Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "High open porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

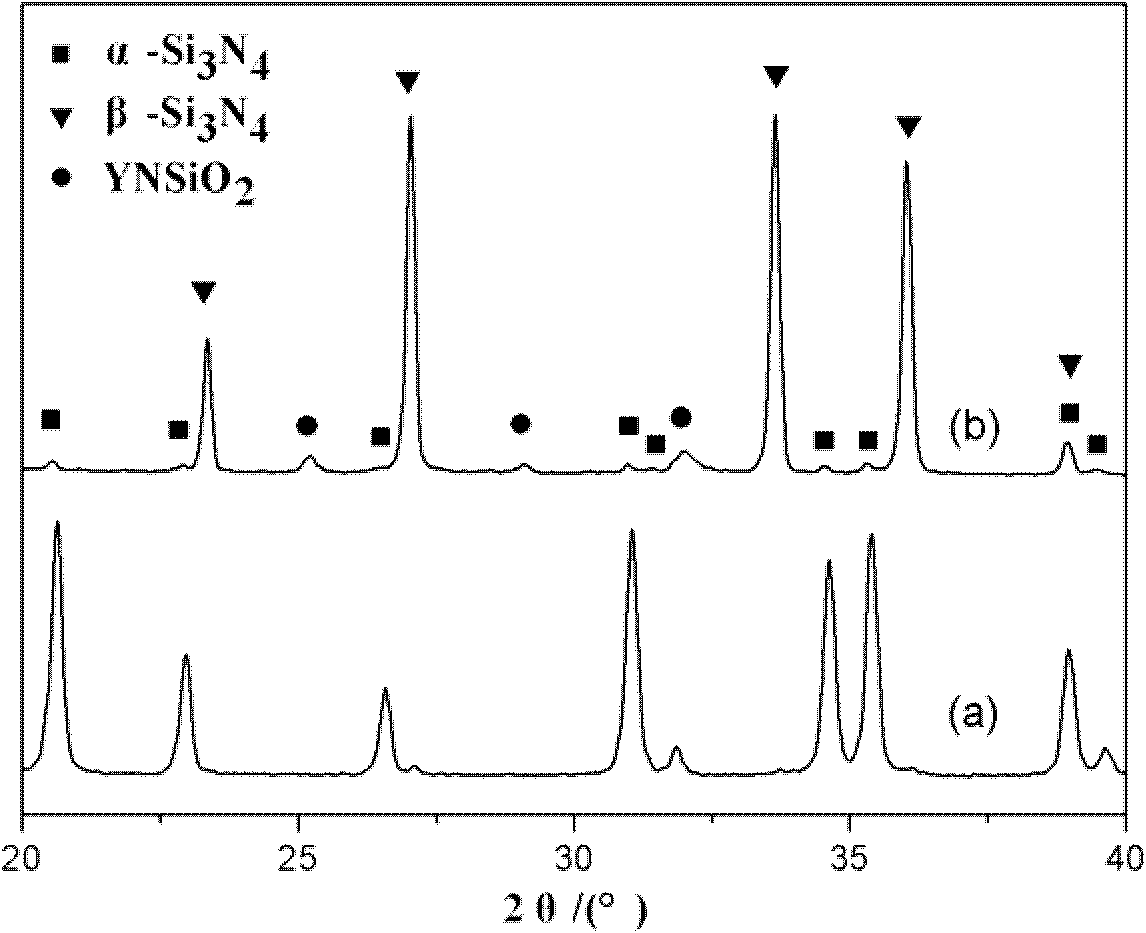

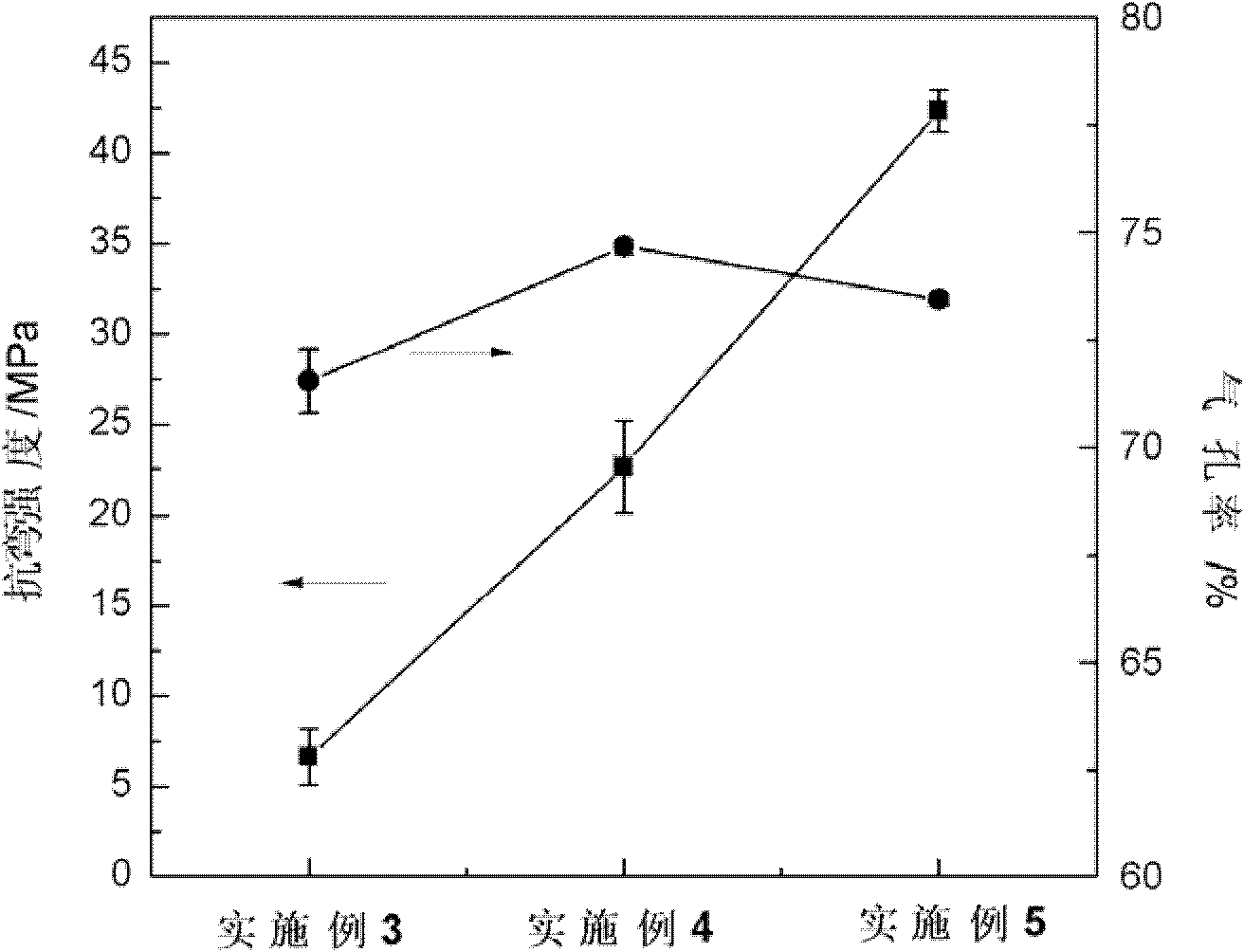

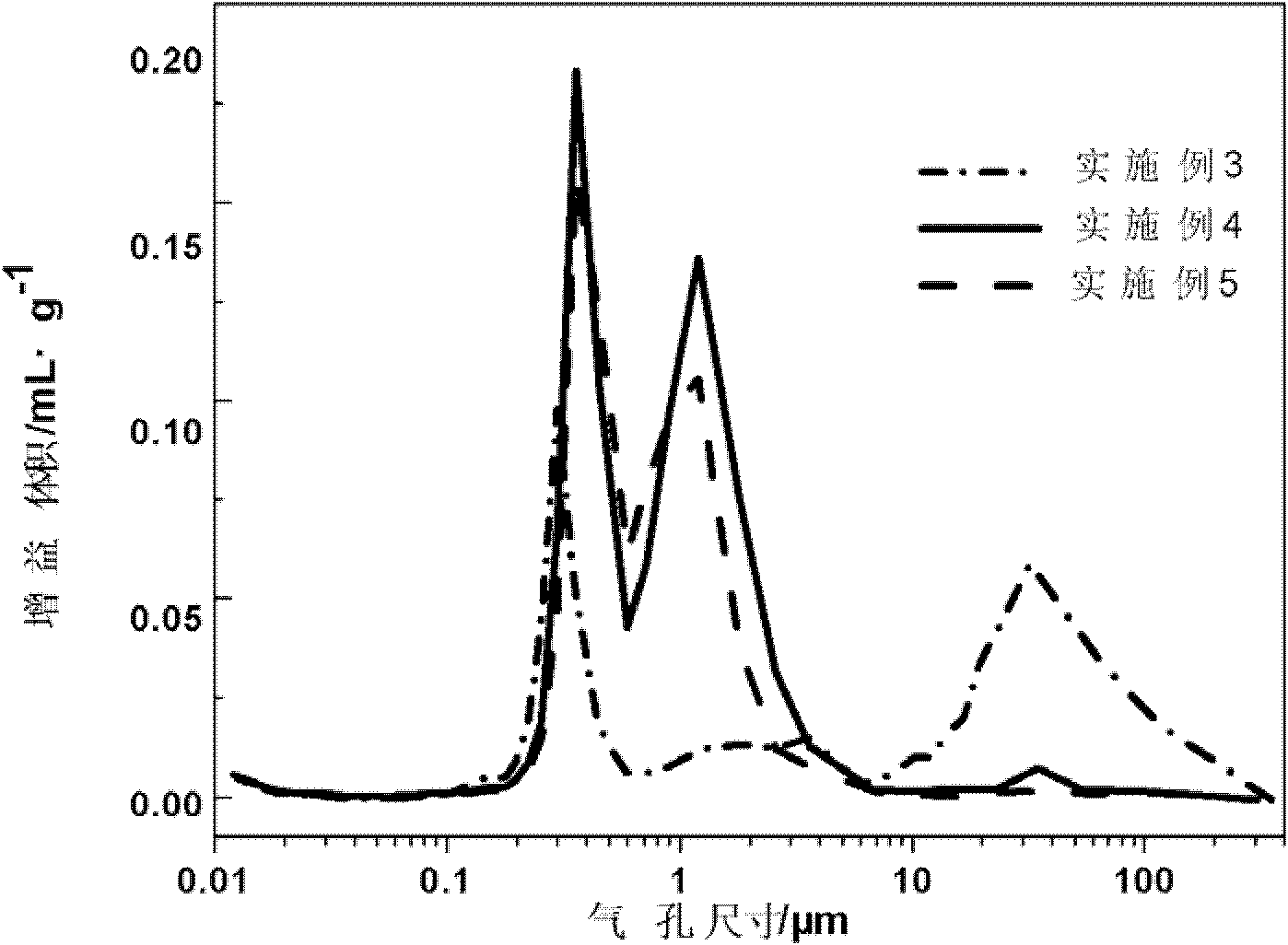

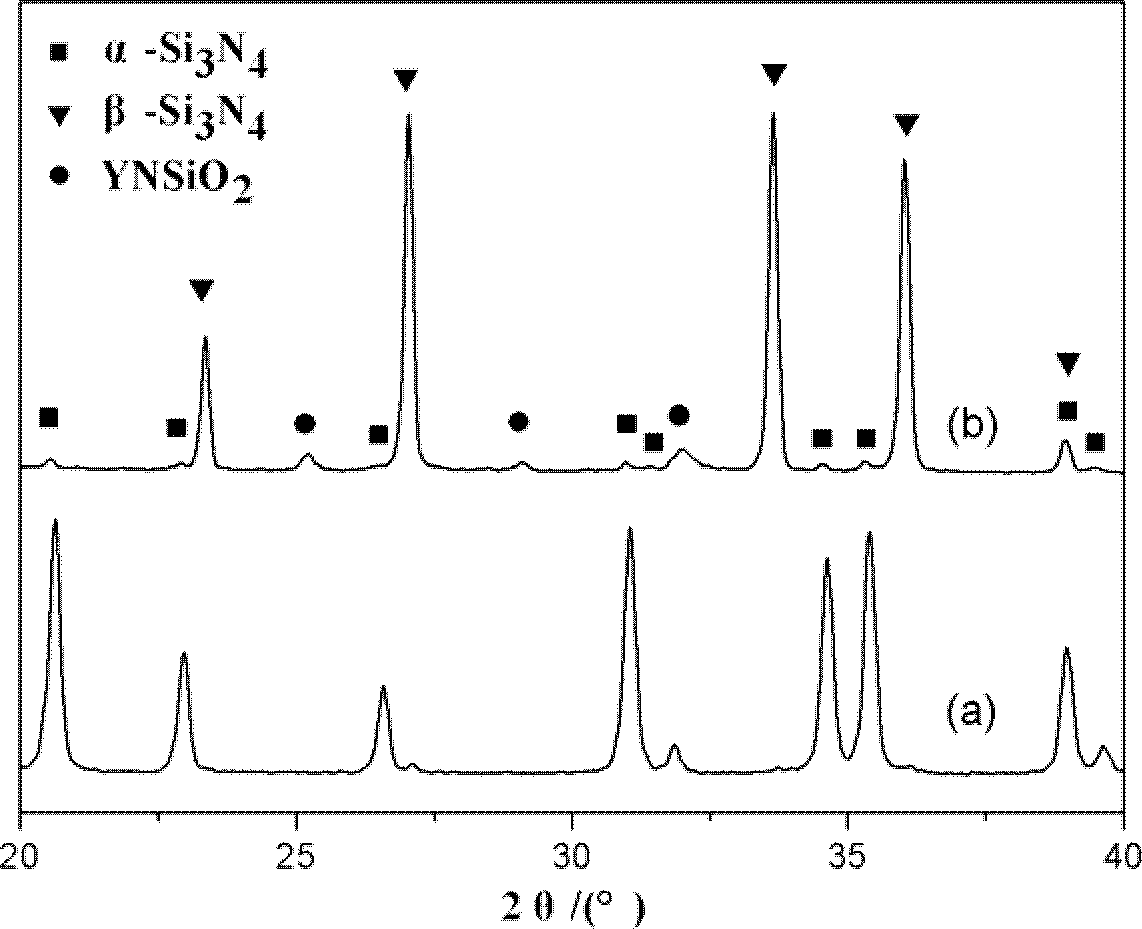

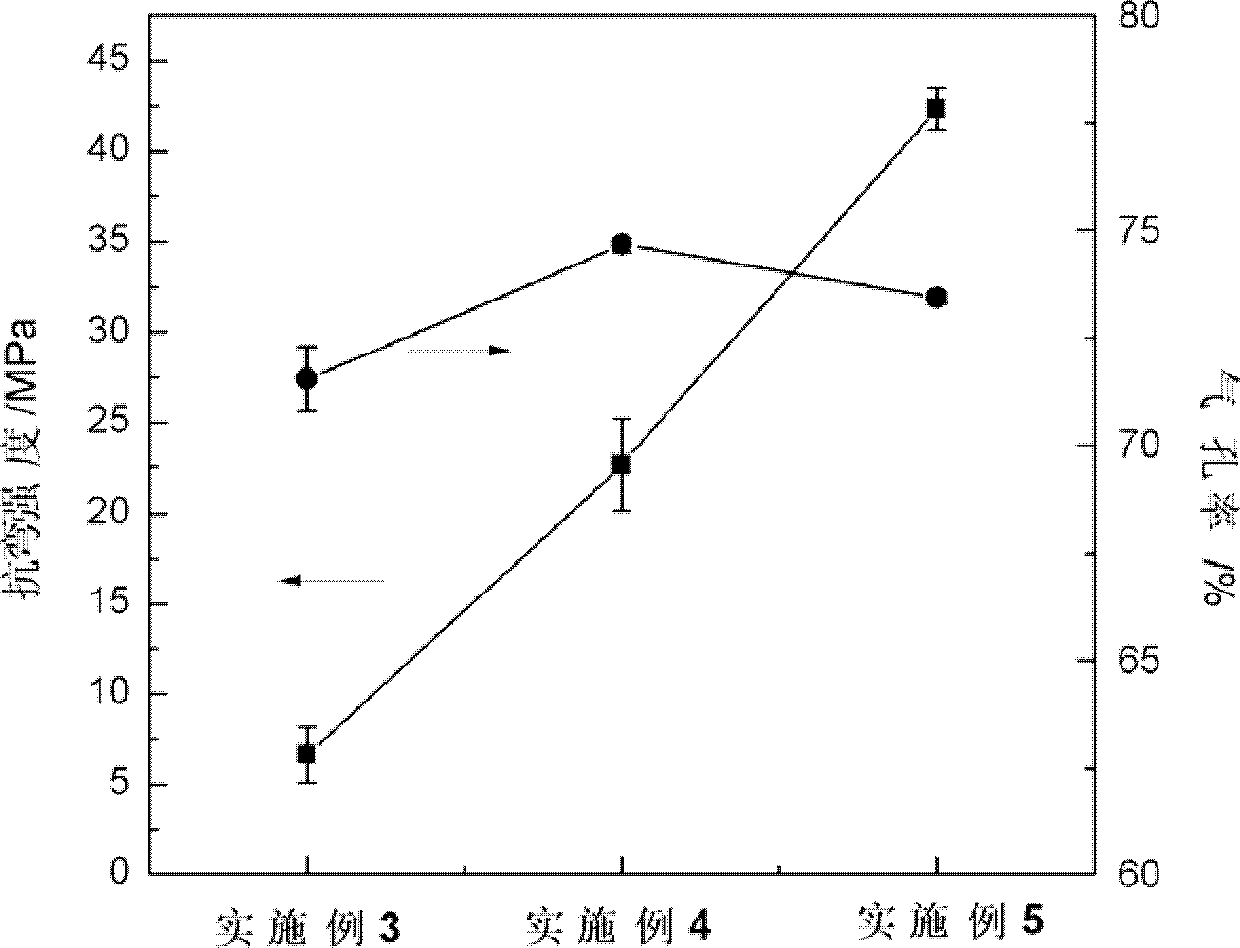

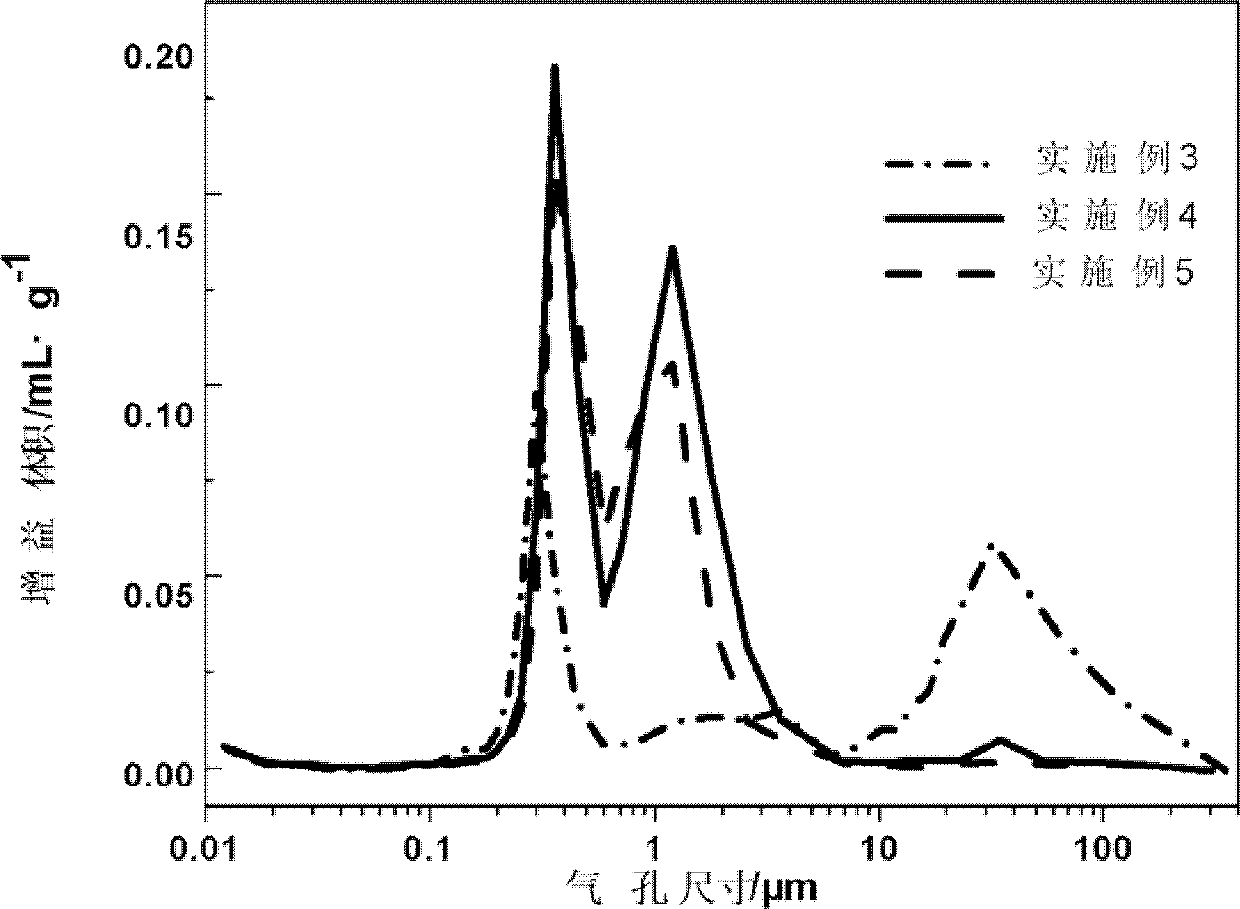

Method for preparing porous silicon-nitride ceramic material

The invention discloses a method for preparing a porous silicon-nitride ceramic material, which comprises the following steps of: stirring starch and water at the temperature of 40-90 DEG C to prepare pre-gelatinized starch; adding silicon nitride, a sintering aid, a bonding agent and a defoaming agent to the pre-gelatinized starch, and uniformly mixing through ball milling to prepare a mixed slurry; molding the mixed slurry through casting, and carrying gout degassing, curing, complete sample-freezing and freeze-drying processing to prepare a porous silicon-nitride ceramic blank body; removing organic volatile substances in the porous silicon-nitride ceramic blank body through heating; and sintering, and cooling a sample along with a furnace after sintering. The silicon-nitride ceramic material prepared by utilizing the preparation method disclosed by the invention has high open porosity (which can reach 60-90 percent) and low density (0.32-1.28g / <cm>3), the bending strength can be regulated within the range of 5-140MPa, and the application-performance requirements of materials in the fields of high-temperature gas and liquid filtration, purification and separation, chemical catalytic carriers and the like can be met.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

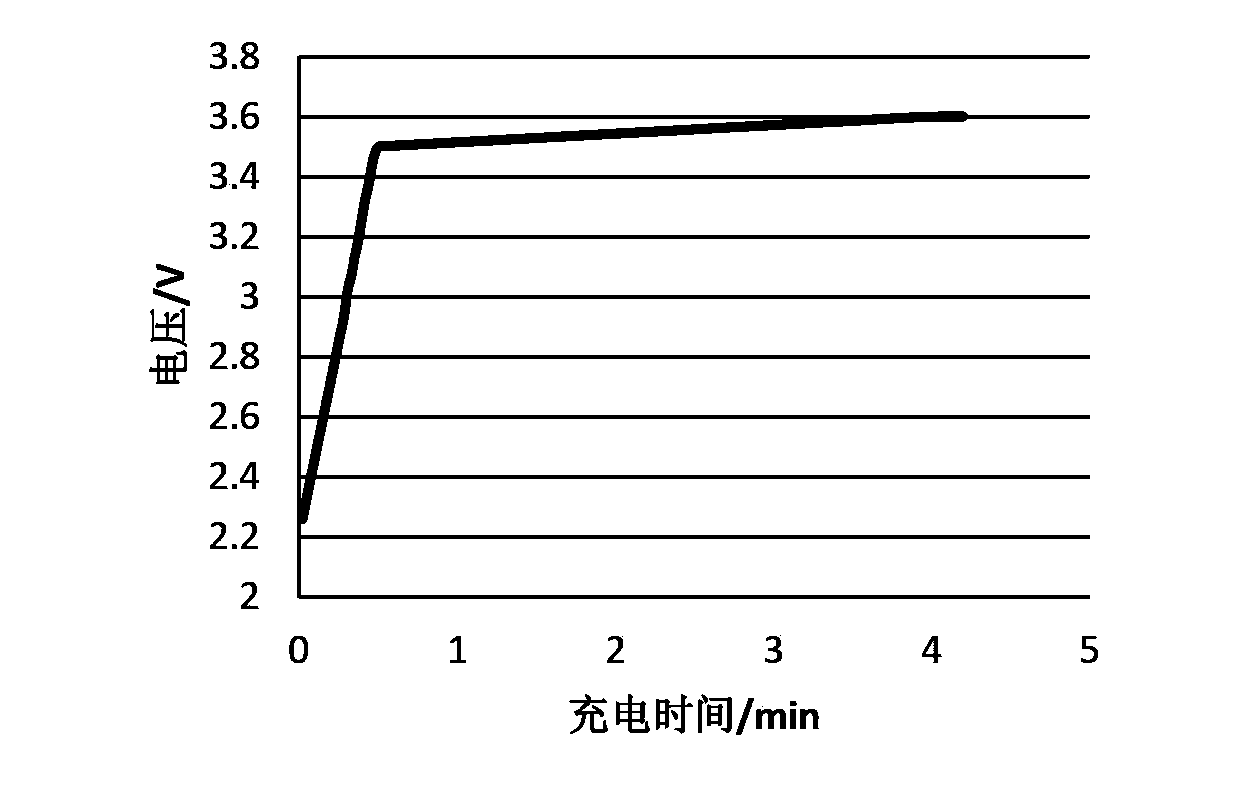

Negative electrode slurry of lithium ion battery, positive electrode of lithium ion battery prepared by slurry and battery

ActiveCN103515607AThe compacted density does not decreaseHigh porosityActive material electrodesSecondary cellsPore distributionHigh energy

The invention provides negative electrode slurry of a lithium ion battery, a positive electrode of the lithium ion battery prepared by using the slurry, and the battery. The negative electrode slurry comprises a negative-electrode active material, a bonding agent, a solvent and a pore-forming agent, wherein the pore-forming agent is selected from one or more in azo-compound and / or sulfonylhydrazine compound. The slurry, the positive electrode and the battery have the advantages that under the condition of guaranteeing no reduction of the compaction density of a negative electrode piece, the porosity of the electrode piece can be increased, the uniformity of pore distribution is increased, the effective area of a liquid phase for conducting lithium ions is improved, the high energy density of the battery is guaranteed, simultaneously the rate capability and the low-temperature performance of the battery are improved and simultaneously the capacity is also improved.

Owner:BYD CO LTD

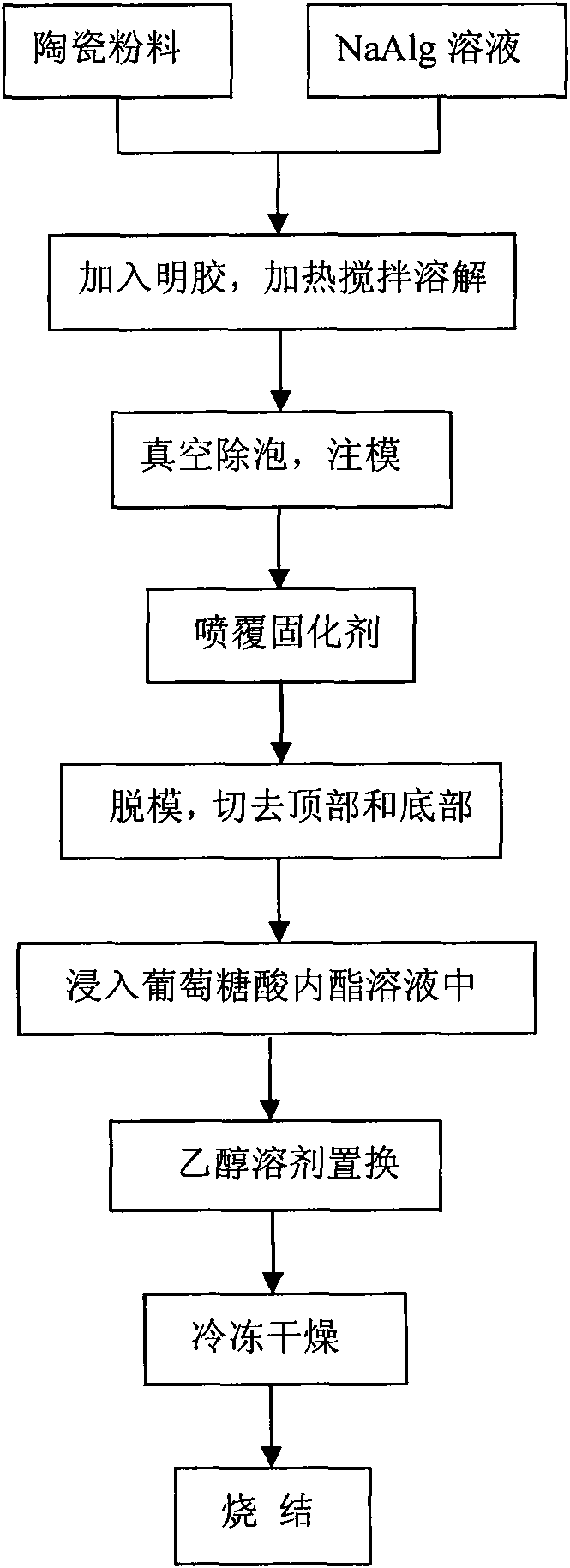

Porous ceramics and preparation method thereof

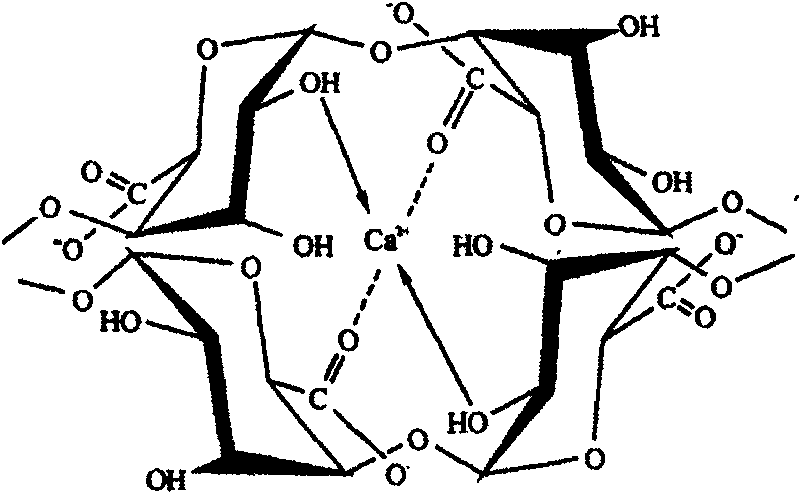

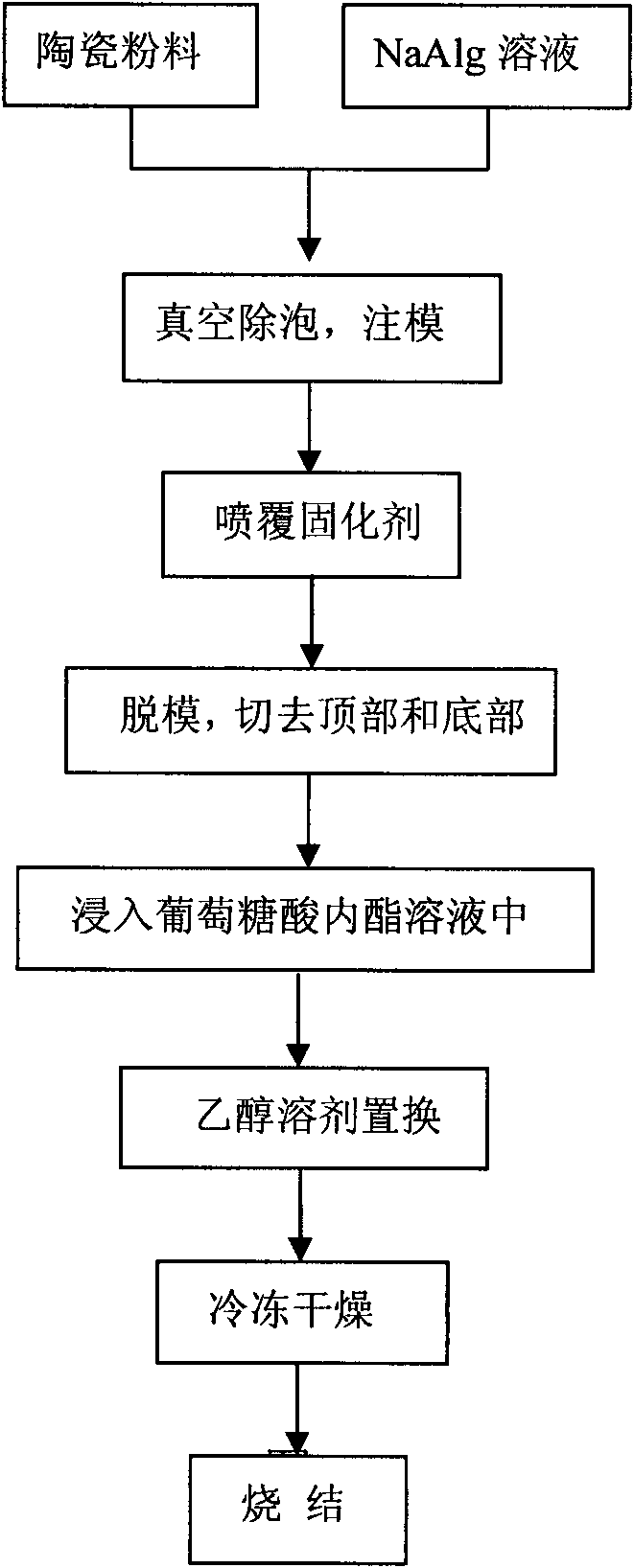

InactiveCN101618972ANo pollution in the processThe process is non-toxicCeramicwareFirming agentSolvent

The invention discloses a porous ceramics and a preparation method thereof. The preparation method comprises the following steps: (1) preparing a sizing agent with solid content of 2-30 percent by sodium alginate and ceramic powder; (2) injecting the sizing agent obtained in the step (1) into a mold, spraying a firming agent and obtaining a wet greenware A after demoulding; (3) obtaining a wet greenware B after dehydrating the wet greenware A obtained in the step (2) in a sour environment; (4) obtaining a wet greenware C after performing solvent exchange on the wet greenware B obtained in the step (3); and (5) obtaining the porous ceramics after drying and sintering the wet greenware C obtained in the step (4). The sample of the porous ceramics has high and controllable open porosity of 40-80 percent and has higher strength, thereby being capable of satisfying the requirements of machine tooling and use.

Owner:TSINGHUA UNIV

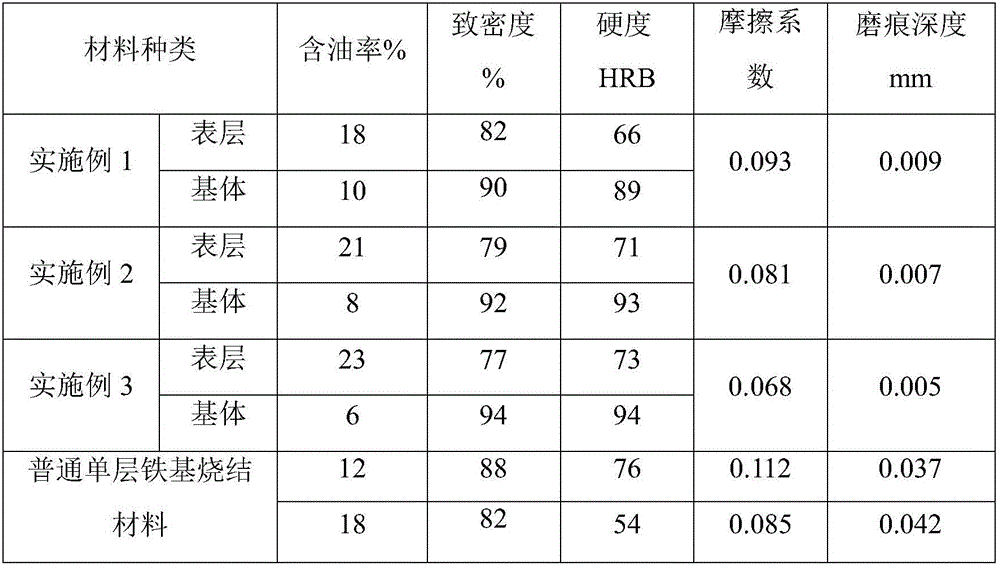

High-strength antifriction double-layered iron base powder metallurgy material and preparation method thereof

ActiveCN106041099AImprove carrying capacitySpeed up the flowTransportation and packagingMetal-working apparatusSurface layerHardness

The invention discloses a high-strength antifriction double-layered iron base powder metallurgy material and a preparation method thereof. The preparation method comprises the following steps that a densification enhancer is mixed in a matrix, so that a matrix material is dense and high in strength; a compound pore-forming agent is mixed in a surface layer to enable a surface layer material to be porous and oil-bearing, and besides, the requirements on the hardness and the wear resistance of the surface layer are met, and the contact interface and the lubricating condition of a friction pair are kept stable, so that the novel high-strength antifriction double-layered iron base powder metallurgy material is prepared. The bearing property, the wear resistance and the antifriction anti-seizing property of the iron base powder metallurgy material are improved remarkably, and high strength and a high lubricating property are effectively combined.

Owner:HEFEI UNIV OF TECH

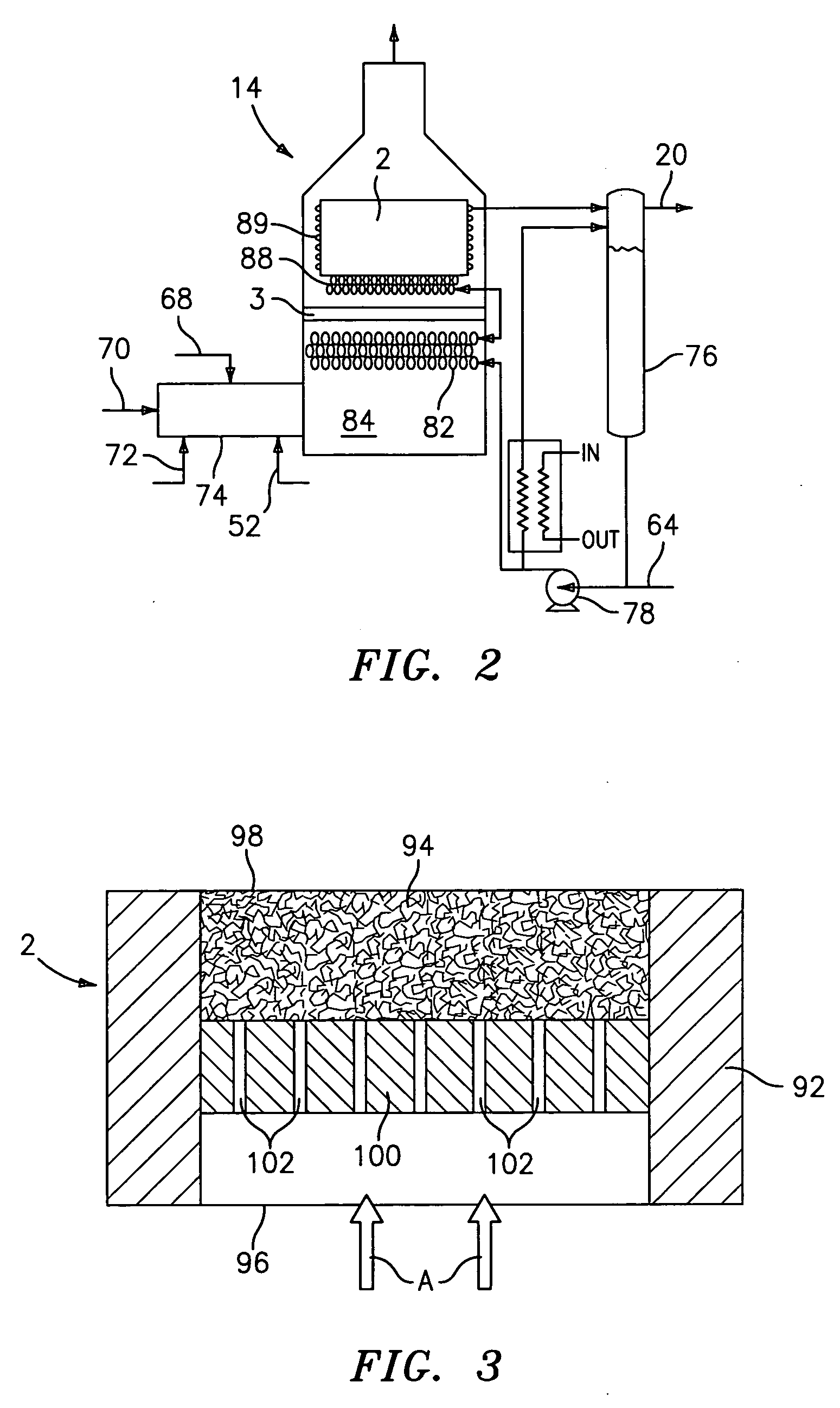

Burner for combusting the anode exhaust gas stream in a PEM fuel cell power plant

InactiveUS20050053816A1High open porosityIncreased catalytic surface areaBurnersFuel cells groupingAmbient pressureEngineering

A catalyzed burner is operative to combust an anode exhaust stream from a polymer electrolyte membrane (PEM) fuel cell power plant. The catalysts coated onto the burner can be platinum, rhodium, palladium, or mixtures thereof. The burner includes open cells which are formed by a lattice, which cells communicate with each other throughout the entire catalyzed burner. The burner is able to combust hydrogen in the anode exhaust stream. The catalyzed burner has a high surface area wherein about 70-90% of the volume of the burner is preferably open pores, and the burner has a low pressure drop of about two to three inches water from the anode exhaust stream inlet to the anode exhaust stream outlet. The burner assembly operates at essentially ambient pressure and at a temperature of up to about 1,700° F. (927° C.). The burner can combust anode exhaust during normal operation of the fuel cell assembly. The burner is not adversely affected by gasoline, gasoline combustion products, or anode bypass gas, the latter of which is a reformed fuel gas which is tapped off of the fuel cell stack fuel inlet line.

Owner:INT FUEL CELLS

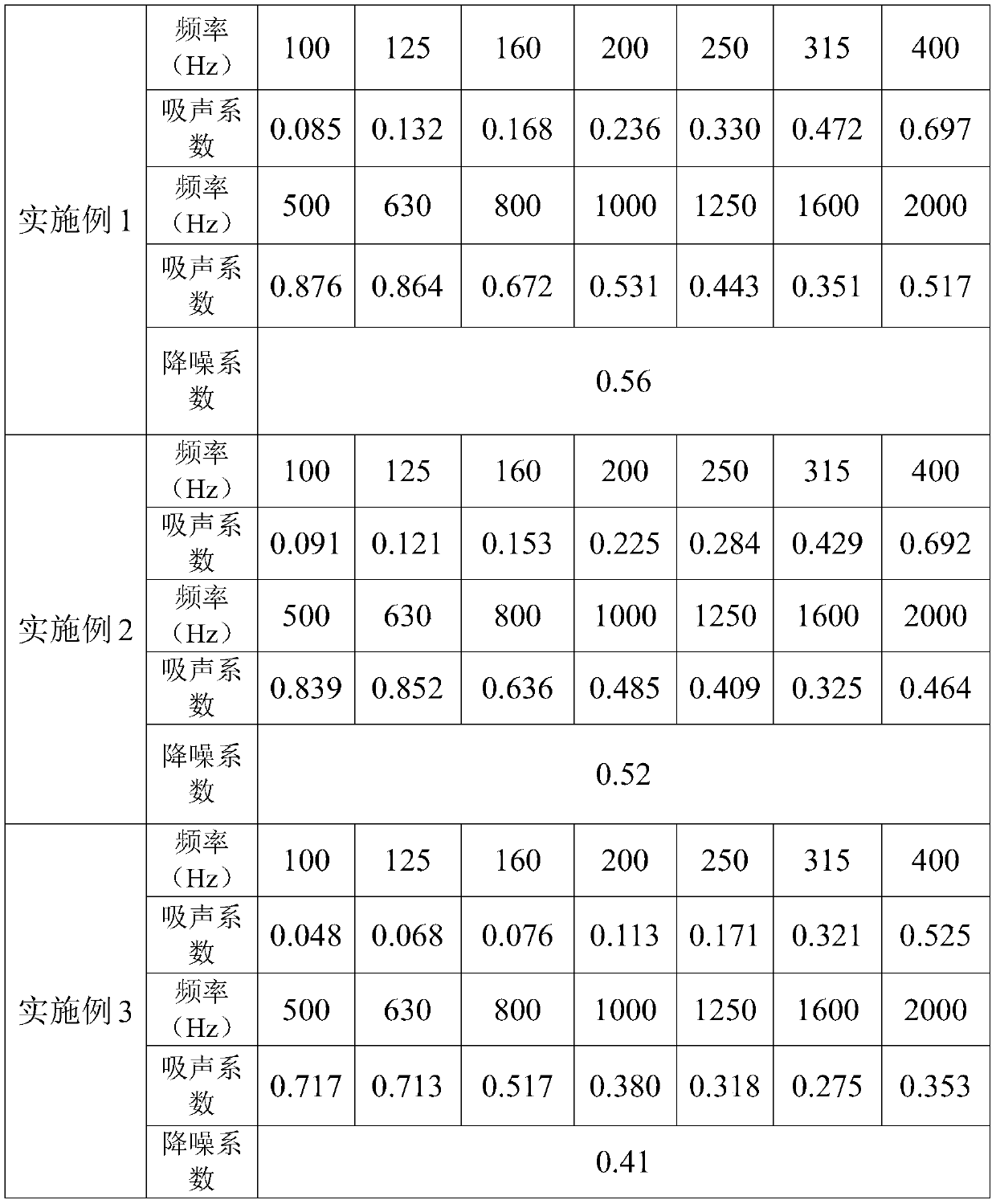

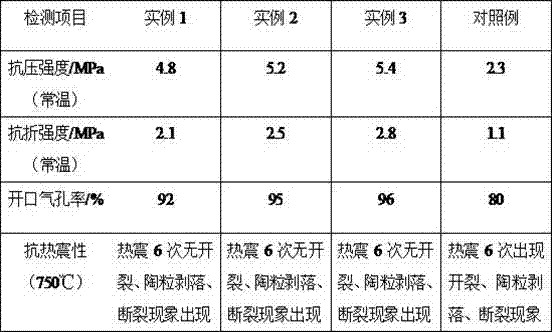

Low-cost ecological ceramic material having a plurality of sound absorbing structures and preparation method thereof

ActiveCN110342956AHigh open porosityImprove sound absorption performanceSound proofingCeramic materials productionPorosityWater vapor

The invention discloses a low-cost ecological ceramic material having a plurality of sound absorbing structures. The low-cost ecological ceramic material having the plurality of sound absorbing structuresis prepared from the following components: 22% to 27% offly ash, 13% to 18%ofcoal gangue, 8% to 12% ofred mud, 40%to 45% ofshale, 5%to 10% offeldspar, 0.2%to 2% of foaming agent, 0.5%to 3% of binder, 7%to 12% of pore forming agent, and 0% to 1% ofsurfactant; a variety of pore structures are arranged, and water vapor in the environment is absorbed to adjust the humidity of the air. The invention further discloses a preparation method of the low-cost ecological ceramic material.A perforated plate sound absorbing structure, a microperforated resonance sound absorbing structure, and a thin plate resonance sound absorbing structure are formed by three pore-forming methods of mechanical punching, pore forming agent, and foaming agent respectively, the open porosity of the material is increased, the high-frequency sound absorption effect is improved, the plurality of sound absorbing structures improve the sound absorption effect of the low and medium frequency, the preparation material islow in cost, and the environment-friendly effect is conformed.

Owner:SHANXI TIANHE NEW MATERIAL TECH CO LTD

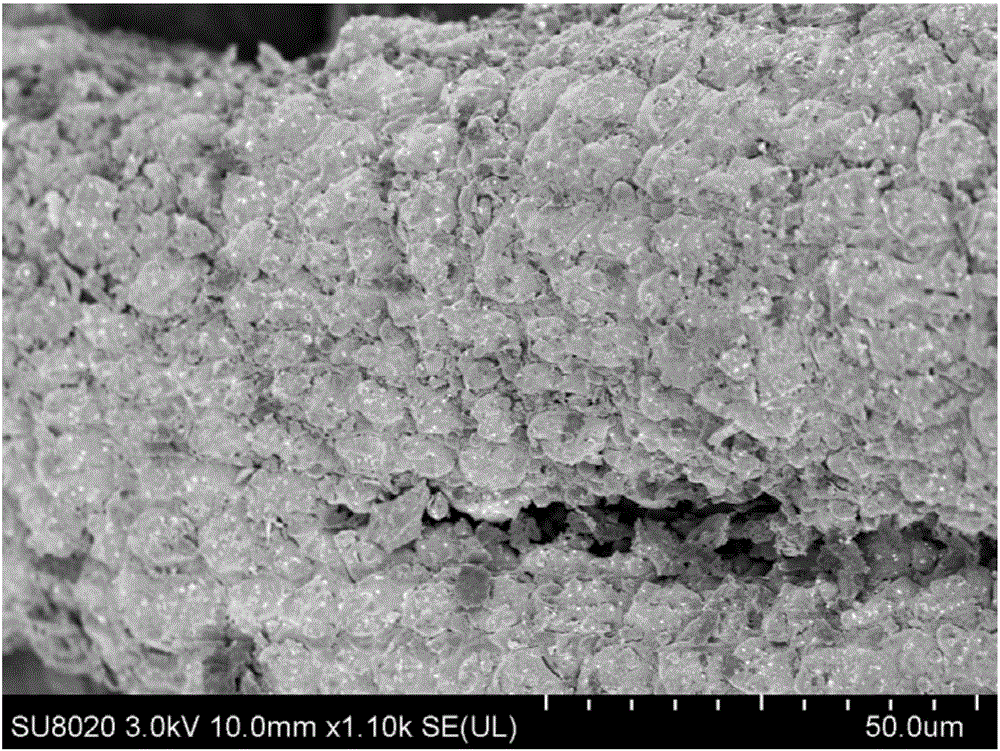

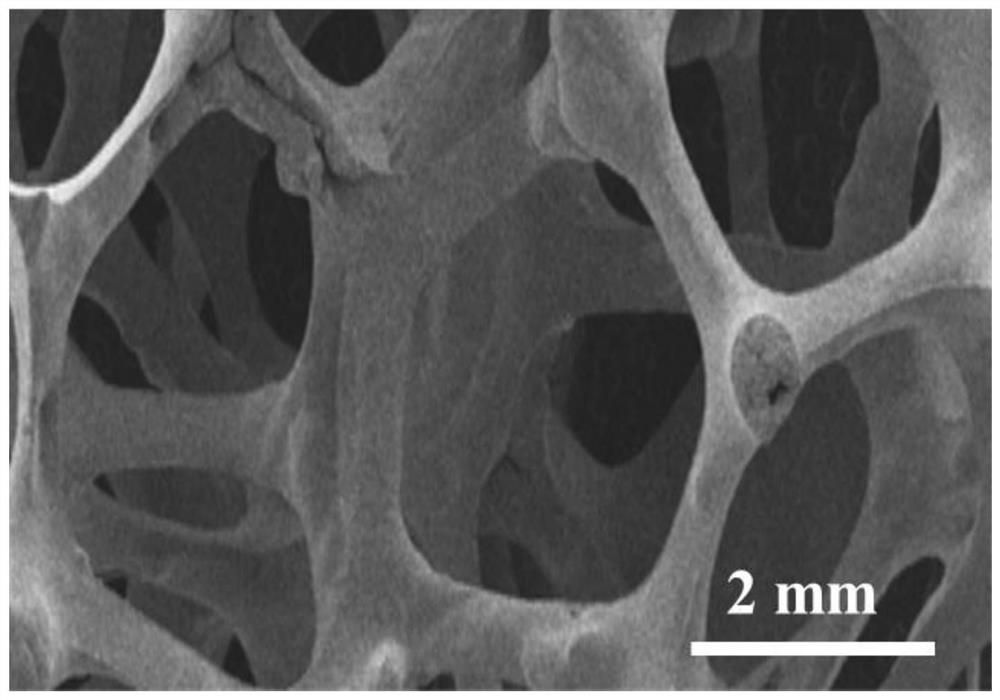

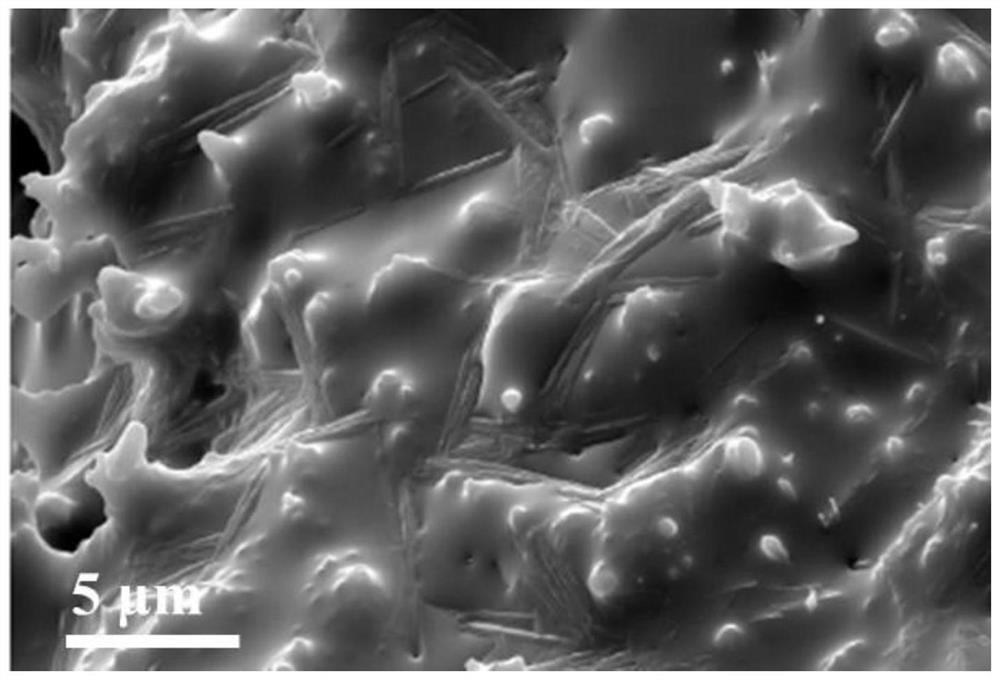

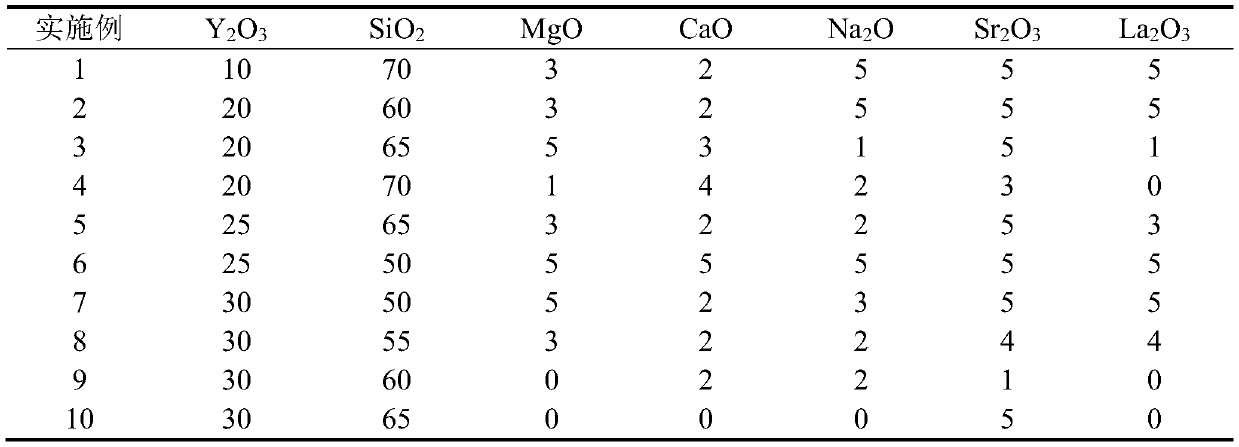

Preparation method of zirconium oxide-mullite high-porosity ceramic material

ActiveCN107903080AAvoid introducingImprove high temperature resistanceCeramicwareZirconium hydrideMullite

The invention discloses a preparation method of a zirconium oxide-mullite porous ceramic material. The preparation method is characterized in that aluminum oxide and zircon sand are taken as main rawmaterials, yttrium oxide is taken as a stabilizer, aluminum fluoride is taken as an additive, a forming mode combining polyurethane foam dipping and gel solidification is adopted, and the zirconium oxide-mullite porous ceramic material with a needle-shaped mullite whisker structure is prepared through an in-situ synthesis technology; and a solvent in a blank is volatilized and organic substances are split at a high temperature to form a porous structure which has the characteristics of being high in porosity (greater than 80%), uniform in aperture distribution, excellent in high-temperature mechanical property and excellent in thermal impact resistance.

Owner:武汉钢铁有限公司

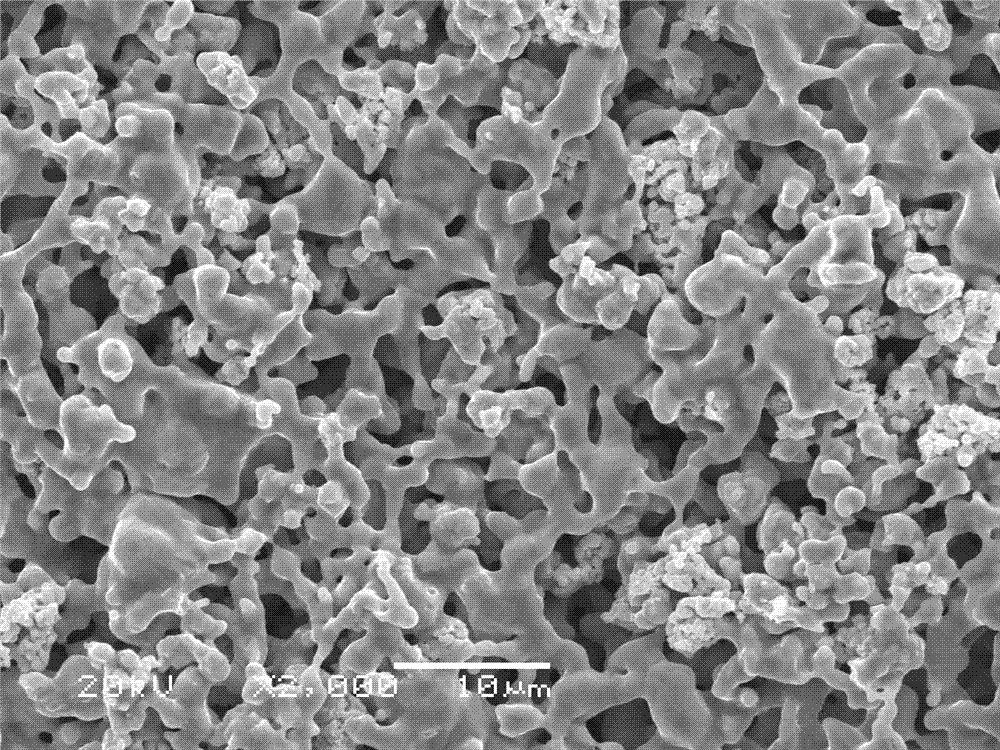

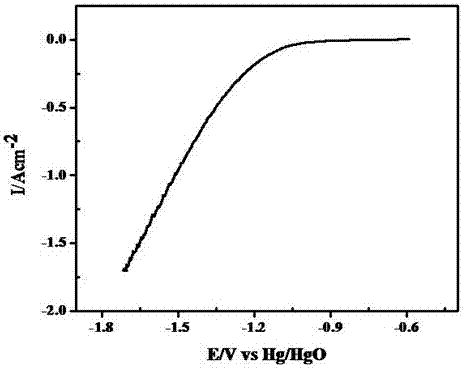

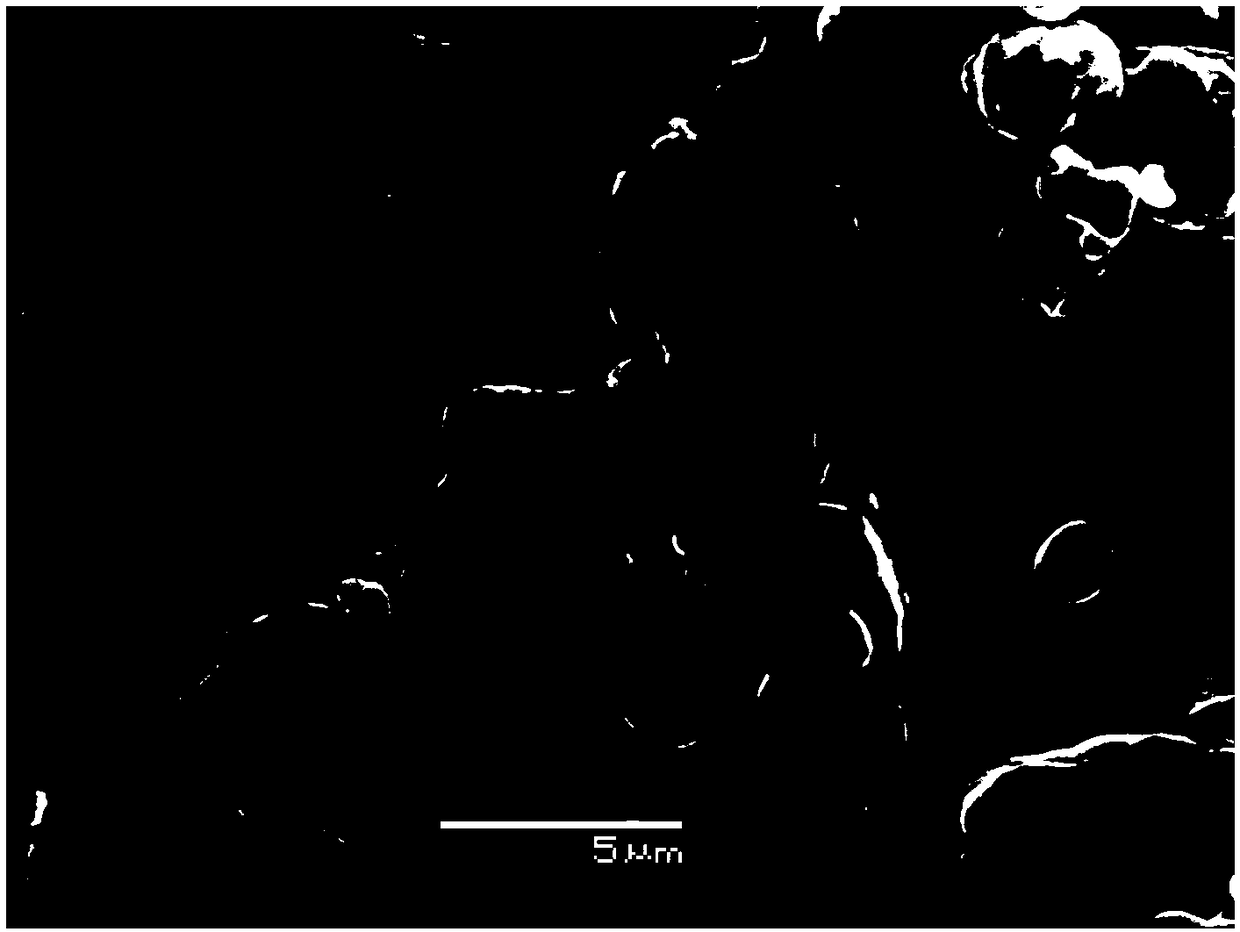

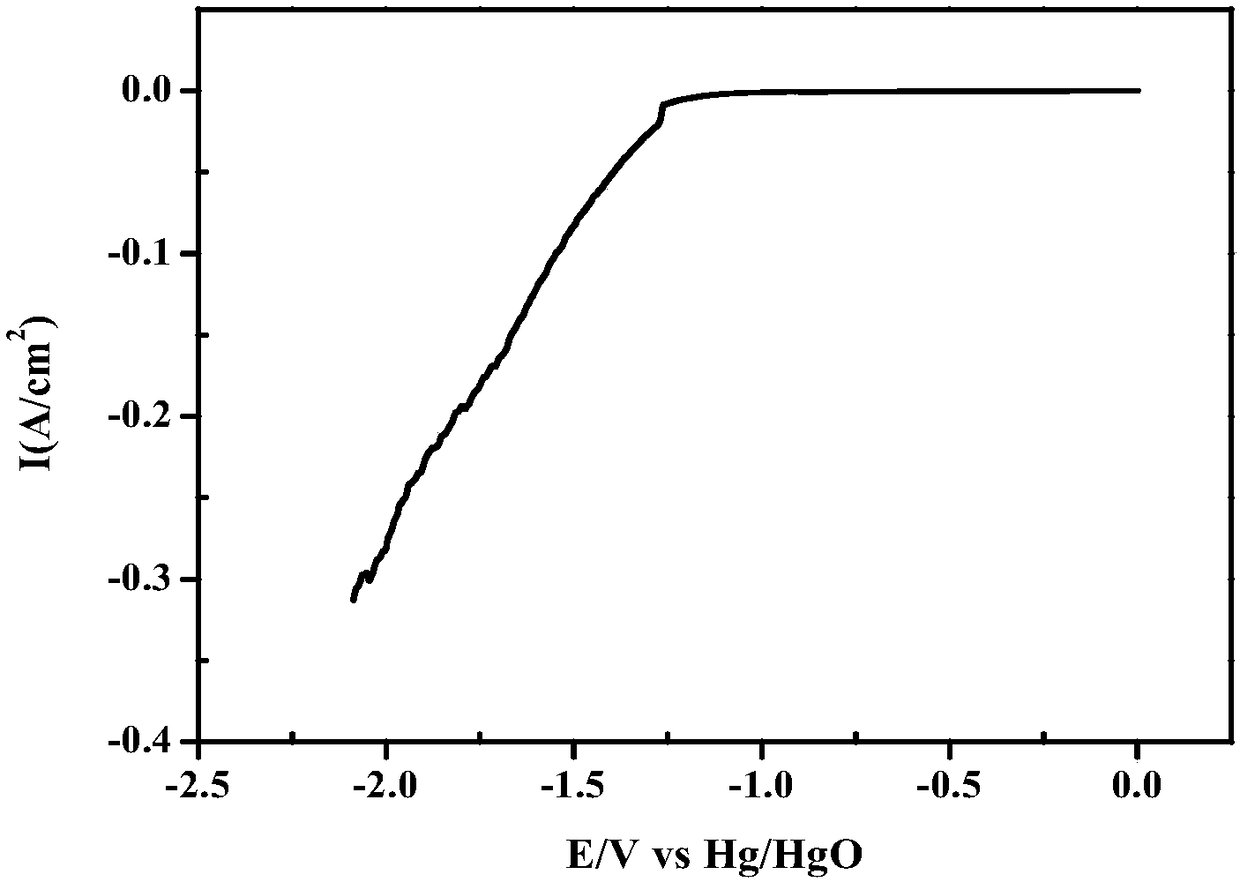

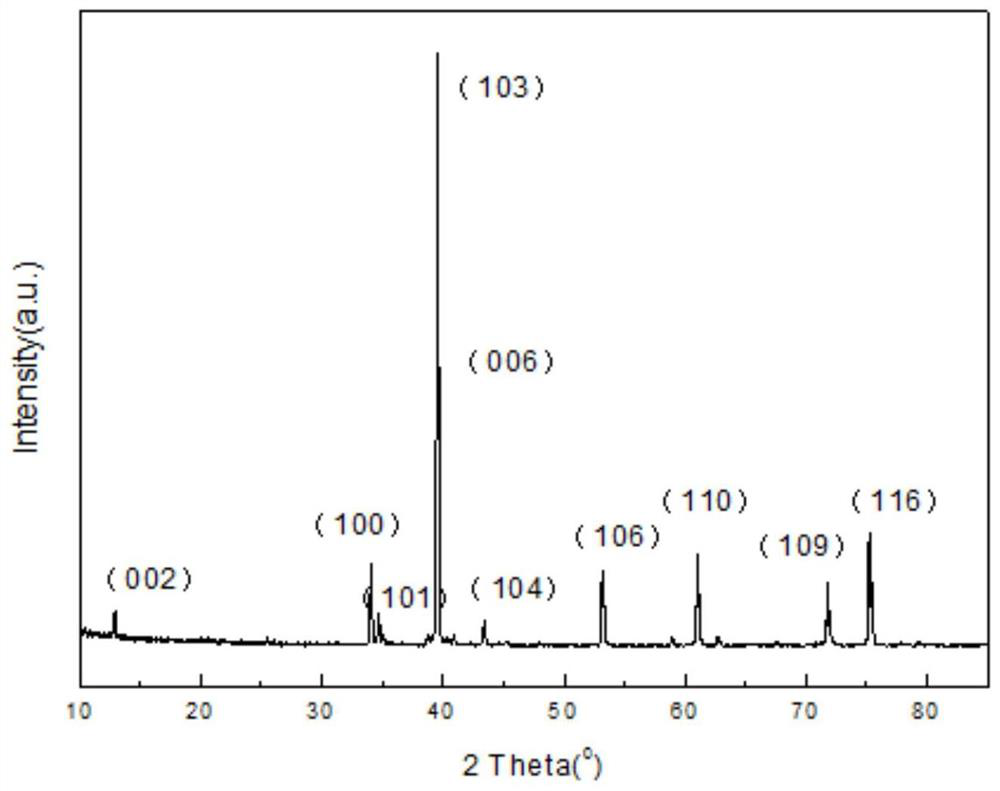

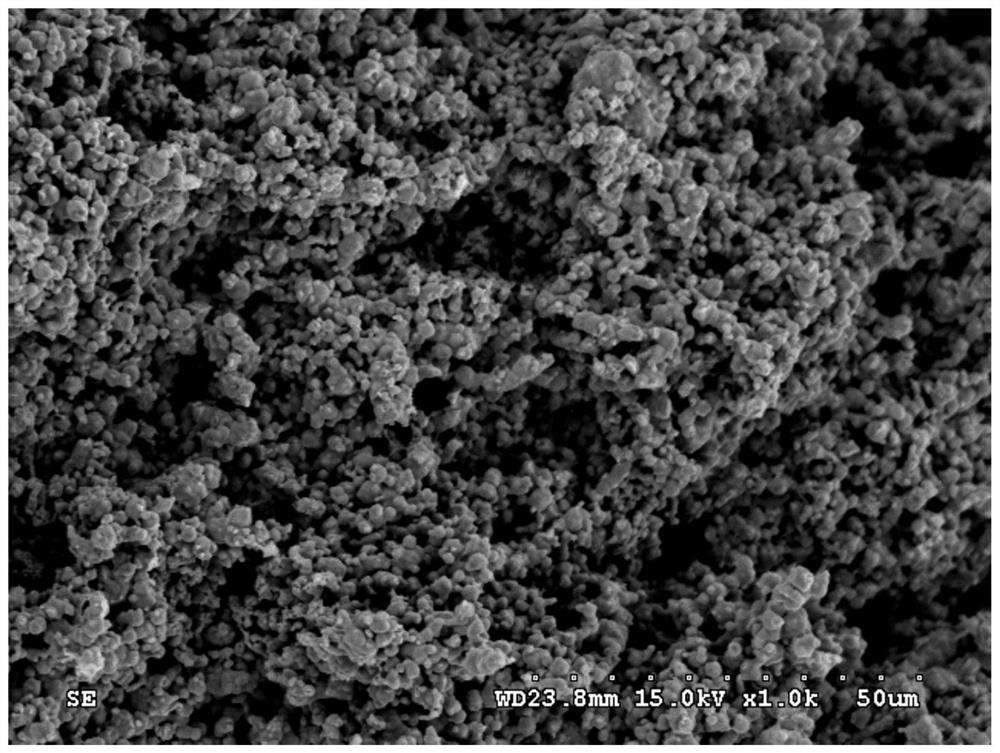

Preparation method of porous nickel base alloy electrolysis hydrogen evolution cathode material

InactiveCN107268019ALarge specific surface areaImprove hydrogen evolution catalytic activityElectrode shape/formsElectrolysisOverpotential

The invention discloses a preparation method of a porous nickel base alloy electrolysis hydrogen evolution cathode material. The preparation method is characterized in that four kinds of high-purity element powder, by mass percent, namely, 20-42% of Cr, 4-12% of Fe, 1-6% of Co and the balance Ni are mixed uniformly and dried, then compression moulding is carried out and thus a green body is obtained, and by using the solid phase partial diffusion principle, the green body is subjected to vacuum sintering, and a Ni-Cr-Fe-Co porous material is synthesized after reaction. The prepared porous material has the advantages of high specific surface area, low hydrogen evolution overpotential, relatively excellent corrosion resistance, good chemical stability, high mechanical strength and the like, and the preparation method is simple and environment-friendly, and has great significance in the development and application of hydrogen energy.

Owner:XIANGTAN UNIV

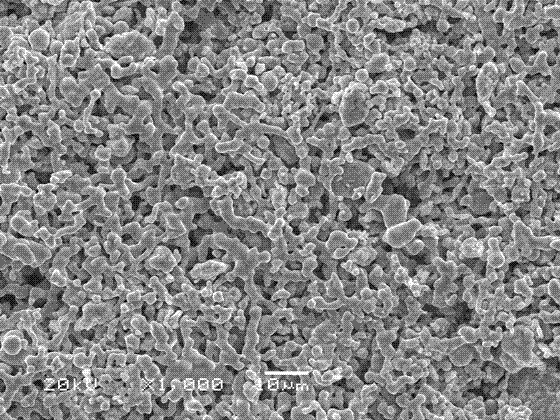

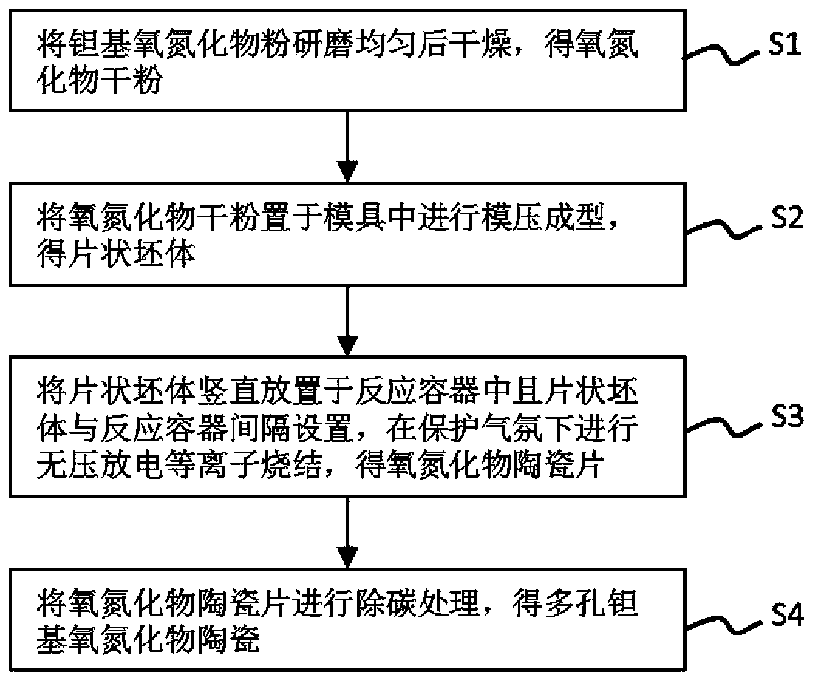

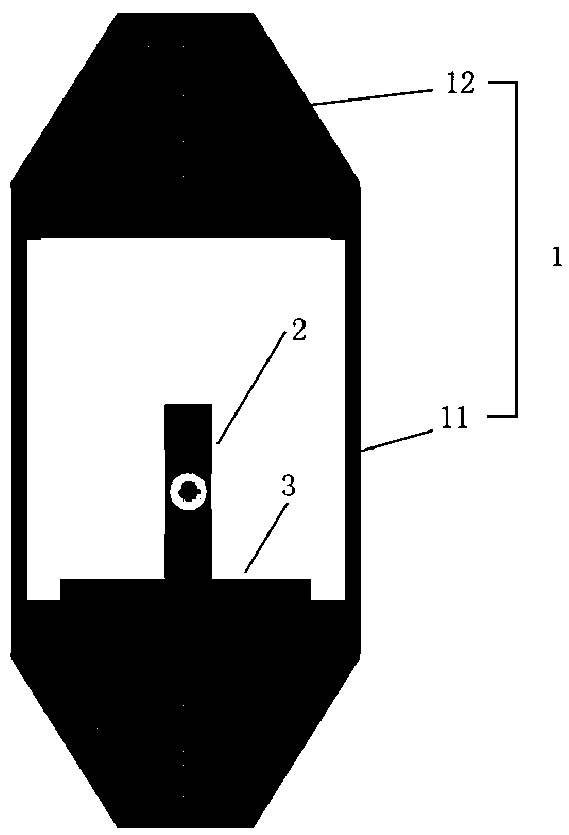

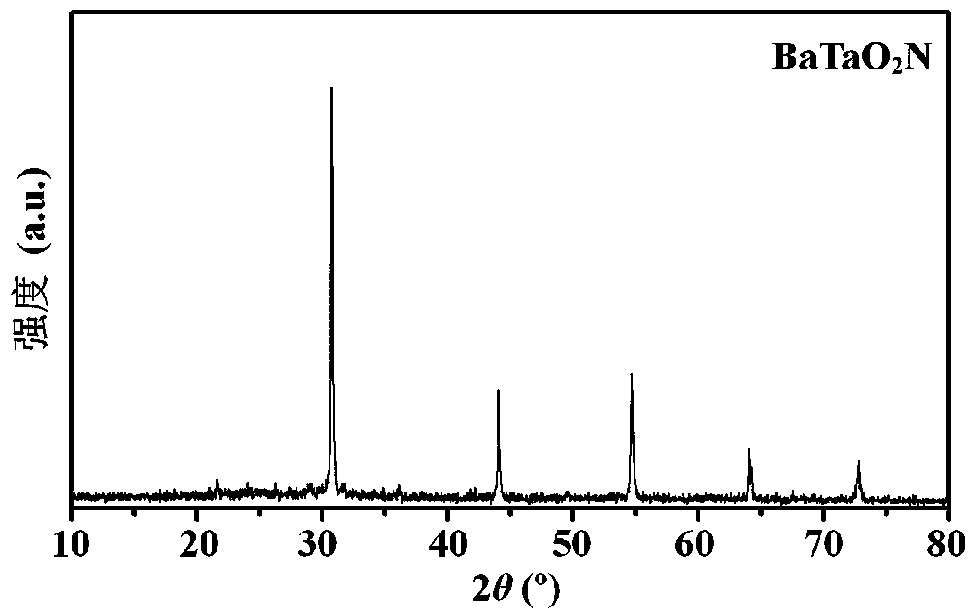

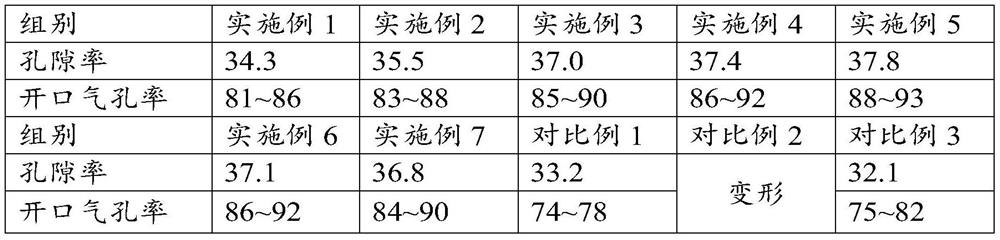

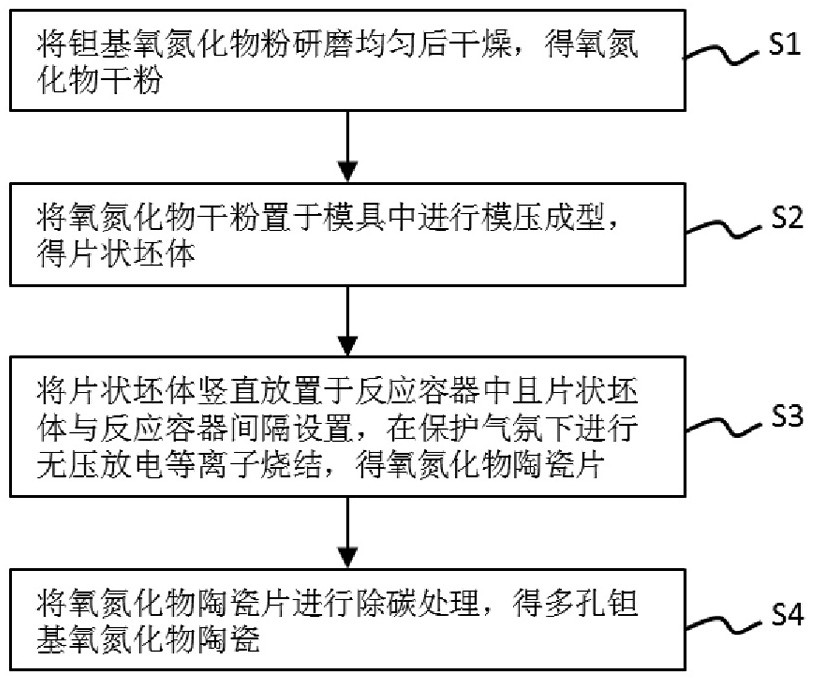

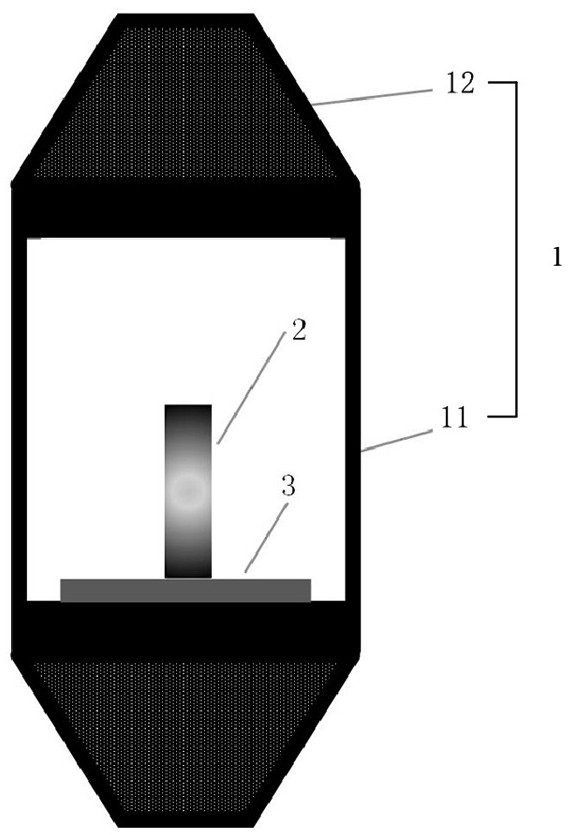

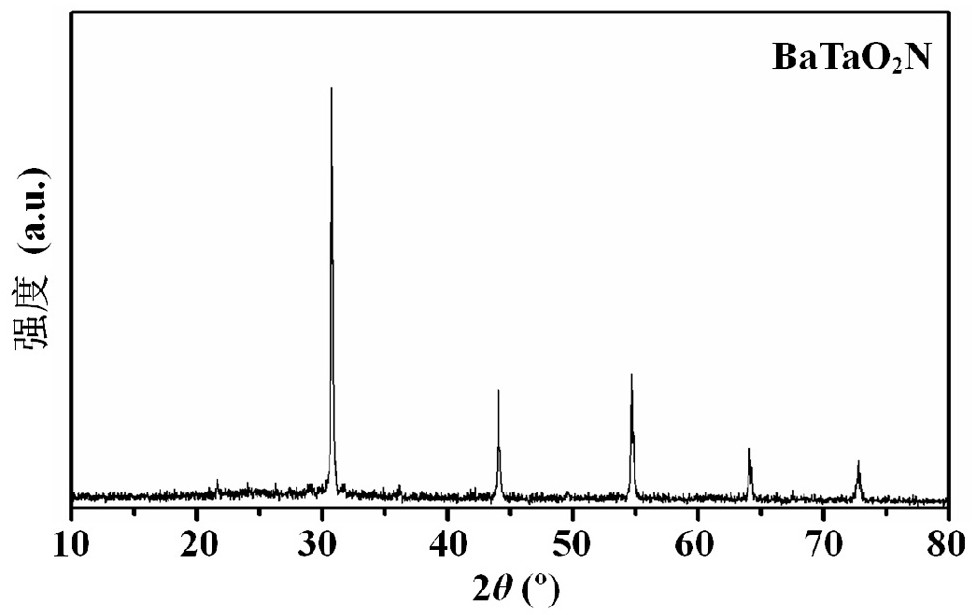

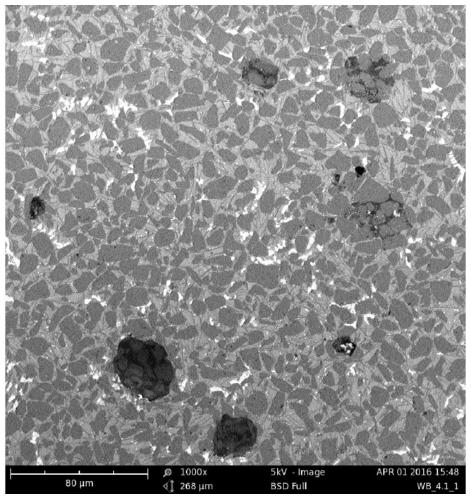

Porous tantalum-based oxynitride ceramic, and preparation method thereof

ActiveCN110156474ANo carburizationImprove heating efficiencyCeramicwarePorous tantalumHeat transfer efficiency

The invention discloses a preparation method of a porous tantalum-based oxynitride ceramic. The preparation method comprises following steps: 1, a tantalum-based oxynitride powder is grinded to be uniform, and is dried so as to obtain an oxynitride dry powder; 2, the oxynitride dry powder is introduced into a die for compression moulding to obtain sheet shaped blank bodies; 3, the sheet shaped blank bodies are vertically placed in reaction containers, wherein the sheet shaped blank bodies and the reaction containers are arranged at intervals, at a protective atmosphere, no-voltage spark plasmasintering is carried out so as to obtain oxynitride ceramic sheets; and 4, the oxynitride ceramic sheets are subjected to decarbonizing so as to obtain the porous tantalum-based oxynitride ceramic. The advantages of the preparation method are that: the sintering time is short, heat transfer efficiency is high, and product purity is high.

Owner:NAT UNIV OF DEFENSE TECH

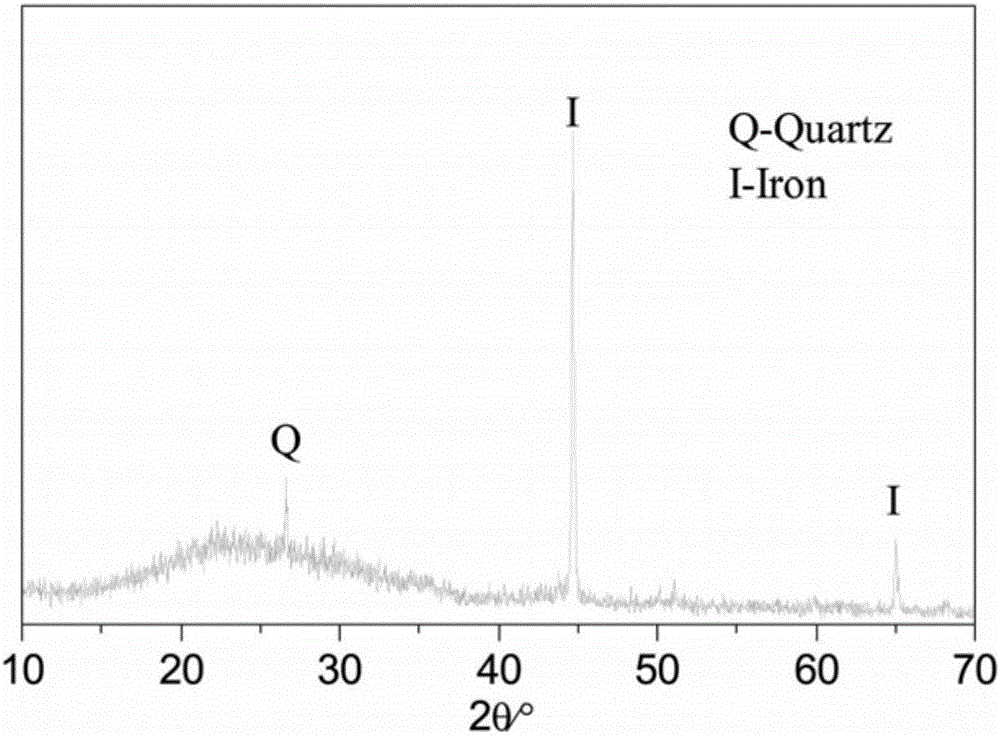

Method for preparing Fe/C composite material of porous structure by using sedimentary siderite

ActiveCN105817212AHigh particle strengthHas a bonding effectOther chemical processesWater contaminantsPorosityMagnetic susceptibility

The invention discloses a method for preparing a Fe / C composite material of a porous structure by using sedimentary siderite .The method is characterized in that the Fe / C composite material is obtained by using the low-grade sedimentary siderite and biomass powder as raw materials, performing mixing and forming and then performing pyrolysis and reduction reaction at the temperature of 650-900 DEG C under a reducing atmosphere, and the main phase of the material is biomass charcoal and zero-valent iron .The Fe / C composite material of the porous structure has high open porosity, high magnetic susceptibility, high adsorption and high biochemical activity, is a cheap biological carrier material having biological activity and adsorption performance, has a great application prospect in slightly polluted water purification and is especially suitable for simultaneous denitrification treatment of an eutrophic water body.

Owner:HEFEI UNIV OF TECH

Gradient pore silicon carbide ceramic filter plate and preparation method thereof

InactiveCN107266113AGood hanging effectHigh mechanical strengthCeramicwarePorosityCarboxymethyl cellulose

The invention discloses a gradient pore silicon carbide ceramic filter plate and a preparation method thereof, and belongs to the field of filtering media. Coarse pore, medium pore and fine pore soft polyurethane foam bodies are cut into the same size of wafer shapes, the wafer shapes are in turn soaked with a sodium hydroxide solution and a sodium carboxymethyl cellulose solution to obtain coarse pore, medium pore and fine pore pretreated soft polyurethane foam bodies, silicon carbide, kaolin and the like are mixed by ball milling, all size levels of composite powder are screened, and respectively evenly mixed with deionized water and aluminium dihydrogen phosphate to obtain all size levels of ceramic slurry, the all size levels of ceramic slurry are added into respectively the coarse pore, medium pore and fine pore pretreated soft polyurethane foam bodies for soaking, rolling and stacking neatly according to the order of coarse pores, medium pores and fine pores to obtain a combined foam body, the combined foam body is dried, and the gradient pore silicon carbide ceramic filter plate is prepared by hanging slurry and drying of the combined foam body. The beneficial effects are that the gradient pore silicon carbide ceramic filter plate has high strength, ceramsite is not easy to flake off, the opening porosity is high, and the pores are not easy to be plugged.

Owner:常州市瑞泰物资有限公司

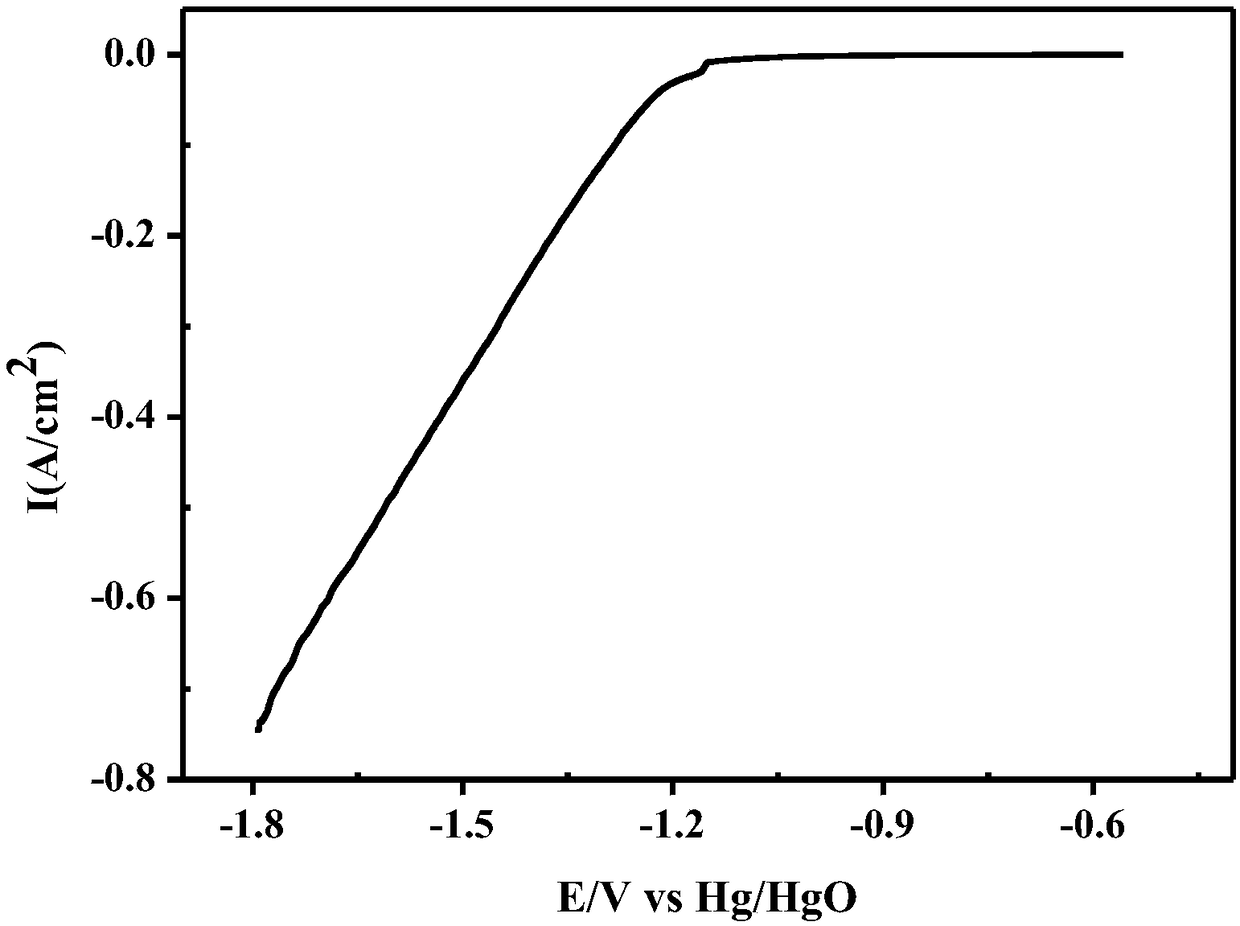

Porous nickel-based cathode material for hydrogen evolution reaction and preparation method thereof

The invention provides a porous nickel-based cathode material for a hydrogen evolution reaction and a preparation method of the porous nickel-based cathode material for the hydrogen evolution reaction. Ni, Mo, Fe and W are evenly mixed and dried, and a green body is obtained after compression forming, wherein the purities of the Ni, the Mo, the Fe and the W are 99.5% or over, and the mixture of the Ni, the Mo, the Fe and the W comprises, by mass, 12%-25% of Mo, 5%-15% of Fe, 1%-10% of W and the balance Ni; and a vacuum sintering reaction is conducted on the green body through the solid phase partial diffusion principle, and then the Ni-Mo-Fe-W porous material is synthesized. The prepared novel porous nickel-based cathode material for the hydrogen evolution reaction is abundant and uniform in pore and has the advantages of being large in specific surface area, low in hydrogen evolution overpotential, good in catalytic performance, excellent in corrosion resistance, stable in work performance, simple and environment-friendly in preparation technology and the like; and besides, the preparation cost is low, and the preparation technology is simple and easy to implement.

Owner:XIANGTAN UNIV

Ni-Fe-Mo-Cu porous material and preparation method thereof

ActiveCN108315596AMany poresEvenly distributedTransportation and packagingMetal-working apparatusEnvironmental resistanceElectrolysis

The invention discloses a preparation method of a Ni-Fe-Mo-Cu porous material. The preparation method comprises the following steps: uniformly mixing powder with the granularity of 3 to 10mu m of fourtypes of high-purity elements including Ni, Fe, Mo and Cu according to the mass percent ratio of 15 to 35 percent of the Fe, 1 to 8 percent of the Mo, 1 to 7 percent of the Cu and the balance of theNi, and drying; then doping stearic acid and pressing and molding to obtain a green body; carrying out vacuum sintering on the green body by utilizing a solid-phase partial diffusion principle to prepare the Ni-Fe-Mo-Cu porous material. The porous material prepared by the preparation method has the advantages of abundant and uniformly-distributed pores, relatively high specific surface area and mechanical strength, relatively low hydrogen evolution overpotential and relatively good corrosion resistance property and chemical stability; a preparation technology is simple and environmentally friendly, has potential application value in the fields of electrolysis hydrogen evolution and industrial filtering and has great significance.

Owner:XIANGTAN UNIV

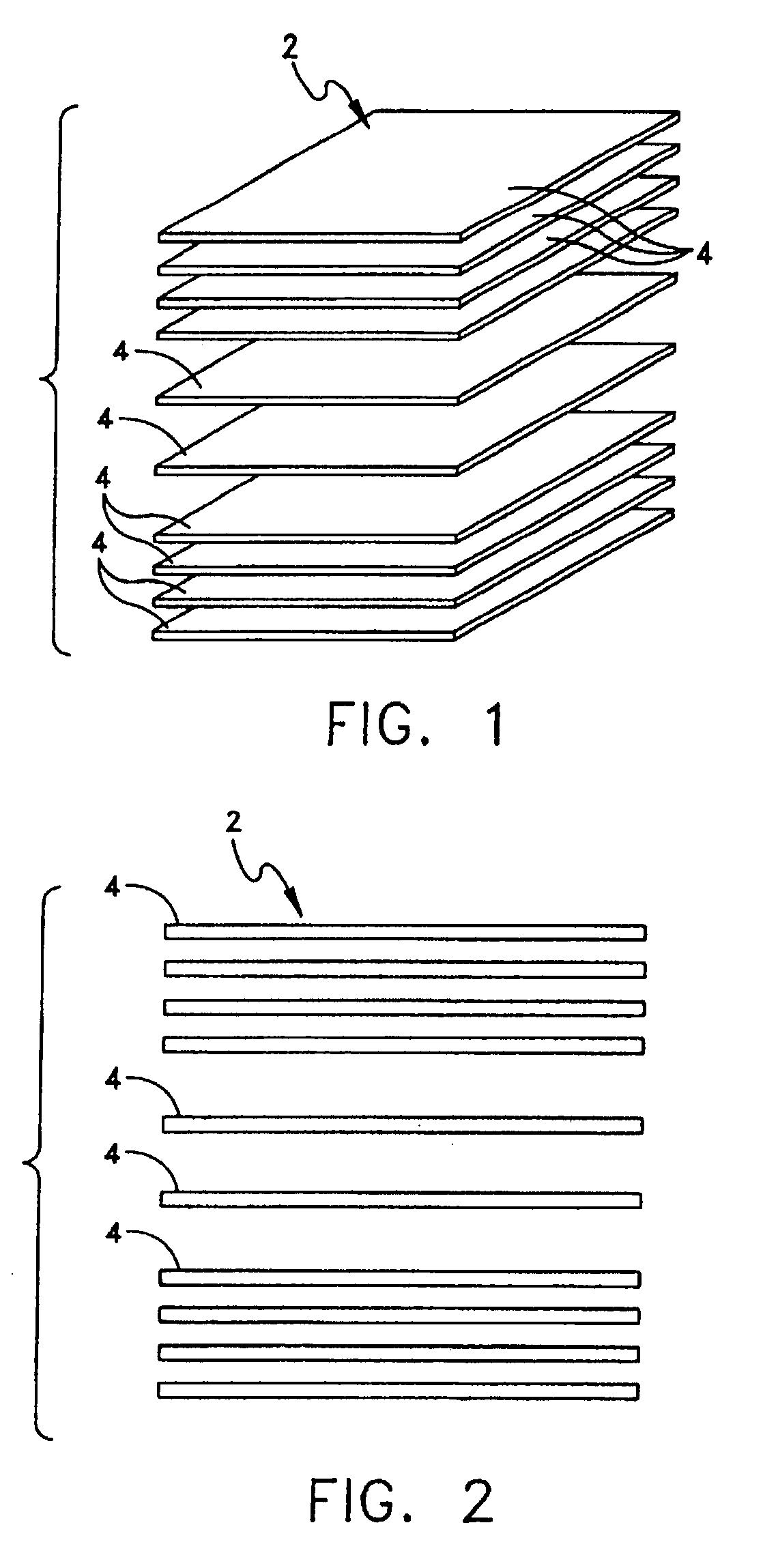

Method of using a water transport plate

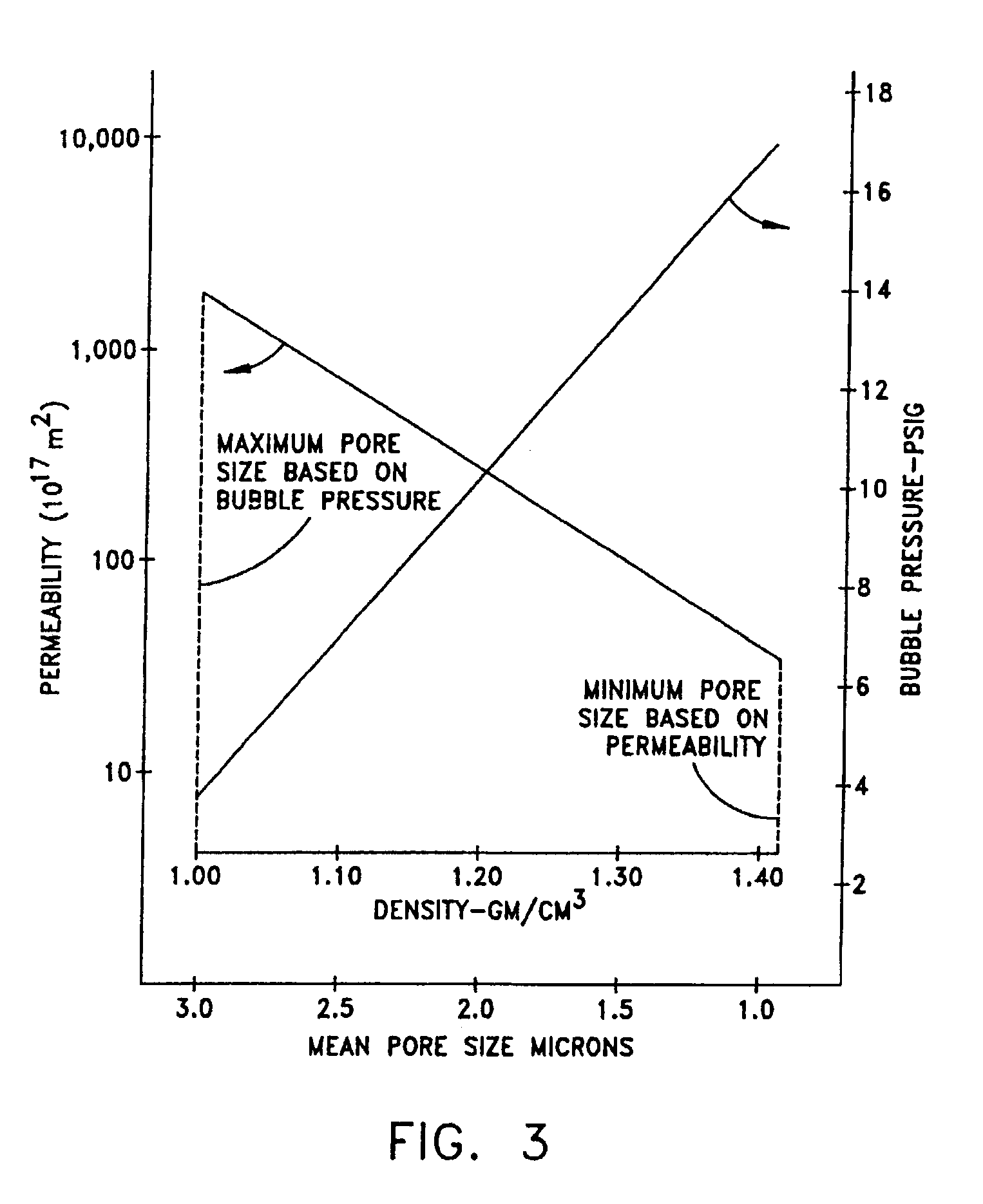

InactiveUSRE39348E1Improve balanceHigh open porositySolid electrolytesFinal product manufacturePorosityFuel cells

A water transport plate is provided with optimized physical characteristics to greatly improve fuel cell operation. In a preferred method of manufacturing, graphite powder, reinforcing fibers, cellulosic fibers, and a thermosetting resin are mixed with a liquid to form a slurry and showered onto a screen to form a planar sheet which is dried to form paper. The paper is cut into the desired size and is laid-up. The lay-up is laminated with pressure and heat, carbonized, and graphitized to form a water transport plate for later machining as desired. The finished water transport plate exhibits optimal physical characteristics for bubble pressure, water permeability, median pore size, porosity, thru-plane resistivity and compressive yield strength.

Owner:AUDI AG

Prealloyed 3D formed high-entropy alloy porous material and preparation method thereof

InactiveCN111036913ASolve uneven distributionImprove sintering performanceAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysOxidation resistant

The invention provides a prealloyed 3D formed high-entropy alloy porous material and a preparation method thereof. The prealloyed 3D formed high-entropy alloy porous material comprises CrMoNbTaV, theporous material adopts high-entropy alloy powder as a raw material, a three-dimensional grid structure is used as a frame, and a porous sintered body sintered by the high-entropy alloy powder is nested inside the porous material. According to the scheme, the high-entropy alloy powder produced by an atomization method is uniform in chemical composition and fine in crystallization, and high-qualitypowder raw materials are provided for preparing a high-performance porous filtering material by powder metallurgy at the rear; and moreover, the prepared porous material has good physical and chemicalstability and good corrosion resistance, and provides stable guarantee for subsequent filtration. The open porosity is high, the specific surface area is large, the sintering time is shortened on a large scale, the corrosion resistance and the oxidation resistance are high, the chemical stability and the mechanical strength are good, the self-corrosion is not easy, the process is simple and environment-friendly, and the batch production can be realized.

Owner:永州市产商品质量监督检验所

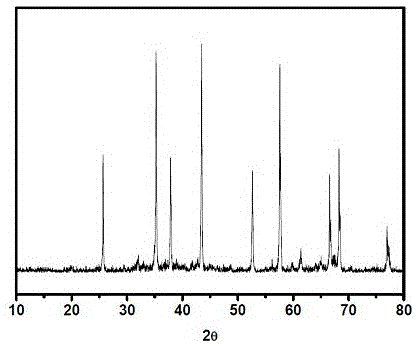

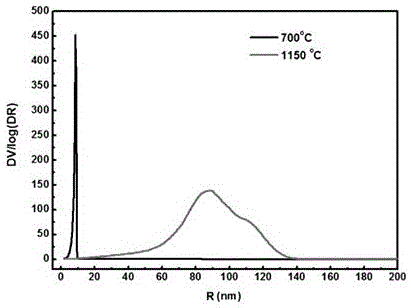

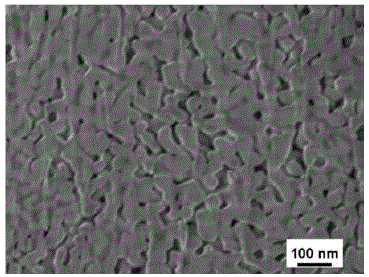

Alpha crystal form nano alumina porous ceramic with high apparent porosity and preparation method thereof

The invention discloses an alpha crystal form nano alumina porous ceramic with a high apparent porosity and a preparation method thereof, and belongs to the field of nano porous materials. The preparation method comprises the following steps: filling gamma-Al2O3 powder into a graphite mould, placing the mould into a discharging plasma sintering furnace, loading an axial load pressure of 30 to 100 MPa, sintering the powder in vacuum at a temperature of 1100 to 1250 DEG C, maintaining the temperature for 3 to 5 minutes; or placing a gamma-Al2O3 blank in a conventional air furnace, sintering the blank under zero pressure at a temperature of 1350 to 1450 DEG C, and maintaining the temperature for 30 to 120 minutes to obtain the alpha crystal form nano alumina porous ceramic with a high apparent porosity; wherein the average particle size of the porous ceramic is smaller than 160 nm, and the apparent porosity is more than 95%. The provided preparation method has the advantages of low cost and good repeatability. The porous structure is formed without any sintering aid or pore forming agent. The prepared alumina porous ceramic has the advantages of evenly-distributed pores, small pore diameter, high apparent porosity (more than 95%), and excellent mechanical properties.

Owner:HUBEI UNIV OF TECH

Ni-Cr-Al-Cu porous material and manufacturing method thereof

ActiveCN108380882AOvercome efficiencyOvercome mechanical propertiesElectrode shape/formsAl powderHydrogen

The invention discloses a manufacturing method of an Ni-Cr-Al-Cu porous material. The manufacturing method comprises the steps that a powder reaction synthesis method is adopted, and high-purity Ni powder, high-purity Cr powder, high-purity Al powder and high-purity Cu powder are prepared in a certain ratio, wherein the total content of the Cr powder, the Al powder and the Cu powder is 22wt%-45wt%of the total content; after the prepared powder is uniformly mixed and dried, stearic acid is added, and drying is conducted again; pressure forming is conducted, so that a green blank is obtained; and vacuum sintering is conducted on the green blank by the use of the solid phase partial diffusion principle, so that the Ni-Cr-Al-Cu porous material is manufactured. The porous material manufacturedaccording to the manufacturing method has the low hydrogen evolution overpotential, the large specific surface area, excellent corrosion resistance, good catalytic performance and stable working performance, and a manufacturing technology of the porous material is simple and environmentally friendly, has the potential application value in the fields of hydrogen electrolysis evolution and industrial filtering, and has an important significance.

Owner:XIANGTAN UNIV

Porous silicon nitride capillary core for a loop heat pipe

ActiveCN106066131BGood chemical stabilityImprove acid and alkali corrosion resistanceIndirect heat exchangersDecompositionChemical stability

A porous silicon nitride capillary core for a loop heat pipe is formed by firing raw materials including silicon nitride powder, a sintering aid and a pore forming agent, wherein the content of silicon nitride is not smaller than 90% by weight. The average grain size of the silicon nitride powder ranges from 0.1 micrometer to 10 micrometers, and the proportion of the alpha-phase silicon nitride is larger than 90%. Micropores included in the porous silicon nitride capillary core communicate with one another, the pore diameter of the micropores ranges from 0.5 micrometer to 5 micrometers, and the open porosity is larger than 50%. The porous silicon nitride capillary core is formed by sintering the silicon nitride powder, has good chemical stability and is resistant to corrosion of acid and alkali, decomposition of working media in the loop heat pipe can be effectively restrained, and the service life of the loop heat pipe is prolonged. Meanwhile, the porous silicon nitride capillary core is high in brittleness and good in machining performance, the surface micropores cannot be closed during outer wall finish machining, and the high open porosity of the capillary core is guaranteed.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Method for preparing mullite porous ceramics by freeze-drying method

The invention relates to a method for preparing mullite porous ceramics by a freeze-drying method. The method comprises the following steps: (1) adding modified opoka, alpha-alumina and sintering aidsinto an agate jar, and ball milling at a rate of 300 revolutions per minute for 2 hours by using a planetary ball mill so as to obtain uniformly mixed powder; (2) mixing the uniform powder and water,and preparing ceramic slurry having the starch content of 6-10 vol%; (3) rapidly pouring the prepared ceramic slurry into a mold of a certain shape for casting and molding, performing vacuum degassing, removing bubbles in the slurry, placing the sample in a cryogenic refrigerator, enabling the sample to be completely frozen, and demolding; (4) performing freeze drying on the sample in a vacuum freeze drier at the temperature of 30 DEG C below zero at a vacuum degree of 10 Pa for 36 hours; (5) sintering, and cooling, thereby obtaining the mullite porous ceramics. According to the method disclosed by the invention, the opoka serves as the main ingredient and a pore forming material, so that the void ratio of the mullite ceramics can be effectively improved, the usage amount of the adhesiveis reduced, and the strength of the product is further improved.

Owner:WUHU YUANKUI NEW MATERIAL TECH CO LTD

Method for preparing mullite porous ceramic by alumina fiber reinforced opoka

The invention relates to a method for preparing a mullite porous ceramic by alumina fiber reinforced opoka. The method includes the steps: (1) placing raw materials including modified opoka, aluminumhydroxide, rho-alumina, alumina fibers and sintering aids according to the weight ratio of 3:4:0.9:0.1:0.1 into an agate jar, and performing ball-milling for 3 hours at the speed of 300rpm by a planetary ball mill to obtain uniformly mixed powder; (2) adding water into the powder and preparing ceramic slurry with the solid content of 55%; (3) rapidly pouring the prepared ceramic slurry into a diein a certain shape, casting and forming the ceramic slurry, performing vacuum degassing, removing bubbles in the slurry and then drying a sample at room temperature for 48 hours to obtain a ceramic green body; (4) sintering and cooling the ceramic green body to obtain the mullite porous ceramic. The mullite porous ceramic has the advantages that preparation technology is simple and easy to control, pollution is low in the preparation process, production cost is low, and the prepared mullite porous ceramic is high in strength and open porosity.

Owner:WUHU YUANKUI NEW MATERIAL TECH CO LTD

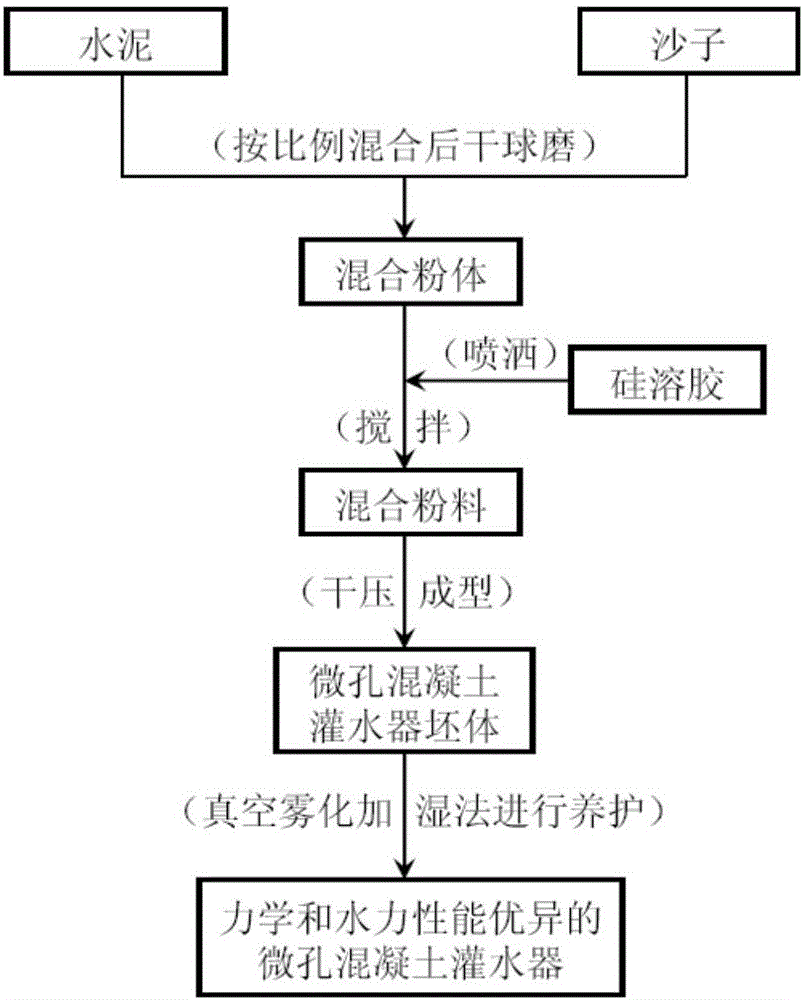

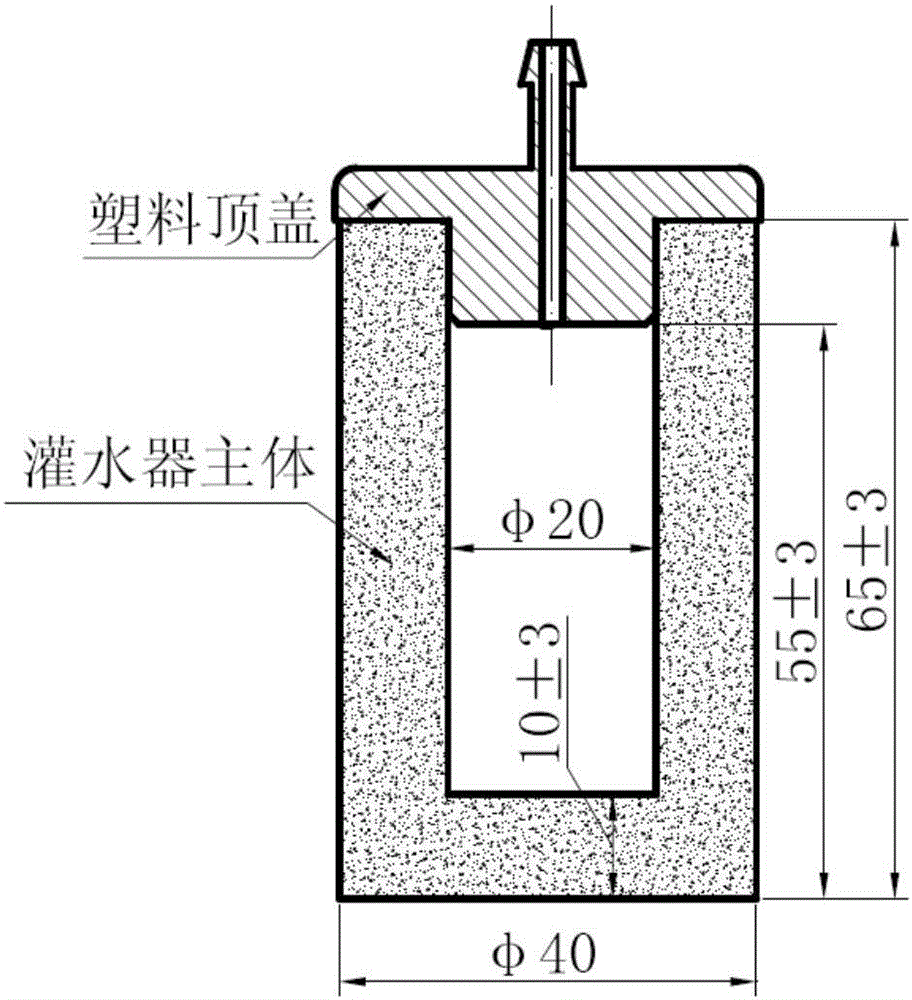

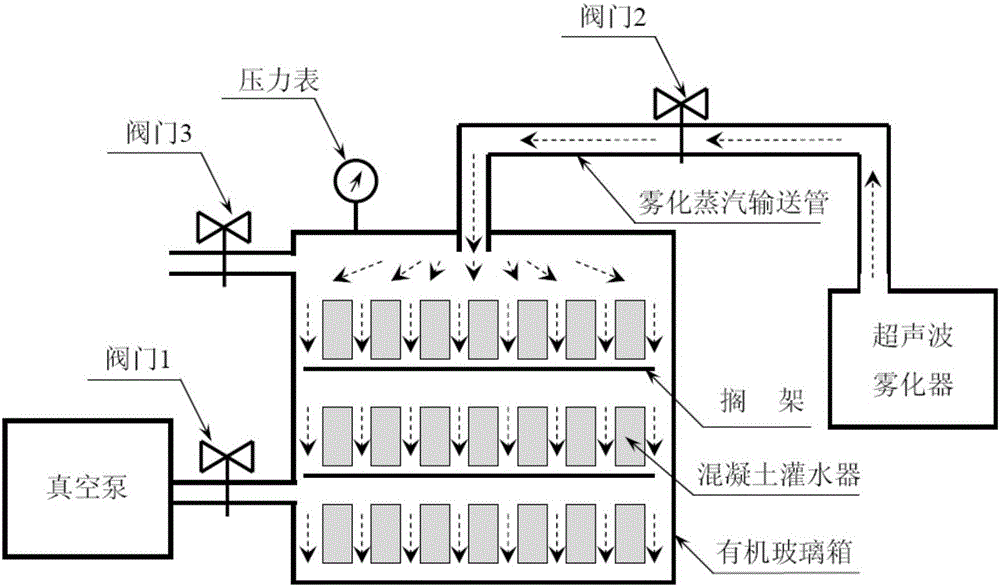

Method for preparing microporous concrete emitter through combination of dry pressing and vacuum atomization

InactiveCN106565191AHigh strengthHigh trafficCeramic shaping apparatusCeramicwareAdhesiveMechanical properties of carbon nanotubes

The invention discloses a method for preparing a microporous concrete emitter through combination of dry pressing and vacuum atomization. According to the method, cement and sand are adopted as raw materials, a silica sol is adopted as a mold pressing adhesive, a microporous concrete billet is prepared by using a dry pressing method, and an emitter billet is subjected to curing by using a vacuum atomization and humidification method so as to finally obtain the microporous concrete emitter. According to the present invention, by regulating the cement content in the raw materials, the particle size of the sand, and the vacuum atomization maintenance process, the opening porosity of the microporous concrete emitter can be effectively regulated so as to achieve the accurate control of the seepage amount of the emitter; the manufacturing cost is much lower than the cost of the microporous ceramic emitter, and the performance test results show that the microporous concrete emitter has the same excellent mechanical property and the same excellent water permeability as the microporous ceramic; and the method has advantages of cheap and easily-available raw materials, simple and easy-performing curing process, high opening porosity, stable mechanical property, excellent water permeability, and the like.

Owner:NORTHWEST A & F UNIV

Method for preparing high-performance insulating brick from solid waste sludge

PendingCN113788700AHigh strengthUniform heating rate inside and outsideCeramic materials productionCeramicwareBrickSludge

The invention discloses a method for preparing a high-performance insulating brick from solid waste sludge. The method comprises the following specific steps: (1) mixing coal gangue, iron tailings, shale and boron magnesium sludge, adding the formed mixture into solid waste sludge, and carrying out uniform stirring to obtain mixed sludge; (2) partially dehydrating the mixed sludge, adding a fluxing agent and a pore-forming agent, carrying out uniform mixing, and putting the formed mixture into a hydraulic forming machine to prepare a green brick; and (3) drying the green brick, and firing the green brick in a kiln to obtain the insulating brick. According to the preparation method provided by the invention, the pore-forming agent is added to prepare the insulating brick, so the problems of low activity and difficult forming of solid waste raw materials such as sludge are solved, the additional value of a sludge-based sintered brick is improved, and the application range of the sludge-based sintered brick is widened. The insulating brick prepared by the preparation method provided by the invention also has excellent heat-insulating property and compression resistance, and the sludge is used for making the brick, so pollution is eliminated, resources are saved, an urban environment is protected, the reutilization of the waste is effectively realized, and good economic benefits can be brought.

Owner:LONGYAN UNIV

Method for preparing porous silicon-nitride ceramic material

The invention discloses a method for preparing a porous silicon-nitride ceramic material, which comprises the following steps of: stirring starch and water at the temperature of 40-90 DEG C to prepare pre-gelatinized starch; adding silicon nitride, a sintering aid, a bonding agent and a defoaming agent to the pre-gelatinized starch, and uniformly mixing through ball milling to prepare a mixed slurry; molding the mixed slurry through casting, and carrying gout degassing, curing, complete sample-freezing and freeze-drying processing to prepare a porous silicon-nitride ceramic blank body; removing organic volatile substances in the porous silicon-nitride ceramic blank body through heating; and sintering, and cooling a sample along with a furnace after sintering. The silicon-nitride ceramic material prepared by utilizing the preparation method disclosed by the invention has high open porosity (which can reach 60-90 percent) and low density (0.32-1.28g / <cm>3), the bending strength can be regulated within the range of 5-140MPa, and the application-performance requirements of materials in the fields of high-temperature gas and liquid filtration, purification and separation, chemical catalytic carriers and the like can be met.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

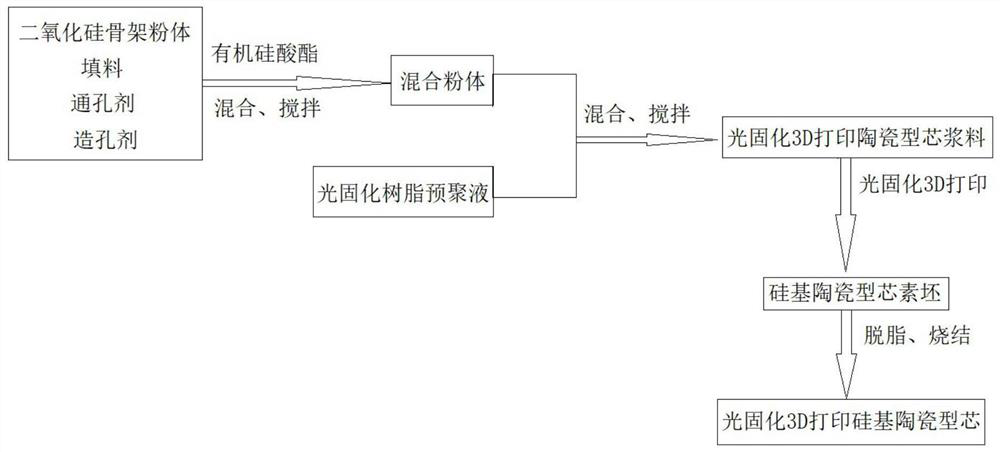

Photocuring 3D printing silicon-based ceramic core and preparation method thereof

ActiveCN114085073AHigh strengthHigh open porosityAdditive manufacturing apparatusFoundry moulds3d printFiber

The invention relates to a photocuring 3D printing silicon-based ceramic core and a preparation method thereof, and relates to the field of additive manufacturing ceramic materials. According to the main technical scheme, the preparation method of the photocuring 3D printing silicon-based ceramic core comprises the following steps: 1) preparing photocuring 3D printing ceramic core slurry; wherein the light-cured 3D printing ceramic core slurry is prepared from the following components in parts by weight: 30 to 50 parts of silicon dioxide skeleton powder, 20 to 50 parts of filler, 10 to 15 parts of through hole agent and 15 to 30 parts of light-cured resin premixed liquid, the through hole agent is formed by coating organic fibers with organic siloxane; 2) performing photocuring 3D printing treatment on the photocuring 3D printing ceramic slurry through photocuring 3D printing equipment to obtain a silicon-based ceramic core biscuit; and 3) degreasing and sintering the silicon-based ceramic core biscuit to obtain the photocuring 3D printing silicon-based ceramic core. The method is mainly used for improving the open porosity of the silicon-based ceramic core on the basis of ensuring that the silicon-based ceramic core has relatively high strength.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of lithium ion battery negative electrode slurry, negative electrode and battery

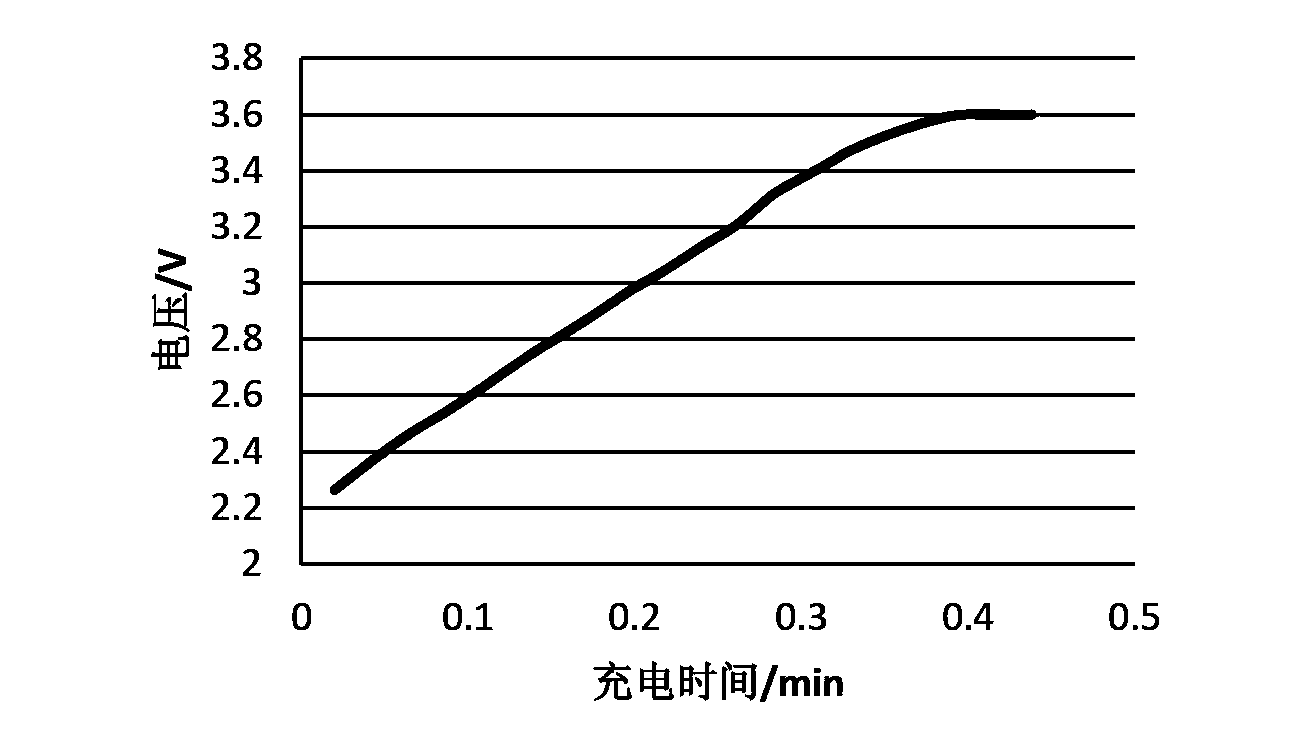

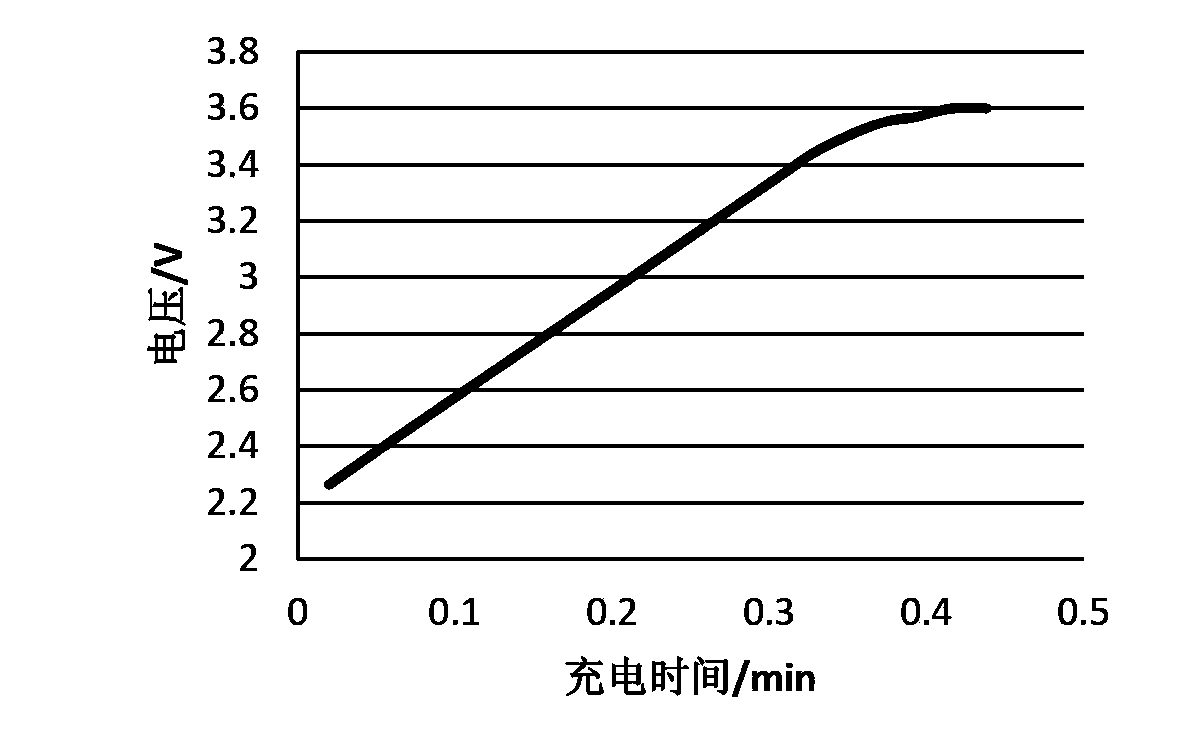

ActiveCN103515607BThe compacted density does not decreaseHigh porosityElectrode rolling/calenderingNegative electrodesSulfohydrazideElectrical battery

The invention provides a lithium ion battery negative electrode slurry and a lithium ion battery negative electrode and battery prepared by using the negative electrode slurry. The lithium ion battery negative electrode slurry includes a negative active material, a binder, a solvent and a pore-forming agent. The pore-forming agent is selected from one or more azo compounds and / or sulfonyl hydrazide compounds. Without reducing the compaction density of the negative electrode piece, it can increase the porosity of the electrode piece, increase the uniformity of pore distribution, increase the effective conduction area of lithium ions in the liquid phase, and improve the battery's performance while ensuring the high energy density of the battery. The rate performance and low-temperature performance are also improved, while the capacity is also improved.

Owner:BYD CO LTD

A kind of preparation method of zirconia-mullite high porosity ceramic material

ActiveCN107903080BAvoid introducingImprove high temperature resistanceCeramicwareAluminum fluorideMullite

The invention discloses a preparation method of a zirconium oxide-mullite porous ceramic material. The preparation method is characterized in that aluminum oxide and zircon sand are taken as main rawmaterials, yttrium oxide is taken as a stabilizer, aluminum fluoride is taken as an additive, a forming mode combining polyurethane foam dipping and gel solidification is adopted, and the zirconium oxide-mullite porous ceramic material with a needle-shaped mullite whisker structure is prepared through an in-situ synthesis technology; and a solvent in a blank is volatilized and organic substances are split at a high temperature to form a porous structure which has the characteristics of being high in porosity (greater than 80%), uniform in aperture distribution, excellent in high-temperature mechanical property and excellent in thermal impact resistance.

Owner:武汉钢铁有限公司

a ti 2 alc porous material and preparation method thereof

ActiveCN109553418BUniform distribution of poresHigh porosityFiltration separationCeramicwareActivated carbonPhysical chemistry

Owner:WUHAN POLYTECHNIC UNIVERSITY

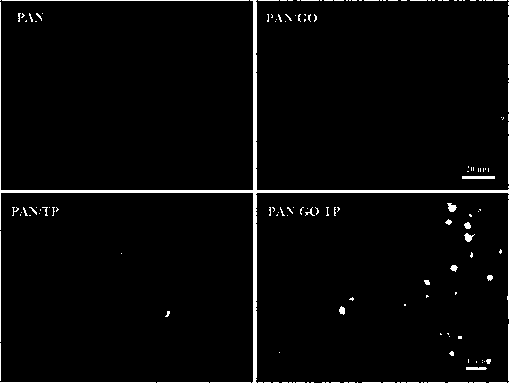

An antibacterial air filter membrane based on polyacrylonitrile/graphene oxide/tea polyphenol composite and its preparation method

InactiveCN108295675BAdd filter effectImprove antibacterial propertiesMembranesSemi-permeable membranesPhenolic content in teaAir filter

The invention discloses an antibacterial air filter membrane based on a polyacrylonitrile / graphene oxide / tea polyphenol compound. The antibacterial air filter membrane takes a non-woven fabric as a base material, and a composite membrane formed by the polyacrylonitrile / graphene oxide / tea polyphenol compound is deposited on the surface of the base material; the mass ratio of polyacrylonitrile to graphene oxide to tea polyphenol is (16 to 30) : (4 to 10) : (1 to 16). Meanwhile, the invention provides a corresponding preparation method. A microscopic structure of the antibacterial air filter membrane provided by the invention is as follows: polyacrylonitrile (PAN) nano-fibers form a staggered net-shaped structure aggregate, and the diameter is about 50 to 300nm; the graphene oxide (GO) is dispersed between the PAN fibers and between crossed points of the fibers; the diameter distribution of the GO is relatively great, and is in a micron grade; a structure that the nano-fibers is combinedwith a micron layered object is formed by the GO and the PAN. By adopting the structure disclosed by the invention, the thickness of the filter membrane can be improved and the porosity of the filtermembrane is kept; the filtering efficiency of the filter membrane is improved, and the pressure drop of the filter membrane is effectively kept; the filter membrane has the effect of filtering PM2.5 (Particulate Matter 2.5) in the air and has good antibacterial performance.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

A kind of porous tantalum-based oxynitride ceramics and its preparation method

ActiveCN110156474BNo carburizationImprove heating efficiencyCeramicwareCompression moldingPorous tantalum

The invention discloses a preparation method of porous tantalum-based oxynitride ceramics, which comprises the following steps: S1, uniformly grinding tantalum-based oxynitride powder and then drying to obtain dry oxynitride powder; S2, placing the oxynitride dry powder in Carry out compression molding in a mold to obtain a sheet-shaped green body; S3, place the sheet-shaped green body vertically in a reaction vessel and set the sheet-shaped green body and the reaction container at intervals, and perform pressureless discharge plasma sintering under a protective atmosphere to obtain oxygen Nitride ceramic sheet; S4, decarbonizing the oxynitride ceramic sheet to obtain a porous tantalum-based oxynitride ceramic. The invention has the advantages of short sintering time, high heat transfer efficiency and high product purity.

Owner:NAT UNIV OF DEFENSE TECH

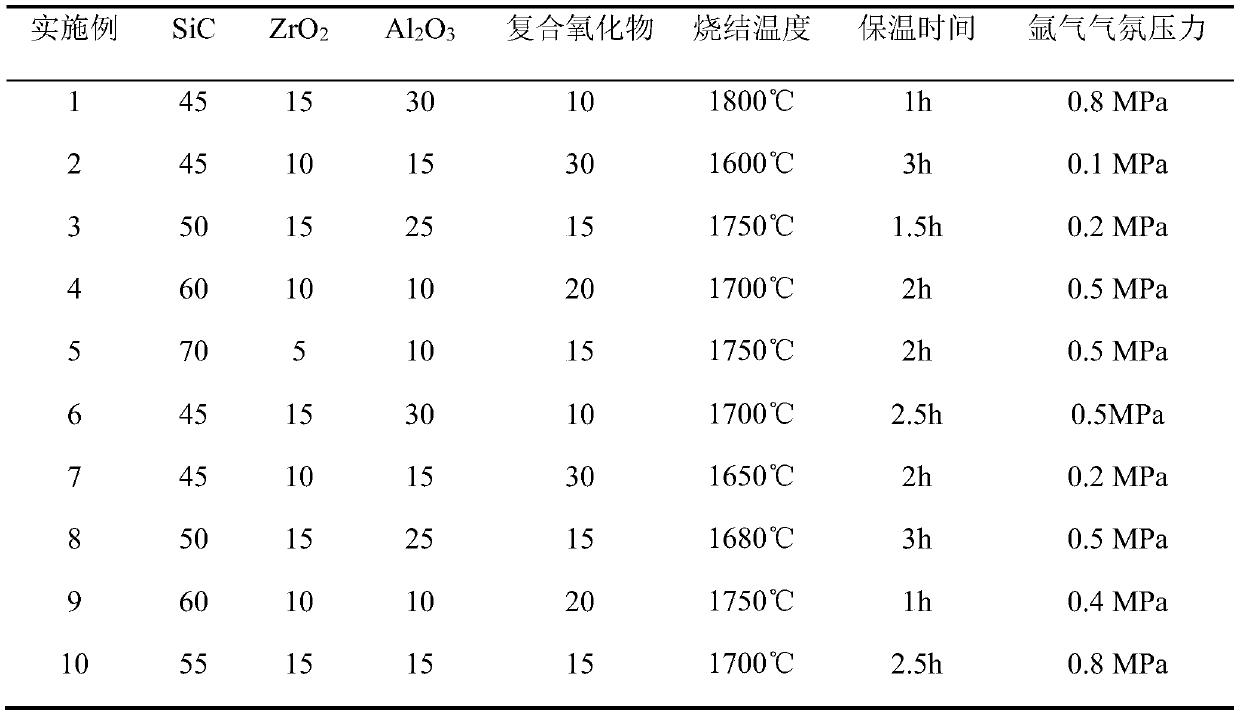

A kind of preparation method of low-voltage high-energy sic semiconductor nozzle material

The invention discloses a preparation method of a low-pressure and high-energy SiC semiconductor spark plug material. The method comprises the steps as follows: 1) 45%-70% of SiC powder, 5%-15% of ZrO2 powder, 10%-30% of Al2O3 powder and 10%-30% of composite oxide powder constituting a glass system are selected in the volume ratio, are uniformly mixed and pass a 200-mesh sieve to be stored for later use; 2) PVA with the solid content being 8% is added in the weight ratio of powder to PVA being 95:5 and manually and uniformly mixed, and the mixture passes a 80-mesh sieve and is pressed under the pressure of 80 MPa to form a green body; 3) the green body is placed in an air furnace to be sintered, heated to 450 DEG C at the heating rate of 5 DEG C / h and kept at the constant temperature for 12 h; 4) the green body with glue removed is placed in a vacuum sintering furnace, filled with Ar, heated to 1,600-1,800 DEG C at the heating rate of 5 DEG C / min to be sintered and kept at the constant temperature for 1-3 h. The prepared SiC semiconductor composite has excellent performance of low ignition voltage, high spark capacity, capability of avoiding effects of air pressure and environmental media, heat shock resistance, electric spark corrosion resistance, good extinguishment restart and high-attitude performance and the like.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com