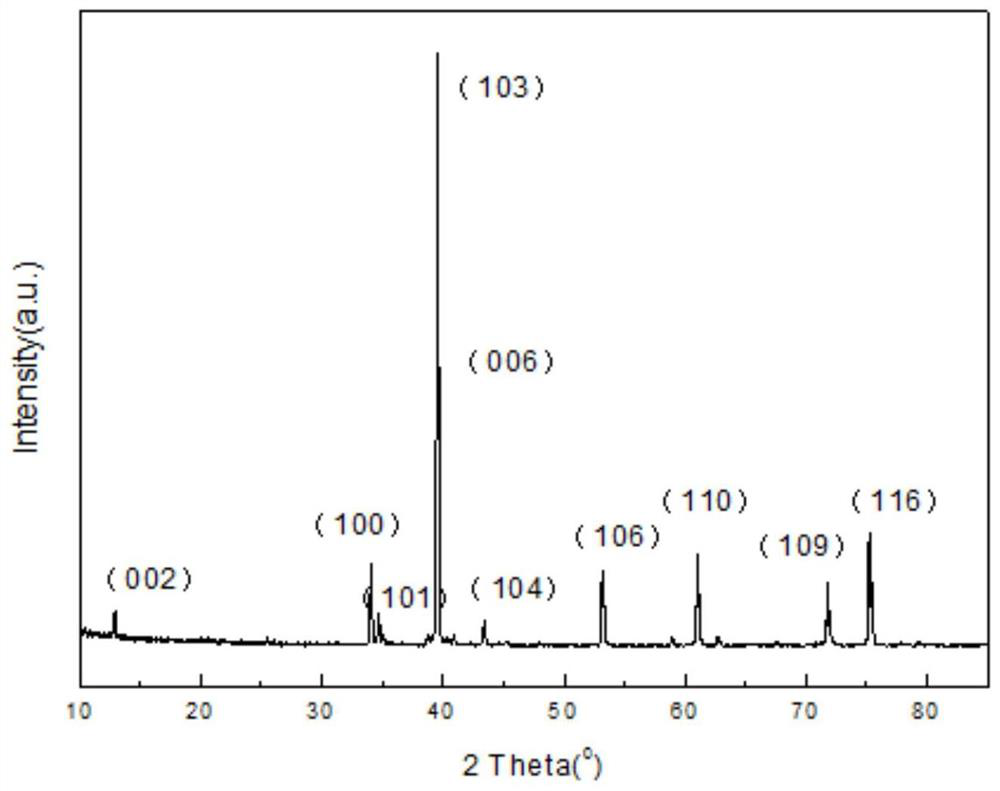

a ti 2 alc porous material and preparation method thereof

A technology of porous materials and mixed powders, applied in separation methods, chemical instruments and methods, ceramic products, etc., can solve the problems of pore-forming agent residue and uneven pore distribution, and achieve high porosity and no pore-forming agent residue , Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

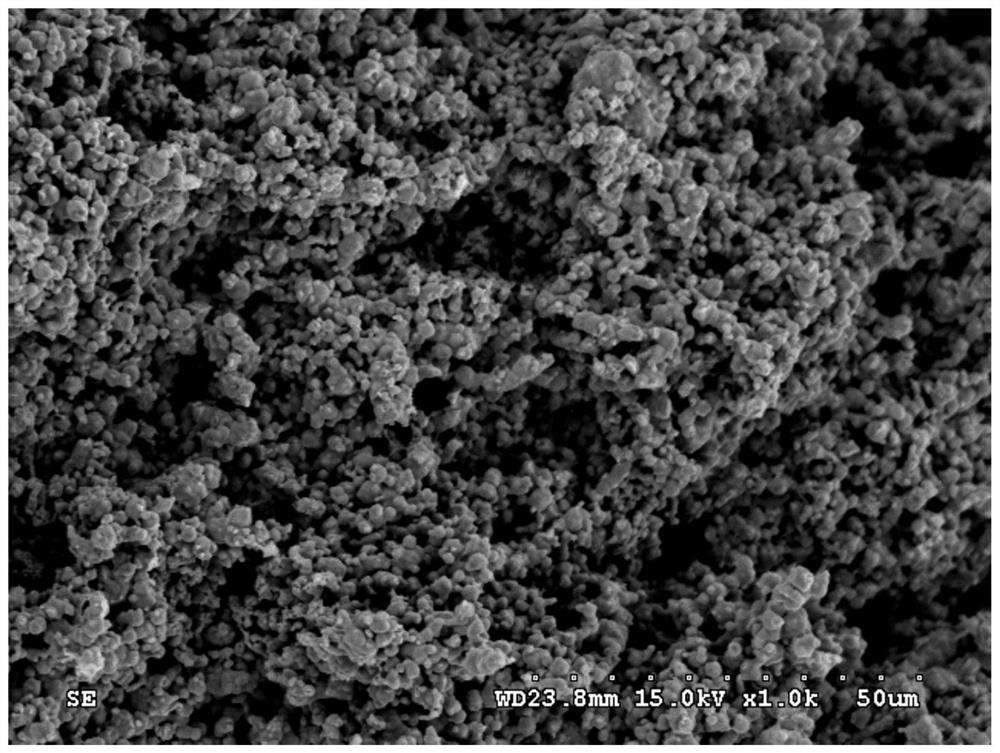

[0026] A kind of Ti 2 The preparation method of AlC porous material comprises:

[0027] S1. Mix titanium powder, aluminum powder and dry activated carbon powder evenly. The mass ratio of carbon powder to aluminum powder is 65-69:33. The ratio of dry activated carbon powder to the sum of the mass of carbon powder and aluminum powder 2~10:100.

[0028] Specifically, material preparation is performed first. Weigh titanium powder, aluminum powder, dry activated carbon powder and grinding balls so that the mass ratio of titanium powder to aluminum powder is 65-69:33, and the sum of the mass of dry activated carbon powder, carbon powder and aluminum powder The ratio is 2 to 10:100.

[0029] Then mix titanium powder, aluminum powder and dry activated carbon powder evenly. Preferably, in order to fully mix the titanium powder, aluminum powder and dry activated carbon powder to obtain a mixed powder, put the titanium powder, aluminum powder and dried activated carbon powder in a ba...

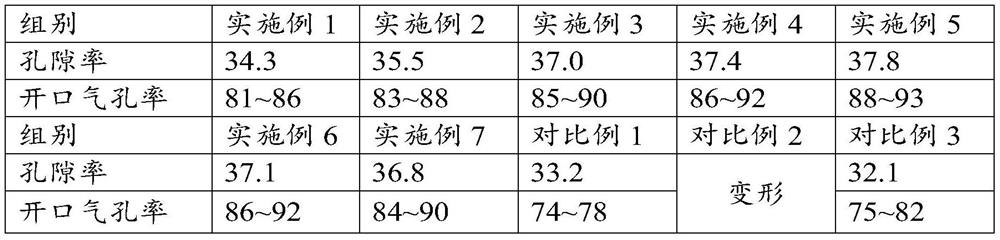

Embodiment 1

[0043] This embodiment provides a Ti 2 AlC porous material and its preparation method.

[0044] A kind of Ti 2 The preparation method of AlC porous material comprises: will weigh titanium powder 67g, aluminum powder 33g dry activated carbon powder 2g, titanium powder, aluminum powder and activated carbon powder are placed in ball mill and put into the grinding ball of 300g as medium, mix Mix the materials for 8 hours, and mix them evenly to obtain a mixed powder. The particle sizes of the selected titanium powder and aluminum powder are both -200 mesh to +325 mesh. The particle size of the dry activated carbon powder is -800 mesh.

[0045] The mixed powder was placed in a Φ25mm mold, and a pressure of 190MPa was applied to it to form a green body.

[0046] Place the green body under vacuum conditions for sintering, raise the temperature to 190°C in the first stage at a heating rate of 9°C / min, and keep it for 3.3h, then raise the temperature to 560°C in the second stage at ...

Embodiment 2

[0048] This embodiment provides a Ti 2 AlC porous material and its preparation method.

[0049] A kind of Ti 2 The preparation method of AlC porous material comprises: will weigh titanium powder 67g, aluminum powder 33g dry activated carbon powder 4g, titanium powder, aluminum powder and activated carbon powder are placed in ball mill and put into the grinding ball of 310g as medium, mix Mix the materials for 8 hours, and mix them evenly to obtain a mixed powder. The particle sizes of the selected titanium powder and aluminum powder are both -200 mesh to +325 mesh. The particle size of the dry activated carbon powder is -800 mesh.

[0050] The mixed powder is placed in a Φ25mm mold, and a pressure of 220MPa is applied to it to form a green body.

[0051] The green body was sintered under vacuum conditions, the temperature was raised to 200°C in the first stage at a heating rate of 10°C / min, and kept for 2 hours, and the temperature was raised to 600°C in the second stage at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com