Process of hot-pressing dipped glue film decorative paper on pure solid wood or raw wood allomorphia balansae line

A technology of hot-pressed impregnation and wood strips, which is applied in lamination devices, laminations, and layered products, etc., can solve the problems of low defective rate, inability to realize hot-pressed impregnated adhesive film decorative paper, etc., so as to reduce product cost, Guaranteed permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

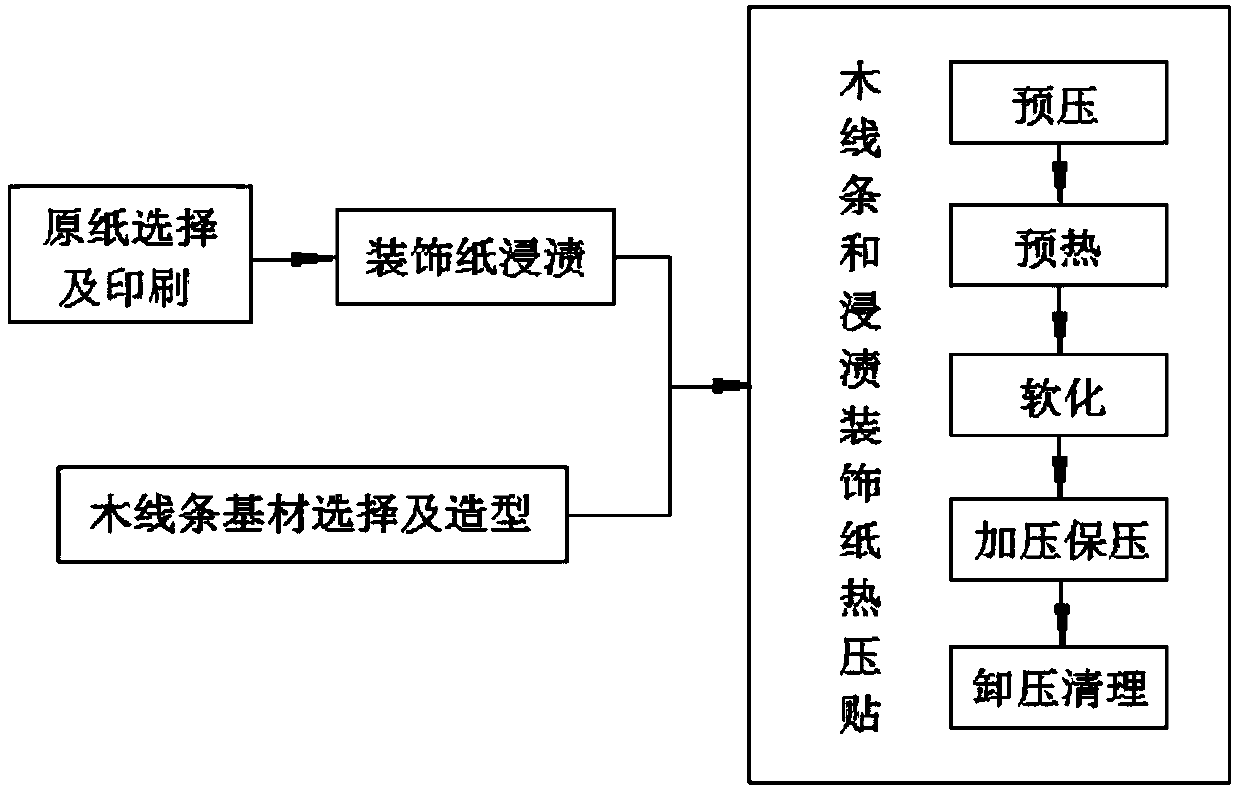

[0038] combine figure 1 , a process of pure solid wood or log special-shaped wood moldings hot-pressed and impregnated with film decorative paper in this embodiment. Suitable moulding-based substrates and base papers for impregnated laminated decorative papers.

[0039] For the base paper impregnated with film decorative paper, it is made of pure virgin pulp, because the wood fiber of pure virgin pulp is relatively long, which is conducive to the extension of the paper. For the paper made of secondary or tertiary recycled paper beating, the wood fiber is reused. The fibers are very short, and this type of short-fiber paper can cause breakage or other problems after heat pressing, so it is not recommended. At the same time, in order to meet the subsequent use of hot pressing and improve the quality of the product, the thickness of the decorative paper needs to be increased compared with the traditional decorative paper, and the general paper thickness is 70-110g / m 2 It is b...

Embodiment 2

[0055] The process of hot-pressing and impregnating film decorative paper for pure solid wood or logs with special-shaped wood moldings in this embodiment is basically the same as that in Embodiment 1, except that the thickness of the decorative paper used in this embodiment is 70g / m 2 , the paper thickness is relatively thin, when impregnating the decorative paper, the impregnating temperature is 100°C, the vehicle speed is 12m / s; the amount of glue applied is 140%, and the volatility of the impregnated film decorative paper is 7%. In this embodiment, when the wood strips and the impregnated film decorative paper are hot-pressed, the temperature of the hot press in step (1) is 120°C; in step (2), when the mold is completely closed, the impregnated film decoration The paper stays for 3 seconds under the condition of temperature but no pressure; in step (3), the hot pressing pressure is 2kg / m 2 , and keep the pressure for 30 seconds.

Embodiment 3

[0057] The process of hot-pressing and impregnating film decorative paper for pure solid wood or logs with special-shaped wood moldings in this embodiment is basically the same as that in Embodiment 1, except that the thickness of the decorative paper used in this embodiment is 110g / m 2 , the paper thickness is thicker, when impregnating the decorative paper, the impregnating temperature is 160°C, the vehicle speed is 28m / s; the amount of glue applied is 170%, and the volatility of the impregnated film decorative paper is 9%. In this embodiment, when the wood strips and the impregnated film decorative paper are hot-pressed, the temperature of the hot press in step (1) is 200°C; in step (2), when the mold is completely closed, the impregnated film decoration The paper stays for 20 seconds under the condition of temperature but no pressure; in step (3), the hot pressing pressure is 8kg / m 2 , and keep the pressure for 80 seconds.

[0058] A process of hot-pressing impregna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com