Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50 results about "Biomass to liquid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biomass to liquid (BtL or BMtL) is a multi-step process of producing synthetic hydrocarbon fuels made from biomass via a thermochemical route. Such a fuel has been called grassoline.

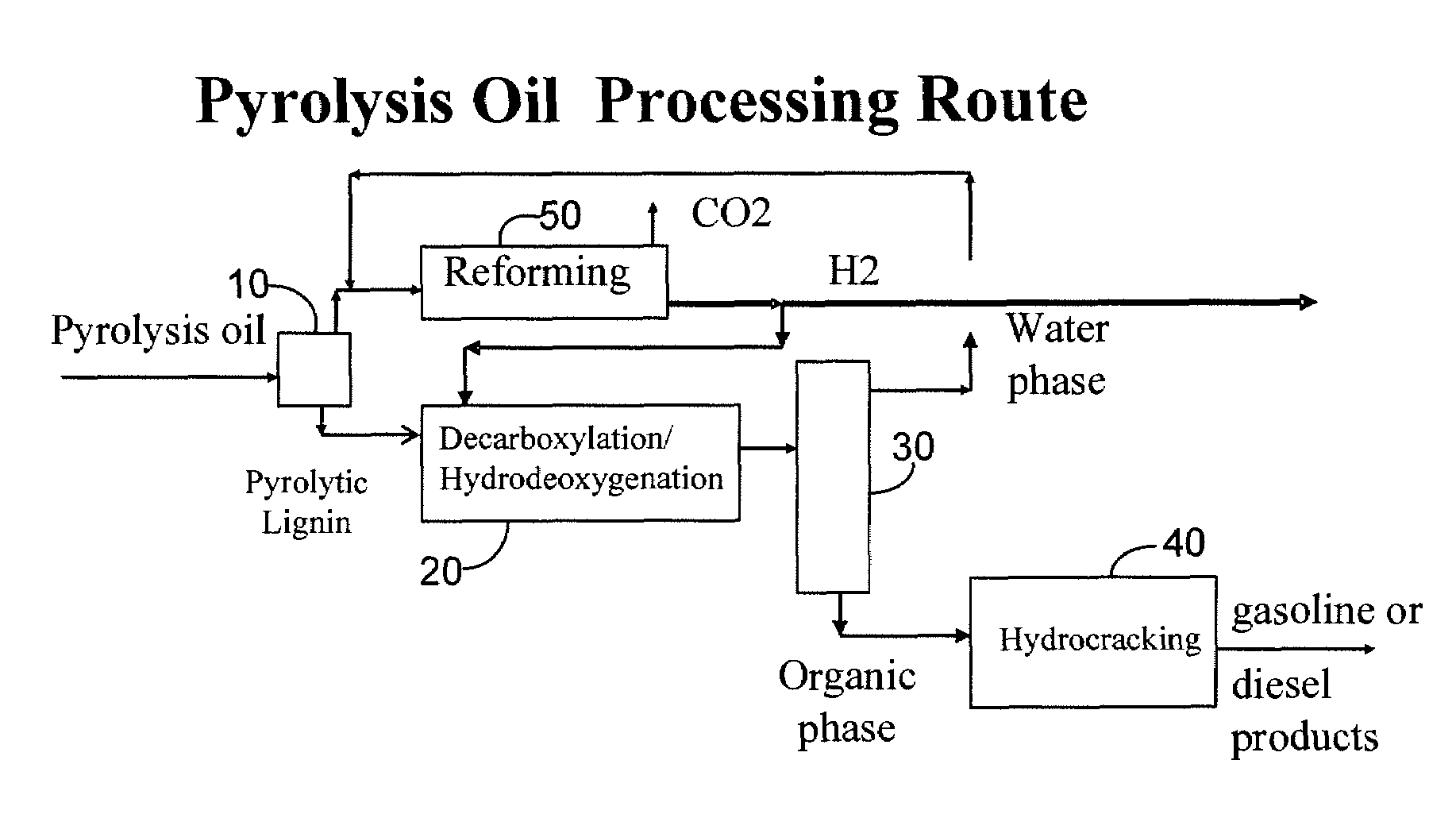

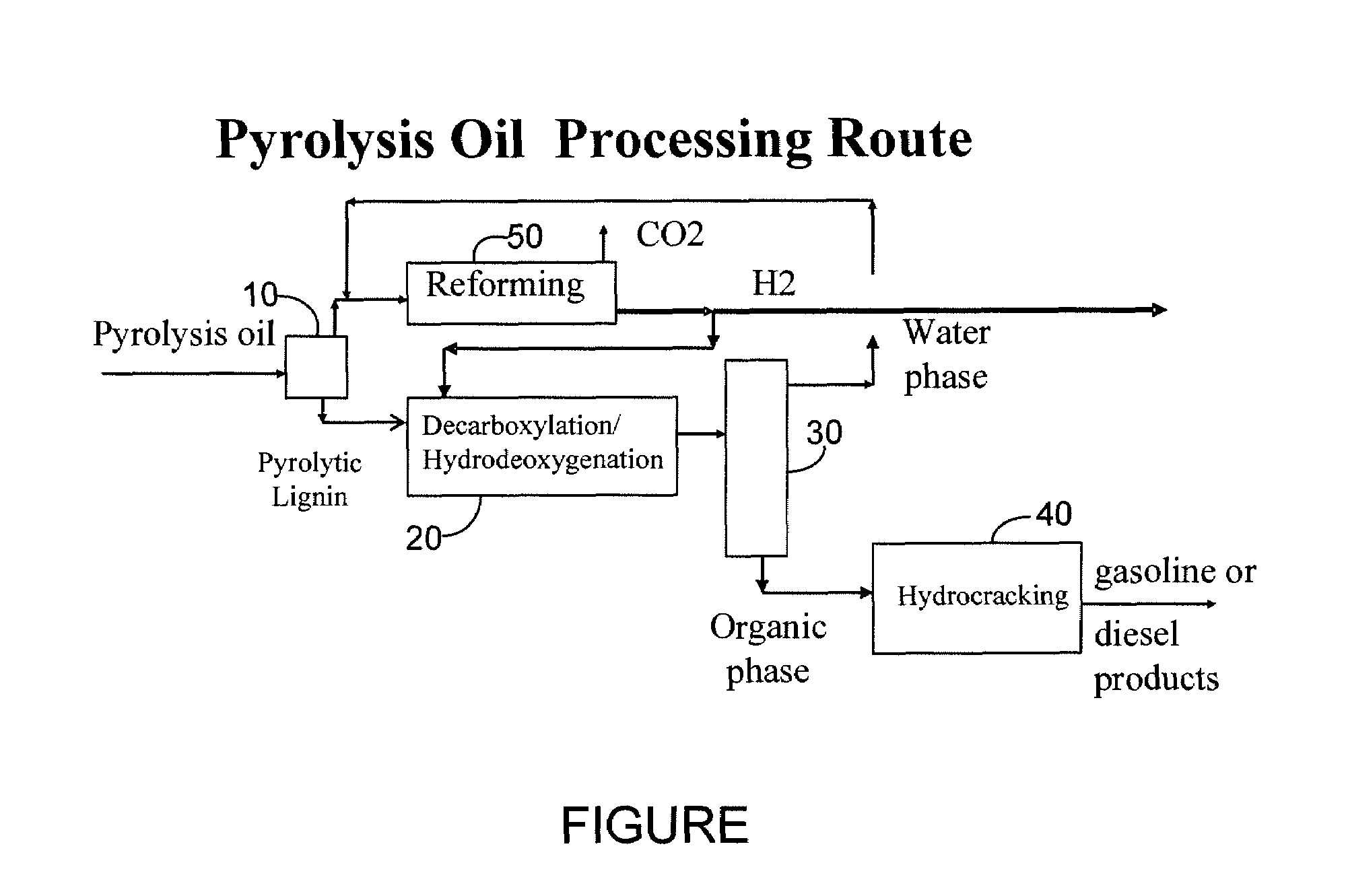

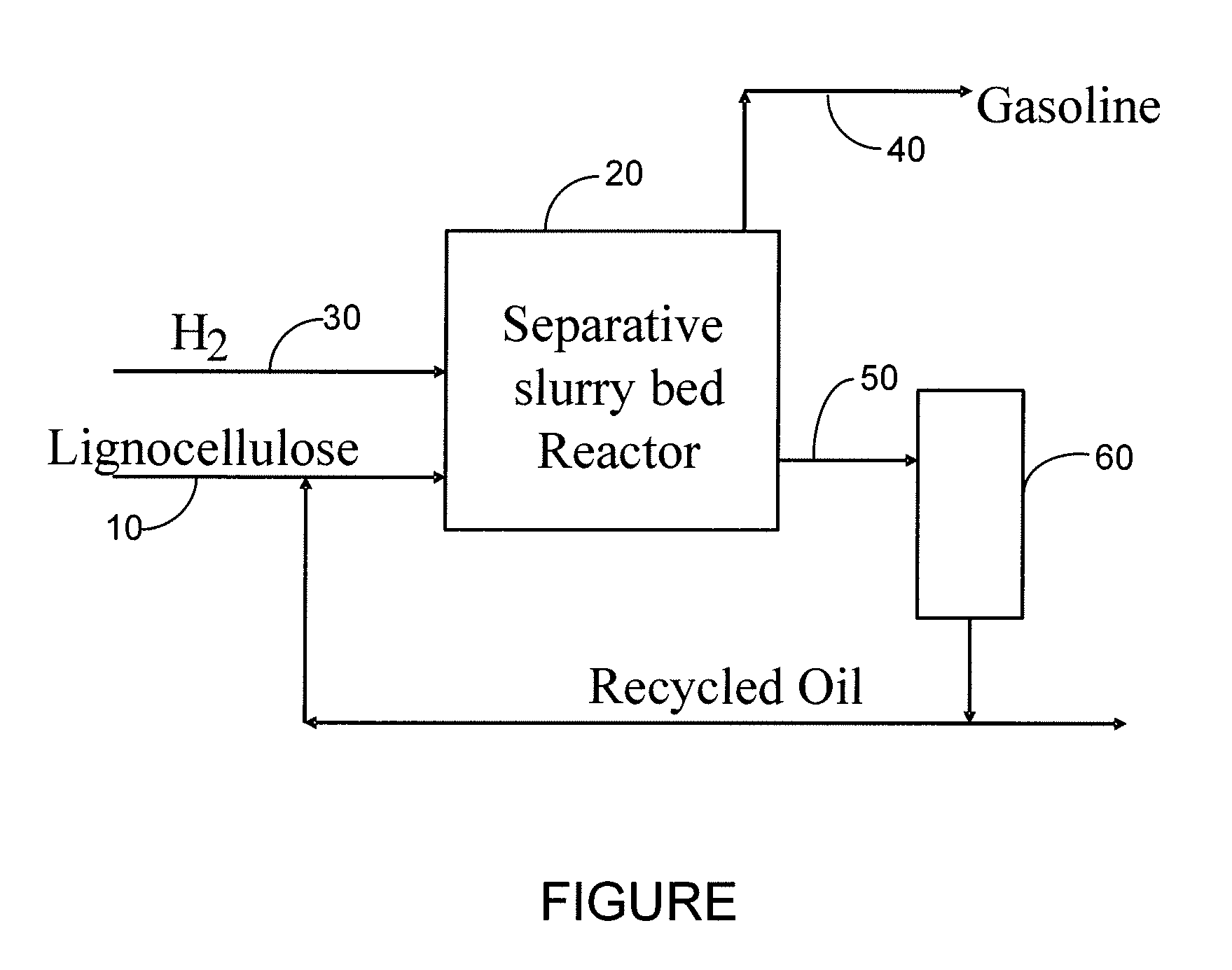

Gasoline and diesel production from pyrolytic lignin produced from pyrolysis of cellulosic waste

InactiveUS7578927B2Treatment with plural serial cracking stages onlyTreatment with plural serial stages onlyCelluloseNaphtha

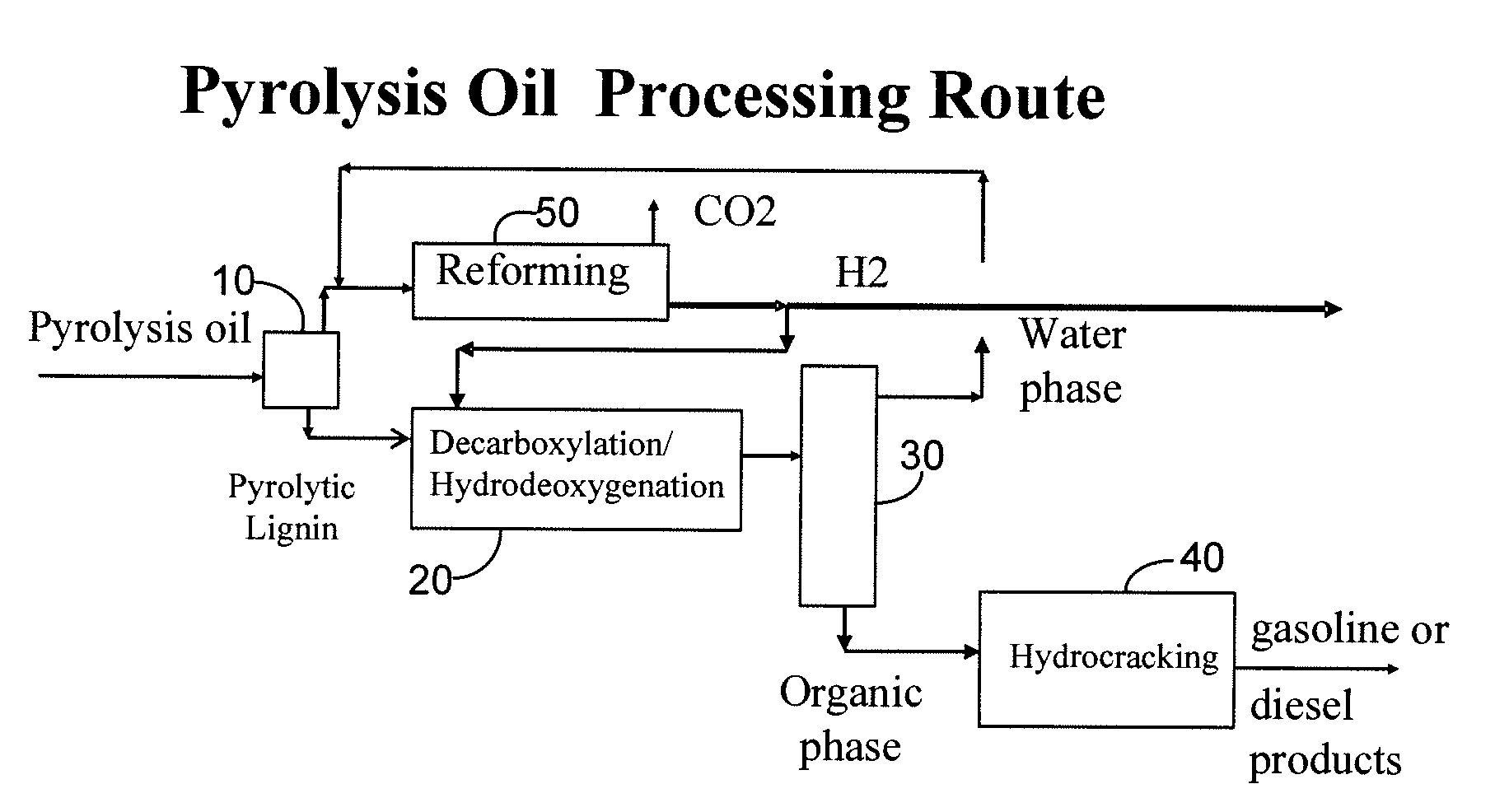

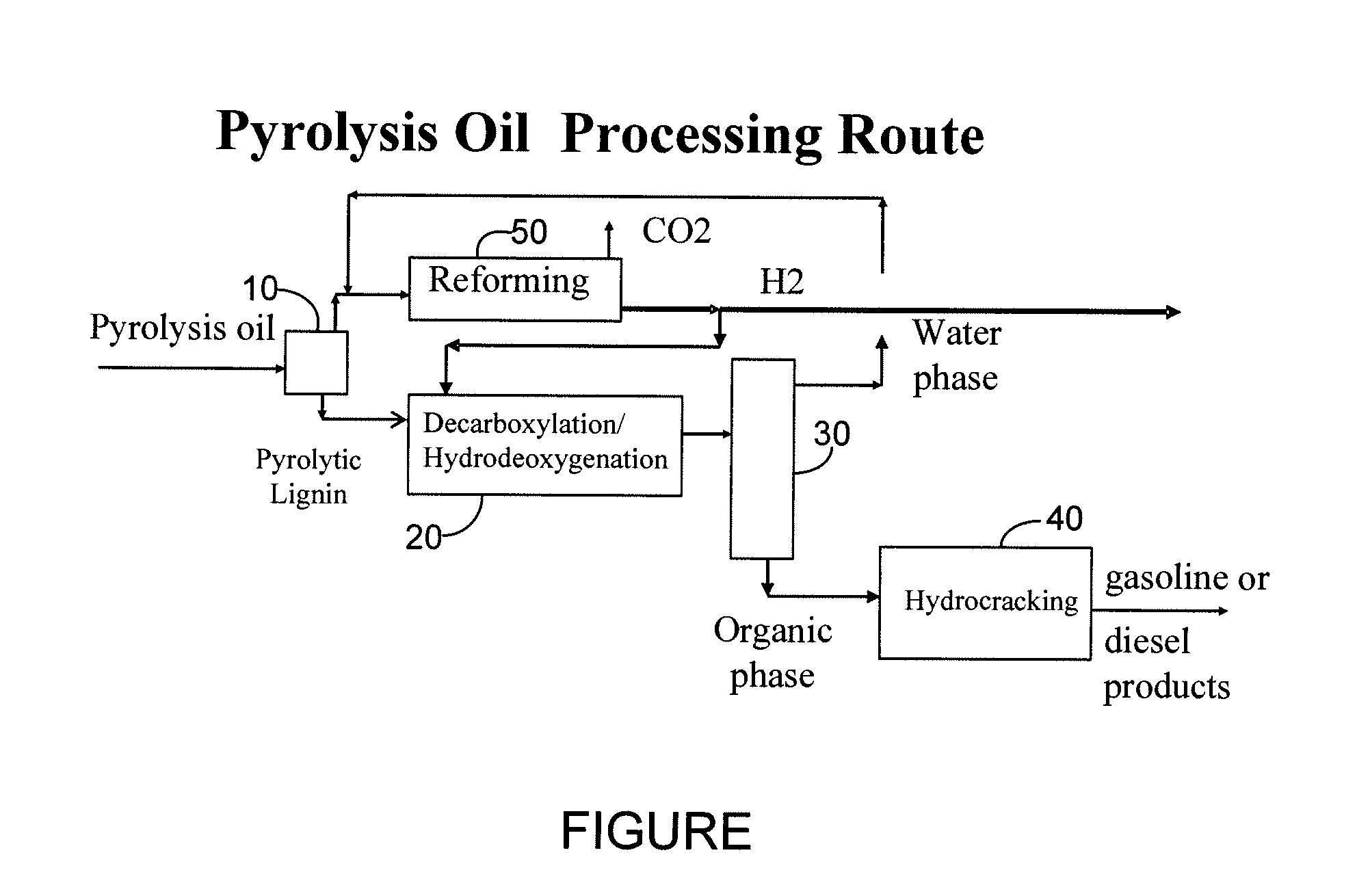

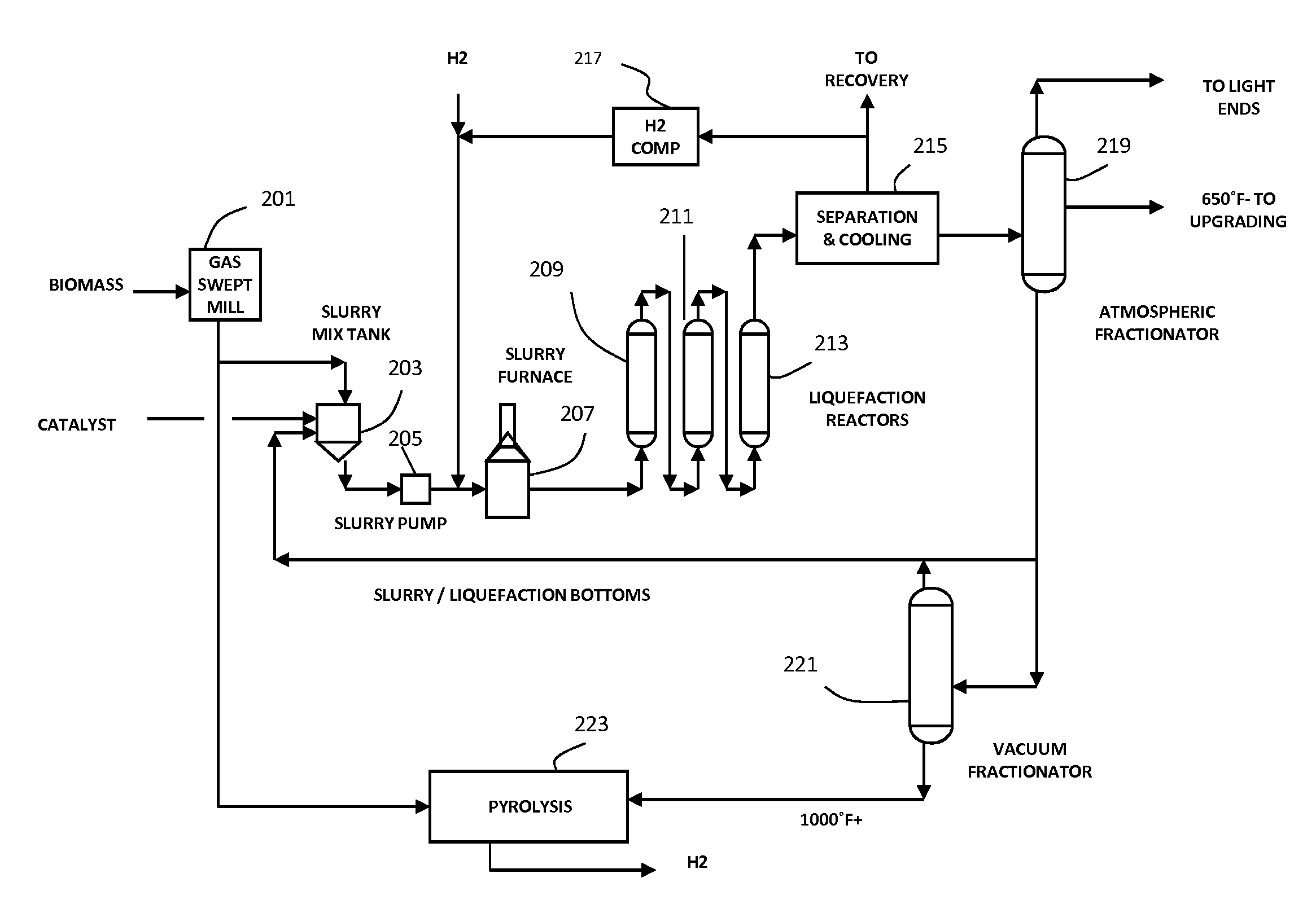

A process for the conversion of biomass to a liquid fuel is presented. The process includes the production of diesel and naphtha boiling point range fuels by hydrocracking of pyrolysis lignin extracted from biomass.

Owner:UOP LLC

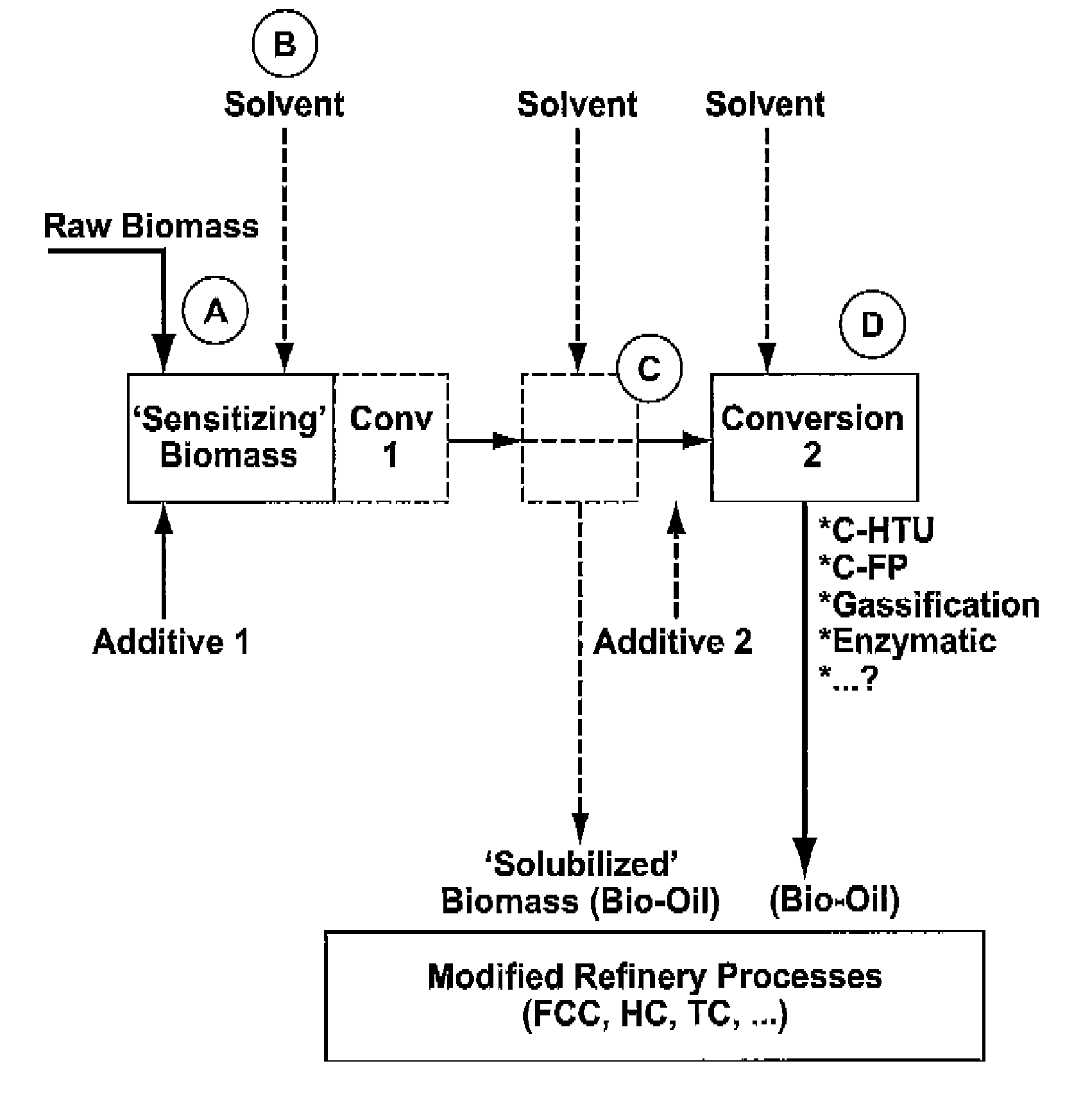

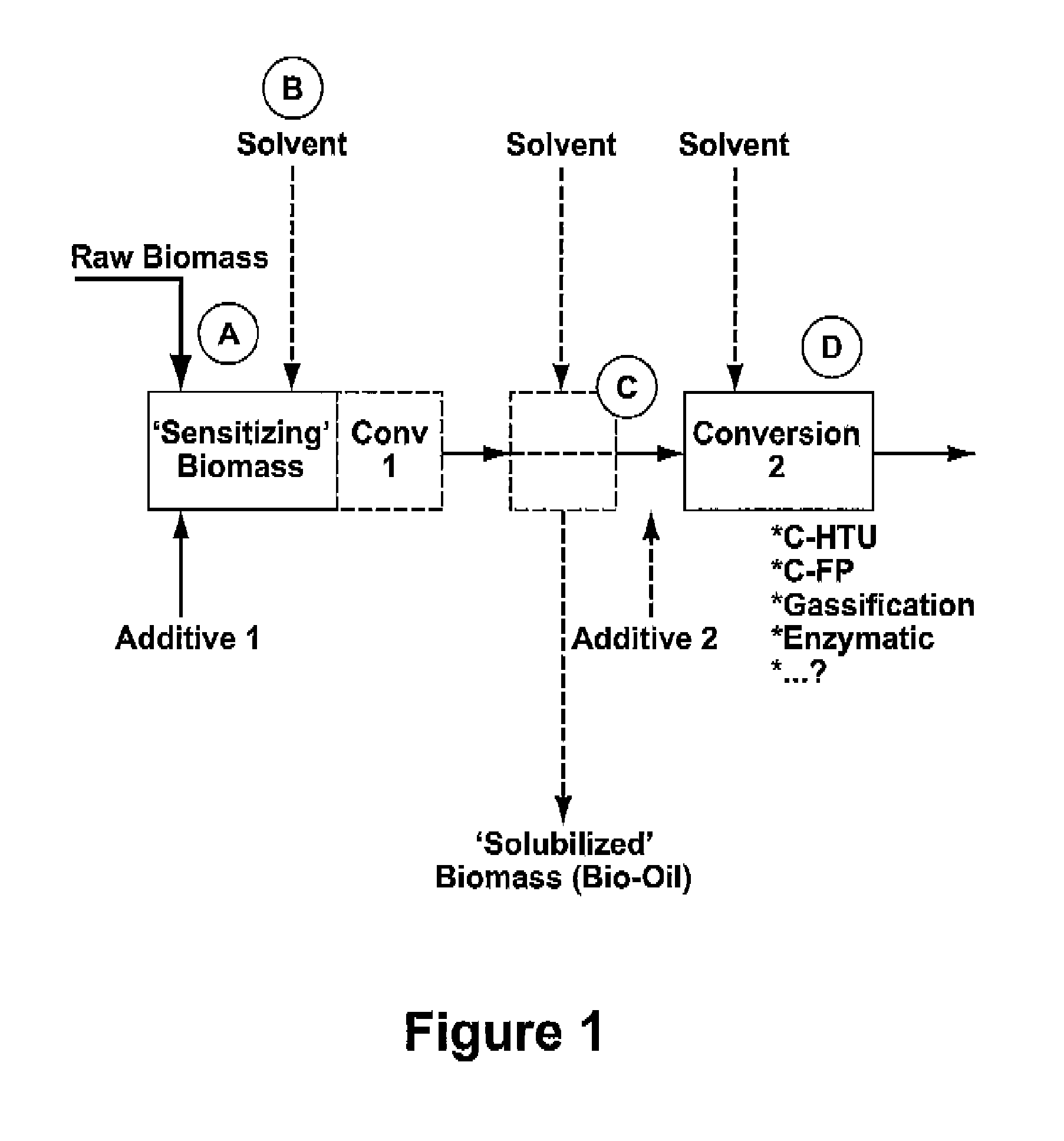

Process for the conversion of biomass to liquid fuels and specialty chemicals

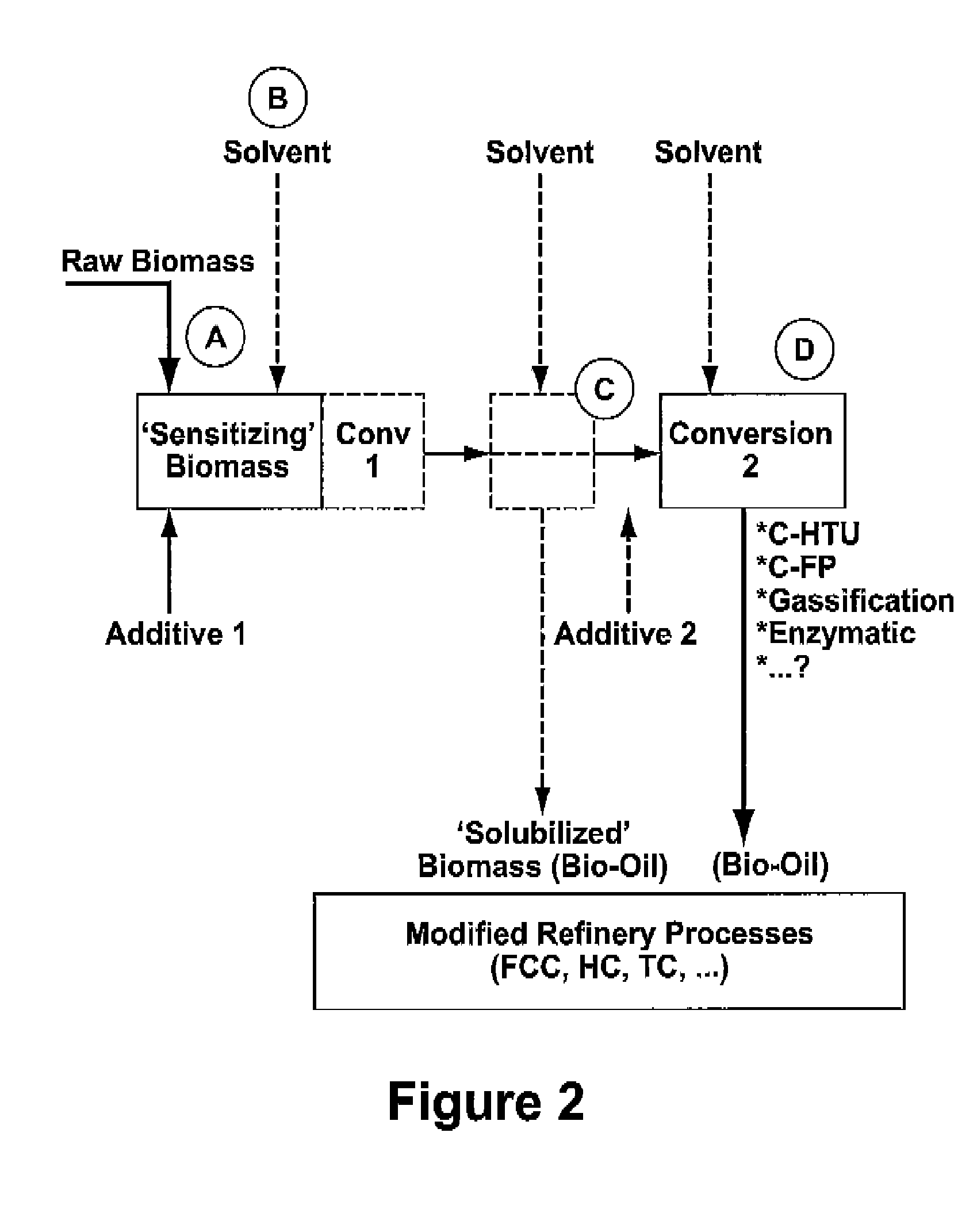

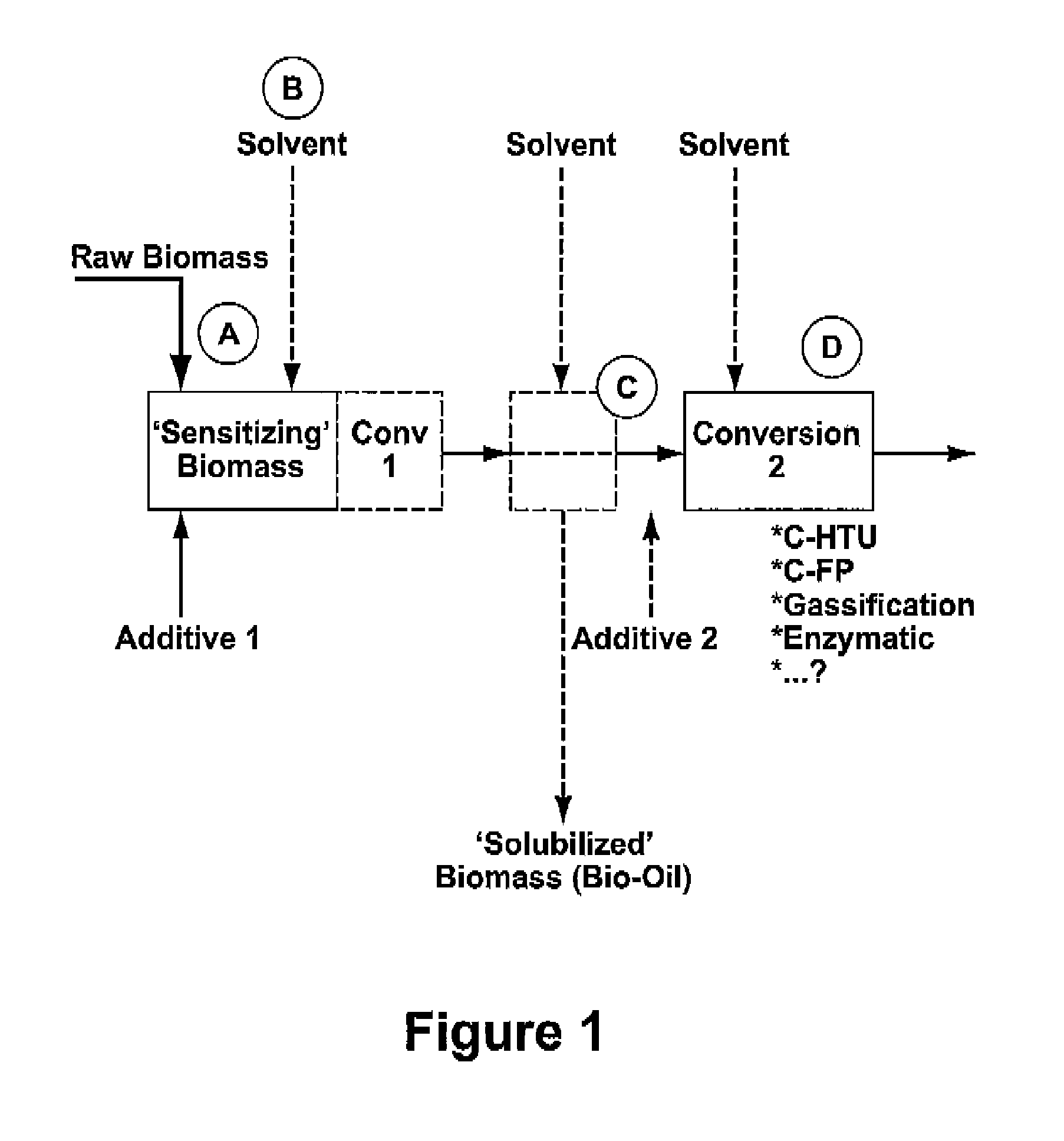

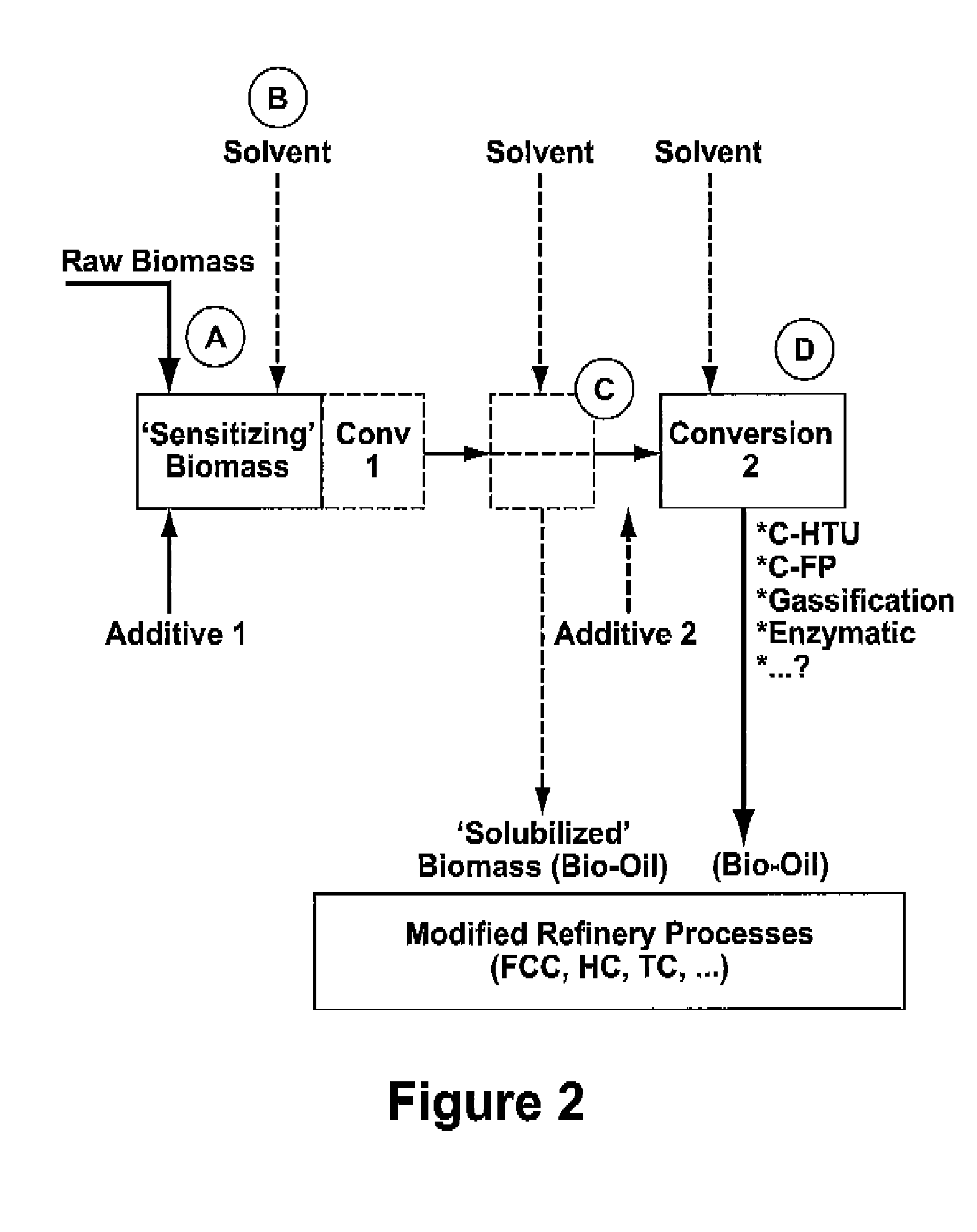

Disclosed is a hydrothermal treatment process for conversion of a carbon-based energy carrier material. The process comprises a step for sensitizing or activating the carbon based energy carrier material to increase its susceptibility to hydrothermal conversion. As a result of the sensitization step, the hydrothermal conversion step itself may be carried out under relatively mild conditions.The process comprises the steps of sensitizing the carbon-based energy carrier material to increase its susceptibility to hydrothermal conversion; and subjecting the sensitized carbon-based energy carrier material to hydrothermal conversion at a temperature of less than 300 degrees centigrade in a hydrothermal treatment reactor.

Owner:MARD INC

Gasoline and diesel production from pyrolytic lignin produced from pyrolysis of cellulosic waste

InactiveUS20080053870A1High yieldTreatment with plural serial cracking stages onlyTreatment with plural serial stages onlyCelluloseNaphtha

Owner:UOP LLC

Production of gasoline, diesel, naphthenes and aromatics from lignin and cellulosic waste by one step hydrocracking

ActiveUS20080076945A1Oxygen-containing compound preparationOrganic compound preparationCelluloseNaphtha

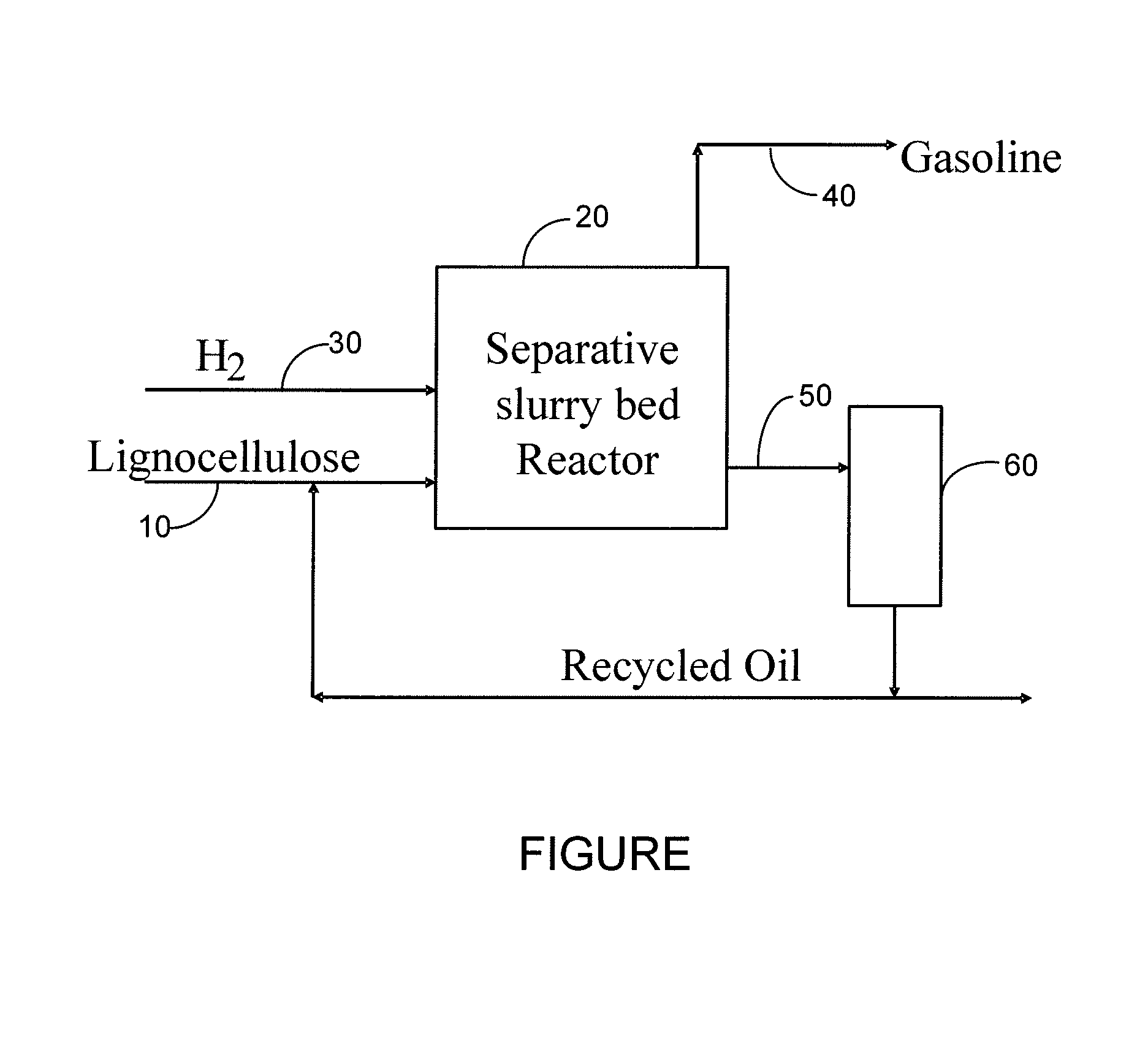

A process for the conversion of biomass to a liquid fuel is presented. The process includes the production of diesel and naphtha boiling point range fuels by hydrotreating and hydrocracking of lignin in the biomass in a one step process.

Owner:UOP LLC

Process for the conversion of biomass to liquid fuels and specialty chemicals

The present invention relates to the conversion of solid biomass to liquid fuels and specialty chemicals. The process utilizes an activating step to make the biomass more susceptible to conversion, that is the biomass is broken down such that the components of the biomass are dissociated. Subsequently, the activated biomass undergoes a reaction to convert it to a bio-oil.

Owner:MARD INC

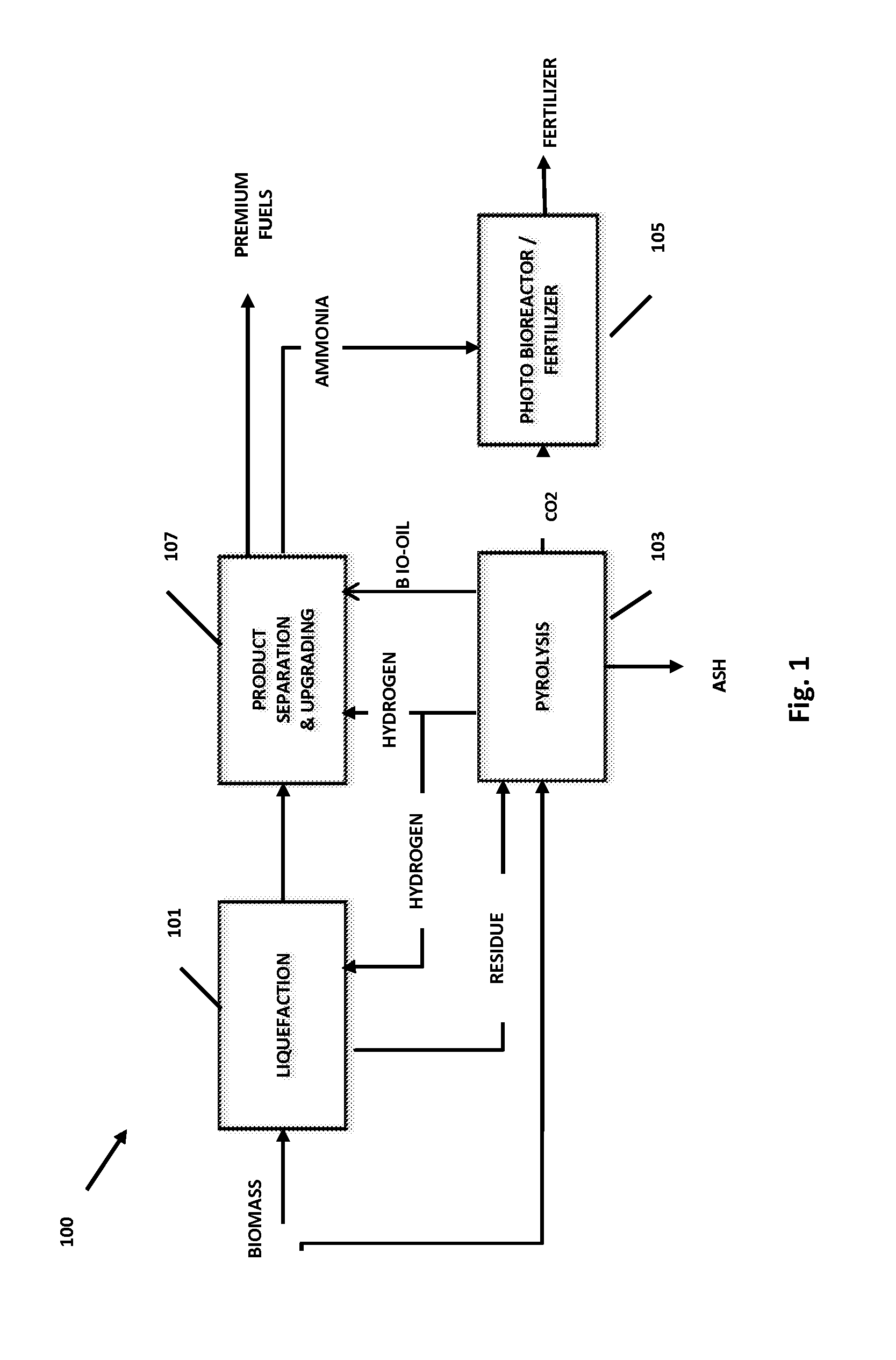

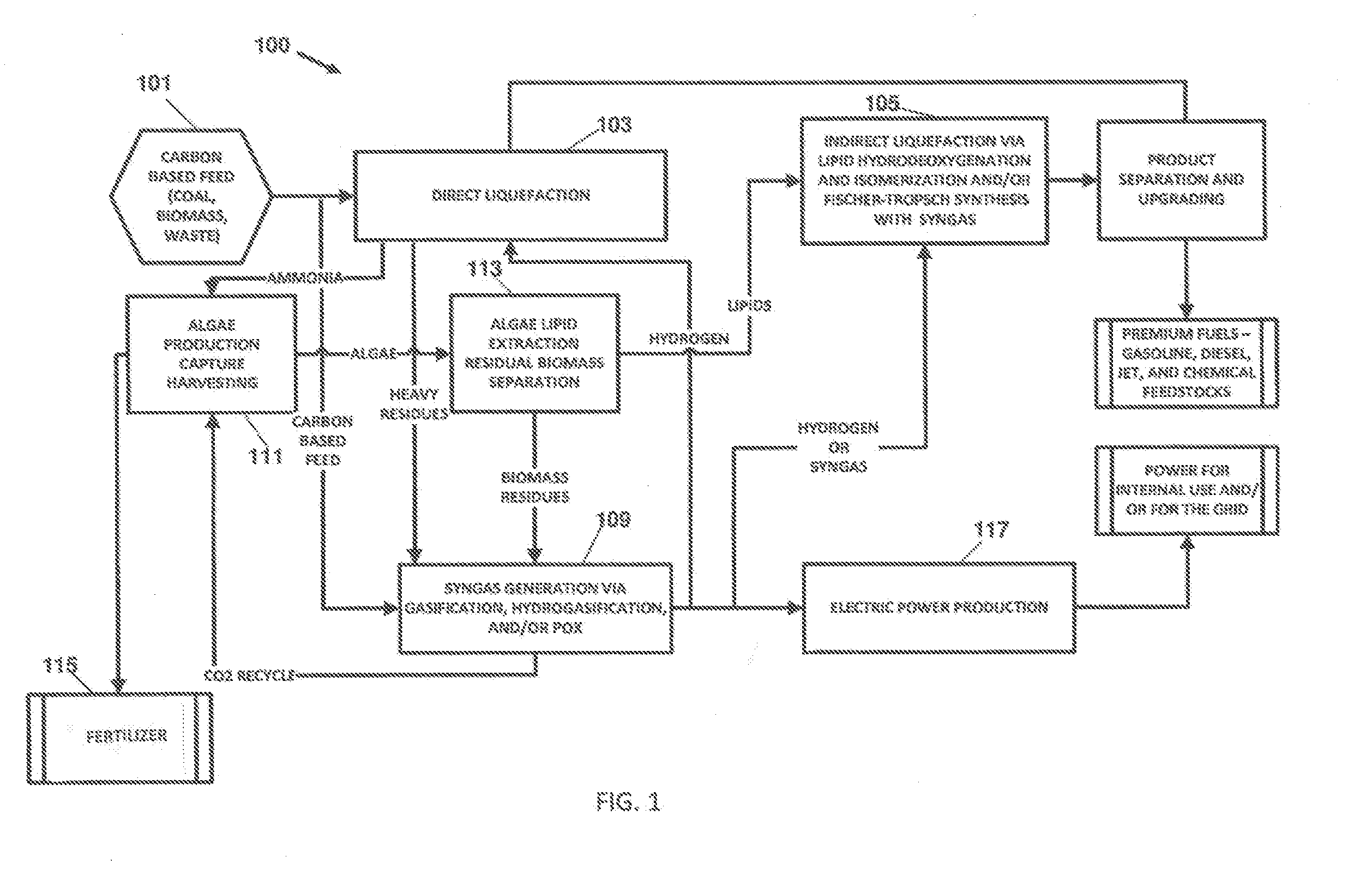

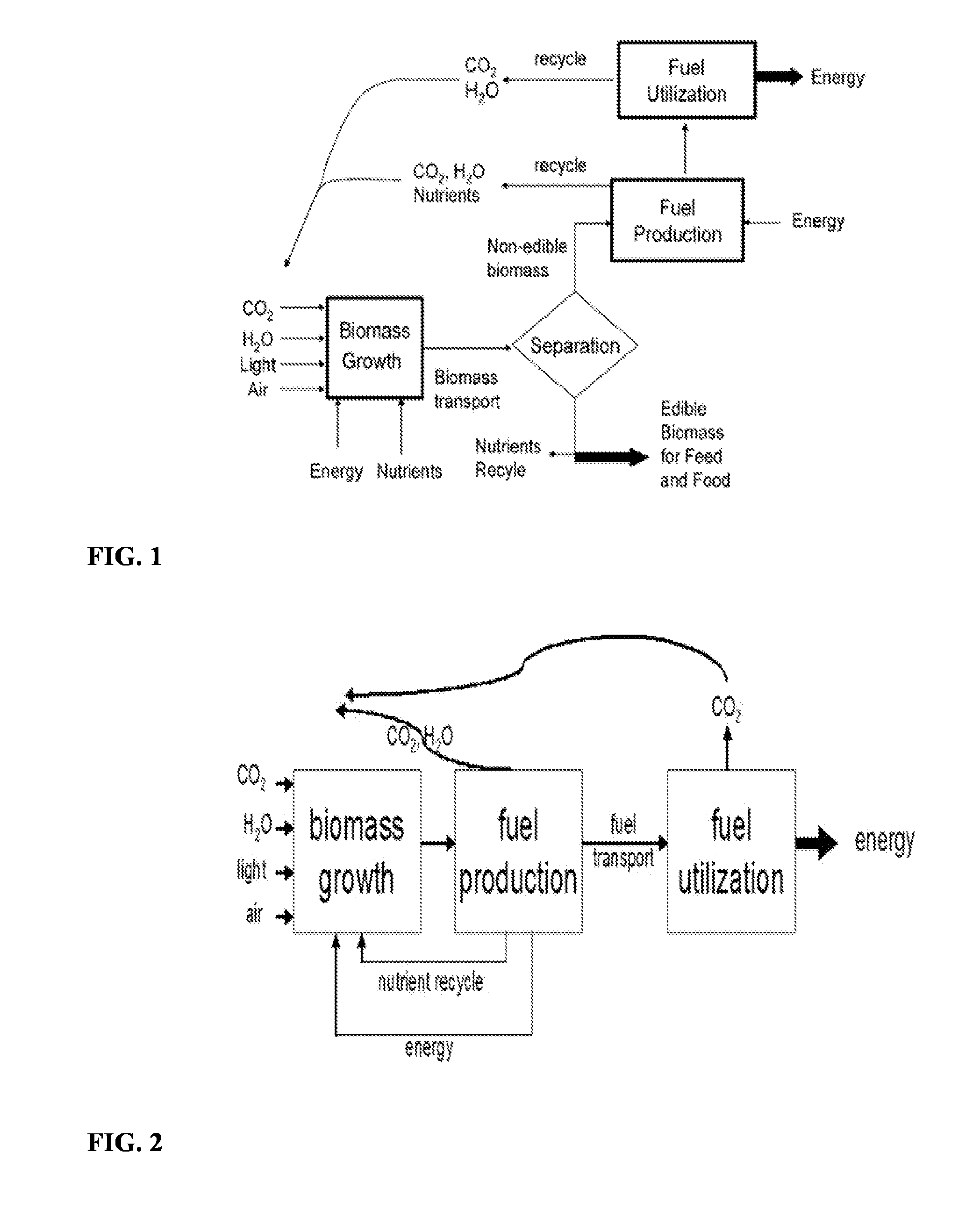

Integrated processes for producing fuels and biofertilizers from biomass and products produced

ActiveUS20140345341A1Magnifies overall carbon sequestration potentialMaximize useElectrical coke oven heatingBio-organic fraction processingLiquid fuelBiochar

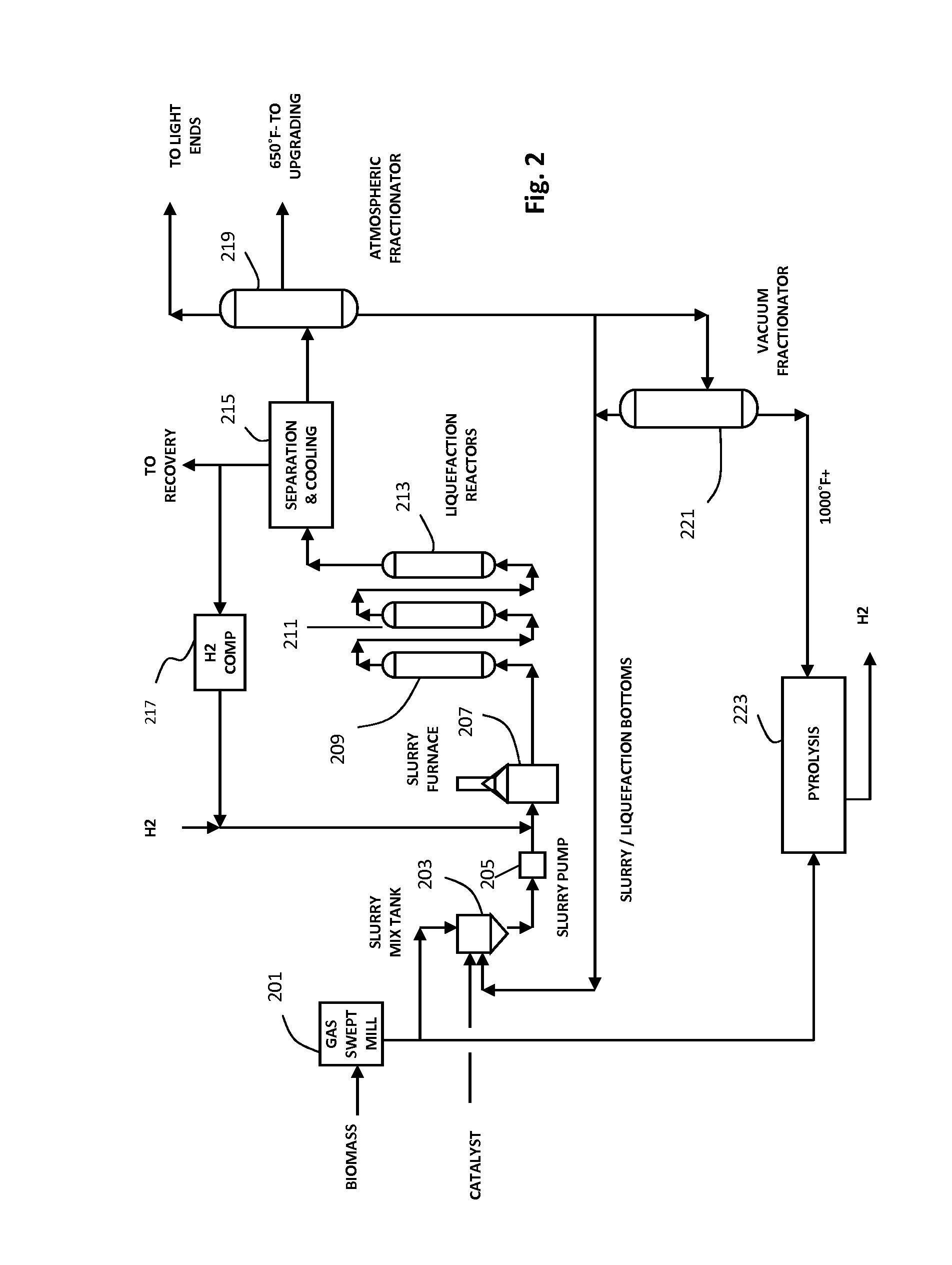

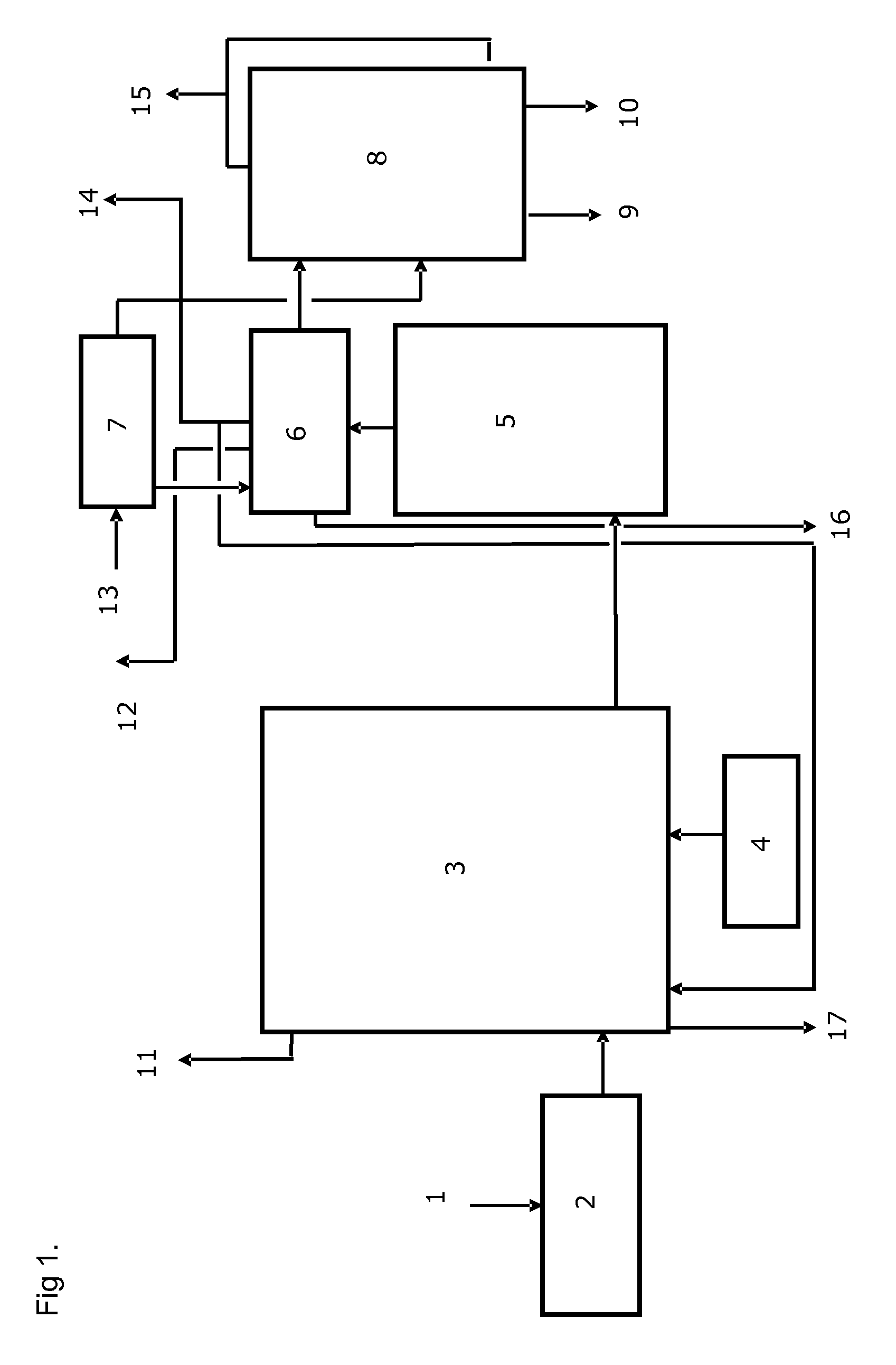

An IBTL system having a low GHG footprint for converting biomass to liquid fuels in which a biomass feed is converted to liquids by direct liquefaction and the liquids are upgraded to produce premium fuels. Biomass residues from the direct liquefaction, and optionally additional biomass is pyrolyzed to produce structured biochar, hydrogen for the liquefaction and upgrading, and CO2 for conversion to algae, including blue green algae (cyanobacteria) in a photobioreactor (PBR). Produced algae and diazotrophic microorganisms are used to produce a biofertilizer that also contains structured biochar. The structured biochar acts as a nucleation agent for the algae in the PBR, as a absorption agent to absorb inorganics from the biomass feed to direct liquefaction or from the liquids produced thereby, and as a water retention agent in the biofertilizer. The ratio of cyanobacteria to diazotrophic microorganisms in the biofertilizer can be selected to optimize the so as to achieve desired total chemically active carbon and nitrogen contents in the soil for a given crop.

Owner:ACCELERGY CORP +1

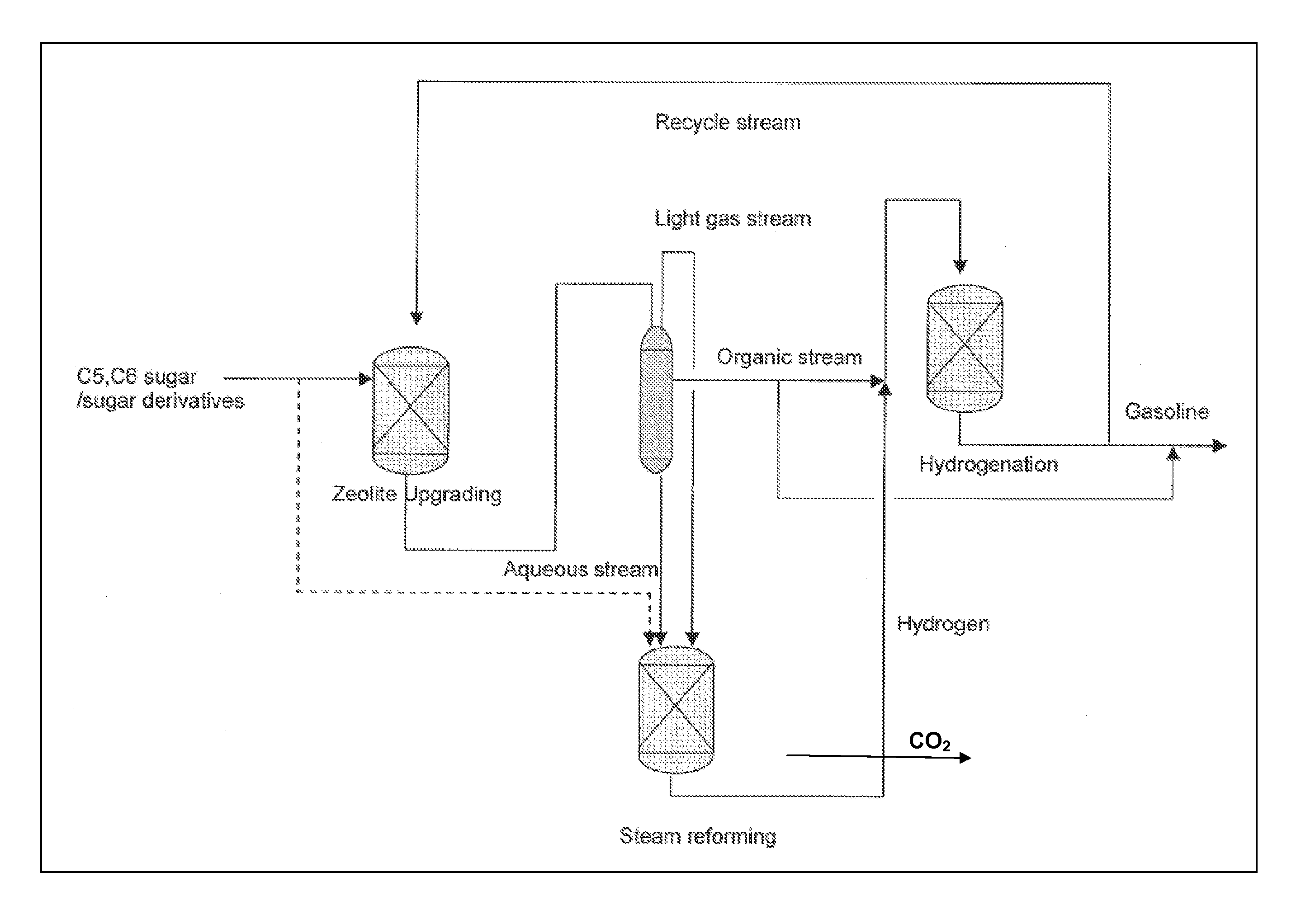

Carbohydrates upgrading and hydrotreating to hydrocarbons

ActiveUS20110263916A1Easy to convertReduced liquid yieldHydrogenBiofuelsCarbon footprintLiquid hydrocarbons

Technologies to convert biomass to liquid hydrocarbon fuels are currently being developed to decrease our carbon footprint and increase use of renewable fuels. Since sugars / sugar derivatives from biomass have high oxygen content and low hydrogen content, coke becomes an issue during zeolite upgrading to liquid hydrocarbon fuels. A process was designed to reduce the coke by co-feeding sugars / sugar derivatives with a saturated recycle stream containing hydrogenated products.

Owner:PHILLIPS 66 CO

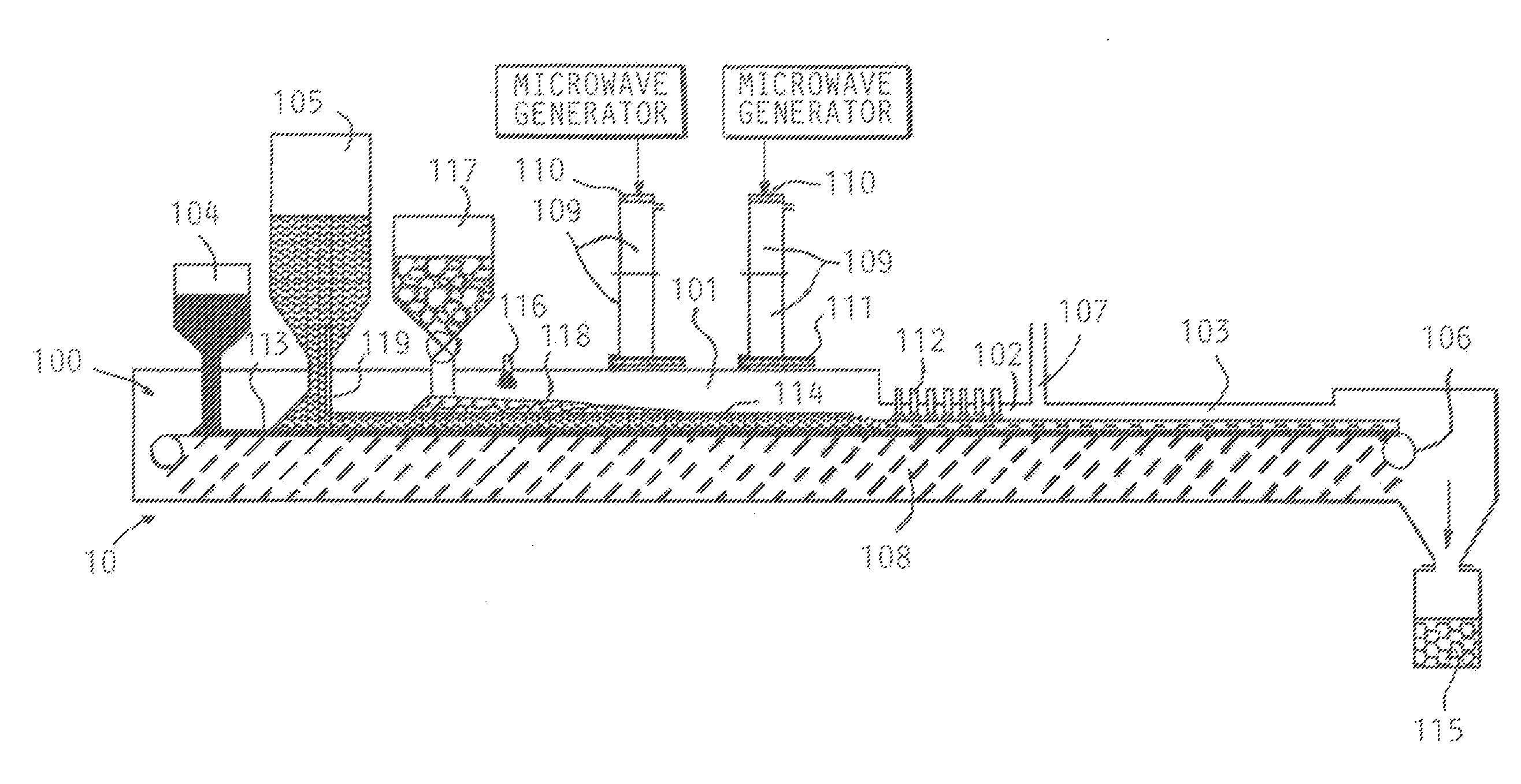

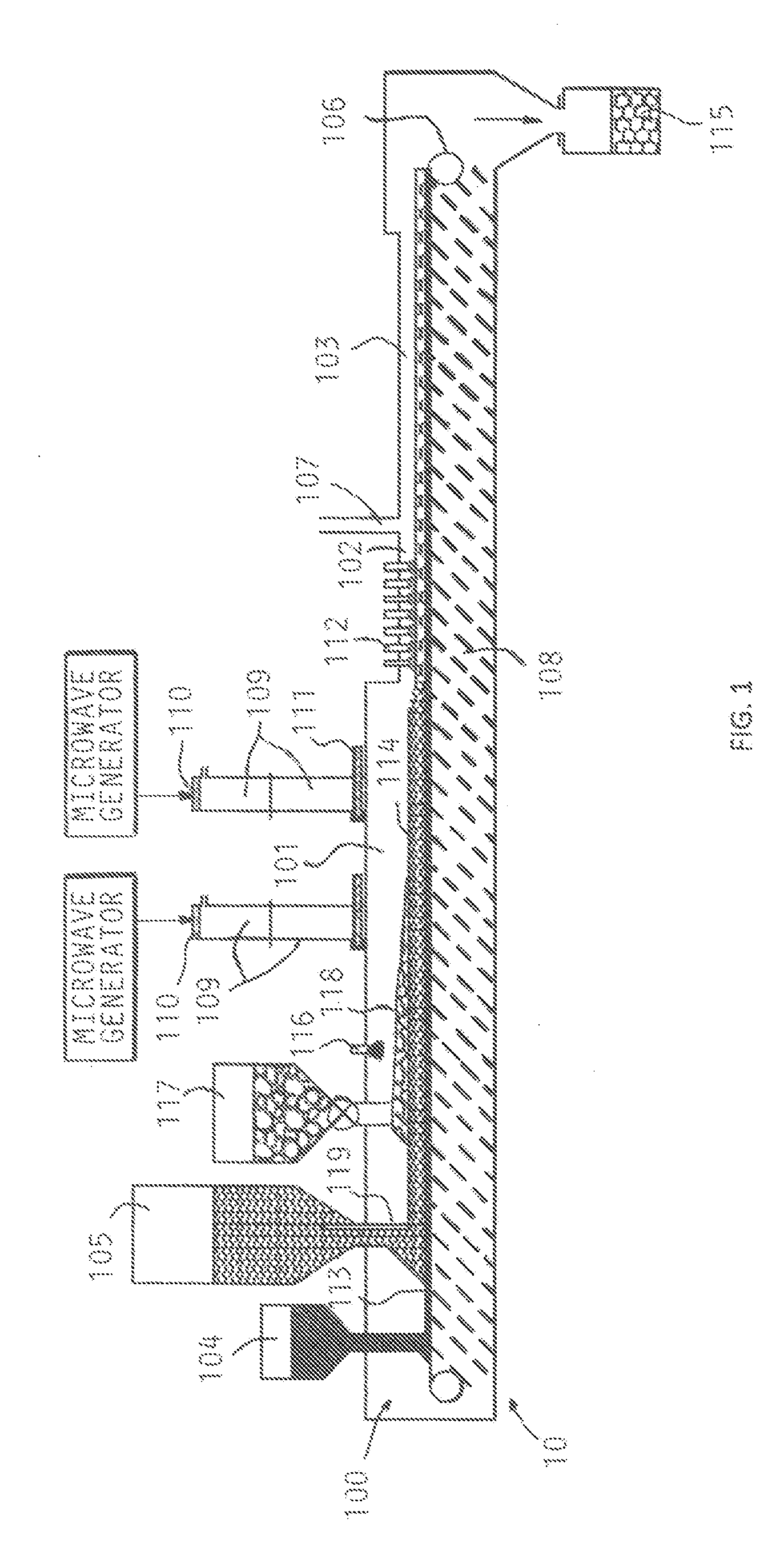

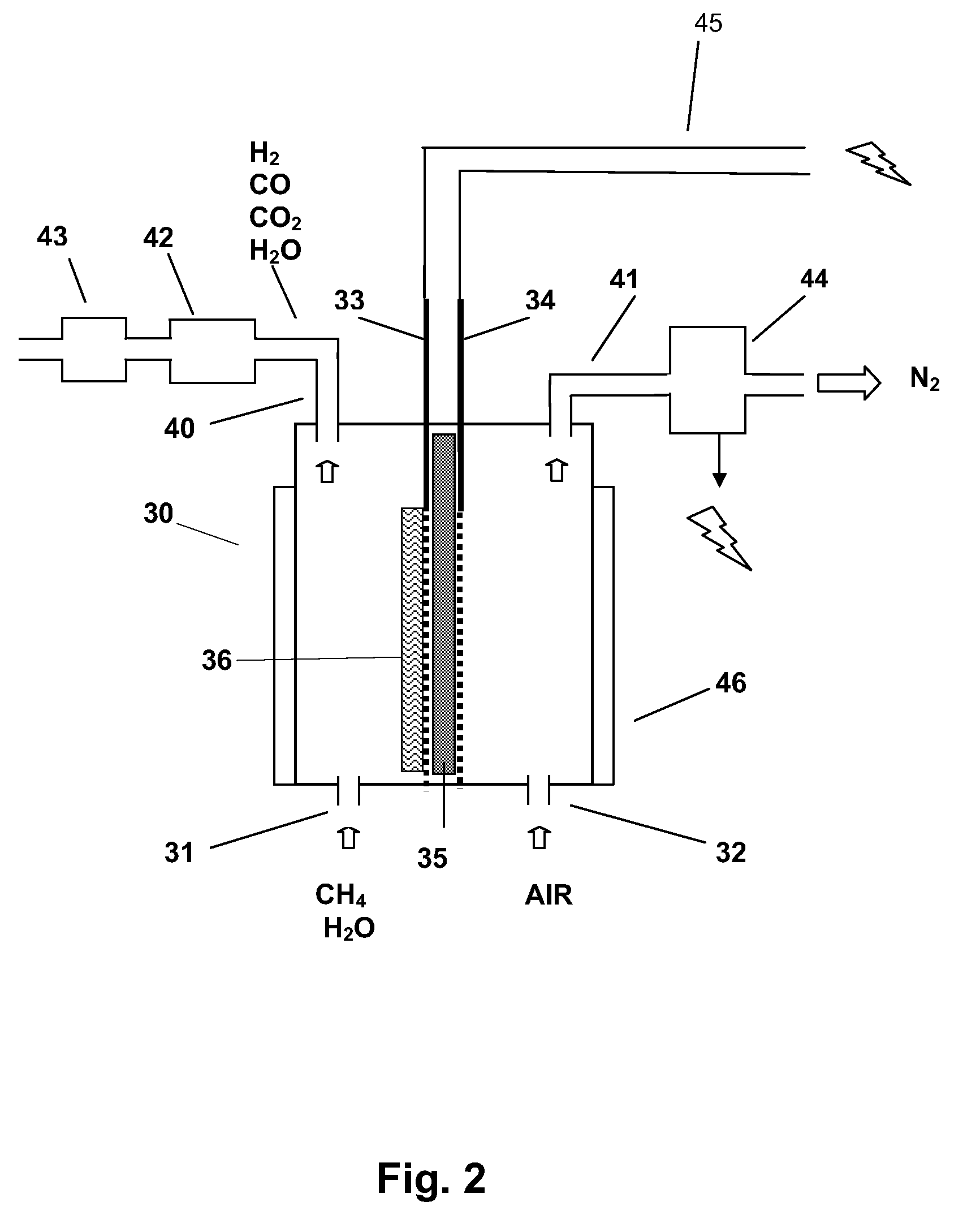

Method and Apparatus For Coproduction of Pig Iron and High Quality Syngas

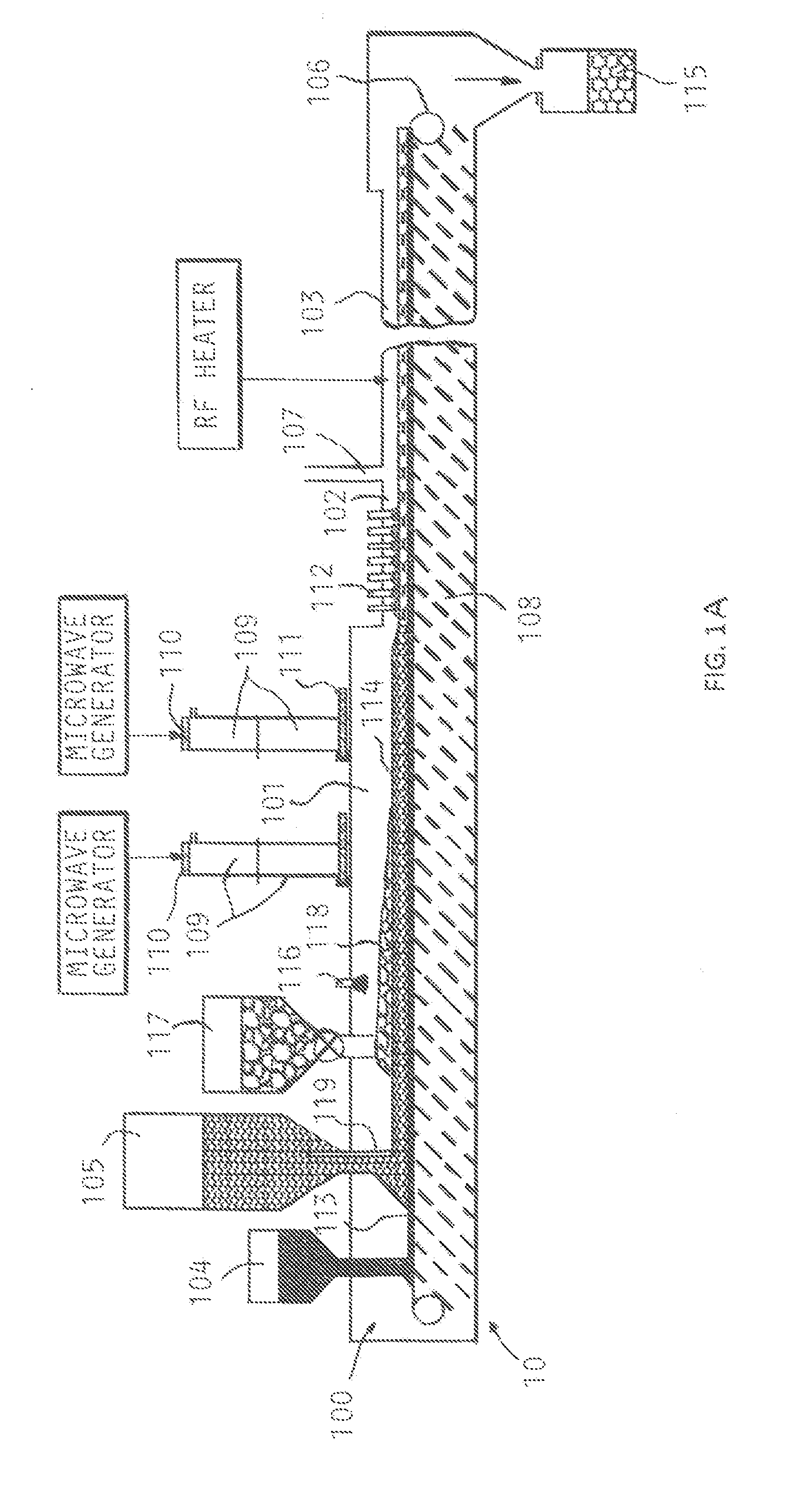

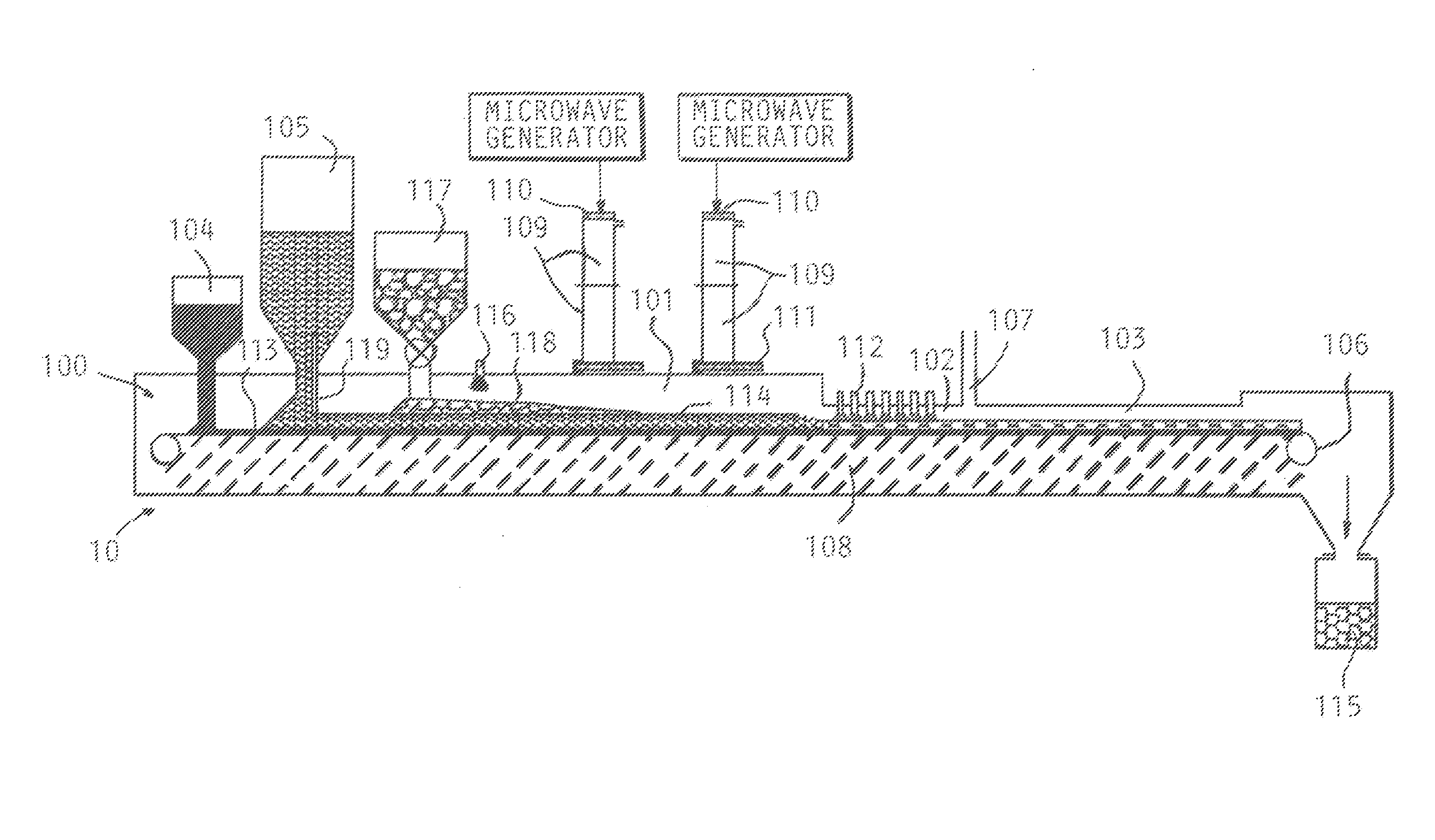

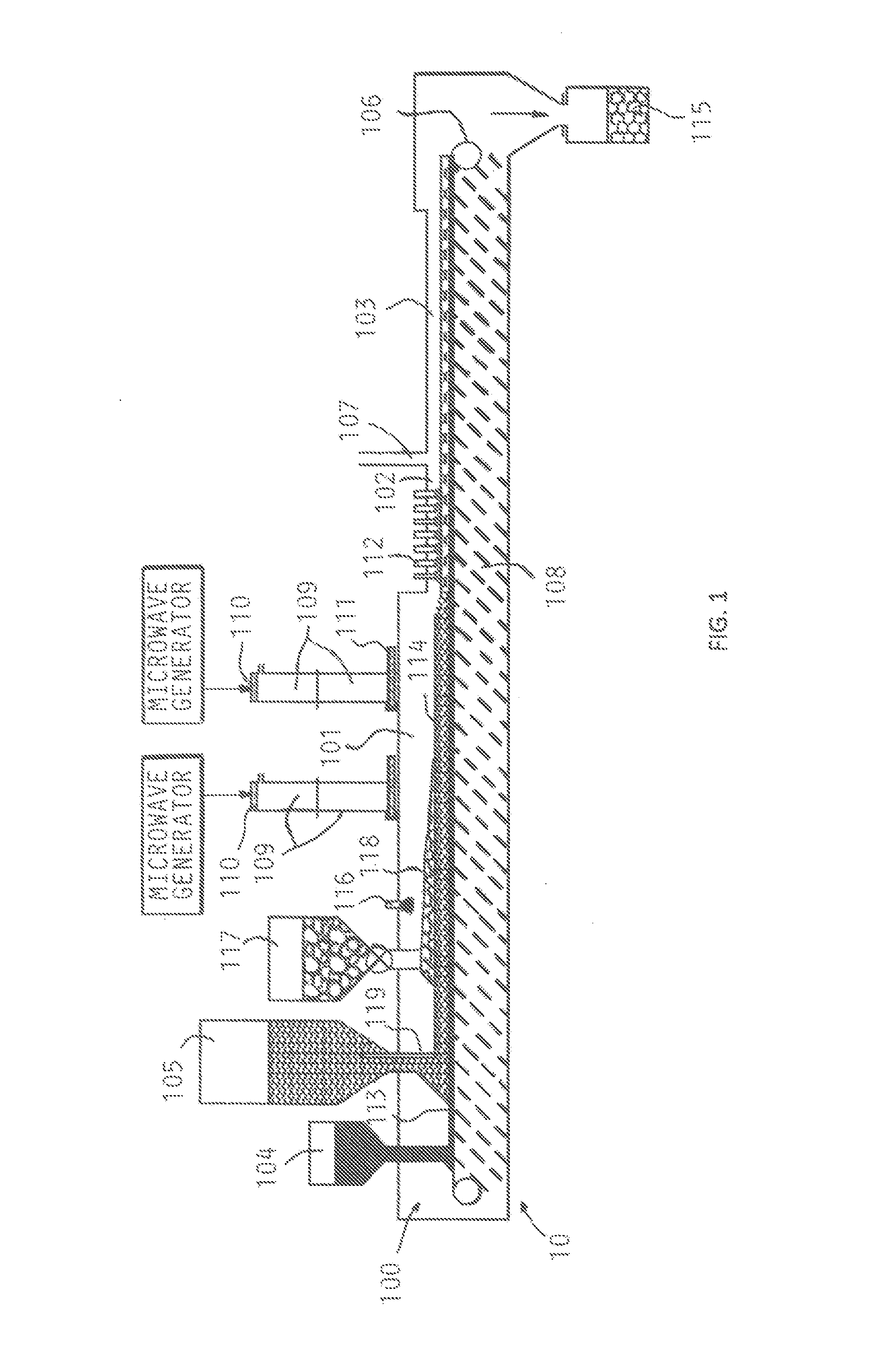

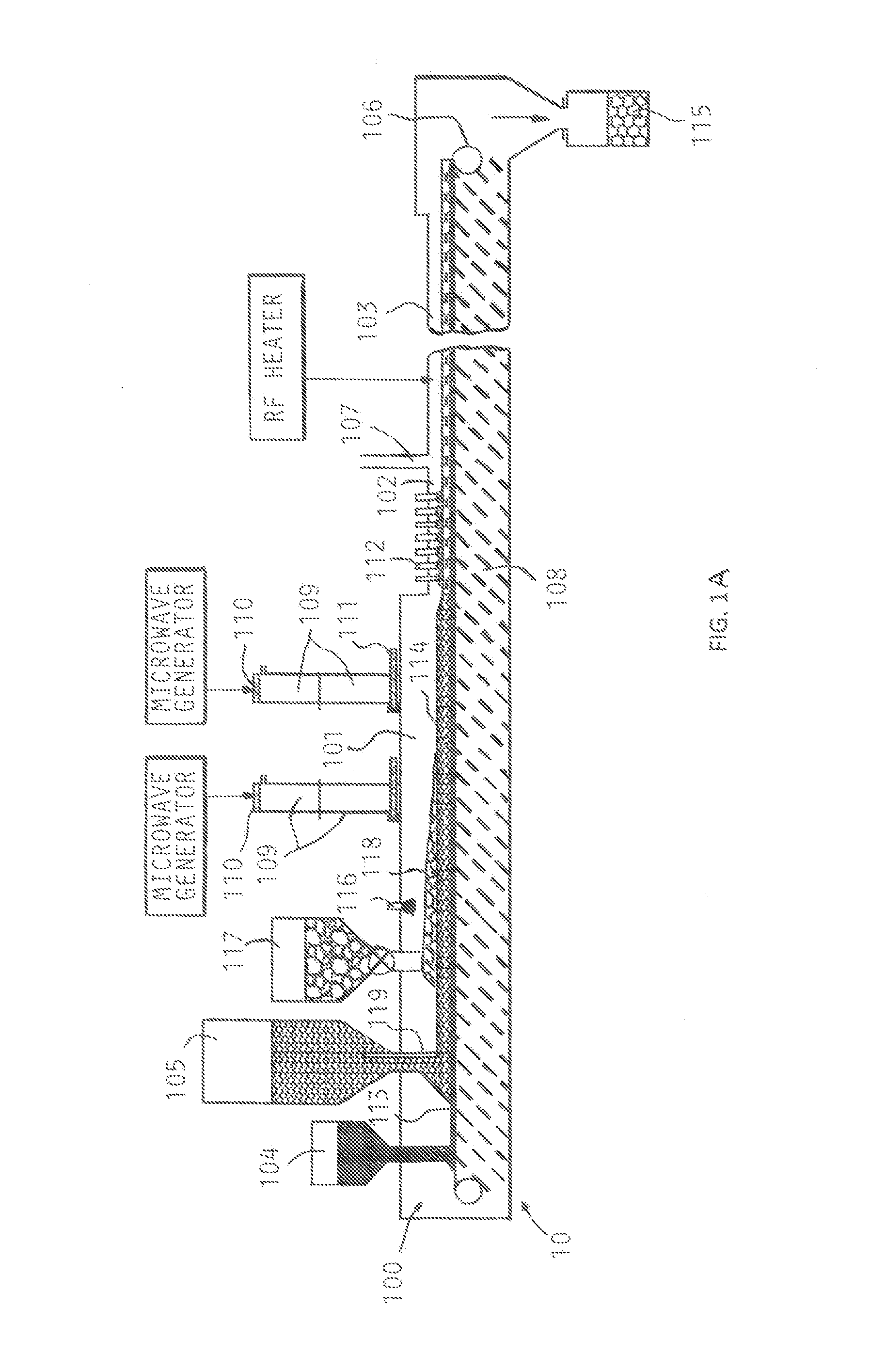

ActiveUS20120031232A1Improve microwave absorption performanceHeating up fastBlast furnace detailsCharge manipulationSludgeLiquid fuel

Combined microwave heating and plasma / electric arc heating is utilized in several processes and apparatus which involve co-production of pig iron and high quality syngas, biomass to liquid fuel production, coal to liquid fuel production, co-gasification of biomass and coal, municipal solid waste treatment, waste-to-energy (agriculture waste, ASR and PEF), EAF dust and BOF sludge treatment to recover zinc and iron, hazardous bottom ash vitrification, and bromine, chlorine and sulfur removal / recycling.

Owner:HUANG XIAODI +1

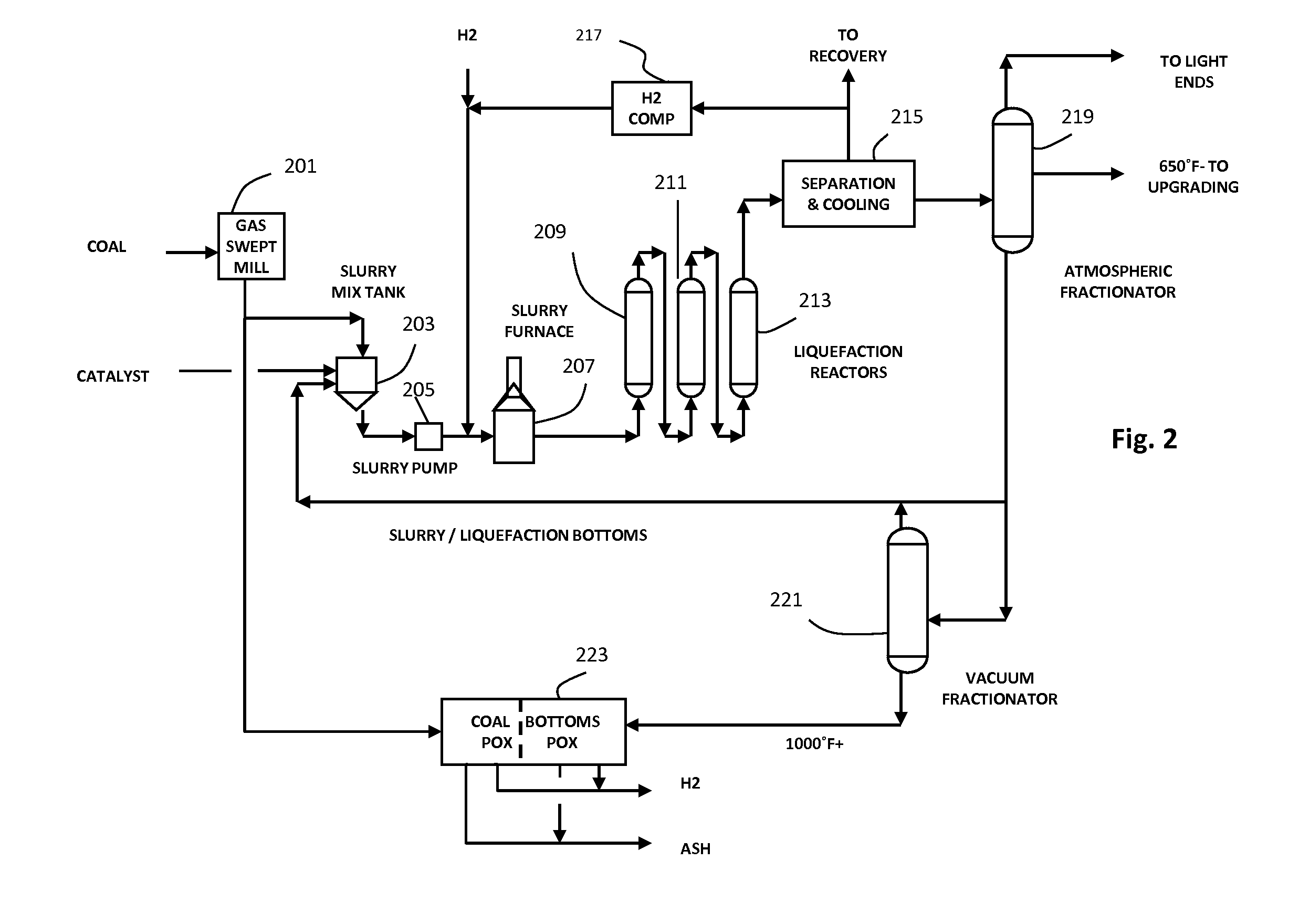

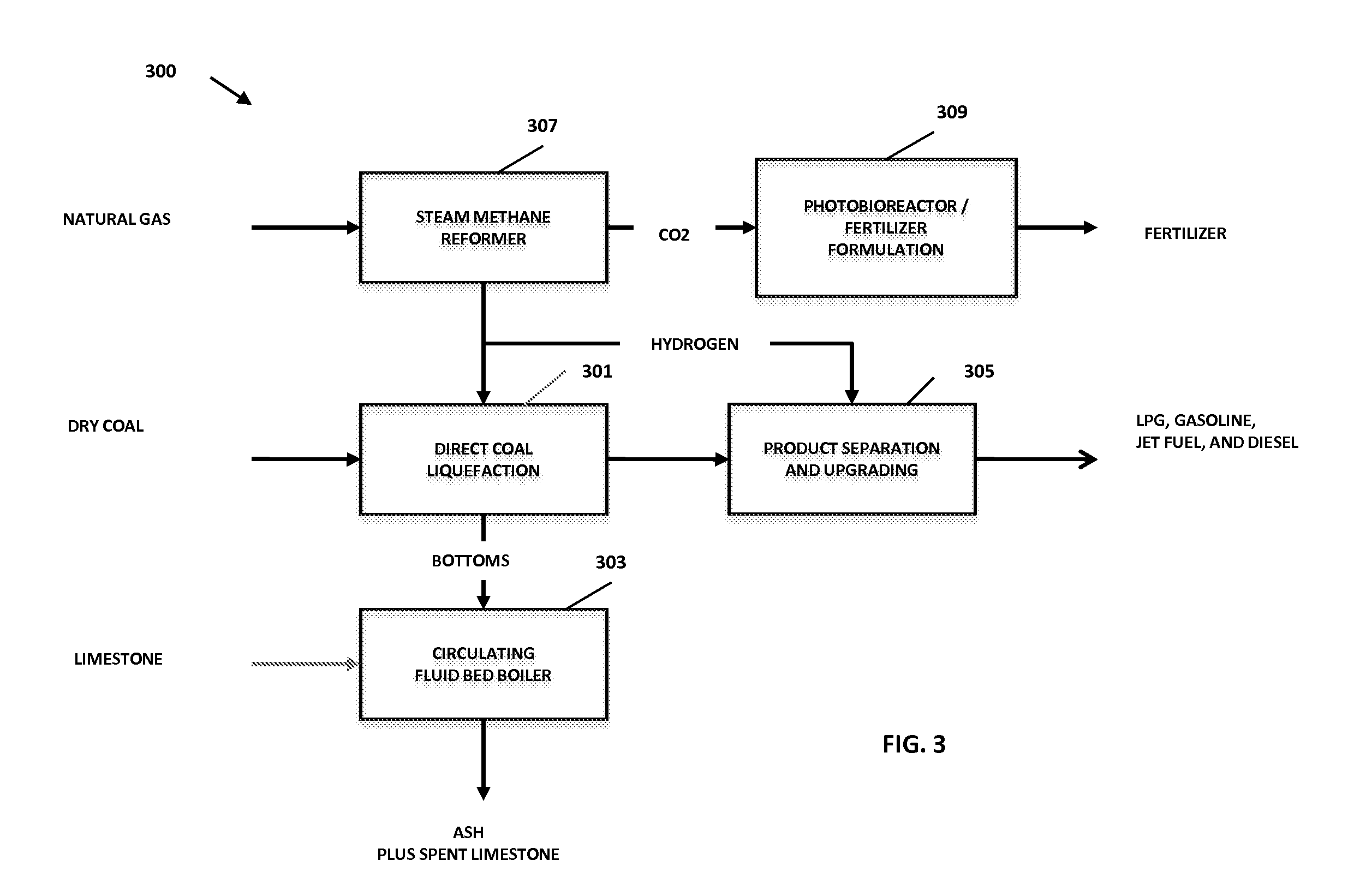

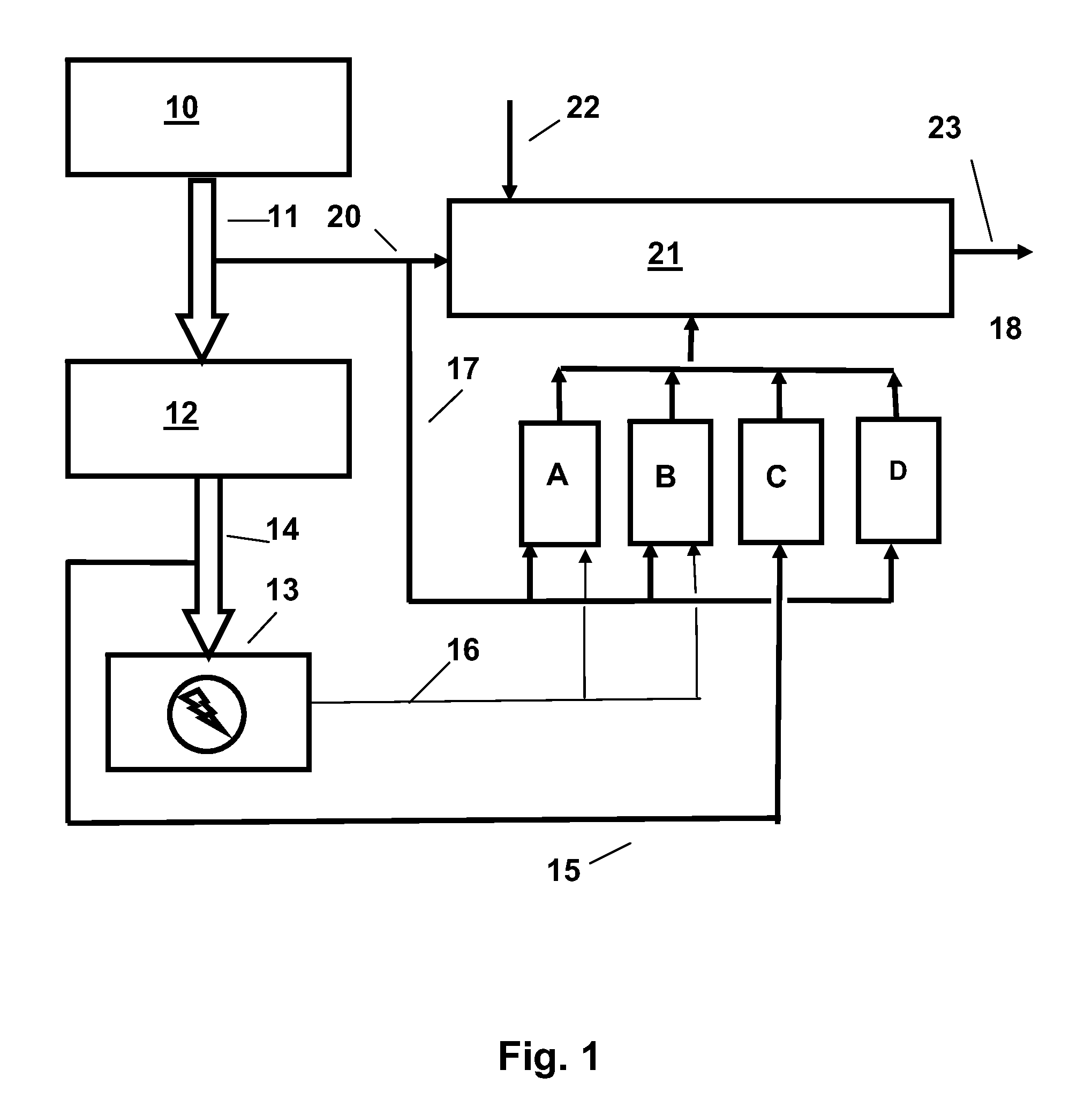

Integrated Coal To Liquids Process And System With Co2 Mitigation Using Algal Biomass

InactiveUS20120144887A1High thermal efficiencyReduced footprintBioreactor/fermenter combinationsBio-organic fraction processingMethane reformerSyngas

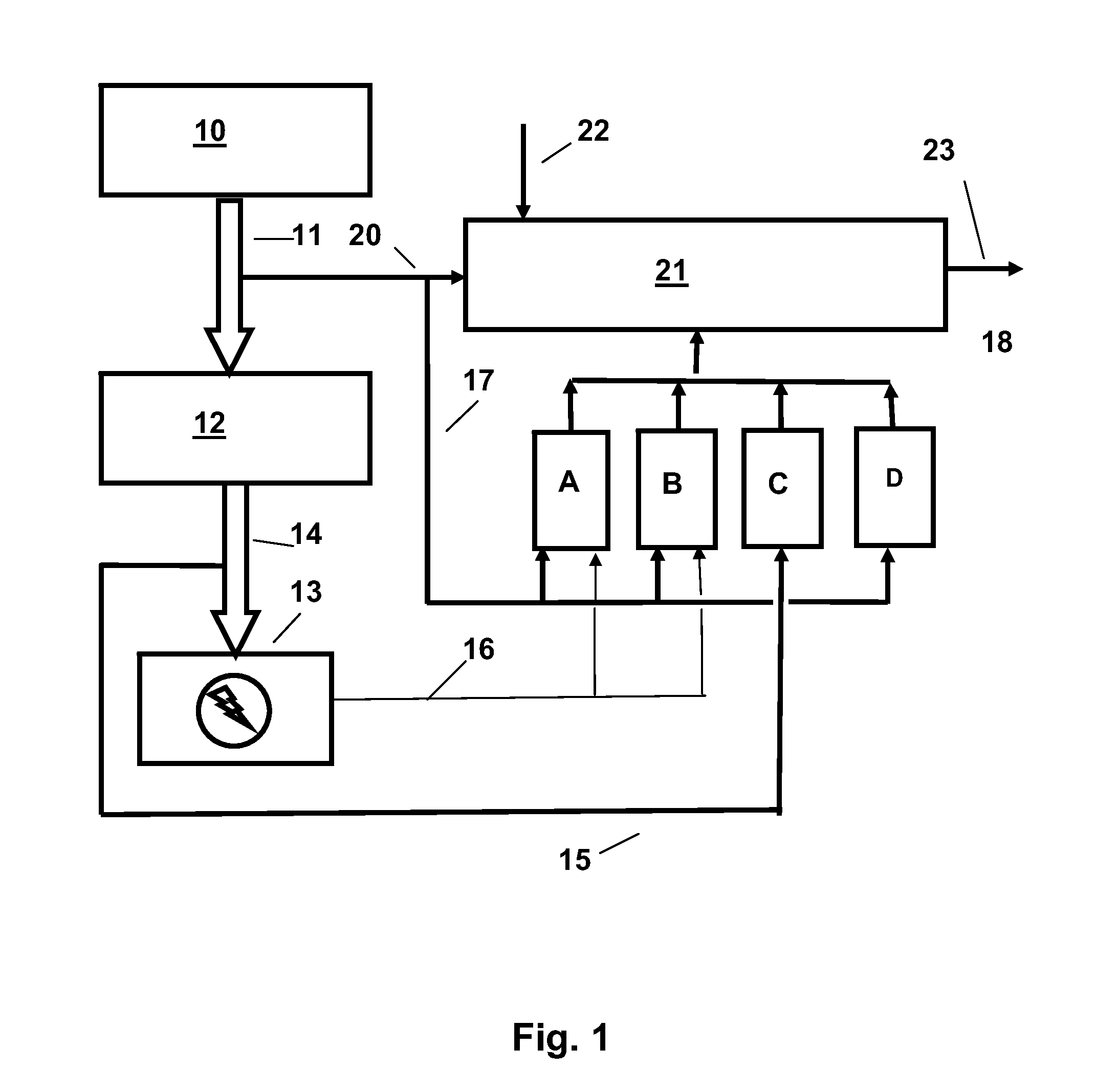

An ICBTL system having a low GHG footprint for converting coal or coal and biomass to liquid fuels in which a carbon-based feed is converted to liquids by direct liquefaction and optionally by indirect liquefaction and the liquids are upgraded to produce premium fuels. CO2 produced by the process is used to produce algal biomass and photosynthetic microorganisms in a photobioreactor. Optionally, lipids extracted from the some or all of the algal biomass is hydroprocessed to produce fuel components and biomass residues and the carbon-based feed our gasified to produce hydrogen and syngas for the direct and indirect liquefaction processes. Some or all of the algal biomass and photosynthetic microorganisms are used to produce a natural biofertilizer. CO2 may also be produced by a steam methane reformer for supplying CO2 to produce the algal biomass and photosynthetic microorganisms.

Owner:ACCELERGY CORP

Production of gasoline, diesel, naphthenes and aromatics from lignin and cellulosic waste by one step hydrocracking

Owner:UOP LLC

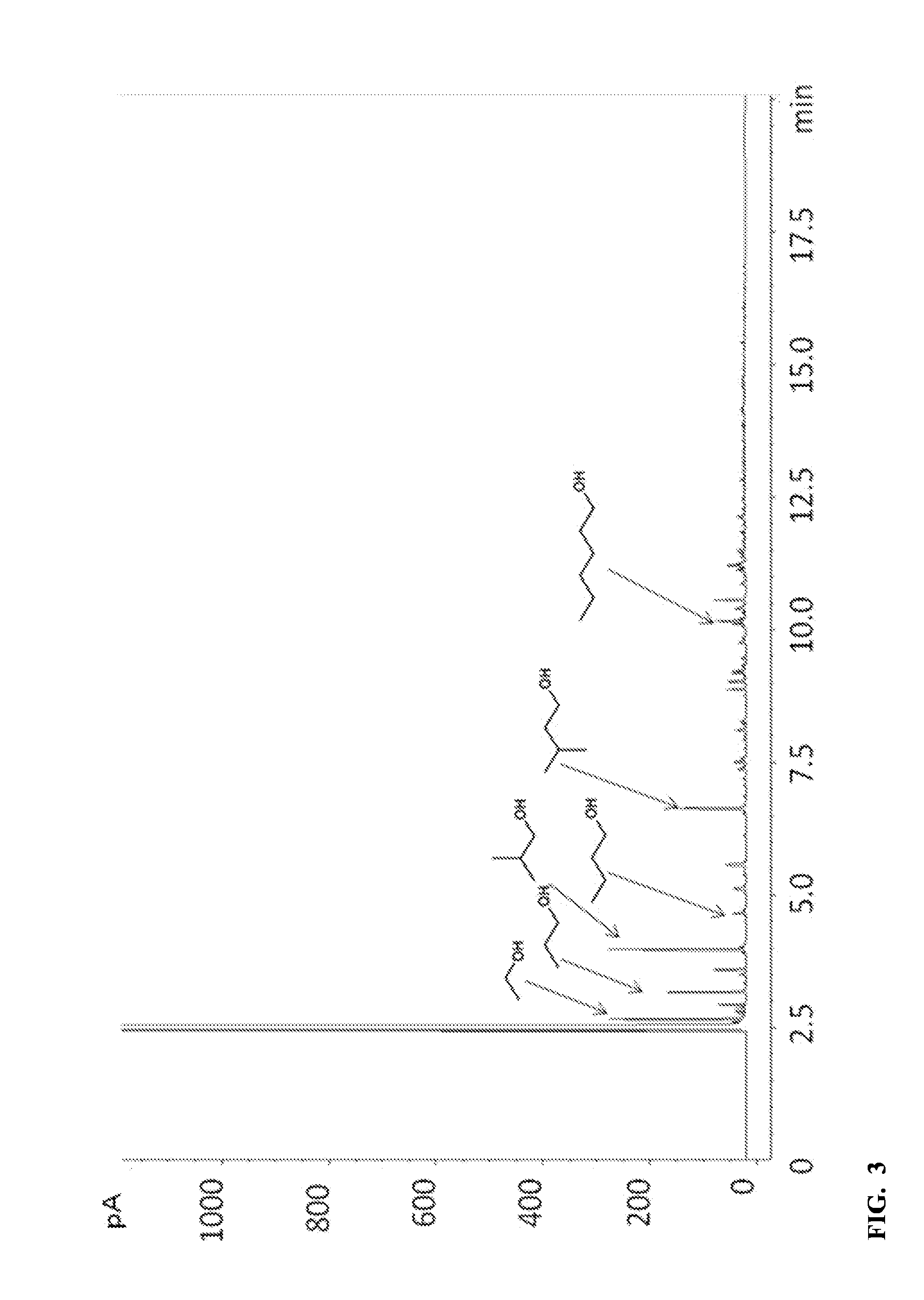

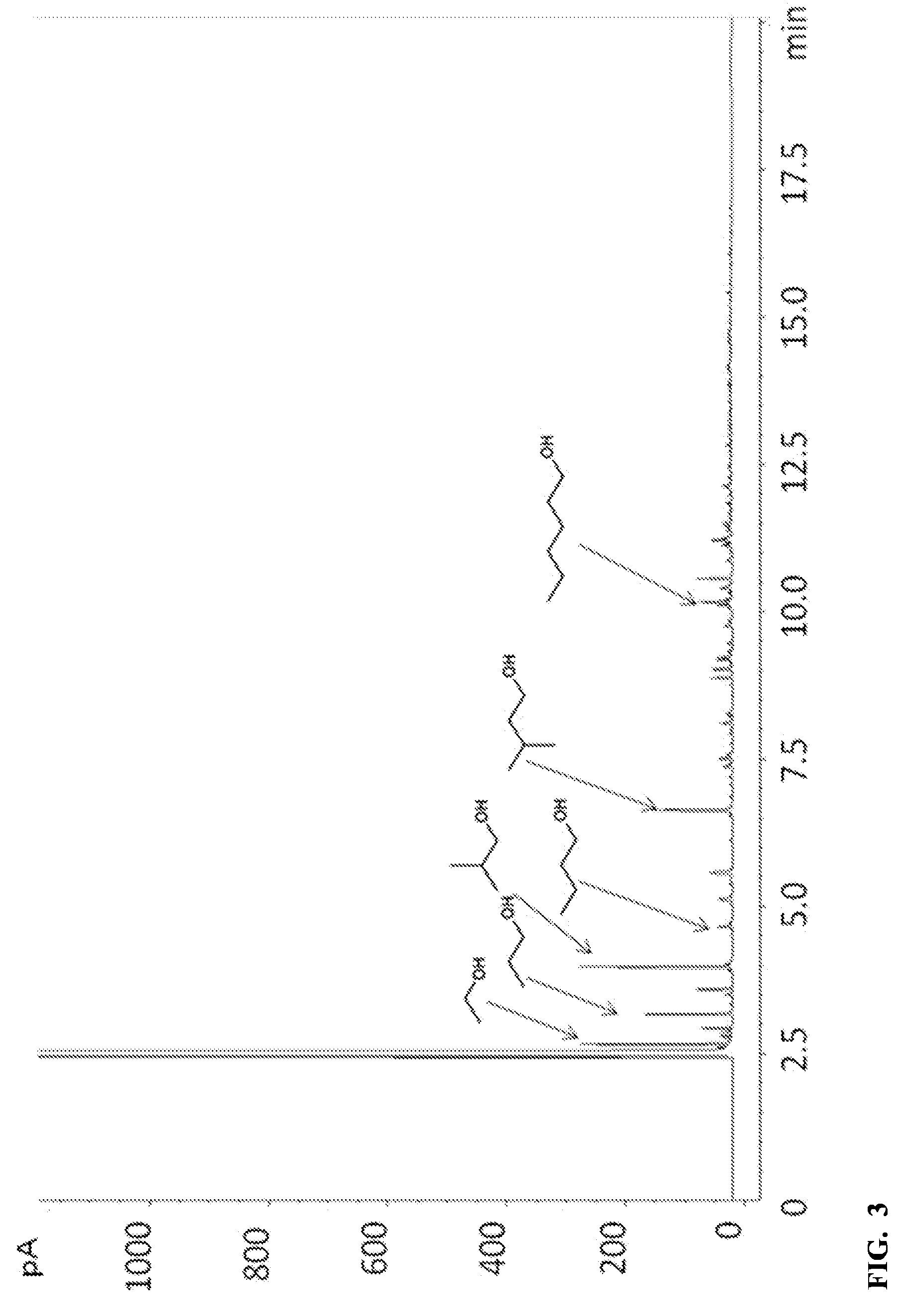

Process for direct conversion of biomass to liquid fuels and chemicals

ActiveUS20110065814A1Rapidly hydrogenatedAvoid excessive dehydrationBiofuelsWaste based fuelAlcoholLiquid fuel

A method of catalytically preparing a fluid product from solid carbonaceous material is described. In the method, at least one of the following equilibria is established by one or more catalysts: a) CH3OH═CO+2H2, b) CO+H2O═CO2+H2. In some embodiments, the solid carbonaceous material is woody biomass. Components of the fluid product can include one or a combination of C5-C9 alcohols. In certain embodiments, the method can be practiced with substantially all of the carbon in the carbonaceous material being converted to the fluid product. Also, in some embodiments, the fluid product can be prepared with substantially no char formation. The fluid product of various embodiments can be used directly as fuel or as a reagent for preparing commodity chemicals without the need for separating the fluid product components.

Owner:RGT UNIV OF CALIFORNIA

Process for the conversion of lipid-containing biomass

A process is disclosed for converting lipid-containing biomass to a liquid fuel and / or platform chemicals.The process comprises the steps of dissolving the lipid-containing biomass in an ionic liquid, whereby a lipid phase and a hydrophilic phase are formed. The lipid phase contains primarily triglycerides, which can be converted to biodiesel by transesterification to, e.g., methyl esters. The hydrophilic phase comprises dissolved biopolymers, such as cellulose, hemicellulose, and protein. The biopolymers are converted in situ to compounds that are insoluble in the ionic liquid.The ionic liquid is regenerated by removing insolubles, such as lignin, ash from the biomass, and water.

Owner:BIOECON INT HLDG NV +1

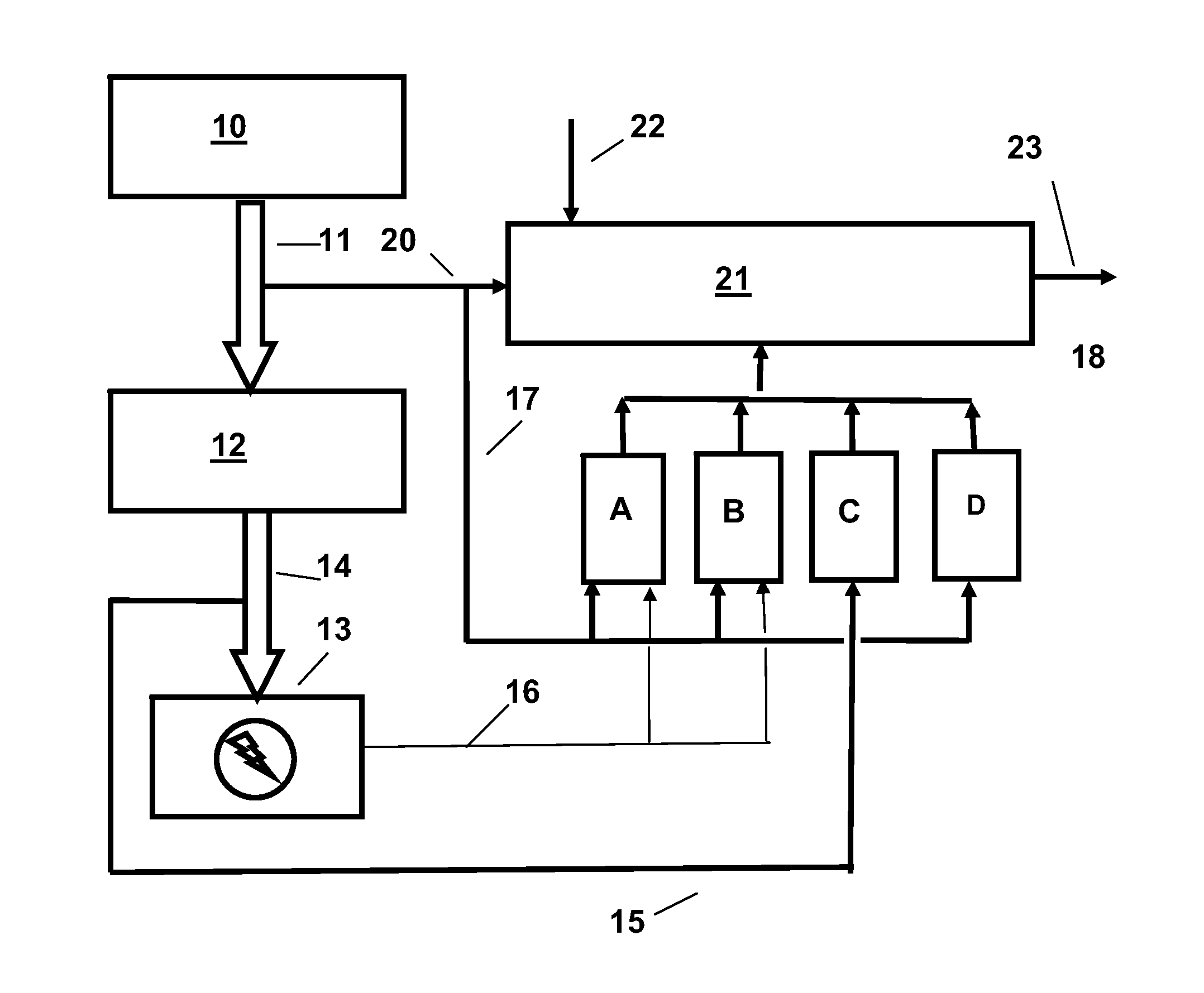

High temperature hydropyrolysis of carbonaceous materials

InactiveUS20100314235A1Efficient supplyMinimizes problemCombustible gas coke oven heatingFuel cell heat exchangeSulphur iodideResource utilization

Heat from a concentrated solar power source is applied to the conversion of carbonaceous materials such as heavy petroleum crude oils, coals and biomass to liquid hydrocarbons. The solar heat is applied to provide at least a portion of the process heat used in the high temperature, short contact time hydropyrolysis of the carbonaceous material which is supplied with hydrogen generated by a high temperature process such as high temperature steam electrolysis, the sulfur-iodine cycle, the hybrid sulfur cycle, the zinc-zinc oxide cycle or by methane steam cracking. The heat from the solar source may be used to generate electricity to operate high temperature steam electrolysis used in generation of the hydrogen. By the use of solar thermal energy sources, hydrocarbon resource utilization for process heat is eliminated along with carbon dioxide evolution associated with burning of the hydrocarbon resource to generate process heat. The substitution of zero carbon emission sources therefore offers the potential for significant carbon emission reductions in refinery operations where external process heat can be applied and effectively utilized.

Owner:EXXON RES & ENG CO

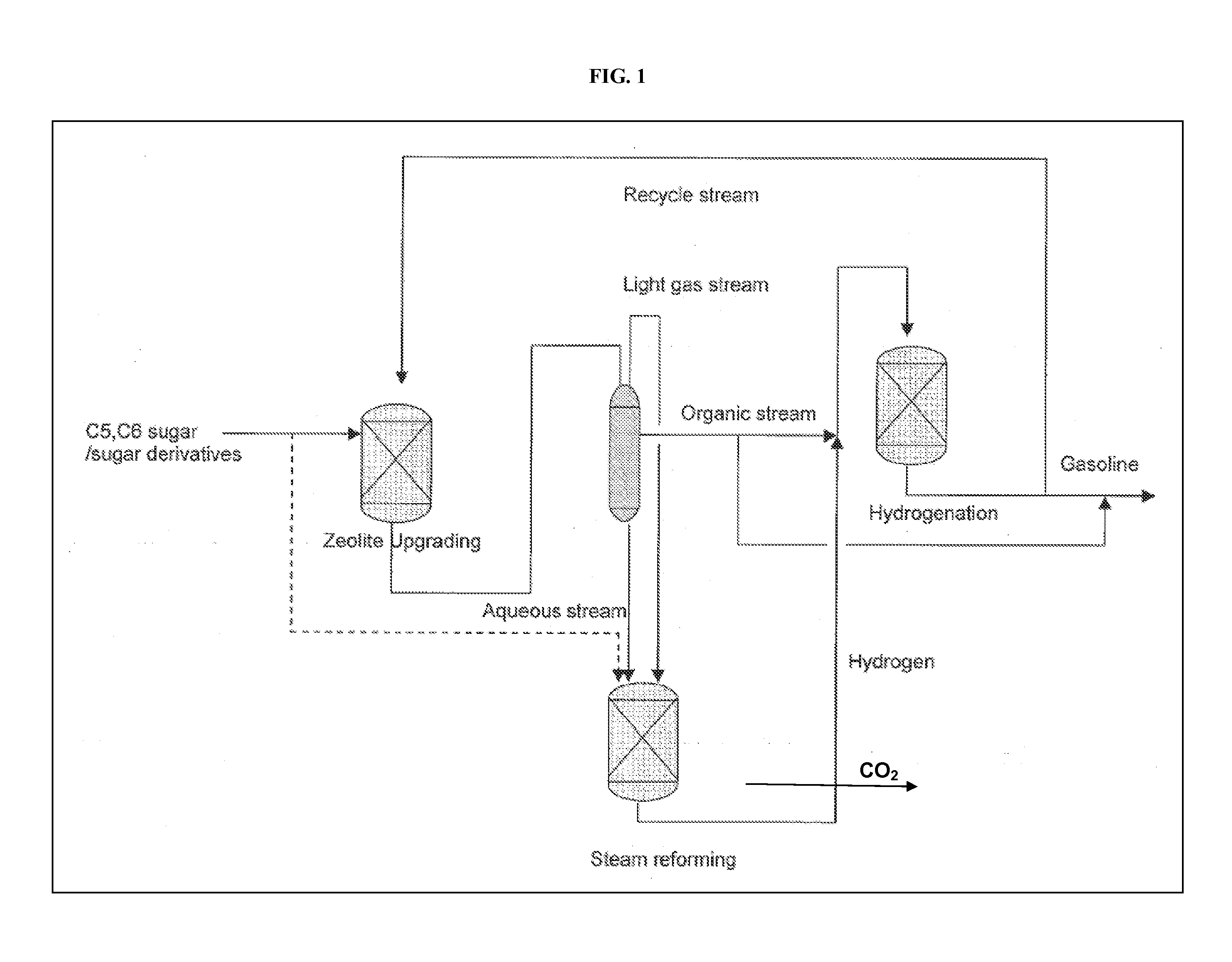

Combination of zeolite upgrading with hydrogenation upgrading to produce renewable gasoline from biomass

ActiveUS20120095274A1Low vapor pressureReduce cokingMolecular sieve catalystsRaney catalystAlkaneParaffin wax

Technologies to convert biomass to liquid hydrocarbon fuels are currently being developed to decrease our carbon footprint and increase use of renewable fuels. Since sugars / sugar derivatives from biomass have high oxygen content and low hydrogen content, coke becomes an issue during zeolite upgrading to liquid hydrocarbon fuels. A self-sustainable process was designed to reduce the coke by co-feeding sugars / sugar derivatives with the paraffin products from hydrogenation of sugars / sugar derivatives. Paraffins without complete conversion result in products with less aromatics and relatively low density compared with the products directly from zeolite upgrading. Thus, the process is more economically favorable.

Owner:PHILLIPS 66 CO

Process for upgrading biomass derived products

ActiveUS20130043192A1Dewatering/demulsification with chemical meansLiquid separation by electricityOil phaseMetal

Disclosed is a process for the alteration of the ratio of the specific gravities of the oil and water phases resulting from the conversion of biomass to liquid products, the reduction of the conductivity and of metals of the product mixture, which each can aid in the removal of solids contained in the oil phase.

Owner:MARD INC

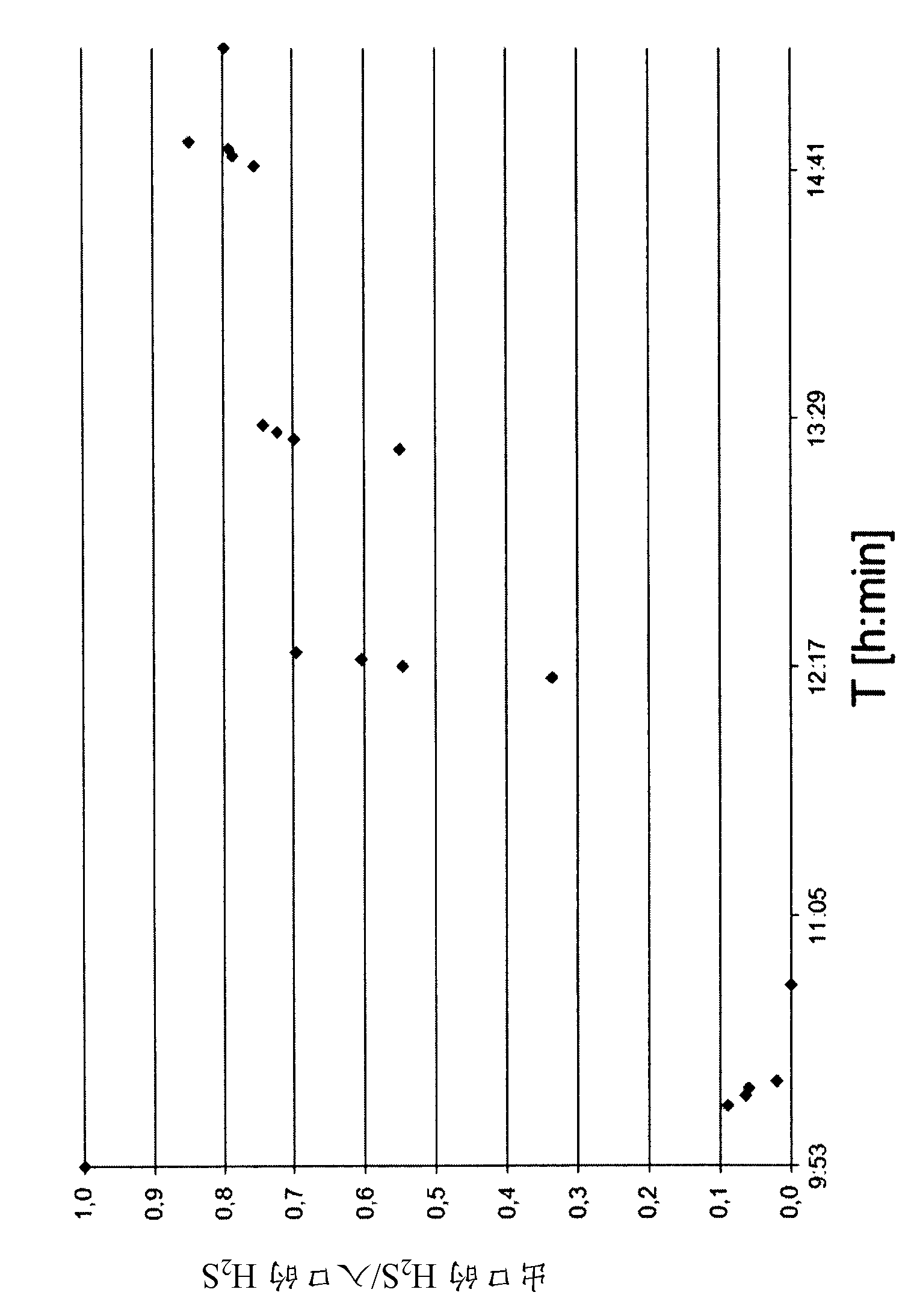

Two-stage gas washing method

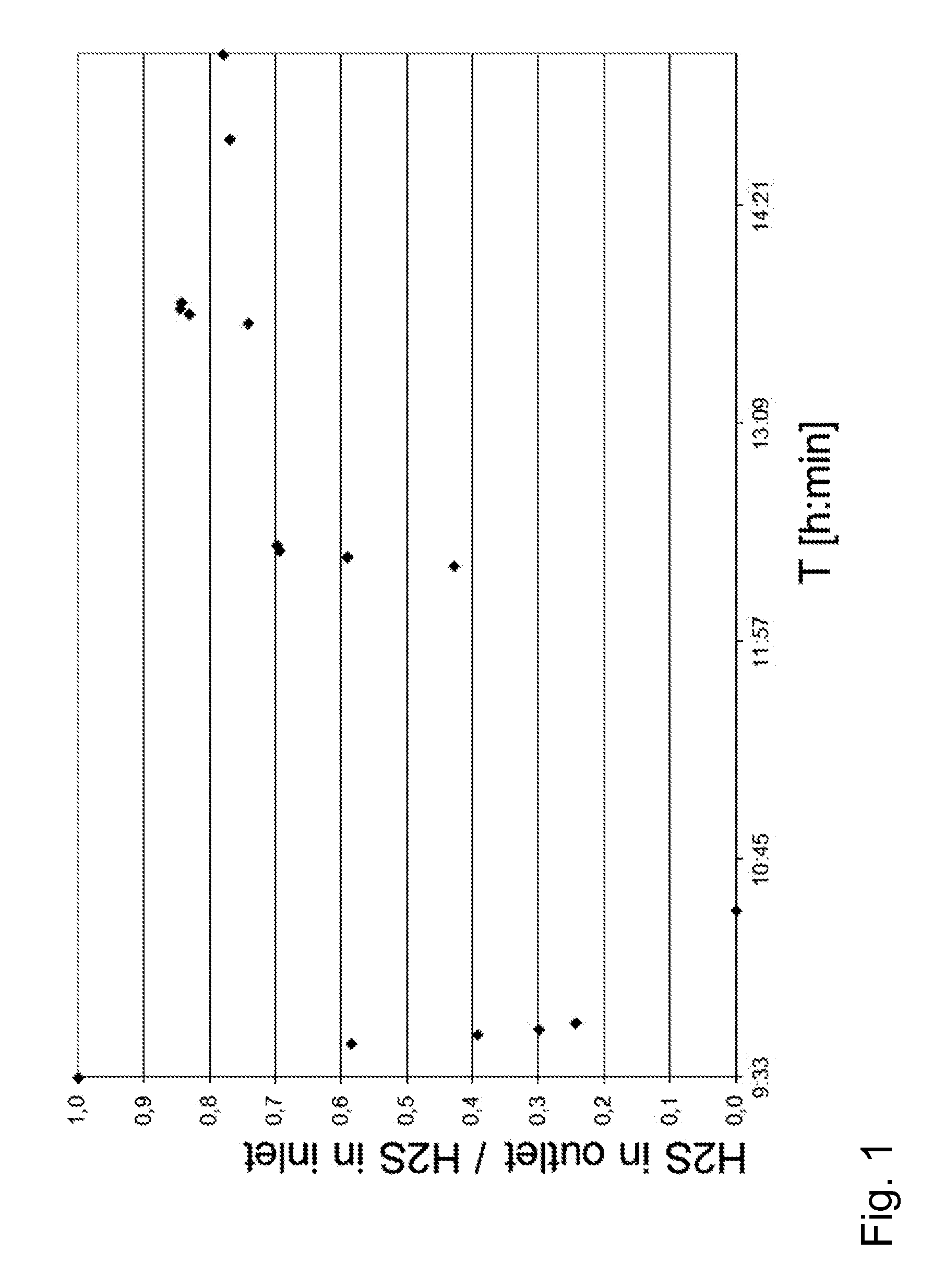

ActiveUS20120214881A1Solve the large energy consumptionReduce needWaste based fuelBio-feedstockSyngasProduct gas

The present description is related to the field of hydrocarbon production by gasification of carbonaceous material. It provides a two-stage gas washing method as a part of gas refining. More specifically it discloses a method for hydrogen sulfide and carbon dioxide removal from synthesis gas produced by gasification. It introduces a use of a novel combination of wash approaches for this application. As a specific application, this process is utilized as a part of biomass to liquid (BTL) process.

Owner:NESTE OIL OY

Waste water treatment from a biomass-to-liquid process comprising synthesis gas production and integrated factory facility

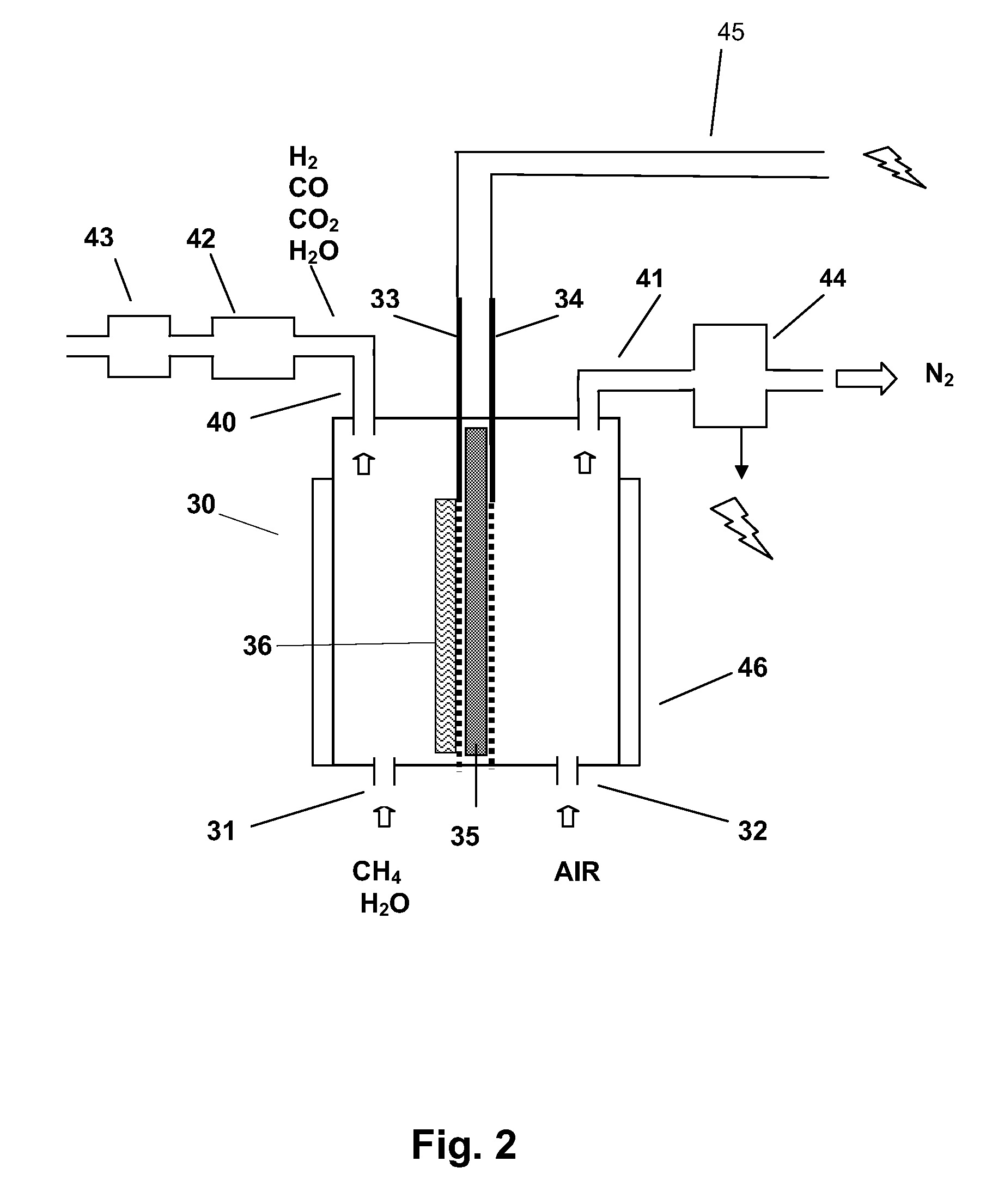

ActiveUS8591737B2Effective in stabilizing and/or improving said purification processCombustible gas catalytic treatmentWaste based fuelPetrochemicalElectric power

Treatment of waste water from a biomass-to-liquid process, said process comprising producing synthesis gas from biomass and conversion of said synthesis gas into liquid hydrocarbons by a Fisher-Tropsch process. The waste waters obtained are purified in common with waste waters from another industrial process to which said biomass-to-liquid process is integrated, such as in forestry, power and / or heat generation, waste incineration or a process in a metal-, petrochemical and / or oil refining industry. The biomass-to-liquid. process and said another industrial process may have a common feed water process unit, a common cooling water process unit and a common waste water treatment unit. The waste water treatment process may comprise a biological purification process and said Fischer-Tropsch process may utilize a cobalt catalyst. An integrated factory comprising a biomass-to-liquid plant and another industrial facility in which both plants are connected to a common waste water treatment facility is also described.

Owner:UPM-KYMMENE OYJ

Waste Water Treatment From A Biomass-To-Liquid Process Comprising Synthesis Gas Production and Integrated Factory Facility

ActiveUS20100317749A1Effective in stabilizing and/or improving said purification processCombustible gas catalytic treatmentWaste based fuelPetrochemicalElectric power

Treatment of waste water from a biomass-to-liquid process, said process comprising producing synthesis gas from biomass and conversion of said synthesis gas into liquid hydrocarbons by a Fisher-Tropsch process. The waste waters obtained are purified in common with waste waters from another industrial process to which said biomass-to- liquid process is integrated, such as in forestry, power and / or heat generation, waste incineration or a process in a metal-, petrochemical and / or oil refining industry. The biomass-to-liquid. process and said another industrial process may have a common feed water process unit, a common cooling water process unit and a common waste water treatment unit. The waste water treatment process may comprise a biological purification process and said Fischer-Tropsch process may utilize a cobalt catalyst. An integrated factory comprising a biomass-to-liquid plant and another industrial facility in which both plants are connected to a common waste water treatment facility is also described.

Owner:UPM-KYMMENE OYJ

Process for Upgrading Biomass Derived Products Using Liquid-Liquid Extraction

ActiveUS20130306557A1Dewatering/demulsification with chemical meansRefining with metal saltsCompounds of carbonMetal

Disclosed is a process for the alteration of the ratio of the specific gravities of the oil and water phases resulting from the conversion of biomass to liquid products, the reduction of the conductivity and of metals of the product mixture, which each can aid in the removal of solids contained in the oil phase; and a liquid-liquid extraction method for partitioning desirable carbon containing compounds into the oil phase and undesirable carbon containing compounds into the water phase.

Owner:MARD INC

Catalyst for thermocatalytic conversion of biomass to liquid fuels and chemicals

Catalyst compositions comprising a phosphorous-promoted ZSM-5 component and a silica-containing binder, and methods for making and using same, are disclosed. More specifically, processes for making a catalyst for biomass conversion are provided. The process includes: treating a ZSM-5 zeolite with a phosphorous-containing compound to form a phosphorous-promoted ZSM-5 component; preparing a slurry comprising the phosphorous-promoted ZSM-5 component and a silica-containing binder; and shaping the slurry into shaped bodies. Such catalysts can be used for the thermocatalytic conversion of particulate biomass to liquid products such as bio-oil, resulting in higher bio-oil yields and lower coke than conventional catalysts.

Owner:MARD INC

Catalyst Composition With Increased Bulk Active Site Accessibility For The Catalytic Thermoconversion Of Biomass To Liquid Fuels And Chemicals And For Upgrading Bio-Oils

InactiveUS20150352541A1Improve accessibilityMolecular sieve catalystsOther chemical processesReactive siteActive site

Processes for making a catalytic system and catalytic systems for converting solid biomass into fuel or specialty chemical products, or for upgrading bio-oils are described. The catalyst system may comprise a non-zeolitic matrix with a hierarchical pore structure ranging from 300 to about 104 Angstrom pore size, a zeolite, such as MFI-type or IM-5 zeolite, and a binder.

Owner:MARD INC

Process for upgrading biomass derived products using liquid-liquid extraction

ActiveUS20160317947A1Dewatering/demulsification with chemical meansUltrafiltrationEnvironmental engineeringOil phase

Disclosed is a process for the alteration of the ratio of the specific gravities of the oil and water phases resulting from the conversion of biomass to liquid products, the reduction of the conductivity and of metals of the product mixture, which each can aid in the removal of solids contained in the oil phase; and a liquid-liquid extraction method for partitioning desirable carbon containing compounds into the oil phase and undesirable carbon containing compounds into the water phase.

Owner:MARD INC

Method and apparatus for coproduction of pig iron and high quality syngas

Combined microwave heating and plasma / electric arc heating is utilized in several processes and apparatus which involve co-production of pig iron and high quality syngas, biomass to liquid fuel production, coal to liquid fuel production, co-gasification of biomass and coal, municipal solid waste treatment, waste-to-energy (agriculture waste, ASR and PEF), EAF dust and BOF sludge treatment to recover zinc and iron, hazardous bottom ash vitrification, and bromine, chlorine and sulfur removal / recycling.

Owner:HUANG XIAODI +1

High temperature hydropyrolysis of carbonaceous materials

InactiveUS20100320120A1Significant carbon emissionEfficient use ofMolecular sieve catalystsLiquid hydrocarbon mixture productionHydrocotyle bowlesioidesPetroleum oil

Heat from nuclear reactor as a source of thermal energy is applied to the conversion of carbonaceous materials such as heavy petroleum crude oils, coals and biomass to liquid hydrocarbons. The heat is applied to provide at least a portion of the process heat used in the high temperature, short contact time hydropyrolysis of the carbonaceous material which is supplied with hydrogen generated by a high temperature process such as high temperature steam electrolysis, the sulfur-iodine cycle, the hybrid sulfur cycle, the zinc-zinc oxide cycle, a solid oxide fuel cell or by methane steam cracking. The heat from the nuclear reactor may be used to generate electricity to operate high temperature steam electrolysis used in generation of the hydrogen. By the use of nuclear thermal energy, hydrocarbon resource utilization for process heat is eliminated along with carbon dioxide evolution associated with burning of the hydrocarbon resource to generate process heat. The substitution of zero carbon emission sources therefore offers the potential for significant carbon emission reductions in refinery operations where external process heat can be applied and effectively utilized.

Owner:EXXON RES & ENG CO

Process for upgrading biomass derived products using liquid-liquid extraction

ActiveUS9387415B2Dewatering/demulsification with chemical meansRefining with metal saltsCompounds of carbonMetal

Disclosed is a process for the alteration of the ratio of the specific gravities of the oil and water phases resulting from the conversion of biomass to liquid products, the reduction of the conductivity and of metals of the product mixture, which each can aid in the removal of solids contained in the oil phase; and a liquid-liquid extraction method for partitioning desirable carbon containing compounds into the oil phase and undesirable carbon containing compounds into the water phase.

Owner:MARD INC

A two-stage gas washing method

Owner:NESTE OIL OY

Process for direct conversion of biomass to liquid fuels and chemicals

ActiveUS20140343174A1Rapidly hydrogenatedAvoid excessive dehydrationBiofuelsWaste based fuelAlcoholLiquid fuel

A method of catalytically preparing a fluid product from solid carbonaceous material is described. In the method, at least one of the following equilibria is established by one or more catalysts: a) CH3OH═CO+2H2, b) CO+H2O═CO2+H2. In some versions, the solid carbonaceous material is woody biomass. Components of the fluid product can include one or a combination of C5-C9 alcohols, In certain versions, the method can he practiced with substantially all of the carbon in the carbonaceous material being converted to the fluid product. Also, in some versions, the fluid product can be prepared with substantially no char formation. The fluid product of various versions can be used directly as fuel or as a reagent for preparing commodity chemicals without the need for separating the fluid product components.

Owner:RGT UNIV OF CALIFORNIA

Carbohydrates upgrading and hydrotreating to hydrocarbons

ActiveUS8809605B2Improve purity/separationBiofuelsLiquid hydrocarbon mixture productionCarbon footprintHydrogen content

Technologies to convert biomass to liquid hydrocarbon fuels are currently being developed to decrease our carbon footprint and increase use of renewable fuels. Since sugars / sugar derivatives from biomass have high oxygen content and low hydrogen content, coke becomes an issue during zeolite upgrading to liquid hydrocarbon fuels. A process was designed to reduce the coke by co-feeding sugars / sugar derivatives with a saturated recycle stream containing hydrogenated products.

Owner:PHILLIPS 66 CO

Process for upgrading biomass derived products

ActiveUS9315739B2Dewatering/demulsification with chemical meansLiquid separation by electricityOil phaseMetal

Disclosed is a process for the alteration of the ratio of the specific gravities of the oil and water phases resulting from the conversion of biomass to liquid products, the reduction of the conductivity and of metals of the product mixture, which each can aid in the removal of solids contained in the oil phase.

Owner:MARD INC

Process for direct conversion of biomass to liquid fuels and chemicals

ActiveUS8796494B2Rapidly hydrogenatedAvoid excessive dehydrationBiofuelsWaste based fuelAlcoholLiquid fuel

A method of catalytically preparing a fluid product from solid carbonaceous material is described. In the method, at least one of the following equilibria is established by one or more catalysts: a) CH3OH=CO+2H2, b) CO+H2O=CO2+H2. In some versions, the solid carbonaceous material is woody biomass. Components of the fluid product can include one or a combination of C5-C9 alcohols. In certain versions, the method can be practiced with substantially all of the carbon in the carbonaceous material being converted to the fluid product. Also, in some versions, the fluid product can be prepared with substantially no char formation. The fluid product of various versions can be used directly as fuel or as a reagent for preparing commodity chemicals without the need for separating the fluid product components.

Owner:RGT UNIV OF CALIFORNIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com