Insulated panels and shipping container incorporating said panels

a technology of insulated panels and shipping containers, applied in the field of insulated panels, can solve the problems of affecting the quality of insulated containers,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

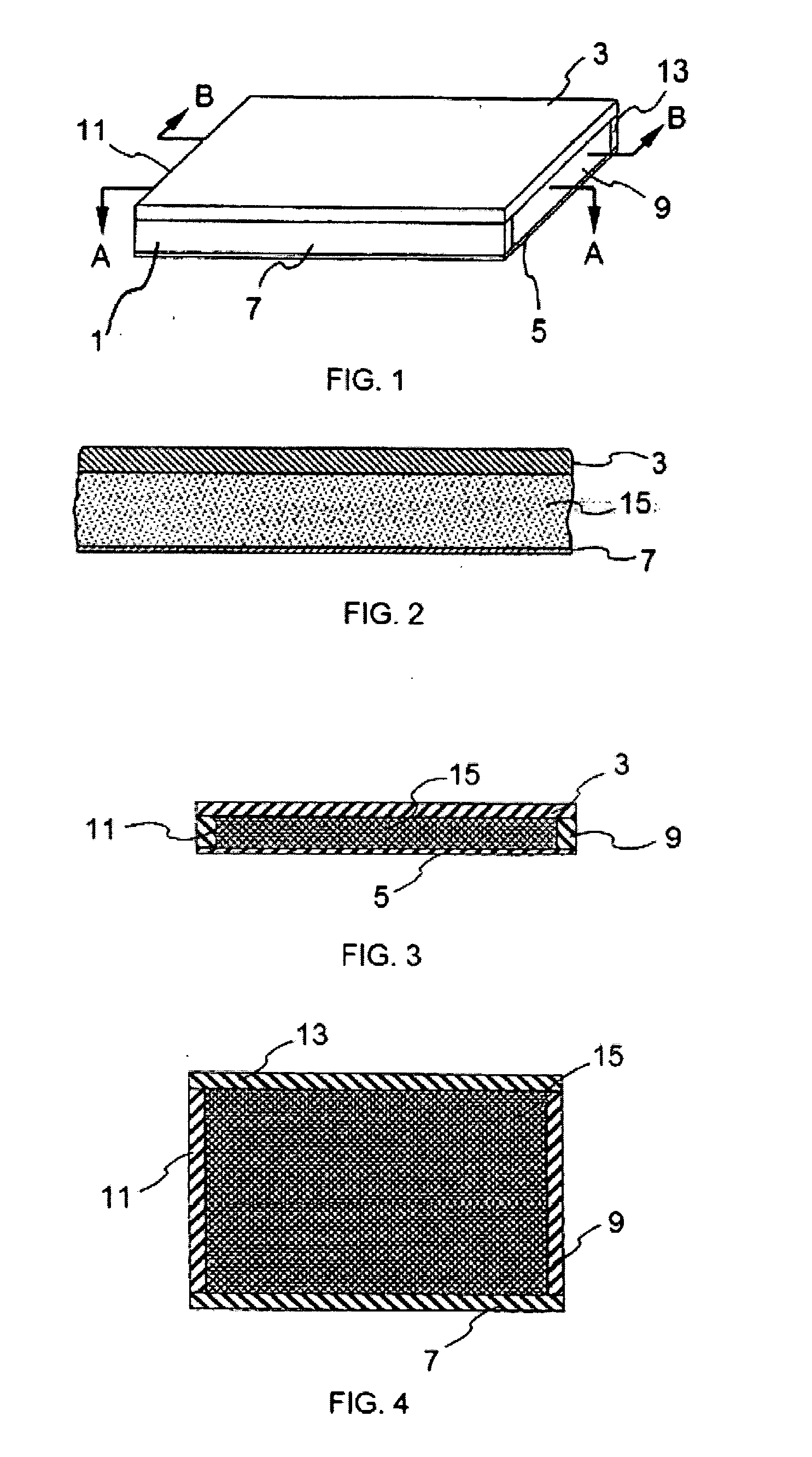

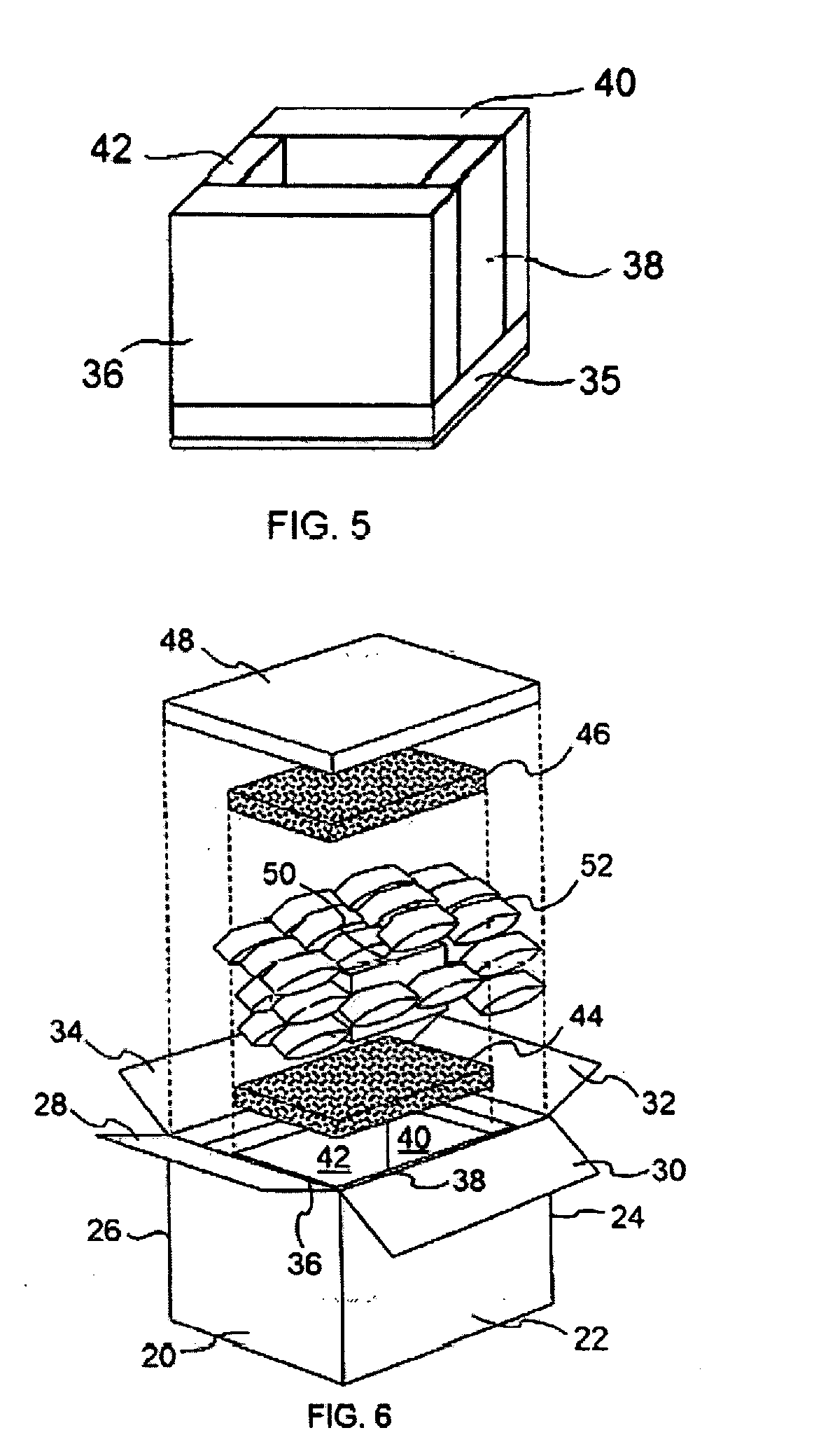

[0062] The invention is predicated on the finding that the insulation panels of the invention can, when fitted together to form a thermally insulated container, provide a container having enhanced thermal insulation properties over that expected from a similarly sized mass of foam insulation, such as rigid polyurethane or EPS insulation material. The improvement appears to be as a result of wholly encompassing the core insulation material within a polyethylene foam envelope. It is speculated that the envelope improves the insulation characteristics of core insulation material by providing an improved seal at the seams between interconnected panels. The envelope may also improve the insulation properties of the insulation material by providing an airtight covering over the core insulation material.

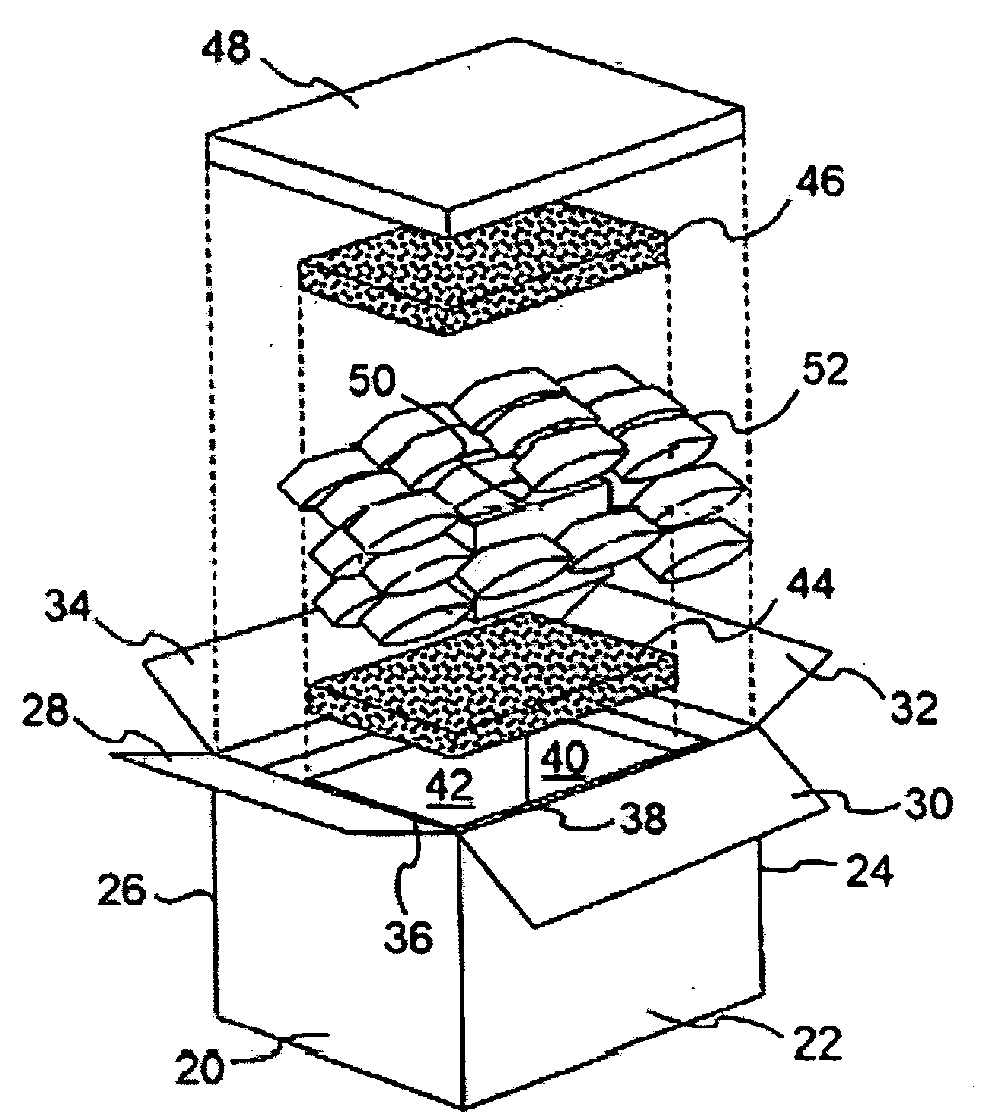

[0063] An insulation panel is depicted in FIGS. 1 to 4. Each panel comprises a core of insulation material and polyethylene foam. The depicted insulation panel (1) is rectangular although ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com