Low-cost ecological ceramic material having a plurality of sound absorbing structures and preparation method thereof

A technology of ecological materials and ecological ceramics, which is applied in the field of preparation of low-cost ecological ceramic materials, can solve the problems of high cost of raw materials, single function, single sound absorption structure, etc., so as to improve the sound absorption effect, reduce the cost, and increase the open porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

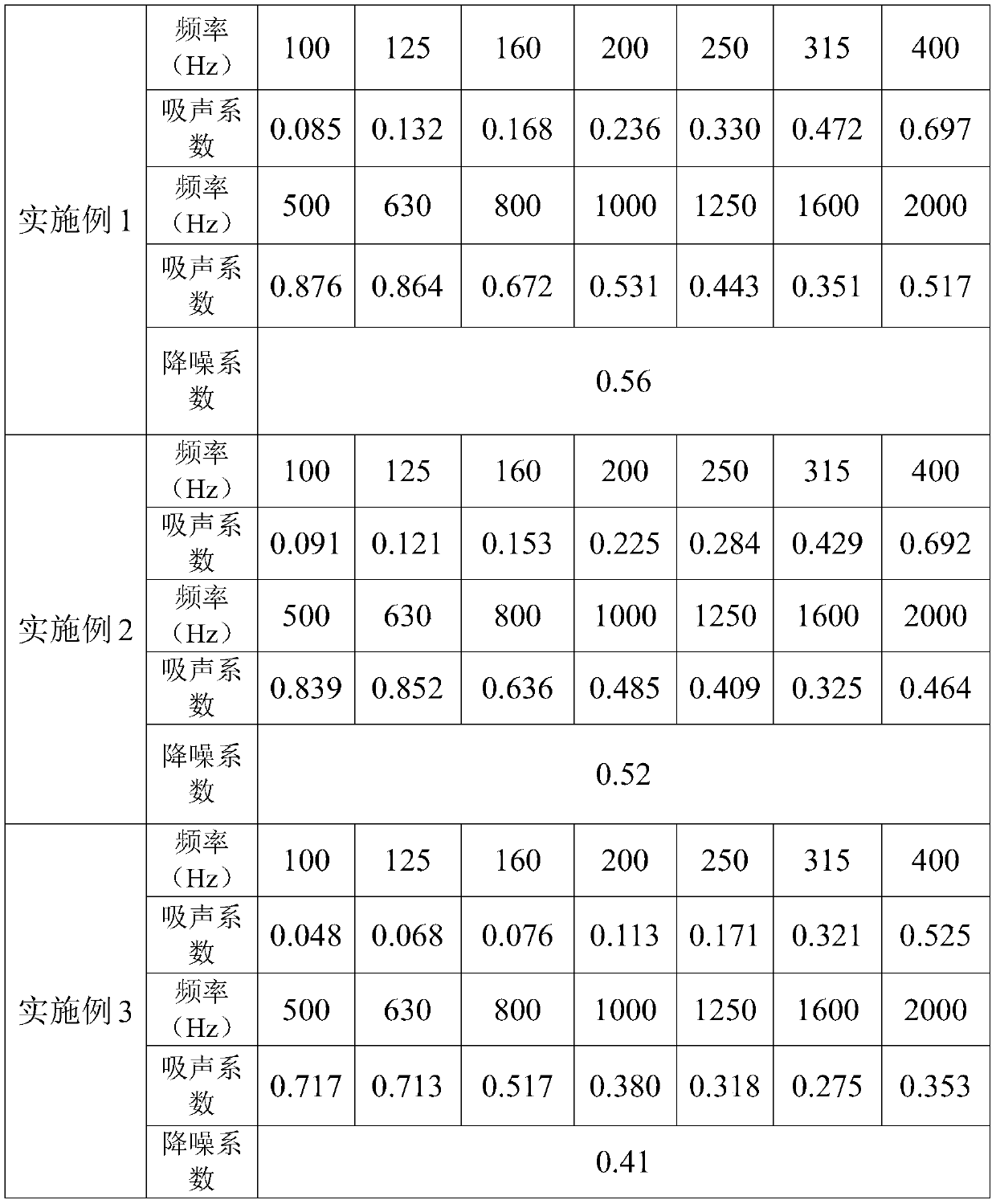

Examples

preparation example Construction

[0044] A method for preparing a low-cost ceramic ecological material with multiple sound-absorbing structures of the present invention, the specific operation process includes the following steps:

[0045] Step 1, weighing raw materials according to the following mass percentages: 22% to 27% of fly ash, 13% to 18% of coal gangue, 8% to 12% of red mud, 40% to 45% of shale, 5% to 10% of feldspar %, foaming agent 0.2%~2%, binder 0.5%~3%, pore forming agent 5%~10%, surfactant 0%~1%, spare;

[0046] Foaming agent is calcium carbonate, calcium sulfate and silicon carbide any one or several compositions according to arbitrary proportion;

[0047] The binding agent is one or both of sodium carboxymethyl cellulose and xanthan gum in any proportion;

[0048] The pore forming agent is any one of polystyrene balls, spherical plastic particles, spherical activated carbon and coal powder or a combination of several in any proportion;

Embodiment 1

[0057] A method for preparing a low-cost ceramic ecological material with multiple sound-absorbing structures, the specific operation process includes the following steps:

[0058] Step 1, weigh raw materials according to the following mass percentages: fly ash 25%, coal gangue 15%, red mud 10%, shale 43%, feldspar 7%, silicon carbide 0.5%, xanthan gum 2%, polyphenylene Ethylene balls (diameter 1-2mm) 8%, coal powder (40-60 mesh) 4% and polyvinyl alcohol 1% spare;

[0059] Wherein, the mass percent of each component in the fly ash is as follows: SiO 2 48%, Al 2 o 3 27%, Fe 2 o 3 8%, TiO 2 1%, CaO 8%, MgO 1%, K 2 O is 1%, Na 2 O is 0.3%;

[0060] The mass percent of each component in coal gangue is as follows: SiO 2 43%, Al 2 o 3 27%, Fe 2 o 3 5%, TiO 2 1%, CaO 1%, MgO 1%, K 2 O is 1%, Na 2 O is 0.3%;

[0061] The mass percent of each component in the red mud is as follows: SiO 2 30%, Al 2 o 3 27%, Fe 2 o 3 10%, CaO 12%, Na 2 O is 7%.

[0062] The mass p...

Embodiment 2

[0072] A method for preparing a low-cost ceramic ecological material with multiple sound-absorbing structures, the specific operation process includes the following steps:

[0073] Step 1, weigh raw materials according to the following mass percentages: 22% fly ash, 14% coal gangue, 8% red mud, 45% shale, 5% feldspar, 1% mixture of silicon carbide and calcium carbonate, carboxymethyl Sodium cellulose 1%, spherical plastic particles (diameter 2-3mm) 8%; coal powder (40-60 mesh) 4% and polyvinyl alcohol 0.3% for later use;

[0074] Wherein, the mass percent of each component in the fly ash is as follows: SiO 2 45%, Al 2 o 3 25%, Fe 2 o 3 5%, TiO 2 0.5%, CaO 5%, MgO 0.5%, K 2 O is 0.5%, Na 2 O is 0.1%;

[0075] The mass percent of each component in coal gangue is as follows: SiO 2 40%, Al 2 o 3 25%, Fe 2 o 3 3%, TiO 2 0.5%, CaO 0.5%, MgO 0.5%, K 2 O is 0.5%, Na 2 O is 0.1%;

[0076] The mass percent of each component in the red mud is as follows: SiO 2 20%, Al ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com