Repair method for transversal cracks of welding seams of thick-wall submerged arc welded pipe

A technology for submerged arc welded pipes and transverse cracks, which is applied to arc welding equipment, welding equipment, manufacturing tools, etc., and can solve problems such as large heat input, no preheating, and insufficient preheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

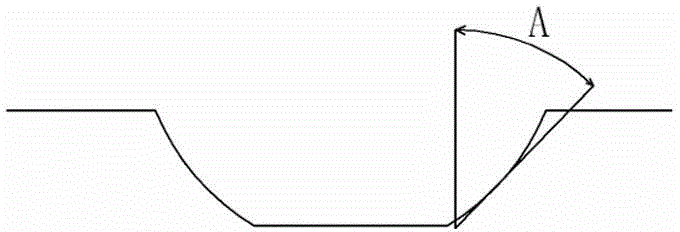

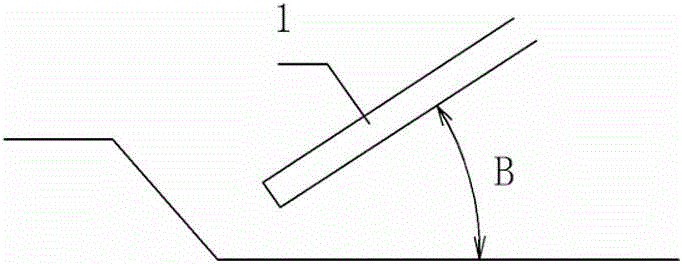

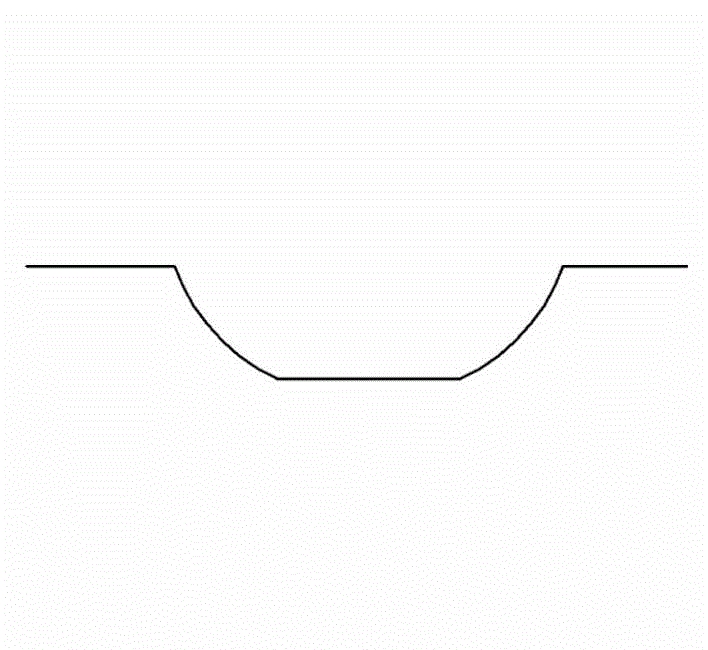

[0040] like Figure 1 to Figure 3 As shown, a method for repairing transverse cracks in thick-walled submerged arc welded pipes includes the following steps: a. Defect confirmation: carry out 100% UT inspection on all welds, including scanning on both sides of the weld and scanning on the surface of the weld. Check and mark the position, length, depth and direction of the cracks. If the whole weld is defective, plan the whole weld and then perform submerged arc welding, and use electrode arc welding for partial repair; b. Preheat before planing : The preheating temperature is 110°C-170°C, the detection position of the preheating temperature is within 75mm on both sides of the weld, and the heating range is within 500mm around the defect; Gouging from the 50mm seam to the middle, the two ends of the gouging are smooth and gentle transition, such as figure 1 As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com