Large vacuum solar heat collecting system

A technology of solar heat collection and large vacuum, which is applied in the field of solar heat collection systems, can solve the problems of poor thermal insulation performance, large heat dissipation, and occupying a lot of space, and achieve the effect of ensuring reliability and reducing heat emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

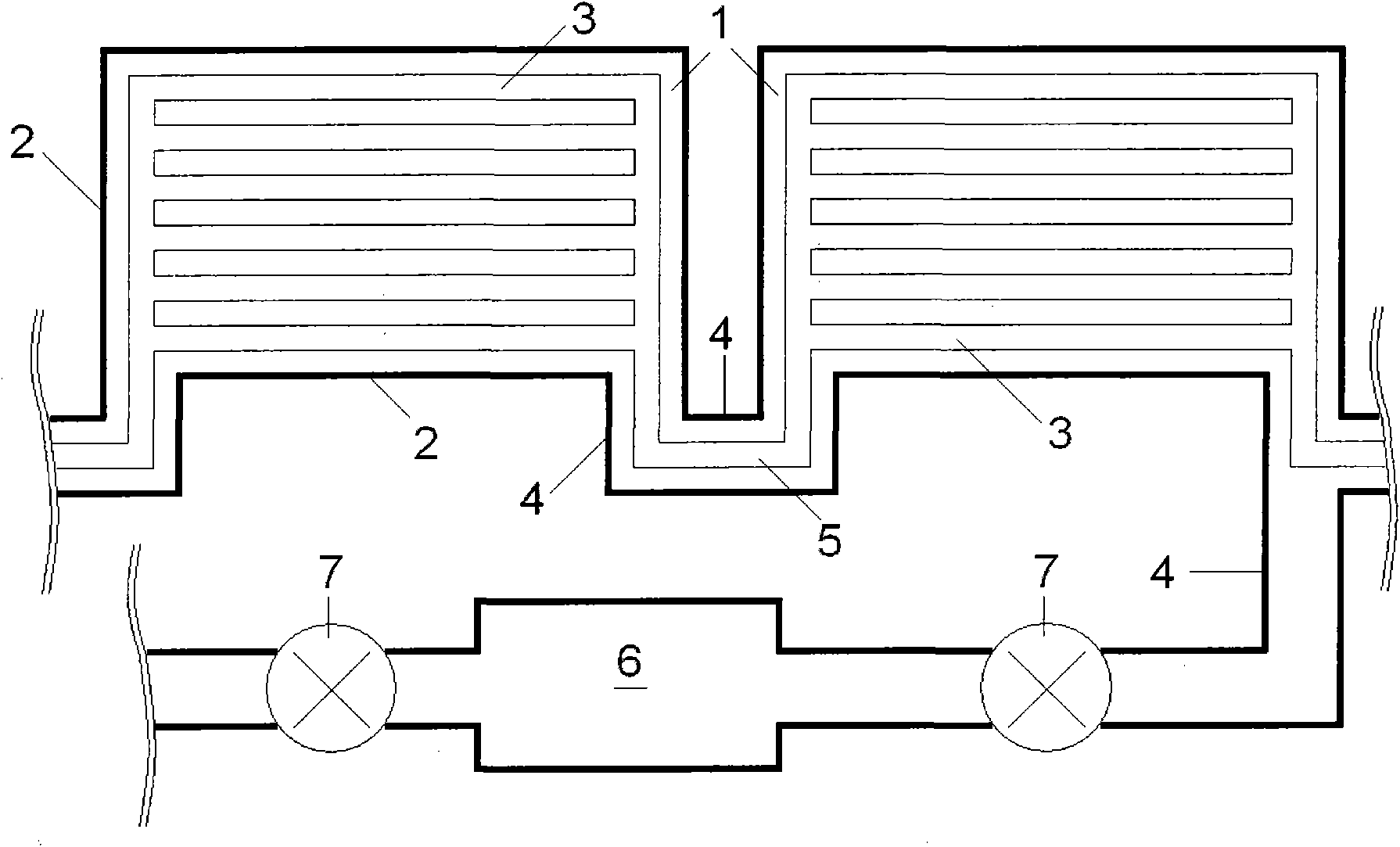

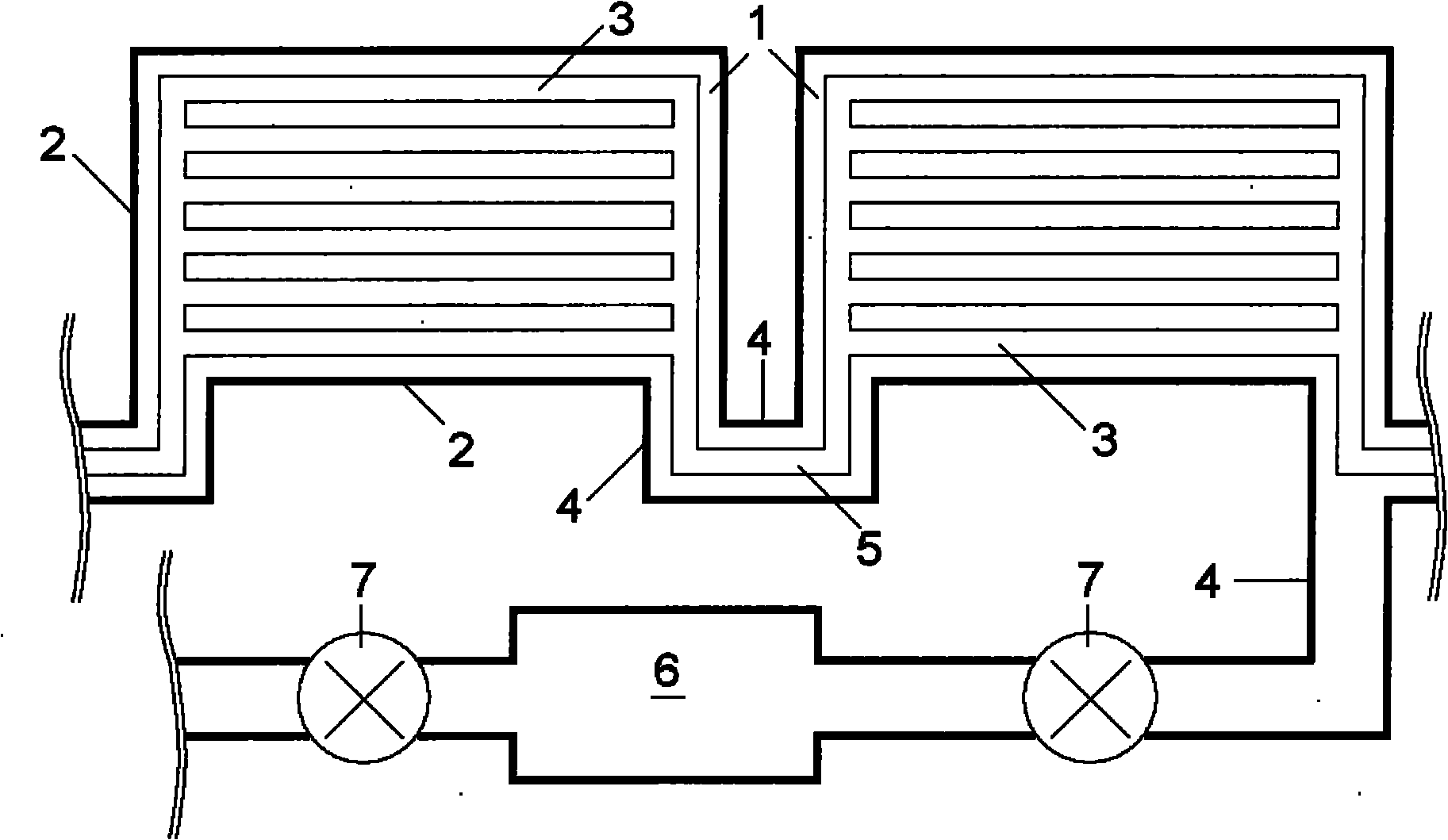

[0016] figure 1 Shown is a schematic diagram of the principle of an embodiment of the present invention. The heat collection system includes a plurality of heat collection units 1. The main structure of the heat collection unit 1 is a shell 2 and a heat absorber 3. The shell 2 is in the shape of a flat box and contains a light-transmitting surface with a high light transmittance. It has a high heat absorption rate and a low heat radiation rate and is placed inside the shell 2. Except for some auxiliary supporting contacts, the rest of the shell 2 should be kept separated as much as possible, and the separated part forms a vacuum heat insulation layer. The shells 2 of the heat collecting units 1 communicate with each other through the vacuum connection pipe 4, so that the vacuum heat insulation layers of the heat collecting units 1 communicate with each other to form a closed large vacuum union.

[0017] The heat collection system also includes a heat transfer pipe 5, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com