Recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst containing tungsten, vanadium and titanium

A waste catalyst, honeycomb technology, applied in the direction of vanadium compounds, tungsten compounds, titanium oxide/hydroxide, etc., can solve the problem of heavy metal treatment that has not been proposed and described in detail, and the recovery of TiO in SCR denitrification catalysts has not been mentioned. Disposal methods and other issues to achieve the effect of high recovery rate and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

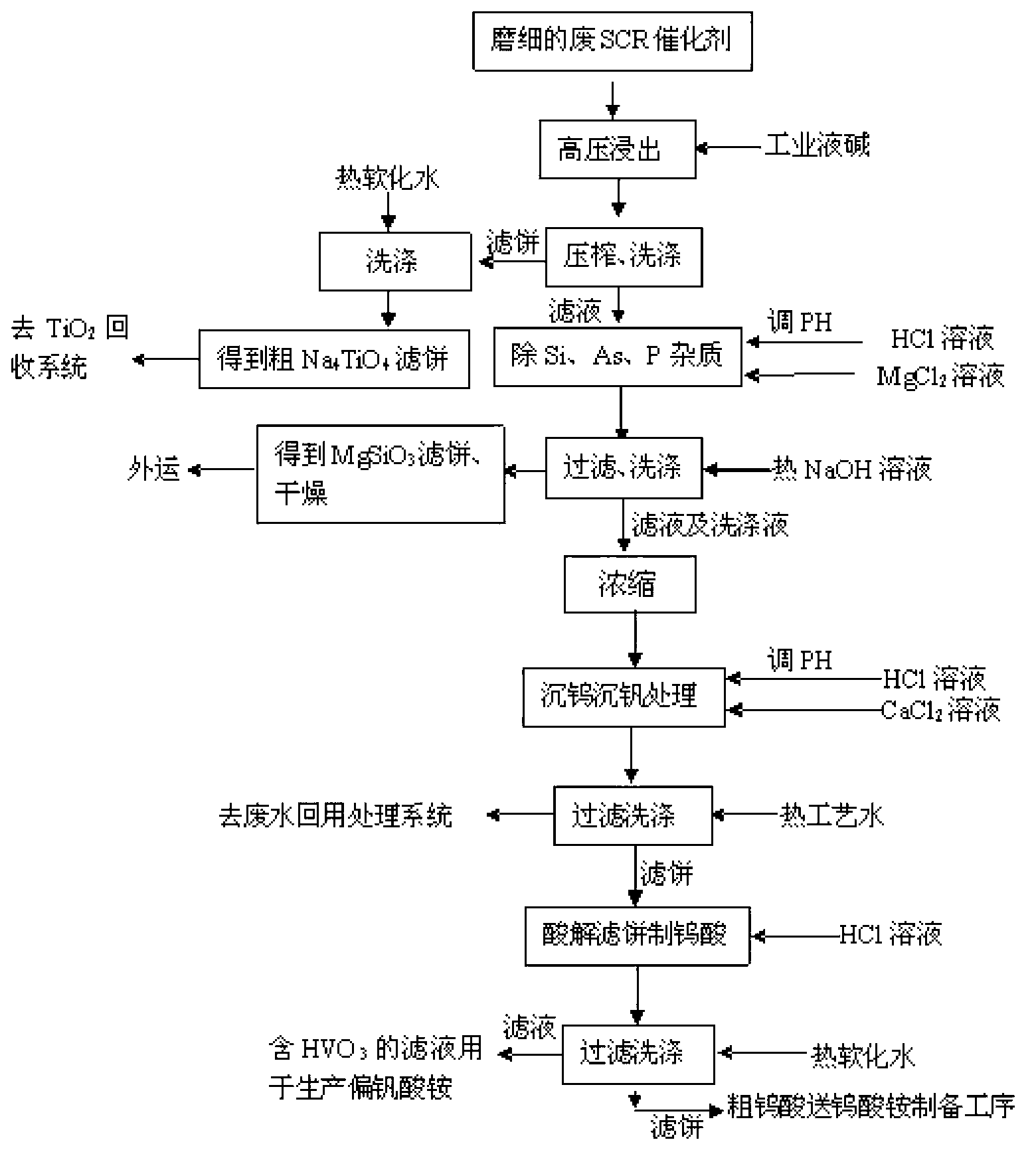

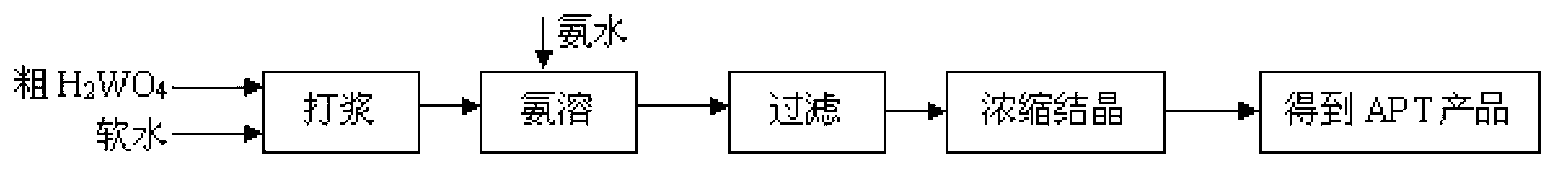

[0095] The recovery process from the honeycomb SCR waste catalyst containing tungsten, vanadium and titanium includes the following steps in sequence:

[0096] (1) Contains WO 3 4.35% (wt%), V2 o 5 1% (wt%), TiO 2 80% (wt%) of the spent SCR catalyst is washed with high-pressure water to remove ash, crushed by a jaw crusher to a particle size of ≤20cm, wet-milled by a ball mill to a particle size of 120 mesh, and passed through completely; in the leaching balls, 666g / l concentration of industrial liquid is used Alkali is leached for 4 hours at 155°C and a pressure of 0.6Mpa, and the liquid-solid ratio of leaching (NaOH solution volume m 3 : SCR quality t) is 3.2; leachate and filter residue are obtained after solid-liquid separation, the filter residue is washed with deionized process water, and the washing liquid is merged into the filtrate; the filter residue is used for the production of rutile titanium dioxide, and the filtrate is used for ammonium paratungstate and metav...

Embodiment 2

[0107] The recovery process from the honeycomb SCR waste catalyst containing tungsten, vanadium and titanium includes the following steps in sequence:

[0108] (1) Contains WO 3 6.09% (wt%), V 2 o 5 0.5% (wt%), TiO 2 80% (wt%) of the spent SCR catalyst was washed with high-pressure water to remove ash, crushed by a jaw crusher to a particle size of ≤20cm, and wet-milled by a ball mill until the particle size was 120 mesh; Industrial liquid caustic soda is leached for 4 hours at 180°C and a pressure of 0.7Mpa, and the leaching liquid-solid ratio (volume of NaOH solution m 3 : SCR quality t) is 3.5; leachate and filter residue are obtained after solid-liquid separation, the filter residue is washed with deionized process water, and the washing liquid is merged into the filtrate; the filter residue is used for the production of rutile titanium dioxide, and the filtrate is used for ammonium paratungstate and metavanadate production of ammonium;

[0109] (2) The filtrate from ...

Embodiment 3

[0119] The recovery process from the honeycomb SCR waste catalyst containing tungsten, vanadium and titanium includes the following steps in sequence:

[0120] (1) Contains WO 3 5.22% (wt%), V 2 o 5 0.47% (wt%), TiO 2 80.5% (wt%) of the SCR waste catalyst was washed with high-pressure water to remove ash, crushed by a jaw crusher to a particle size of ≤20cm, and wet-milled by a ball mill until the particle size was 120 mesh; the leaching ball was treated with industrial liquid with a concentration of 670g / l The alkali is leached for 4 hours at 175°C and a pressure of 0.7Mpa, and the ratio of liquid to solid (volume of NaOH solution m 3 : SCR quality t) is 3; leachate and filter residue are obtained after solid-liquid separation, the filter residue is washed with deionized process water, and the washing liquid is merged into the filtrate; the filter residue is used for the production of rutile titanium dioxide, and the filtrate is used for ammonium paratungstate and metavana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com