Gasoline engine cooling system

A cooling system, gasoline engine technology, applied in the direction of engine cooling, liquid cooling, coolant flow control, etc., can solve the problem of engine emissions and fuel economy deterioration, reduced cooling system cooling performance, engine outlet water temperature response lag, etc. problems, to achieve the effect of reducing fuel consumption and emissions, improving cooling performance, and reducing the frequency of opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

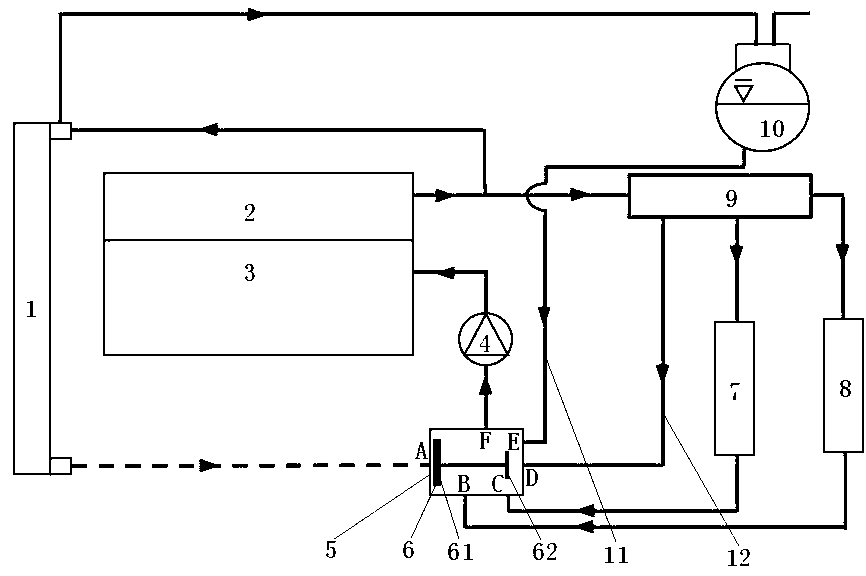

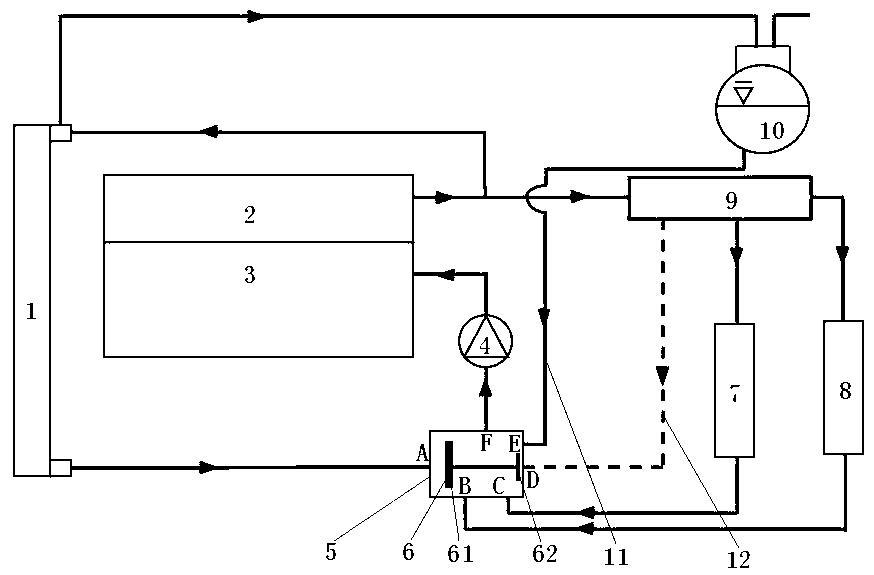

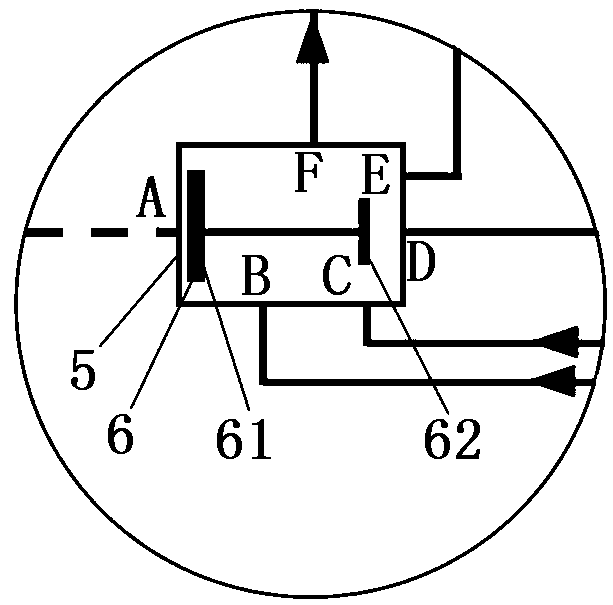

[0018] see figure 1 , a gasoline engine cooling system includes a radiator 1, a cylinder head water jacket 2, a cylinder block water jacket 3, a water pump 4 and an expansion tank 10. The upper water chamber of the radiator 1 is connected to the water inlet of the expansion tank 10, and the water outlet of the cylinder head water jacket 2 is respectively connected to the upper water chamber of the radiator 1 and the water inlet of the water distribution pipe 9 through a three-way pipe. The second outlet and the first outlet of the valve are respectively connected to the inlet of the throttle valve 7 and the inlet of the heater 8; the water outlet of the cylinder block water jacket 3 is connected to the water inlet of the cylinder head water jacket 2; the water outlet of the water pump 4 is connected to the cylinder The water inlet of body water jacket 3. see image 3 , a thermostat 6 is installed inside the thermostat valve seat 5, and there are five inlets and one outlet F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com