Intelligent combustion comprehensive optimization control method for boiler

A technology of optimal control and combustion optimization, which is applied in the directions of combustion method, controlled combustion, and adaptive control, and can solve the problems that the optimization method of boiler combustion is not well solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

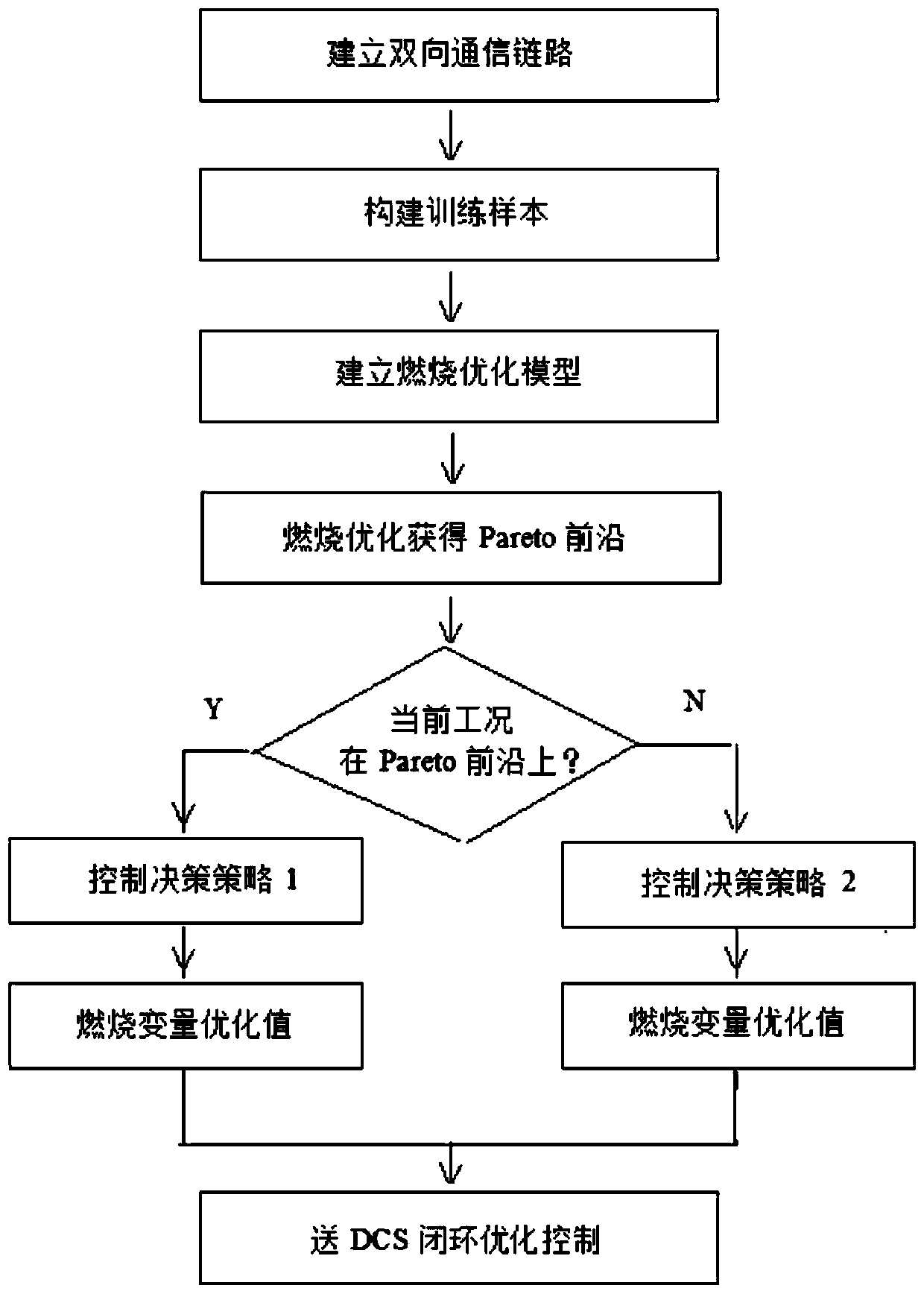

[0051] In order to describe the technical solutions disclosed in the present invention in detail, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

[0052] The engineering application object is a 600MW unit, and the boiler is a direct-blown pulverizing system with four-corner tangential combustion, combined with figure 1 Shown, use the concrete steps of the inventive method as follows:

[0053] Step 1: Optimize the control system and configure a workstation and a PLC, connect the data communication port of the PLC with the DCS data communication port of the unit, and use the Modbus method for data exchange; connect the communication interface of the workstation with the PLC data communication port, and use the OPC method Data exchange, establishing a two-way data communication link between the optimized control system and the DCS of the unit;

[0054] In actual engineering application, the workstati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com