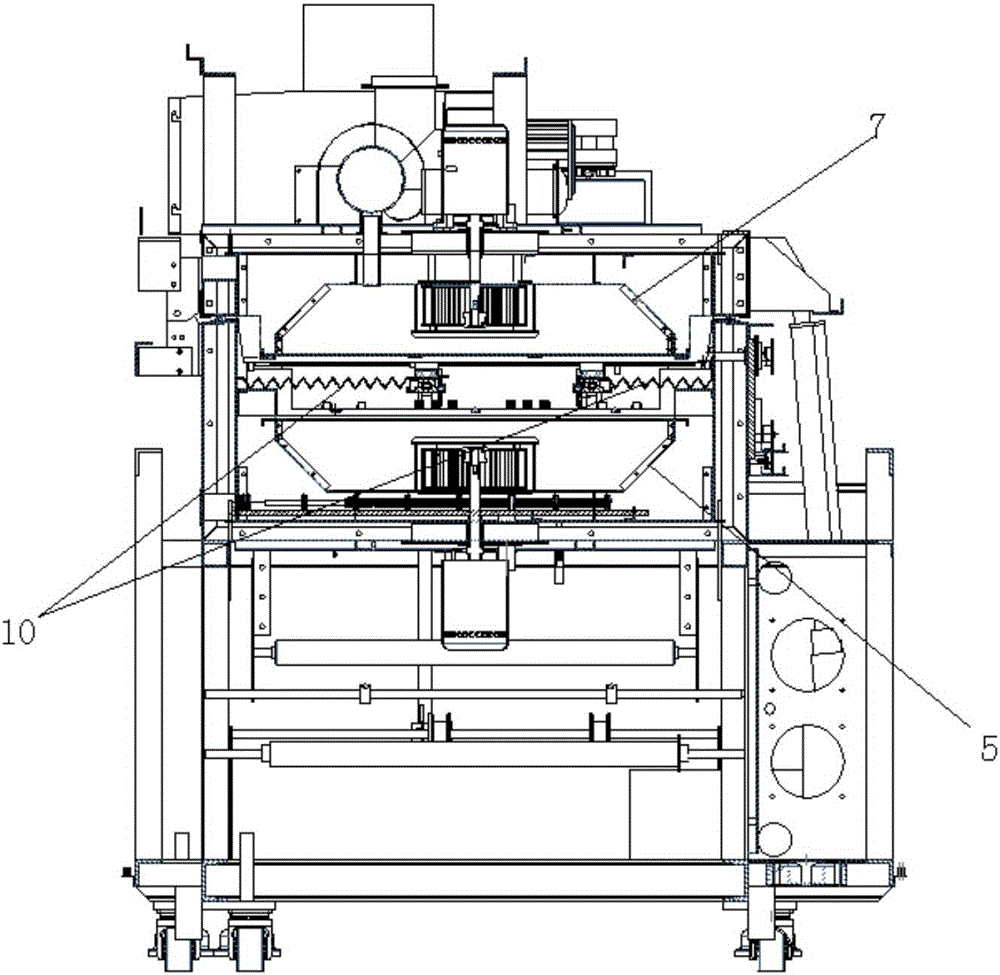

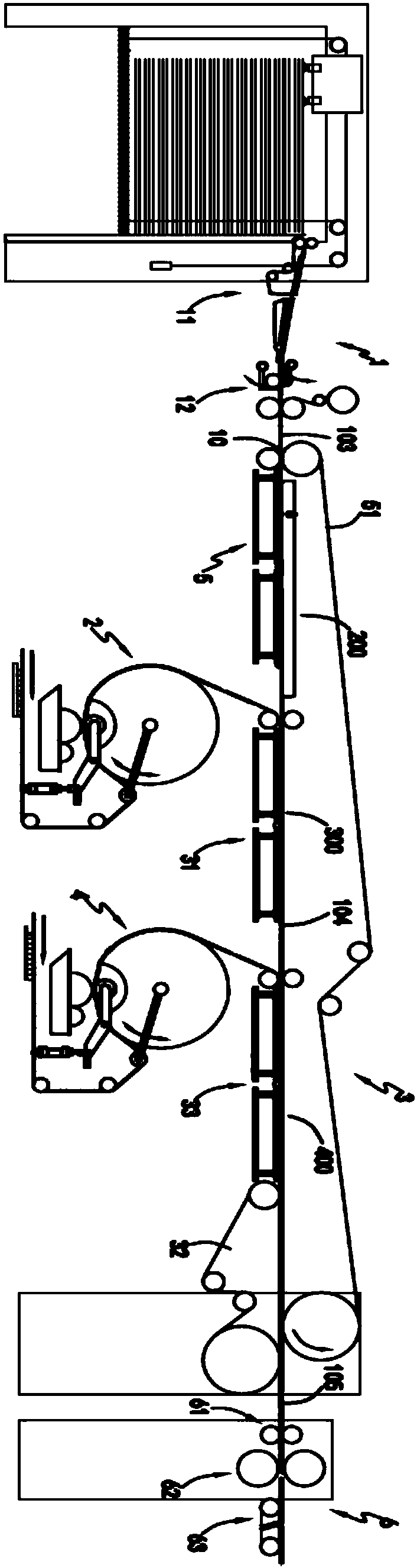

Multi-purpose type double-sided film laminating system

InactiveCN107160852AAvoid wrinklesFully warmed upLamination ancillary operationsLaminationMechanical engineeringEnergy conservation

The invention discloses a multi-purpose type double-sided film laminating system applied to a film laminating machine. The multi-purpose type double-sided film laminating system comprises a rack (14), an upper film roller (1) and a hot-pressing mechanism, wherein a gluing mechanism and a drying mechanism (5) are installed in sequence on the rack and above the hot-pressing mechanism, and a preheating roller (13) and a lower film roller (10) are installed in sequence on the rack and below the hot-pressing mechanism. An extension roller (11) is installed on the rack and between the preheating roller and the lower film roller, and the extension roller is connected with an extension power source (12).According to the multi-purpose type double-sided film laminating system, instant coating or precoating can be flexibly selected, so that the convenience is provided for the next processing procedure after a film is laminated on paper, the film can be effectively prevented from generating wrinkles during operation, a big enough wrap angle between the film and the preheating roller is guaranteed so as to be fully preheated, and the film laminating quality is high. The multi-purpose type double-sided film laminating system has the advantages of reasonable structure, simplicity in operation, energy conservation, environmental friendliness and high heat utilization rate, multiple purposes of one machine are realized, and the multi-purpose type double-sided film laminating system can be widely used for various paper materials.

Owner:RUIAN GREAT PRINTING & PACKAGING MACHINERY

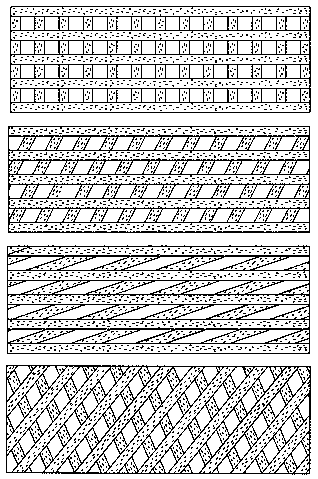

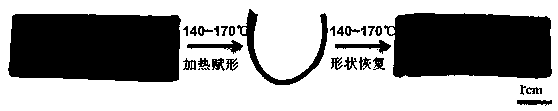

Preparing method of 3D printing intelligent deforming material

ActiveCN109648817AChange crossing angleThe pre-deformation structure is complex and diverseAdditive manufacturing apparatus3D object support structuresFiberCarbon fibers

The invention relates to a preparing method of a 3D printing intelligent deforming material. The method aims at printing complex irregular shapes such as a gradient structure, a biology structure, a spiral structure and a microstructure, the method is precise and efficient, simple and easy to implement, and the 3D printing intelligent deforming material of a complex structure and with large deforming is prepared, and the method comprises following steps of firstly, preparing of polymer wires, and secondly, 3D printing of the intelligent deforming material. On the basis of the 3D printing technology, polyether-ether-ketone powder and a carbon fiber serve as the main material, through control design of the printing shape in the 3D printing process, the path can be programmed, the crossed angle between layers can be changed, the pre-deformed structure is more complicated and diverse, deforming is benefited due to being parallel to the printing path, the larger deforming and the deformingrestore rate can be obtained, through the preparing method, the machining step is simplified, production cost is saved, and machining efficiency is improved.

Owner:JILIN UNIV

Denitrification method and system of cement rotary kiln

PendingCN107174927ATake advantage ofEvenly distributedGas treatmentMethane captureReducing atmosphereEngineering

The invention discloses a denitrification method and system of a cement rotary kiln. The method comprises the steps as follows: conveying fuel into a rising flue and / or a smoke chamber, conveying the fuel to the lower part and / or middle and / or upper part inside the lower section of a pyrolysis furnace, and conveying first tertiary air to the bottom and / or a lower conical part in the pyrolysis furnace; conveying second tertiary air to the middle and / or upper part inside the lower section of the pyrolysis furnace and / or the lower part inside the upper section of the pyrolysis furnace, conveying third tertiary air to the middle and / or the upper part inside the upper section of the pyrolysis furnace to enable the fuel to be burned in an oxygen lack state for generating a reducing agent. A part of NOx in smoke is reduced to a harmless substance by the action of the reducing agent in a reducing atmosphere zone, the fuel is prevented from generating NOx at the same time, and accordingly, emission concentration of NOx is effectively reduced. Meanwhile, combined with an SNCR denitrification technology and / or an SCR denitration technology, emission concentration of NOx is significantly reduced. The denitrification method and system have the advantages that travel of the smoke in the reducing atmosphere zone can be extended, denitrification efficiency is further improved, and denitrification cost of a cement enterprise is reduced.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

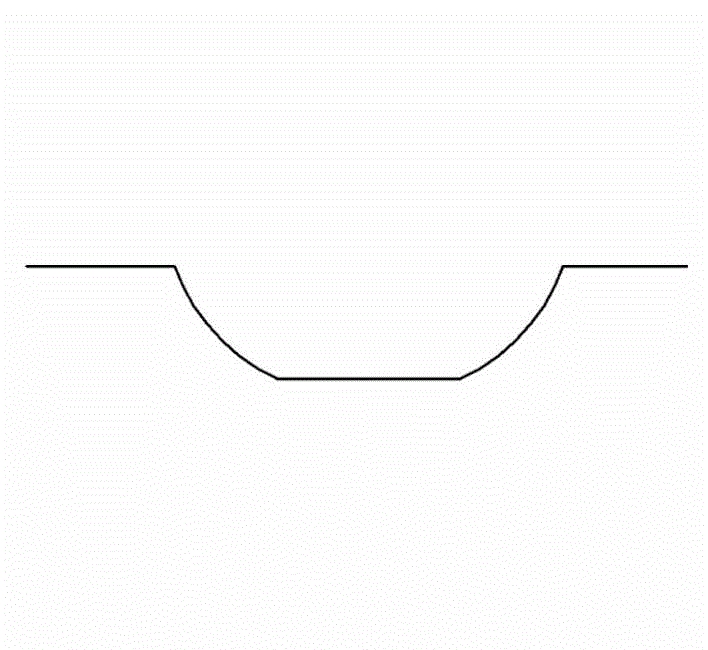

Reverse bending type glass hot-bending furnace

ActiveCN108640488APrevent burstReduce scrap rateGlass reforming apparatusEngineeringElectrical and Electronics engineering

The invention discloses a reverse bending type glass hot-bending furnace which comprises a preheating box and a hot-bending furnace. A hot-bending mold is arranged on a support block; a fixed heatingwire plate is arranged above the hot-bending mold; local telescopic heating devices are symmetrically arranged on inner side walls, close to the fixed heating wire plate, of a hearth; each local telescopic heating device comprises a screw rod; a driven bevel gear is connected with a worm wheel through a connecting rod; the worm wheel is movably arranged on a worm; one side, far away from a rotaryrod, of the worm is connected with the screw rods through connecting blocks; the screw rods penetrate through an operation plate; and a movable heating wire plate is arranged on an extending rod. According to the reverse bending type glass hot-bending furnace provided by the invention, through the built-in preheating box, glass can be fully preheated before hot-bending, so that the hidden danger that the glass is ruptured due to shock heating in the hot-bending chamber is eliminated; and multiple local telescopic heating devices are arranged in the hot-bending furnace, so that the deep-bendinghot-bending glass is promoted to be fit to the mold under the traceless state, and the hot-bending accuracy is improved.

Owner:东莞市宏波光电科技有限公司

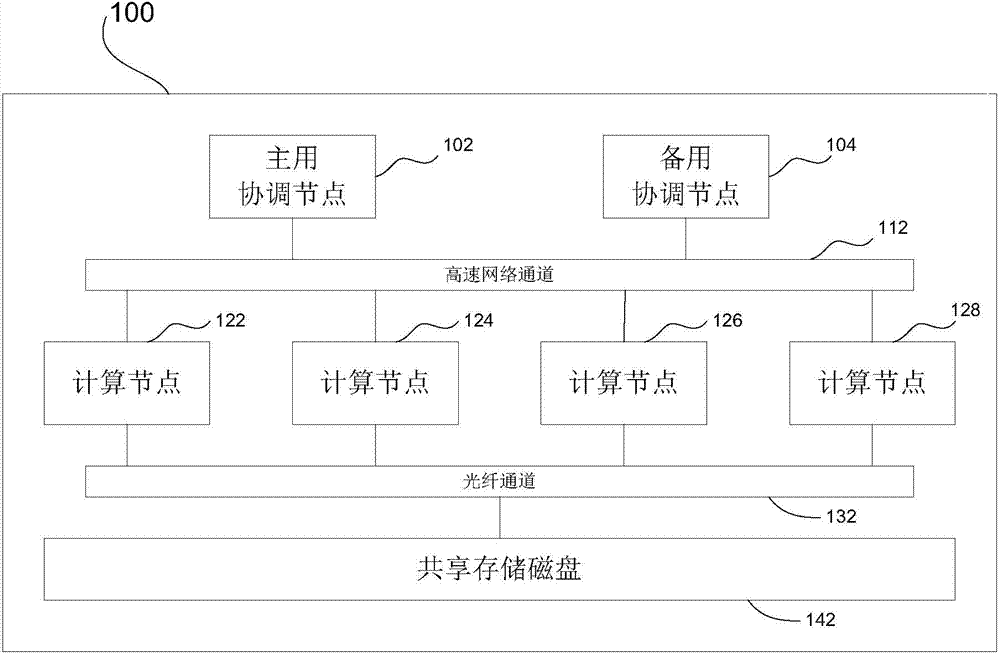

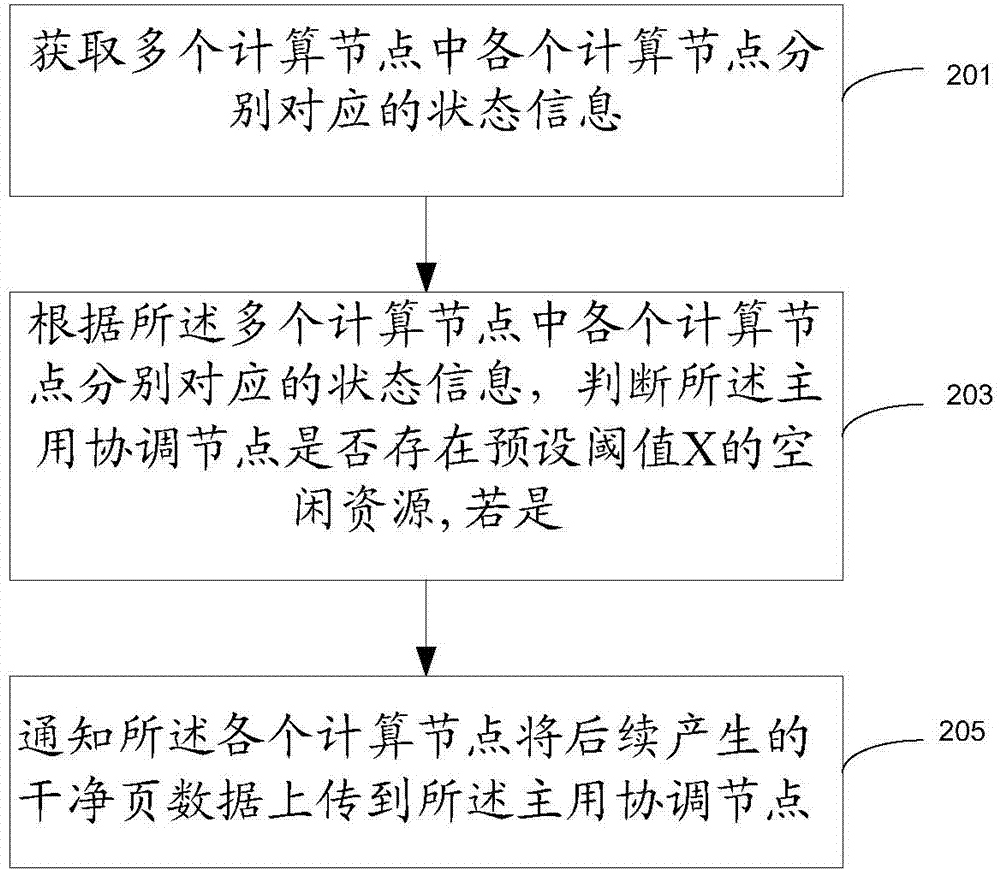

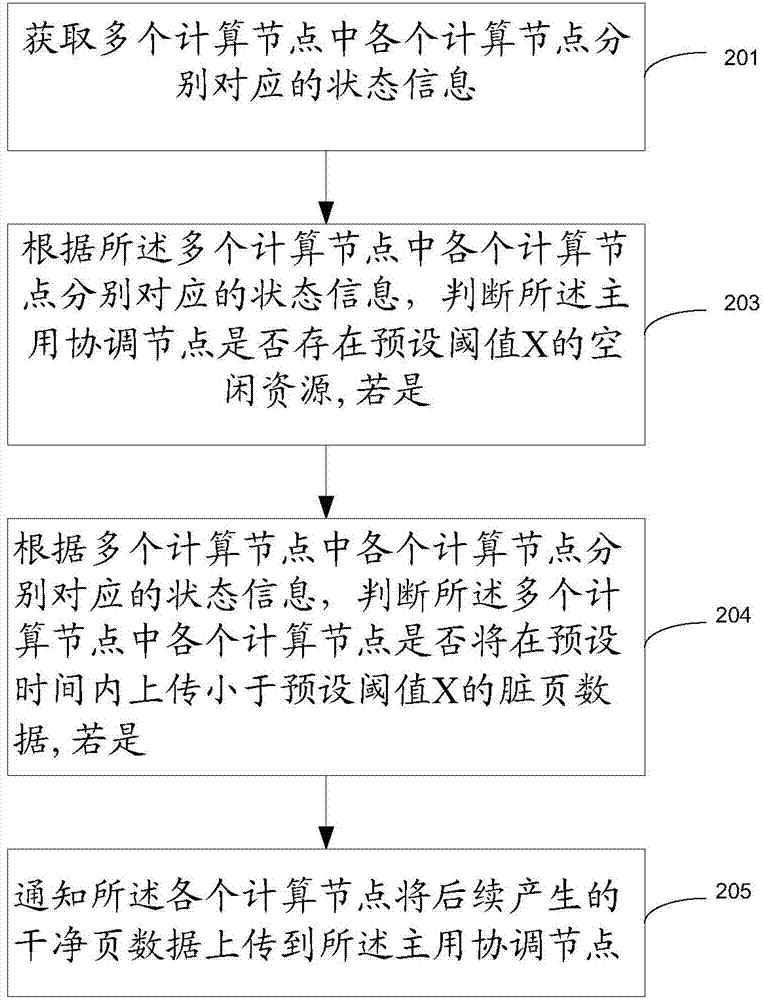

Resource coordination method, device and system for database cluster

ActiveCN104504147AFully warmed upTake advantage ofInput/output to record carriersError detection/correctionCommunication interfaceResource coordination

An embodiment of the invention provides a resource coordination method, device and system for a database cluster. The method comprises that a primary coordination node obtains corresponding state messages of all computer nodes in a plurality of computer nodes, wherein the state messages are used for representing operation load states of the computer nodes; whether the primary coordination node has free resources of a preset threshold X is determined according to the state messages of all the computer nodes in the plurality of the computer nodes; all the computer nodes are notified to upload subsequently produced clean page data to the primary coordination node if the primary coordination node has the free resources. By means of the method, the device and the system, more data produced by the computer nodes can be stored on coordination nodes, the free resources on the coordination nodes and Infiniband (coordination node and computer node communication interfaces) high-speed communication characteristics are fully used, and accordingly, the computer node starting is rapid and efficient.

Owner:HUAWEI TECH CO LTD

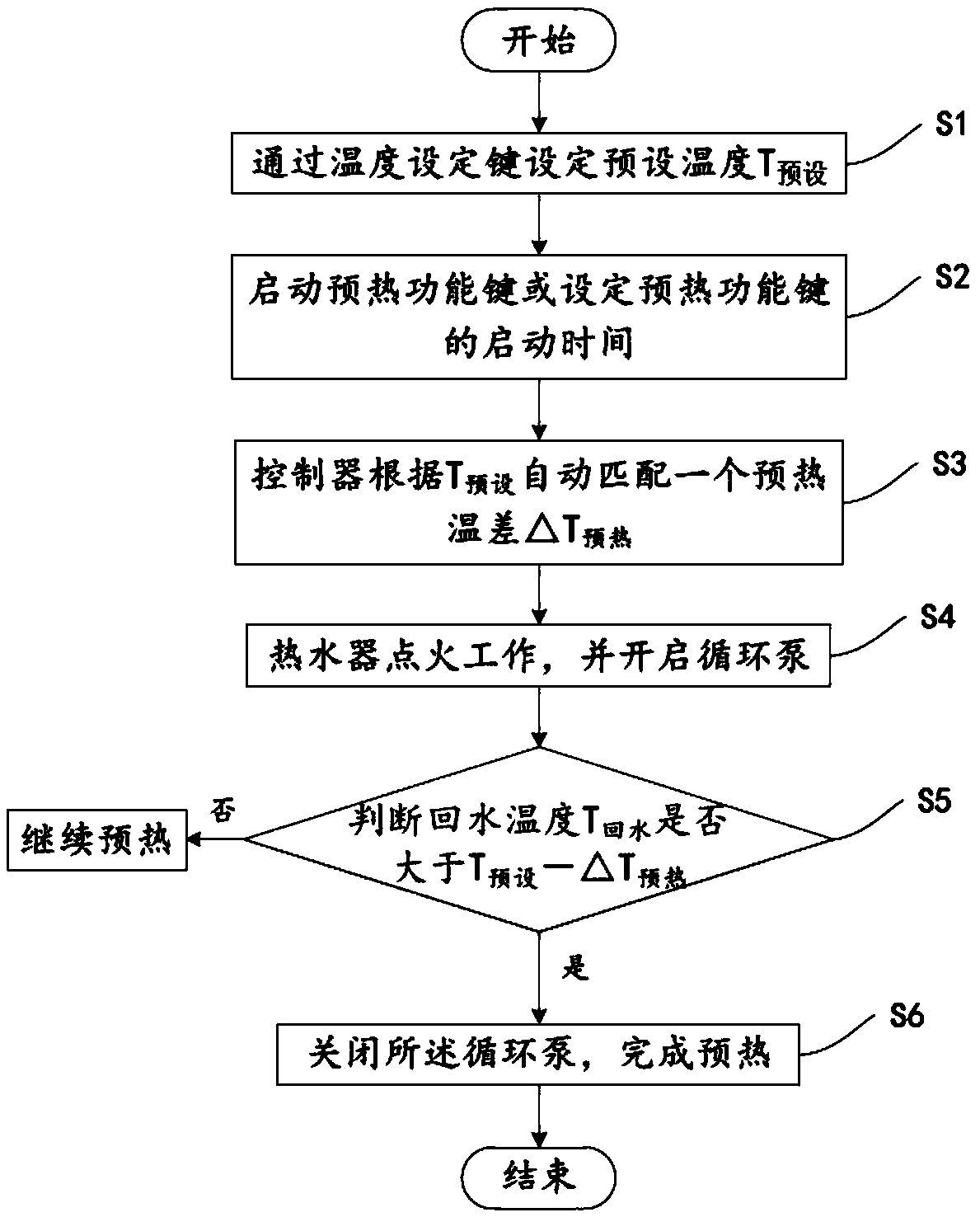

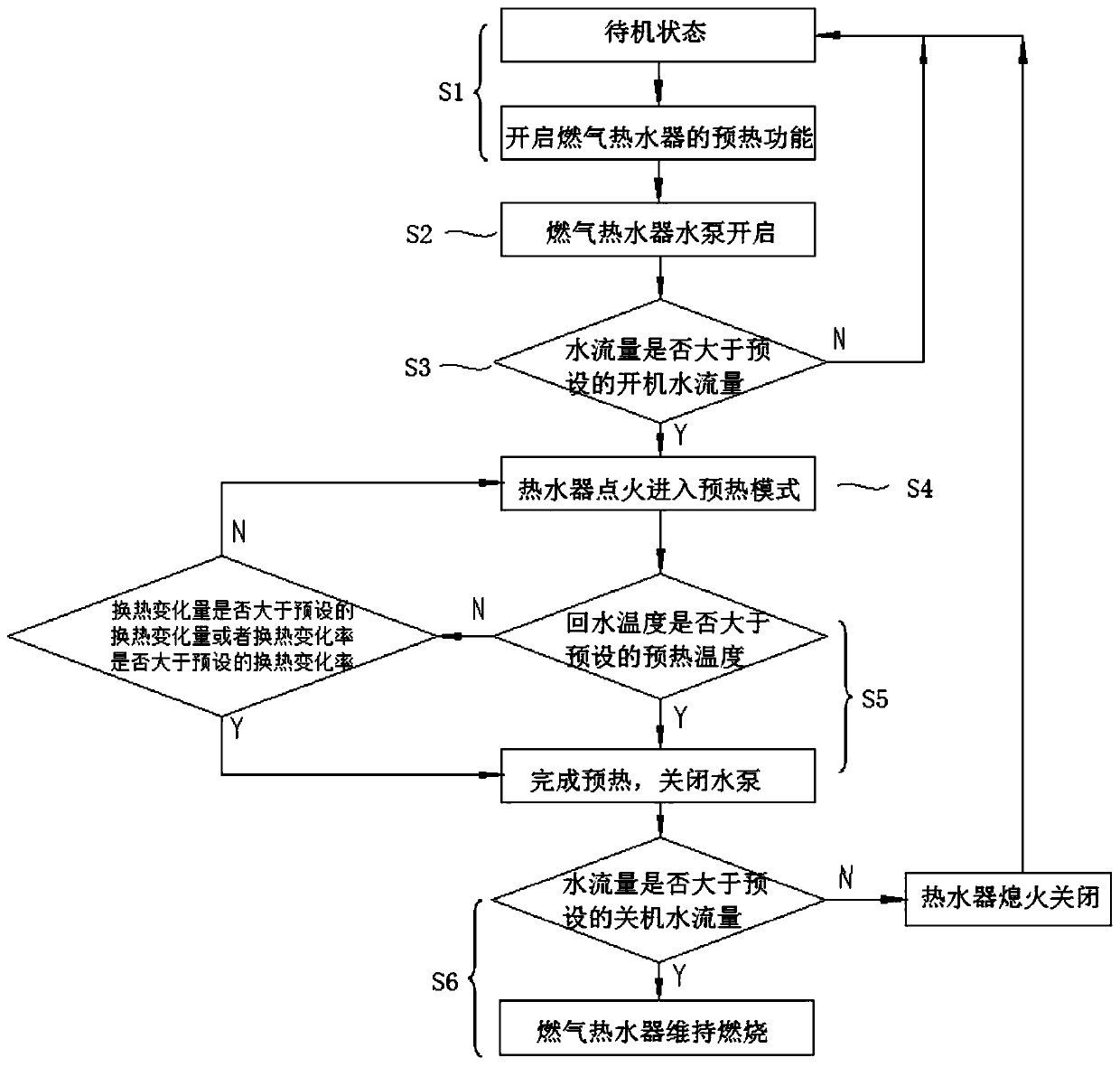

Gas water heater control method and gas water heater

The invention discloses a gas water heater control method. The method specifically comprises the following steps of S1, starting a preheating function of a gas water heater in a standby state; S2, starting a water pump of the gas water heater; S3, detecting a water flow on a main water path of the gas water heater, entering the step S4 when the water flow is larger than a preset starting water flow, and otherwise, keeping the standby state of the gas water heater; S4, igniting the gas water heater to enter a preheating mode; S5, detecting a water return temperature of the gas water heater, completing preheating treatment and closing the water pump when the water return temperature is larger than a preset preheating temperature, and otherwise, controlling a working state of the gas water heater through the change of the heat exchange amount of the gas water heater; and S6, keeping burning of the gas water heater when the water flow on the main water path of the gas water heater is larger than a preset shutdown water flow, and otherwise, turning off and closing the gas water heater. The invention further discloses the gas water heater. According to the control method, in the preheating process, rapid pump closing can be realized through recognizing hot water starting action of a user, so that electric power consumption is reduced, and the product intelligentization is embodied.

Owner:VATTI CORP LTD

Multifunctional reflow soldering device and control method thereof

InactiveCN105772887AReduce the temperatureRealize the function of weldingPrinted circuitsMetal working apparatusCold airMan machine

The invention discloses a multifunctional reflow soldering device. The multifunctional reflow soldering device comprises a reflow soldering machine platform. A soldering machine platform cover which can be opened and closed is arranged at the back edge of the upper plane of the reflow soldering machine platform. The upper plane of the reflow soldering machine platform is provided with a product conveying line adjustable in width. The reflow soldering machine platform is internally provided with first lower furnace pipes and second lower furnace pipes from left to right in sequence. A first warm area upper furnace pipe used for air draft is arranged in the position, corresponding to each first lower furnace pipe, of the interior of the soldering machine platform cover. A second warm area upper furnace pipe blowing hot air or cold air downwards is arranged in the position, corresponding to each second lower furnace pipe, of the interior of the soldering machine platform cover. Each first warm area upper furnace pipe and the corresponding first lower furnace pipe form a first warm area. Each second warm area upper furnace pipe and the corresponding second lower furnace pipe form a second warm area. Air blocking curtains which are used for separating the cold air from the hot air and can be stretched or shortened are arranged in the positions, located between the first warm areas and the second warm areas, of the product conveying line. The reflow soldering machine platform is provided with a man-machine control interface and further provided with a cooling area. Each second warm area upper furnace pipe is internally provided with a second warm area upper furnace pipe heating wire for independently controlling heating. According to the multifunctional reflow soldering device, the function of soldering SMT boards and PCB through holes can be achieved.

Owner:东莞市创威自动化科技有限公司

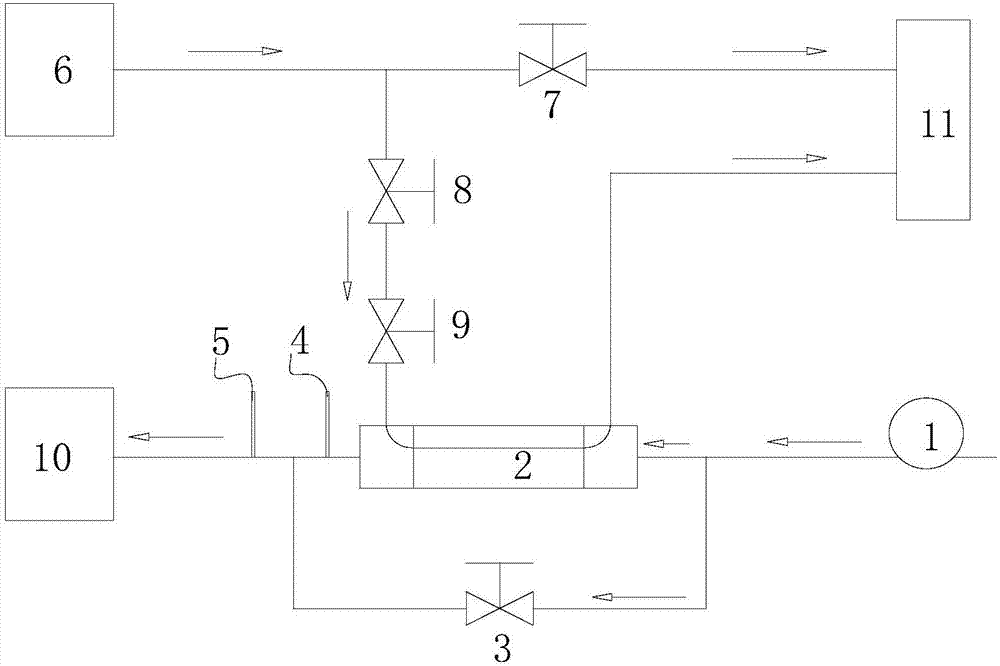

Steam generator feed-water temperature control simulation system

ActiveCN107145175AFully warmed upImprove energy utilizationAuxillary controllers with auxillary heating devicesEngineeringControl valves

The present invention discloses a steam generator feed-water temperature control simulation system. A main feed-water pipe, arranged between a main feed pump and the secondary side inlet of a steam generator, passes through a heat regenerator, the secondary side outlet of the steam generator is connected with two parallel branch pipelines, one of the two parallel branch pipelines passes through the steam flow control valve of a main steam pipeline and is connected to a condenser, and the other one of the parallel branch pipelines passes through a steam by-pass stop valve, a steam by-pass flow control valve and the heat regenerator in order and then is connected with the condenser. According to the invention, high-temperature steam generated by the steam generator is employed as a heating source to perform preheating of feed water entering the steam generator to eliminate energy consumption caused by preheating depending on an extra power supply and improve the energy utilization rate of a test device, and high-temperature steam preheating output by the steam generator itself is employed to realize feeding water temperature control in a large flow variation range. The mode of combination of steam by-pass adjustment and feed-water by-pass adjustment is employed to rapidly, effectively and accurately realize adjustment of the feed-water temperature of the steam generator.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

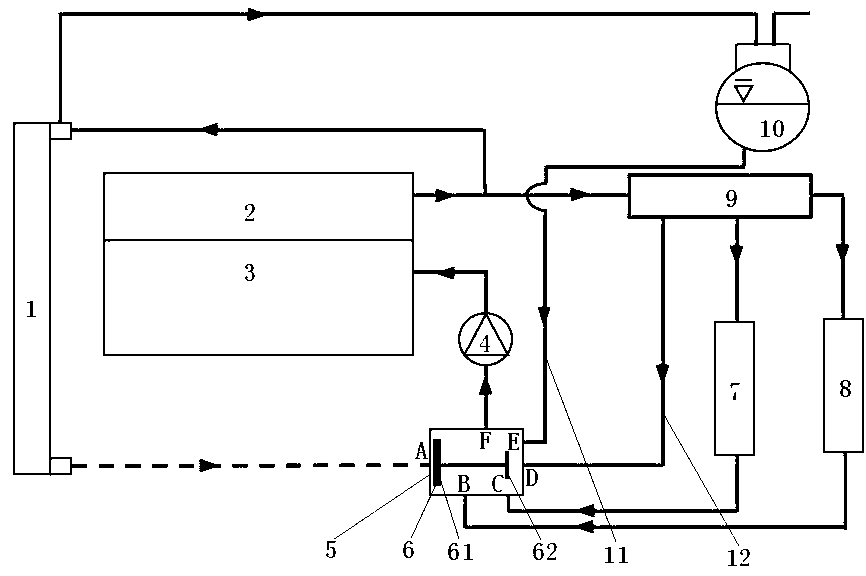

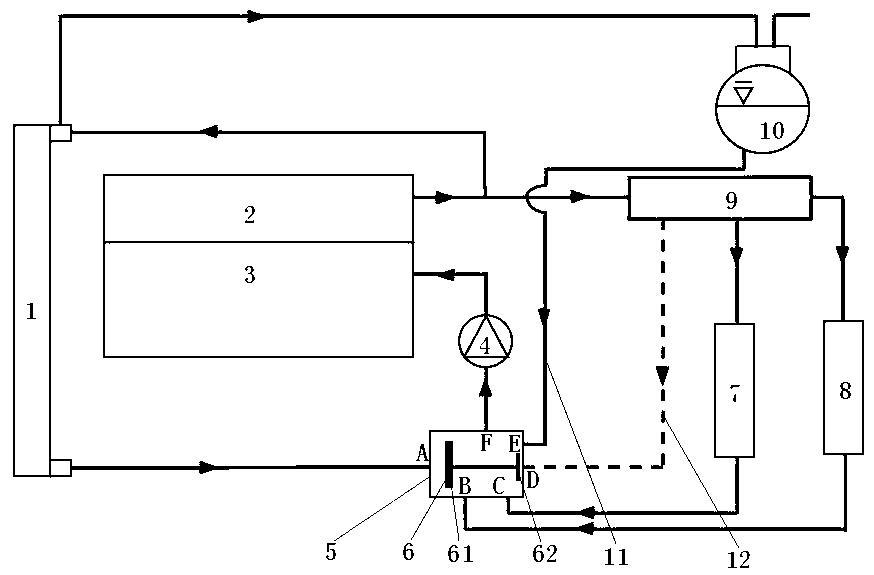

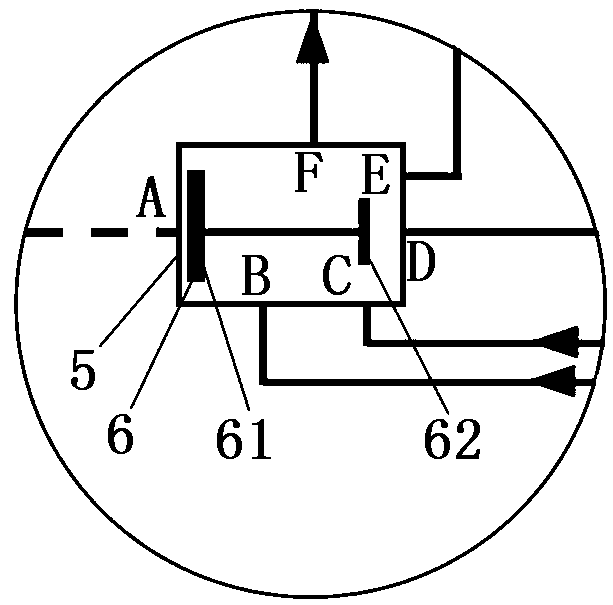

Gasoline engine cooling system

ActiveCN102705055AAvoid cavitationImprove cooling performanceLiquid coolingCoolant flow controlExpansion tankThermal shock

The invention discloses a gasoline engine cooling system, which comprises a radiator, a cylinder cover water jacket, a cylinder body water jacket, a water pump, an expansion tank and a thermoregulator valve seat, wherein a thermoregulator is arranged in the thermoregulator valve seat; the thermoregulator valve seat is provided with five inlets and one outlet F; the first inlet A is communicated with a lower water chamber of the radiator; the second inlet B is communicated with the outlet of a fan heater; the third inlet C is communicated with the outlet of an air damper; the fourth inlet D is communicated with the outlet of a distributive pipe via a small circulation circuit; the fifth inlet E is communicated with the expansion tank via a water replenishing circuit; the outlet F is communicated with the water inlet of the water pump; the thermoregulator is a double-valve wax type thermoregulator and comprises a main valve and an auxiliary valve, wherein the main valve is installed on the first inlet A of the thermoregulator valve seat; and the auxiliary valve is just against the fourth inlet D of the thermoregulator valve seat. According to the gasoline engine cooling system disclosed by the invention, gas in cooling liquid can be removed to protect the water pump from cavitation, the cooling performance of the cooling system is improved, an engine is prevented from overheating, and thermal shock is prevented from generating in the cooling system.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Continuous forging heating furnace

ActiveCN103302223AMeet the temperature requirementsEasy to saveForge furnacesAcute angleHeating furnace

The invention provides a continuous forging heating furnace which comprises a furnace body, a heating mechanism and a machine frame; the furnace body and the heating mechanism is arranged on the machine body; the furnace body comprises a furnace chamber which runs through the furnace body; a furnace wall as well as the feeding end and the discharging end of the furnace body are correspondingly formed; a guide groove is formed in the furnace chamber; the heating mechanism comprises a plurality of burners; the burners are installed at the discharging end close to the furnace body and the top part of the furnace body, and enter into the furnace chamber through the furnace wall in a way that acute angles are formed between the directions of the burners and the material guiding direction. The continuous forging heating furnace can fully preheat materials and facilitates heat energy conservation and utilization.

Owner:彭亦楚

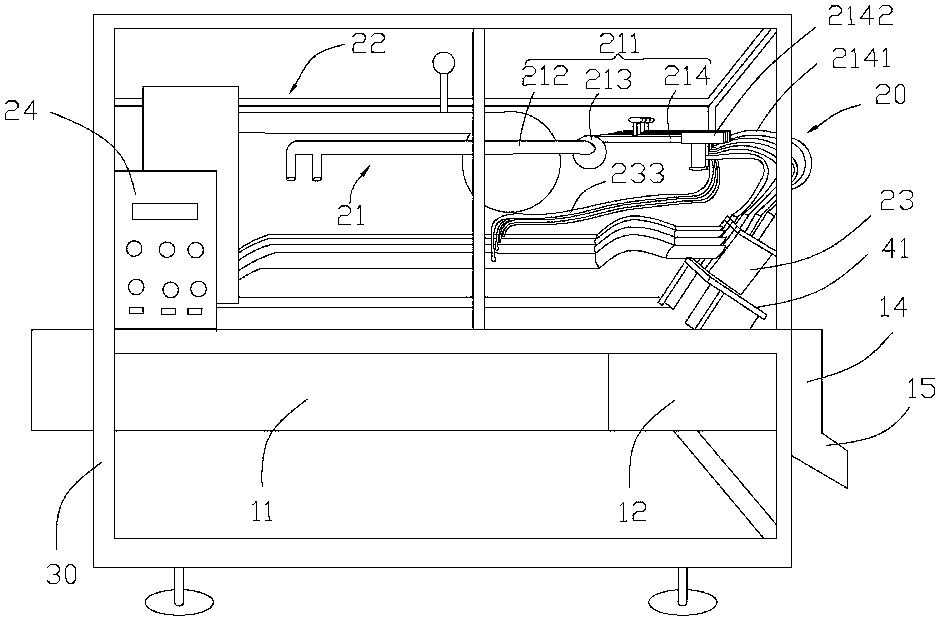

Sludge hydrothermal oxidization reaction system and method with function of product reflux pretreatment

ActiveCN106630526AFully warmed upLow viscositySludge treatment by thermal conditioningSludge treatment by oxidationLiquid productSludge

The invention discloses a sludge hydrothermal oxidization reaction system and method with a function of product reflux pretreatment, and belongs to the field of municipal sludge treatment. A gaseous product generated through hydrothermal oxidation is led out from the top of a reactor, residual oxygen and produced carbon dioxide after the reaction are removed, and then the gaseous product is introduced into a sludge pretreatment tank and directly contacted with sludge for preheating the sludge; a divided flow part of a liquid product flows back to the sludge pretreatment tank; steam and hot water preheat sludge under the stirring action, and the problem that heat recovered by the system is not enough to preheat the sludge to reach the feeding temperature is solved; the residual liquid product is treated with a vacuum flashing method, flash steam is recovered and sent to a pretreatment sludge feeding pipe for tracing heat, and meanwhile, a liquid phase after flash deoxidization enters a downstream heat-exchange device for waste heat recovery. With the adoption of measures, high-temperature material heat of the system can be recovered to preheat sludge, corrosion of dissolved oxygen to a heat exchanger can be relieved, system investment is reduced, and energy utilization rate and economic efficiency of the system are increased.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

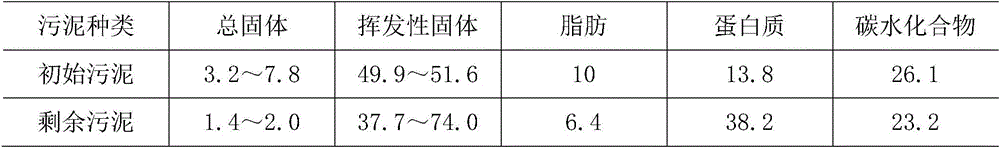

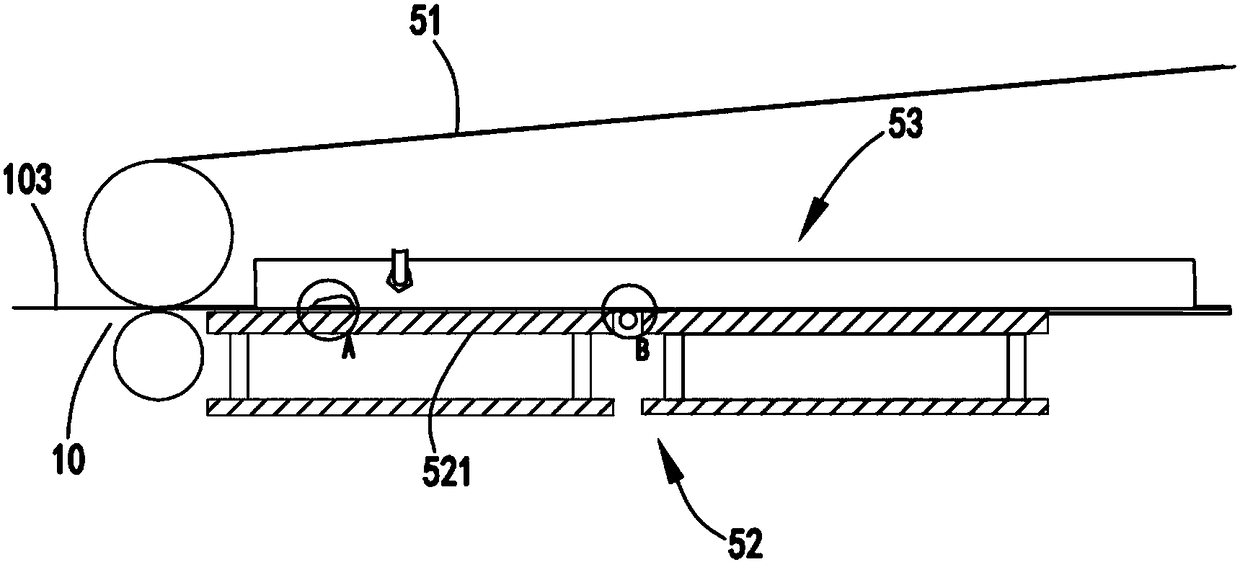

Single-sheet surface paper preheating mechanism, corrugated paper board production lines and process and control method

PendingCN108582896AReduce moistureSmooth connectionMechanical working/deformationProduction linePulp and paper industry

The invention relates to a single-sheet surface paper preheating mechanism, corrugated paper board production lines and process and a control method. The single-sheet surface paper preheating mechanism comprises a surface paper feeding device for continuously conveying single-sheet surface paper to a first paper feeding part, and further comprises a surface paper preheating device arranged behindthe surface paper feeding device. The surface paper preheating device comprises a conveying belt a and a preheating mechanism body arranged below the conveying belt a. A preheating channel for conveying and preheating of the single-sheet surface paper is reserved between the conveying belt a and the preheating mechanism body. The conveying belt a is divided into a section a, a section b and a section c, when the single-sheet surface paper is located at the section a, the single-sheet surface paper and the conveying belt a are relatively static, and under driving of the conveying belt a, the front and rear single-sheet surface paper are backwards conveyed in an end-to-end connected mode. The preheating mechanism body is arranged along the conveying path of the single-sheet surface paper andpreheats the single-sheet surface paper in the single-sheet surface paper conveying process. The problems that when the surface paper and corrugated paper simultaneously enter drying equipment, the surface paper is located at the upper portion and cannot be fully dried, and preheating and continuous conveying of the single-sheet surface paper cannot be simultaneously conducted are solved.

Owner:王慧明

Use method of quenching device

ActiveCN108004379AReduce labor intensityImplement auto-replenishmentFurnace typesHeat treatment furnacesHeating furnaceVacuum pump

The invention belongs to the technical field of heat treatment and particularly discloses a use method of the quenching device. The use method comprises the following steps that (1) the quenching device is inspected; (2) a metal workpiece is placed in a preheating furnace for preheating; (3) the preheated metal workpiece is placed on a roll-over stand, and an electric heating wire and a vacuum pump are started to suck out gas in a vacuum heating furnace; (4) the heated metal workpiece is manually transferred to an oil quenching bath after the metal workpiece is heated to the fixed temperature,and the preheated metal workpiece is supplemented to the roll-over stand; (5) after a new metal workpiece is supplemented into the vacuum heating furnace automatically, the vacuum pump is started tosuck gas out; and (6) after a period of time, a pressure valve is opened again, the metal workpiece on the roll-over stand is transferred to the oil quenching bath and the metal workpiece in the preheating furnace is transferred onto the roll-over stand, and circulating operation is carried out in this way. By using the used method, the metal workpiece can be supplemented automatically, and the metal workpiece is automatically sent into the oil quenching bath after the metal workpiece is heated, so that the machining efficiency is improved.

Owner:宁波隆锐机械制造有限公司

Overcritical Fischer-Tropsck synthesis method

InactiveCN101215213ARaw materials are cheap and easy to getImprove wear resistanceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSynthesis methodsGas phase

The invention discloses a method of super-critical Fischer-Tropsch synthesis, using molten-iron as catalyst to convert synthetic gas (CO+H2) into hydrocarbon in the presence of supercritical media. The process comprises as follows: mixing the synthetic gas and supercritical media, performing super-critical Fischer-Tropsch synthesis under the conditions of temperature of 180-350DEG C, pressure of 3.0-10.0MPa and synthetic gas airspeed of 1000h-1-30000h-1 and converting the synthetic gas into liquid fuel. The molten-iron catalyst has the advantages of easy obtaining of raw material, strong abrasive resistance, high space time yield, high selectivity of olefin, simple preparing process, stable catalyst property, more suitability of industrial production and the like. Under the same reaction condition, compared with gas-phase and liquid-phase Fischer-Tropsch synthesis, the super-critical Fischer-Tropsch synthesis can reduce temperature jump of beds, decrease carbon deposit on surface of the catalyst, prevent devitalization of the catalyst and prolong the service life of the catalyst. In terms of reaction property, the invention can increase conversion rate of CO, reduce selectivity of methane and increase selectivity of C5+ and olefin in products.

Owner:ZHEJIANG UNIV OF TECH

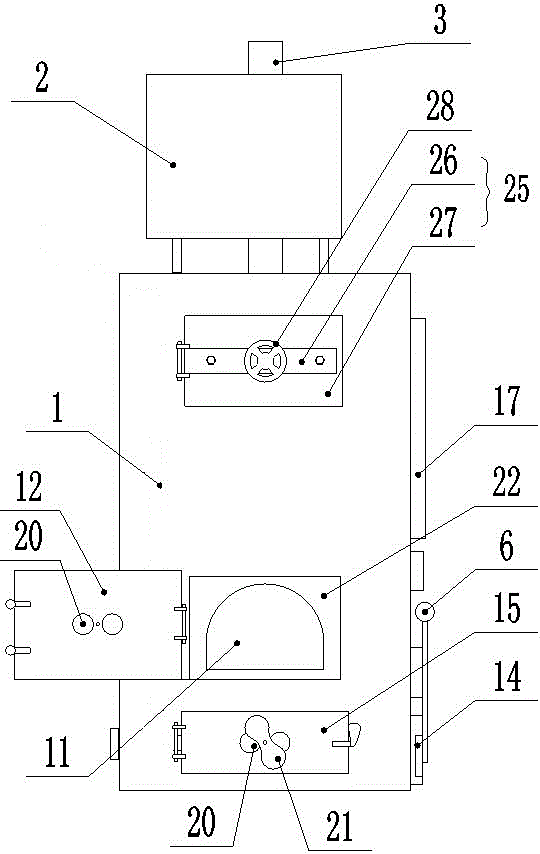

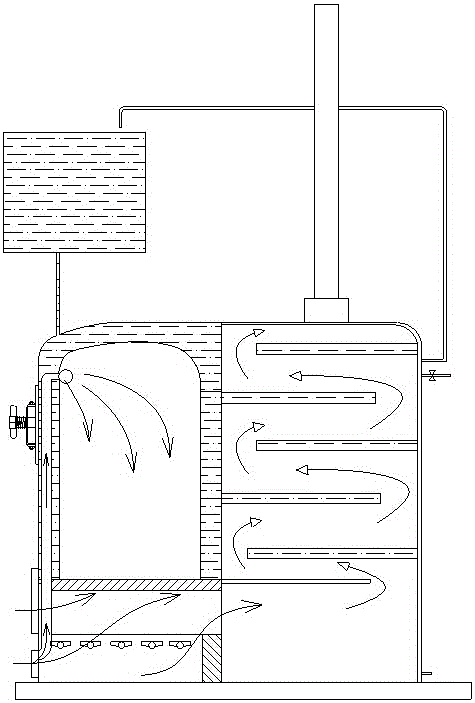

Normal-pressure smoke-free environment-friendly combustion furnace

ActiveCN106322439ABurn fullyControl the feeding speedLighting and heating apparatusStove/ranges for heating waterCombustion chamberEngineering

The invention discloses a normal-pressure smoke-free environment-friendly combustion furnace and relates to the technical field of combustion furnaces. The combustion furnace comprises a furnace body and a water jacket, wherein the water jacket is arranged inside the furnace body and is communicated with a water tank; a rotary smoke flue connected with a chimney is arranged at the upper part of the back of the furnace body; a feeding opening communicated with a dry distillation chamber is formed in the upper part of the side wall of the furnace body; a water discharging opening and a water returning opening are formed in the back of the furnace body; a combustion kiln is arranged at the lower part of the dry distillation chamber; the combustion kiln is horizontal; the longitudinal section of the combustion kiln is arched; one end of the combustion kiln is fixed at the front of the furnace body; a kiln door is formed in an open end; the other end of the combustion kiln is fixed in the middle of the furnace body; gaps are formed between two sides of the combustion kiln and the inner wall of the dry distillation chamber; the back of the combustion kiln is communicated with a secondary combustion chamber; a furnace grate is arranged under the combustion kiln; a furnace dust cleaning mechanism connected with the furnace grate is arranged on the outer side of the furnace body; a main dust cleaning door with an air inlet is arranged under the furnace grate. According to the normal-pressure smoke-free environment-friendly combustion furnace, the fuel can be dispersed in the dry distillation chamber and the furnace grate by virtue of the combustion kiln; through the adoption of the combustion kiln and the secondary combustion chamber, the fuel can be fully combusted; through the adoption of the S-shaped rotary smoke flue, the dust emission is reduced; the purposes of saving energy, avoiding smoke and protecting environment can be achieved.

Owner:SHIJIAZHUANG CHUNYAN HEATING EQUIP

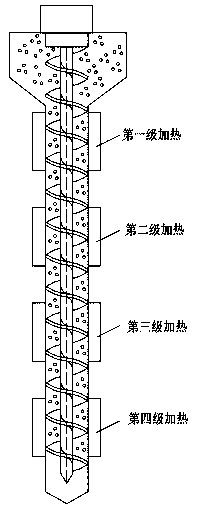

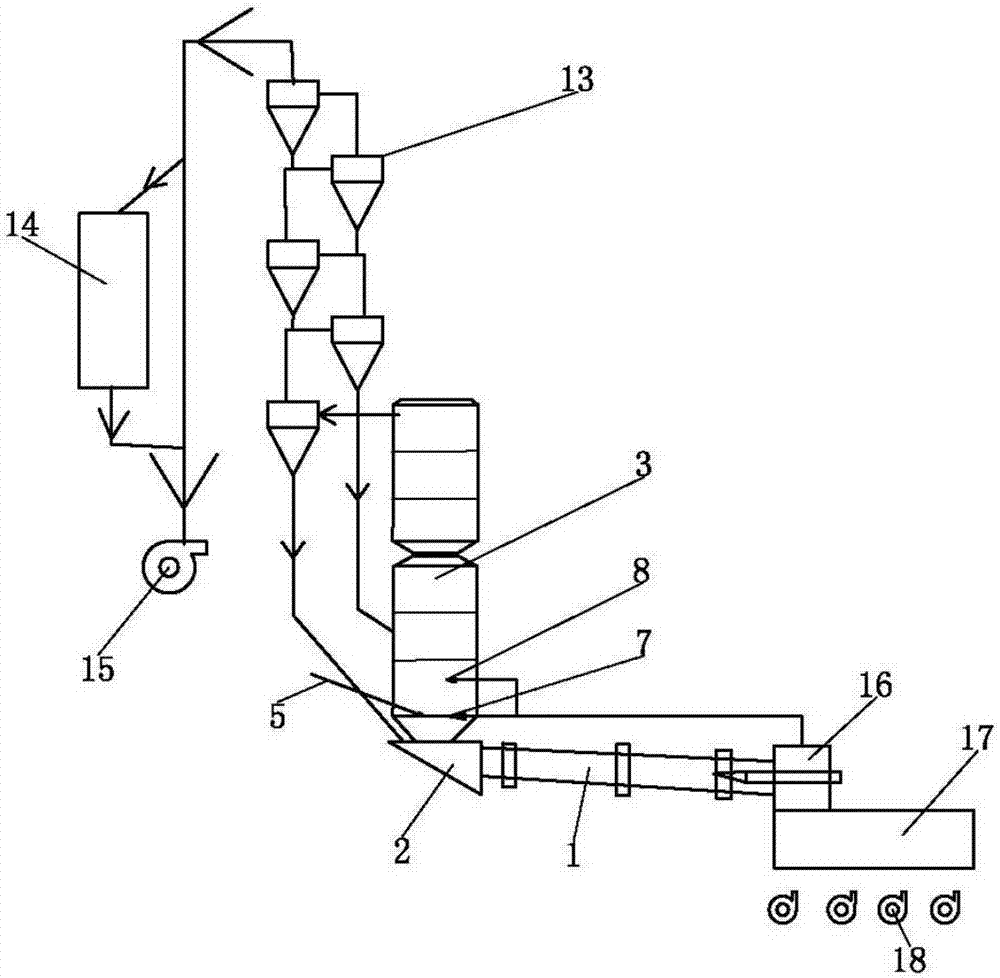

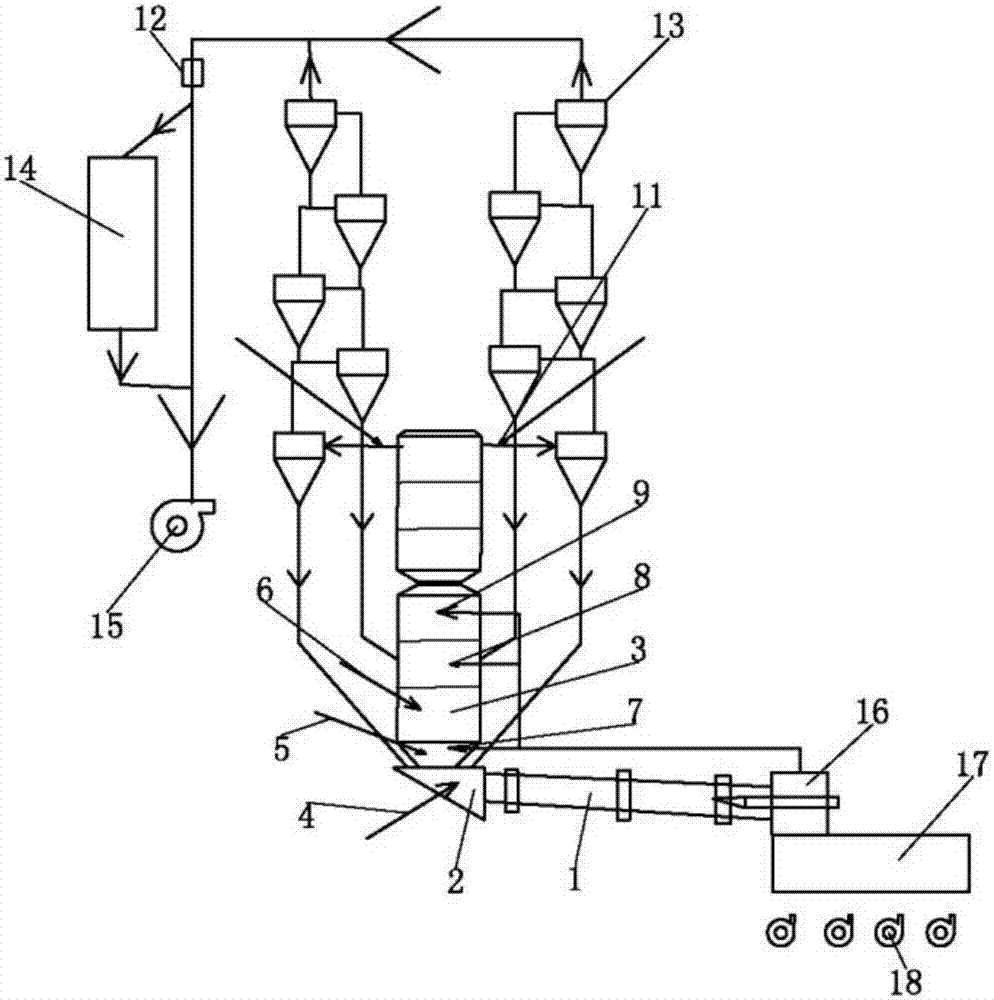

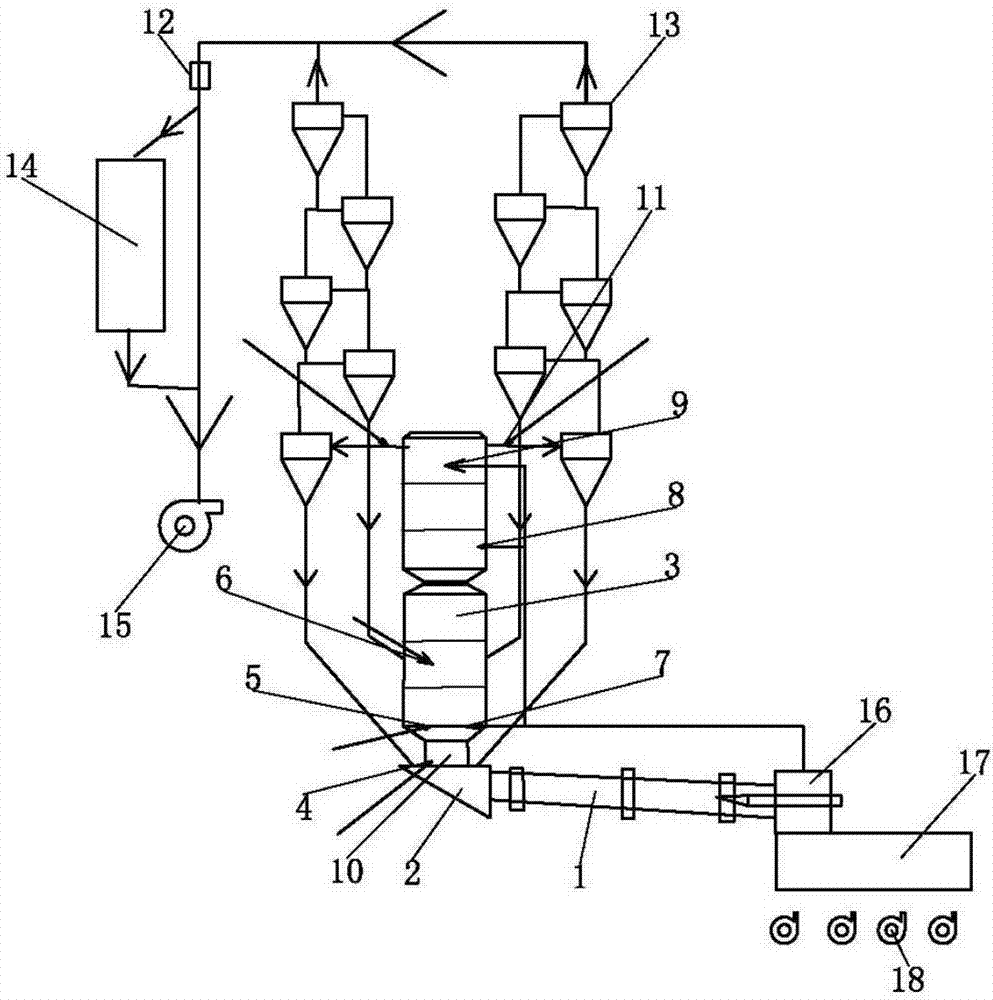

Nepheline preheating, pre-decomposing and dry sintering technology and device for producing alumina clinker

PendingCN107758712AImprove qualityLow costChemical industryAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSlurryNepheline

The invention discloses a nepheline preheating, pre-decomposing and dry sintering technology and device for producing an alumina clinker. The technology comprises the following steps: powdering and homogenizing raw materials including nepheline, limestone and white slurry; feeding the homogenized powder into a preheater; preheating through the preheater; decomposing through a decomposing furnace;entering a rotary kiln for roasting for 20-50min at the temperature of 1200-1400 DEG C; and then entering a grate cooler for cooling, thus obtaining the qualified alumina clinker. The device comprisesthe preheaters, the decomposing furnace, the rotary kiln and the grate cooler, wherein the preheater comprises at least three grades of preheaters which sequentially communicate; a smoke channel at the tail of the rotary kiln is provided with a bypass air exhausting device; an alumina clinker outlet is formed in the end part of the grate cooler; the decomposing furnace is subjected to tertiary air one-side feeding. According to the technology, the nepheline is used as the aluminum raw material; the alumina sintering technology is developed from the wet technology to the preheating and decomposing dry technology; massive production is realized; the energy conservation and the consumption reduction are greatly realized; the system operation is simple; the raw material cost and the fuel costare decreased; and the automation degree is high.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Mild gas turbine combustion chamber

ActiveCN111520747AReasonable coolingFully warmed upContinuous combustion chamberCombustion chamberCombustor

The invention provides a mild gas turbine combustion chamber, and relates to the technical field of gas turbines. Based on the defects that a traditional gas turbine combustion chamber is severe in working environment, large in heat load, high in temperature and speed, complex in flow field and the like, a fuel oil single-point injection combustor is changed into multi-point injection of the wallsurface of a flame tube, multi-point mixing of fuel oil and air can be achieved, a mild combustion area is established, and stable and efficient combustion is achieved; the wall surface of the flame tube is designed to be of a double-layer wall structure, the middle of the flame tube is designed to be of a honeycomb sandwich structure, high-temperature airflow inside the flame tube can be reasonably cooled, it is guaranteed that the fuel oil in a fuel oil branch pipe is sufficiently preheated, and meanwhile, the effect of reducing noise generated in the working process of the combustion chamber can be achieved; and a boss structure is designed in the flame tube, the flame tube can be partitioned, flames can be quenched to the mild combustion area from an fuel-rich combustion area rapidly,emission of nitric oxide is reduced, and the stable combustion of the fuel in the flame tube is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Cast high-temperature alloy and martensitic stainless steel diffusion welding method

ActiveCN110666328ASimple processEasy to operateNon-electric welding apparatusThermal dilatationMartensitic stainless steel

The invention discloses a cast high-temperature alloy and martensitic stainless steel diffusion welding method. According to percentage by mass: 55-60% of nickel powder, 25-30% of chromium powder and10-15% of molybdenum powder are uniformly mixed for ball milling, and then, are pressed as an intermediate layer; the intermediate layer is positioned between two welding base metals; the placed welding base metals and the intermediate layer are positioned between an upper pressing head and a lower pressing head of a vacuum hot pressing furnace; pre-pressure is applied to the welding base metals through the upper pressing head; the vacuumization is performed; after the temperature is increased to 980-1020 DEG C, the pressure is increased; the diffusion welding is performed after temperature and pressure maintenance by 1.5-2 h; then, the pressure is released; firstly, the slow cooling is performed; and then, the cooling along with a furnace is performed. The method is simple in process, high in operability and easy to popularize. The intermediate layer adopted by the welding method is the common component of the base metals; and the thermal expansion coefficient is within the base metalto achieve excellent transition between chemical properties and physical properties. After welding, the welding line compactness is high, the mechanical performance is excellent, and such defects ascracks and air holes are not generated.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

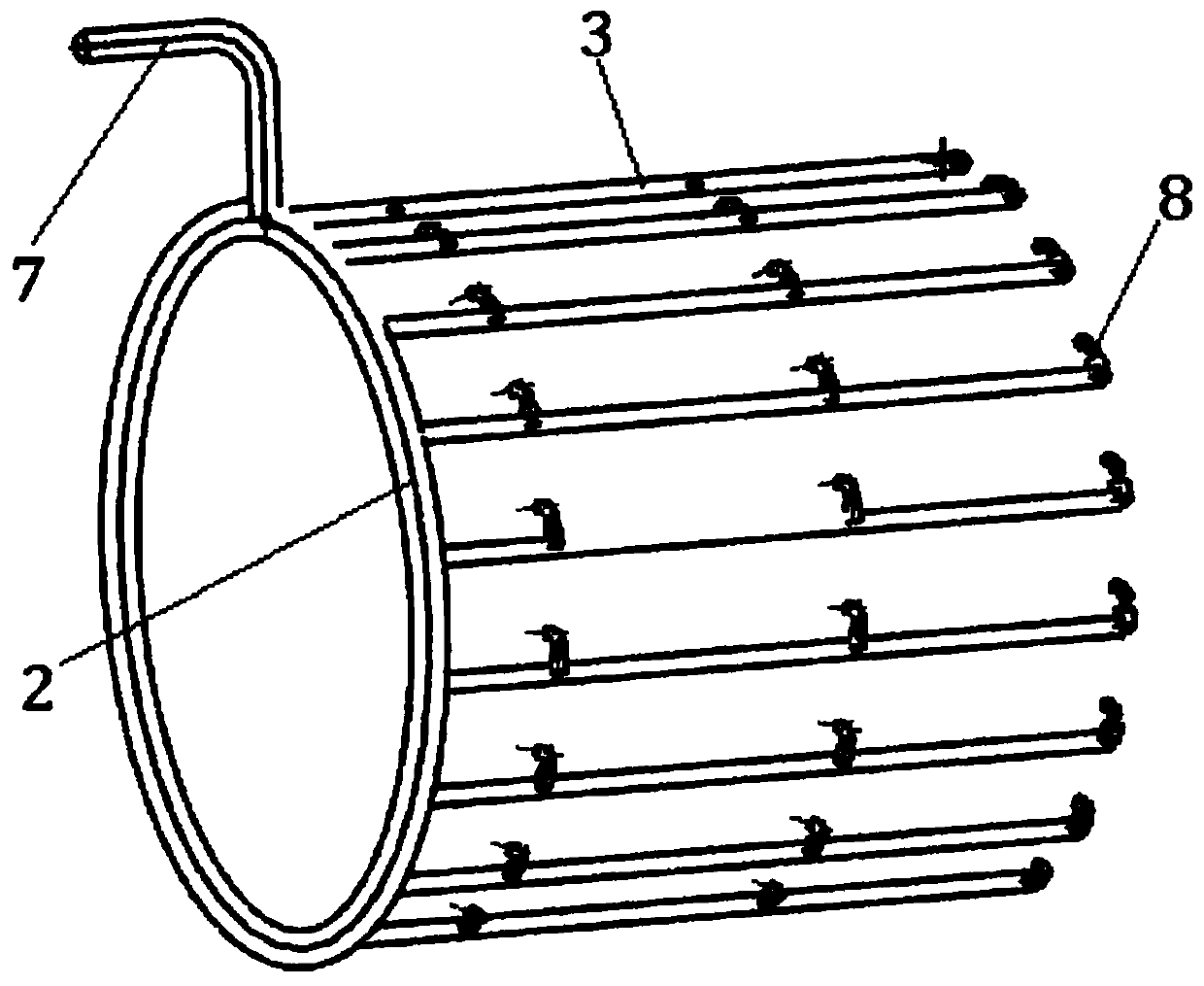

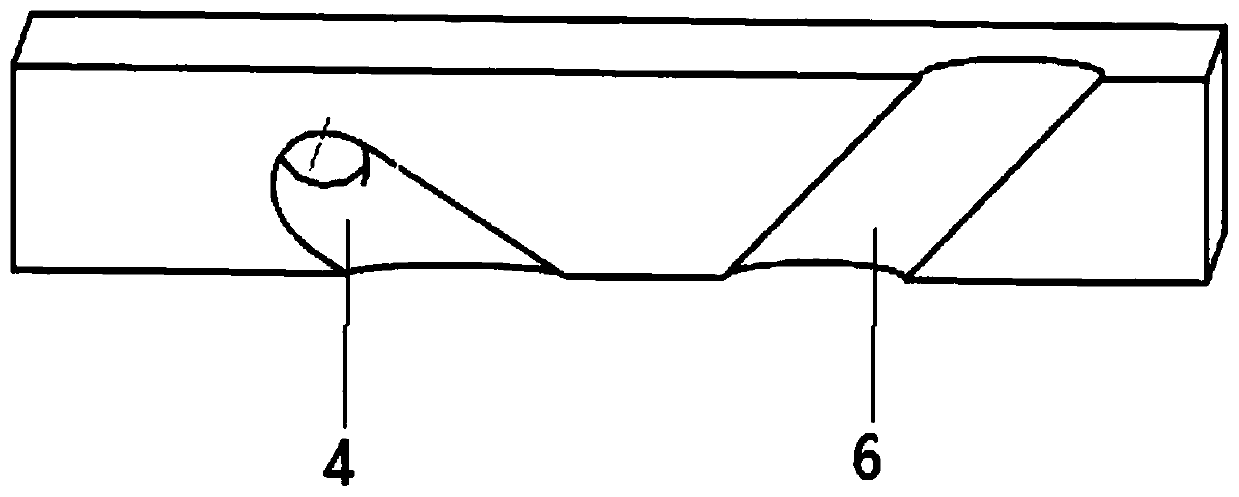

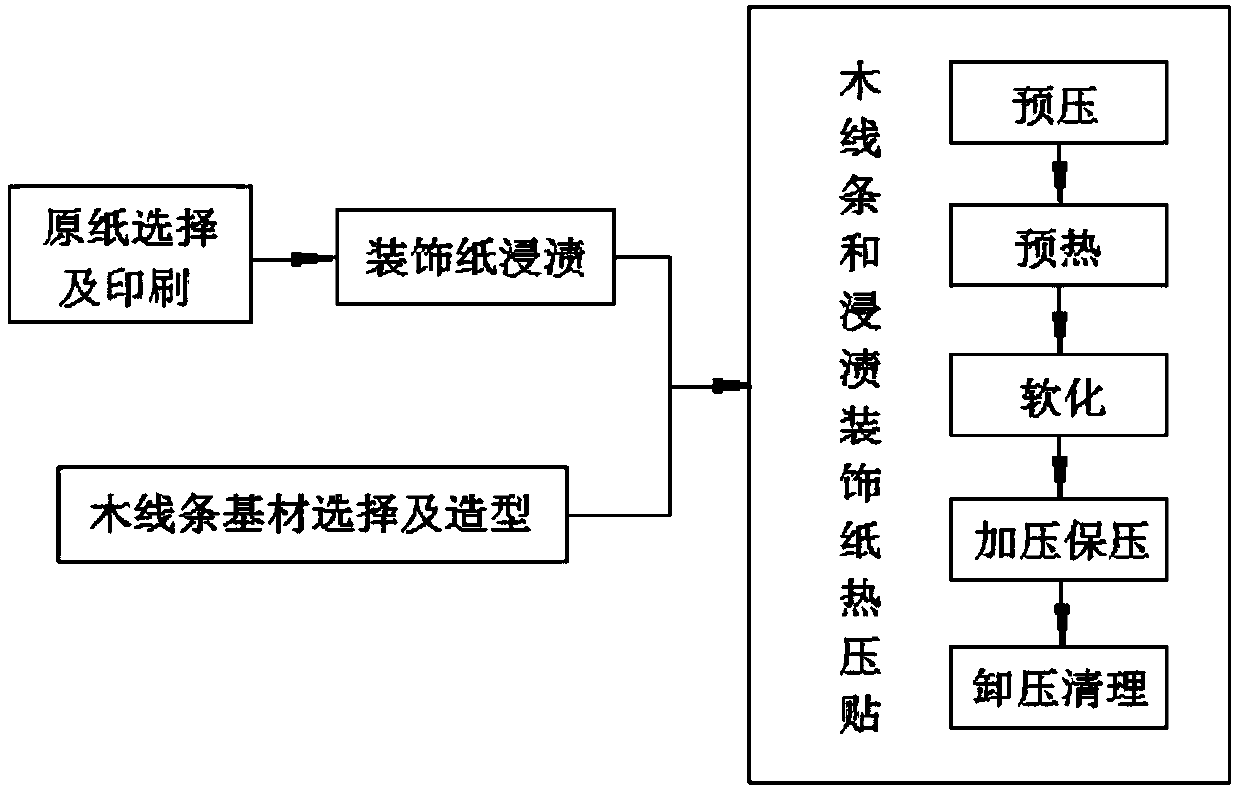

Process of hot-pressing dipped glue film decorative paper on pure solid wood or raw wood allomorphia balansae line

ActiveCN104191791ALow costThe solution cannot be realized in pure solid woodLaminationLamination apparatusSolid woodAllomorphia

Owner:CHANGZHOU JIASHIJIA DECORATIVE NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com