LCP substrate-based encapsulation shell and preparation method

A technology for encapsulating shells and substrates, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as complex manufacturing process, inability to achieve airtight packaging, and use restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

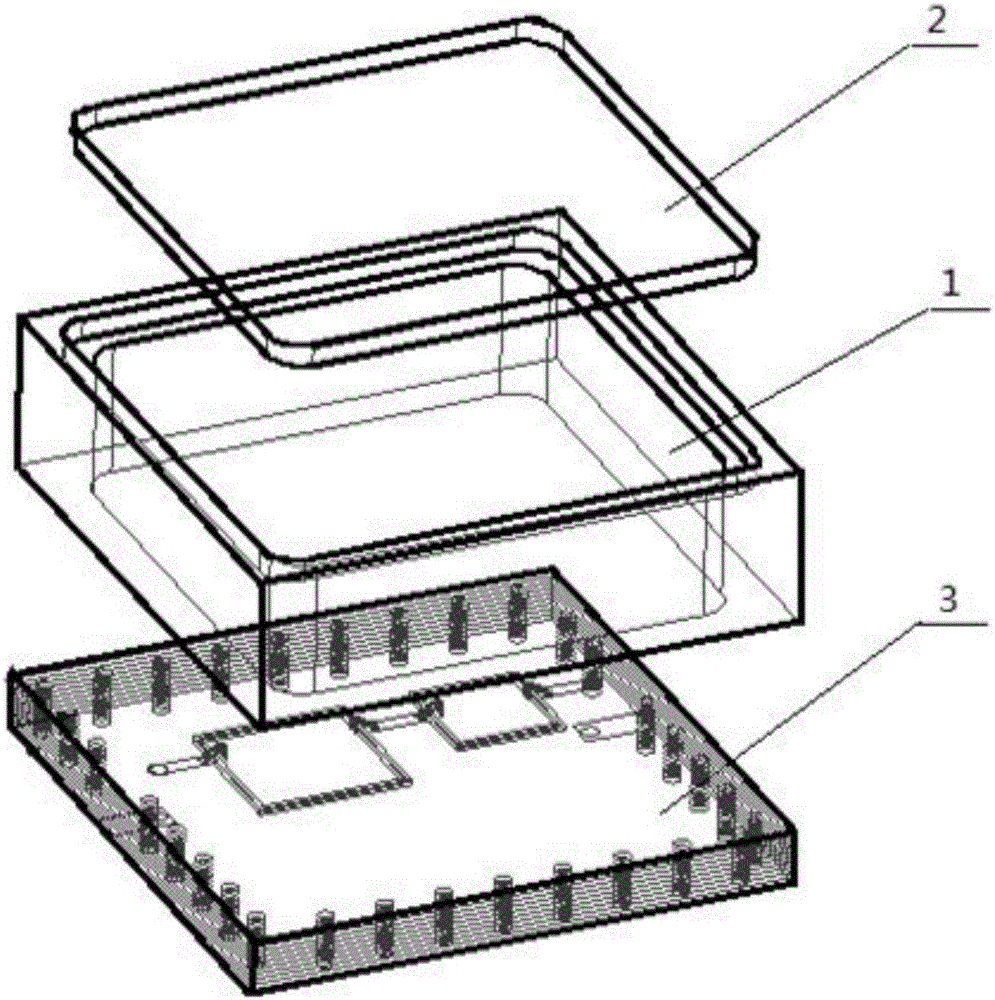

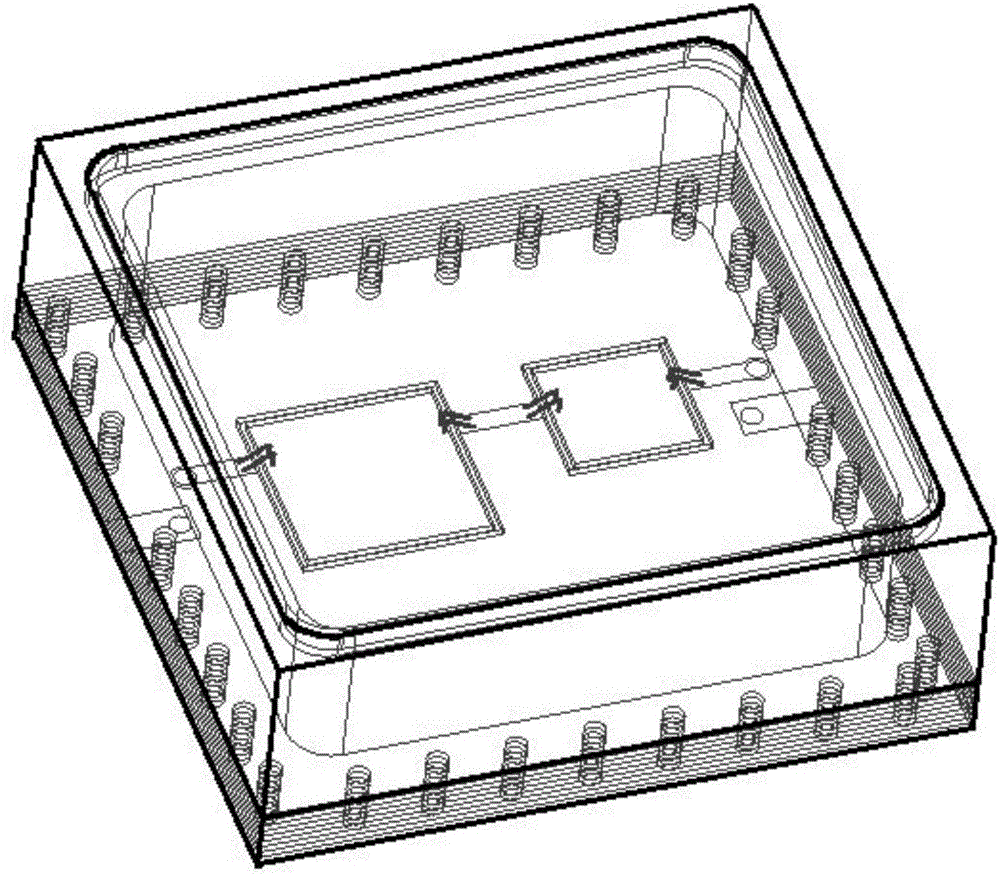

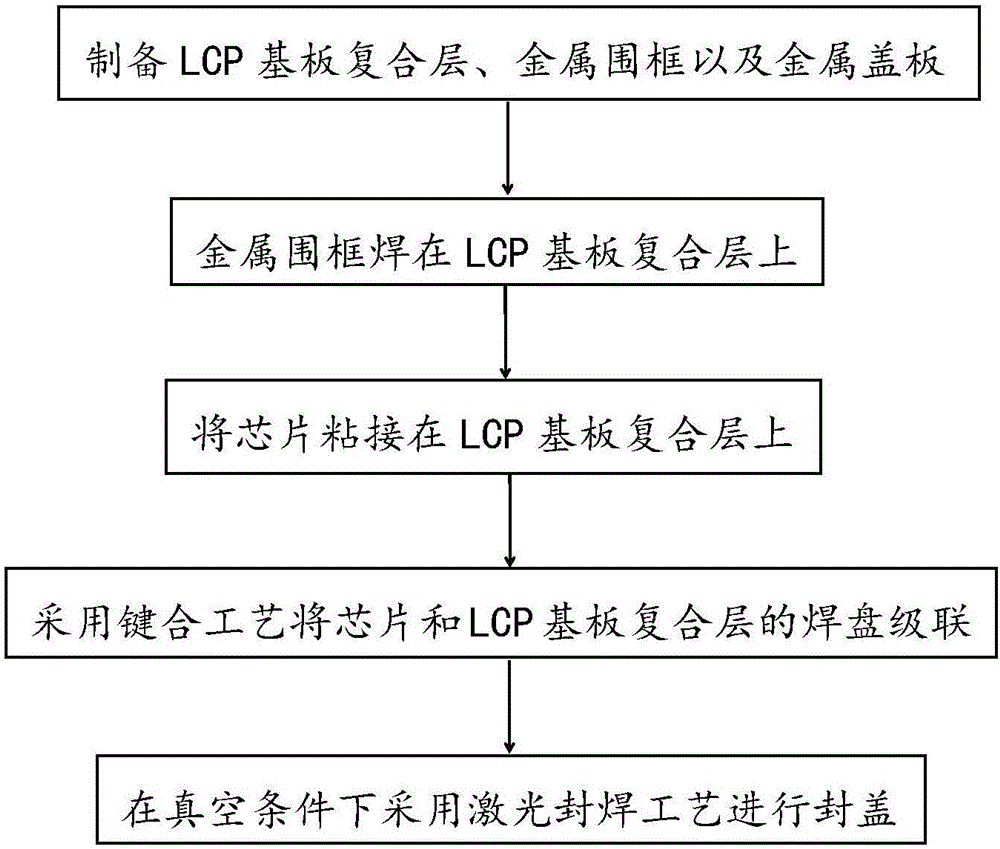

[0052] Such as figure 1 , figure 2 Shown, a kind of encapsulation shell based on LCP substrate, metal enclosure 1, the LCP substrate composite layer 3 that is arranged under the metal enclosure 1 with the multilayer LCP substrate lamination of arbitrary layer interconnection and is covered on the metal enclosure The metal cover plate 2 on 1, the LCP substrate composite layer 3 includes a chip bonding layer, a gold wire bonding layer, components and metal frame welding layers, and the metal frame welding layer is provided with through holes to achieve good grounding and space Isolation; each layer of the LCP substrate composite layer 3 is provided with electroplated solid holes to realize electrical connection of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com