Gas water heater and control method

A gas water heater and control method technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of prolonged user waiting time, insufficient preheating, large heat loss, etc., and improve self-adaptive ability. , Improve user experience, intelligent high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

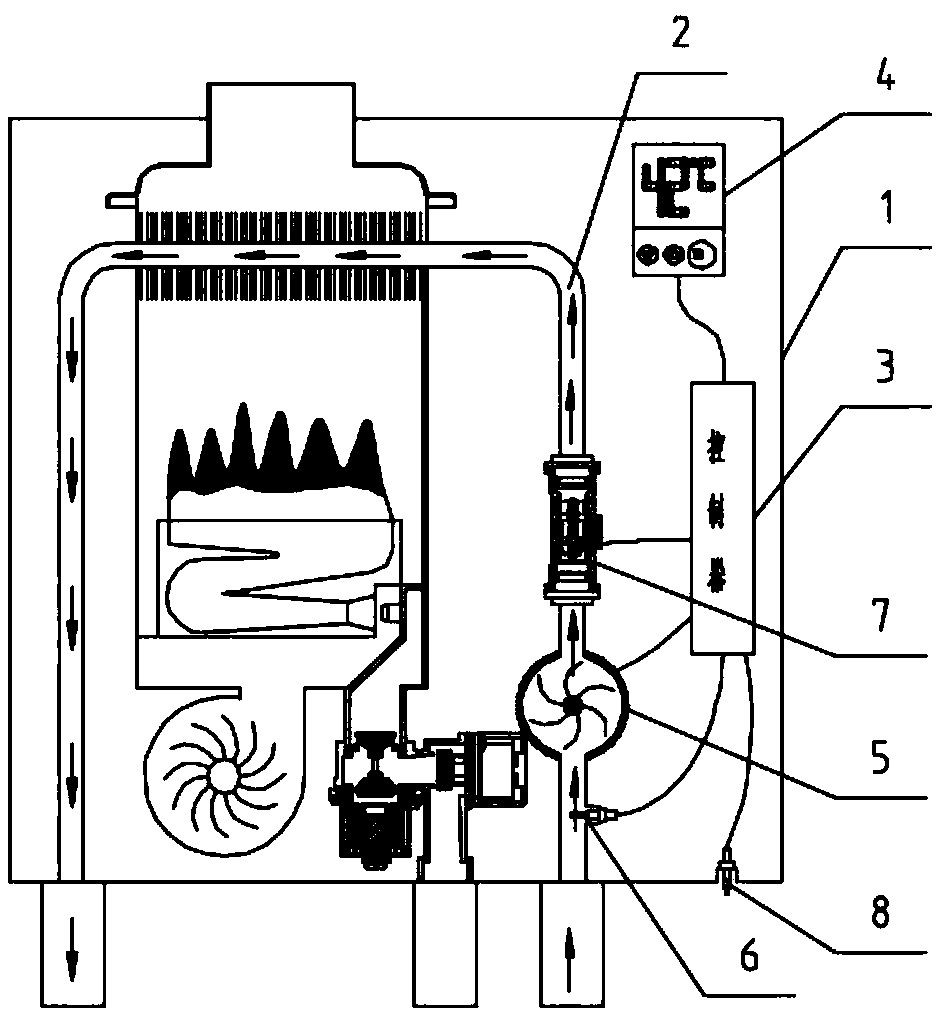

[0037] see figure 1 , a gas water heater in this embodiment includes a water heater body 1 , an inlet pipe 2 , a controller 3 , an operating device 4 , a circulation pump 5 , a first temperature probe 6 , a water flow sensor 7 and a second temperature probe 8 . The controller 3 is electrically connected to the operating device 4, the circulating pump 5, the first temperature probe 6, the water flow sensor 7 and the second temperature probe 8, so that the controller 3 can The signals from the sensor 7 and the second temperature probe 8 accurately control the start and stop of the circulation pump 5 and improve the control accuracy of the circulation pump 5 .

[0038] Further, the circulation pump 5 is installed in the water inlet pipeline 2 inside the water heater body 1, and is used to drive the stored water to circulate. The first temperature probe 6 is installed in the water inlet pipeline 2 in the water heater body 1, and is used to detect the return water temperature and ...

Embodiment 2

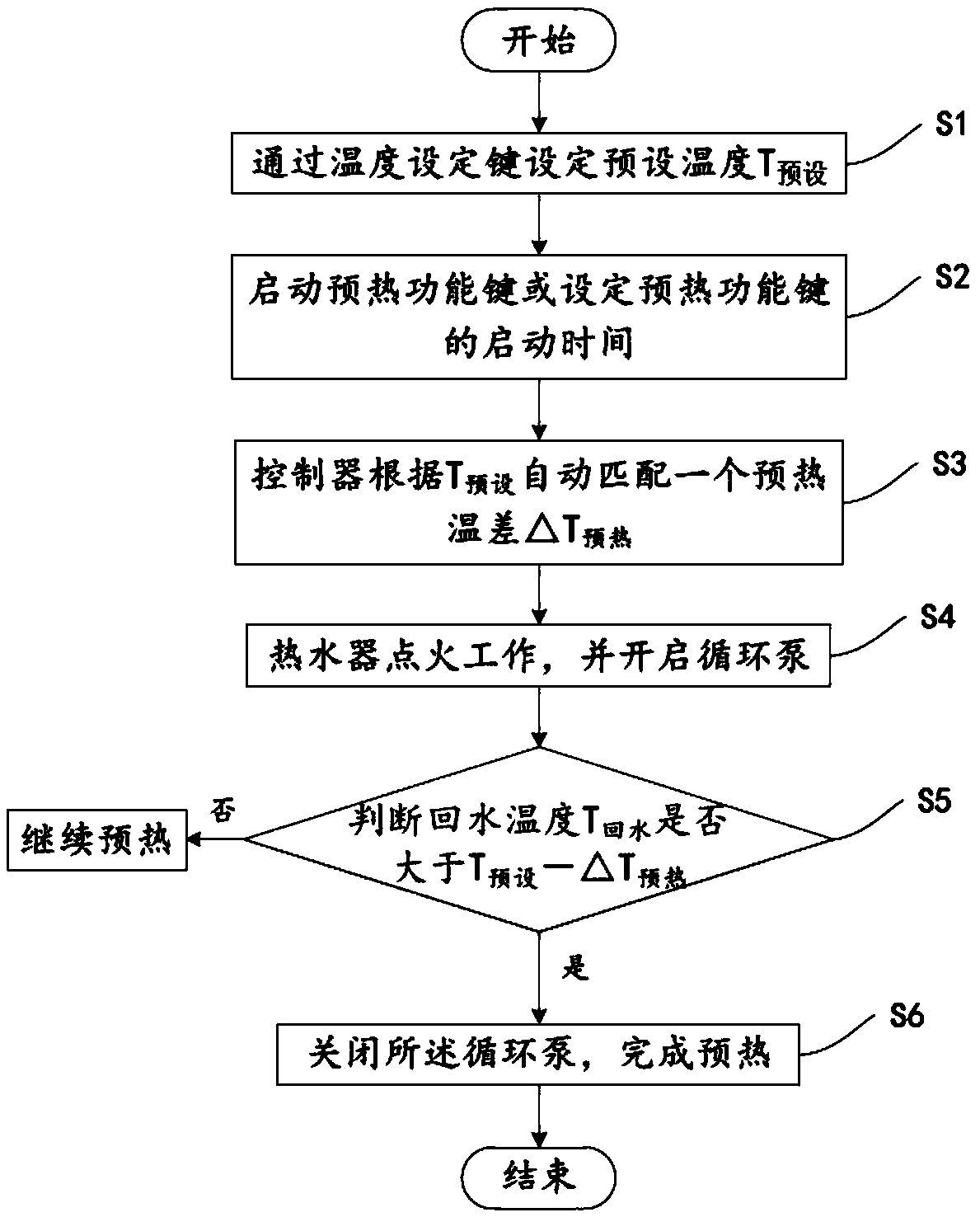

[0044]see image 3 , a control method of a gas water heater described in Embodiment 1, which is a kind of application of this embodiment, includes the following steps:

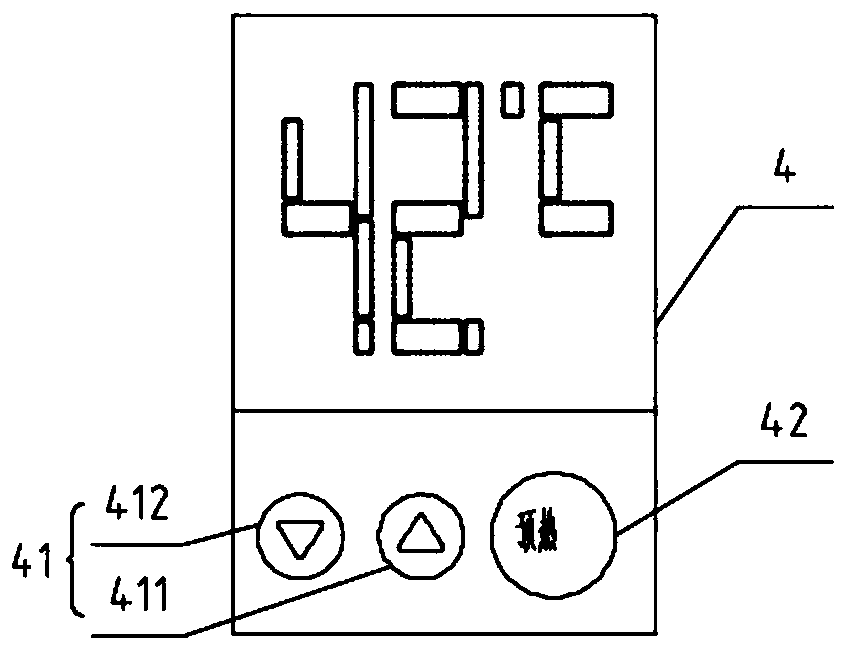

[0045] S1: Set the preset temperature T through the temperature setting key 41 预设 ;

[0046] Specifically, when the water heater is powered on, the user can set the required preset temperature T through the temperature increase key 411 and the temperature decrease key 412 of the temperature setting key 41 according to the actual demand for water temperature. 预设 ;

[0047] S2: start the preheating function key 42 or set the start time of the preheating function key 42;

[0048] Specifically, before starting the preheating function key 42, the first temperature probe 6 can be used to detect whether the stored water temperature in the water inlet pipeline 2 is greater than or equal to T 预设 -△T 预热 , if so then start the preheating function key 42, otherwise start the preheating function key 42 or set the star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com