Method for preparing microporous concrete emitter through combination of dry pressing and vacuum atomization

An irrigation and concrete technology, applied in the manufacture of tools, ceramic products, applications, etc., can solve the problems of high manufacturing cost and difficult agricultural promotion, and achieve the effects of excellent hydraulic performance, large flow, and high bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

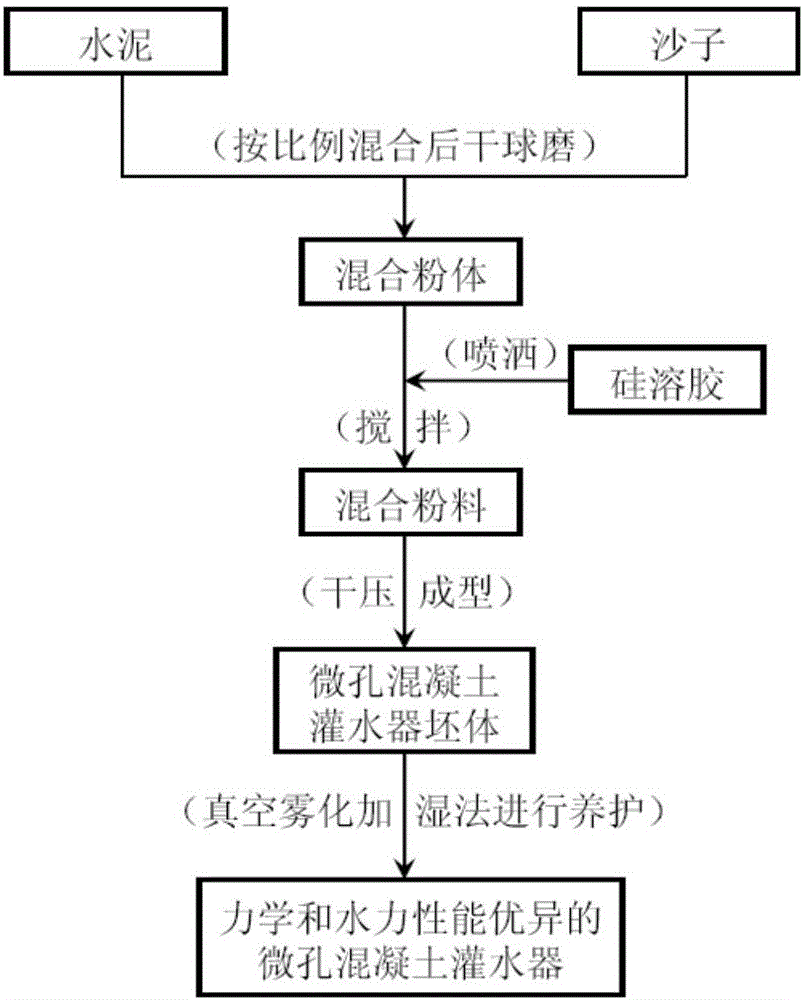

[0025] The process of preparing microporous concrete sprinkler by dry pressing combined with vacuum atomization method in this embodiment is as follows figure 1 Shown:

[0026]The sand excavated from the sand field is passed through 12-mesh and 18-mesh sieves in turn, and the sand with a particle size range of 1.0-1.7 mm is selected. Mix the selected sand with the cement labeled P.O32.5 in a ratio of 80:20 and pour it into the ball mill tank. Add 15 to 25 alumina balls with a diameter of 8 to 12 mm per 100 grams of the mixture. The mixture was obtained by mixing for 1.0 hour using a tumble ball mill. Pour the mixture into the cement mortar mixer, and spray the silica sol with a concentration of 10% while stirring, and spray 35 grams of silica sol per 100 grams of cement. After the silica sol is sprayed, continue to stir the mixture for 15 minutes, then pour it into a mold and mold it into an emitter with a pressure of 10 MPa, and open the mold after holding the pressure for ...

Embodiment 2

[0029] The process of preparing microporous concrete sprinkler by dry pressing combined with vacuum atomization method in this embodiment is as follows figure 1 Shown:

[0030] The sand excavated from the sand field is passed through 18-mesh and 30-mesh sieves in turn, and the sand with a particle size range of 0.6-1.0 mm is selected. Mix the selected sand with the cement labeled P.O32.5 at a ratio of 82:18 and pour it into the ball mill tank. Add 15 to 25 alumina balls with a diameter of 8 to 12 mm per 100 grams of the mixture. Mixed for 0.5 hour with a roller ball mill to obtain a mixture. The mixture is poured into a cement mortar mixer, and the silica sol with a concentration of 15% is sprayed while stirring, and 30 grams of silica sol is sprayed per 100 grams of cement. After the silica sol is sprayed, continue to stir the mixture for 20 minutes, then pour it into a mold and mold it into an emitter with a pressure of 8 MPa, and open the mold after holding the pressure f...

Embodiment 3

[0033] The process of preparing microporous concrete sprinkler by dry pressing combined with vacuum atomization method in this embodiment is as follows figure 1 Shown:

[0034] The sand excavated from the sand field is passed through 30-mesh and 80-mesh sieves in turn, and the sand with a particle size range of 0.18-0.6 mm is selected. Mix the selected sand with the cement labeled P.O42.5 in the ratio of 82:18 and pour it into the ball mill tank. Add 15 to 25 alumina balls with a diameter of 8 to 12 mm per 100 grams of the mixture. Mixed for 0.5 hour with a roller ball mill to obtain a mixture. Pour the mixture into the cement mortar mixer, and spray the silica sol with a concentration of 15% while stirring, and spray 25 grams of silica sol per 100 grams of cement. After the silica sol is sprayed, continue to stir the mixture for 15 minutes, then pour it into a mold and mold it into an emitter with a pressure of 5 MPa, and open the mold after holding the pressure for 20 seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com