Multi-purpose type double-sided film laminating system

A double-sided lamination and lamination technology, which is used in general parts of printing machinery, lamination auxiliary operations, printing, etc., can solve the problem of paper lamination requirements that cannot fully meet the requirements of different materials and thicknesses, and cannot meet the needs of producers. , Insufficient adhesion of printed matter, etc., to achieve the effect of reasonable structure, increase production profit, and avoid wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below with reference to the drawings and embodiments.

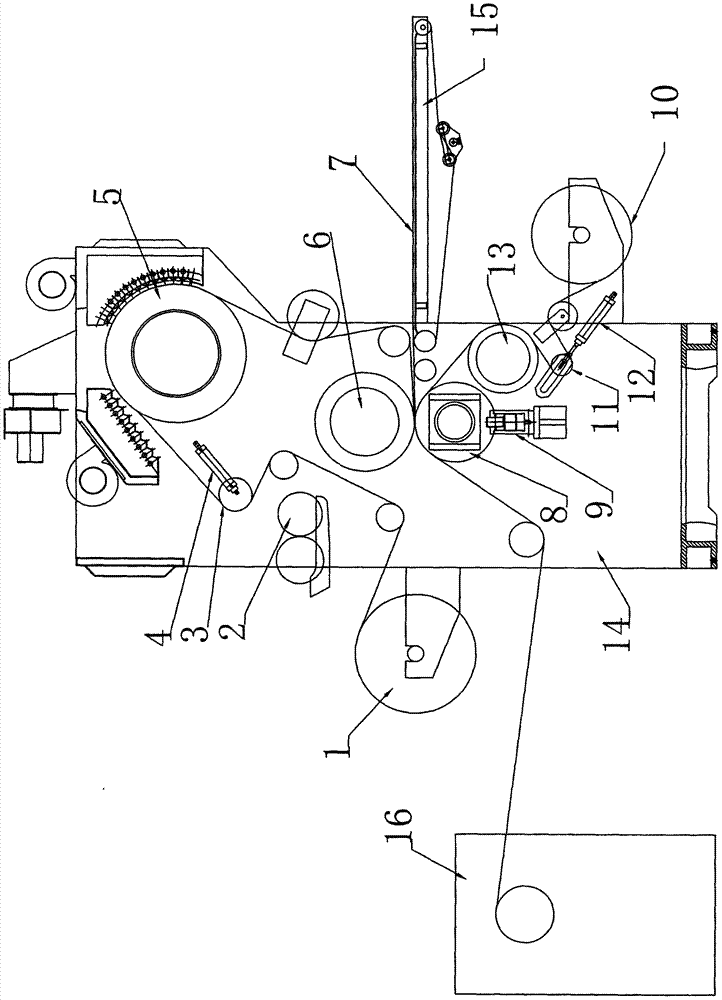

[0010] Refer to attached figure 1 It can be seen that the multi-purpose double-sided laminating system of the present invention includes a frame 14, an upper film roll 1, and a hot-pressing mechanism. On the left side, it is the previous process), drying mechanism 5 (on the right side, it is the subsequent process), on the frame 14, a preheating roller 13 and a lower film roll are successively installed at the place below the hot pressing mechanism 10. On the frame 14, and between the preheating roller 13 and the lower film roller 10, a spreading roller 11 (movable type) is installed, and the spreading roller 11 is connected with a stretching power source 12 (which can be a stretching cylinder) .

[0011] Wherein, the gluing mechanism includes a gluing roller 2, a gluing guide roller 3, and a gluing cylinder 4, and the hot pressing mechanism includes a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com