Multifunctional reflow soldering device and control method thereof

A reflow soldering and multi-functional technology, applied in the direction of auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of manual repair soldering, high temperature resistance of components, and large manual labor, so as to reduce energy loss and save energy , easy-to-implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

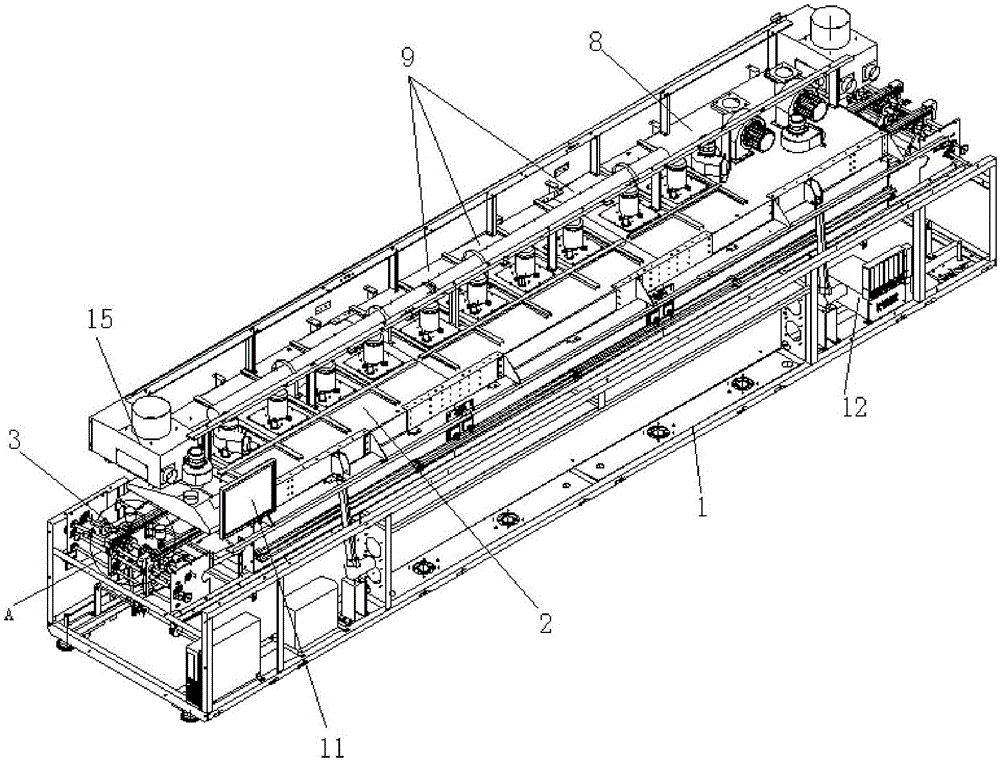

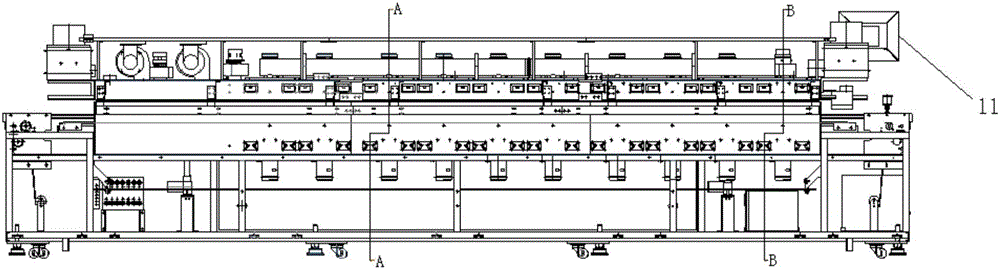

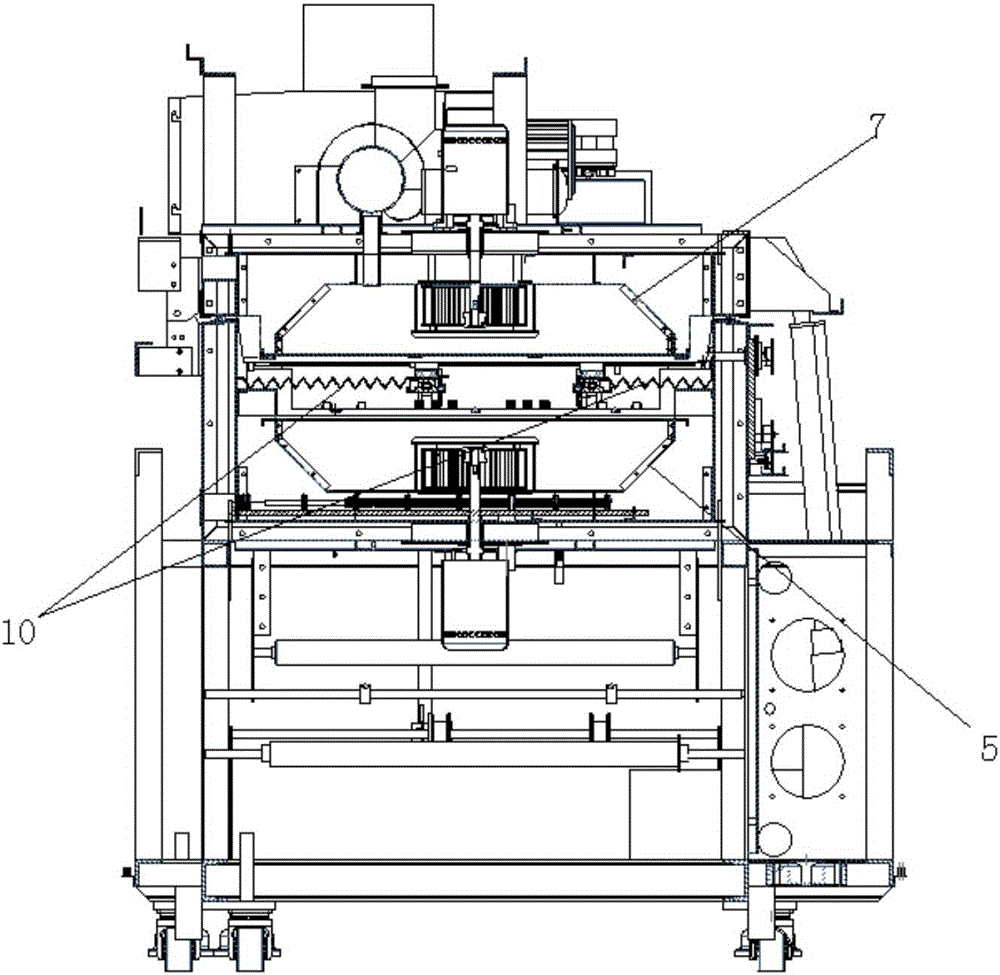

[0036] Example 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 11 As shown, a multifunctional reflow soldering device includes a reflow soldering machine table 1, and a soldering machine table cover 2 that can be opened and closed is provided on the rear edge of the upper plane of the reflow soldering machine table 1, and the soldering machine table cover 2 is composed of a can The telescopic support arm is connected and controlled to open or close. The upper plane of the reflow soldering machine 1 is provided with a product conveying line 3 whose width can be adjusted. The reflow soldering machine 1 is sequentially provided with two upwardly blowing hot air from left to right. The lower furnace 4 and a second lower furnace 5 blowing upwards, the position corresponding to the first lower furnace 4 in the welding machine cover 2 is provided with a first temperature zone upper furnace 6 for air extraction, and t...

Embodiment 2

[0047] Embodiment 2: a multifunctional reflow soldering device, comprising a reflow soldering machine table 1, a soldering machine table cover 2 that can be opened and closed is provided on the rear edge of the upper plane of the reflow soldering machine table 1, and the soldering machine table cover 2 is composed of a The telescopic support arm is connected to control the opening or closing. The upper plane of the reflow soldering machine 1 is provided with a product conveying line 3 whose width can be adjusted. The lower furnace 4 and a second lower furnace 5 blowing upward, the welding machine cover 2 is provided with a first temperature zone upper furnace 6 for air extraction at the position corresponding to the first lower furnace 4, and the welding machine cover The position corresponding to the second lower furnace 5 in 2 is provided with a second temperature zone upper furnace 7 that blows hot air downward, the first temperature zone upper furnace 6 and the first lower ...

Embodiment 3

[0048] Embodiment 3: A control method of a multifunctional reflow soldering device, comprising the following steps:

[0049] A) Control the temperature zone, set the first temperature zone (preheating zone), the second temperature zone (reflow soldering zone) and the cooling zone which can be reflowed; The furnace is formed, and the second temperature zone is formed by the upper furnace and the second lower furnace in the second temperature zone; in the upper furnace of the second temperature zone, there is a heating wire that can control heating or turn off the heating independently; The furnace is blown hot air, and the cooling area is blown cold air;

[0050] B) Set the temperature value of the first temperature zone and the second temperature zone, and sense the temperature value of the temperature zone through the temperature sensor, so that the temperature between the upper furnace and the first lower furnace in the first temperature zone of the first temperature zone is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com