Preparation method and use of manganese dioxide having hollow structure

A manganese dioxide, hollow structure technology, applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of preparing manganese dioxide hollow spheres, which is difficult, and achieve good catalytic activity, good process repeatability, and uniform morphology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

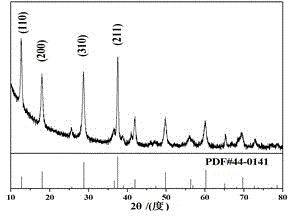

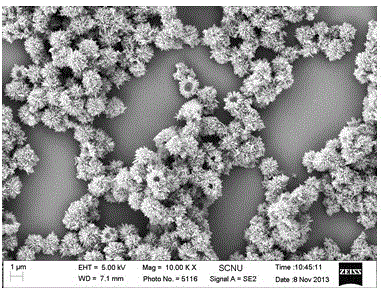

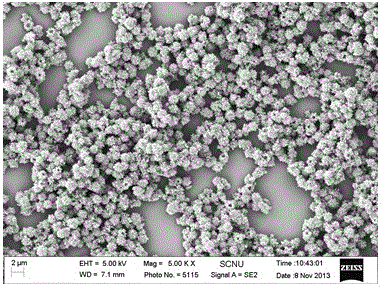

[0028] First, dissolve 2mmol of manganese sulfate, 2mmol of potassium persulfate and 2mmol of potassium sulfate in 15mL of distilled water, stir and dissolve completely to form solution A; while stirring the solution A, add concentrated sulfuric acid to solution A, stir well and form a mixed Solution B; wherein the volume ratio of concentrated sulfuric acid to the distilled water is 0.9:15; put the mixed solution B into a 25 mL autoclave, and place the autoclave at a temperature of 140°C for 12 hours Finally, the product was obtained; the product was washed several times with distilled water and absolute ethanol, and dried in a drying oven at 60° C. to obtain the manganese dioxide with the hollow structure. The product was identified as α-MnO by X-ray powder diffraction 2 ; Powder X-ray diffraction results such as figure 1 shown; the material morphology was obtained by transmission electron microscopy, such as figure 2 , image 3 As shown in the figure, it can be seen tha...

Embodiment 2

[0030] First, dissolve 2mmol of manganese sulfate, 1.6mmol of potassium persulfate and 2.4mmol of potassium sulfate in 15mL of distilled water, stir and dissolve completely to form solution A; while stirring the solution A, add concentrated sulfuric acid to the solution A, after stirring evenly A mixed solution B is formed; the volume ratio of concentrated sulfuric acid to the distilled water is 0.8:15; the mixed solution B is placed in a 25 mL autoclave, and the autoclave is placed in a temperature environment of 140°C for reaction The product was obtained after 24 hours; the product was washed several times with distilled water and absolute ethanol, and dried in a drying oven at 100° C. to obtain the manganese dioxide with the hollow structure. The obtained product is identified by X-ray powder diffraction and scanning electron microscope (similar to the manganese dioxide with a hollow structure prepared in Example 1), which shows that it is a manganese dioxide with a hollow ...

Embodiment 3

[0032] First, dissolve 2mmol of manganese sulfate, 2.2mmol of potassium persulfate and 1.8mmol of potassium sulfate in 15mL of distilled water, stir and dissolve completely to form solution A; while stirring the solution A, add concentrated sulfuric acid to the solution A, after stirring evenly A mixed solution B is formed; the volume ratio of concentrated sulfuric acid to the distilled water is 1:15; the mixed solution B is placed in a 25 mL autoclave, and the autoclave is placed in a temperature environment of 140°C for reaction The product was obtained after 12 hours; the product was washed several times with distilled water and absolute ethanol, and dried in a drying oven at 80° C. to obtain the manganese dioxide with the hollow structure. The obtained product is identified by X-ray powder diffraction and scanning electron microscope (similar to the manganese dioxide with a hollow structure prepared in Example 1), which shows that it is a manganese dioxide with a hollow str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com