Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Avoid thermal shock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

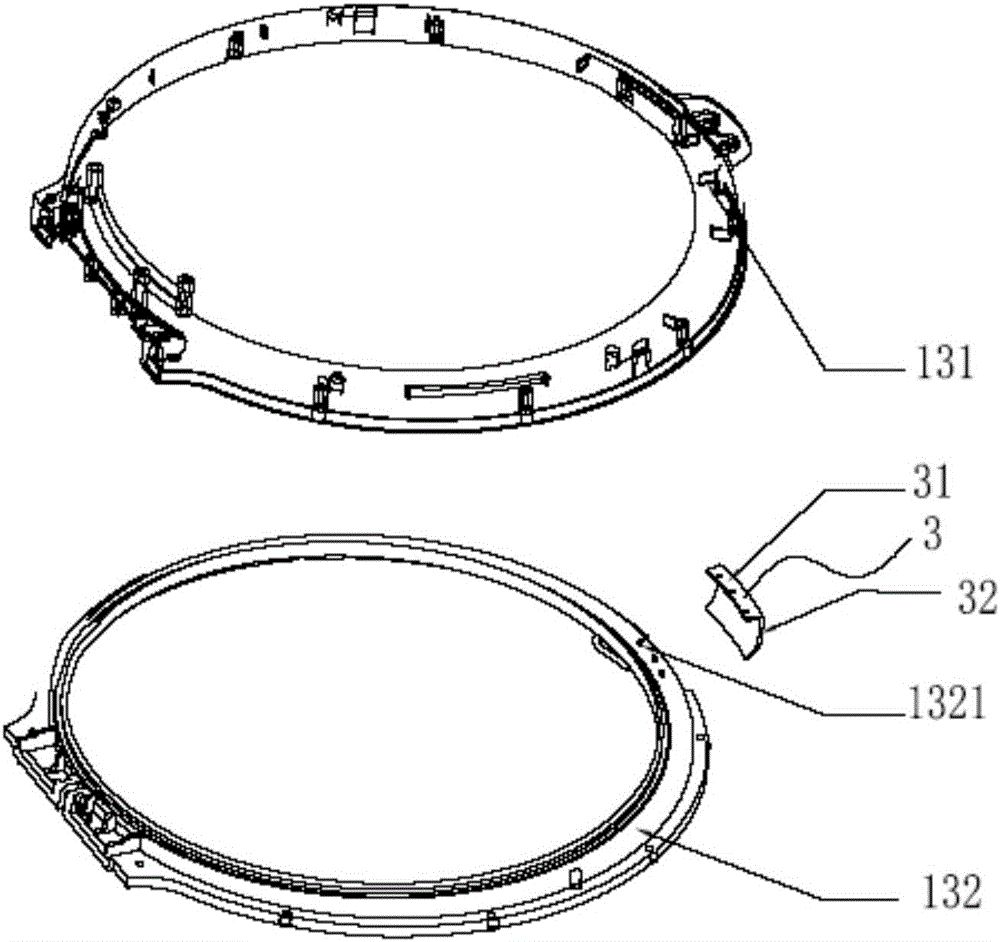

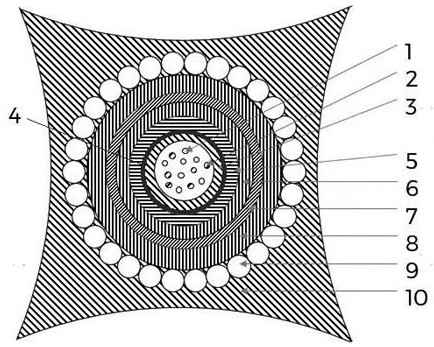

Liner and liquid heating container

InactiveCN108926249AEasy to passReduce deliveryWater-boiling vesselsWarming devicesEngineeringPower density

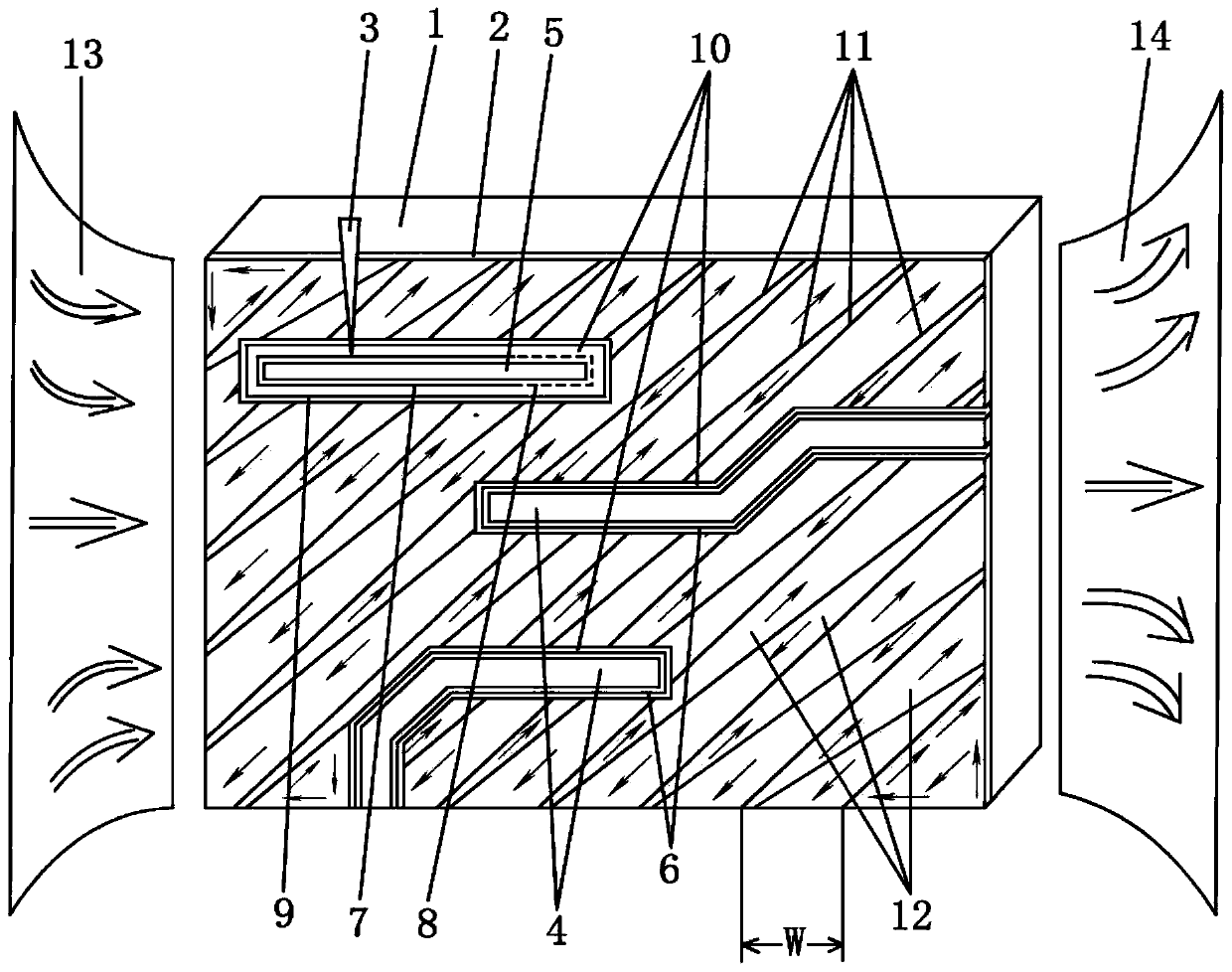

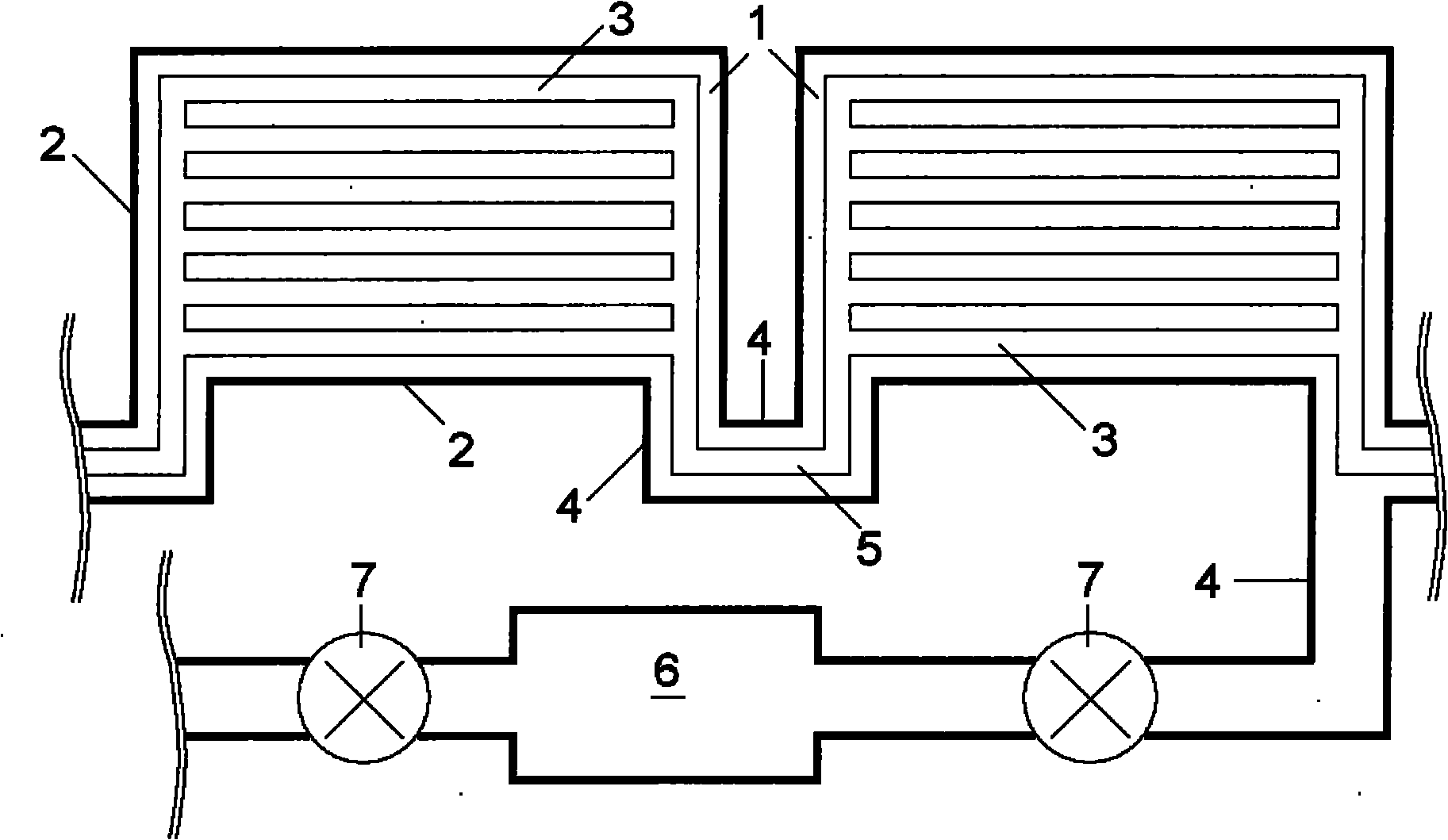

The invention provides a liner and a liquid heating container. The liner comprises a body, a heat conduction plate and a heating part, wherein the body comprises a barrel body and a barrel bottom connected with the bottom of the barrel body; the heat conduction plate fits to the outer wall face of the barrel bottom, and the heat conduction coefficient of the heat conduction plate is greater than that of the barrel bottom; the heating part is ring-shaped and fits to the lower surface of the heat conduction plate, and the projection of the heating part is positioned in the heat conduction plate;the thickness of the heat conduction plate is greater than or equal to 2mm; and / or, a spacing between the outer periphery of the contact part of the heating part and the heat conduction plate and theouter periphery of the heat conduction plate is greater than or equal to 3mm. For the liner provided by the invention, by increasing the spacing between the outer periphery of the contact part of theheating part and the heat conduction plate and the outer periphery of the heat conduction plate, heat generated by the heating part becomes bidirectional heat conduction from unidirectional heat conduction, so that the local thermal power density is greatly reduced, and the noises caused by heating water are reduced; and / or, the heat conduction plate is thickened, so that the local thermal shockis prevented, heat is uniformly transmitted as far as possible, and further, the noises caused by heating water are reduced.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

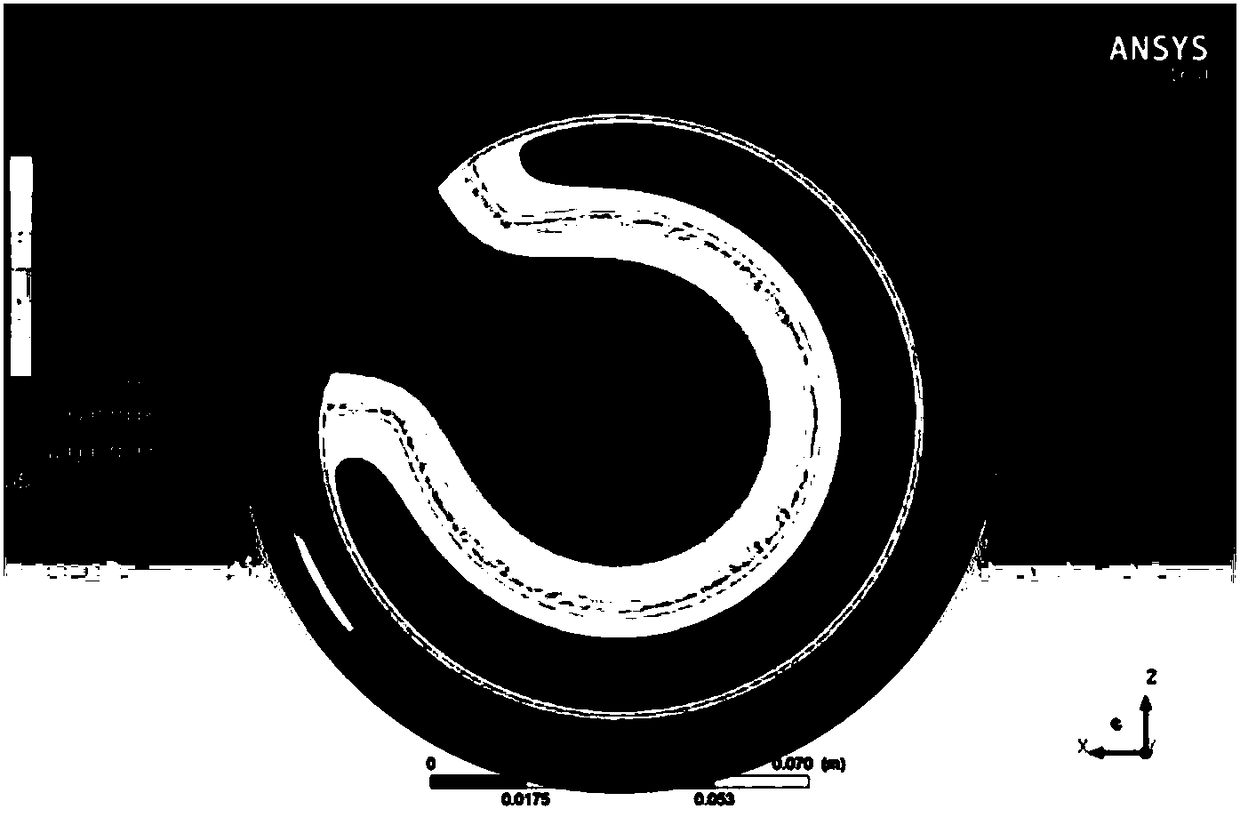

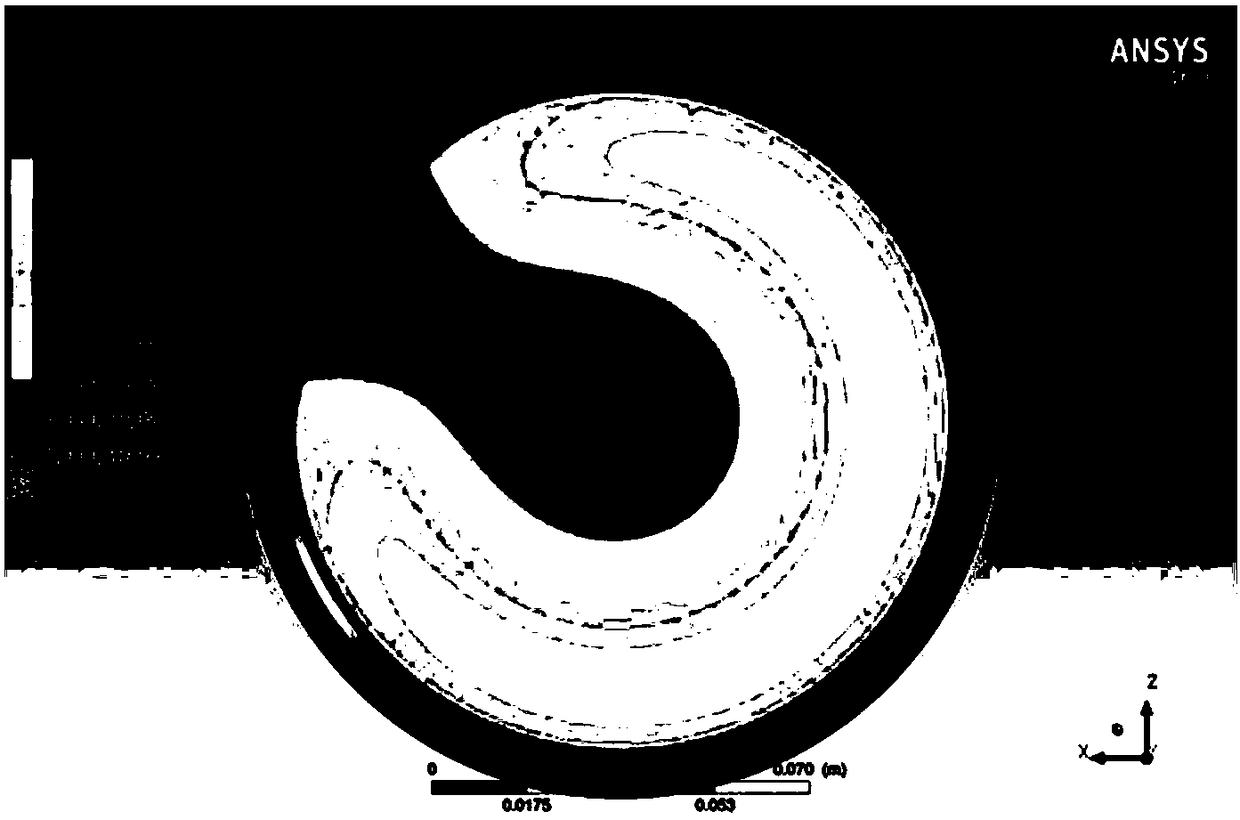

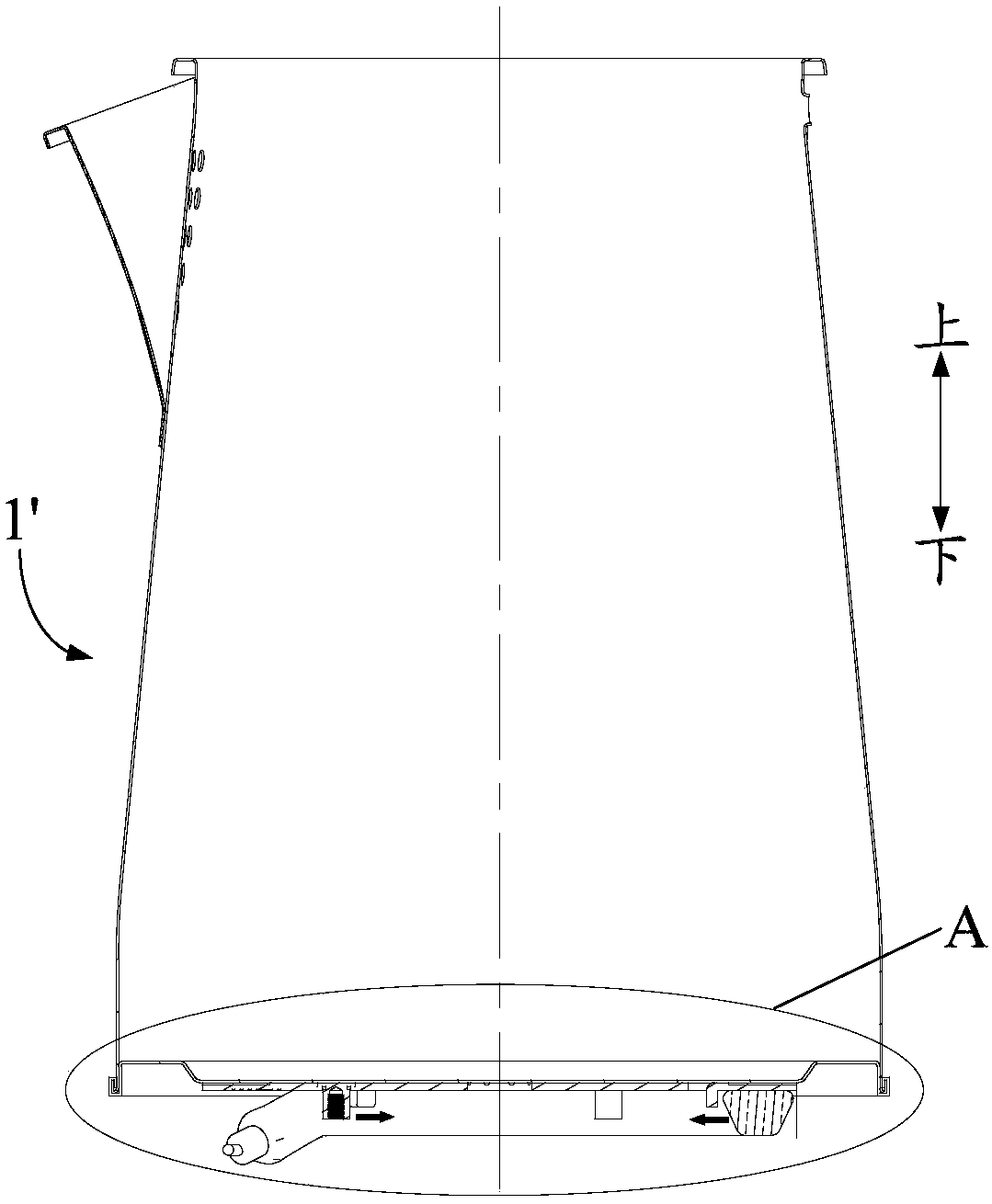

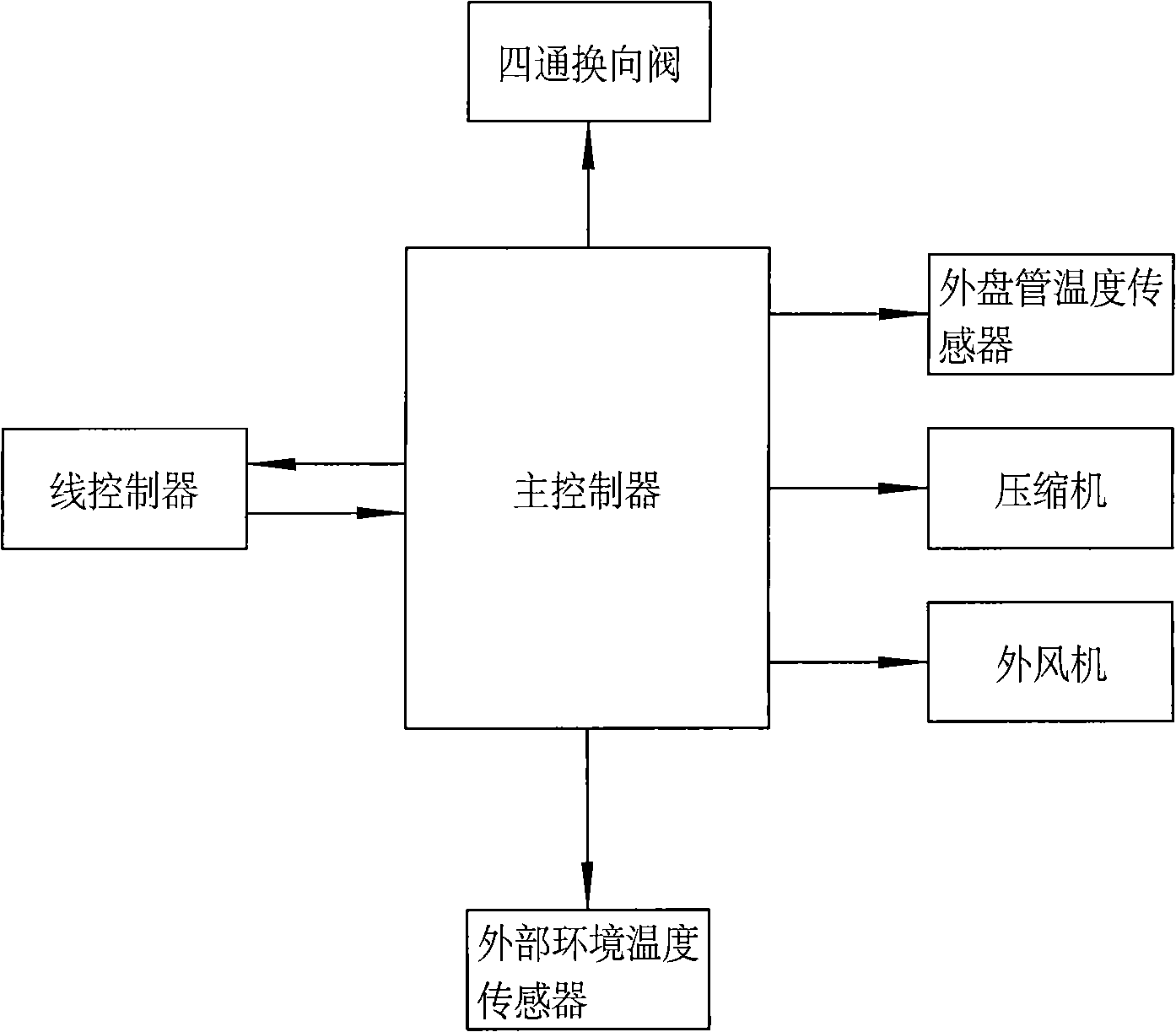

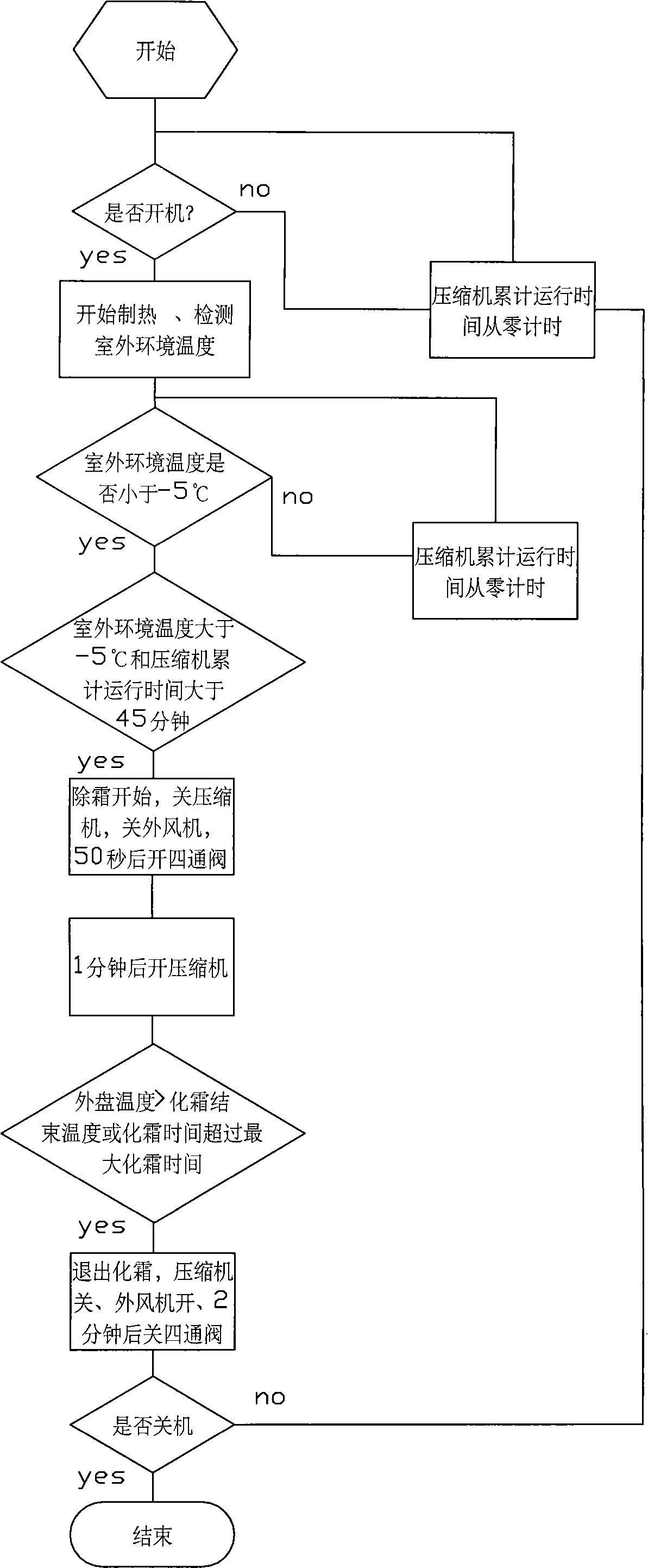

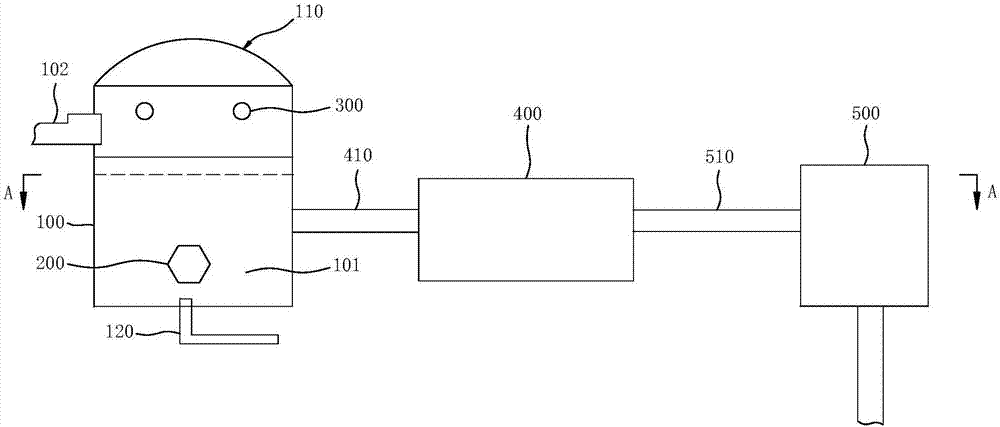

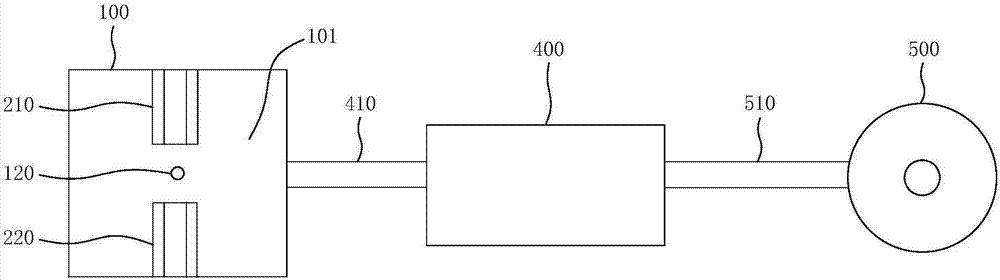

Air energy water heater and defrosting method thereof

The invention discloses an air energy water heater, which comprises a main controller, a compressor and an external environment temperature sensor, wherein the compressor and the external environment temperature sensor are electrically connected with the main controller through leads. The defrosting method mainly comprises the following steps: in the normal heating process, continuously monitoring outdoor environment temperature through the external environment temperature sensor; if the outdoor environment temperature is lower than the defrosting starting temperature, accumulating the running time of the compressor; when the accumulated running time of the compressor reaches the defrosting starting time, starting a defrosting program; and finishing defrosting when the external environment temperature is higher than the defrosting finishing temperature or the defrosting time exceeds the maximum defrosting time, thereby determining whether the defrosting program needs to be started or not by comparing the defrosting starting temperature with the temperature transferred by the external environment temperature sensor to avoid cold shock and thermal shock of external environment to the sensor and ensure the normal use of a sensor chip, so that normal and real judgment of the system can be ensured to enable the defrosting effect to be better.

Owner:宁波海诚电器有限公司

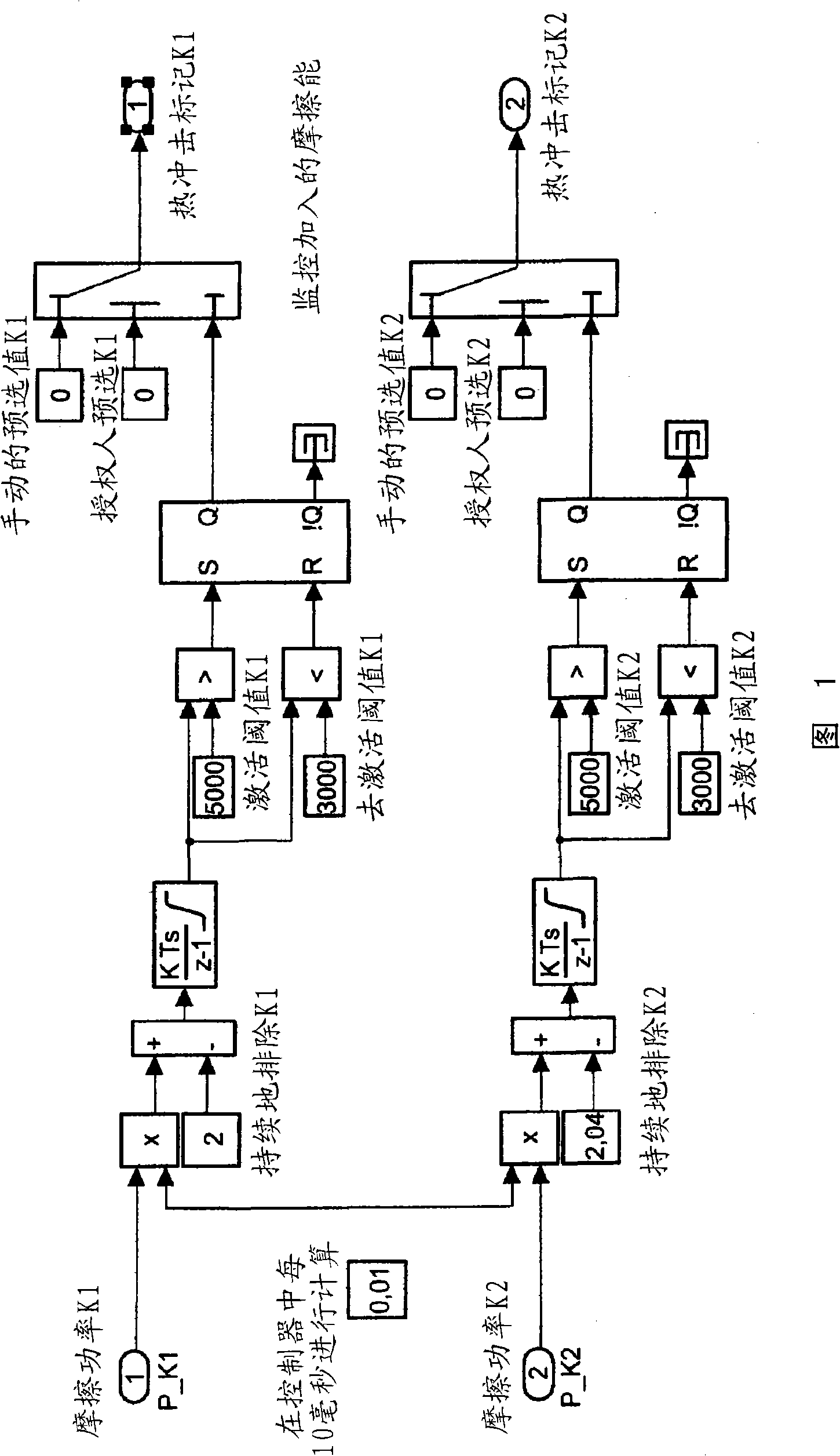

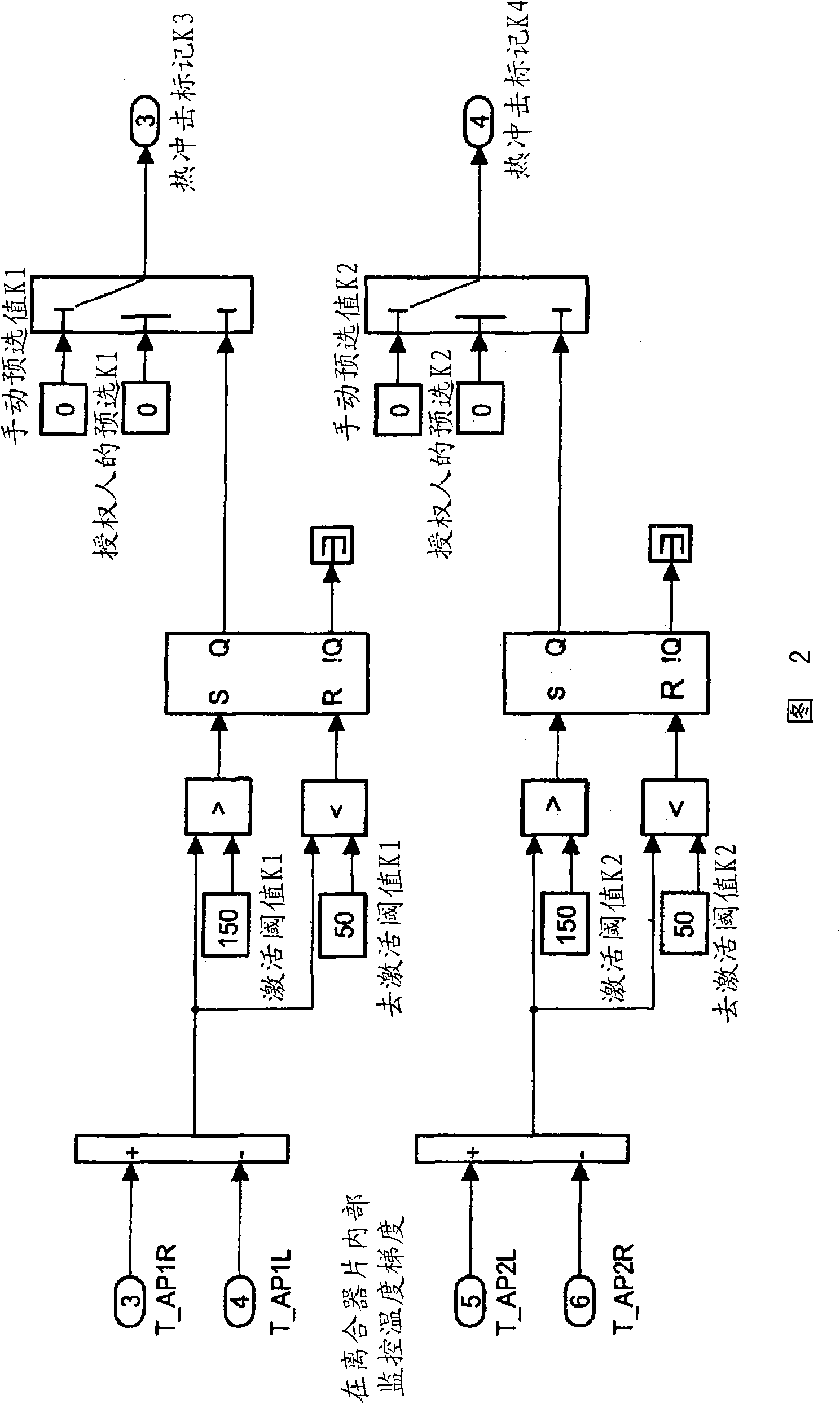

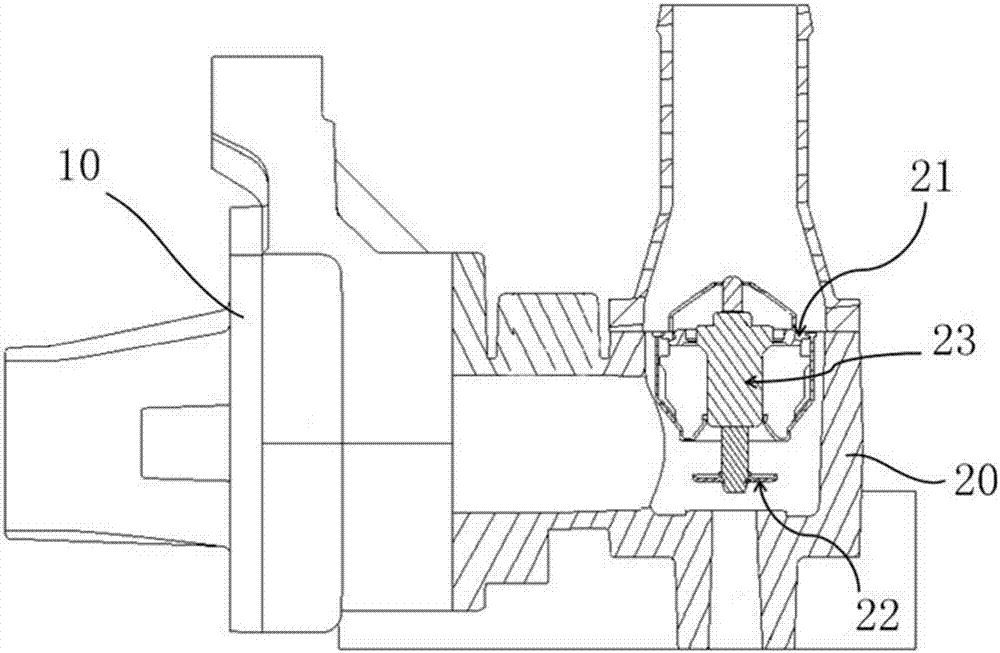

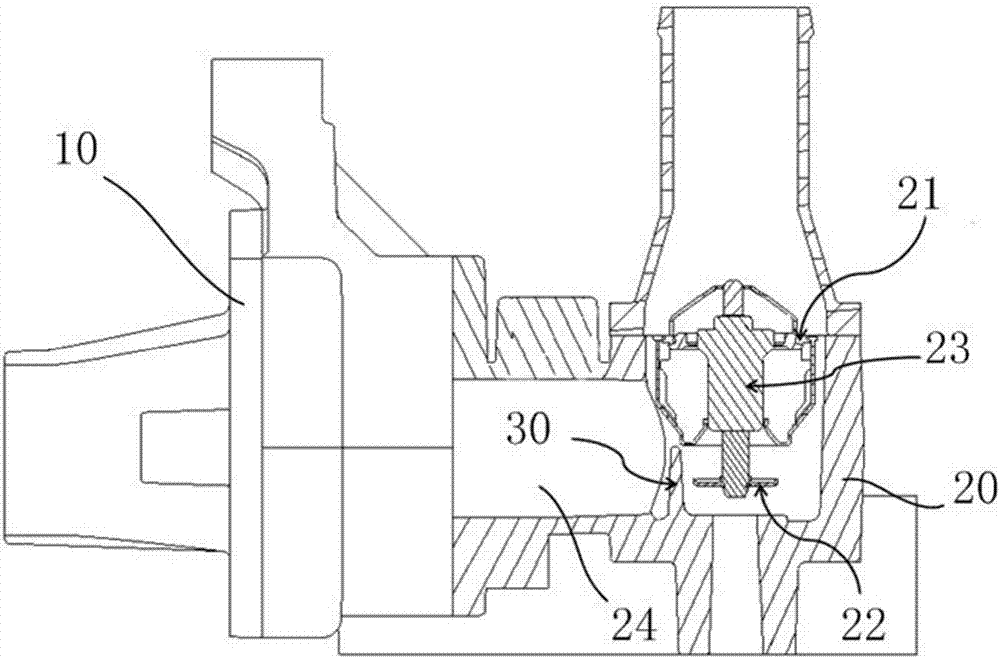

Method and apparatus for monitoring thermal load of vehicle clutch

The invention discloses a method for monitoring a thermal load of a clutch a car, specifically for avoiding a thermal shock of the clutch, preferably a double clutch of double clutch transmission, wherein comprising calculating and / or determining a thermal load of the clutch. A controller is provided for controlling the clutch. Therefore, the shortage is overcame to confirm and / or calculate the speed and / or the torque of an engine and / or the rotation speed of a transmission input shaft, and thereby determining the friction power of the clutch; the friction power is integrated over a certain time interval. When the integrated friction power is currently matched and reaches the determined frictional energy threshold value, that is, during danger of a thermal overloading of the clutch, the clutch is at least partially disconnected.

Owner:VOLKSWAGEN AG

Formula of heating powder for thermal battery

InactiveCN102244206AExtended working hoursImprove securityDeferred-action cellsCell component detailsWorking lifeIron powder

The invention discloses a formula of heating powder for a thermal battery. An eutectic salt accounting for 7-12% of the total weight is added into the heating powder for a thermal battery formed by mixing iron powder and potassium perchlorate. The weight ratio of iron powder to potassium perchlorate is 84:16, 83:17 or 82:18. The eutectic salt is the mixture of NaCl and Li2SO4, wherein the NaCl accounts for 38-45% of the weight of the eutectic salt, and the Li2SO4 accounts for 55-62%. The formula can prolong the service life of the thermal battery so as to prolong the working life of the thermal battery.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Interlayer fluorescent glass and preparation method and application thereof

ActiveCN106816521APlay a protective effectAvoid direct contactSemiconductor devicesWhole bodyFluorescence

The invention discloses an interlayer fluorescent glass and a preparation method and applications thereof; the interlayer fluorescent glass comprises a first glass substrate, a second glass substrate and a Ce:YAG fluorescent glass layer clamped between the first and second glass substrates; the first glass substrate, the Ce:YAG fluorescent glass layer and the second glass substrate are directly and firmly combined so as to form a whole body; the visible light transmittance of the first and second glass substrates is bigger than 90%, and the softening point temperature is bigger than 800 DEG C; the melting point of the Ce:YAG fluorescent glass layer is below 700 DEG C; the refractive indexes of the first and second glass substrate are equal, and are respectively close to or equal to that of the Ce:YAG fluorescent glass layer; the thicknesses of the first and second glass substrates are respectively 0.4-3mm; the thickness of the Ce:YAG fluorescent glass layer is 15-200 micron. The interlayer fluorescent glass is used for white light LED device preparations, and the sandwich structure and well protect the fluorescent glass layer, thus prolonging the service life.

Owner:WENZHOU UNIVERSITY

Control method of air fryer

The invention relates to the technical field of kitchen appliance, in particular to a control method of an air fryer. The air fryer comprises an upper shell, a lower shell, a cooking cavity formed in the lower shell, a hot air device, a main control panel and an air flue, the hot air device, the main control panel and the air flue are arranged in the upper shell, wherein the main control panel and the hot air device are arranged on the cooking cavity, the hot air device comprises a heating element and a fan, and after the heating element stops working, the fan continues to work and drives airflow in the cooking cavity and the upper shell to move circularly. Wind generated by the fan drives waste heat of the heating element to move downwards, waste heat of the heating element is effectively prevented from moving upwards, the waste heat is prevented from causing heat impact on the main control panel in the upper shell, and the life of the main control panel is effectively prolonged.

Owner:JOYOUNG CO LTD

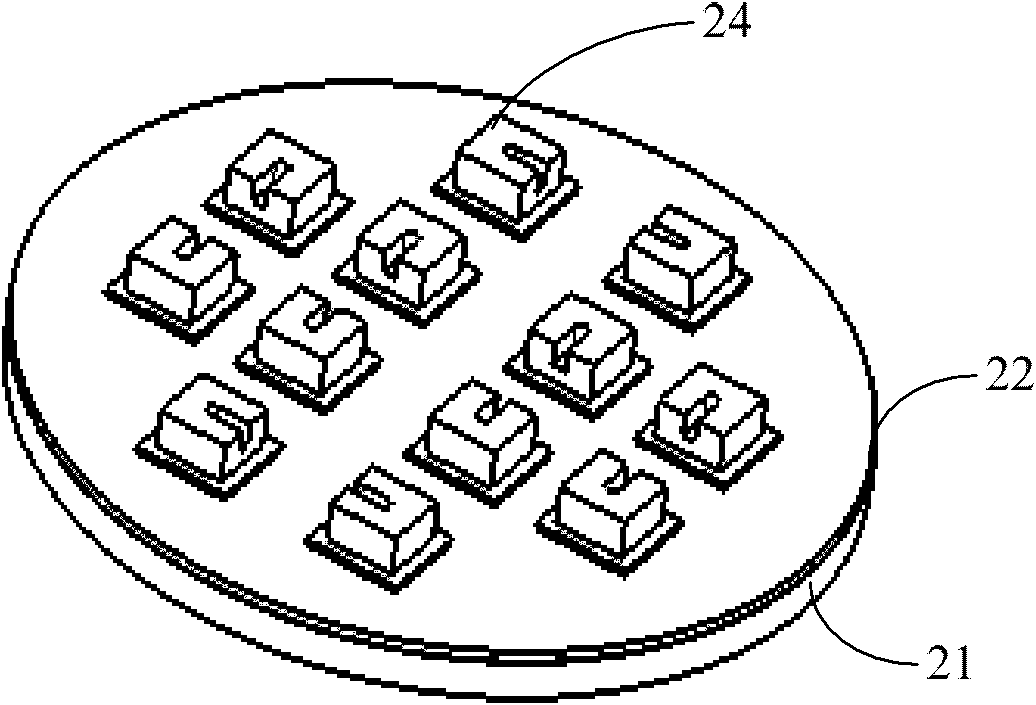

Silicon carbide power module and packaging method thereof

ActiveCN102130021AAvoid thermal shockImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesEpoxyIsolation layer

The invention relates to a packaging method of a silicon carbide power module. The packaging method comprises the following steps of: welding an aluminum nitride isolation layer on a molybdenum plate, placing a silicon carbide chip in a blank of the aluminum nitride isolation layer, and welding the silicon carbide chip with the molybdenum plate; welding a molybdenum block on the silicon carbide chip, and reserving a gate electrode lead slot on the molybdenum block; placing a lead in the gate electrode lead slot, arranging a compression ring on the lead, placing a spring used for crimping in the compression ring, and collecting and leading out the lead; and carrying out integral casting forming on the molybdenum plate, the silicon carbide isolation layer and the silicon carbide chip through using epoxy resin, installing a base, a tube shell and a tube cap, and packaging. The invention also discloses a silicon carbide power module. The invention ensures that the silicon carbide power module has higher reliability and stronger thermal cycle capacity under the working conditions of high power and high temperature.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD +1

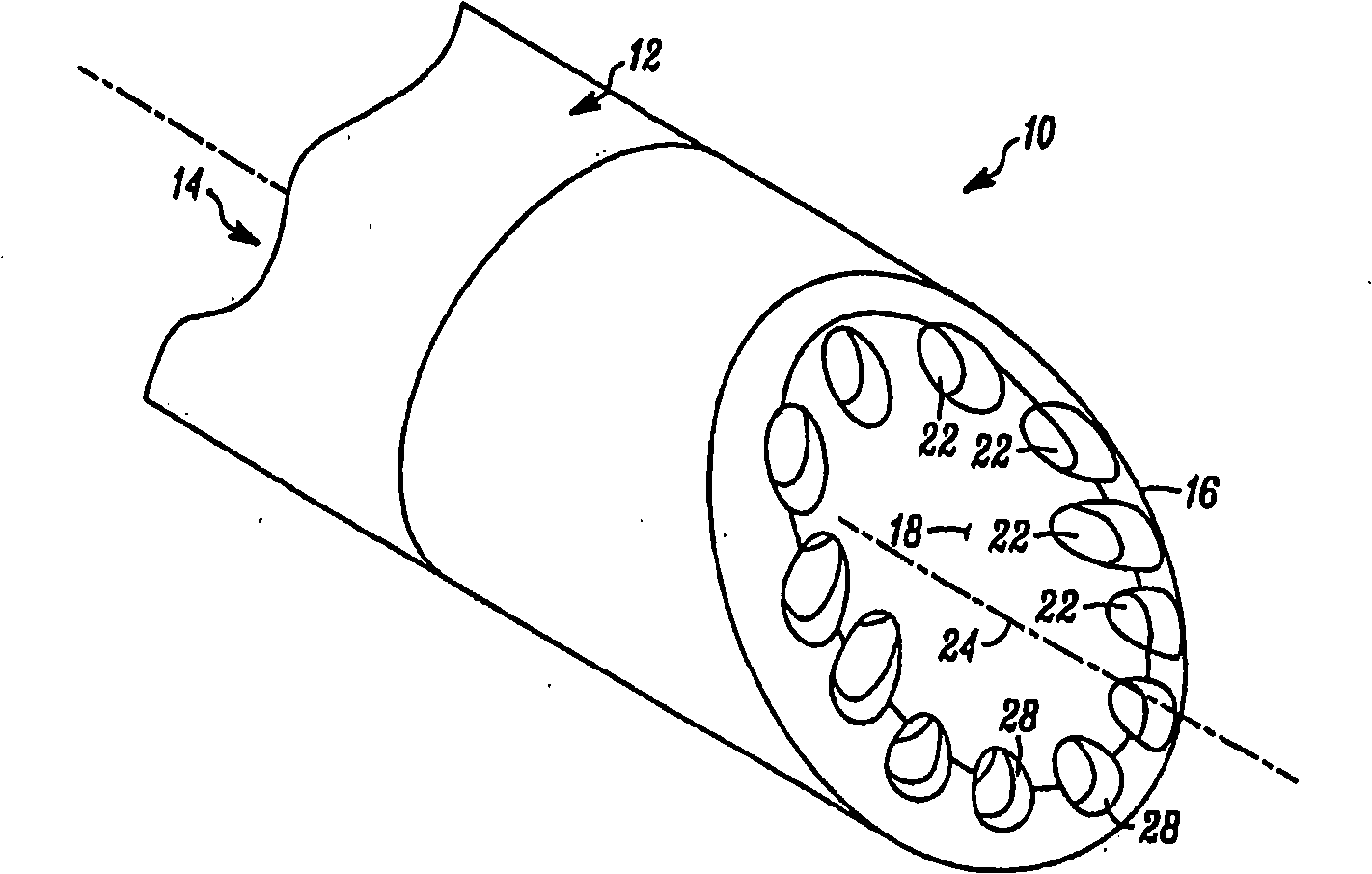

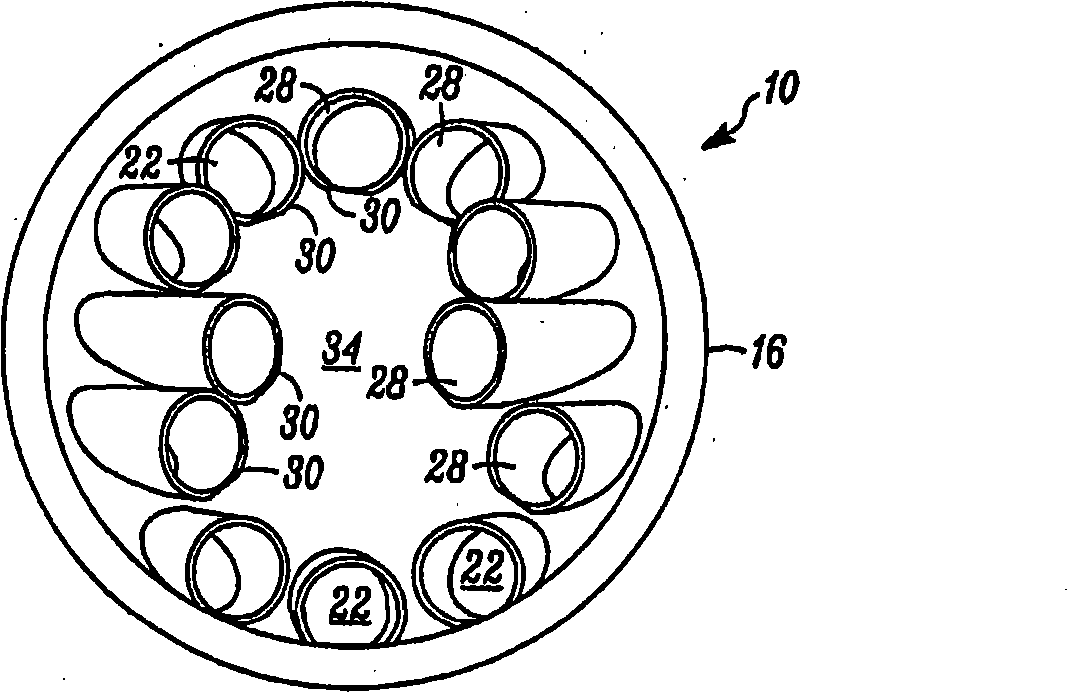

Spray nozzles

A nozzle for discharging first and second fluids in a spray pattern into a vessel, such as oil and steam in a catalytic cracking unit, includes various configurations for preventing erosion of the outlet portion of the nozzle that otherwise might be due, for example, to contact with a catalyst or other predetermined substance. In one such nozzle, the exterior surface of the outlet portion substantially conforms to the internal contour of the vessel. In another such nozzle, the outlet portion defines a plurality of substantially concentric, substantially elliptical-shaped outlet apertures. In another nozzle, the outlet portion is formed of ceramic and is connected to the inlet portion by a metal connector. In another nozzle, the outlet portion defines a plurality of apertures angularly spaced about a peripheral region of the outlet portion for discharging a substantially flat fan spray pattern, and a second outlet portion extending along an upstream portion of the outlet portion for discharging at least part of its spray to prevent any catalyst from contactin the downstream surfaces of the outlet ortion.

Owner:BETE FOG NOZZLE

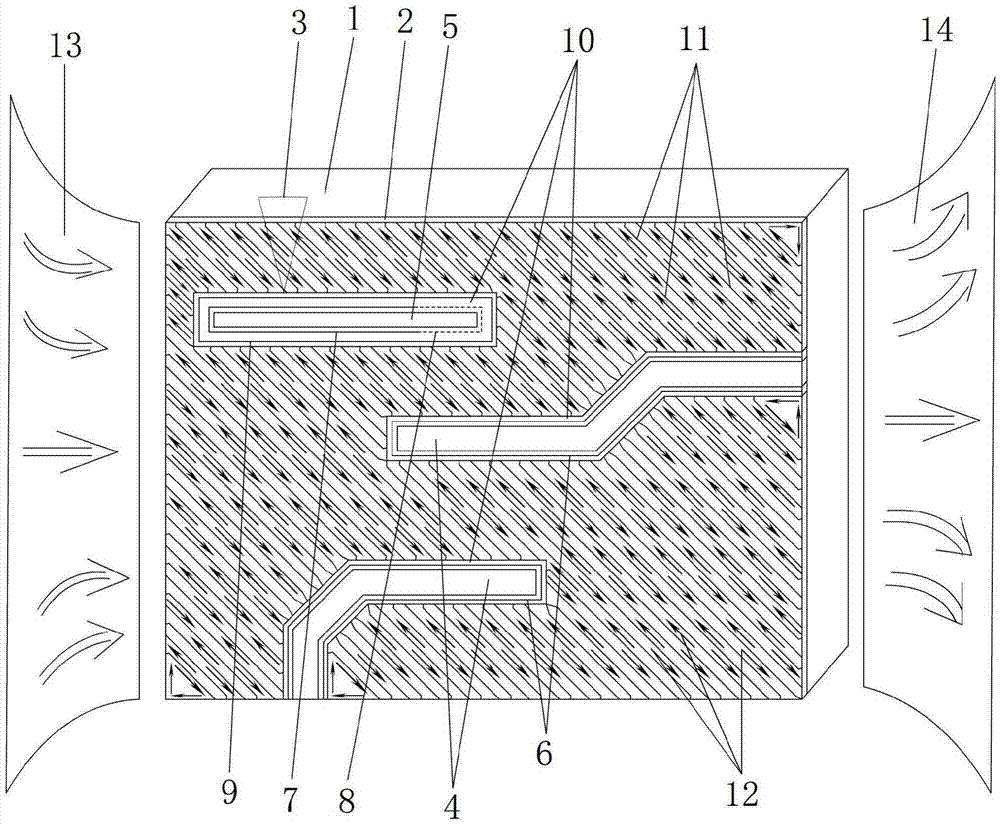

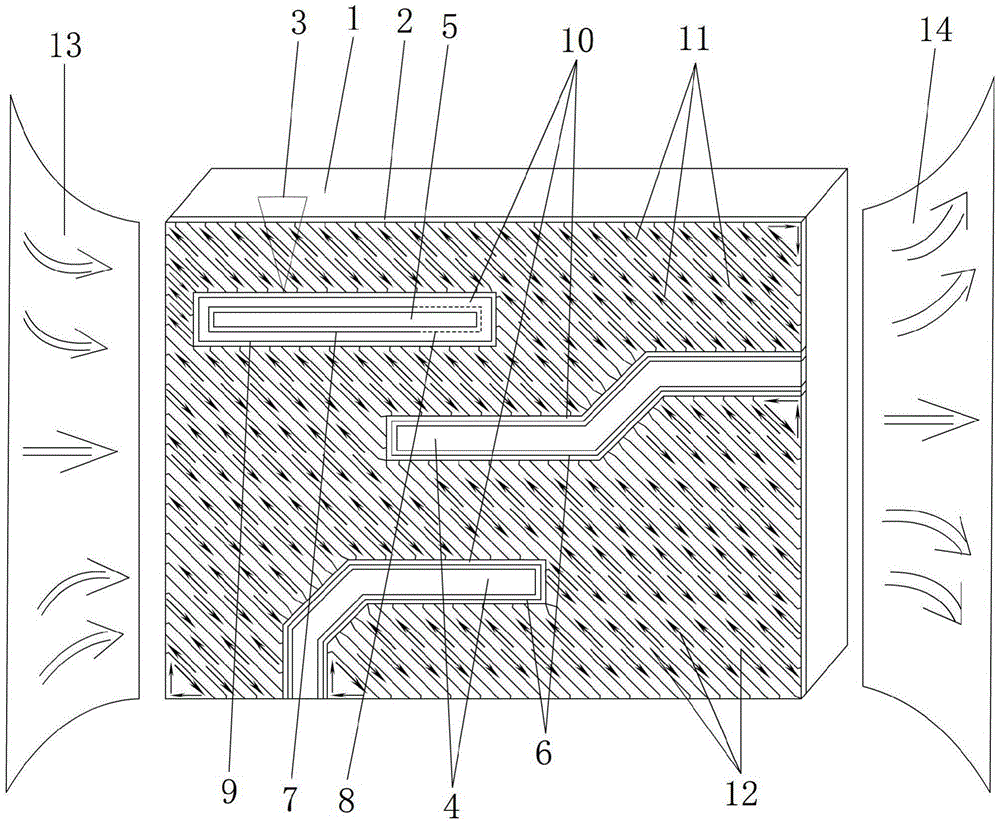

Method for selectively removing conductive layer on baseplate material

The invention relates to a method for selectively removing a conductive layer on a baseplate material. The method comprises the following steps: processing to manufacture an insulated enveloping channel on the periphery of a to-be-reserved conductive layer, wherein an isolated wire with over-narrow width is processed twice or more than twice; subdividing a to-be-removed conductive layer into a plurality of insulated small blocks, wherein the adjacent insulated small blocks are of complementary shapes such as inverted quadrangle, trapezoid or triangle; projecting electromagnetic waves onto the subdivided insulated small blocks so as to ensure that the subdivided insulated small blocks are separated from the baseplate material to be removed, wherein during heating, the projected laser moves from the narrower end of each small block of the conductive layer to the wider end of each small block. According to the method, the projecting parameter, projecting path and projecting environment of the laser are regulated and the conductive layer on the substrate material is removed, so that a preset conductive structure is formed, and the method can be used for replacing a corresponding technical process adopted in the process of manufacturing a conductive structure by virtue of an existing chemical method, an existing physical method and an existing laser method.

Owner:德中(天津)技术发展股份有限公司

Engine cooling system

InactiveCN107387221AAvoid thermal shockImprove cooling effectLiquid coolingCoolant flow controlAutomotive engineeringCylinder block

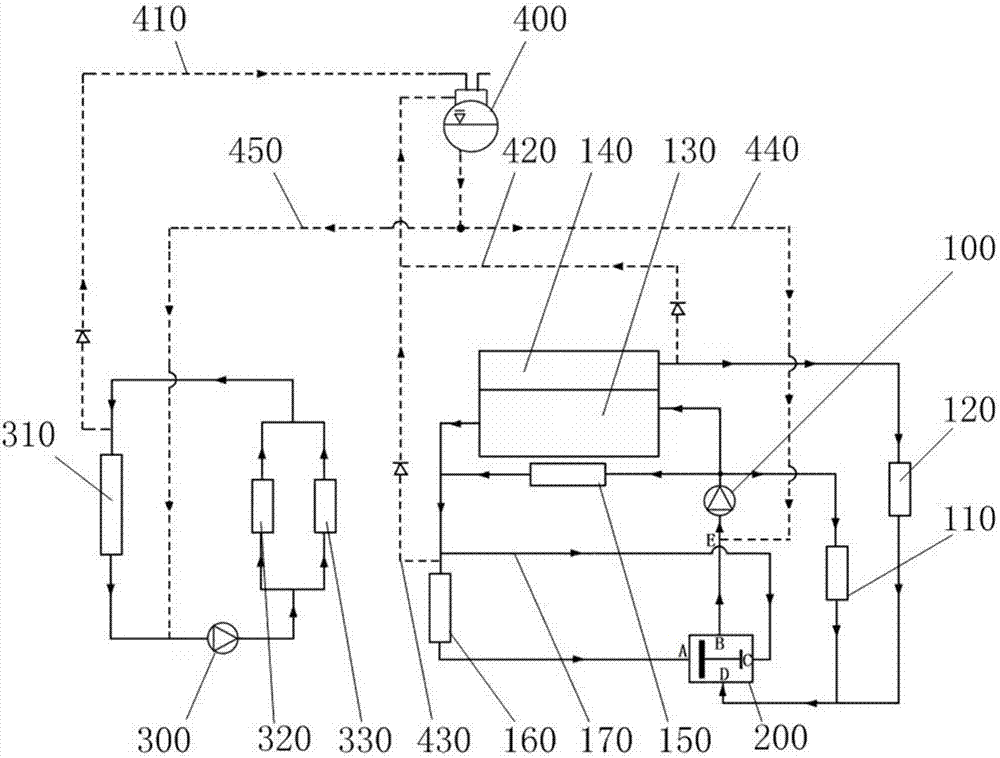

The invention discloses an engine cooling system. The engine cooling system comprises an expansion kettle, a high-temperature circulation system and a low-temperature circulation system, wherein the high-temperature circulation system comprises a mechanical water pump, a thermostat, an engine oil cooler, a gearbox oil cooler and a cylinder body water jacket; a water outlet of the mechanical water pump is provided with a first branch, a second branch and a third branch, and the third branch communicates with a liquid inlet of the gearbox oil cooler; the thermostat comprises an inlet channel, a liquid outlet of the gearbox oil cooler communicates with the inlet channel, and a liquid outlet of the thermostat communicates with a water inlet of the mechanical water pump; and the low-temperature circulation system comprises an electronic water pump and a low-temperature radiator, a closed loop is formed by the electronic water pump and the low-temperature radiator, and an air inlet of the expansion kettle communicates with the closed loop through a first degassing pipeline. According to the engine cooling system, the low-temperature circulating system can be used for degassing under various working conditions, and meanwhile, precise control over the temperature of a high-temperature circulating loop is realized.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

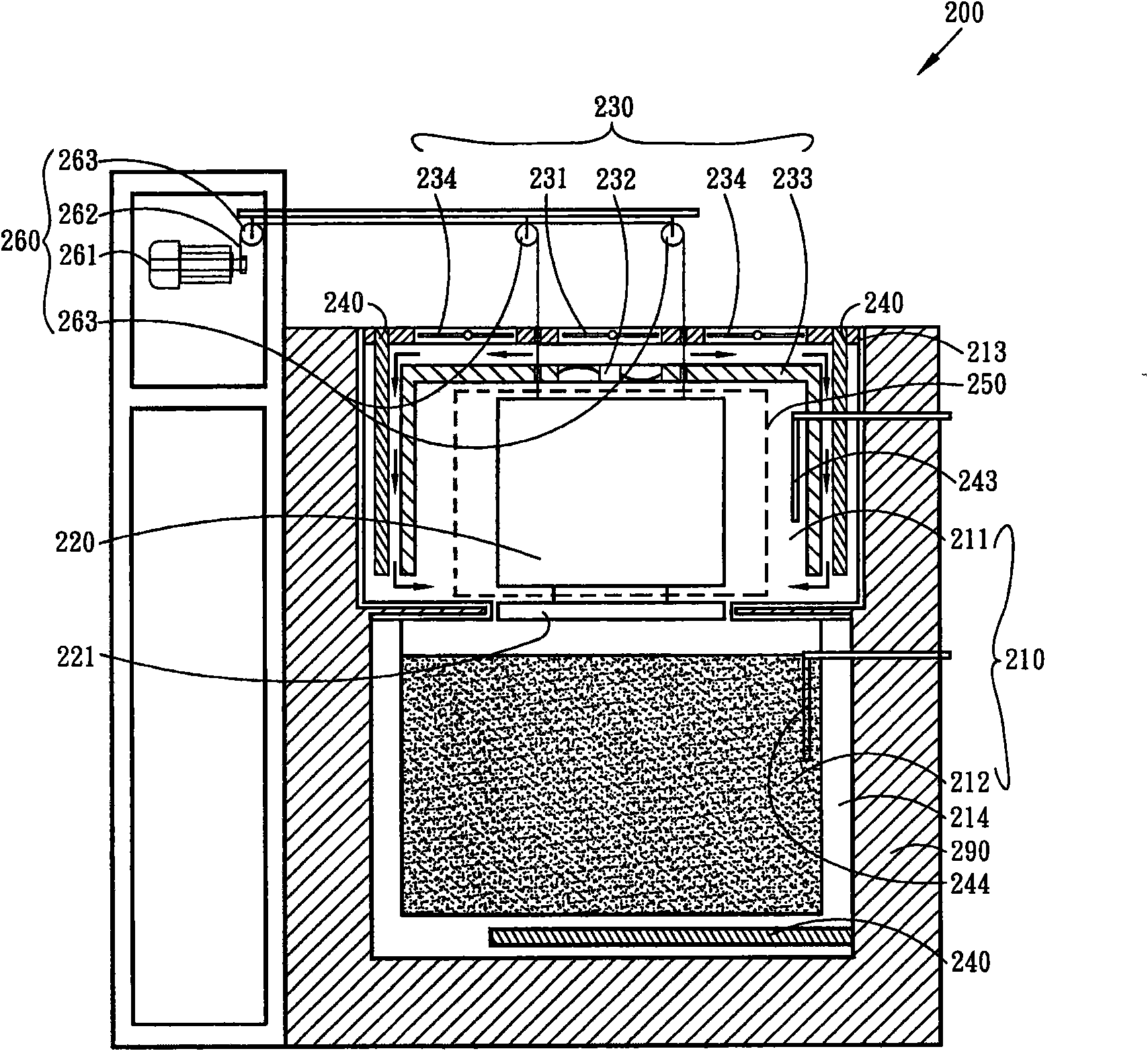

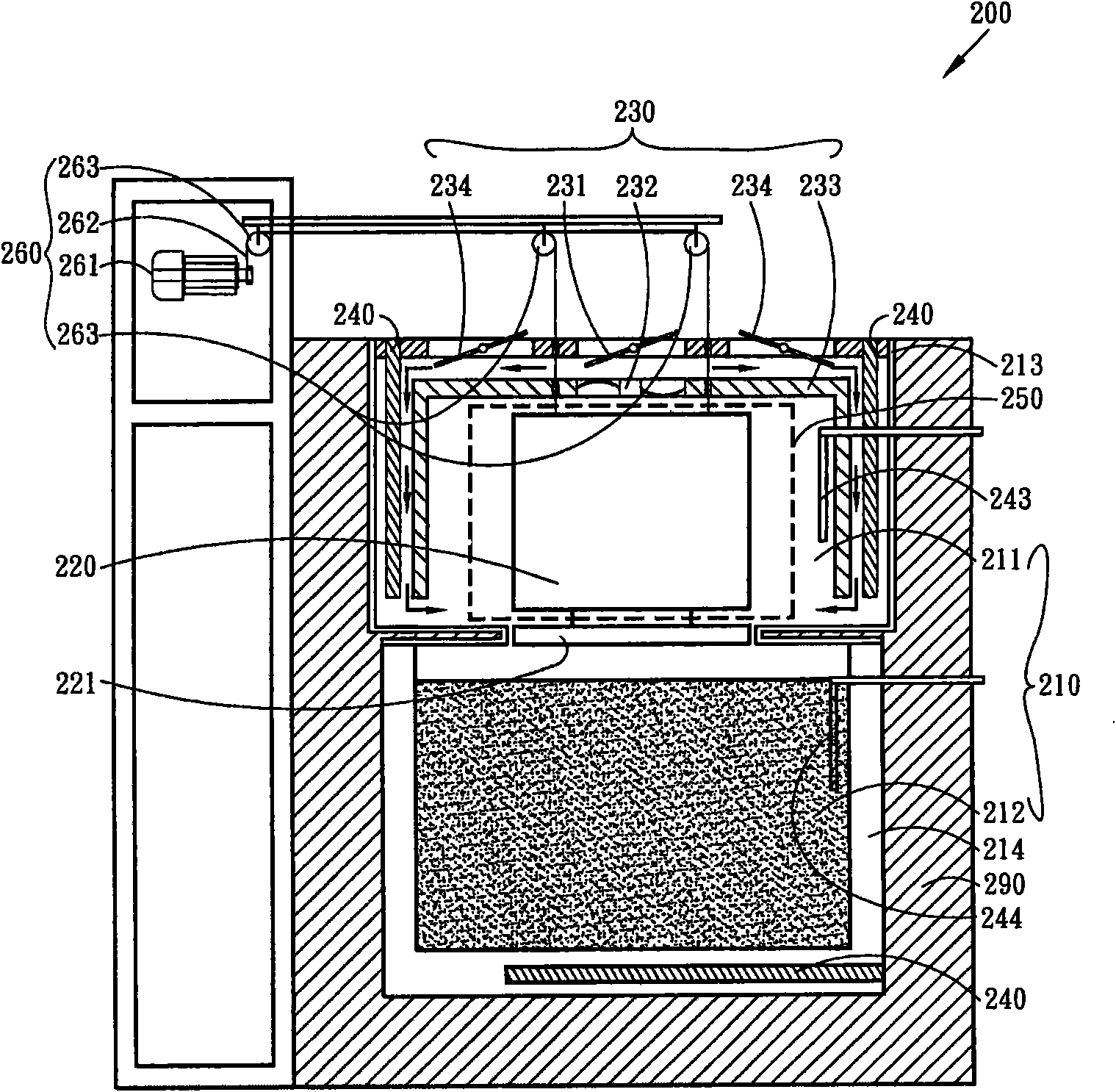

One-piece tempering furnace

InactiveCN101993192ASimple structureThe influence of ambient temperature difference is smallGlass tempering apparatusMetallurgyMobile phone

The invention relates to a one-piece tempering furnace, comprising a groove body, a material shelf, and a wind circulating system. The groove body comprises a thermoregulation area and a chemical tempering area, wherein the thermoregulation area is arranged above the chemical tempering area, the thermoregulation area and the chemical tempering area are thermally isolated from the outside world, and the temperatures of the thermoregulation area and the chemical tempering area can be adjusted independently; the material shelf can move vertically in a one-dimensional direction and traverse between the thermoregulation area and the chemical tempering area; and the wind circulating system is arranged above the thermoregulation area so that the groove body becomes an airtight space and the temperature of the thermoregulation area can be adjusted. The one-piece tempering furnace has the advantages of simple structure, lower cost and practicability, and the product is isolated from the outside air to guarantee the preheating effect without suffering cold and hot impact, therefore, the one-piece tempering furnace can be applied to the window glass lens of a common mobile phone and to the strengthening of glass with a big size.

Owner:TPK LENS SOLUTIONS INC

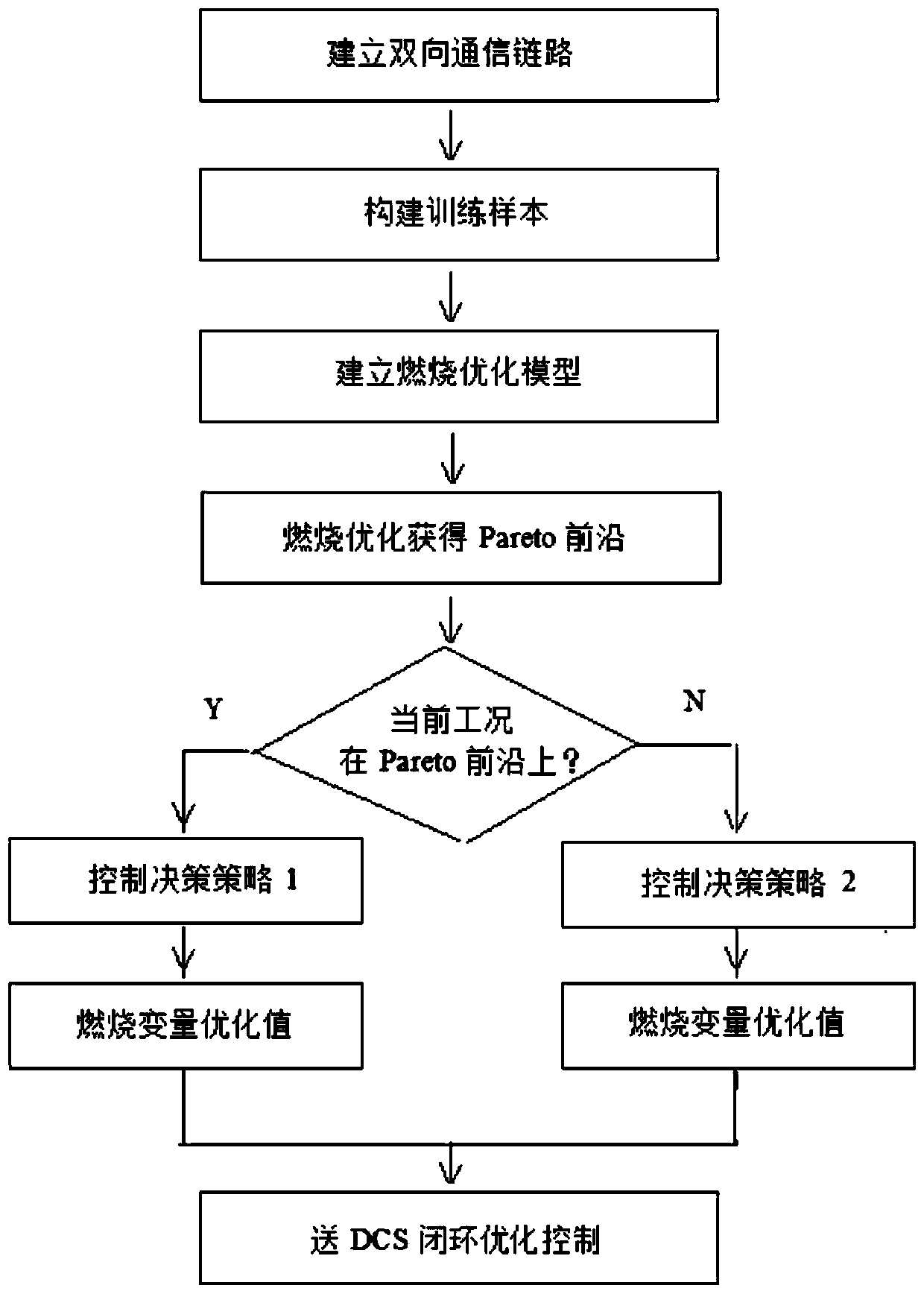

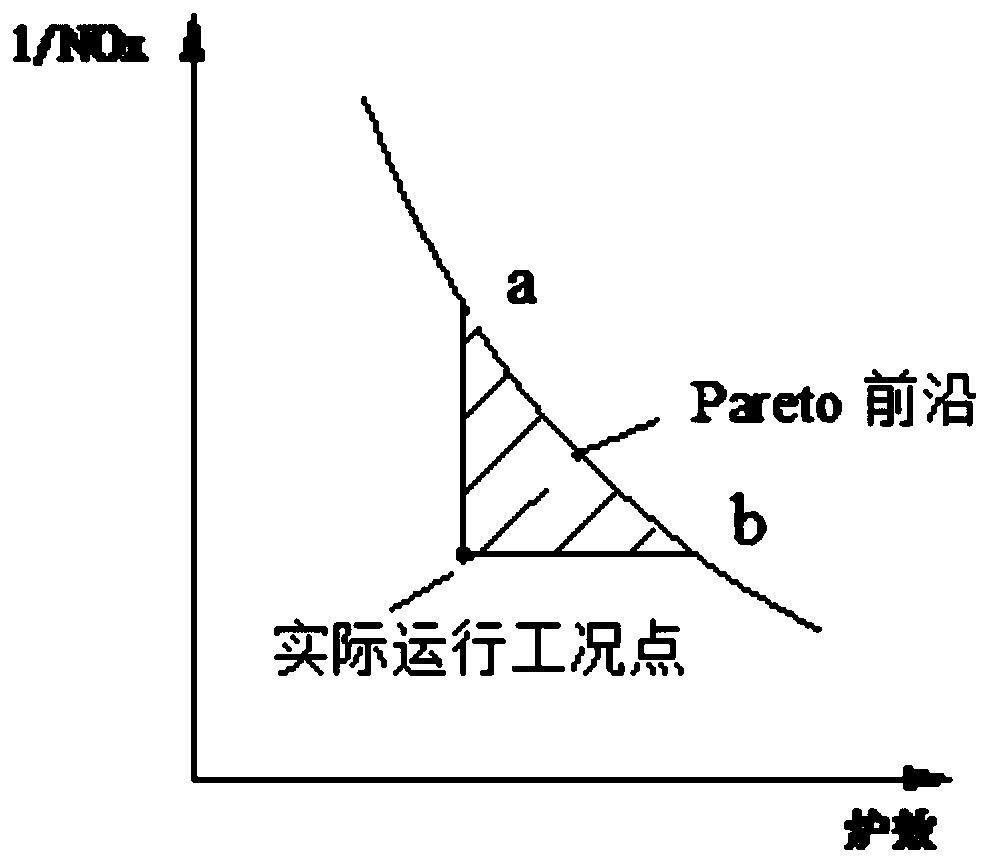

Intelligent combustion comprehensive optimization control method for boiler

InactiveCN110793059AQuality improvementImprove quality and efficiencyFuel supply regulationAdaptive controlControl systemDecision strategy

The invention discloses an intelligent combustion comprehensive optimization control method for a boiler. The intelligent combustion comprehensive optimization control method includes the steps that firstly, a two-way data communication link between an optimization control system and a unit DCS is established; then unit operation historical data are collected and acquired, a combustion optimization neural network training sample is established, and a combustion optimization neural network model is established; and finally, according to the combustion optimization neural network model, combustion parameters are optimized through a multi-target non-dominated quick-sorting genetic algorithm (NSGA-II), different optimization control decision strategies are adopted according to different operating working conditions, and thus boiler combustion closed-loop optimization control is realized. According to a neural network training sample obtaining method, the quality and modeling efficiency ofa combustion optimization model can be effectively improved; and through a provided combustion optimization algorithm based on the genetic algorithm, an operator can conveniently and effectively balance boiler efficiency and flue gas NOx emission, energy-saving and environment-friendly operation of the boiler is realized, jump of the optimized combustion parameters can be reduced, and practical application of a project is facilitated.

Owner:南京昆岳智能电力科技有限公司

Water leakage automatically protecting device of solar water heater

InactiveCN101539345ASafe to useEasy to useSolar heat devicesSolar thermal energy generationSolar waterPull force

The invention relates to a water leakage automatically protecting device of a solar water heater, which comprises a connecting pipe, a water cork, a free block, a pulley, a rope and a pore plate, wherein the connecting pipe comprises a circular bedplate, a big circular pipe and a small circular pipe; the big circular pipe and the small circular pipe are respectively sleeved with a big sealing ring and a small sealing ring; the big circular pipe is connected with a hot water storage tank through the big sealing ring in a socket joint and sealing way and is communicated with the hot water storage tank; the small circular pipe is connected with the inner pipe wall of a vacuum pipe through the small sealing ring in a socket joint and sealing way and is communicated with the vacuum pipe; one end of the water cork is fixed on the circular bedplate in the connecting pipe, the other end of the water cork is connected with one end of the rope, and the other end of the rope is connected with the free block through the pulley. When the vacuum pipe is broken to leak water, water in the vacuum pipe is directly communicated with air to lead the upper face and the lower face of the water cork to form the pressure difference, the water cork overcomes the pull force of the free block under the action of the water flow and the pressure difference and rapidly plugs on the circular bedplate so as to block the channel of the hot water storage tank and the broken vacuum pipe.

Owner:唐晓东

Large vacuum solar heat collecting system

InactiveCN101806498AGuaranteed reliabilityAvoid tight weldingSolar heating energySolar heat devicesOptical transmittanceAbsorption rate

The invention relates to a large vacuum solar heat collecting system comprising a plurality of heat collecting units with vacuum heat insulating layers, each heat collecting unit comprises a shell and a heat absorber, wherein the shells are in a flat box shape and comprise light transmitting faces with higher light transmittance, the heat absorbers have higher heat absorption rates and lower heat radiation rates and are arranged in the shells, the shells of the heat collecting units are communicated with each other through vacuum connecting pipes, and the vacuum heat insulating layers of the heat collecting units are communicated with each other to form a closed large vacuum combination. The heat collecting system also comprises heat energy transmitting pipelines which are arranged in the vacuum connecting pipes and are connected with the heat absorber of each heat collecting unit. In addition, the heat collecting system is also provided with a vacuum supplying maintenance system which comprises a vacuum source, an auxiliary valve, the vacuum connecting pipes and the like and is communicated with the large vacuum combination.

Owner:徐旻晖

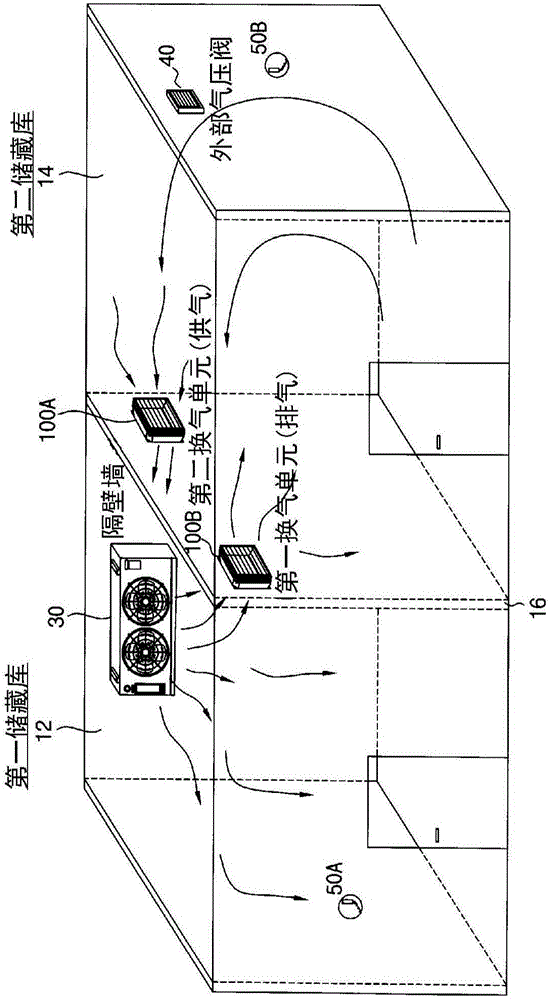

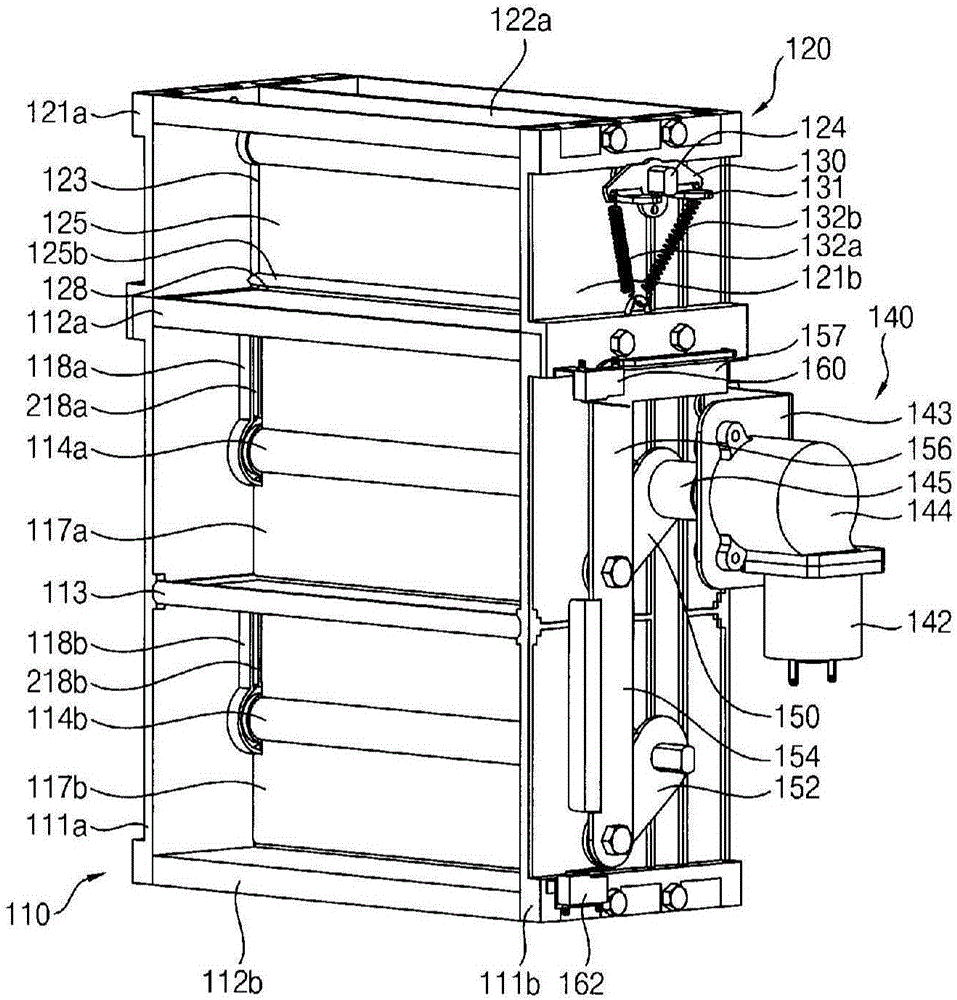

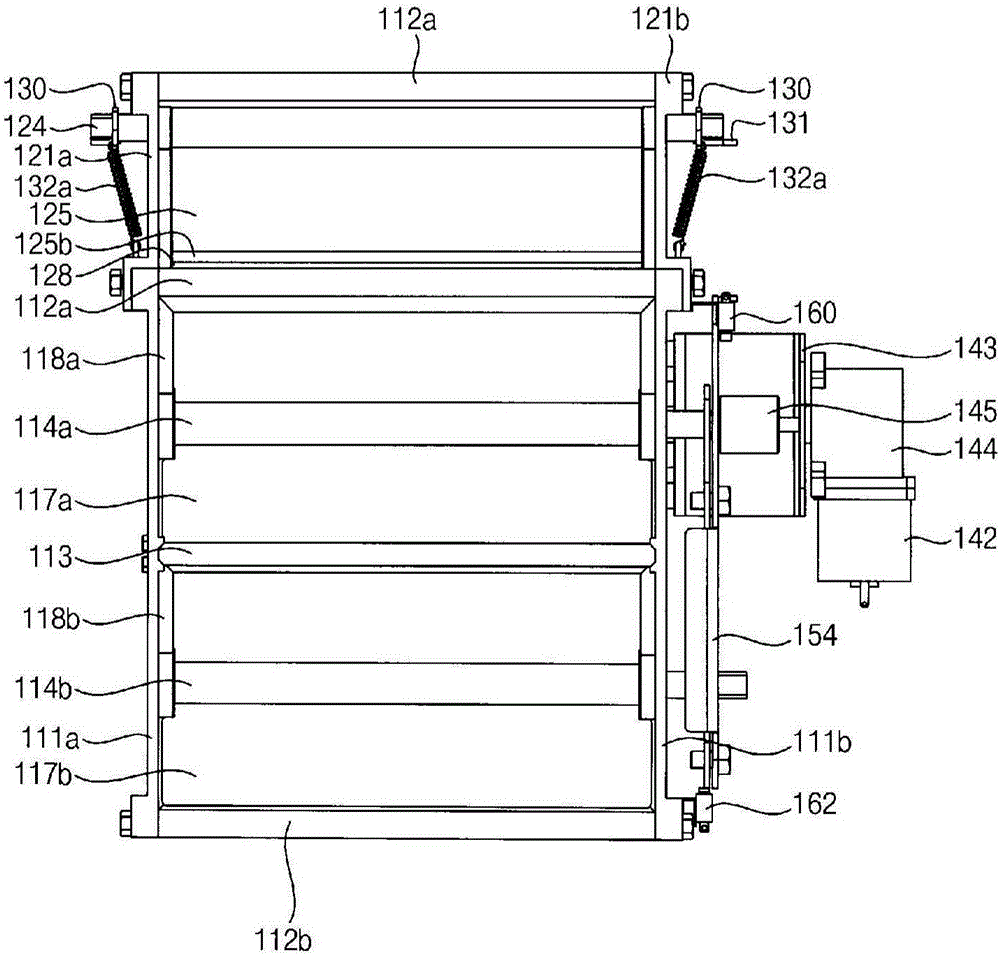

Ventilation unit using temperature and atmospheric pressure equilibrium and preservation system using same

InactiveCN105121968ATemperature controlAvoid thermal shockMechanical apparatusSpace heating and ventilation safety systemsAir cyclePositive pressure

The present invention relates to a ventilation unit using equilibrium of temperature and pressure, and a storage system using the same, and more specifically, to a pressure equilibrium ventilation unit to control the temperature of a closely located place using heating source or cooling source generated from one heating device or cooling device, and to a storage system using the same. According to an embodiment of the present invention, the pressure equilibrium ventilation unit comprises: a first frame assembly having a first frame and a first opening and closing plate; a second frame assembly having a second frame and a second opening and closing plate; a driving part having a forward and reverse motor; and a lock control part which maintains a second ventilation unit in a closed condition when a first rotation axis opens a first ventilation unit as rotated by the preset angle according to an opening signal.

Owner:沈棋燮

Method for making electric conduction patterns on metal-foil-clad insulating substrate

ActiveCN103769749AInhibit sheddingFinely craftedMetal working apparatusLaser beam welding apparatusMetal foilLaser beams

The invention relates to a method for making electric conduction patterns on a metal-foil-clad insulating substrate. The method comprises the steps that insulating envelope grooves are machined in the periphery of a conducting layer which needs to be reserved, and machining is conducted twice or more when excessively narrow isolated wires are encountered; a conducting layer which needs to be removed is subdivided into a plurality of strip-shaped heat-insulating small blocks, wherein one end of each small block is narrowed, the other end of each small block is widened, and the narrowed end of one metal foil layer small block and the widened end of another metal foil layer small block adjacent to the metal foil layer small block are arranged in a corresponding mode; next, laser beams are projected onto the heat-insulating small blocks obtained after subdivision, so that the small blocks are separated from the substrate material and removed. According to the method for making the electric conduction patterns on the metal foil-clad insulating substrate, by means of adjusting the projection parameters, a projection path and the projection environment of a laser, the conducting layer on the substrate material is removed, a predetermined electric conduction structure is formed, corresponding technological processes adopted for manufacturing the electric conduction structure through a chemical method, a physical method and a laser method in the prior art are replaced, the laser is directly used for forming and making the electric conduction patterns, as a result, multiple devices and materials are omitted, environmental friendliness is achieved, the process is short, the technology is simple and easy to implement, and the method is suitable for manufacturing multiple types of circuit board samples with higher accuracy in a small-batch mode and general circuit boards.

Owner:德中(天津)技术发展股份有限公司

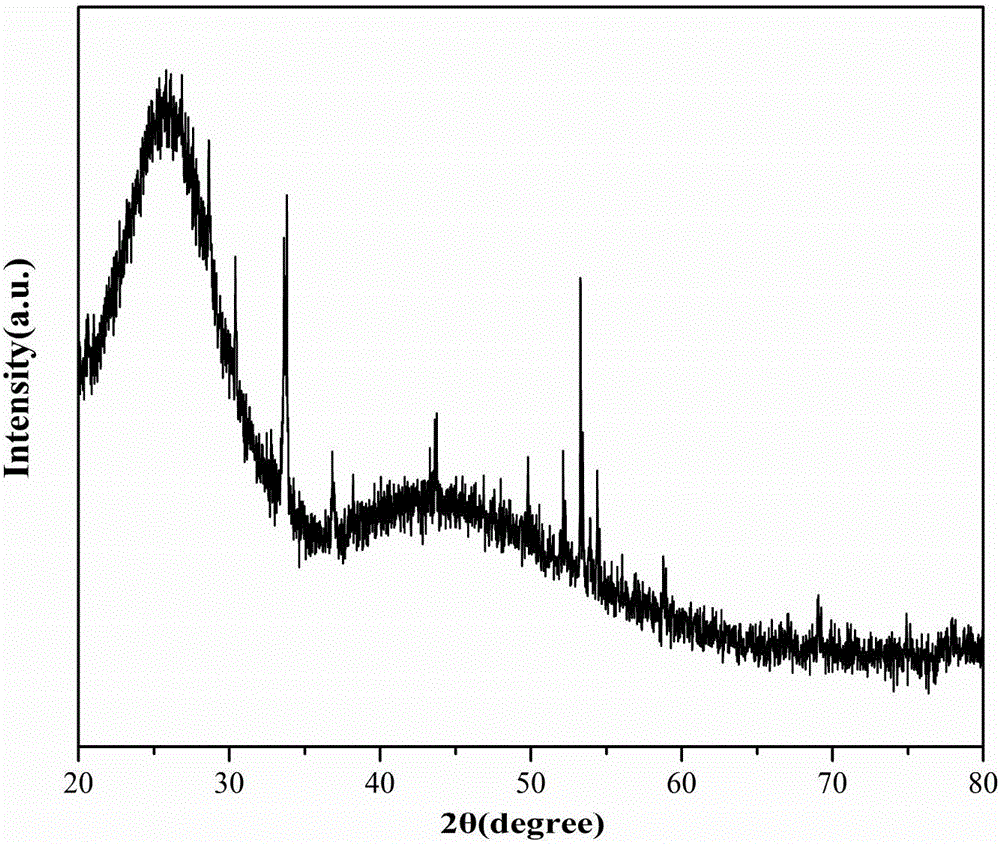

Special high temperature resistant binder for lithium batteries and preparation method of special high temperature resistant binder

ActiveCN108123139AHigh bonding strengthEasy to prepareCell electrodesLi-accumulatorsMicrosphereLithium-ion battery

The invention relates to a special high temperature resistant binder for lithium batteries and a preparation method of the special high temperature resistant binder, and belongs to the technical fieldof lithium batteries. The preparation method comprises the following steps: adding zirconium oxide into an oxidized graphene nanosheet aqueous dispersion, mechanically stirring and uniformly mixing to obtain a mixed solution; adopting a spraying method to spray the mixed solution into liquid nitrogen dispersed with GeSbTe phase-change powder, freezing into microspheres, and drying to obtain compound microspheres; and mixing the compound microspheres, resin, an inorganic filler, a modifier and a diluent to obtain the special high temperature resistant binder for lithium batteries. The binder comprises compound microspheres containing zirconium oxide and oxidized graphene wrapped GeSbTe phase-change powder, the compound microspheres are high in electrical conductivity, thermal shock can beovercome, and after the binder is used for binding electrodes of the lithium batteries, the attenuation of the batteries and the reduction of cycle performance caused by thermal impact are effectivelyrelieved. When the temperature of the batteries is high, the volume cracking, caused by high temperature, of the electrodes is effectively relieved through crystal transfer stress.

Owner:东营诺瑞克电池有限公司

Glass manufacture device and manufacture method for high-transmittance optical glass

ActiveCN107298521AReduce oxidation rateReduce the degree of oxidationCharging furnaceGlass furnace apparatusMelting tankVitreous Humors

The invention belongs to the technical field of glass manufacture, particularly discloses a glass manufacture device and a manufacture method for high-transmittance optical glass, and aims to solve the problem that an electrode easily generates corrosion to influence the quality of produced glass in a traditional glass manufacture device use process. The glass manufacture device comprises a melting tank and an electrode, wherein a melting cavity is arranged in the melting tank; the electrode is arranged on the side wall of the melting cavity; the upper edge of the electrode is positioned below the upper limit of the liquid level of vitreous humour. The manufacture method for high-transmittance optical glass adopts the glass manufacture device to manufacture the high-transmittance optical glass. Since the electrode is under the liquid level of vitreous humour in a production process and only the vitreous humour is in contact with the electrode, the chemical property of the electrode is stable, oxide etch is unlikely to generate, and service life is prolonged; in addition, when a glass raw material is continuously or intermittently supplied to the melting tank, since a bare electrode is not arranged above the vitreous humour, the electrode is prevented from being subjected to powerful thermal shock, and the fatigue or damage of the electrode due to thermal shock can be avoided.

Owner:CDGM OPTICAL GLASS

A method of making conductive patterns on metal foil-clad insulating substrates

ActiveCN103769749BInhibit sheddingFinely craftedMetal working apparatusLaser beam welding apparatusMetal foilPhysical approach

The invention relates to a method for making electric conduction patterns on a metal-foil-clad insulating substrate. The method comprises the steps that insulating envelope grooves are machined in the periphery of a conducting layer which needs to be reserved, and machining is conducted twice or more when excessively narrow isolated wires are encountered; a conducting layer which needs to be removed is subdivided into a plurality of strip-shaped heat-insulating small blocks, wherein one end of each small block is narrowed, the other end of each small block is widened, and the narrowed end of one metal foil layer small block and the widened end of another metal foil layer small block adjacent to the metal foil layer small block are arranged in a corresponding mode; next, laser beams are projected onto the heat-insulating small blocks obtained after subdivision, so that the small blocks are separated from the substrate material and removed. According to the method for making the electric conduction patterns on the metal foil-clad insulating substrate, by means of adjusting the projection parameters, a projection path and the projection environment of a laser, the conducting layer on the substrate material is removed, a predetermined electric conduction structure is formed, corresponding technological processes adopted for manufacturing the electric conduction structure through a chemical method, a physical method and a laser method in the prior art are replaced, the laser is directly used for forming and making the electric conduction patterns, as a result, multiple devices and materials are omitted, environmental friendliness is achieved, the process is short, the technology is simple and easy to implement, and the method is suitable for manufacturing multiple types of circuit board samples with higher accuracy in a small-batch mode and general circuit boards.

Owner:德中(天津)技术发展股份有限公司

A method for selectively removing a conductive layer on a substrate material

ActiveCN103747626BInhibit sheddingFinely craftedPrinted circuit manufacturePhysicsElectrical and Electronics engineering

The invention relates to a method for selectively removing a conductive layer on a baseplate material. The method comprises the following steps: processing to manufacture an insulated enveloping channel on the periphery of a to-be-reserved conductive layer, wherein an isolated wire with over-narrow width is processed twice or more than twice; subdividing a to-be-removed conductive layer into a plurality of insulated small blocks, wherein the adjacent insulated small blocks are of complementary shapes such as inverted quadrangle, trapezoid or triangle; projecting electromagnetic waves onto the subdivided insulated small blocks so as to ensure that the subdivided insulated small blocks are separated from the baseplate material to be removed, wherein during heating, the projected laser moves from the narrower end of each small block of the conductive layer to the wider end of each small block. According to the method, the projecting parameter, projecting path and projecting environment of the laser are regulated and the conductive layer on the substrate material is removed, so that a preset conductive structure is formed, and the method can be used for replacing a corresponding technical process adopted in the process of manufacturing a conductive structure by virtue of an existing chemical method, an existing physical method and an existing laser method.

Owner:德中(天津)技术发展股份有限公司

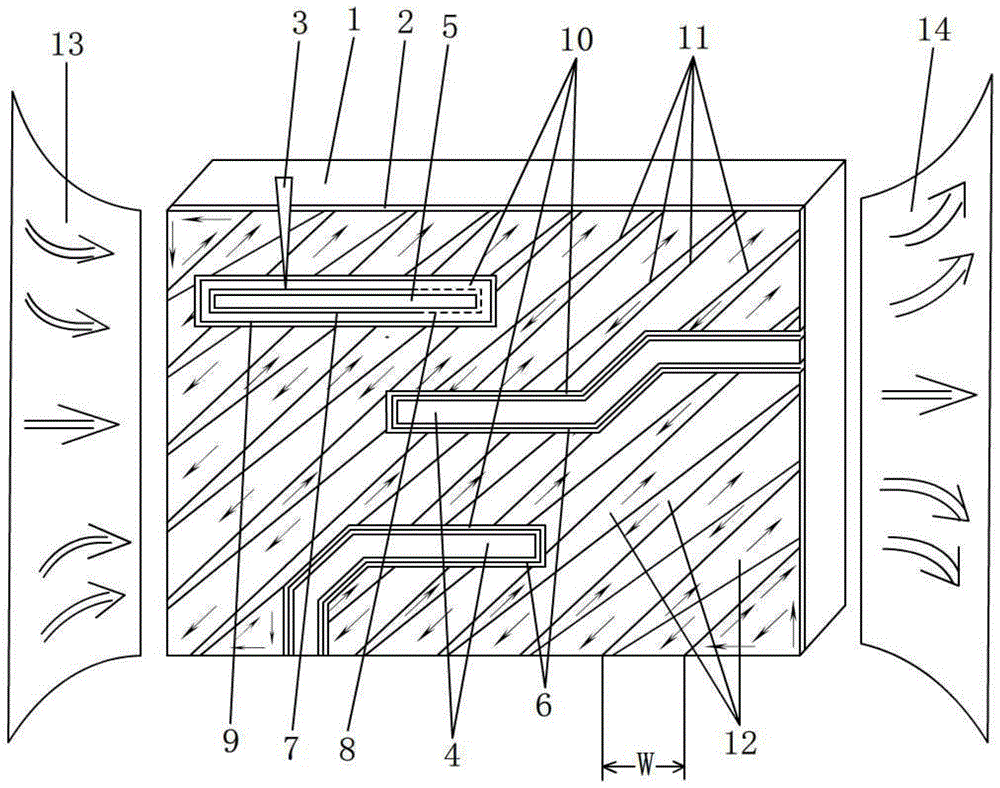

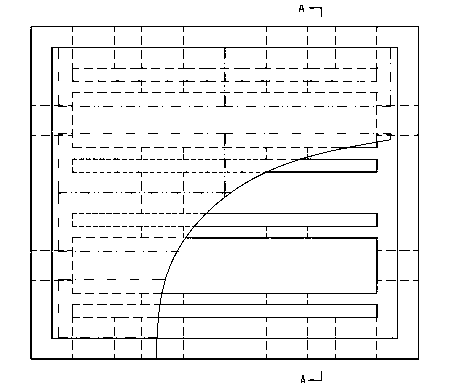

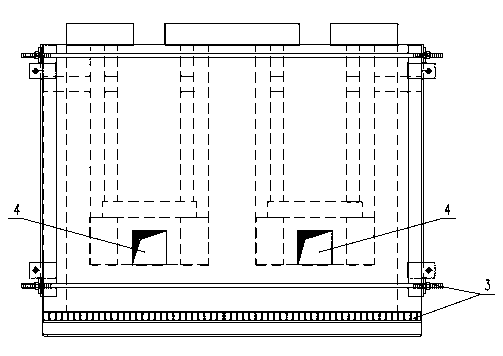

Tin bath flow gate baking furnace

The invention relates to equipment for production of float glass and provides a tin bath flow gate baking furnace. According to the tin bath flow gate baking furnace, a furnace body shell is of a furnace steel structure (3); a furnace lining (8) is arranged on a bottom substrate of the furnace steel structure (3); an inner wall body (2) and a furnace partition wall (10) are paved on the upper part of the furnace lining (8); the inner wall body (2) is arranged at two sides of two ends of the furnace lining (8); the furnace partition wall (10) is arranged between the two inner wall bodies (2); the outer side of the periphery of the inner wall bodies (2) and the top of the baking furnace are provided with outer wall bodies (1); and a gate baking inner cavity and a combustion chamber (14) which are vertically arranged are formed in a cavity between the furnace partition wall (10) and the inner wall bodies (2). The quick heat impact of open fire flame on the gate is avoided, and the phenomenon that the gate is contacted with the high-temperature molten glass and is blasted or has too long bubble removal time because the preheating temperature is extremely low or the temperature difference of the upper and lower parts is high is avoided.

Owner:GUANGDONG AVIC SPECIAL GLASS TECH

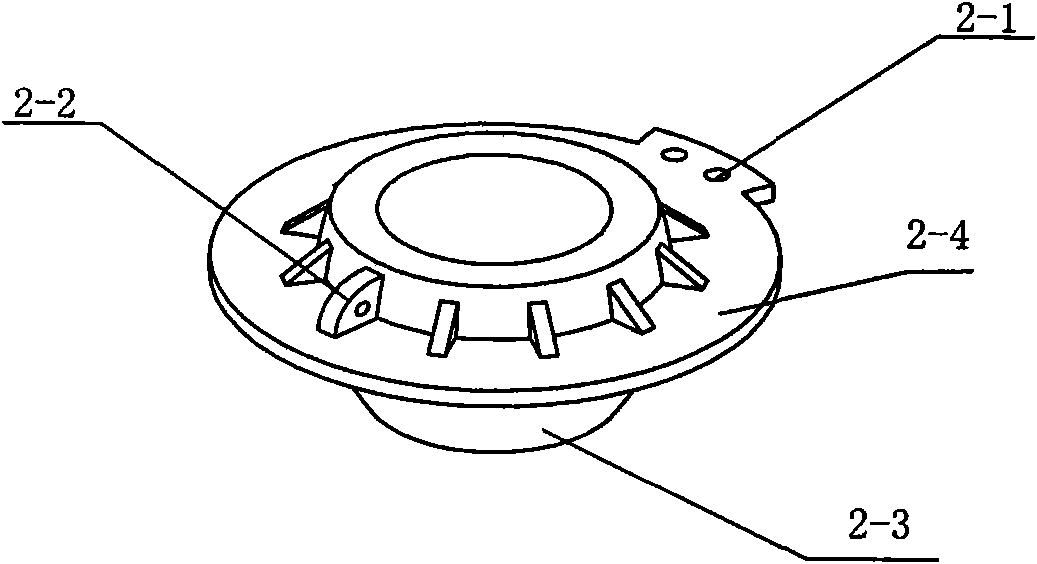

Nuclear power station steam generator cooling system

ActiveCN114234173AAvoid damageReduce trafficSuperheating controlLiquid degasificationNuclear engineeringNuclear power

The invention relates to the technical field of nuclear power station steam generator cooling, in particular to a nuclear power station steam generator cooling system, which is characterized in that a pressure reduction and temperature reduction pipeline is led out from an outlet end of a steam generator and is connected to an inlet of the steam generator, and a pressure reduction valve and a water spray temperature reduction device are arranged on the pressure reduction and temperature reduction pipeline; and an electric boiler, a steam superheater and a steam booster pump are arranged on the auxiliary steam pipeline. And when a single reactor is shut down emergently, main steam generated by the steam generator in normal operation is subjected to temperature and pressure reduction and is introduced into the steam generator corresponding to the emergency shut down for cooling. When the double reactors are shut down emergently, the auxiliary steam generated by the electric boiler is heated and boosted to be respectively introduced into the two steam generators for cooling, and the unit is restarted for grid-connected power generation until the steam generators are cooled to the feed water temperature, so that the cooling time of the steam generators can be greatly shortened, and the unit can perform grid-connected power generation again in a relatively short time; the operation efficiency of the nuclear power station is improved.

Owner:HUANENG SHANDONG SHIDAO BAY NUCLEAR POWER CO LTD

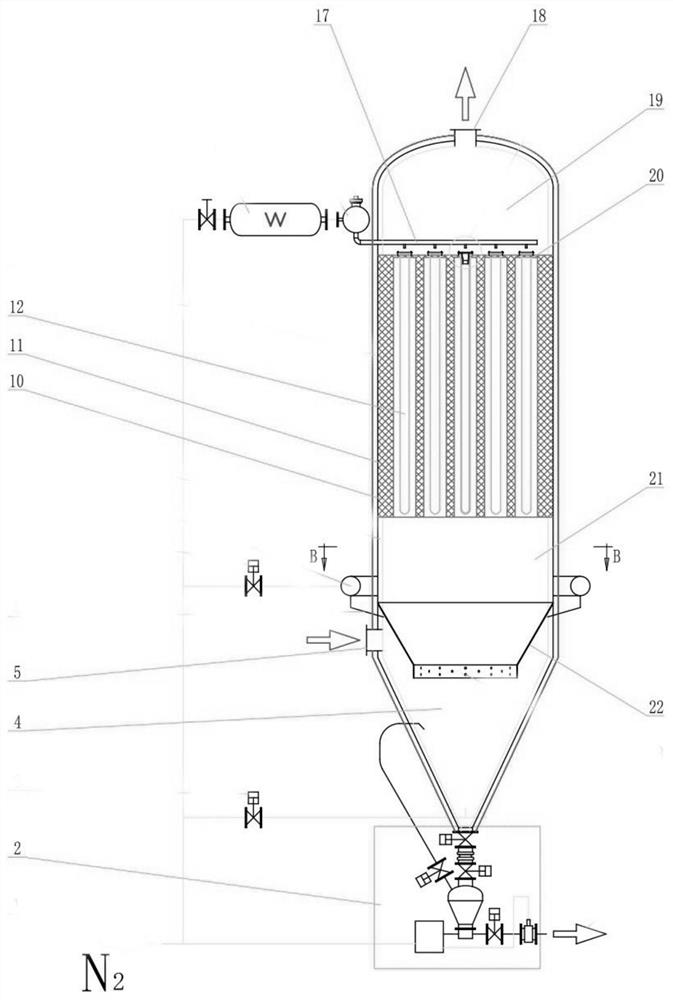

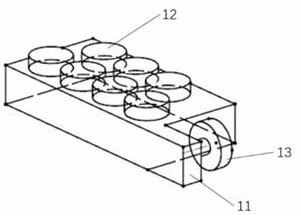

High-temperature constant-temperature pulse-jet ceramic filter pipe type dust removal device integrating high-temperature phase-change heat storage and high-temperature filtration

PendingCN112057980AHigh heat storage densityAchieve storageDispersed particle filtrationTransportation and packagingThermodynamicsFlue gas

The invention relates to the technical field of heat storage and ceramic high-temperature dust removal, in particular to a high-temperature constant-temperature pulse-jet ceramic filter pipe type dustremoval device integrating high-temperature phase-change heat storage and high-temperature filtration. The device comprises a shell and an ash bucket. The shell comprises an upper box body and a middle box body, A clean high-temperature flue gas outlet is formed in the upper box body, a dusty high-temperature flue gas inlet is formed in the middle box body or the ash bucket, a dusty flue gas primary cyclone separation / airflow equipartition device is arranged at the dusty high-temperature flue gas inlet, and a honeycomb-shaped high-temperature phase change heat storage device is arranged in the middle box body. The high-temperature phase change heat storage device is provided with cavities, and a ceramic filter pipe is arranged in each cavity. Compared with other dust removal and purification modes, the high-temperature pulse-jet ceramic filter pipe type dust removal device with the built-in high-temperature phase change heat accumulator is high and stable in efficiency, can guaranteestable recovery of clean dry gas and quality of discharged flue gas, can avoid a micro-explosion phenomenon frequently generated by electric dust removal sparks, and enables the system to operate moresafely.

Owner:北京清皓源技术有限公司 +1

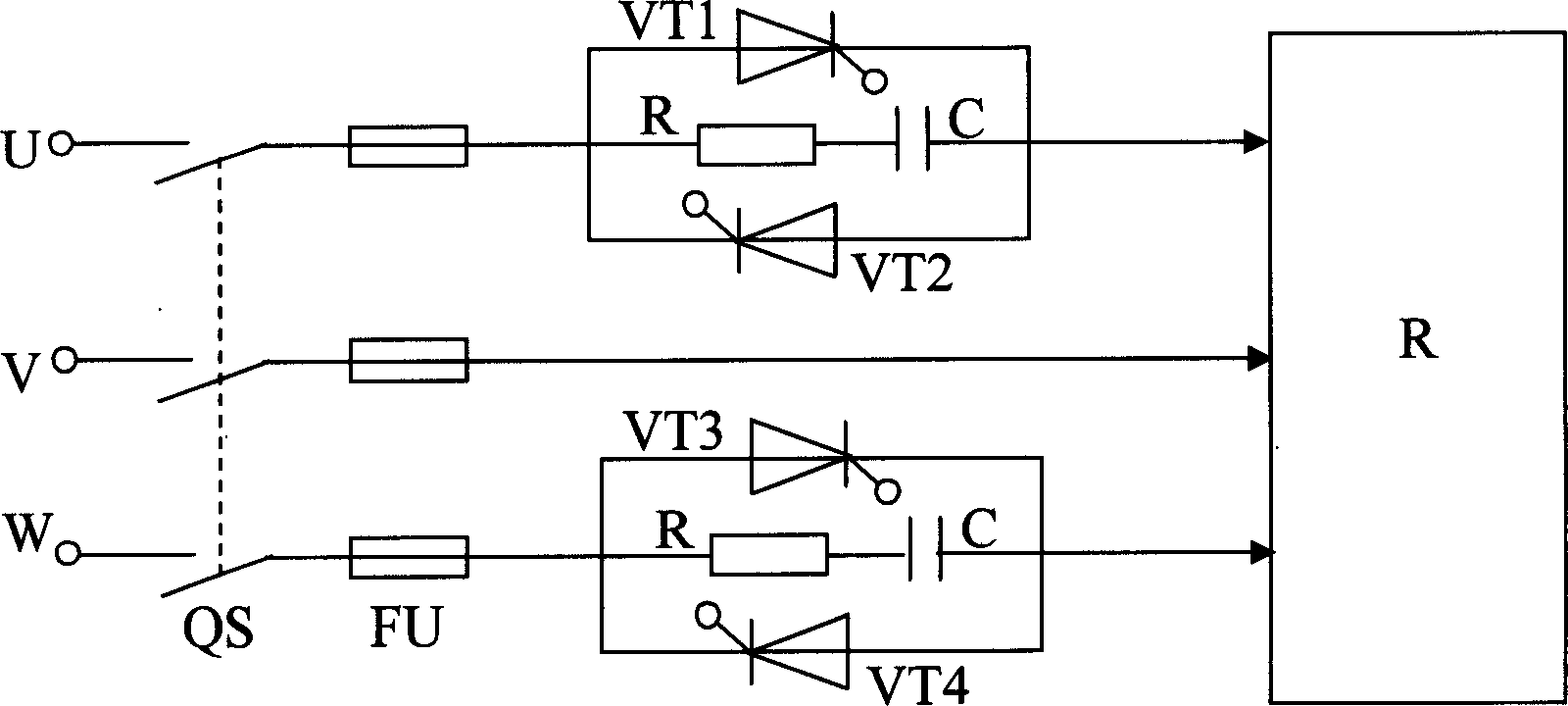

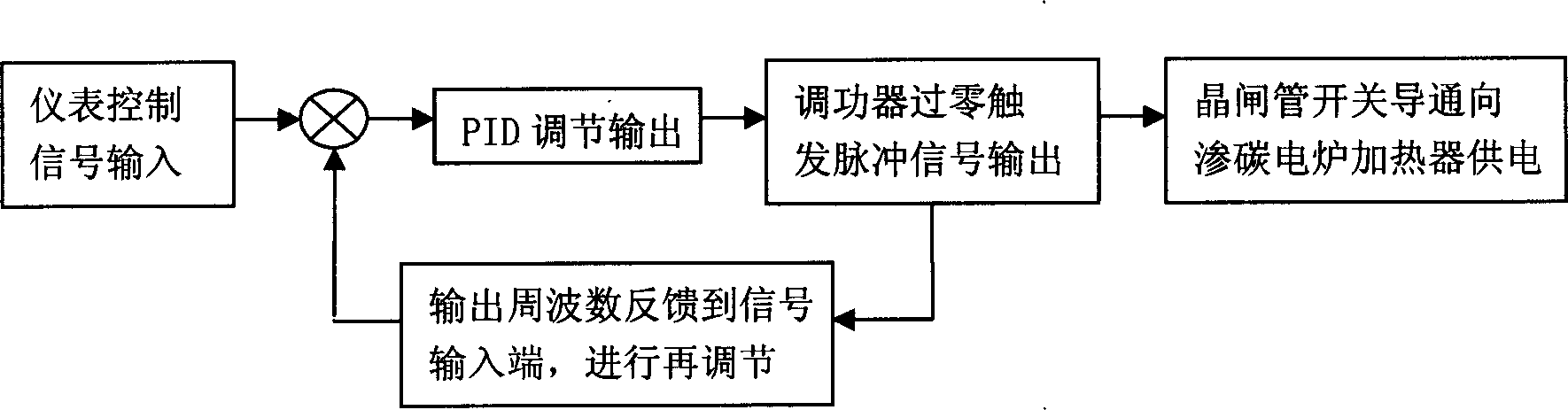

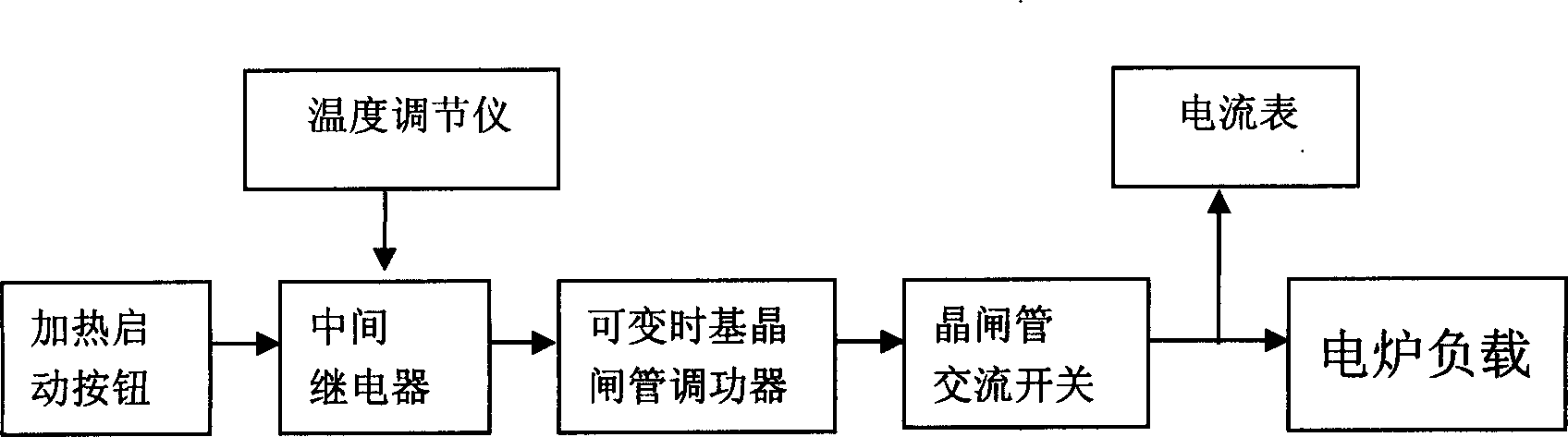

Heating control method for electric carburizing furnace

InactiveCN1827833AImprove matchImprove isolation abilityTemperatue controlSolid state diffusion coatingFurnace temperatureAutomatic control

The invention relates the carbonizing electric stove heating controlling mean. The method adopts the zero-cross triggering gate circuit transistor technology and carbonizing electric stove heating controlling mean, and the relay switch signal is replaced by the gate circuit transistor impulse signal. The gate circuit transistor receives the 0-10V or 4-20mA signal from temperature controller, then the output and input signal from zero-cross impulsion triggers gate circuit transistor to change the gate circuit transistor conducting and cut-off time to control the furnace temperature. The invention has the advantages of good economy, simple structure and easy maintenance. The invention suits to the carburizing furnace heating controlling field.

Owner:WAFANGDIAN BEARING GRP CO LTD

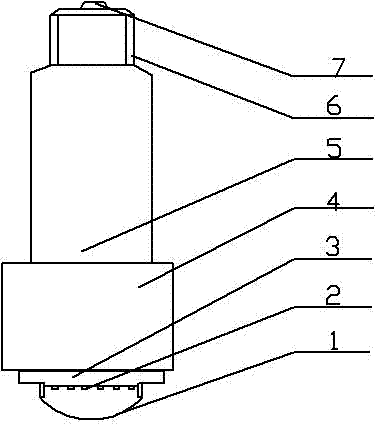

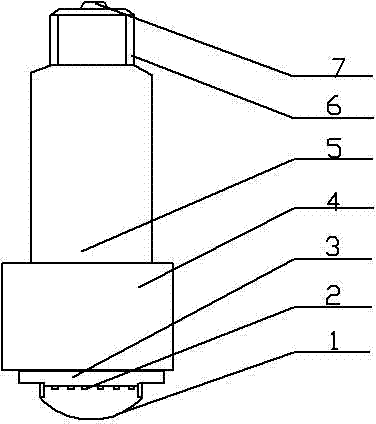

Thermal-shock-proof high-voltage-resistant optical cable

ActiveCN114779421AGuaranteed compression performanceGuaranteed tensionFibre mechanical structuresFiberBi layer

The optical cable comprises an optical cable subunit, a PI film, fiber paste, an inner-layer steel pipe, a foaming layer, an outer-layer steel pipe and an outer sheath which are sequentially arranged from inside to outside, the optical cable subunit comprises a subunit sheath and a plurality of optical fibers, the PI film wraps the outer surface of the subunit sheath, the inner-layer steel pipe, the foaming layer and the outer-layer steel pipe, and the outer-layer steel pipe wraps the PI film. The thickness of the outer-layer steel pipe ranges from 0.9 mm to 1.0 mm, the thickness of the foaming layer ranges from 1.0 mm to 1.5 mm, and the thickness of the inner-layer steel pipe ranges from 0.25 mm to 0.3 mm. Through the inner and outer double-layer steel pipes, the compression resistance of the optical cable is ensured, the tensile property of the optical cable is also ensured, the optical cable can cope with a high-temperature and high-pressure environment, the foaming layer provides buffering, thermal insulation and other effects for the optical cable, the survival ability of the optical cable is further improved, and the service life of the optical cable is prolonged. The optical cable has the characteristics of high voltage endurance capability, strong tensile capability, corrosion resistance, high temperature resistance and the like.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD +1

Radiating structure of heat accumulating light emitting diode (LED) lamp

InactiveCN102401364AEasy to useNo noisePoint-like light sourceLighting heating/cooling arrangementsSodium Thiosulfate PentahydrateEngineering

The invention discloses a radiating structure of a heat accumulating light emitting diode (LED) lamp. The radiating structure comprises a lampshade, an LED chip, a radiating pedestal, a heat accumulating box, a lamp body, a screw mouth and a lamp electrode tip, wherein the LED chip is tightly attached to the radiating pedestal; the lamp body is fixedly connected with the radiating pedestal by the heat accumulating box; a control circuit is arranged in the lamp body; and the control circuit is connected with the LED chip by using a lead. The heat accumulating box is sealed, a heat accumulating material is put into the heat accumulating box, and the heat accumulating material is sodium thiosulfate pentahydrate, the melting point of which is about 50 DEG C. The radiating structure has the advantages that: a fan for radiating is not used, and a moving component is not installed; the LED lamp is reliable in use and energy-saving, and has no noise; heat generated when the LED chip works is absorbed by using melting latent heat of the heat accumulating material, so that the temperature of the LED chip is controlled, and the LED chip is effectively prevented from being impacted by heat; and the radiating structure is easy to make and install and convenient to produce.

Owner:林勇

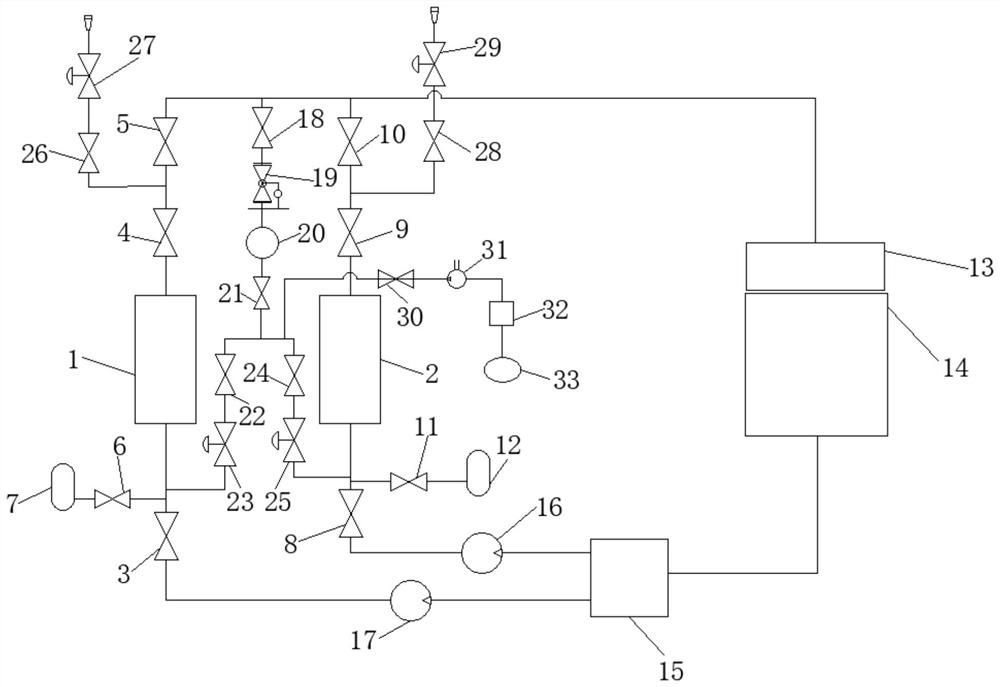

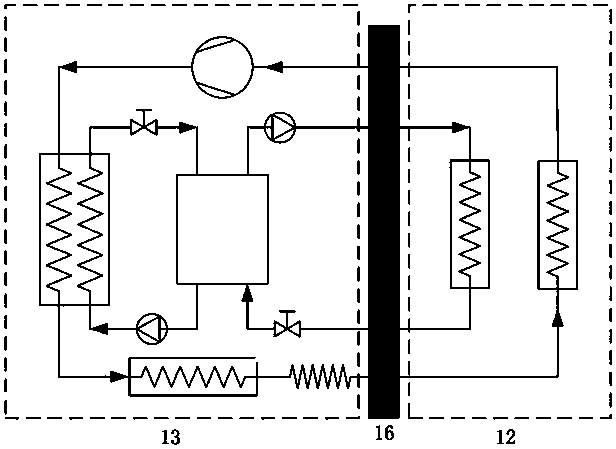

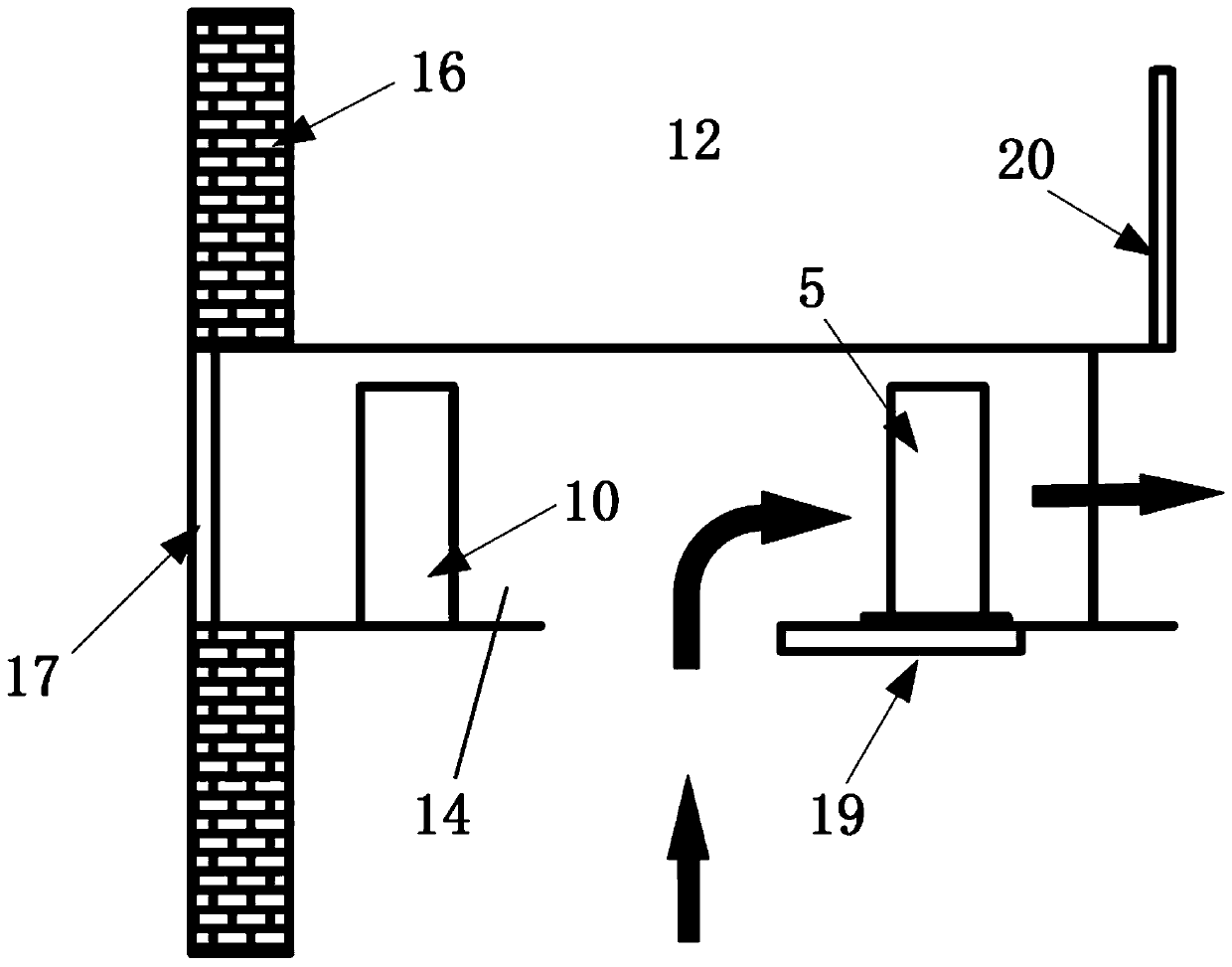

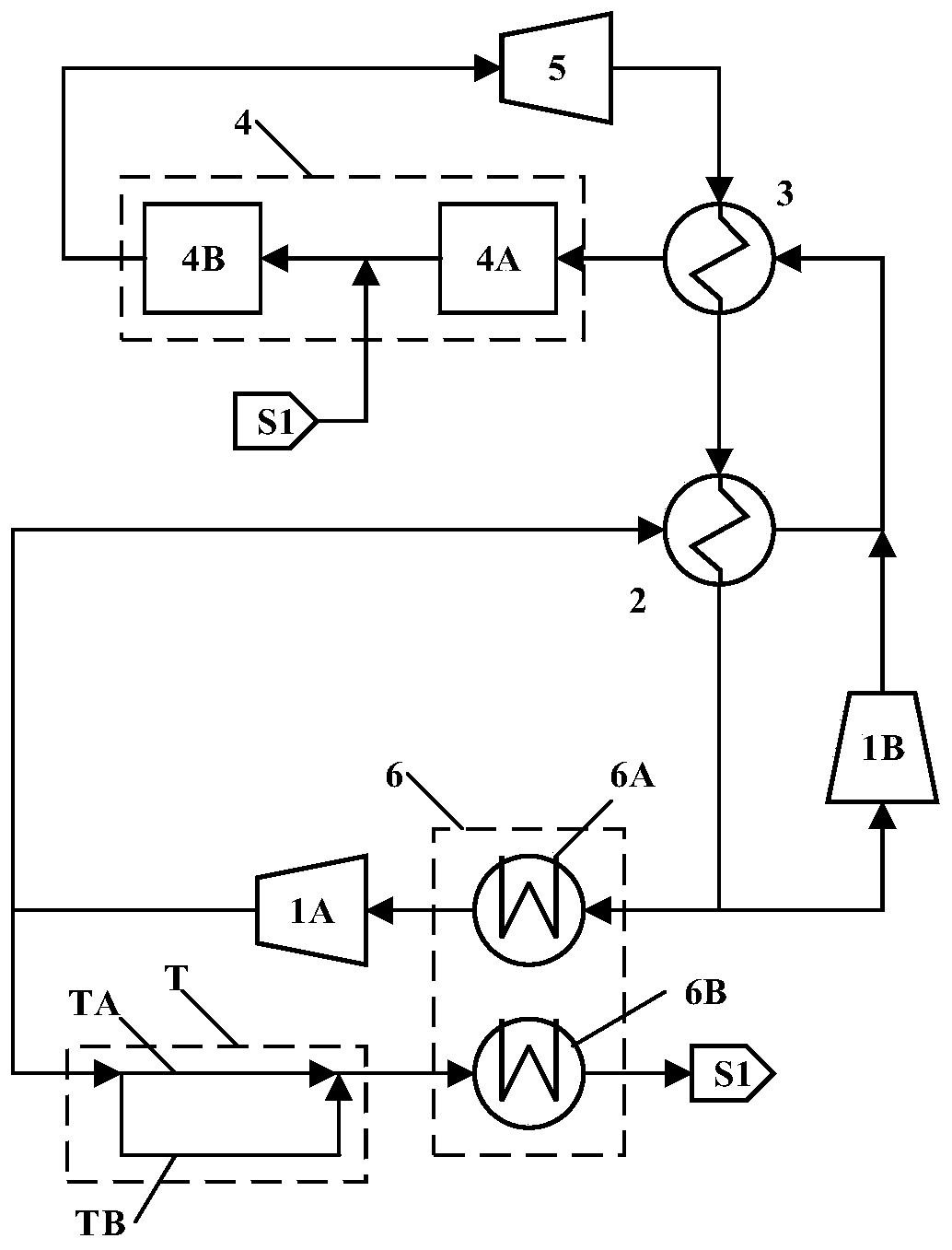

Heat storage defrosting system for cold storage air cooler and cold storage

PendingCN110762936AReduced power consumption for defrostingExtended service lifeLighting and heating apparatusDefrostingHeat recirculationMechanical engineering

The invention relates to a heat storage defrosting system for a cold storage air cooler. The heat storage defrosting system comprises a refrigerating device, a heat storage device and a heat release device, wherein the refrigerating device comprises a compressor, a heat storage heat exchanger, a condenser, a throttling device and an evaporator which are sequentially arranged; the evaporator is connected into the compressor, and a refrigerating circulation loop is formed; the heat storage device comprises a heat storage tank, a heat storage pump, a heat storage heat exchanger and a heat storagevalve which are sequentially arranged; the heat storage valve is connected into the heat storage tank, and a heat storage circulation loop is formed; the heat release device comprises a heat storagetank, a heat release pump, a heat release heat exchanger and a heat release valve which are sequentially arranged; the heat release valve is connected into the heat storage tank, and a heat release circulation loop is formed; the refrigerating device and the heat storage device conduct heat exchange in the heat storage heat exchanger; and the refrigerating device and the heat release device conduct heat exchange through the evaporator and the heat release heat exchanger. The invention further relates to a cold storage. According to the heat storage defrosting system and the cold storage, energy consumption can be reduced, operation is more stable, temperature fluctuation in the cold storage is reduced, and the heat storage defrosting system and the cold storage belong to the technical field of refrigerating and quick freezing.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

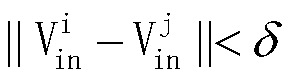

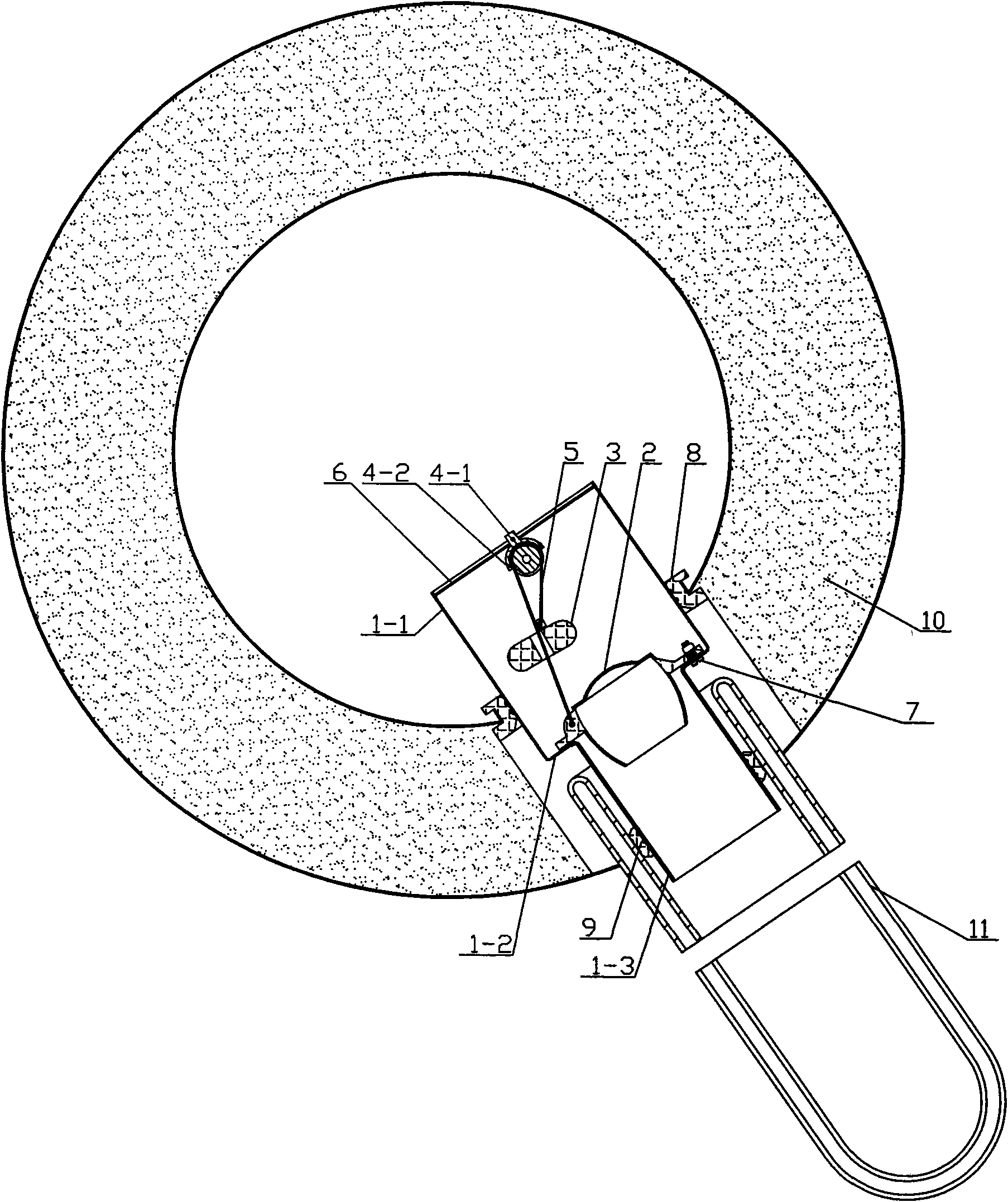

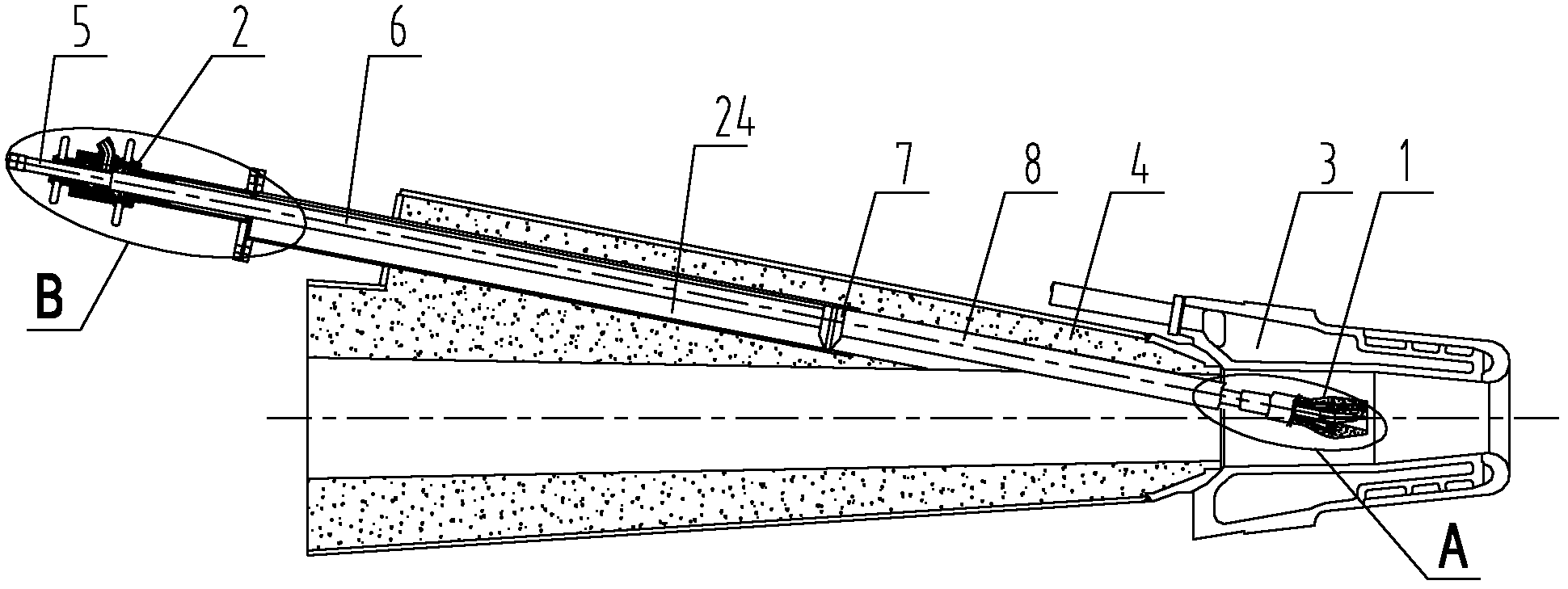

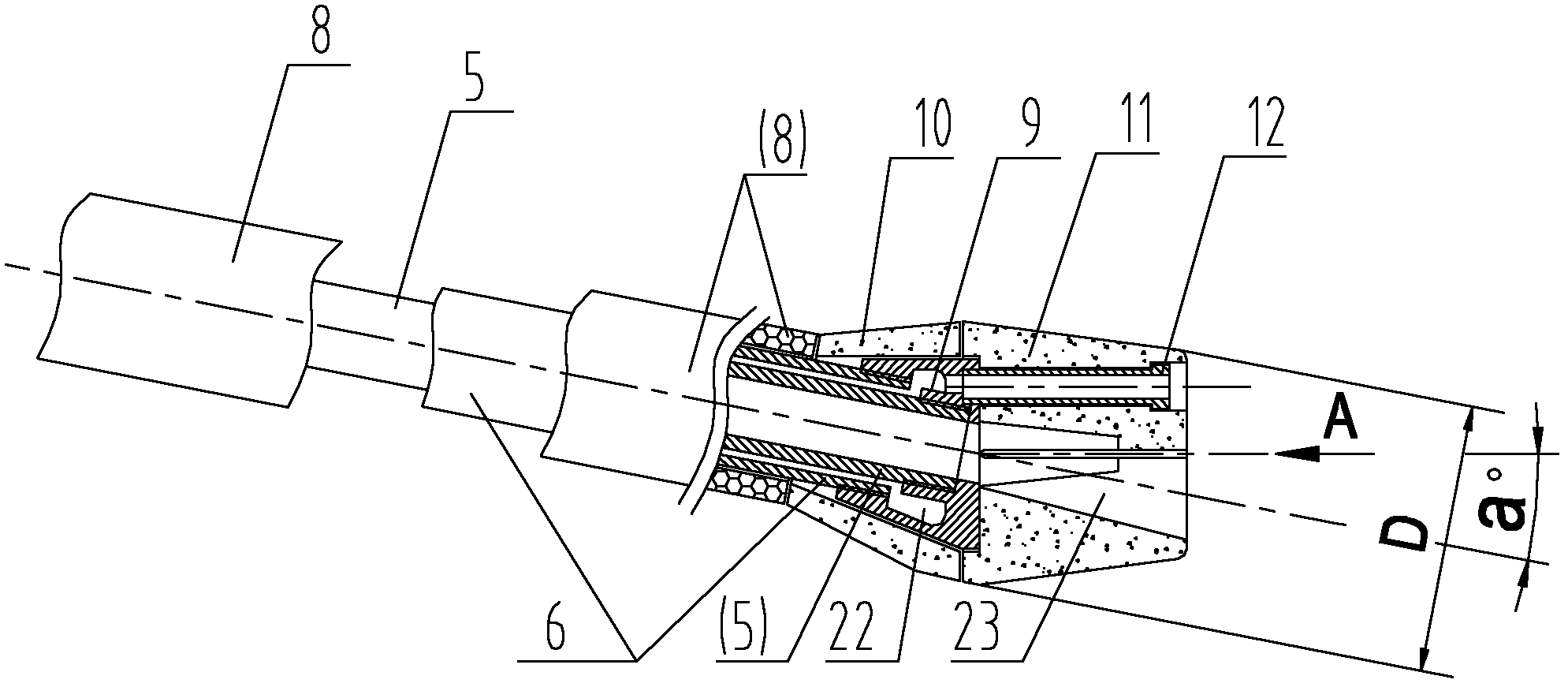

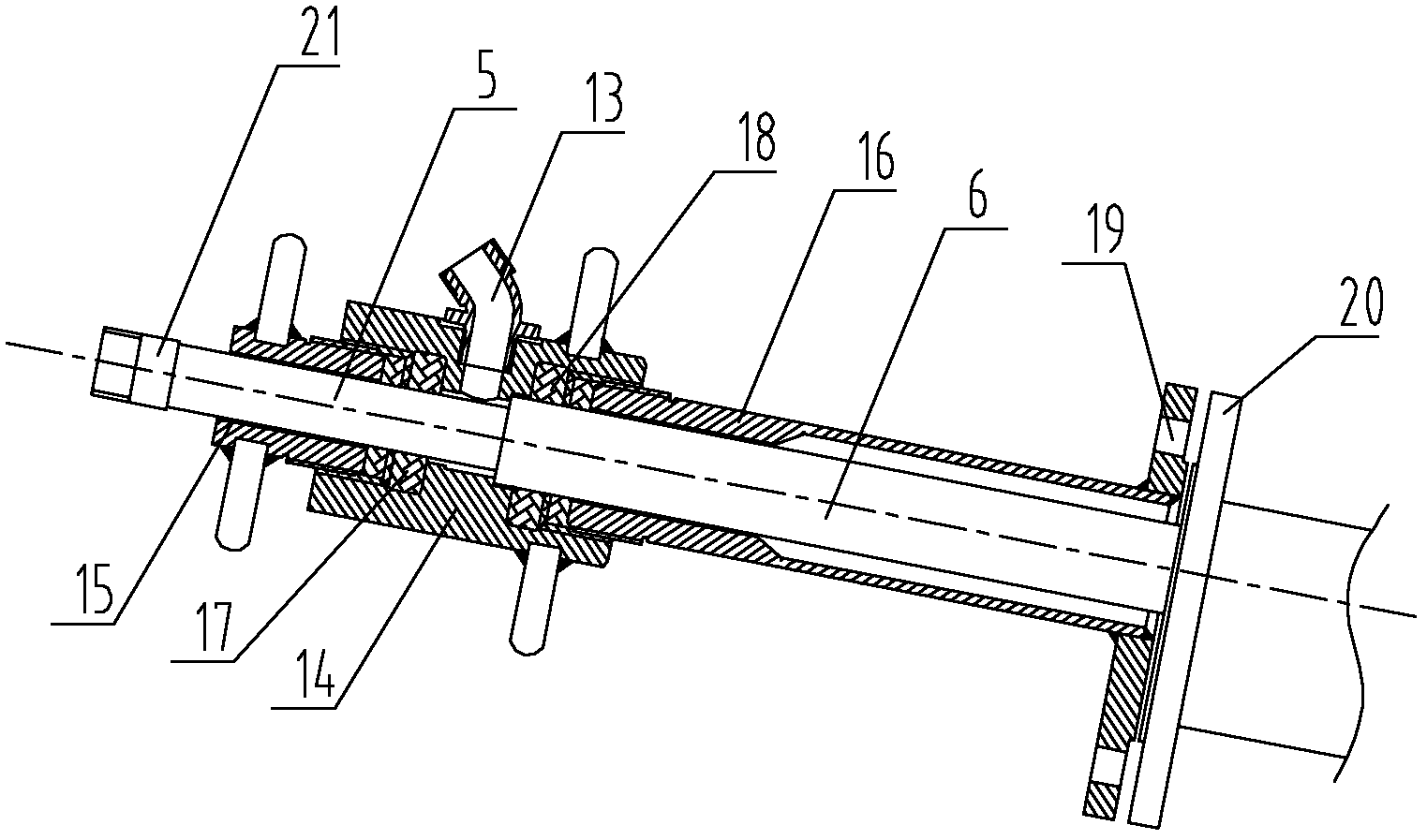

Blast furnace oxygen enrichment coal powder injection device and method off-line assembly and disassembly thereof

InactiveCN103131810AHigh temperature resistantWear-resistantTuyeresBlast furnace detailsMetallurgyHot blast

The invention discloses a blast furnace oxygen enrichment coal powder injection device. The blast furnace oxygen enrichment coal powder injection device adopts nonmetal ceramic to manufacture an oxygen enrichment burner, and the oxygen enrichment burner is arranged at an outlet of a spray gun and an outlet of a sleeve. Simultaneously, the sleeved is protected. The blast furnace oxygen enrichment coal powder injection device has the application performance which is heat-resisting, wear-resisting and oxidation-resisting, and the service life can be prolonged remarkably. A method of off-line assembly and disassembly of the blast furnace oxygen enrichment coal powder injection device is that in the state of blast furnace damping down, through a mode of dismantling a flange, the blast furnace oxygen enrichment coal powder injection device can be inserted in or pulled out from a gun insertion hole passage of a blowing-in branch pipe. By the adoption of the blast furnace oxygen enrichment coal powder injection device and the method of the off-line assembly and disassembly of the blast furnace oxygen enrichment coal powder injection device, the mixture between pulverized coal, oxygen and hot-blast air can be furthest improved, so that a partial oxygen enrichment condition which benefit to pulverized coal firing is produced, and combustion efficiency and coal quantity of blast furnace coal injection can be improved by a large margin.

Owner:无锡市释珑能源科技有限公司

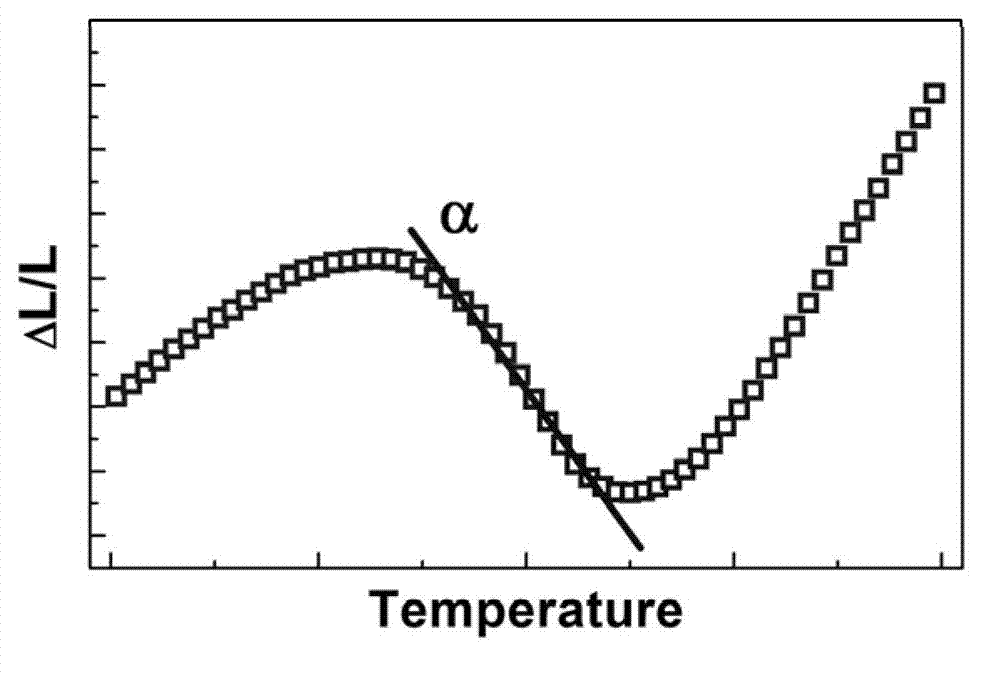

Method for regulating thermal expansion by stress regulation based on strain glass phase transformation

InactiveCN103031429APrecise control of thermal expansion behaviorMeet the requirements of thermal expansion performanceIn situ transmission electron microscopyAlloy

The invention discloses a method for regulating thermal expansion by stress regulation based on strain glass phase transformation, and the method comprises the following steps of: first, selecting any alloy material having martensite phase transformation capable of causing volume expansion as mother alloy; second, performing defect doping in the mother alloy and then utilizing an in situ transmission electron microscopy to perform structure comparison and analysis on a high-temperature parent phase and low-temperature strain glass state so that the volume of similar-martensite divisions in the strain glass state is larger than that of the corresponding parent phase before phase transformation; and at last, applying different external forces to the strain glass alloy, and regulating the thermal expansion action of the strain glass alloy during temperature-rise period and temperature-fall period by changing the quantity and size of the similar-martensite divisions in the alloy. The method disclosed by the invention not only can artificially precisely regulate the thermal expansion action of the material at right time according to the actual needs to avoid thermal stress and thermal vibration that may be generated on precise devices but also can fully utilize the characteristics of the raw materials, such as performances of inherent high conductivity, high thermal conductivity and high mechanical strength of the alloy.

Owner:XI AN JIAOTONG UNIV

Supercritical carbon dioxide boiler working medium temperature adjusting system and method

PendingCN110056851ASolve the problem of adjusting the working fluid temperatureEasy to adjustBoiler controlSteam engine plantsSteam turbine bladeEngineering

The invention relates to a supercritical carbon dioxide boiler working medium temperature adjusting system. According to another technical scheme, a supercritical carbon dioxide boiler working mediumtemperature adjusting method is provided. The system and the method effectively solve the temperature adjustment problem of a supercritical carbon dioxide boiler working medium. A part of carbon dioxide working medium in a closed system is cooled and then directly in contact with a high-temperature carbon dioxide working medium for heat exchange, through maintaining reasonable temperature and flowof a low-temperature carbon dioxide working medium entering a temperature adjusting point of the supercritical carbon dioxide boiler, the temperature of the supercritical carbon dioxide boiler working medium is rapidly and flexibly adjusted, the overtemperature of a heating surface of the boiler is avoided, the operation safety of the system is obviously improved, and the service lives of the high-temperature heating surface, pipelines and turbine blades in the system are greatly prolonged.

Owner:SHANGHAI BOILER WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com