Preparation method and application research of WO3 nanosheet array film

A nanosheet array and thin film technology, applied in the field of nanomaterials, can solve the problems of inability to prepare nanostructured thin films, poor reproducibility, disordered thin films, etc., achieve good visible light absorption performance, good effect, and overcome the effect of thin film inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

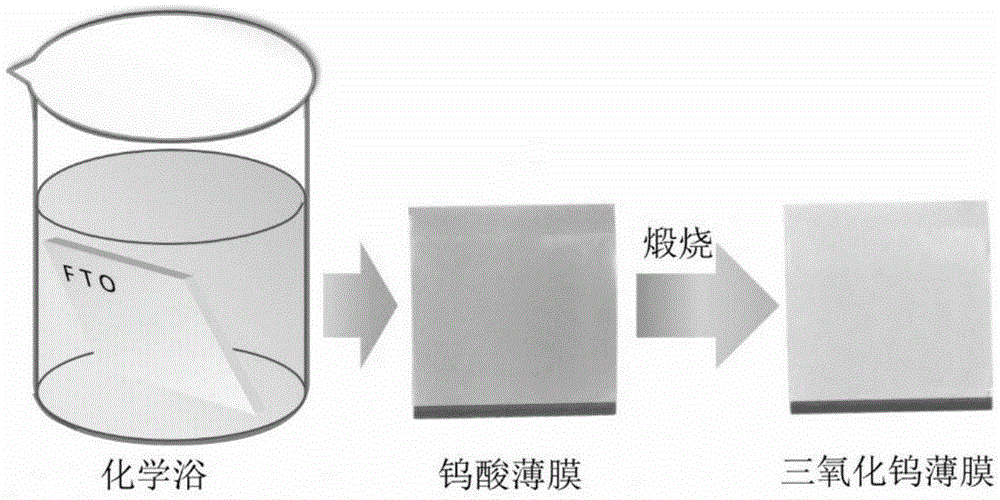

[0035] 1) Add 0.4gNa 2 WO 4 2H 2 O and 0.15g of ammonium oxalate were dissolved in 30mL of deionized water, and 9mL of 37% hydrochloric acid was added to obtain a yellow tungstic acid precipitate. After stirring for 10 minutes, 8mL of 37% H 2 o 2 , the precipitate was dissolved and a clear peroxytungstic acid solution was obtained. After stirring for 10 minutes, 30 mL of ethanol was added and stirred for another 10 minutes. The fluorine-doped tin oxide (FTO) conductive glass was used as the substrate, and the FTO leaned against the wall with the face down. Water bath at 85°C for 200 minutes, and slowly precipitate tungstic acid on the FTO substrate to obtain a uniform tungstic acid film. The above tungstic acid film is rinsed with deionized water and dried at about 50°C for more than 1 hour;

[0036] 2) heat-treat the dry tungstic acid film obtained in step 1) at a temperature of 500°C for 2 hours, and obtain the WO after natural cooling 3 Nanosheet array thin film electro...

Embodiment 2

[0042] 1) Add 0.2gNa 2 WO 4 2H 2 O and 0.06g of ammonium oxalate were dissolved in 30mL of deionized water, and 5mL of 37% hydrochloric acid was added to obtain a yellow tungstic acid precipitate. After stirring for 10 minutes, 5mL of 37% H 2 o 2 , the precipitate was dissolved and a clear peroxytungstic acid solution was obtained. After stirring for 10 minutes, 30 mL of ethanol was added and stirred for another 10 minutes. The fluorine-doped tin oxide (FTO) conductive glass was used as the substrate, and the FTO leaned against the wall with the face down. Water bath at 95°C for 120 minutes, and slowly precipitate tungstic acid on the FTO substrate to obtain a uniform tungstic acid film. The above tungstic acid film is rinsed with deionized water and dried at about 50°C for more than 1 hour;

[0043] 2) The dried tungstic acid film obtained in step 1) was heat-treated at 400°C for 6h, and the WO was obtained after natural cooling. 3 Nanosheet array thin film electrodes.

...

Embodiment 3

[0046] 1) Add 0.6gNa 2 WO 4 2H 2 O and 0.2g of ammonium oxalate were dissolved in 30mL of deionized water, and 15mL of 37% hydrochloric acid was added to obtain a yellow tungstic acid precipitate. After stirring for 10 minutes, 10mL of 37% H 2 o 2 , the precipitate was dissolved and a clear peroxytungstic acid solution was obtained. After stirring for 10 minutes, 30 mL of ethanol was added and stirred for another 10 minutes. The fluorine-doped tin oxide (FTO) conductive glass was used as the substrate, and the FTO leaned against the wall with the face down. Water bath at 75°C for 220 minutes, and slowly precipitate tungstic acid on the FTO substrate to obtain a uniform tungstic acid film. The above tungstic acid film is rinsed with deionized water and dried at about 50°C for more than 1 hour;

[0047] 2) heat-treat the dried tungstic acid film obtained in step 1) at a temperature of 550°C for 1 hour, and obtain the WO after natural cooling 3 Nanosheet array thin film elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com